1. Introduction

IN 20 century, D. Kahng and S. M. Sze proposed a floating gate (FG) device to obtain the non-volatility characteristic in memory applications. This was the first time that the possibility of nonvolatile MOS memory was recognized. It is worth mentioning that flash memory, based on the MOSFET transistors with a floating gate, has become a common component of USB flash drive and solid-state disk (SSD) [

1].

Due to the physical limit, DRAM, SRAM, and flash memory are currently facing challenges to scale down to 10 nm node. It has become much difficult and expensive to enhance the performance and reliability. At first, the Silicon-Oxide-Nitride-Oxide-Silicon (SONOS) flash memory, which uses a silicon nitride as a charge trapping layer, relieves the problems caused by scaling down. However, when the gate oxide thickness is down to about 7 nm, the scaling-down problems are also inevitable [

2].

RRAM, comprised of a simple capacitor-like structure, has great potential to replace the flash memory and DRAM, becoming the next-generation non-volatile memory. A great number of kinds of materials have been research for acting as resistive switching layers, such as binary metal oxides, perovskite oxides, and chalcogenide materials. Above them, the binary metal oxides, like HfO

x, TiO

x, AlO

x, ZrO

x, have been the great candidates for the use of switching layer owing to the simplicity of materials and good compatibility with silicon CMOS fabrication. Thus, many research activities have bloomed with a few demonstrations of various RRAM structure with insulator layer of various binary metal oxides [

3,

4]. Wide bandgap materials, especially HfO

2 (around 5.7 eV), play important roles in many fields of semiconductor industry, such as MOSFET, RRAM, laser diode. Ga

2O

3, which is thought of as the fourth-generation semiconductor material, has been demonstrated that it is one of promising material to replace GaN and SiC because of wide bandgap of 4.9 eV in -phase and high breakdown field. Therefore, it is considered as the most appropriate candidate of high-power devices. However, few group have researched Ga

2O

3 material for memory applications. Based on the quantum effect, the amorphous-phase Ga

2O

3 (a-Ga

2O

3) is more suitable than -phase Ga

2O3 (-Ga

2O

3) as the switching layer of RRAM because the leakage current is smaller and the bandgap of a-Ga

2O

3 is also quite large [

5].

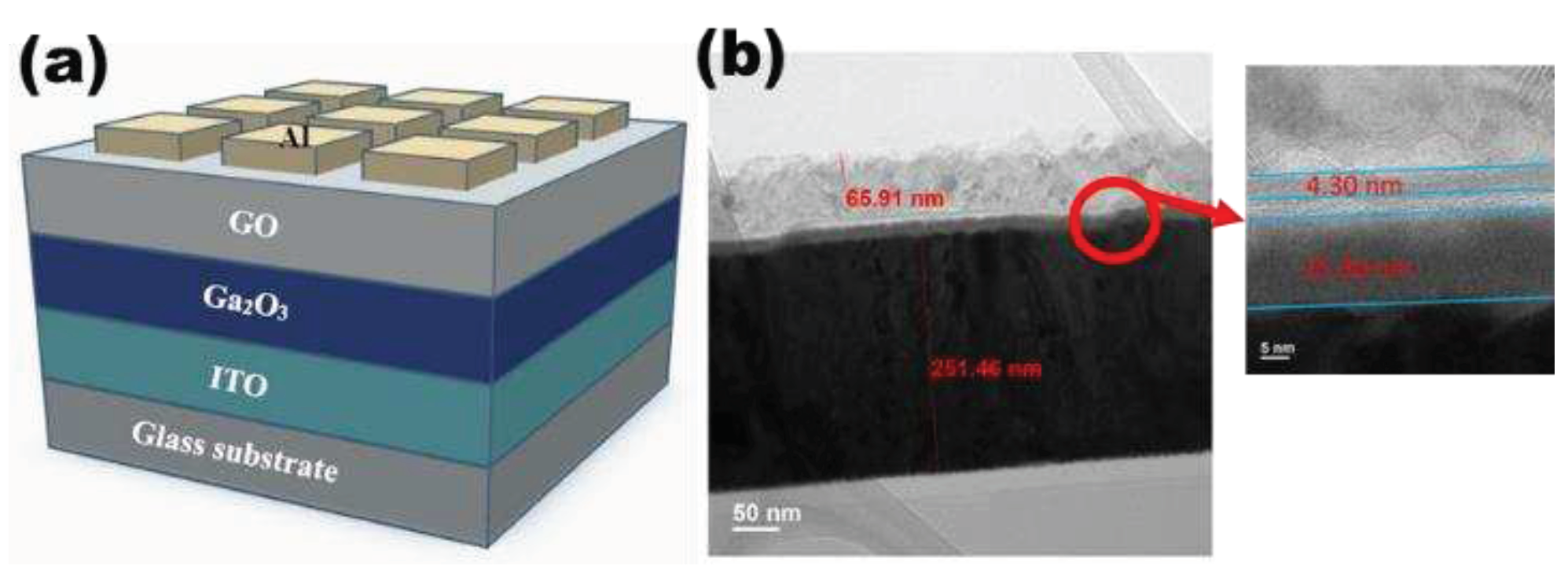

In this study, the bilayer Al/GO/a-Ga2O3/ITO RRAM was proposed and the monolayer Al/a-Ga2O3/ITO RRAM was also fabricated to draw a comparison between two structures. Compared with the monolayer structure, the bilayer one had better electrical properties and reliability characteristics. The multilevel characteristic was presented through modulating the current compliance, and the possibility of lower power consumption was also demonstrated due to lower operation voltage and current compliance.

2. Results and Discussion

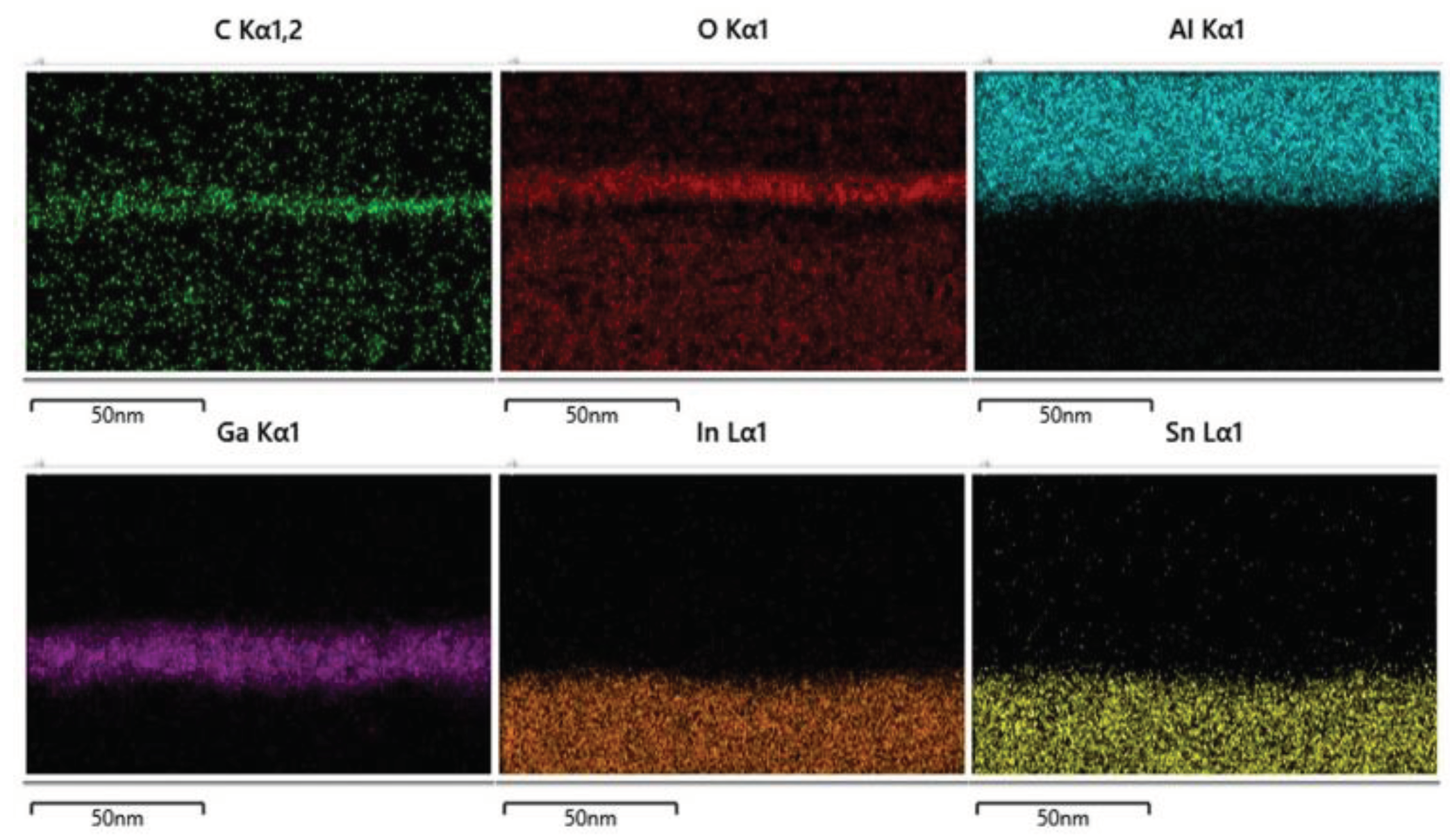

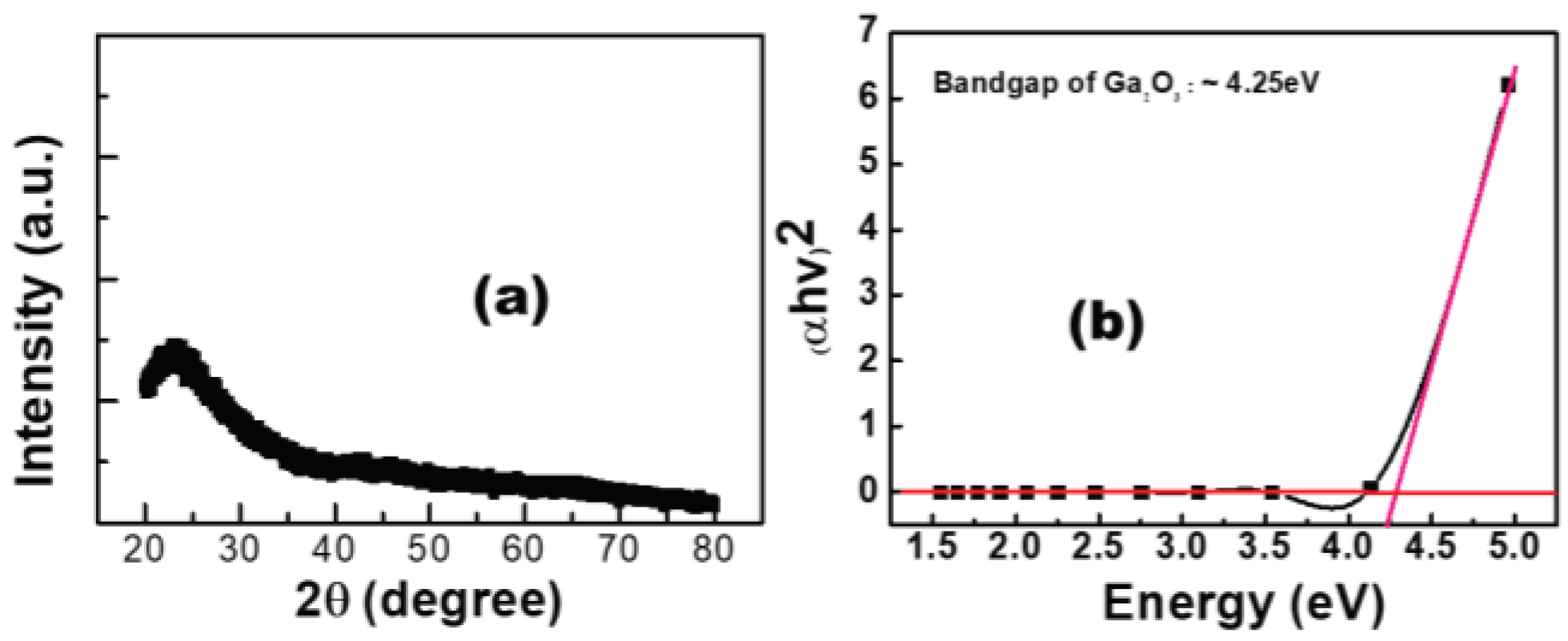

Figure 1 shows the element distribution analyzed through energy dispersive spectroscopy (EDS) mapping. Based on this mapping, the relative positions of all elements can be clearly distinguished. The EDS mapping can also prove the scavenging phenomenon between the Al top electrode and the GO layer. The crystal structure analysis of Ga

2O

3 thin film on a glass substrate is depicted in

Figure 2 (a). This result shows that the structure of Ga

2O

3 deposited by RF sputtering was in amorphous phase. For the purpose of the low leakage current in RRAM devices, the amorphous phase is better than crystalline phase [

6]. It is noteworthy that the peak around 24 degrees was attributed to the substrate [

7]. The bandgap of Ga

2O

3 varies in different phase [

8,

9]. In this measurement, the bandgap of the Ga

2O

3 film was confirmed by a U-3310 spectrophotometer, as shown in

Figure 2 (b). The bandgap of Ga

2O

3 in amorphous phase is around 4.25eV.

The electrical properties of monolayer and bilayer structures were characterized by an Agilent B1500A parameter analyzer. The ITO bottom electrode was grounded, and the applied voltage was exerted on the Al top electrode.

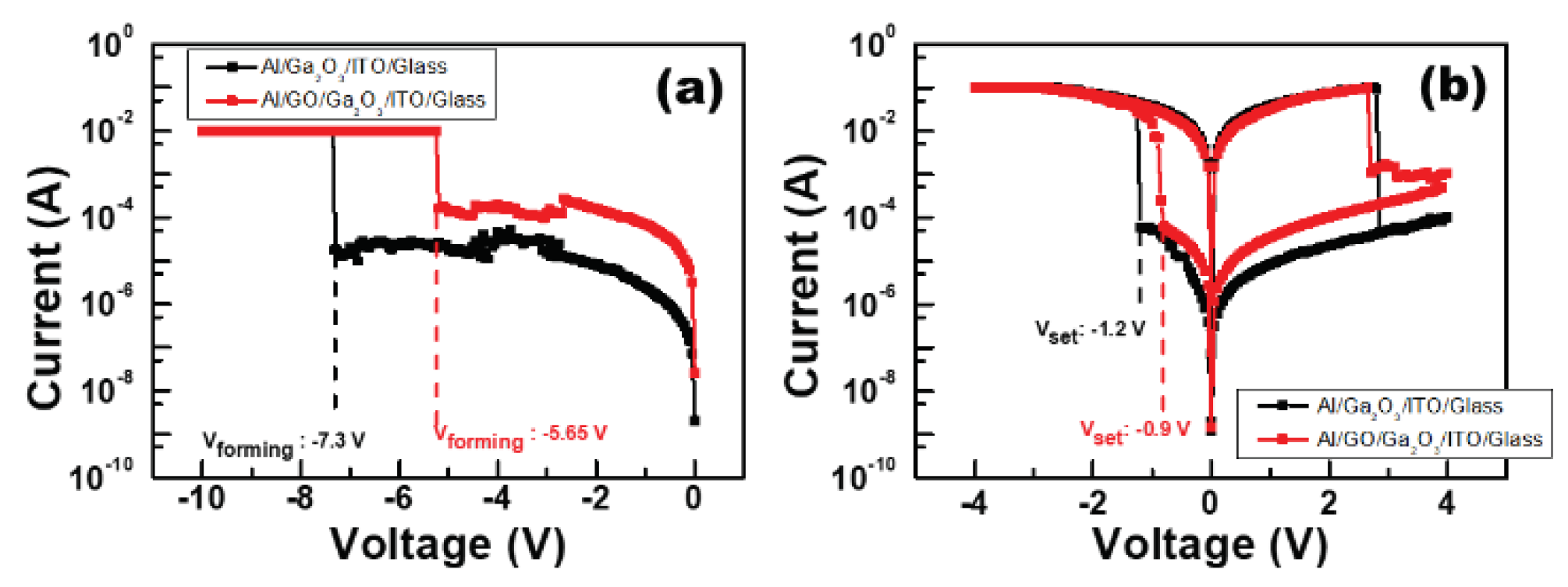

Figure 3 shows the resistive switching behaviors of the Al/Ga

2O

3/ITO/glass RRAM device and Al/GO/Ga

2O

3/ITO/glass RRAM device. The forming processes of Al/Ga

2O

3/ITO/glass and Al/GO/Ga

2O

3/ITO/glass RRAMs devices occurred under negative voltage sweeps (0V→-10V→0V) at -50 mV intervals, and the compliance current was set to 10 mA to prevent the device from soft breakdown of the devices. In

Figure 3 (a), the forming voltage of the Al/Ga

2O

3/ITO/glass RRAM device and Al/GO/Ga

2O

3/ITO/glass RRAM device were -7.3 V, -5.65 V, respectively.

Figure 3 (b) show the I-V curve of the SET and RESET process of the device. Obviously, the I-V curves exhibited bipolar switching behavior in both structures. The SET/RESET processes occurred under applied negative voltage sweeps (0 V→-4 V→ 0 V) and positive voltage sweeps (0 V→+4 V→0 V), respectively, and the compliance current was set to 100 mA. For monolayer structure RRAM, the set voltage and reset voltage were -1.2 V and 2.95 V, respectively. The ON/OFF ratio was approximately 10

4 at -0.1 volts. The V

set and V

reset of Al/GO/Ga

2O

3/ITO/glass is -0.9 V and 2.65 V, respectively. The ON/OFF ratio was approximately 10

3 at -0.1 volts.

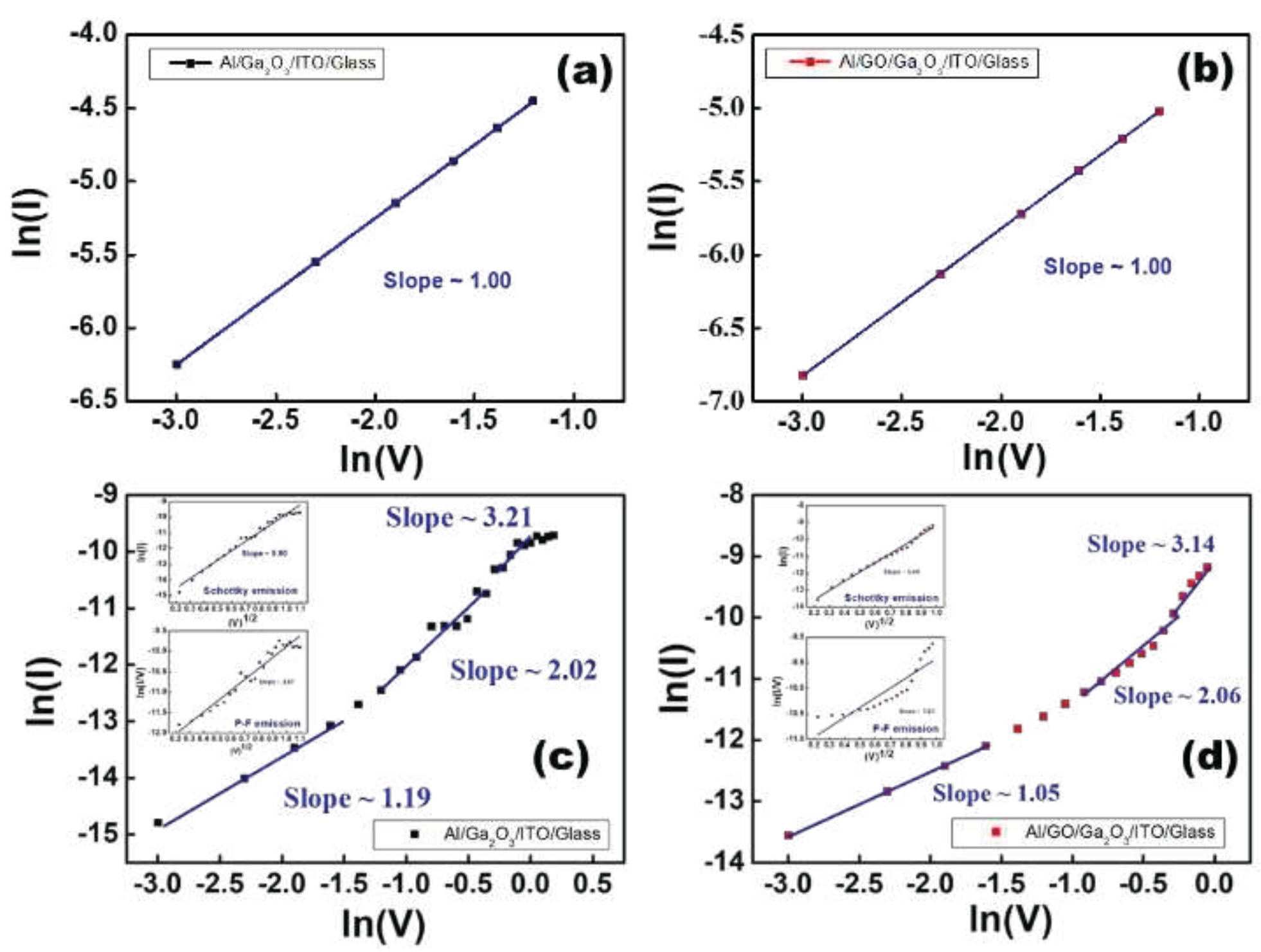

So as to investigate the conduction mechanism of Al/Ga

2O

3/ITO/glass and Al/GO/Ga

2O

3/ITO/glass RRAMs in the LRS and HRS, the DC I-V characteristics were fitted after we programed the device. Figure 6 shows the fitting results of the I-V characteristics. According to the Ohmic conduction equation (V=IR), the current conduction is dominated by Ohmic conduction if the slope of ln(I)-ln(V) is close to 1. For Al/Ga

2O

3/ITO/glass and Al/GO/Ga

2O

3/ITO/glass structures, the slope of LRS in the low-voltage region is around 1.00, which indicates that the current conduction behavior is Ohmic conduction, as shown in

Figure 4 (a)-(b). Moreover, if the I-V curve plotted using ln-ln scale in HRS exhibits a complicated shape, the conduction mechanism is dominated by Space-Charge-Limited Conduction (SCLC). In the low-voltage region, the slope of HRS is approximately 1. As the bias voltage increases, the slope increases to 2 in the square region. When the bias voltage further increases, the current in HRS increases rapidly and the slope is much sharp in high-voltage region [

10]. For Al/Ga

2O

3/ITO/glass device, the slope in the HRS region changed from 1.19 to 2.02 to 3.21 with increasing voltage, which can be explained by the SCLC, as shown in

Figure 4 (c). For Al/GO/Ga

2O

3/ITO/glass device, the slope of 1.05, 2.06, and 3.14 were obtained in low-voltage, square, and high-voltage regions (

Figure 4 (d)), indicating that the conduction mechanism follows SCLC. Furthermore, the fitting results of HRS using Schottky emission (ln(I)∝V

1/2) and Poole-Frenkel (ln(I/V) ∝V

1/2), as shown in

Figure 4 (c)-(d). The results were not fitted well by these two mechanisms.

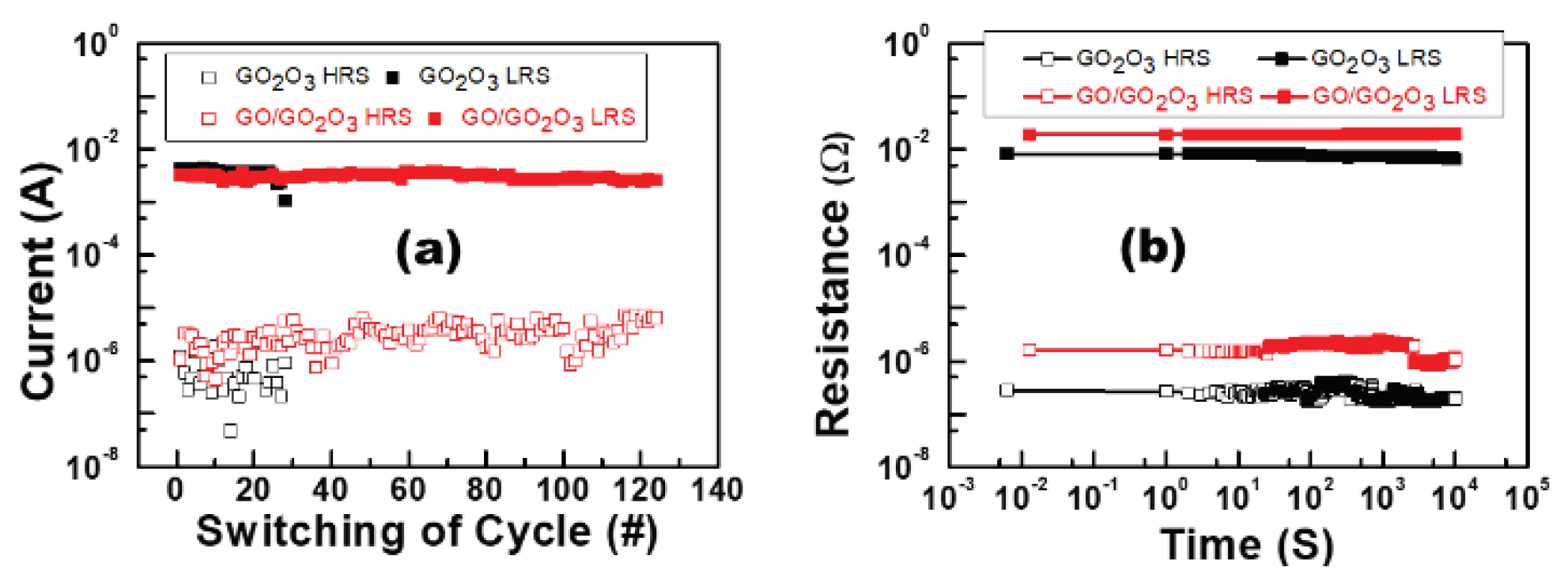

Figure 5 (a) show the endurance tests of DC resistive switching. The current values were extracted at -0.1 V in the test. The Al/Ga

2O

3/ITO structure can maintain the ON/OFF ratio around 10

4 only after 28 DC switching cycles. This result demonstrates that the Al/Ga

2O

3/ITO structure was not stable for resistive switching. However, The Al/GO/Ga

2O

3/ITO structure can maintain the ON/OFF ratio around 10

3 after 126 DC switching cycles. This result demonstrates that the GO insertion layer played a key role in improvement of endurance test.

Figure 5 (b) show the retention performance of HRS and LRS without any considerable degradation in the resistance was observed after 10

4 s at room temperature, indicating the device’s stability and non-volatile storage properties.

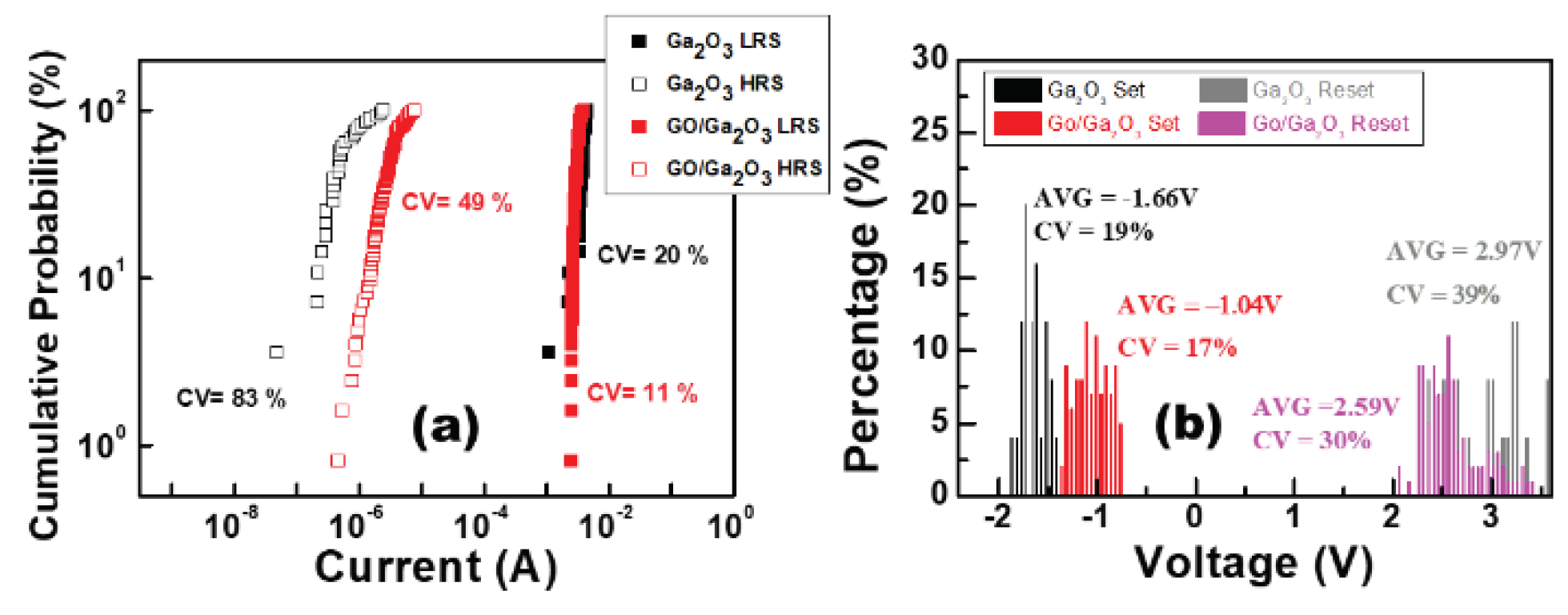

Based on the filament theory, the non-uniformity is an essential issue for RRAM device due to the random conformation and rupture during set and reset processes, respectively. Two parameters generally observed in resistive switching characteristics to quantify the non-uniformity are cycle-to-cycle uniformity and device-to-device uniformity.

Figure 6 (a) shows the current distribution of HRS and LRS. The current values in both states were measured at read voltage of -0.1 volts and the compliance current of 100 mA.

Figure 6 (a) shows the result of cycle-to-cycle variation of Al/Ga

2O

3/ITO device in LRS at the average value was 3.61×10

-3, and the coefficient of variation was about 20%. In HRS at the average value was 7.21×10

-7, and the coefficient of variation was about 83%. The HRS was not uniform during resistive switching. The result of cycle-to-cycle variation of Al/GO/Ga

2O

3/ITO device in LRS at the average value was 3.04×10

-3, and the coefficient of variation was about 11%. In HRS at the average value was 3.31×10

-6, and the coefficient of variation was about 49%.

Figure 6 (b) shows that the V

SET has about 19% probability to be at −1.66 V, and V

RESET has about 39% probability to be at 2.97 V for Ga

2O

3 devices. The mean and standard deviation of V

SET/V

RESET for GO/Ga

2O

3 devices are −1.04 V/17% and 2.59 V/30%, respectively. The distribution of switching voltages V

SET and V

RESET is very concentrated highlighting the good uniformity.

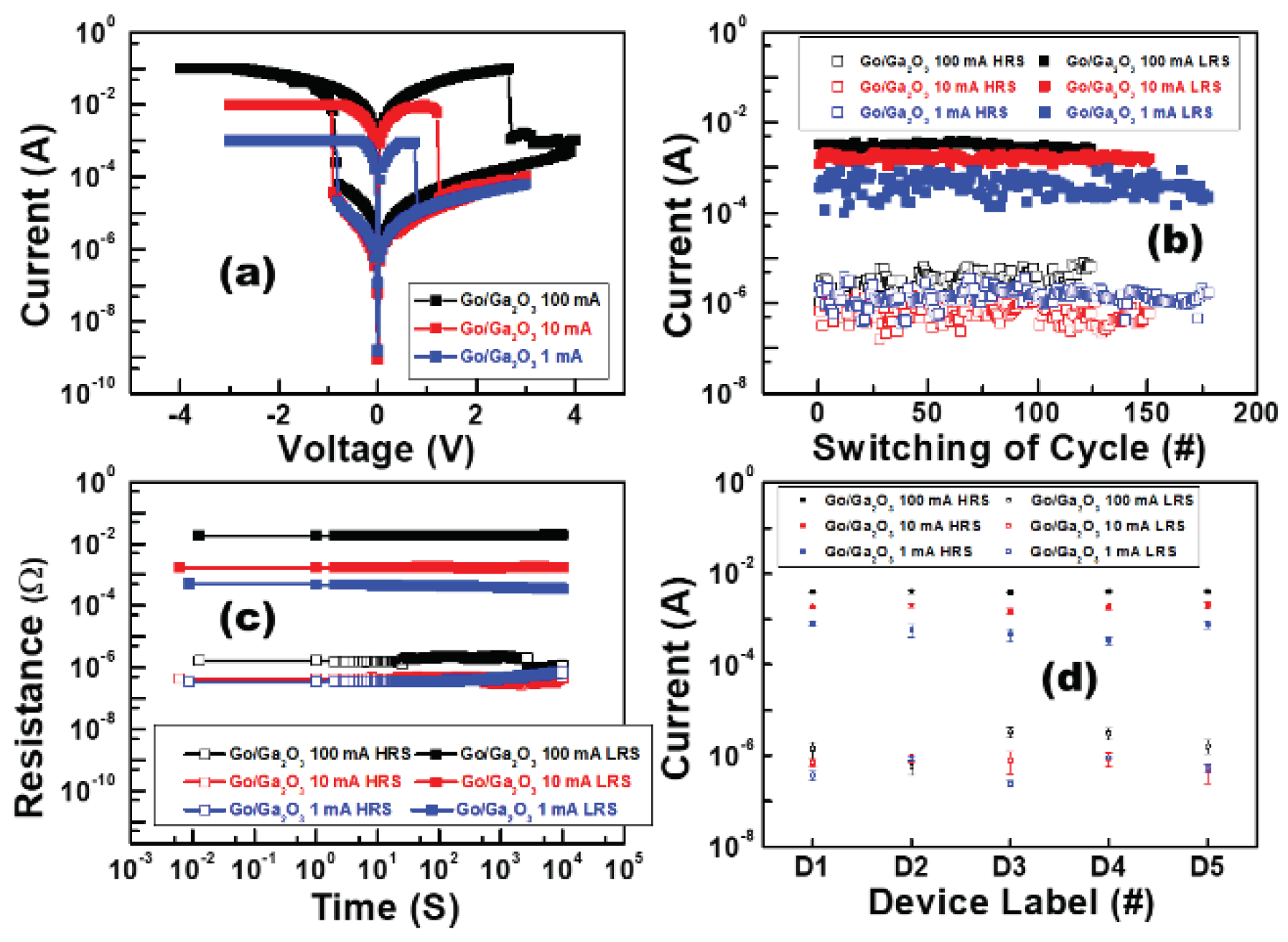

Multi-level cell (MLC) storage is the simplest technology to accommodate more information with low cost for high density storage applications. RRAM has particularly attracted lots of attention owing to its simplicity of obtaining the multi-state characteristics. In the bilayer structure, the switching layer can be distinguished into vacancy-rich region and vacancy-deficient region owing to the intrinsic nature of defect generation. The filament can be well controlled in the vacancy-poor region by modulating the current compliance, which further obtains the multiple LRS to achieve MLC storage capability [

11,

12].

Figure 7 (a) show the I-V characteristics of Al/GO/Ga

2O

3/ITO device at compliance currents of 100 mA, 10 mA and 1 mA, respectively.

Figure 7 (b) show the endurance characteristics of Al/GO/Ga

2O

3/ITO device at 100 mA, 10 mA and 1 mA current compliance. The ON/OFF ratio can maintain over 10

3 after 126 DC cycles at 100 mA compliance current. The ON/OFF ratio can maintain over 10

3 after 161 DC cycles at 10 mA compliance current and after 178 DC cycles at 1mA compliance current.

Figure 7 (c) shows the retention characteristics of bilayer device at 100 mA, 10mA and 1mA current compliance, respectively. The result exhibits the possibility of 2-bit storage, including three LRS and 1HRS [

13].

Figure 7 (d) shows the current distribution of HRS and LRS to assess the device-to-device uniformity. Five different devices on the sample were randomly selected to conduct the DC I-V measurement for 5 cycles. The voltage sweeping from -4V to 4V was applied on all devices. For this analysis, the current values were also extracted at -0.1 volts. The results of device-to-device variation for GO/Ga

2O

3 at 100 mA, 10 mA and 1 mA are also presented. Because of the GO layer, the GO/Ga

2O

3 device had excellent device-to-device uniformity.

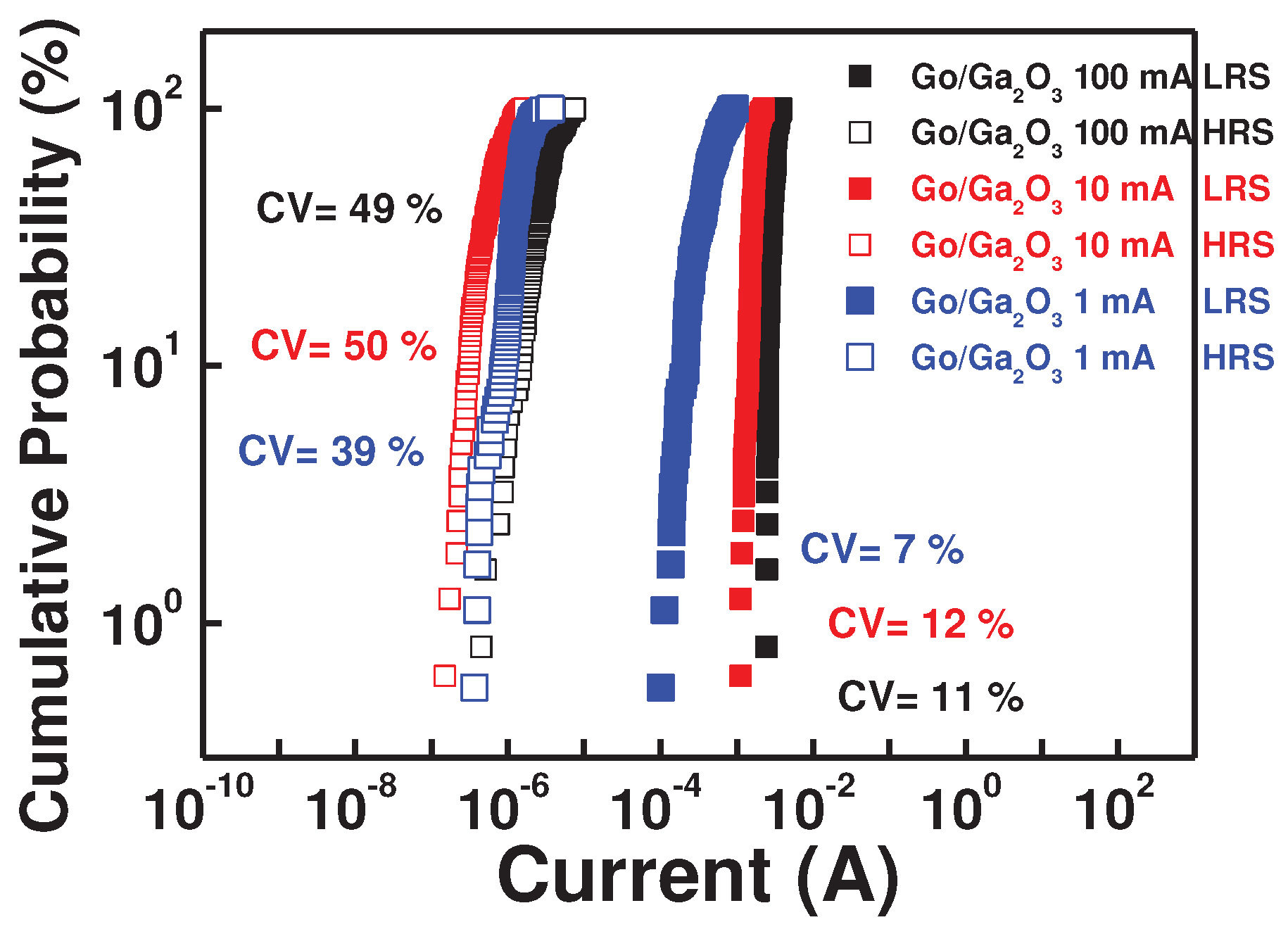

The results of cycle-to-cycle variation of Al/GO/Ga

2O

3/ITO device at the compliance current of 100 mA, 10mA and 1mA are also shown in

Figure 8. The GO/Ga

2O

3 device values of coefficient of variation in LRS and HRS were about 11% and 49% at 100 mA. The GO/Ga

2O

3 device values of coefficient of variation in LRS and HRS were about 12% and 50% at 10 mA. The GO/Ga

2O

3 device values of coefficient of variation in LRS and HRS were about 7% and 39% at 1 mA. Compared to the single-layer structure, the bilayer structure had better cycle-to-cycle uniformity because of the presence of GO insertion layer.

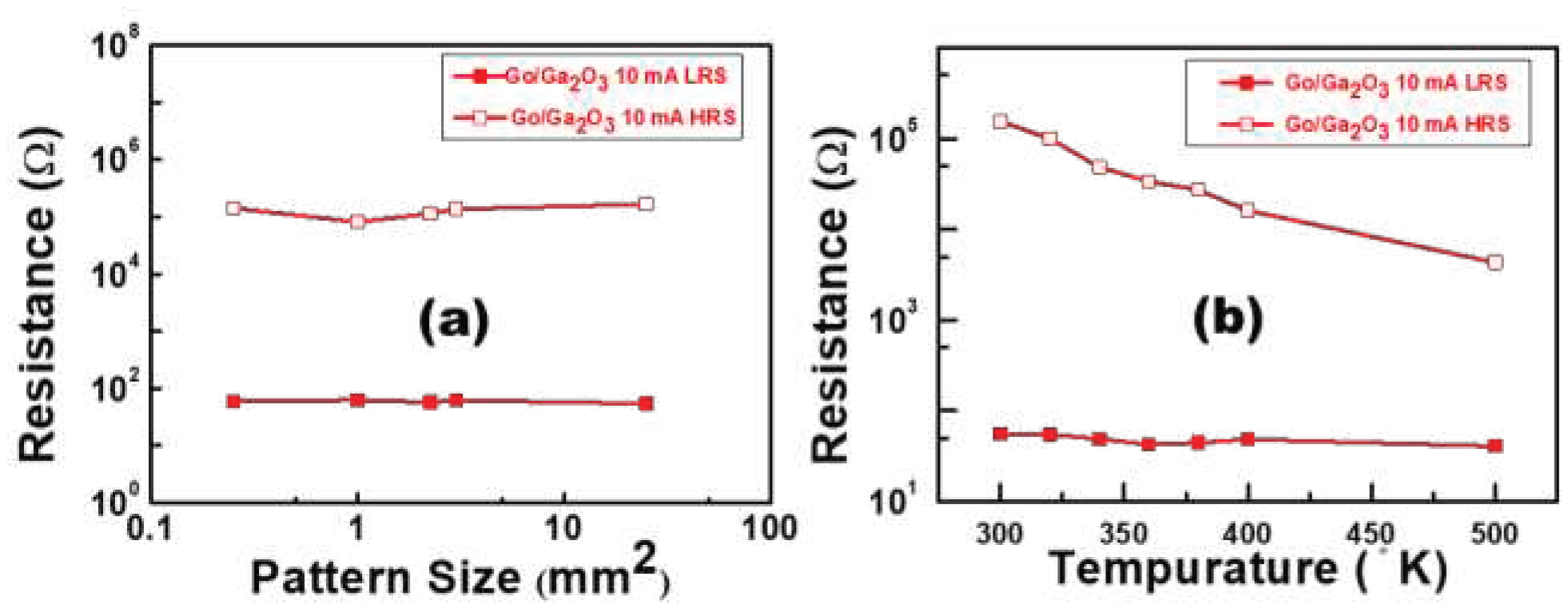

Figure 9 (a) plots the dependences between pattern sizes and resistive states of Al/GO/Ga

2O

3/ITO/glass device at 10 mA current compliance. The resistance values were extracted at -0.1V. This result demonstrates that both states were insensitive to the pattern sizes. Thus, the filament theory is appropriate to explain the operation of resistive switching for this structure.

Figure 9 (b) shows the relationship between both states and temperatures at 10mA current compliance. This result was characterized by an Agilent B1500A parameter analyzer, and the sample was heated ranging from 300K to 500K. In this measurement, the resistance values were also extracted at -0.1 volts under different temperatures. The resistance of HRS decreased with increasing temperature, which exhibited a semiconductor-like behavior. On the other hand, the current of LRS maintained at a fixed value under different temperatures. It is worth noting that the memory window still maintained around 10

2 under the high temperature of 500K, which could be attributed to the wide bandgap of Ga

2O

3.

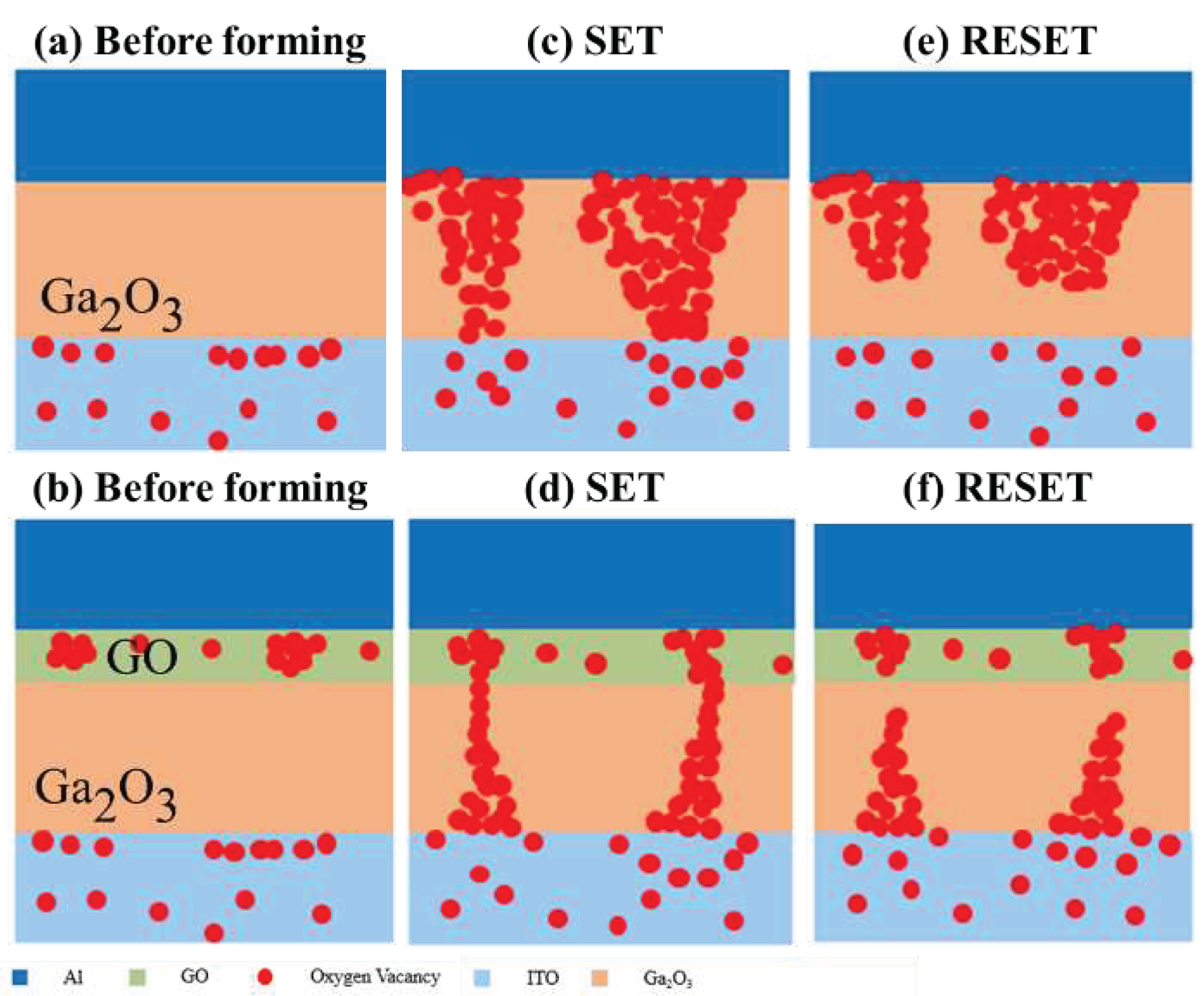

Filament theory is the most widely used theory to elucidate the resistive switching mechanism of RRAM devices. It means the switching behavior relies on the conformation and rupture of the conductive filament (CF) in the switching layer [

14,

15]. In order to explain the resistive switching mechanism, filament models of the Al/Ga

2O

3/ITO/glass and the Al/GO/Ga

2O

3/ITO/glass are constructed in

Figure 10, respectively. The distributions of oxygen vacancies before conducting electrical measurements are presented in

Figure 10 (a)-(b). In

Figure 10 (a), the presence of the oxygen vacancies in ITO makes the forming and set processes under the negative sweep, and reset process under the positive sweep. In

Figure 10 (b), the high concentration of oxygen vacancies makes the forming voltage lower. The distributions of oxygen vacancies under resistive switching (set and reset processes) of both devices are shown in

Figure 10 (c)-(f). Owing to the GO insertion layer, the conformation and rupture of CFs could be more uniform and CFs could be thinner than the pristine device. Moreover, the CFs could be modulated by different compliant currents.