Submitted:

08 May 2023

Posted:

08 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. β-TCP Ceramics

2.3. Three-Dimensional Printing

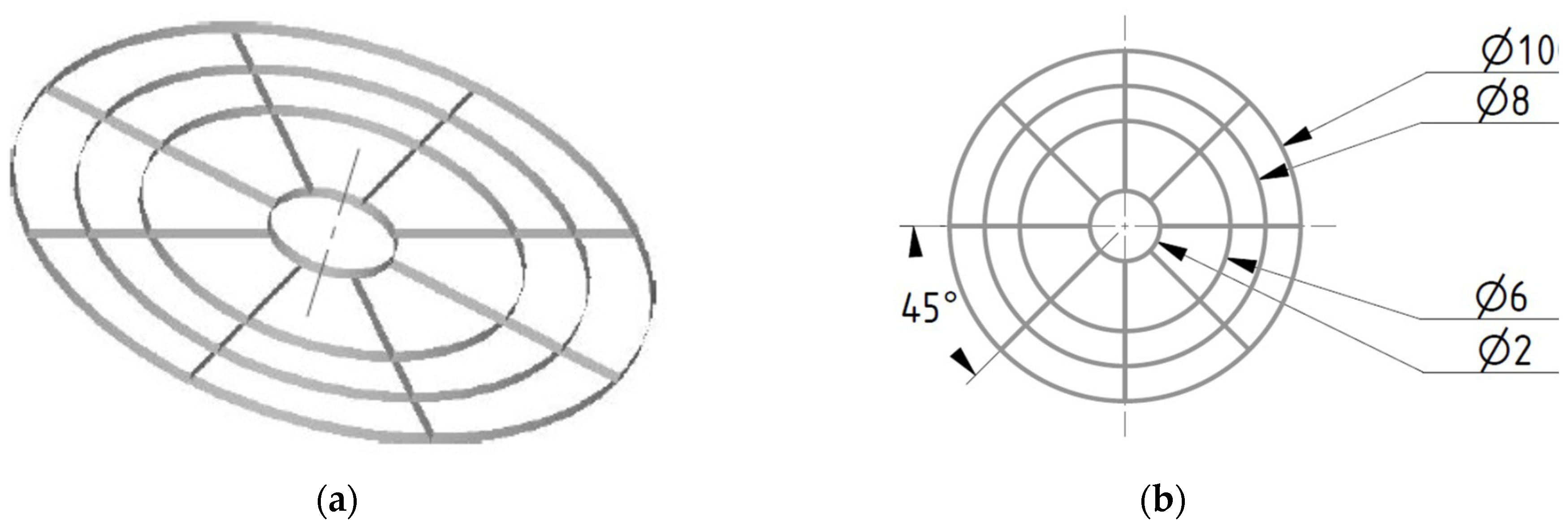

2.3.1. Optimizing Printing Parameters

- the pressure [bar].

- the printing speed [mm/s]

- the Needle Offset [mm]

- the Post-Flow [s]

- Pre-Flow [s]

2.3.2. Printing the round Geometries with more than 12 layers

2.4. Characterization of the Scaffolds: 3D printed and sintered

2.5. Statistics

3. Results

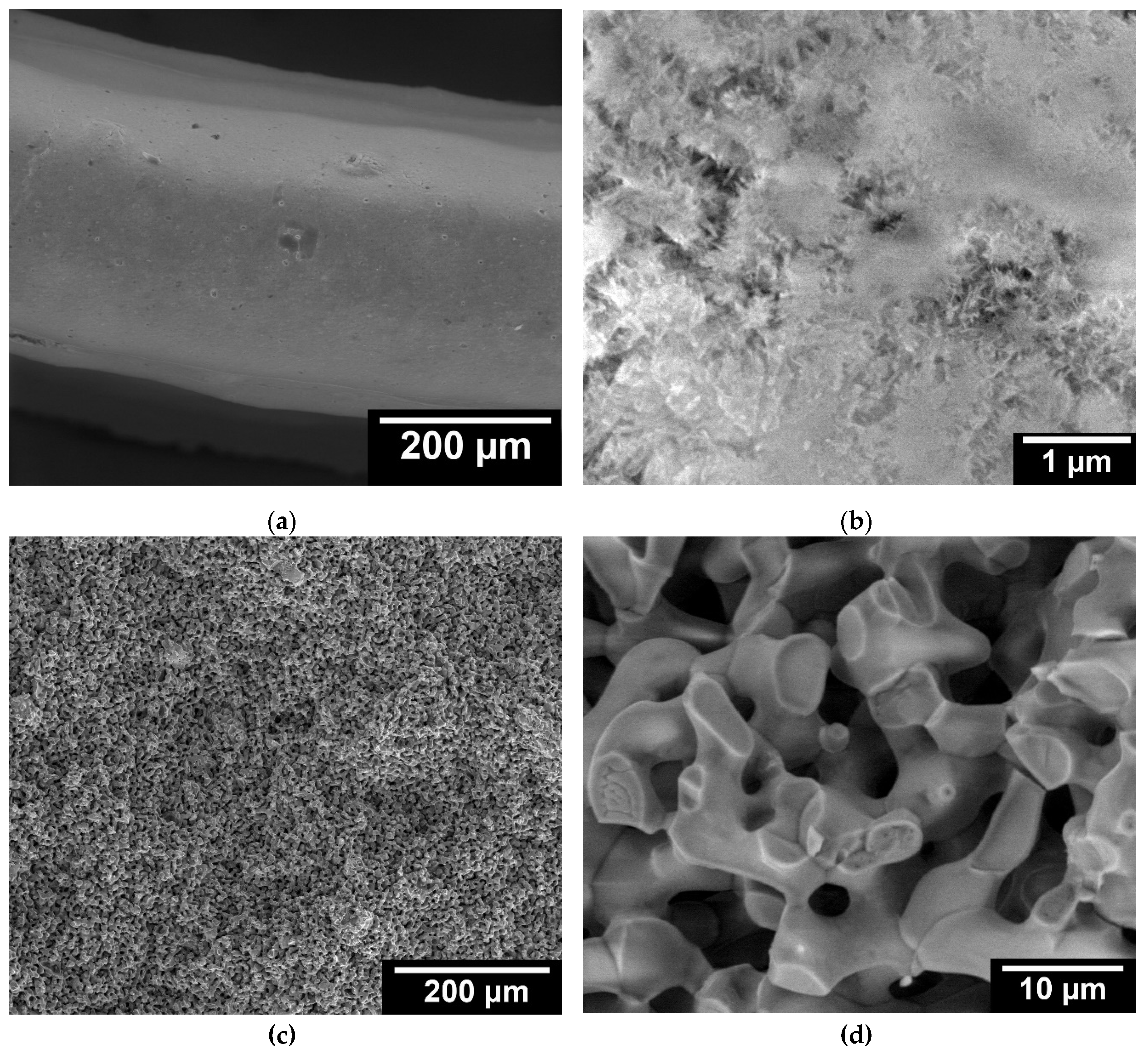

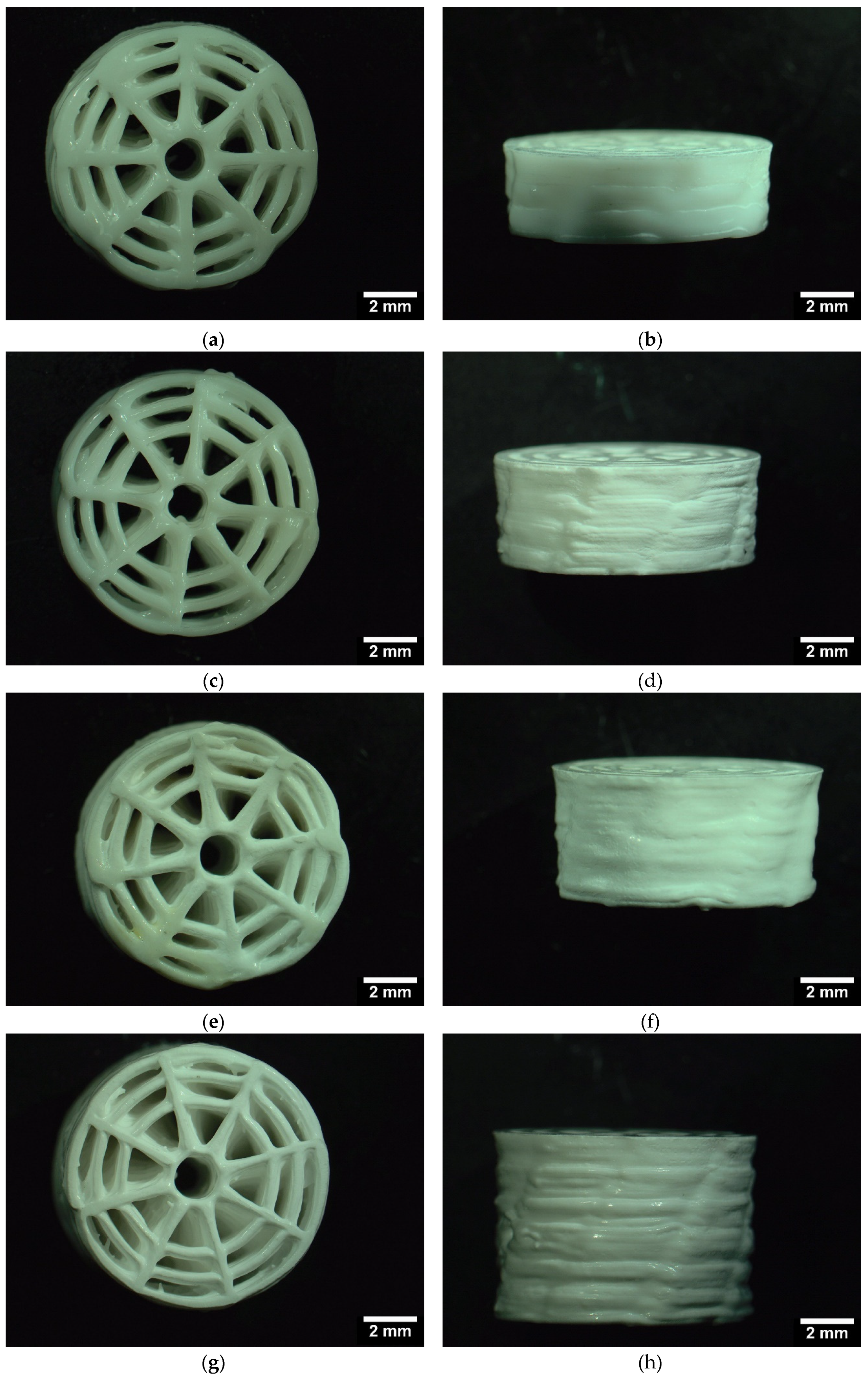

3.1. Characterization of the Scaffolds

3.1.1. Dimensions

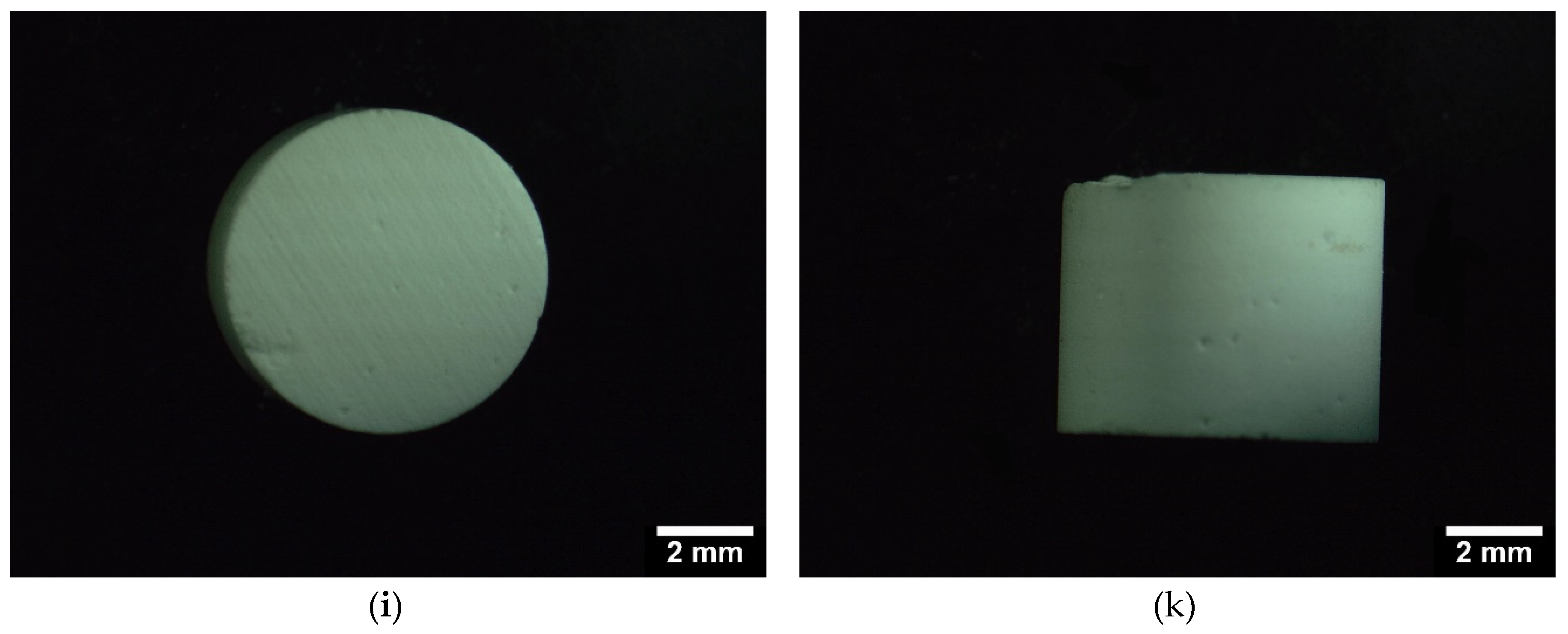

3.1.2. Strand width and Surface roughness (Sa)

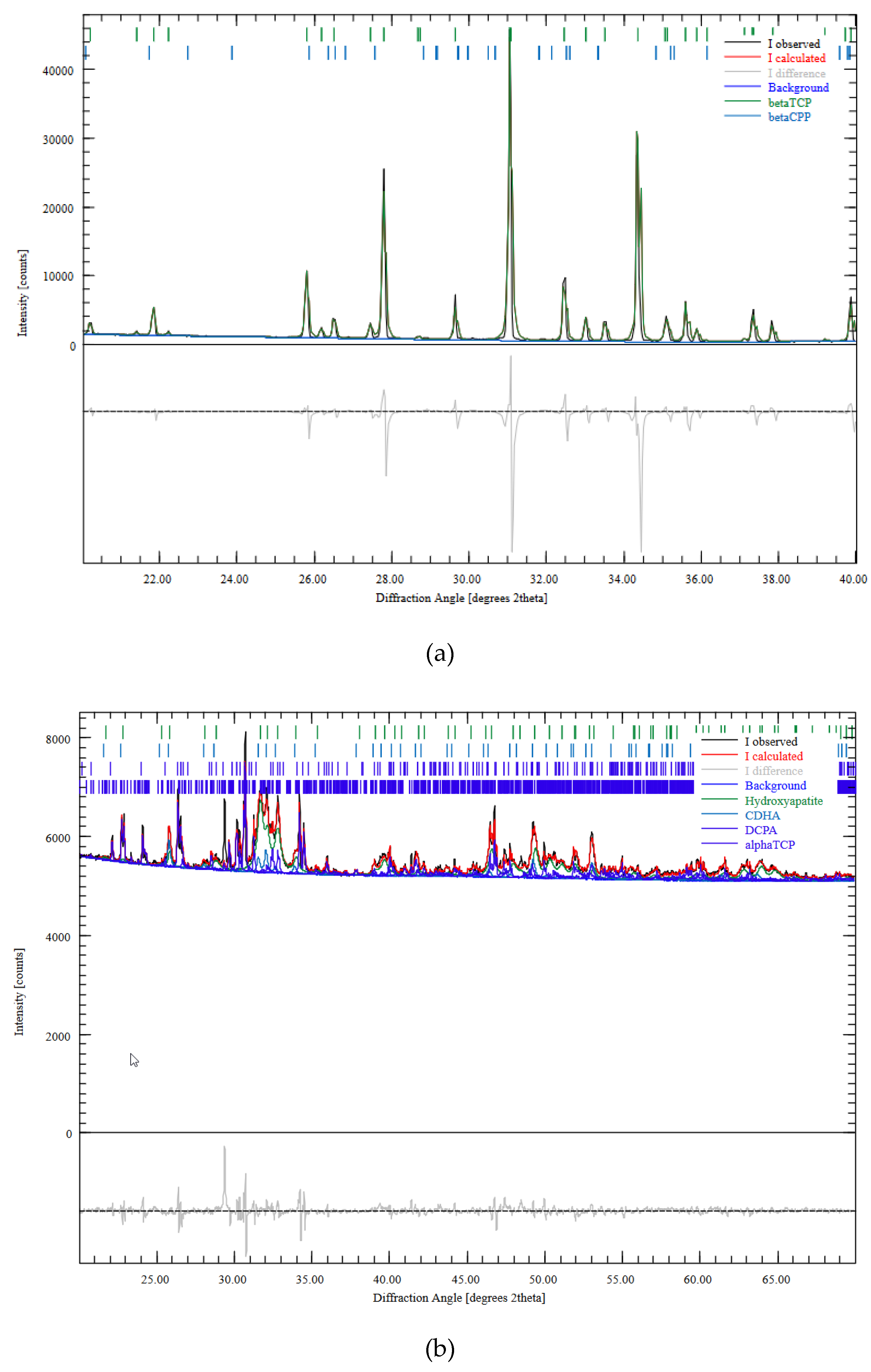

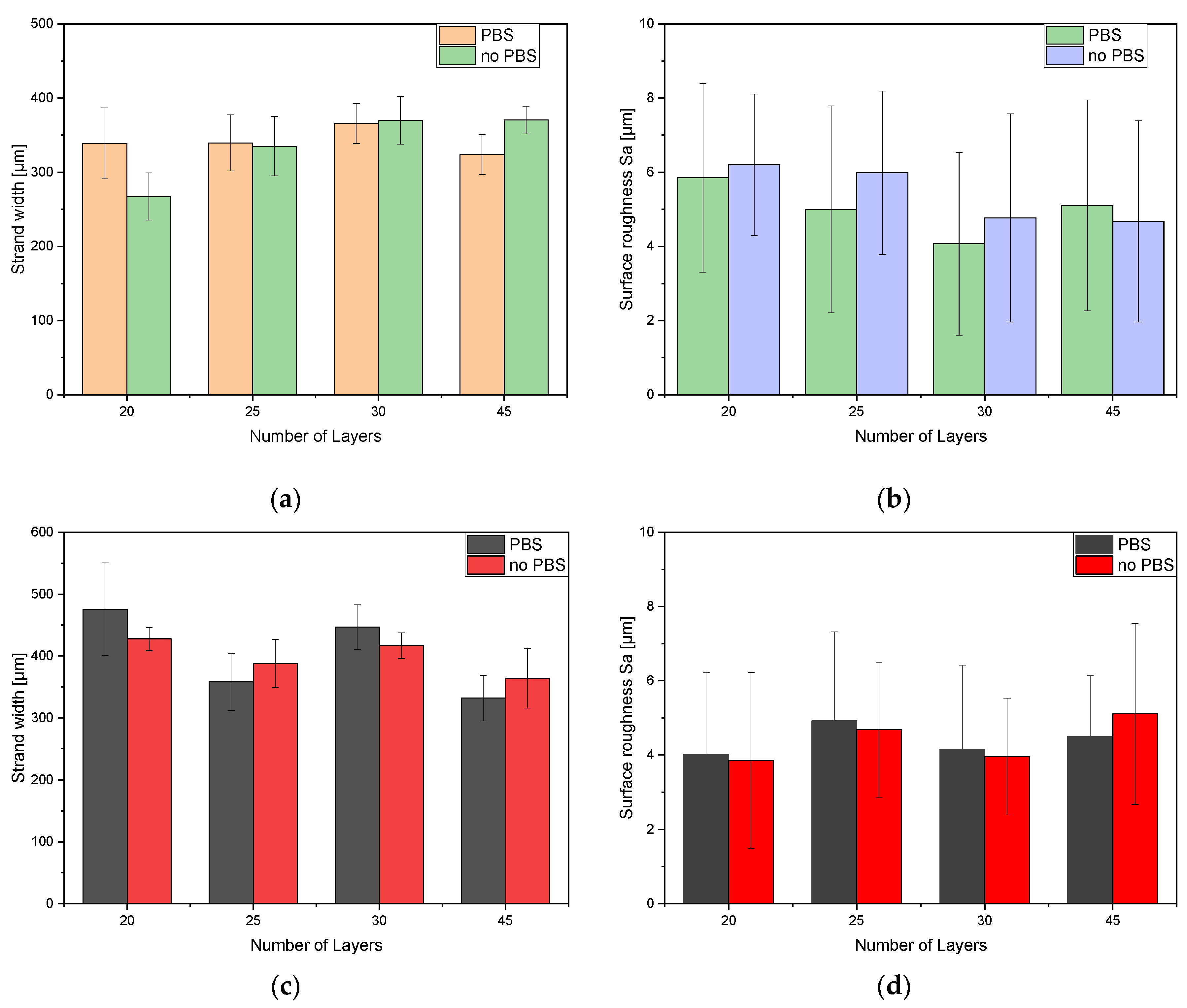

3.1.3. Phase composition (EDX and XRD)

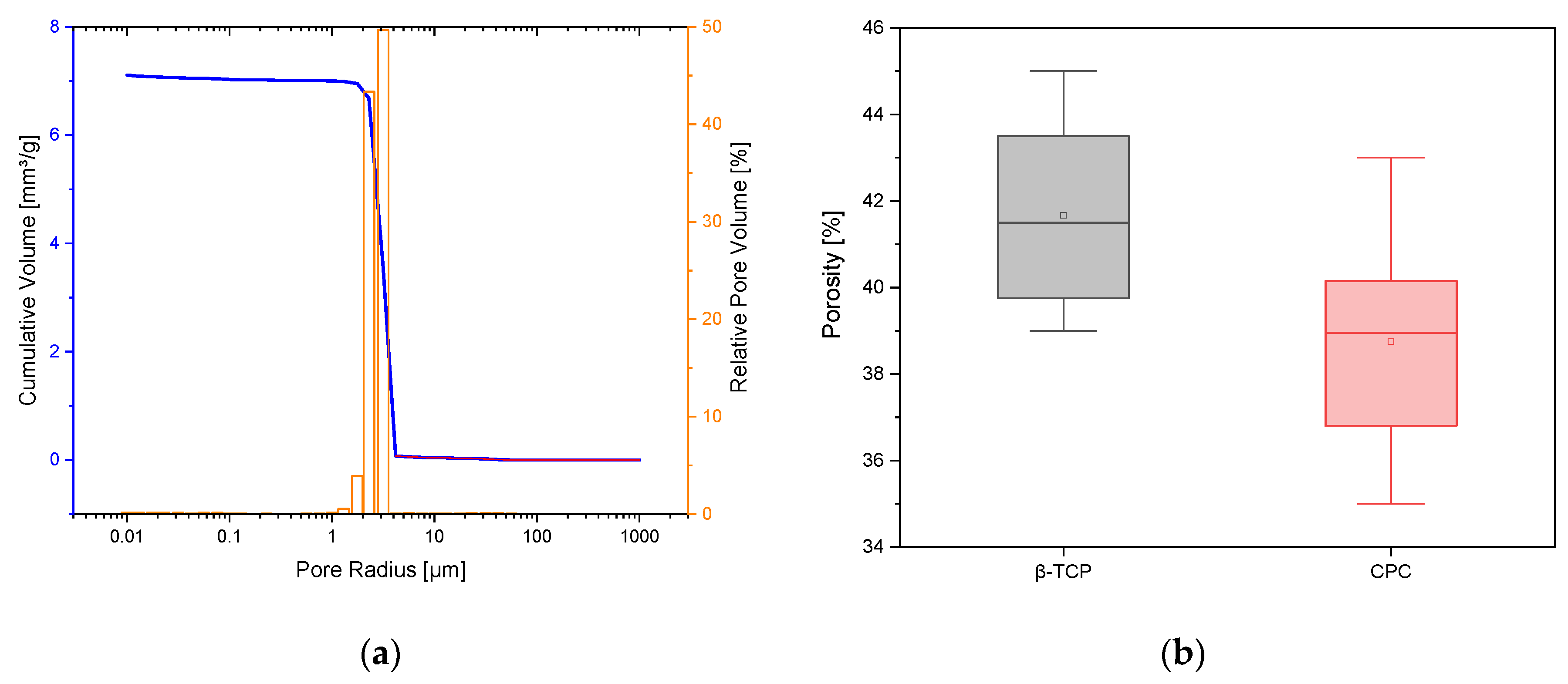

3.1.4. Porosity

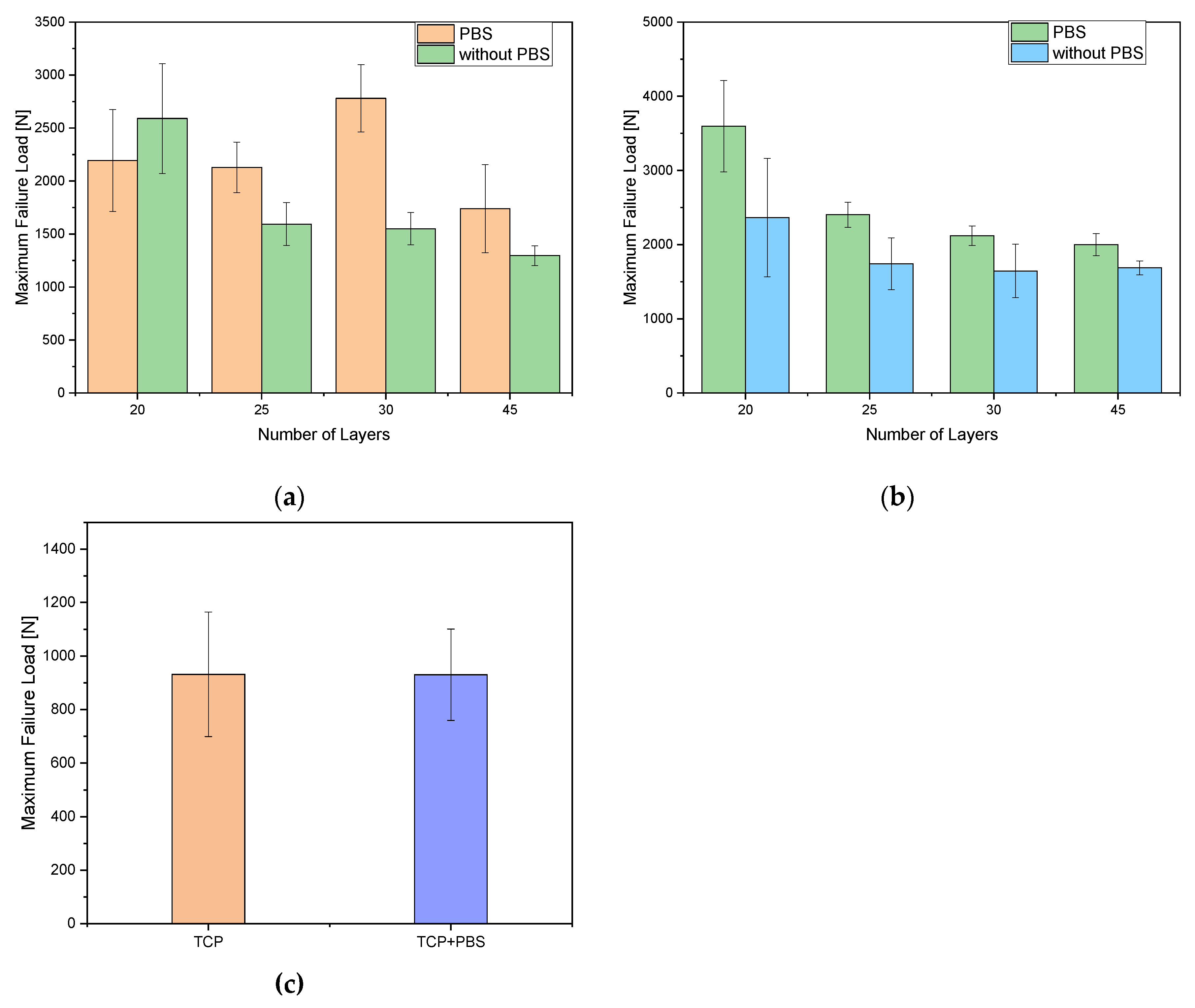

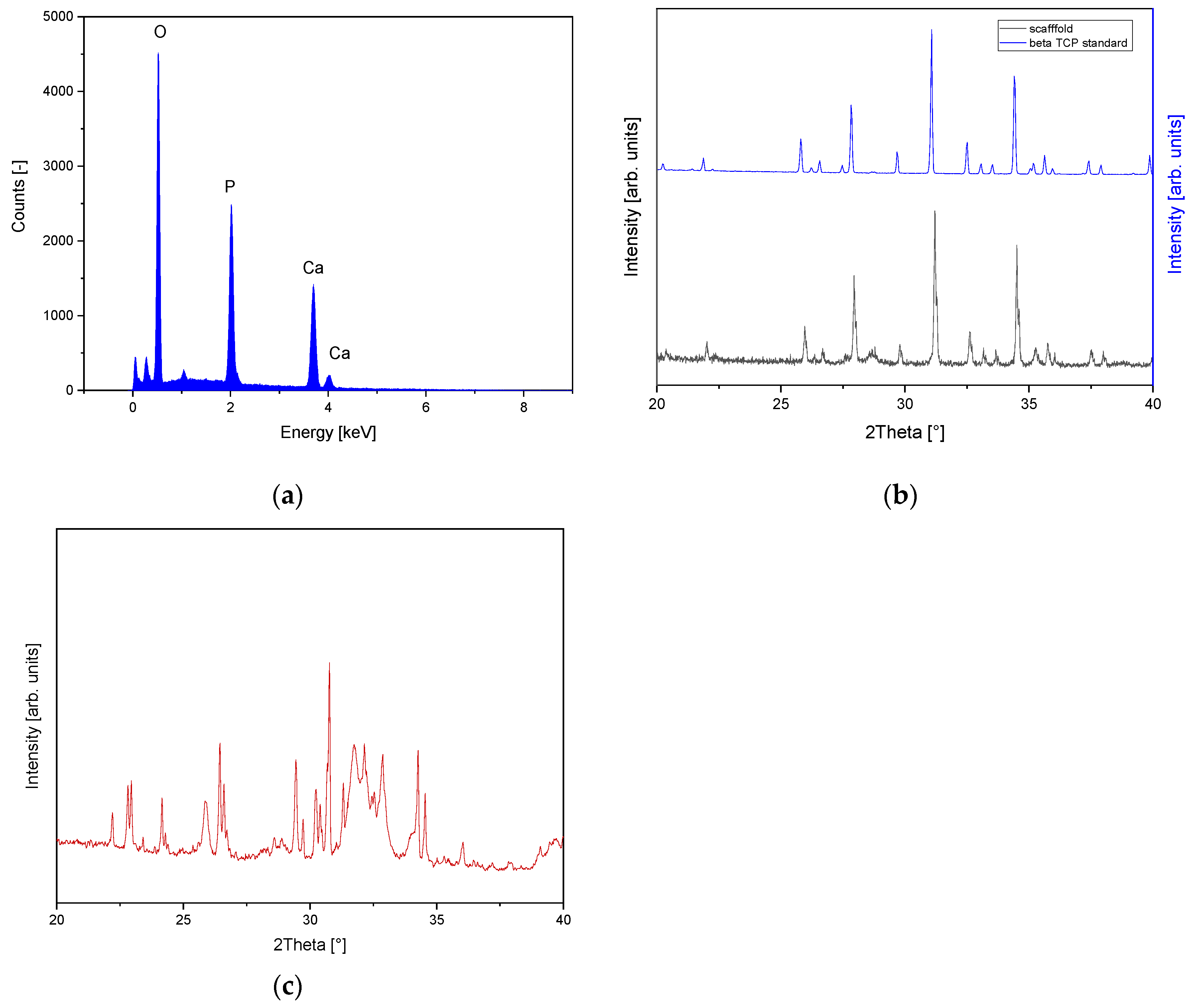

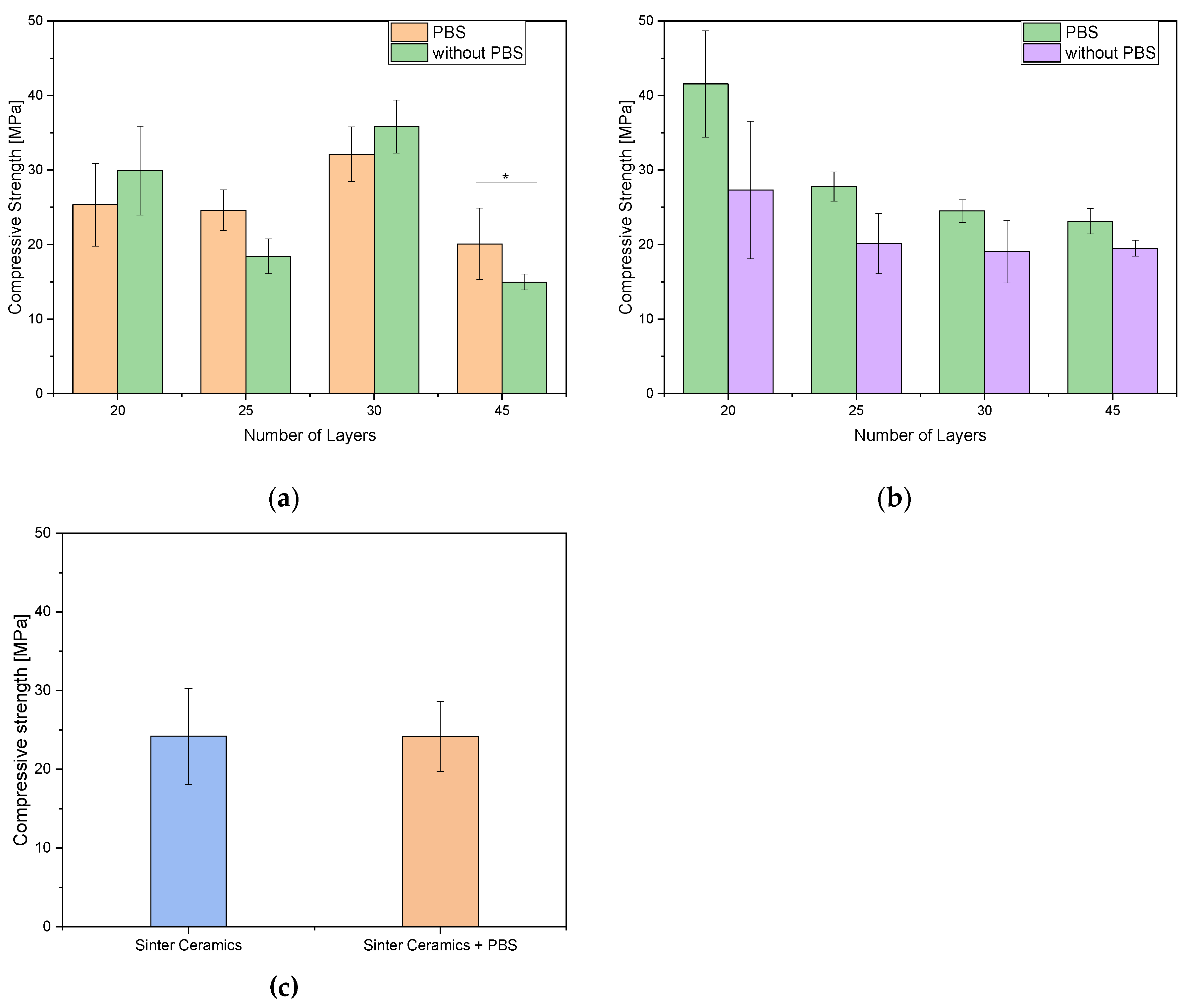

3.1.5. Mechanical properties

4. Discussion

4.1. Strand Width and Surface Roughness Sa

4.2. Elemental Analysis EDX and XRD and microstructure by ESEM

4.3. Mechanical Properties

4.4. Novelty character and limitations of the present study

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix

References

- Behrendt, H.; Runggaldier, K. [a problem outline on demographic change in the federal republic of germany]. Notfall + Rettungsmedizin 2009, 12, 45-50. [CrossRef]

- Peters, E.; Pritzkuleit, R.; Beske, F.; Katalinic, A. Demografischer wandel und krankheitshäufigkeiten. Bundesgesundheitsblatt - Gesundheitsforschung - Gesundheitsschutz 2010, 53, 417-426. [CrossRef]

- Eurostat. European union: Age structure in the member states in 2019 https://de.statista.com/statistik/daten/studie/248981/umfrage/altersstruktur-in-den-eu-laendern/ (03-2020),.

- Destatis. Mitten im demografischen wandel. https://www.destatis.de/DE/Themen/Querschnitt/Demografischer-Wandel/demografie-mitten-im-wandel.html (2020-09-02),.

- U.N., U.N. World population prospects 2022. population.un.org (20-02-2023),.

- Destatis. Gesundheit - fallpauschalenbezogene krankenhausstatistik (drg-statistik) operationen und prozeduren der vollstationären patientinnen und patienten in krankenhäusern (4-steller); Statistisches Bundesamt (Destatis): Wiesbaden, 2020.

- Engh, C.A., Jr.; Young, A.M.; Engh, C.A., Sr.; Hopper, R.H., Jr. Clinical consequences of stress shielding after porous-coated total hip arthroplasty. Clinical Orthopaedics and Related Research® 2003, 417. [CrossRef]

- Epple, M. Biomaterialien und biomineralisation, eine einführung für naturwissenschaftler, mediziner und ingenieure. 2003. [CrossRef]

- Jarcho, M. Calcium phosphate ceramics as hard tissue prosthetics. Clin. Orthop. Relat. Res. 1981, 259-278.

- Ducheyne, P.; Qiu, Q. Bioactive ceramics: The effect of surface reactivity on bone formation and bone cell function. Biomaterials 1999, 20, 2287-2303.

- Bohner, M.; van Lenthe, G.H.; Grünenfelder, S.; Hirsiger, W.; Evison, R.; Müller, R. Synthesis and characterization of porous -tricalcium phosphate blocks. Biomaterials 2005, 26, 6099-6105. [CrossRef]

- Karageorgiou, V.; Kaplan, D. Porosity of 3d biomaterial scaffolds and osteogenesis. Biomaterials 2005, 26, 5474-5491. [CrossRef]

- Jacob, H.A.C. Materialverhalten (knochen und implantatwerkstoffe) bei mechanischer beanspruchung. In Orthopädie und unfallchirurgie: Für praxis, klinik und facharztprüfung, Grifka, J.; Kuster, M., Eds. Springer Berlin Heidelberg: Berlin, Heidelberg, 2011; pp 29-47. [CrossRef]

- Akao, M.; Aoki, H.; Kato, K. Mechanical properties of sintered hydroxyapatite for prosthetic applications. Journal of Materials Science 1981, 16, 809-812. [CrossRef]

- Pearson, O.M.; Lieberman, D.E. The aging of wolff’s “law”: Ontogeny and responses to mechanical loading in cortical bone. Yearbook of Physical Anthropology 2004, 125, 63-99. [CrossRef]

- Tian, J.; Tian, J. Preparation of porous hydroxyapatite. Journal of Materials Science 2001, 36, 3061-3066. [CrossRef]

- Figliuzzi, M.; Mangano, F.; Mangano, C. A novel root analogue dental implant using ct scan and cad/cam: Selective laser melting technology. International Journal of Oral and Maxillofacial Surgery 2012, 41, 858-862. [CrossRef]

- Igawa, K.; Mochizuki, M.; Sugimori, O.; Shimizu, K.; Yamazawa, K.; Kawaguchi, H.; Nakamura, K.; Takato, T.; Nishimura, R.; Suzuki, S.; et al. Tailor-made tricalcium phosphate bone implant directly fabricated by a three-dimensional ink-jet printer. J. Artificial Organs 2006, 9, 234-240. [CrossRef]

- Xu, H.H.K.; Wang, P.; Wang, L.; Bao, C.; Chen, Q.; Weir, M.D.; Chow, L.C.; Zhao, L.; Zhou, X.; Reynolds, M.A. Calcium phosphate cements for bone engineering and their biological properties. Bone Research 2017, 5, 17056. [CrossRef]

- Ghosh, S.; Wu, V.; Pernal, S.; Uskoković, V. Self-setting calcium phosphate cements with tunable antibiotic release rates for advanced antimicrobial applications. ACS Applied Materials & Interfaces 2016, 8, 7691-7708. [CrossRef]

- Seidenstuecker, M.; Ruehe, J.; Suedkamp, N.P.; Serr, A.; Wittmer, A.; Bohner, M.; Bernstein, A.; Mayr, H.O. Composite material consisting of microporous β-tcp ceramic and alginate for delayed release of antibiotics. Acta Biomater. 2017, 433–446. [CrossRef]

- Kuehling, T.; Schilling, P.; Bernstein, A.; Mayr, H.O.; Serr, A.; Wittmer, A.; Bohner, M.; Seidenstuecker, M. A human bone infection organ model for biomaterial research. Acta Biomater. 2022. [CrossRef]

- Vorndran, E.; Geffers, M.; Ewald, A.; Lemm, M.; Nies, B.; Gbureck, U. Ready-to-use injectable calcium phosphate bone cement paste as drug carrier. Acta Biomater. 2013, 9, 9558-9567. [CrossRef]

- Takagi, S.; Chow, L.C.; Hirayama, S.; Sugawara, A. Premixed calcium–phosphate cement pastes. Journal of Biomedical Materials Research Part B: Applied Biomaterials 2003, 67B, 689-696. [CrossRef]

- Lu, J.; Descamps, M.; Dejou, J.; Koubi, G.; Hardouin, P.; Lemaitre, J.; Proust, J.-P. The biodegradation mechanism of calcium phosphate biomaterials in bone. Journal of Biomedical Materials Research 2002, 63, 408-412. [CrossRef]

- Seidenstuecker, M.; Mrestani, Y.; Neubert, R.H.H.; Bernstein, A.; Mayr, H.O. Release kinetics and antibacterial efficacy of microporous β-tcp coatings. Journal of Nanomaterials 2013, 2013, 8. [CrossRef]

- Huber, F.; Vollmer, D.; Vinke, J.; Riedel, B.; Zankovic, S.; Schmal, H.; Seidenstuecker, M. Influence of 3d printing parameters on the mechanical stability of pcl scaffolds and the proliferation behavior of bone cells. Materials 2022, 15, 2091. [CrossRef]

- Blankenburg, J.; Vinke, J.; Riedel, B.; Zankovic, S.; Schmal, H.; Seidenstuecker, M. Alternative geometries for 3d bioprinting of calcium phosphate cement as bone substitute. Biomedicines 2022, 10, 3242. [CrossRef]

- Egorov, A.; Riedel, B.; Vinke, J.; Schmal, H.; Thomann, R.; Thomann, Y.; Seidenstuecker, M. The mineralization of various 3d-printed pcl composites. J Funct Biomater 2022, 13, 238. [CrossRef]

- Seidenstuecker, M.; Schmeichel, T.; Ritschl, L.; Vinke, J.; Schilling, P.; Schmal, H.; Bernstein, A. Mechanical properties of the composite material consisting of β-tcp and alginate-di-aldehyde-gelatin hydrogel and its degradation behavior. Materials 2021, 14, 1303. [CrossRef]

- Stahli, C.; Bohner, M.; Bashoor-Zadeh, M.; Doebelin, N.; Baroud, G. Aqueous impregnation of porous beta-tricalcium phosphate scaffolds. Acta Biomater. 2010, 6, 2760-2772. [CrossRef]

- Khairoun, I.; Boltong, M.G.; Driessens, F.C.; Planell, J.A. Effect of calcium carbonate on clinical compliance of apatitic calcium phosphate bone cement. J Biomed Mater Res 1997, 38, 356-360. [CrossRef]

- Seidenstuecker, M.; Schilling, P.; Ritschl, L.; Lange, S.; Schmal, H.; Bernstein, A.; Esslinger, S. Inverse 3d printing with variations of the strand width of the resulting scaffolds for bone replacement. Materials 2021, 14, 1964. [CrossRef]

- Muallah, D.; Sembdner, P.; Holtzhausen, S.; Meissner, H.; Hutsky, A.; Ellmann, D.; Assmann, A.; Schulz, M.C.; Lauer, G.; Kroschwald, L.M. Adapting the pore size of individual, 3d-printed cpc scaffolds in maxillofacial surgery. Journal of Clinical Medicine 2021, 10, 2654. [CrossRef]

- Akkineni, A.R.; Luo, Y.; Schumacher, M.; Nies, B.; Lode, A.; Gelinsky, M. 3d plotting of growth factor loaded calcium phosphate cement scaffolds. Acta Biomater. 2015, 27, 264-274. [CrossRef]

- Raymond, S.; Maazouz, Y.; Montufar, E.B.; Perez, R.A.; González, B.; Konka, J.; Kaiser, J.; Ginebra, M.-P. Accelerated hardening of nanotextured 3d-plotted self-setting calcium phosphate inks. Acta Biomater. 2018, 75, 451-462. [CrossRef]

- Seidenstuecker, M.; Kissling, S.; Ruehe, J.; Suedkamp, N.; Mayr, H.; Bernstein, A. Novel method for loading microporous ceramics bone grafts by using a directional flow. J Funct Biomater 2015, 6, 1085. [CrossRef]

- Bernstein, A.; Niemeyer, P.; Salzmann, G.; Südkamp, N.P.; Hube, R.; Klehm, J.; Menzel, M.; von Eisenhart-Rothe, R.; Bohner, M.; Görz, L.; et al. Microporous calcium phosphate ceramics as tissue engineering scaffolds for the repair of osteochondral defects: Histological results. Acta Biomater. 2013, 9, 7490-7505. [CrossRef]

- Fathi, M.; Kholtei, A.; El Youbi, S.; Chafik El Idrissi, B. Setting properties of calcium phosphate bone cement. Materials Today: Proceedings 2019, 13, 876-881. [CrossRef]

- Mayr, H.O.; Klehm, J.; Schwan, S.; Hube, R.; Sudkamp, N.P.; Niemeyer, P.; Salzmann, G.; von Eisenhardt-Rothe, R.; Heilmann, A.; Bohner, M.; et al. Microporous calcium phosphate ceramics as tissue engineering scaffolds for the repair of osteochondral defects: Biomechanical results. Acta Biomater. 2013, 9, 4845-4855. [CrossRef]

- Miyamoto, Y.; Ishikawa, K.; Fukao, H.; Sawada, M.; Nagayama, M.; Kon, M.; Asaoka, K. In vivo setting behaviour of fast-setting calcium phosphate cement. Biomaterials 1995, 16, 855-860. [CrossRef]

- Li, C.; Jiang, C.; Deng, Y.; Li, T.; Li, N.; Peng, M.; Wang, J. Rhbmp-2 loaded 3d-printed mesoporous silica/calcium phosphate cement porous scaffolds with enhanced vascularization and osteogenesis properties. Scientific Reports 2017, 7, 41331. [CrossRef]

- Wu, C.; Fan, W.; Zhou, Y.; Luo, Y.; Gelinsky, M.; Chang, J.; Xiao, Y. 3d-printing of highly uniform casio3 ceramic scaffolds: Preparation, characterization and in vivo osteogenesis. Journal of Materials Chemistry 2012, 22, 12288-12295. [CrossRef]

- Richard, H.A.; Kullmer, G. Biomechanik – definitionen, aufgaben und fragestellungen. In Biomechanik: Anwendungen mechanischer prinzipien auf den menschlichen bewegungsapparat, Richard, H.A.; Kullmer, G., Eds. Springer Fachmedien Wiesbaden: Wiesbaden, 2020; pp 1-14. [CrossRef]

- Olszta, M.J.; Cheng, X.; Jee, S.S.; Kumar, R.; Kim, Y.-Y.; Kaufman, M.J.; Douglas, E.P.; Gower, L.B. Bone structure and formation: A new perspective. Materials Science and Engineering: R: Reports 2007, 58, 77-116. [CrossRef]

- Kaur, G.; Kumar, V.; Baino, F.; Mauro, J.C.; Pickrell, G.; Evans, I.; Bretcanu, O. Mechanical properties of bioactive glasses, ceramics, glass-ceramics and composites: State-of-the-art review and future challenges. Materials Science and Engineering: C 2019, 104, 109895. [CrossRef]

- Wu, Y.; Woodbine, L.; Carr, A.M.; Pillai, A.R.; Nokhodchi, A.; Maniruzzaman, M. 3d printed calcium phosphate cement (cpc) scaffolds for anti-cancer drug delivery. Pharmaceutics 2020, 12, 1077. [CrossRef]

| Sample | Pressure [bar] | Printing speed [mm/s] | Needle offset [mm] | Post flow [s] | Water applied after layer |

|---|---|---|---|---|---|

| 020_20layers | 1.0 | 4.5 | 0.16 | 0.0 | 7 |

| 020_25layers | 1.0 | 4.5 | 0.16 | 0.0 | 7 |

| 020_30layers | 1.0 | 4.0 | 0.16 | 0.0 | 7 |

| 020_45layers | 1.0 | 4.0 | 0.16 | 0.0 | 7 |

| 025_20layers | 0.9 | 5.2 | 0.22 | -0.05 | 5 |

| 025_25layers | 0.8 | 4.5 | 0.22 | -0.05 | 5 |

| 025_30layers | 0.9 | 4.3 | 0.22 | -0.05 | 5 |

| 025_45layers | 0.9 | 5.3 | 0.22 | -0.05 | 5 |

| Scaffold | Height [mm] | Diameter [mm] |

|---|---|---|

| 020_20layer | 3.4 | 10.5 |

| 020_20layer+PBS | 3.4 | 10.5 |

| 020_25layer | 4.3 | 10.5 |

| 020_25layer+PBS | 4.3 | 10.5 |

| 020_30layer | 5.0 | 10.5 |

| 020_30layer+PBS | 5.0 | 10.5 |

| 020_45layer | 7.5 | 10.5 |

| 020_45layer+PBS | 7.5 | 10.5 |

| 025_20layer | 4.4 | 10.5 |

| 025_20layer+PBS | 4.4 | 10.5 |

| 025_25layer | 5.3 | 10.5 |

| 025_25layer+PBS | 5.3 | 10.5 |

| 025_30layer | 6.4 | 10.5 |

| 025_30layer+PBS | 6.4 | 10.5 |

| 025_45layer | 9.5 | 10.5 |

| 025_45layer+PBS | 9.5 | 10.5 |

| Sinter ceramics | 7 | 7 |

| Compression Modulus [MPa] | ||||

| Number of Layers | 0.20 mm needle inner diameter | 0.25 mm needle inner diameter | ||

| PBS | No PBS | PBS | No PBS | |

| 20 | 5.65 ± 1.19 | 6.62 ± 0.89 | 7.87 ± 1.32 | 6.57 ± 1.93 |

| 25 | 7.46 ± 1.15 | 5.82 ± 1.25 | 9.47 ± 2.60 | 6.06 ± 1.81 |

| 30 | 9.72 ± 0.64 | 10.75 ± 0.81 | 8.47 ± 0.99 | 4.94 ± 1.94 |

| 45 | 10.13 ± 2.54 | 7.67 ± 0.79 | 13.42 ± 1.74 | 9.42 ± 2.84 |

| β-TCP Ceramics | PBS | No PBS | ||

| 50.9 ± 3.81 | 51.92 ± 4.13 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).