Submitted:

06 May 2023

Posted:

08 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

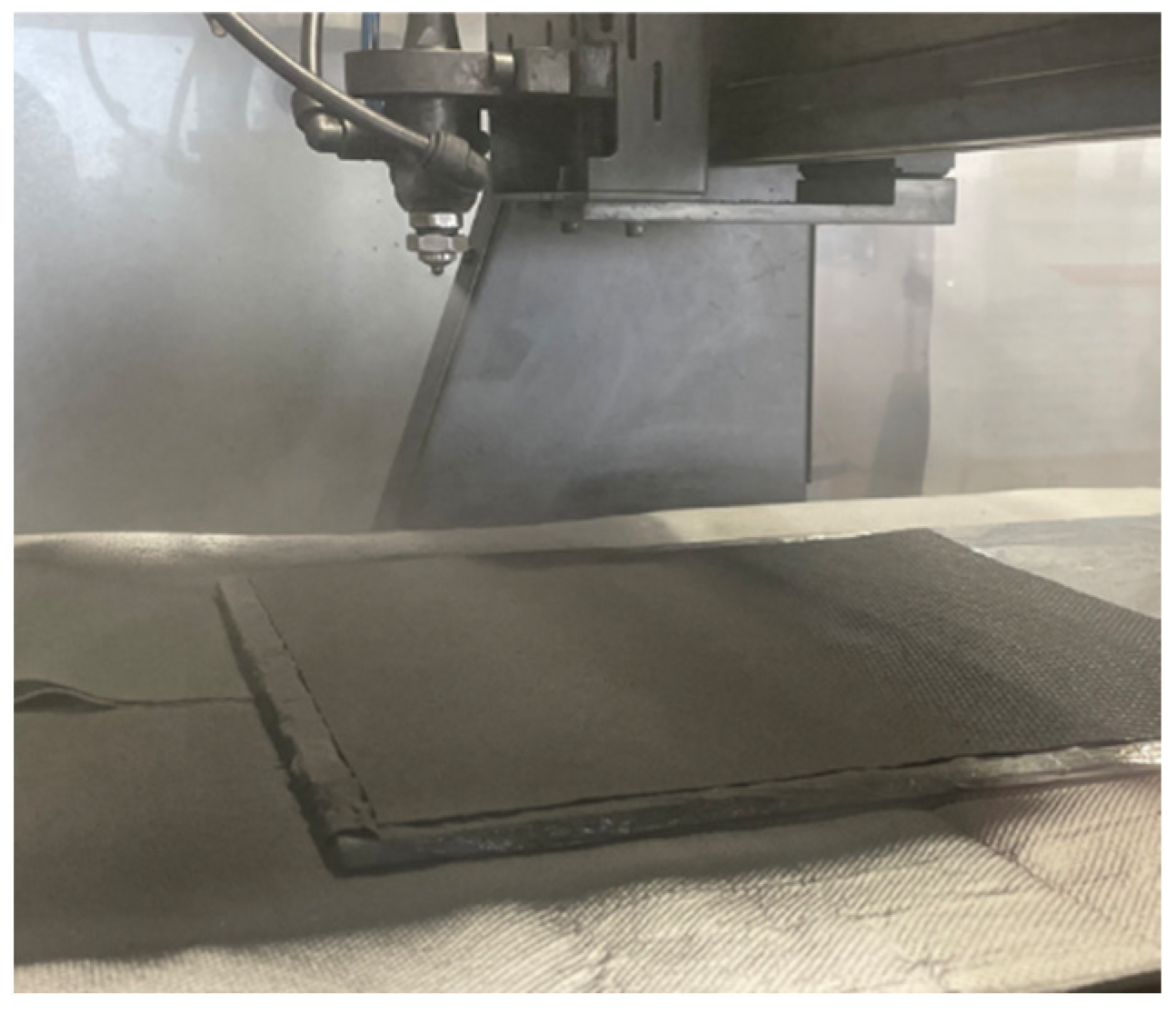

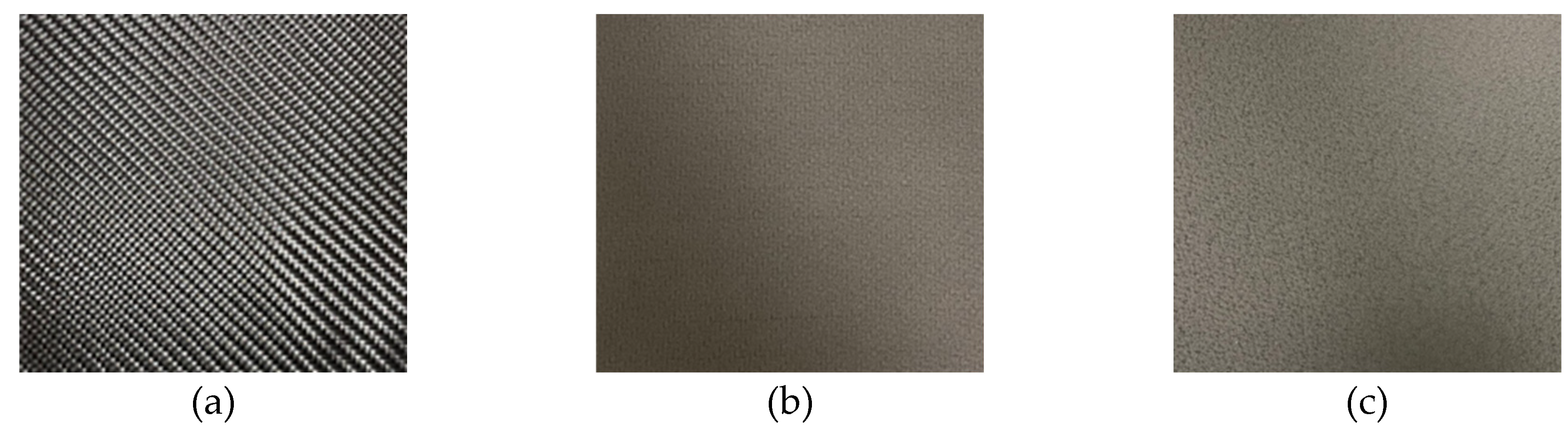

2.1. Integration of GNP high content layer onto carbon fiber prepreg

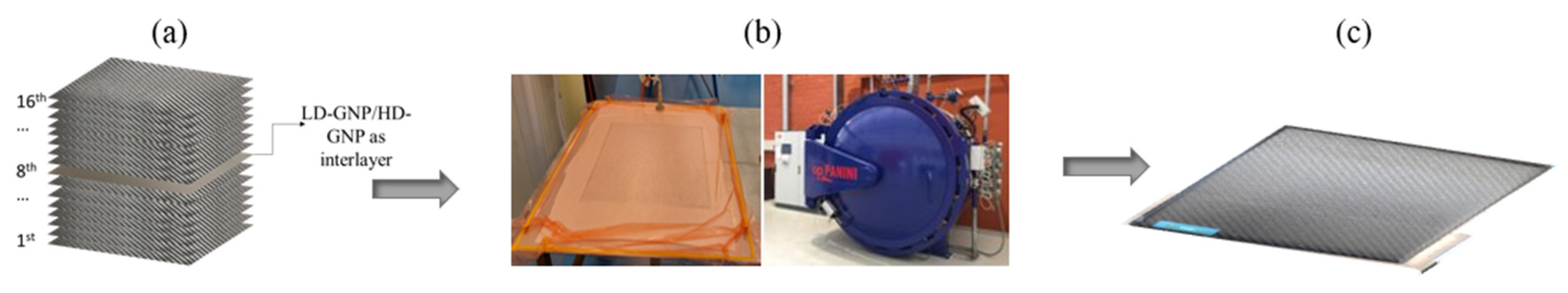

2.2. Manufacturing of hybrid carbon fiber epoxy composites

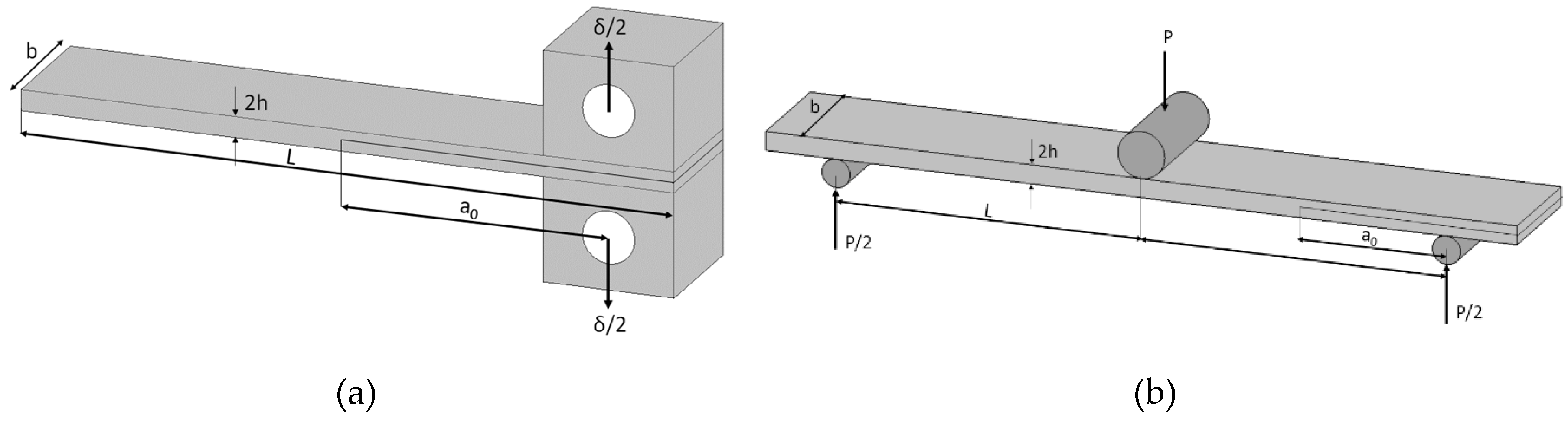

2.3. Experiremental Characterization

3. Results and Discussion

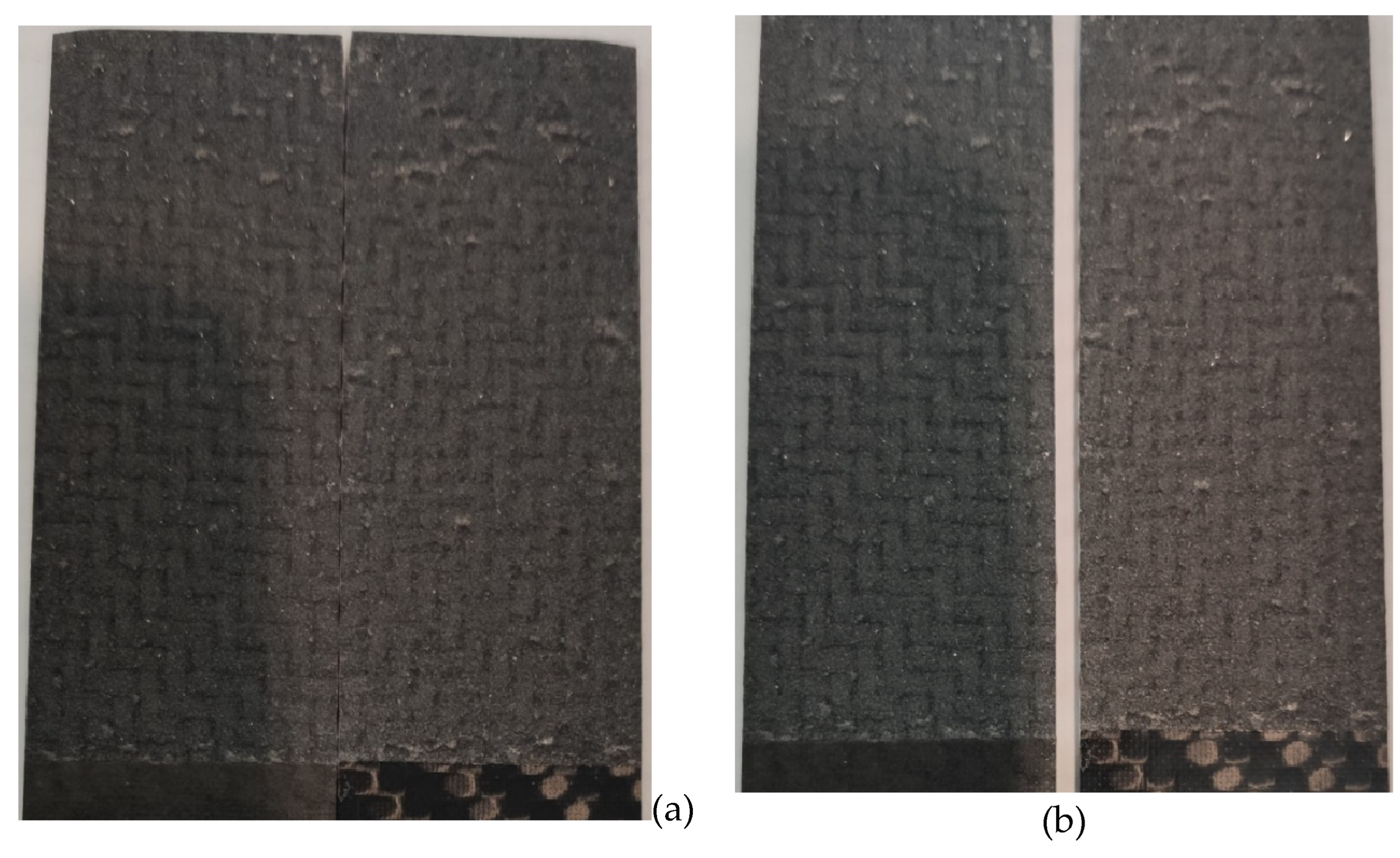

3.1. Characterisation of graphene-coated prepreg

3.2. Characterisation of functionalized laminates

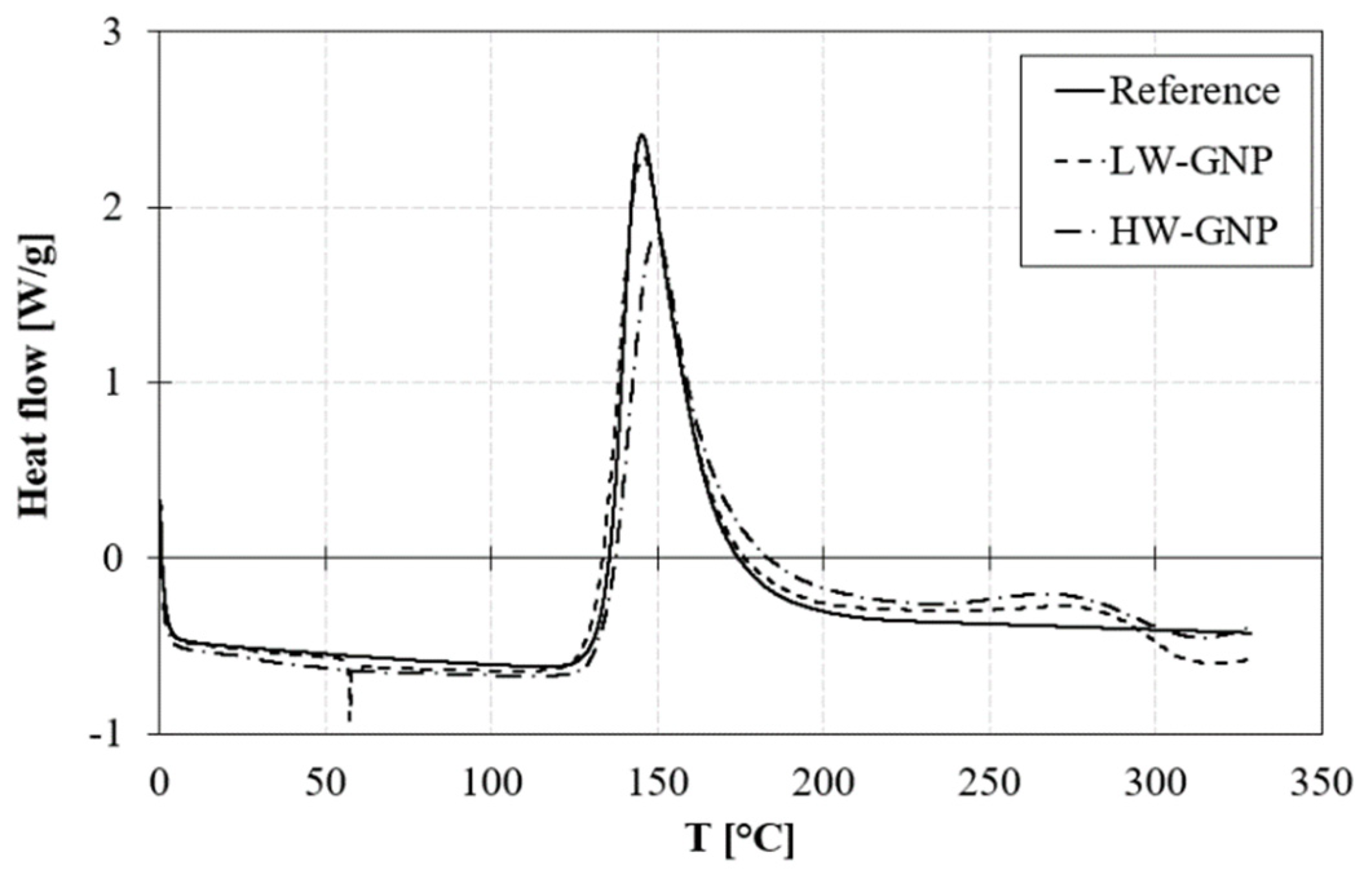

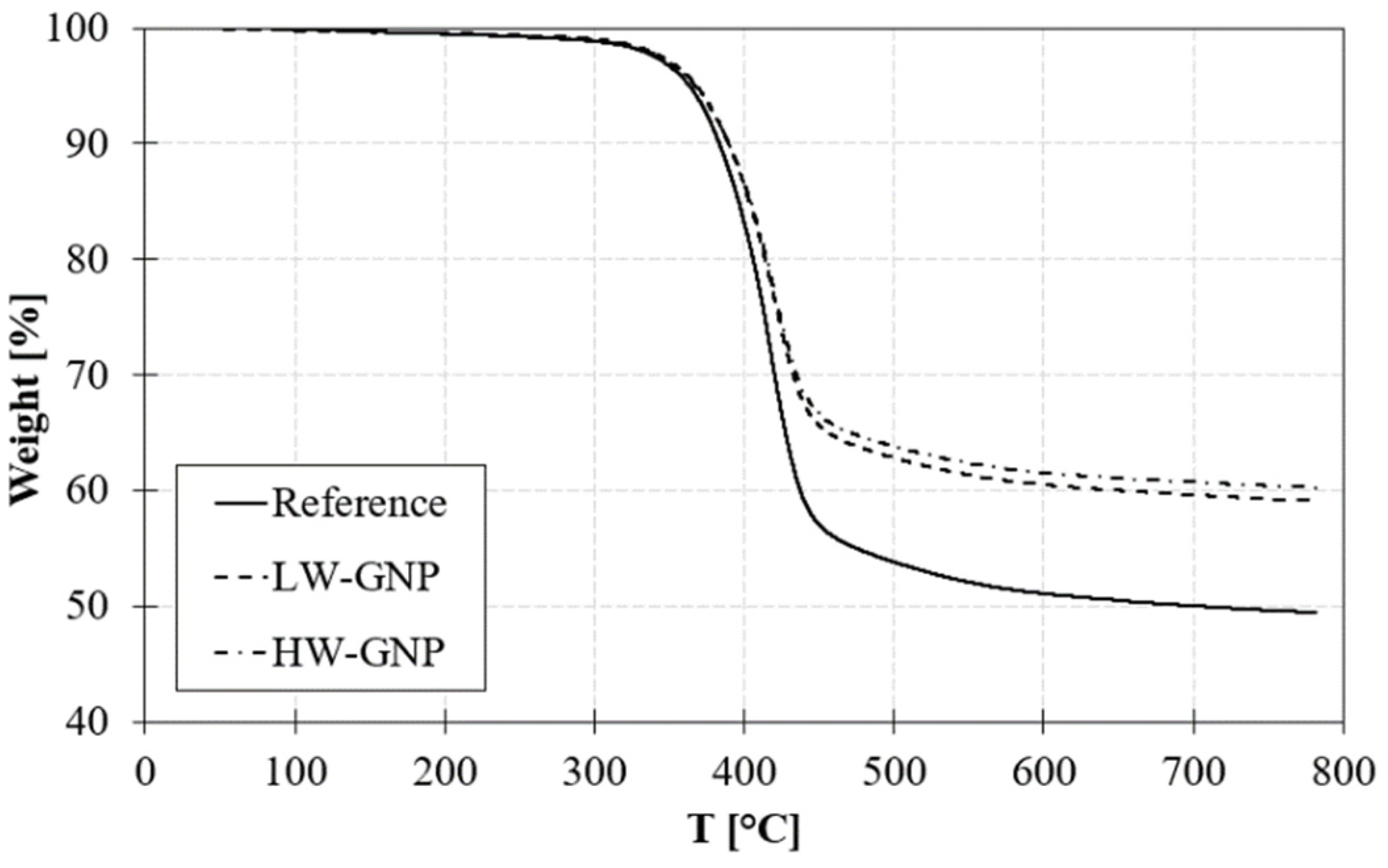

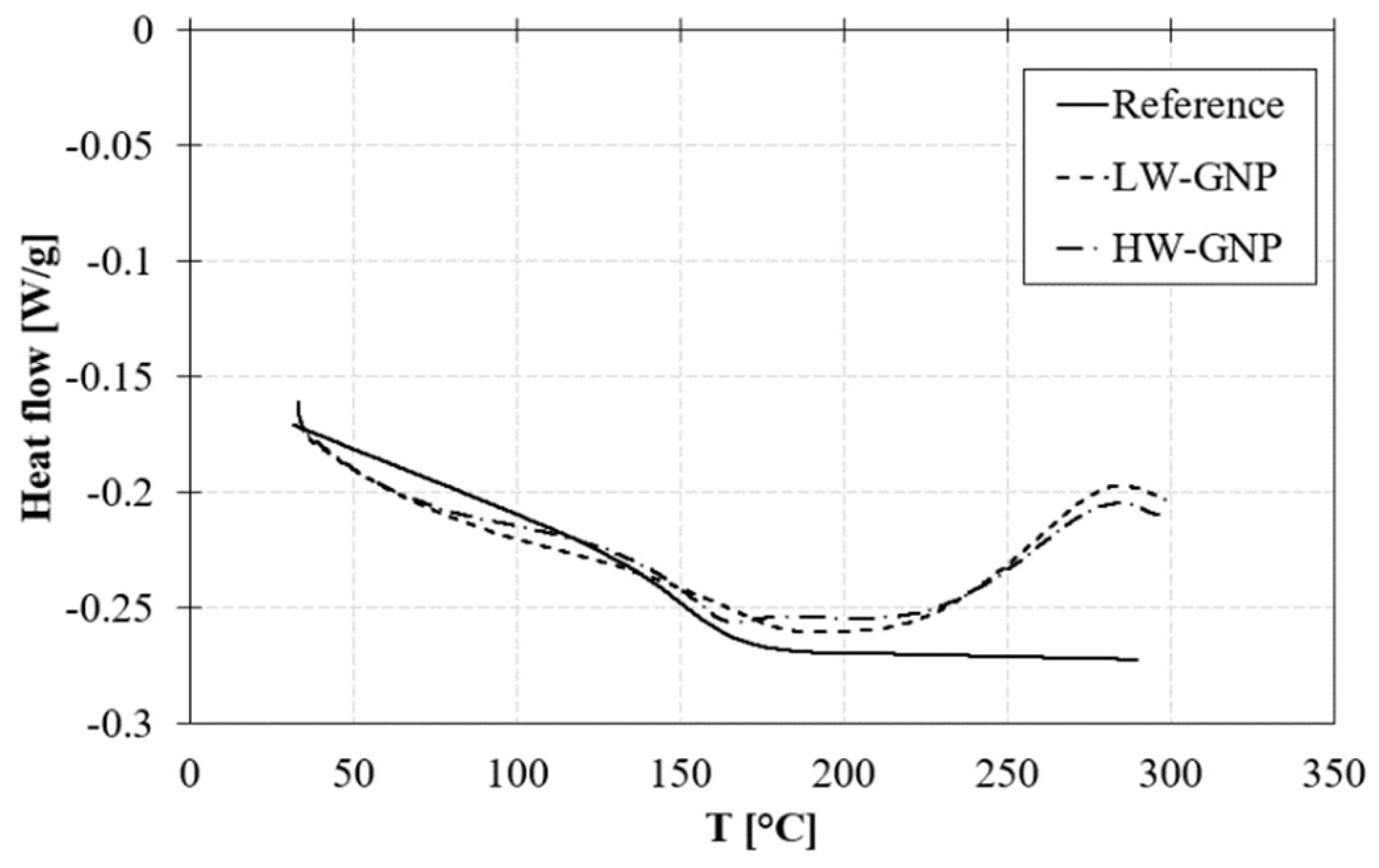

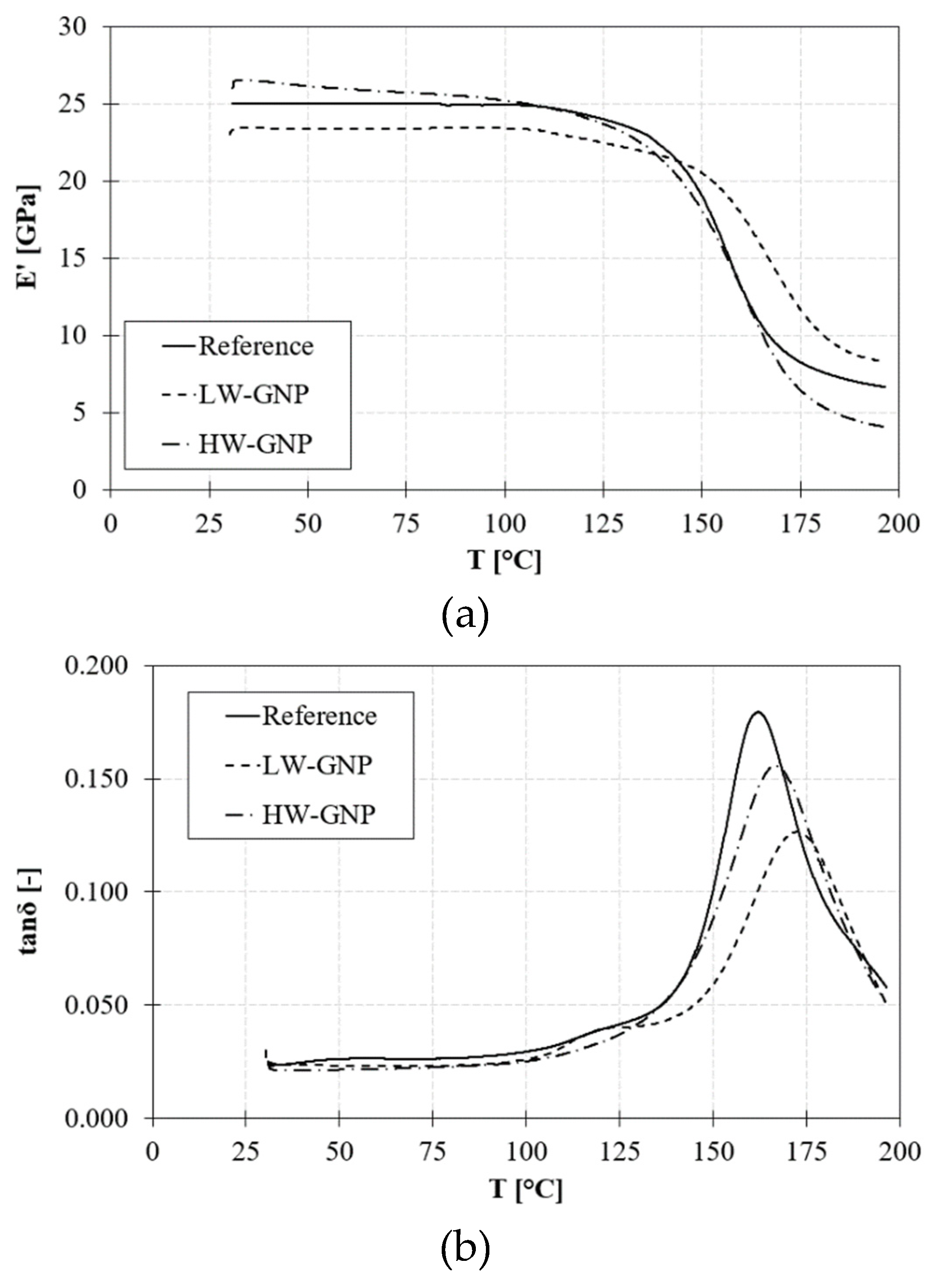

3.2.1. TGA, DSC and DMA results

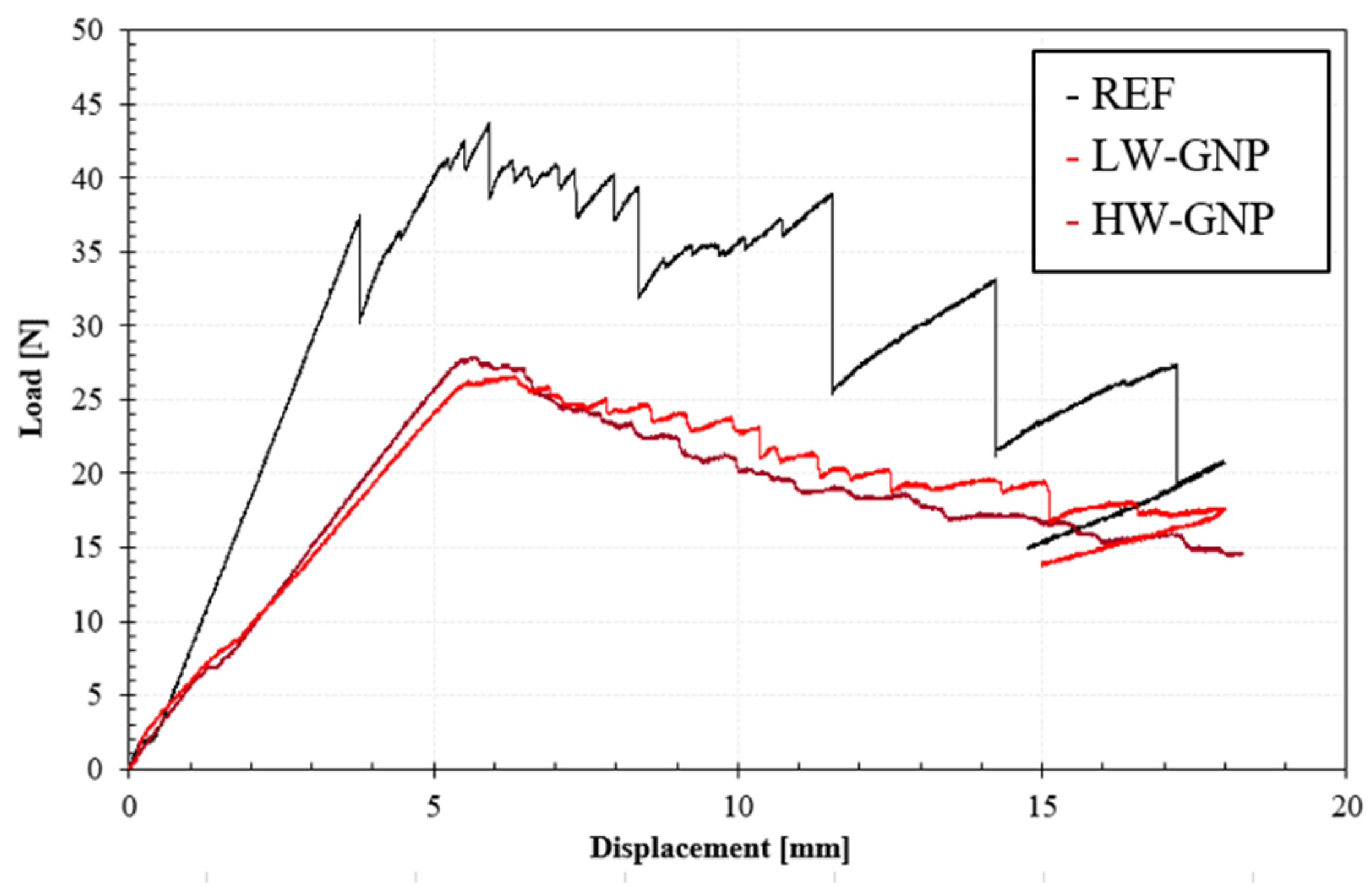

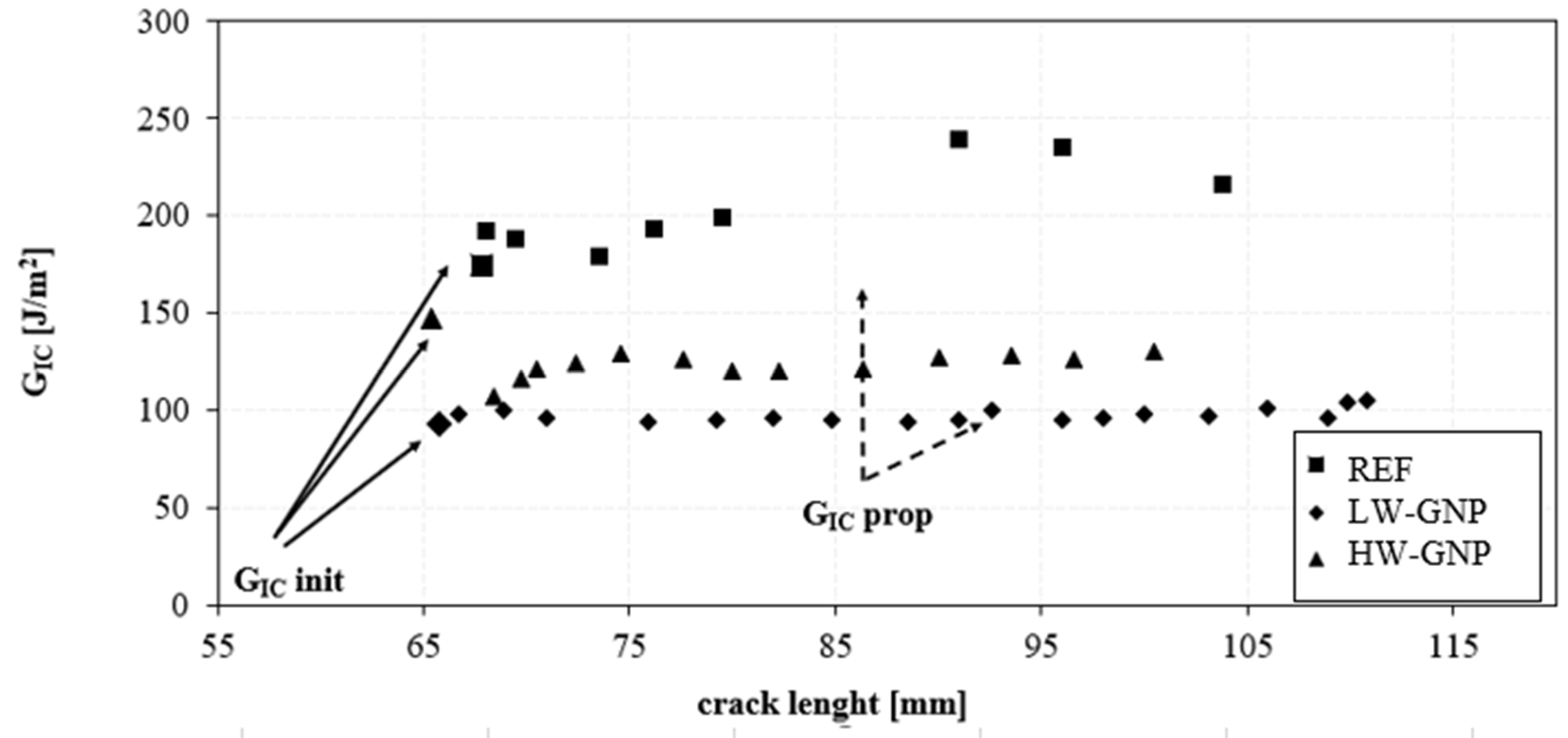

3.2.2. Interlaminar properties

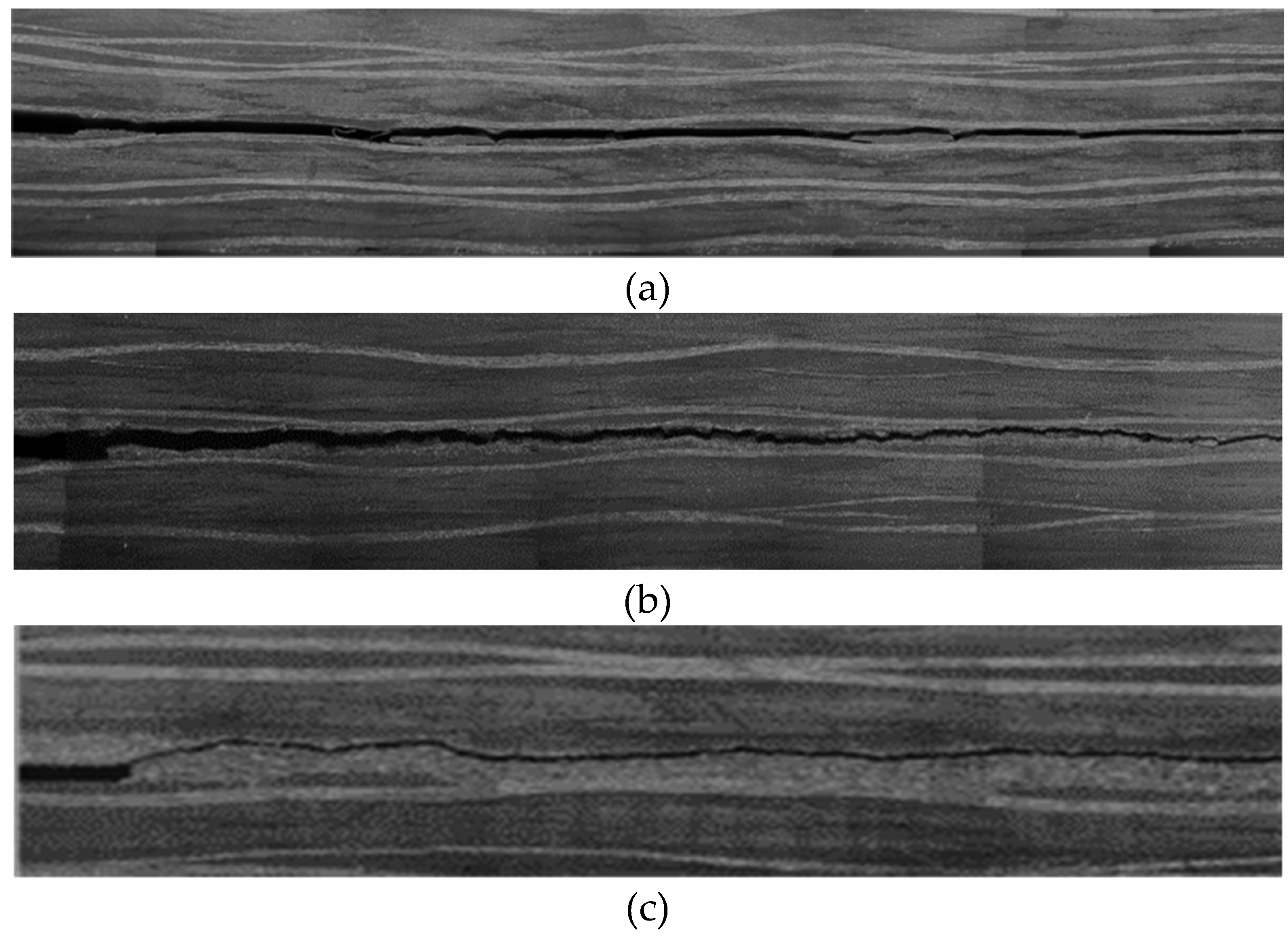

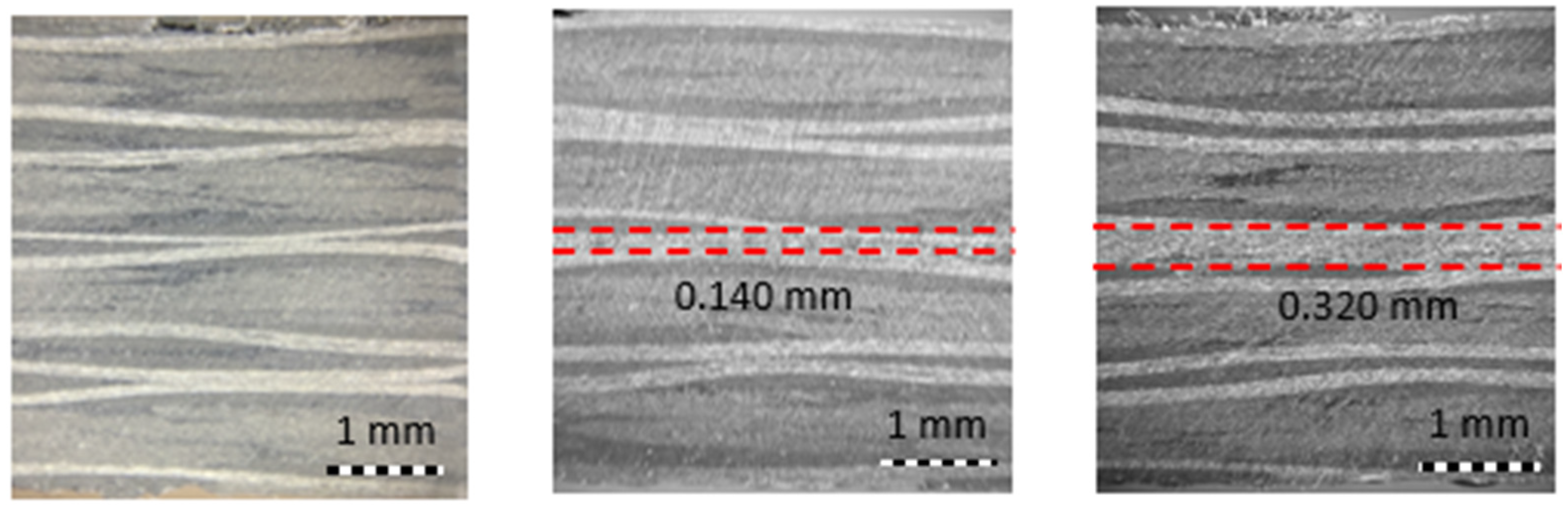

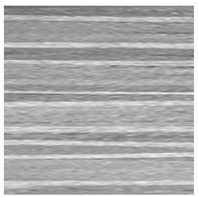

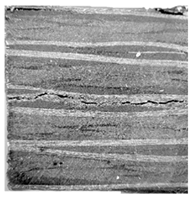

3.3. Morphology of fracture propagation

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Soutis, C. Carbon Fiber Reinforced Plastics in Aircraft Construction. Mater. Sci. Eng. A 2005, 412, 171–176. [Google Scholar] [CrossRef]

- Ni, N.; Wen, Y.; He, D.; Yi, X.; Zhang, T.; Xu, Y. High Damping and High Stiffness CFRP Composites with Aramid Non-Woven Fabric Interlayers. Compos. Sci. Technol. 2015, 117, 92–99. [Google Scholar] [CrossRef]

- Beylergil, B.; Tanoglu, M.; Aktas, E. Mode-I Fracture Toughness of Carbon Fiber/Epoxy Composites Interleaved by Aramid Nonwoven Veils. Steel Compos. Struct 2019, 31, 113–123. [Google Scholar]

- Martone, A.; Antonucci, V.; Zarrelli, M.; Giordano, M. A Simplified Approach to Model Damping Behaviour of Interleaved Carbon Fibre Laminates. Compos. Part B Eng. 2016, 97, 103–110. [Google Scholar] [CrossRef]

- Kishi, H.; Kuwata, M.; Matsuda, S.; Asami, T.; Murakami, A. Damping Properties of Thermoplastic-Elastomer Interleaved Carbon Fiber-Reinforced Epoxy Composites. Compos. Sci. Technol. 2004, 64, 2517–2523. [Google Scholar] [CrossRef]

- Ouyang, Q.; Wang, X.; Yao, Y.; Liu, L. Improved Damping and Mechanical Properties of Carbon Fibrous Laminates with Tailored Carbon Nanotube/Polyurethane Hybrid Membranes. Polym. Polym. Compos. 2021, 29, 1240–1250. [Google Scholar] [CrossRef]

- Zhu, X.; Li, Y.; Yu, T.; Zhang, Z. Enhancement of the Interlaminar Fracture Toughness and Damping Properties of Carbon Fiber Reinforced Composites Using Cellulose Nanofiber Interleaves. Compos. Commun. 2021, 28, 100940. [Google Scholar] [CrossRef]

- Akbolat, M.Ç.; Katnam, K.B.; Soutis, C.; Potluri, P.; Sprenger, S.; Taylor, J. On Mode-I and Mode-II Interlaminar Crack Migration and R-Curves in Carbon/Epoxy Laminates with Hybrid Toughening via Core-Shell Rubber Particles and Thermoplastic Micro-Fibre Veils. Compos. Part B Eng. 2022, 238, 109900. [Google Scholar] [CrossRef]

- Chen, Q.; Wu, F.; Jiang, Z.; Zhang, H.; Yuan, J.; Xiang, Y.; Liu, Y. Improved Interlaminar Fracture Toughness of Carbon Fiber/Epoxy Composites by a Combination of Extrinsic and Intrinsic Multiscale Toughening Mechanisms. Compos. Part B Eng. 2023, 252, 110503. [Google Scholar] [CrossRef]

- Ni, N.; Wen, Y.; He, D.; Yi, X.; Zhao, Z.; Xu, Y. Synchronous Improvement of Loss Factors and Storage Modulus of Structural Damping Composite with Functionalized Polyamide Nonwoven Fabrics. Mater. Des. 2016, 94, 377–383. [Google Scholar] [CrossRef]

- İnal, O.; Katnam, K.B.; Potluri, P.; Soutis, C. Progress in Interlaminar Toughening of Aerospace Polymer Composites Using Particles and Non-Woven Veils. Aeronaut. J. 2022, 126, 222–248. [Google Scholar] [CrossRef]

- Cilento, F.; Martone, A.; Giordano, M. Insights on Shear Transfer Efficiency in “ Brick-and-Mortar ” Composites Made of 2D Carbon Nanoparticles. Nanomaterials 2022, 12. [Google Scholar] [CrossRef] [PubMed]

- Domun, N.; Paton, K.R.; Blackman, B.R.K.; Kaboglu, C.; Vahid, S.; Zhang, T.; Dear, J.P.; Kinloch, A.J.; Hadavinia, H. On the Extent of Fracture Toughness Transfer from 1D/2D Nanomodified Epoxy Matrices to Glass Fibre Composites. J. Mater. Sci. 2020, 55, 4717–4733. [Google Scholar] [CrossRef]

- Wang, J.; Jin, X.; Li, C.; Wang, W.; Wu, H.; Guo, S. Graphene and Graphene Derivatives Toughening Polymers: Toward High Toughness and Strength. Chem. Eng. J. 2019, 370, 831–854. [Google Scholar] [CrossRef]

- Cilento, F.; Martone, A.; Pastore Carbone, M.G.; Galiotis, C.; Giordano, M. Nacre-like GNP/Epoxy Composites: Reinforcement Efficiency Vis-à-Vis Graphene Content. Compos. Sci. Technol. 2021, 211, 108873. [Google Scholar] [CrossRef]

- Park, Y.T.; Qian, Y.; Chan, C.; Suh, T.; Nejhad, M.G.; Macosko, C.W.; Stein, A. Epoxy Toughening with Low Graphene Loading. Adv. Funct. Mater. 2015, 25, 575–585. [Google Scholar] [CrossRef]

- Wang, J.; Li, C.; Zhang, X.; Xia, L.; Zhang, X.; Wu, H.; Guo, S. Polycarbonate Toughening with Reduced Graphene Oxide: Toward High Toughness, Strength and Notch Resistance. Chem. Eng. J. 2017, 325, 474–484. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Kuwata, M.; Bilotti, E.; Peijs, T. Improved Fracture Toughness and Integrated Damage Sensing Capability by Spray Coated CNTs on Carbon Fibre Prepreg. Compos. Part A Appl. Sci. Manuf. 2015, 70, 102–110. [Google Scholar] [CrossRef]

- Huang, S.; Fu, Q.; Yan, L.; Kasal, B. Characterization of Interfacial Properties between Fibre and Polymer Matrix in Composite Materials – A Critical Review. J. Mater. Res. Technol. 2021, 13, 1441–1484. [Google Scholar] [CrossRef]

- Ahmadi-Moghadam, B.; Taheri, F. Fracture and Toughening Mechanisms of GNP-Based Nanocomposites in Modes I and II Fracture. Eng. Fract. Mech. 2014, 131, 329–339. [Google Scholar] [CrossRef]

- Liu, K.; Macosko, C.W. Can Nanoparticle Toughen Fiber-Reinforced Thermosetting Polymers? J. Mater. Sci. 2019, 54, 4471–4483. [Google Scholar] [CrossRef]

- Quan, D.; Mischo, C.; Binsfeld, L.; Ivankovic, A.; Murphy, N. Fracture Behaviour of Carbon Fibre/Epoxy Composites Interleaved by MWCNT- and Graphene Nanoplatelet-Doped Thermoplastic Veils. Compos. Struct. 2020, 235, 111767. [Google Scholar] [CrossRef]

- Nagi, C.S.; Ogin, S.L.; Mohagheghian, I.; Crean, C.; Foreman, A.D. Spray Deposition of Graphene Nano-Platelets for Modifying Interleaves in Carbon Fibre Reinforced Polymer Laminates. Mater. Des. 2020, 193, 108831. [Google Scholar] [CrossRef]

- Wang, F.; Wang, B.; Zhang, Y.; Zhao, F.; Qiu, Z.; Zhou, L.; Chen, S.; Shi, M.; Huang, Z. Enhanced Thermal and Mechanical Properties of Carbon Fiber/Epoxy Composites Interleaved with Graphene/SiCnw Nanostructured Films. Compos. Part A Appl. Sci. Manuf. 2022, 162, 107129. [Google Scholar] [CrossRef]

- Moustapha Sarr, M.; Kosaka, T. Effect of Cellulose Nanofibers on the Fracture Toughness Mode II of Glass Fiber/Epoxy Composite Laminates. Heliyon 2023, 9, e13203. [Google Scholar] [CrossRef] [PubMed]

- Körbelin, J.; Kötter, B.; Voormann, H.; Brandenburg, L.; Selz, S.; Fiedler, B. Damage Tolerance of Few-Layer Graphene Modified CFRP: From Thin-to Thick-Ply Laminates. Compos. Sci. Technol. 2021, 209. [Google Scholar] [CrossRef]

- Cilento, F.; Curcio, C.; Martone, A.; Liseno, A.; Capozzoli, A.; Giordano, M. Effect of Graphite Nanoplatelets Content and Distribution on the Electromagnetic Shielding Attenuation Mechanisms in 2D Nanocomposites. J. Compos. Sci. 2022, 6, 257. [Google Scholar] [CrossRef]

- ASTM D 790-17, Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials1 2017.

- Brittain, R.; Liskiewicz, T.; Morina, A.; Neville, A.; Yang, L. Diamond-like Carbon Graphene Nanoplatelet Nanocomposites for Lubricated Environments. Carbon N. Y. 2023, 205, 485–498. [Google Scholar] [CrossRef]

- Morits, M.; Verho, T.; Sorvari, J.; Liljeström, V.; Kostiainen, M.A.; Gröschel, A.H.; Ikkala, O. Toughness and Fracture Properties in Nacre-Mimetic Clay/Polymer Nanocomposites. Adv. Funct. Mater. 2017, 27, 1605378. [Google Scholar] [CrossRef]

- Reinforced, N.; Fiber, G. Interlaminar Fracture Behavior of Nanoclay Reinforced Glass Fiber Composites. 2008, 42. [CrossRef]

| Sample | Lamination sequence |

Filler/matrix content [wt/wt] |

Number of deposition cycles | Coating areal weight [g/m2] |

|---|---|---|---|---|

| REF | [(90/+45/-45/0)2]S | - | 0 | - |

| LW-GNP | [(90/+45/-45/0)2]S* | 80/20 | 1 | 10 |

| HW-GNP | [(90/+45/-45/0)2]S* | 80/20 | 4 | 40 |

| Actual areal weight [g/m2] |

Tpeak [°C] |

Peak area [J/g] |

|

|---|---|---|---|

| REF | - | 145.13 | 394.80 |

| LW-GNP | 15 | 145.31 | 405.68 |

| HW-GNP | 59 | 148.70 | 371.43 |

| Tg,DSC [°C] |

Tg,DMA [°C] |

E’ [GPa] |

ΔE’* [%] |

tanδ [-] |

Δtanδ* [%] |

|

|---|---|---|---|---|---|---|

| REF | 151.9±0.5 | 159.4±2.4 | 25.1±1.6 | - | 0.024±0.001 | - |

| LW-GNP | 145.1±0.7 | 166.7±0.8 | 23.2±2.0 | -7 | 0.030±0.007 | +25 |

| HW-GNP | 145.9±0.2 | 164.4±0.7 | 26.1±2.5 | +3 | 0.025±0.005 | +6 |

| ILSS [MPa] |

ΔILSS* [%] |

GIC, initial [J/m2] |

ΔGIC, intial* [%] |

GIC, propagation [J/m2] |

ΔGIC, propagation * [%] |

GIIC [J/m2] |

ΔGIIC* [%] |

|

|---|---|---|---|---|---|---|---|---|

| REF | 63.1±0.3 | - | 174±29 | - | 199±12 | - | 1642±206 | - |

| LW-GNP | 38.2±1.4 | -40 | 92±10 | -47 | 101±8 | -49 | 532±56 | -67 |

| HW-GNP | 34.5±0.4 | -46 | 147±29 | -15 | 128±10 | -36 | 206±5 | -87 |

| REF | LW-GNP | HW-GNP | |

|---|---|---|---|

| Bulk |  |

|

|

| ILSS |  |

|

|

| Property @RT | REF | LW-GNP | HW-GNP |

|---|---|---|---|

| E’ [GPa] | 25.1±1.6 | 23.2±2.0 | 26.1±2.5 |

| tanδ [-] | 0.024±0.001 | 0.030±0.007 | 0.025±0.005 |

| ILSS [MPa] | 63.1±0.3 | 38.2±1.4 | 34.5±0.4 |

| GCI [J/m2] | 174±29 | 92±10 | 147±29 |

| GCII [J/m2] | 1642±206 | 532±56 | 206±5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).