Submitted:

03 May 2023

Posted:

04 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methods

3. Results and discussion

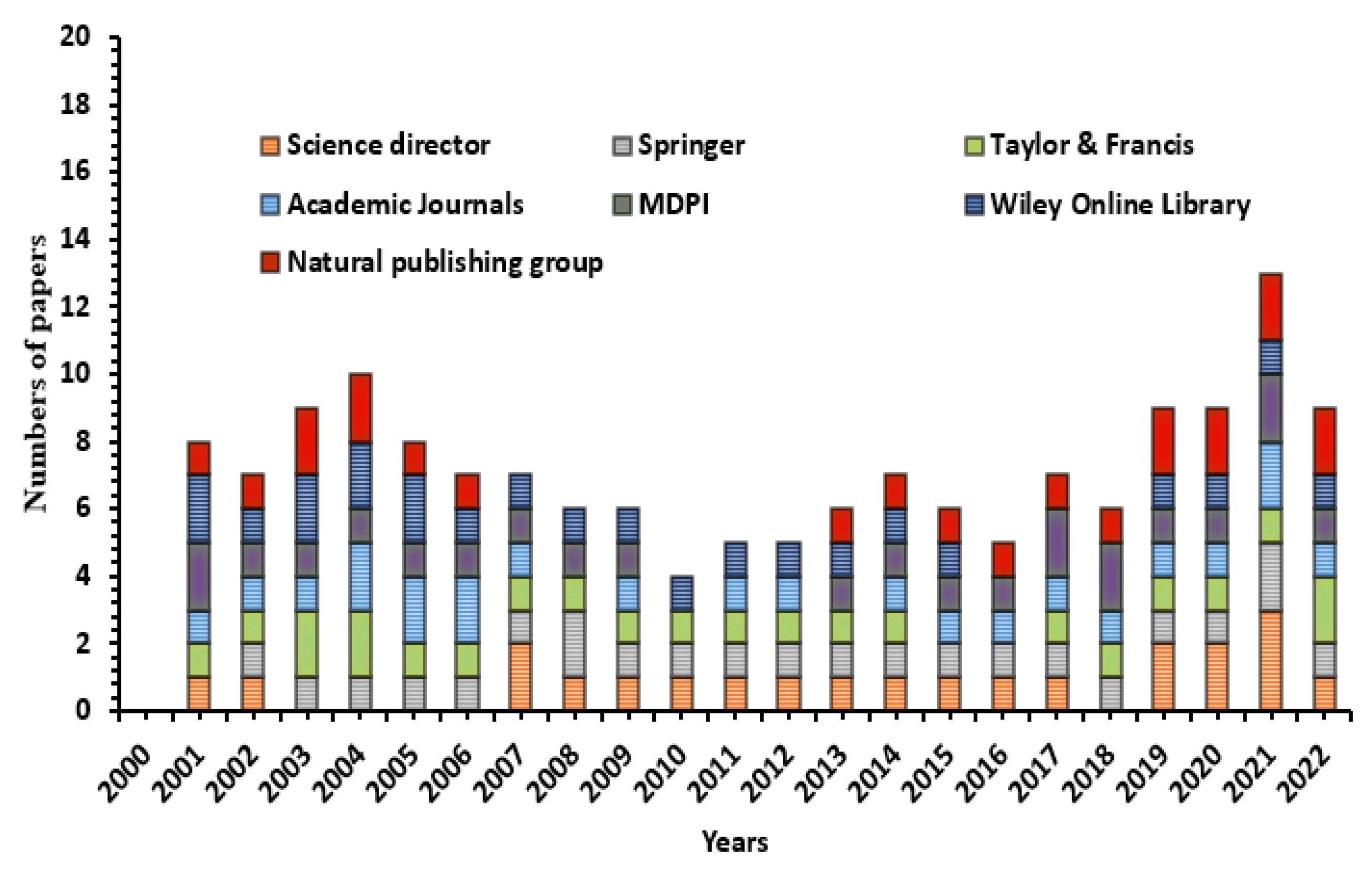

| Groups | Count | Sum | Average | Variance |

|---|---|---|---|---|

| Elsevier | 6 | 30 | 5 | 25.2 |

| Science director | 6 | 26 | 4.333333 | 18.66667 |

| Springer | 6 | 30 | 5 | 26.4 |

| Taylor & Francis | 6 | 24 | 4 | 16.4 |

| Academic Journals | 6 | 16 | 2.666667 | 7.466667 |

| MDPI | 6 | 20 | 3.333333 | 11.06667 |

| Wiley Online Library | 6 | 12 | 2 | 4.4 |

| Natural publishing group | 6 | 18 | 3 | 9.2 |

| Source of Variation | Between Groups | Within Groups |

|---|---|---|

| SS | 50.66667 | 594 |

| DF | 7 | 40 |

| MS | 7.238095 | 14.85 |

| F | 0.487414 | |

| P-value | 0.837994 | |

| F-Critical | 2.249024 |

| Journals | P value (T test) |

|---|---|

| Elsevier VS Science director | 0.00571622985 |

| Elsevier VS springer | 0.00808887445 |

| Elsevier VS Taylor & Francis | 0.00445838342 |

| Elsevier VS Academic Journals | 0.0072884353 |

| Elsevier VS Wiley Online Library | 0.0152502285 |

| Elsevier VS Natural publishing group | 0.028509211 |

| Elsevier VS MDPI | 0.0152502285 |

| Science director VS springer | 0.00784477935 |

| Science director VS Taylor & Francis | 0.00765504048 |

| Science director VS Academic Journals | 0.0115077114 |

| Science director VS Wiley Online Library | 0.033730391 |

| Science director VS Natural publishing group | 0.00783927935 |

| Science director VS MDPI | 0.0273139223 |

| springer VS Taylor & Francis | 0.00619543748 |

| springer VS Academic Journals | 0.0128122349 |

| springer VS Wiley Online Library | 0.0057756315 |

| springer VS Natural publishing group | 0.18690481 |

| springer VS MDPI | 0.026225475 |

| Taylor & Francis VS Academic Journals | 0.0252072 |

| Taylor & Francis VS Wiley Online Library | 0.0115077114 |

| Taylor & Francis VS Natural publishing group | 0.0370555053 |

| Taylor & Francis VS MDPI | 0.00523742436 |

| Academic Journals VS Wiley Online Library | 0.00681057161 |

| Academic Journals VS Natural publishing group | 0.00724465826 |

| Academic Journals VS MDPI | 0.0455366344 |

| Wiley Online Library VS Natural publishing group | 0.0397203841 |

| Wiley Online Library VS MDPI | 0.0172003292 |

| Natural publishing group VS MDPI | 0.00492681049 |

References

- S. Banu, “Precision agriculture: tomorrow’s technology for today’s farmer,” J. Food Process. Technol., vol. 6, no. 8, p. 1, 2015. [CrossRef]

- L. Philip and F. Williams, “Remote rural home based businesses and digital inequalities: Understanding needs and expectations in a digitally underserved community,” J. Rural Stud., vol. 68, pp. 306–318, 2019. [CrossRef]

- G. Castellanos, M. Deruyck, L. Martens, and W. Joseph, “System assessment of WUSN using NB-IoT UAV-aided networks in potato crops,” IEEE Access, vol. 8, pp. 56823–56836, 2020. [CrossRef]

- M. Li, R. R. Shamshiri, M. Schirrmann, and C. Weltzien, “Impact of camera viewing angle for estimating leaf parameters of wheat plants from 3D point clouds,” Agriculture, vol. 11, no. 6, p. 563, 2021. [CrossRef]

- E. Anastasiou, A. Castrignanò, K. Arvanitis, and S. Fountas, “A multi-source data fusion approach to assess spatial-temporal variability and delineate homogeneous zones: A use case in a table grape vineyard in Greece,” Sci. Total Environ., vol. 684, pp. 155–163, 2019. [CrossRef]

- N. M. Betzek, E. G. de Souza, C. L. Bazzi, K. Schenatto, A. Gavioli, and P. S. G. Magalhães, “Computational routines for the automatic selection of the best parameters used by interpolation methods to create thematic maps,” Comput. Electron. Agric., vol. 157, pp. 49–62, 2019. [CrossRef]

- M. Hasan, B. Tanawala, and K. J. Patel, “Deep learning precision farming: Tomato leaf disease detection by transfer learning,” in Proceedings of 2nd international conference on advanced computing and software engineering (ICACSE), 2019. [CrossRef]

- K. Johansen, M. G. Ziliani, R. Houborg, T. E. Franz, and M. F. McCabe, “CubeSat constellations provide enhanced crop phenology and digital agricultural insights using daily leaf area index retrievals,” Sci. Rep., vol. 12, no. 1, pp. 1–12, 2022. [CrossRef]

- J. Jiang et al., “Analysis and evaluation of the image preprocessing process of a six-band multispectral camera mounted on an unmanned aerial vehicle for winter wheat monitoring,” Sensors, vol. 19, no. 3, p. 747, 2019. [CrossRef]

- R. Rayhana, G. G. Xiao, and Z. Liu, “Printed sensor technologies for monitoring applications in smart farming: A review,” IEEE Trans. Instrum. Meas., vol. 70, pp. 1–19, 2021. [CrossRef]

- S. Abba, J. Wadumi Namkusong, J.-A. Lee, and M. Liz Crespo, “Design and performance evaluation of a low-cost autonomous sensor interface for a smart iot-based irrigation monitoring and control system,” Sensors, vol. 19, no. 17, p. 3643, 2019. [CrossRef]

- M. H. Tunio et al., “Potato production in aeroponics: An emerging food growing system in sustainable agriculture forfood security,” Chil. J. Agric. Res., vol. 80, no. 1, pp. 118–132, 2020. [CrossRef]

- N. Singh and A. N. Singh, “Odysseys of agriculture sensors: Current challenges and forthcoming prospects,” Comput. Electron. Agric., vol. 1 71, p. 105328, 2020. [CrossRef]

- I. M. PARTS, “Small farm mechanization systems development, adoption and utilization”.

- S. Mittal, “Global Review of Agricultural Policies”.

- G. A. Graham, “Farming systems research bibliography of Kansas State University’s vertical file materials: Revised,” 1986.

- V. Kumar, G. Mahajan, and B. S. Chauhan, “Rice Weeds and Their Management,” in Rice Production Worldwide, Springer, 2017, pp. 361–392. [CrossRef]

- M. H. Razali, S. Roslan, A. S. M. Abd Halim, and H. Basit, “Design and Development of Mechatronic Application in Agricultural Irrigation Device,” World J. Eng. Technol., vol. 4, no. 03, p. 450, 2016. [CrossRef]

- S. Mekhilef, R. Saidur, A. Safari, and W. Mustaffa, “Biomass energy in Malaysia: Current state and prospects,” Renew. Sustain. Energy Rev., vol. 15, no. 7, pp. 3360–3370, 2011. [CrossRef]

- N. Saba, M. Jawaid, K. R. Hakeem, M. T. Paridah, A. Khalina, and O. Y. Alothman, “Potential of bioenergy production from industrial kenaf (Hibiscus cannabinus L.) based on Malaysian perspective,” Renew. Sustain. Energy Rev., vol. 42, pp. 446–459, 2015. [CrossRef]

- C. Szász, “Last generation mechatronics: A two-level platform-based reconfigurable technology approach,” Recent Innov. Mechatron., vol. 5, no. 1., pp. 1–7, 2018. [CrossRef]

- M. Z. Jin and Z. W. Zhao, “Achieving Flexible Reconfiguration via Mechatronic Modules,” in Applied Mechanics and Materials, 2010, vol. 26, pp. 1215–1219. [CrossRef]

- N. A. Kharrata, M. M. Chaabaneb, R. Plateauxa, C. Karrab, J.-Y. Choleya, and M. Haddarb, “Control vibration of a three-axis robot using the topological modeling,” in The Second International Conference on Acoustics and Vibration, 2018.

- S. Al-Fedaghi and A. Abdullah, “A Unifying Model for Mechatronic Systems Specification,” in Applied Mechanics and Materials, 2015, vol. 789, pp. 803–811. [CrossRef]

- R. Isermann, “Automotive Mechatronic Systems–General Developments and Examples (Mechatronische Systeme in Kraftfahrzeugen–Allgemeine Entwicklungen und Beispiele),” -Autom., vol. 54, no. 9, pp. 419–429, 2006. [CrossRef]

- S. T. Magwaza, L. S. Magwaza, A. O. Odindo, and A. Mditshwa, “Hydroponic technology as decentralised system for domestic wastewater treatment and vegetable production in urban agriculture: A review,” Sci. Total Environ., vol. 698, p. 134154, 2020. [CrossRef]

- R. S. Krishnan, E. G. Julie, Y. H. Robinson, S. Raja, R. Kumar, and P. H. Thong, “Fuzzy logic based smart irrigation system using internet of things,” J. Clean. Prod., vol. 252, p. 119902, 2020. [CrossRef]

- F. A. Khan, “A review on hydroponic greenhouse cultivation for sustainable agriculture,” Int. J. Agric. Environ. Food Sci., vol. 2, no. 2, pp. 59–66, 2018. [CrossRef]

- A. Pawlowski, J. L. Guzman, F. Rodríguez, M. Berenguel, J. Sánchez, and S. Dormido, “Simulation of greenhouse climate monitoring and control with wireless sensor network and event-based control,” Sensors, vol. 9, no. 1, pp. 232–252, 2009. [CrossRef]

- M. K. Sott et al., “A bibliometric network analysis of recent publications on digital agriculture to depict strategic themes and evolution structure,” Sensors, vol. 21, no. 23, p. 7889, 2021. [CrossRef]

- J. Karpagam, I. I. Merlin, P. Bavithra, and J. Kousalya, “Smart irrigation system using IoT,” in 2020 6th International Conference on Advanced Computing and Communication Systems (ICACCS), 2020, pp. 1292–1295. [CrossRef]

- A. Fareed, M. G. Ullah, A. Hussain, M. Zaidi, and M. Baig, “Smart irrigation care unit,” in 2017 First International Conference on Latest trends in Electrical Engineering and Computing Technologies (IN℡LECT), 2017, pp. 1–5.

- M. B. Murugan, M. K. Rajagopal, and D. Roy, “IoT Based Smart Agriculture and Plant Disease Prediction,” in Journal of Physics: Conference Series, 2021, vol. 2115, no. 1, p. 012017. [CrossRef]

- O. Arogundade et al., “A Mobile-Based Farm Machinery Hiring System,” in Proceedings of Second International Conference on Computing, Communications, and Cyber-Security, 2021, pp. 213–226. [CrossRef]

- C. Karmokar, J. Hasan, S. A. Khan, and M. I. I. Alam, “Arduino UNO based smart irrigation system using GSM module, soil moisture sensor, sun tracking system and inverter,” in 2018 International Conference on Innovations in Science, Engineering and Technology (ICISET), 2018, pp. 98–101. [CrossRef]

- C. A. Bolu, J. Azeta, F. Alele, E. O. Daranijo, P. Onyeubani, and A. A. Abioye, “Solar powered microcontroller-based automated irrigation system with moisture sensors,” in Journal of Physics: Conference Series, 2019, vol. 1378, no. 3, p. 032003. [CrossRef]

- A. Khanna, “Agro-based sensor’s deployment for environmental anticipation: An experimental effort for minimal usage of water within agricultural practices,” culture, vol. 4, no. 3, pp. 219–236, 2020. [CrossRef]

- A. Bechar and C. Vigneault, “Agricultural robots for field operations: Concepts and components,” Biosyst. Eng., vol. 149, pp. 94–111, 2016. [CrossRef]

- A. Bechar and C. Vigneault, “Agricultural robots for field operations. Part 2: Operations and systems,” Biosyst. Eng., vol. 153, pp. 110–128, 2017. [CrossRef]

- J. A. Thomasson, C. P. Baillie, D. L. Antille, C. R. Lobsey, and C. L. McCarthy, Autonomous technologies in agricultural equipment: A review of the state of the art. American Society of Agricultural and Biological Engineers St. Joseph, MI, USA, 2019. [CrossRef]

- A. F. dos Santos et al., “Use of real-time extend GNSS for planting and inverting peanuts,” Precis. Agric., vol. 20, no. 4, pp. 840–856, 2019. [CrossRef]

- D. Bochtis, C. A. G. Sorensen, and D. Kateris, Operations management in agriculture. Academic Press, 2018.

- C. Sun, “Research on investment decision-making model from the perspective of ‘Internet of Things+ Big data,’” Future Gener. Comput. Syst., vol. 107, pp. 286–292, 2020. [CrossRef]

- X. Zhang, Z. Cao, and W. Dong, “Overview of edge computing in the agricultural internet of things: Key technologies, applications, challenges,” Ieee Access, vol. 8, pp. 141748–141761, 2020. [CrossRef]

- R. Hassan, F. Qamar, M. K. Hasan, A. H. M. Aman, and A. S. Ahmed, “Internet of Things and its applications: A comprehensive survey,” Symmetry, vol. 12, no. 10, p. 1674, 2020. [CrossRef]

- A. Augustin, J. Yi, T. Clausen, and W. M. Townsley, “A study of LoRa: Long range & low power networks for the internet of things,” Sensors, vol. 16, no. 9, p. 1466, 2016. [CrossRef]

- W.-S. Kim, W.-S. Lee, and Y.-J. Kim, “A review of the applications of the internet of things (IoT) for agricultural automation,” J. Biosyst. Eng., vol. 45, no. 4, pp. 385–400, 2020. [CrossRef]

- P. Asghari, A. M. Rahmani, and H. H. S. Javadi, “Internet of Things applications: A systematic review,” Comput. Netw., vol. 148, pp. 241–261, 2019. [CrossRef]

- A. Čolaković and M. Hadžialić, “Internet of Things (IoT): A review of enabling technologies, challenges, and open research issues,” Comput. Netw., vol. 144, pp. 17–39, 2018. [CrossRef]

- S. Kumar, P. Tiwari, and M. Zymbler, “Internet of Things is a revolutionary approach for future technology enhancement: A review,” J. Big Data, vol. 6, no. 1, pp. 1–21, 2019. [CrossRef]

- S. Kanagasingham, M. Ekpanyapong, and R. Chaihan, “Integrating machine vision-based row guidance with GPS and compass-based routing to achieve autonomous navigation for a rice field weeding robot,” Precis. Agric., vol. 21, no. 4, pp. 831–855, 2020. [CrossRef]

- C. Duarte-Galvan et al., “Advantages and disadvantages of control theories applied in greenhouse climate control systems,” Span. J. Agric. Res., vol. 10, no. 4, pp. 926–938, 2012. [CrossRef]

- J. Li, L. Li, H. Wang, K. P. Ferentinos, M. Li, and N. Sigrimis, “Proactive energy management of solar greenhouses with risk assessment to enhance smart specialisation in China,” Biosyst. Eng., vol. 158, pp. 10–22, 2017. [CrossRef]

- X. Tong, Z. Sun, N. Sigrimis, and T. Li, “Energy sustainability performance of a sliding cover solar greenhouse: Solar energy capture aspects,” Biosyst. Eng., vol. 176, pp. 88–102, 2018. [CrossRef]

- U. Ramani, “User Friendly with Zigbee Technology Control Agricultural Automation using Lab view,” Ann. Romanian Soc. Cell Biol., pp. 7854–7861, 2021.

- C. Bersani, C. Ruggiero, R. Sacile, A. Soussi, and E. Zero, “Internet of Things Approaches for Monitoring and Control of Smart Greenhouses in Industry 4.0,” Energies, vol. 15, no. 10, p. 3834, 2022. [CrossRef]

- R. Aafreen, S. Y. Neyaz, R. Shamim, and M. S. Beg, “An IoT based system for telemetry and control of Greenhouse environment,” in 2019 International Conference on Electrical, Electronics and Computer Engineering (UPCON), 2019, pp. 1–6.

- M. R. Palattella et al., “Internet of things in the 5G era: Enablers, architecture, and business models,” IEEE J. Sel. Areas Commun., vol. 34, no. 3, pp. 510–527, 2016. [CrossRef]

- J. Ruan and Y. Shi, “Monitoring and assessing fruit freshness in IOT-based e-commerce delivery using scenario analysis and interval number approaches,” Inf. Sci., vol. 373, pp. 557–570, 2016. [CrossRef]

- L. Shi, G. Shi, and H. Qiu, “General review of intelligent agriculture development in China,” China Agric. Econ. Rev., 2018. [CrossRef]

- F. H. Khan, M. A. Pasha, and S. Masud, “Advancements in microprocessor architecture for ubiquitous AI—An overview on history, evolution, and upcoming challenges in AI implementation,” Micromachines, vol. 12, no. 6, p. 665, 2021. [CrossRef]

- A. L. Tamiru and F. M. Hashim, “Application of bat algorithm and fuzzy systems to model exergy changes in a gas turbine,” in Artificial intelligence, evolutionary computing and metaheuristics, Springer, 2013, pp. 685–719. [CrossRef]

- R. Sivarethinamohan, D. Yuvaraj, S. Shanmuga Priya, and S. Sujatha, “Captivating profitable applications of artificial intelligence in agriculture management,” in International Conference on Intelligent Computing & Optimization, 2021, pp. 848–861.

- M. Sugano, “Elemental technologies for realizing a fully-controlled artificial light-type plant factory,” in 2015 12th International Conference & Expo on Emerging Technologies for a Smarter World (CEWIT), 2015, pp. 1–5. [CrossRef]

- G. A. Helfer, J. L. V. Barbosa, D. Alves, A. B. da Costa, M. Beko, and V. R. Q. Leithardt, “Multispectral cameras and machine learning integrated into portable devices as clay prediction technology,” J. Sens. Actuator Netw., vol. 10, no. 3, p. 40, 2021. [CrossRef]

- A. Islam and S. Y. Shin, “Bus: A blockchain-enabled data acquisition scheme with the assistance of uav swarm in internet of things,” IEEE Access, vol. 7, pp. 103231–103249, 2019. [CrossRef]

- O. Debauche et al., “Data management and internet of things: A methodological review in smart farming,” Internet Things, vol. 14, p. 100378, 2021. [CrossRef]

- O. Debauche, S. Mahmoudi, P. Manneback, and A. Assila, “Fog IoT for Health: A new Architecture for Patients and Elderly Monitoring.,” Procedia Comput. Sci., vol. 160, pp. 289–297, 2019. [CrossRef]

- O. Debauche, S. Mahmoudi, S. A. Mahmoudi, P. Manneback, and F. Lebeau, “A new edge architecture for ai-iot services deployment,” Procedia Comput. Sci., vol. 175, pp. 10–19, 2020. [CrossRef]

- A. Terenzi, S. Cecchi, and S. Spinsante, “On the importance of the sound emitted by honey bee hives,” Vet. Sci., vol. 7, no. 4, p. 168, 2020. [CrossRef]

- S. Cecchi, S. Spinsante, A. Terenzi, and S. Orcioni, “A smart sensor-based measurement system for advanced bee hive monitoring,” Sensors, vol. 20, no. 9, p. 2726, 2020. [CrossRef]

- O. Debauche, S. Mahmoudi, S. A. Mahmoudi, P. Manneback, J. Bindelle, and F. Lebeau, “Edge computing and artificial intelligence for real-time poultry monitoring,” Procedia Comput. Sci., vol. 175, pp. 534–541, 2020. [CrossRef]

- M. El Moulat, O. Debauche, S. Mahmoudi, L. A. Brahim, P. Manneback, and F. Lebeau, “Monitoring system using internet of things for potential landslides,” Procedia Comput. Sci., vol. 134, pp. 26–34, 2018. [CrossRef]

- R. Tashakkori, A. S. Hamza, and M. B. Crawford, “Beemon: An IoT-based beehive monitoring system,” Comput. Electron. Agric., vol. 190, p. 106427, 2021. [CrossRef]

- O. Debauche, S. Mahmoudi, P. Manneback, and F. Lebeau, “Cloud and distributed architectures for data management in agriculture 4.0: Review and future trends,” J. King Saud Univ.-Comput. Inf. Sci., 2021.

- A. Villa-Henriksen, G. T. Edwards, L. A. Pesonen, O. Green, and C. A. G. Sørensen, “Internet of Things in arable farming: Implementation, applications, challenges and potential,” Biosyst. Eng., vol. 191, pp. 60–84, 2020.

- O. Bongomin et al., “Industry 4.0 disruption and its neologisms in major industrial sectors: A state of the art,” J. Eng., vol. 2020, 2020. [CrossRef]

- R. K. Singh, R. Berkvens, and M. Weyn, “AgriFusion: An architecture for IoT and emerging technologies based on a precision agriculture survey,” IEEE Access, vol. 9, pp. 136253–136283, 2021. [CrossRef]

- H. Mao, L. Zhou, R. Ying, and D. Pan, “Time Preferences and green agricultural technology adoption: Field evidence from rice farmers in China,” Land Use Policy, vol. 109, p. 105627, 2021. [CrossRef]

- H. Li, D. Huang, Q. Ma, W. Qi, and H. Li, “Factors influencing the technology adoption behaviours of litchi farmers in China,” Sustainability, vol. 12, no. 1, p. 271, 2019. [CrossRef]

- L. Qian, H. Lu, Q. Gao, and H. Lu, “Household-owned farm machinery vs. outsourced machinery services: The impact of agricultural mechanization on the land leasing behavior of relatively large-scale farmers in China,” Land Use Policy, vol. 115, p. 106008, 2022. [CrossRef]

- K. Zhang, Y. Li, H. Wei, L. Zhang, F.-M. Li, and F. Zhang, “Conservation tillage or plastic film mulching? A comprehensive global meta-analysis based on maize yield and nitrogen use efficiency,” Sci. Total Environ., vol. 831, p. 154869, 2022. [CrossRef]

- L. Yu, C. Chen, Z. Niu, Y. Gao, H. Yang, and Z. Xue, “Risk aversion, cooperative membership and the adoption of green control techniques: Evidence from China,” J. Clean. Prod., vol. 279, p. 123288, 2021. [CrossRef]

- M. Chen, Y. Cui, S. Jiang, and N. Forsell, “Toward carbon neutrality before 2060: Trajectory and technical mitigation potential of non-CO2 greenhouse gas emissions from Chinese agriculture,” J. Clean. Prod., vol. 368, p. 133186, 2022. [CrossRef]

- M. E. Gözütok, “Designing Programmable Logic Controller for Data Acquisition and Control,” PhD Thesis, Izmir Institute of Technology (Turkey), 2010.

- T. Adame, A. Bel, B. Bellalta, J. Barcelo, and M. Oliver, “IEEE 802.11 AH: The WiFi approach for M2M communications,” IEEE Wirel. Commun., vol. 21, no. 6, pp. 144–152, 2014. [CrossRef]

- G. A. Akpakwu, B. J. Silva, G. P. Hancke, and A. M. Abu-Mahfouz, “A survey on 5G networks for the Internet of Things: Communication technologies and challenges,” IEEE Access, vol. 6, pp. 3619–3647, 2017. [CrossRef]

- L. Chettri and R. Bera, “A comprehensive survey on Internet of Things (IoT) toward 5G wireless systems,” IEEE Internet Things J., vol. 7, no. 1, pp. 16–32, 2019. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).