Submitted:

22 June 2023

Posted:

25 June 2023

You are already at the latest version

Abstract

Keywords:

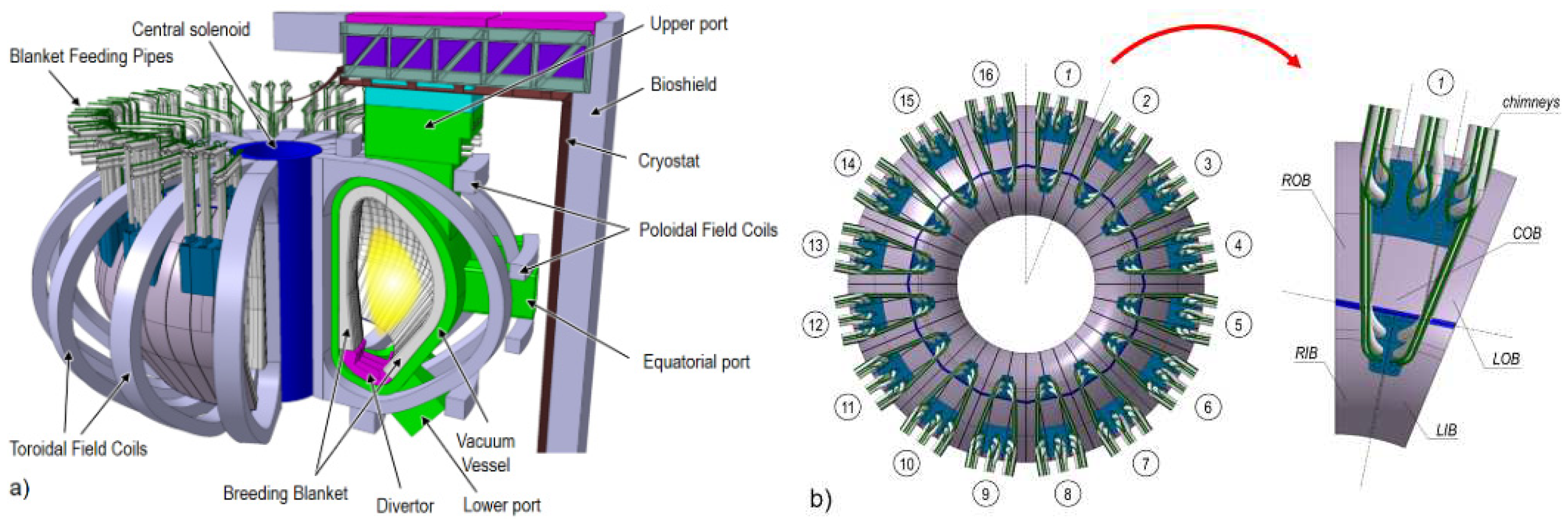

1. Introduction

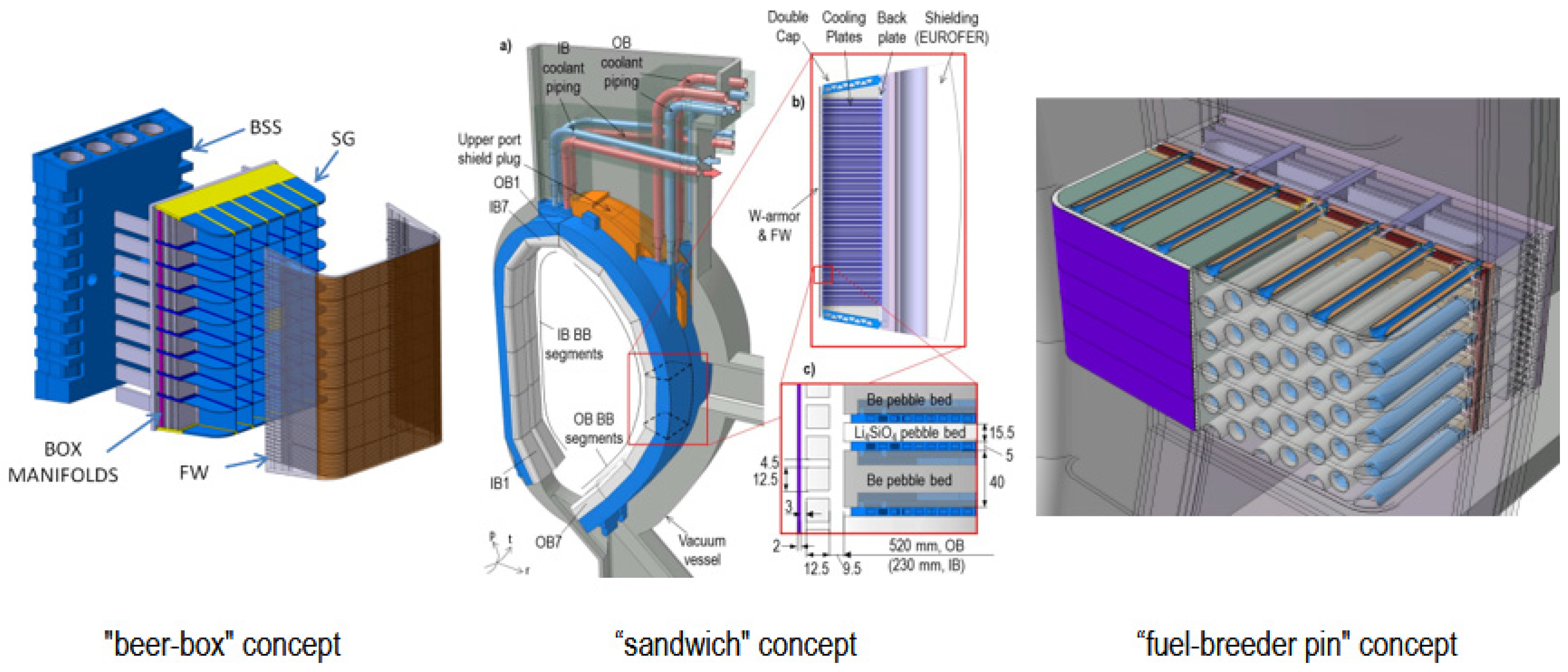

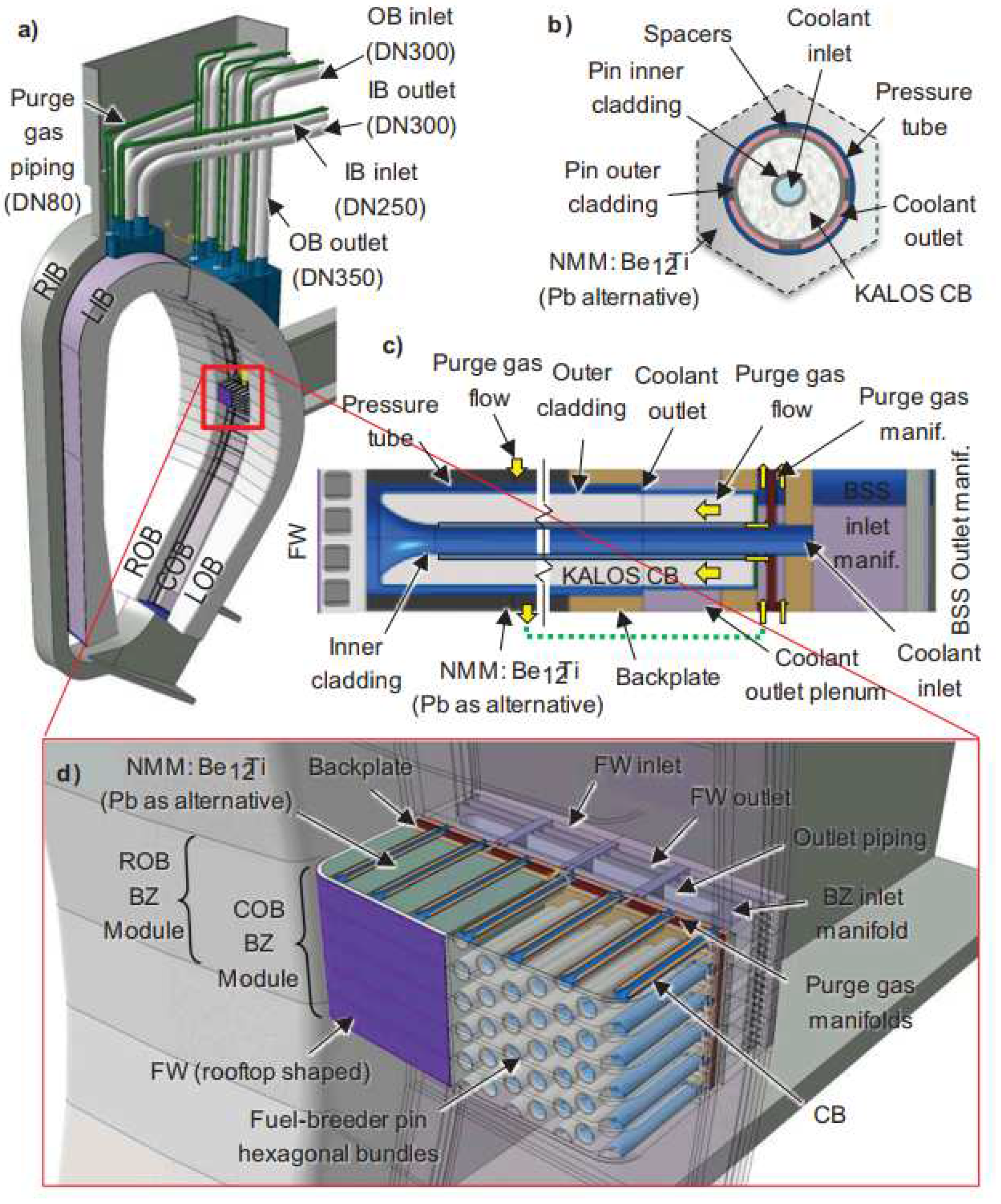

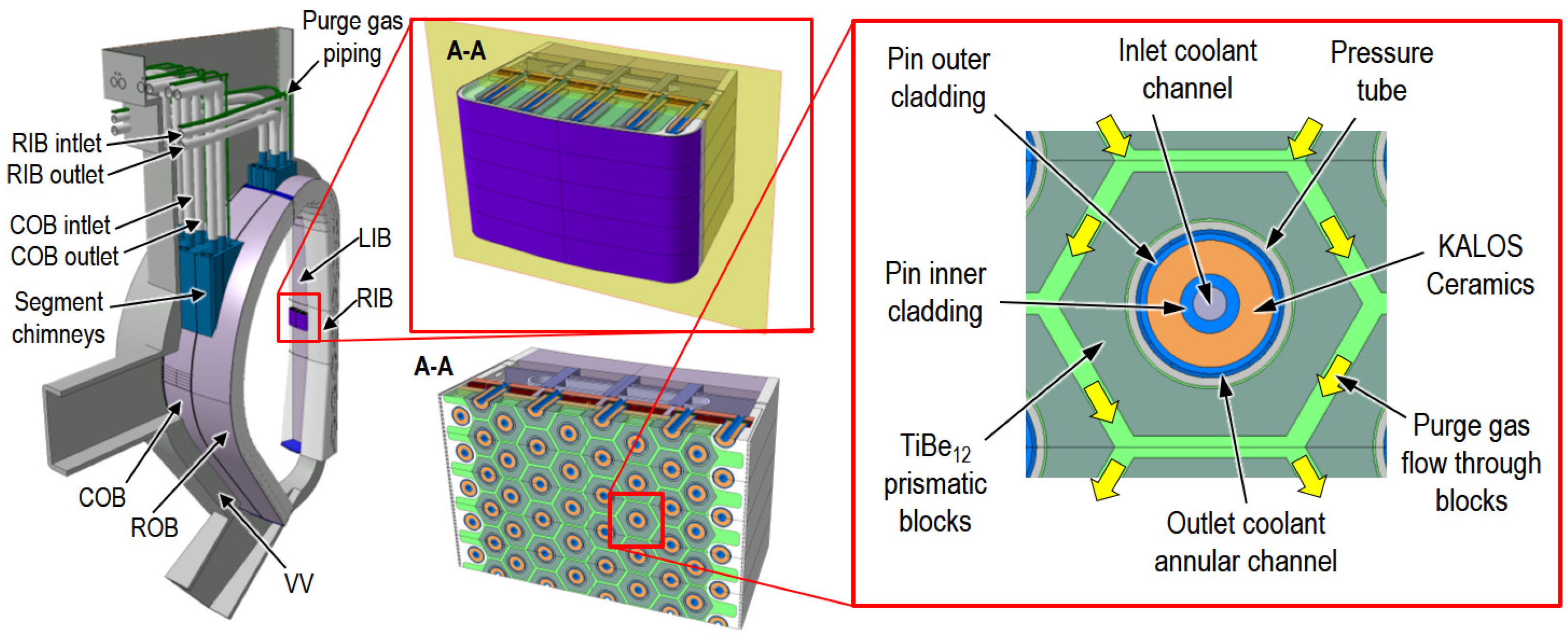

2. Design description of HCPB breeding blanket

2.1. Design evolution

2.2. Layout at end of PCD phase

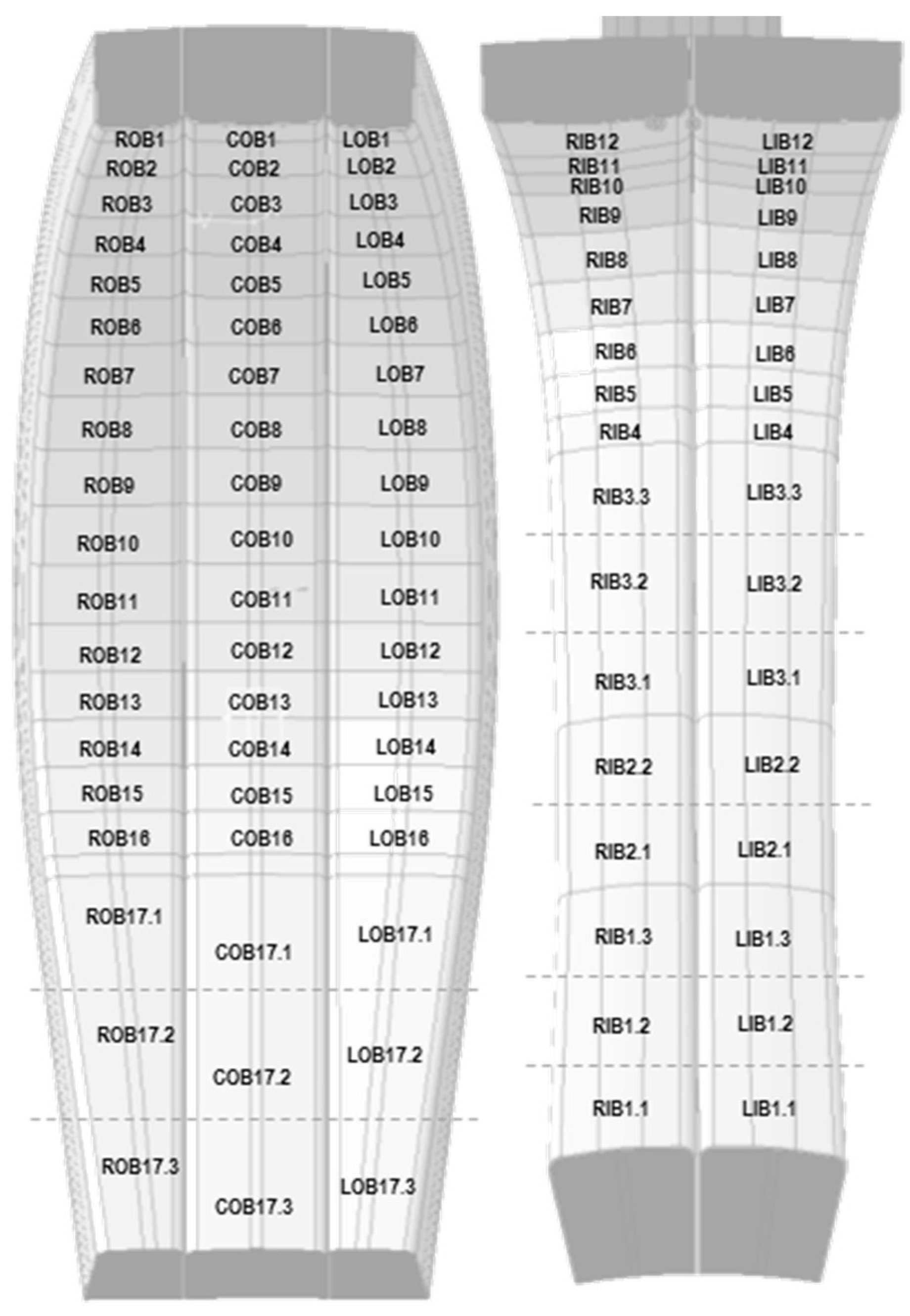

2.2.1. Segmentation and modularization

| BB region | FW height (poloidal) | FW width (toroidal) | FW sidewall length (radial) |

|---|---|---|---|

| [mm] | [mm] | [mm] | |

| R/LOB1 | 531 | 947 | 485 |

| R/LOB2 | 750 | 1046 | 478 |

| R/LOB3 | 750 | 1170 | 474 |

| R/LOB4 | 625 | 1270 | 474 |

| R/LOB5 | 625 | 1355 | 488 |

| R/LOB6 | 625 | 1331 | 495 |

| R/LOB7 | 625 | 1494 | 505 |

| R/LOB8 | 625 | 1547 | 508 |

| R/LOB9 | 625 | 1585 | 510 |

| R/LOB10 | 625 | 1611 | 510 |

| R/LOB11 | 625 | 1624 | 502 |

| R/LOB12 | 500 | 1624 | 489 |

| R/LOB13 | 500 | 1612 | 461 |

| R/LOB14 | 500 | 1578 | 436 |

| R/LOB15 | 500 | 1552 | 416 |

| R/LOB16 | 500 | 1507 | 400 |

| R/LOB17.1 | 1528 | 1406 | 423 |

| R/LOB17.2 | 1528 | 1204 | 464 |

| R/LOB17.3 | 1528 | 1018 | 505 |

| BB region |

FW height (poloidal) | FW width (toroidal) | FW sidewall length (radial) |

|---|---|---|---|

| [mm] | [mm] | [mm] | |

| R/LIB12 | 1406 | 1140 | 658 |

| R/LIB11 | 1406 | 1140 | 497 |

| R/LIB10 | 1406 | 1140 | 352 |

| R/LIB9 | 1151 | 1095 | 291 |

| R/LIB8 | 1151 | 1095 | 291 |

| R/LIB7 | 1125 | 1117 | 322 |

| R/LIB6 | 1125 | 1117 | 415 |

| R/LIB5 | 1125 | 1117 | 482 |

| R/LIB4 | 375 | 1150 | 532 |

| R/LIB3.3 | 375 | 1172 | 573 |

| R/LIB3.2 | 375 | 1210 | 519 |

| R/LIB3.1 | 375 | 1263 | 498 |

| R/LIB2.2 | 375 | 1335 | 466 |

| R/LIB2.1 | 375 | 1414 | 464 |

| R/LIB1.3 | 250 | 1475 | 478 |

| R/LIB1.2 | 250 | 1536 | 488 |

| R/LIB1.1 | 531 | 1614 | 494 |

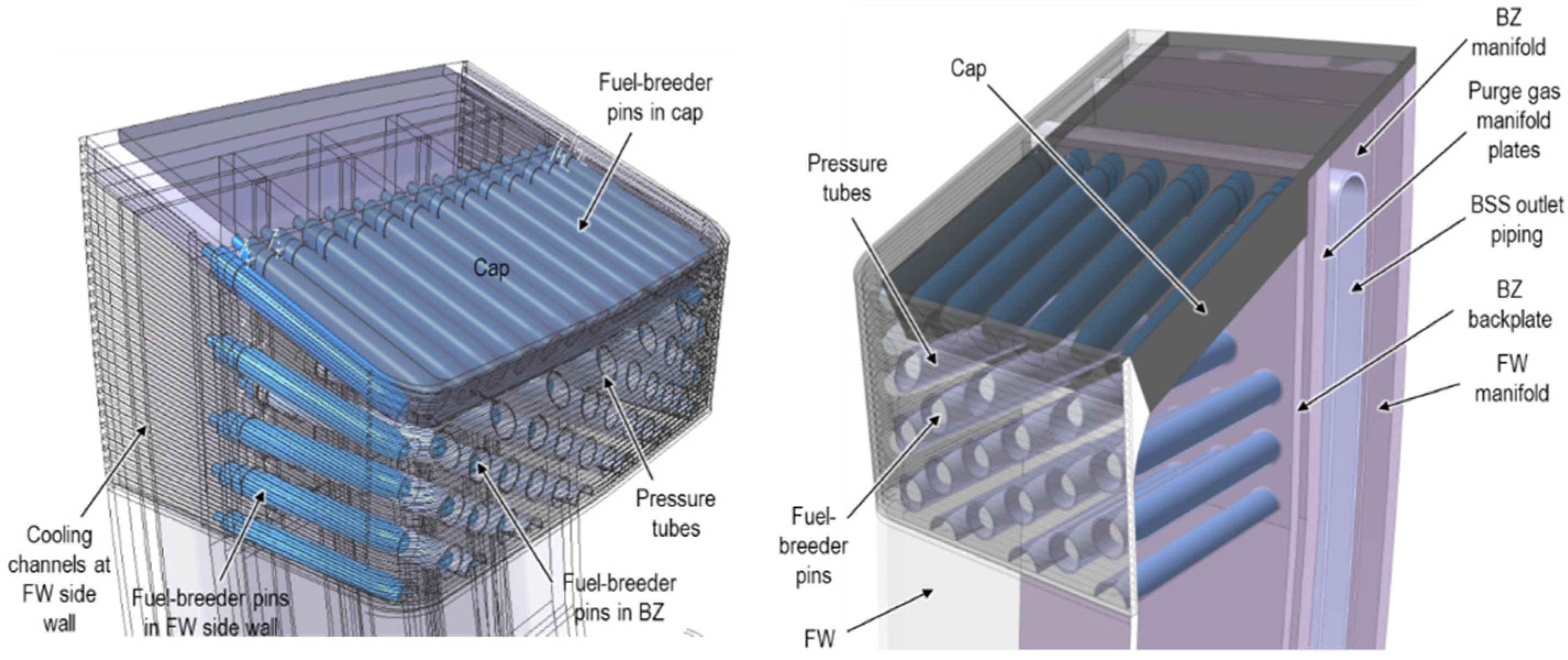

2.2.2. Design features

| BB Region | Width (pol.) |

Height (rad.) |

BB Region | Width (pol.) |

Height (rad.) |

BB Region | Width (pol.) |

Height (rad.) |

|---|---|---|---|---|---|---|---|---|

| [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | |||

| R/LOB1 | 12 | 14 | COB1 | 12 | 12 | R/LIB12 | 12 | 12 |

| R/LOB2 | 12 | 11 | COB2 | 12 | 12 | R/LIB11 | 12 | 12 |

| R/LOB3 | 12 | 11 | COB3 | 12 | 12 | R/LIB10 | 15 | 15 |

| R/LOB4 | 12 | 11 | COB4 | 12 | 12 | R/LIB9 | 15 | 15 |

| R/LOB5 | 12 | 12 | COB5 | 12 | 12 | R/LIB8 | 15 | 15 |

| R/LOB6 | 12 | 12 | COB6 | 12 | 12 | R/LIB7 | 10 | 8 |

| R/LOB7 | 12 | 12 | COB7 | 12 | 12 | R/LIB6 | 10 | 8 |

| R/LOB8 | 12 | 12 | COB8 | 12 | 12 | R/LIB5 | 10 | 8 |

| R/LOB9 | 12 | 12 | COB9 | 12 | 12 | R/LIB4 | 10 | 8 |

| R/LOB10 | 12 | 12 | COB10 | 12 | 12 | R/LIB3.3 | 10 | 8 |

| R/LOB11 | 12 | 12 | COB11 | 12 | 12 | R/LIB3.2 | 10 | 8 |

| R/LOB12 | 12 | 12 | COB12 | 12 | 12 | R/LIB3.1 | 10 | 8 |

| R/LOB13 | 12 | 12 | COB13 | 12 | 12 | R/LIB2.2 | 10 | 8 |

| R/LOB14 | 12 | 12 | COB14 | 12 | 12 | R/LIB2.1 | 10 | 8 |

| R/LOB15 | 12 | 12 | COB15 | 12 | 12 | R/LIB1.3 | 10 | 8 |

| R/LOB16 | 12 | 12 | COB16 | 12 | 12 | R/LIB1.2 | 10 | 8 |

| R/LOB17.1 | 12 | 12 | COB17.1 | 13 | 13 | R/LIB1.1 | 10 | 8 |

| R/LOB17.2 | 12 | 11 | COB17.2 | 13 | 13 | |||

| R/LOB17.3 | 12 | 11 | COB17.3 | 13 | 13 |

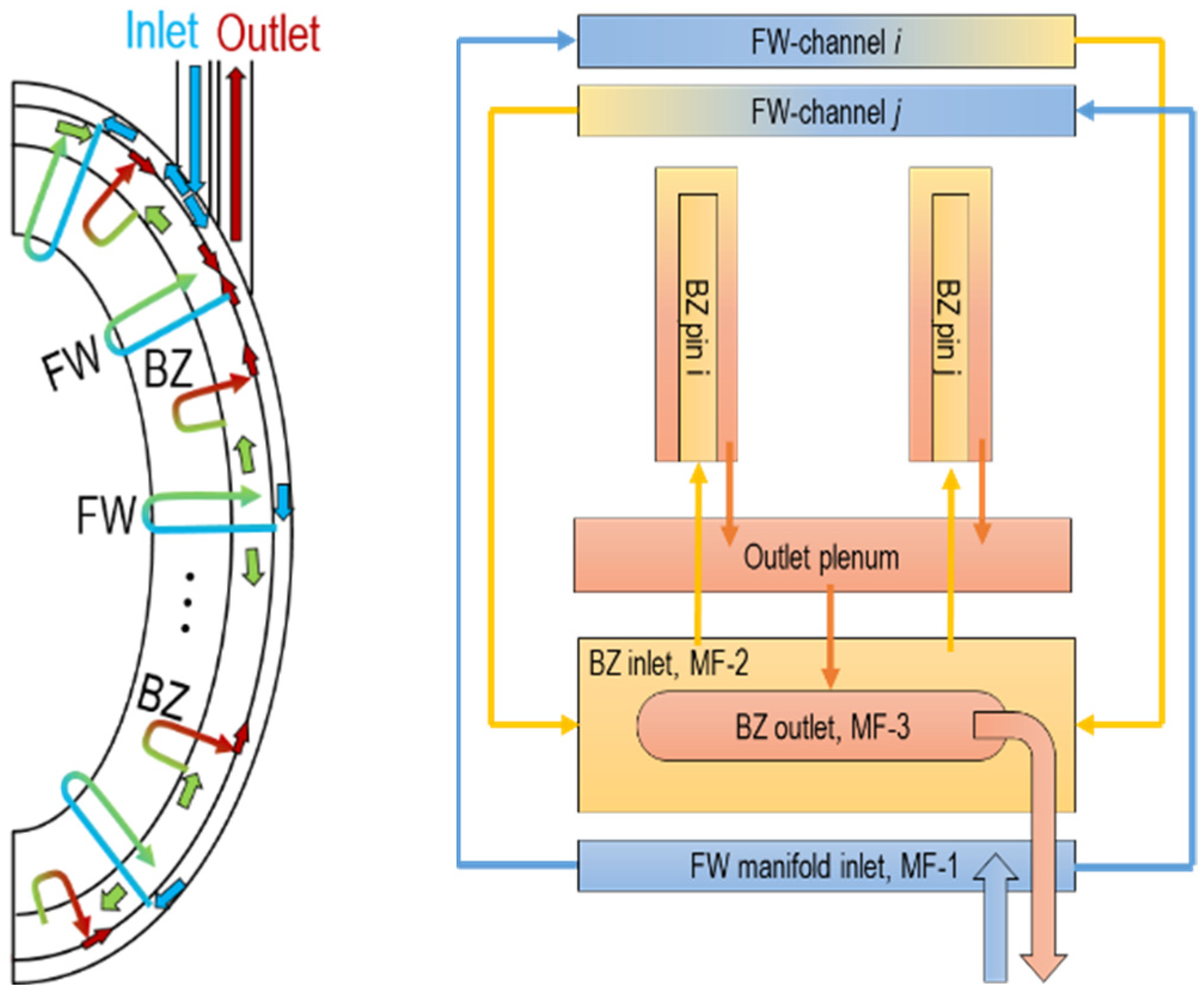

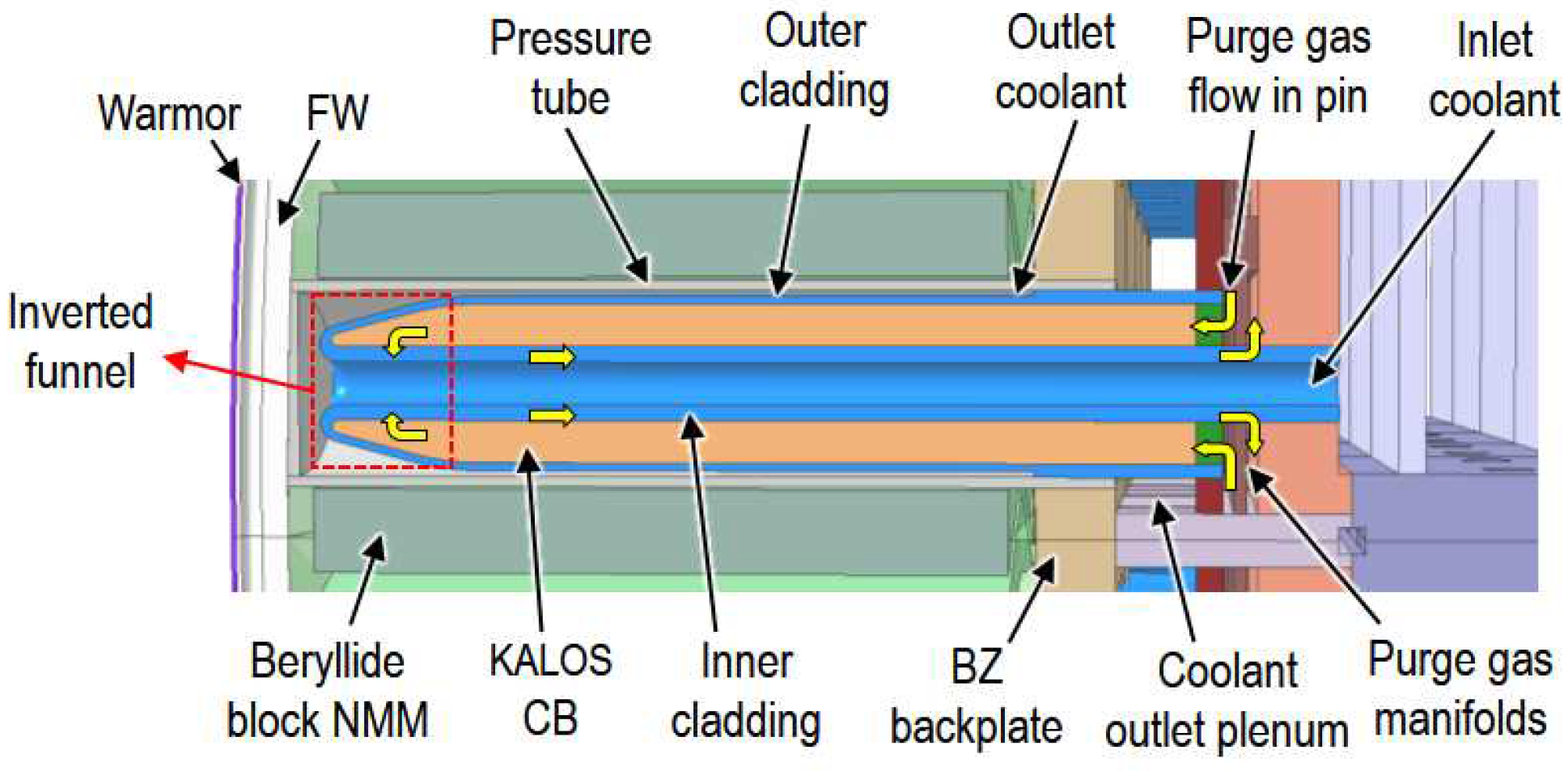

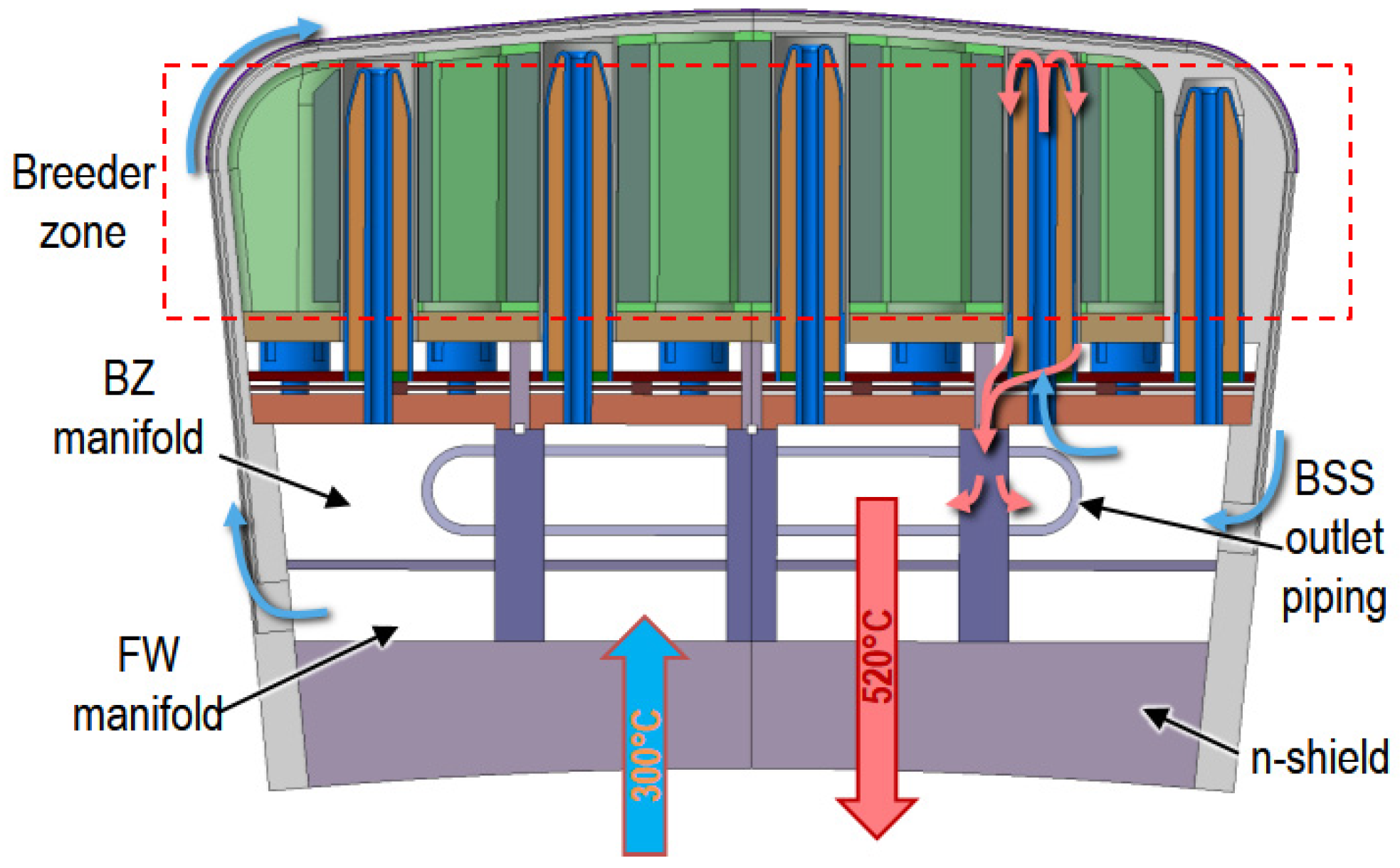

2.2.3. Coolant choice, parameters and flow scheme

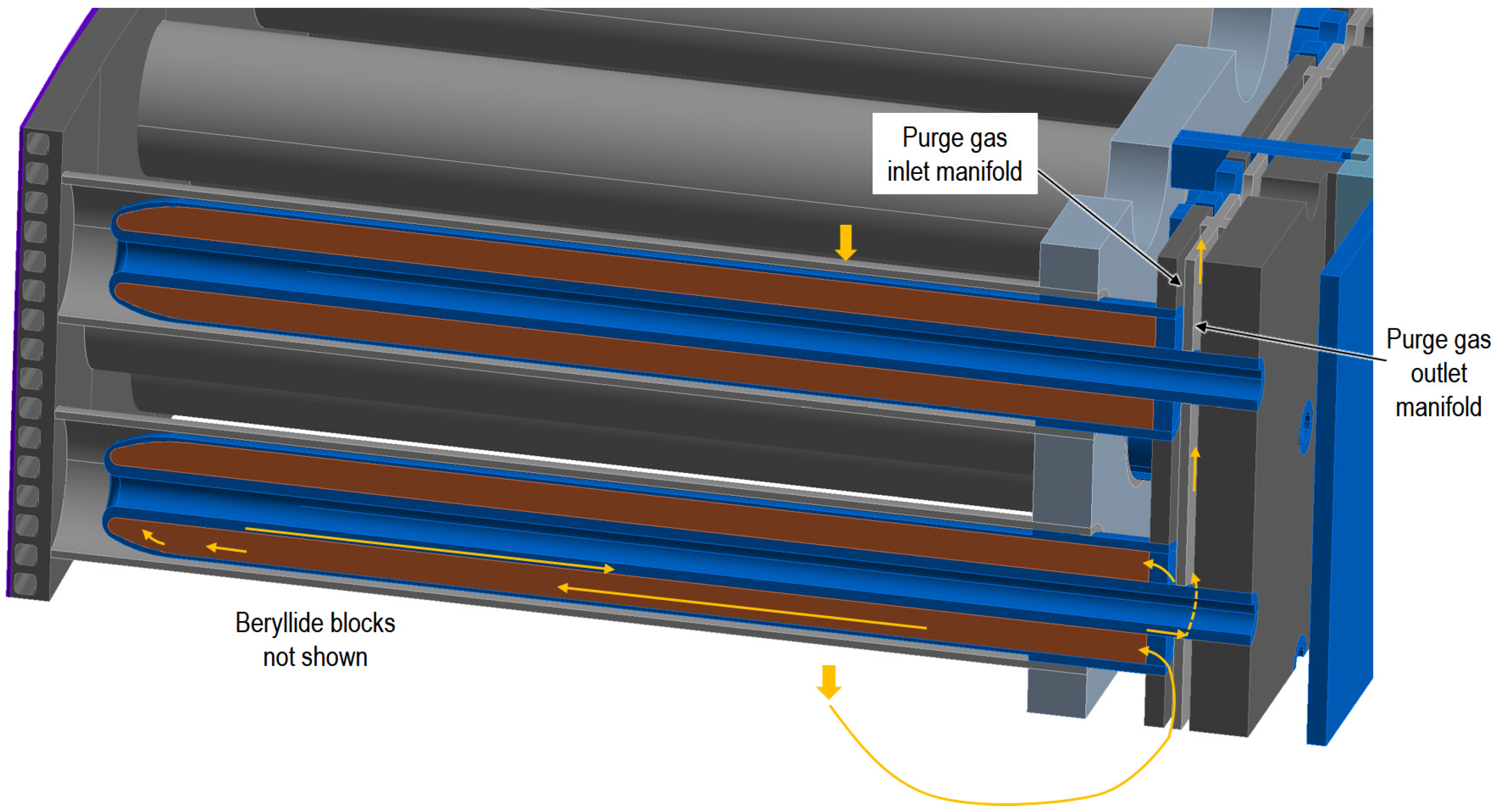

2.2.4. Purge gas choice, parameters and flow scheme

3. Main performance analyses

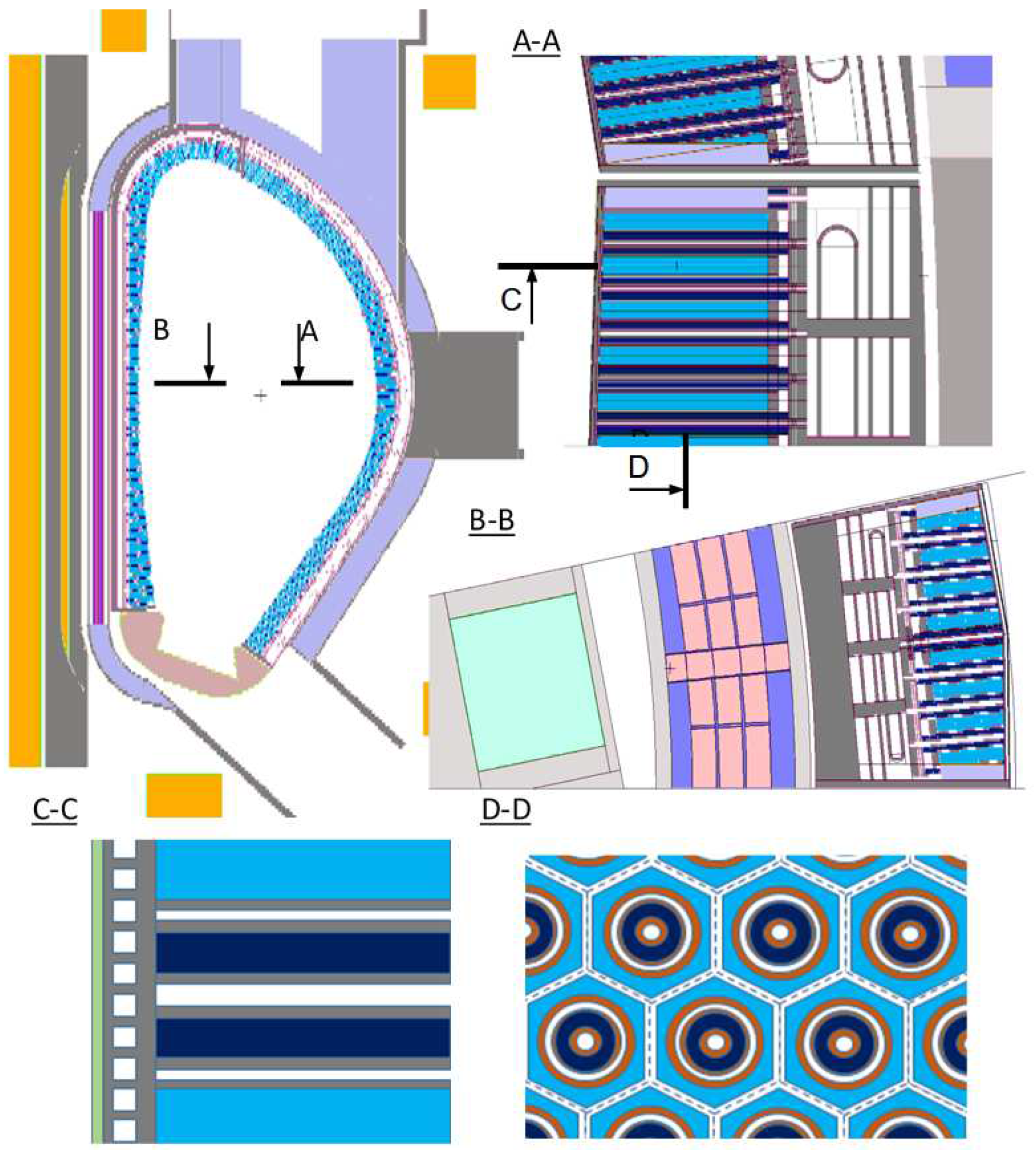

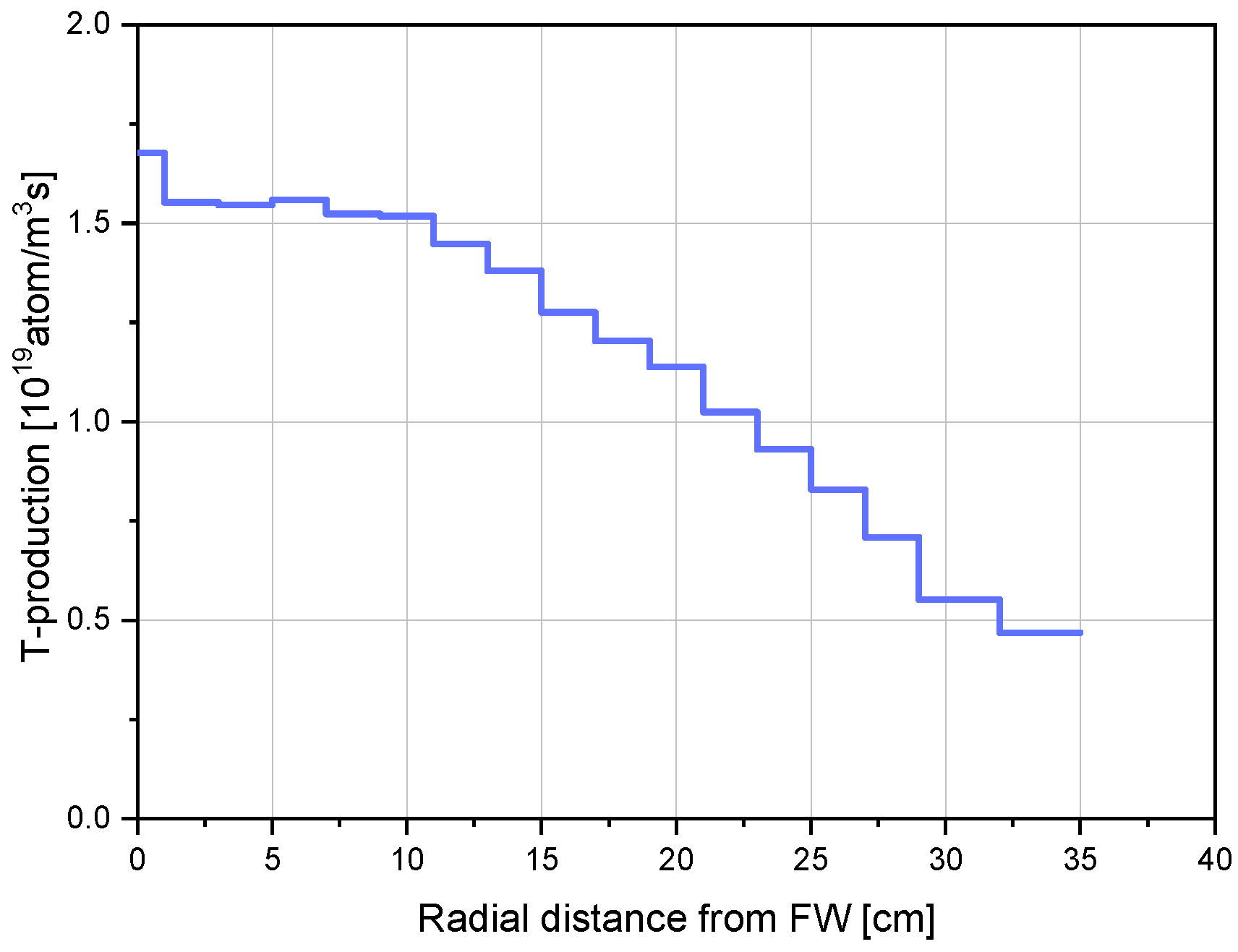

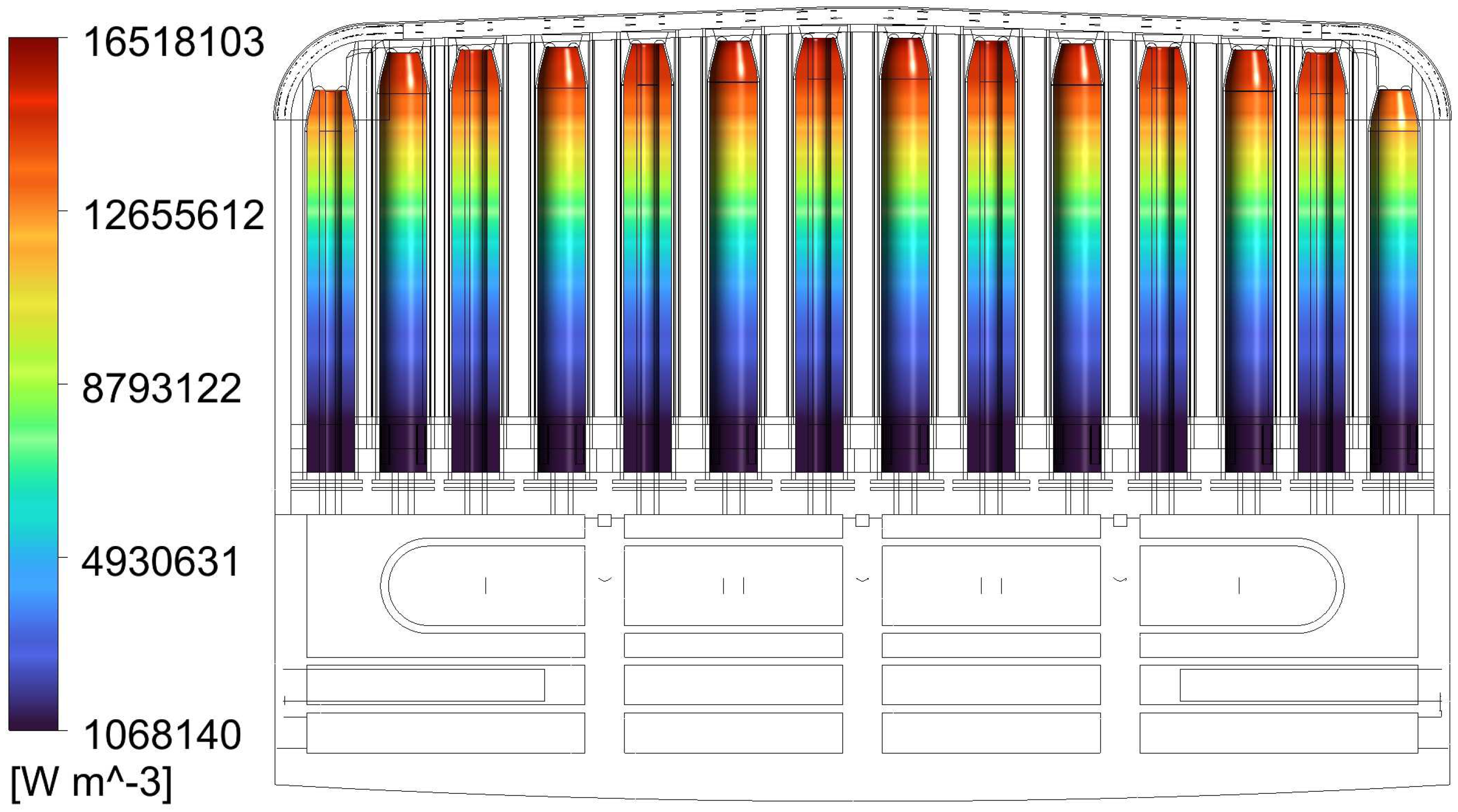

3.1. Nuclear analyses

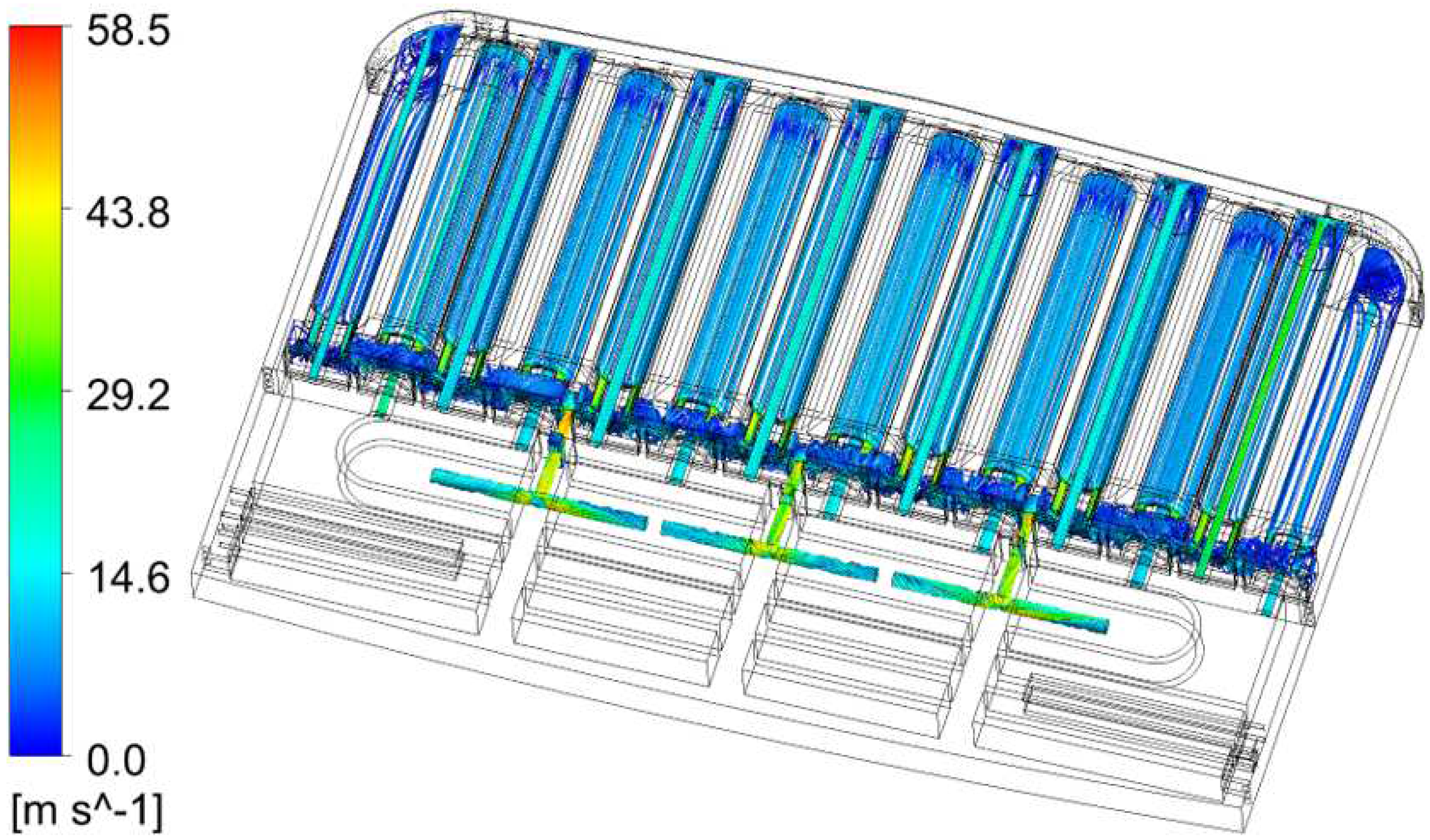

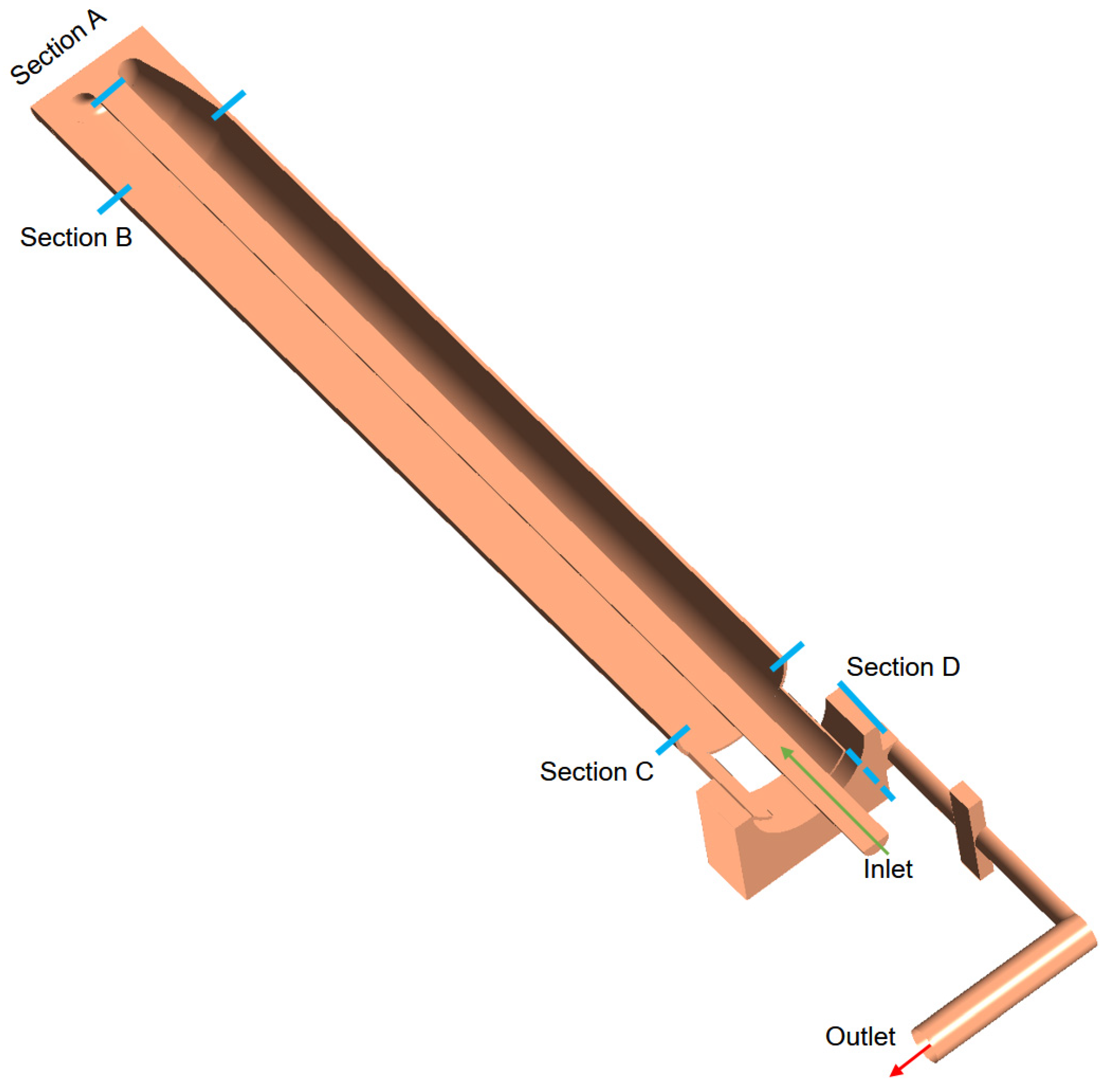

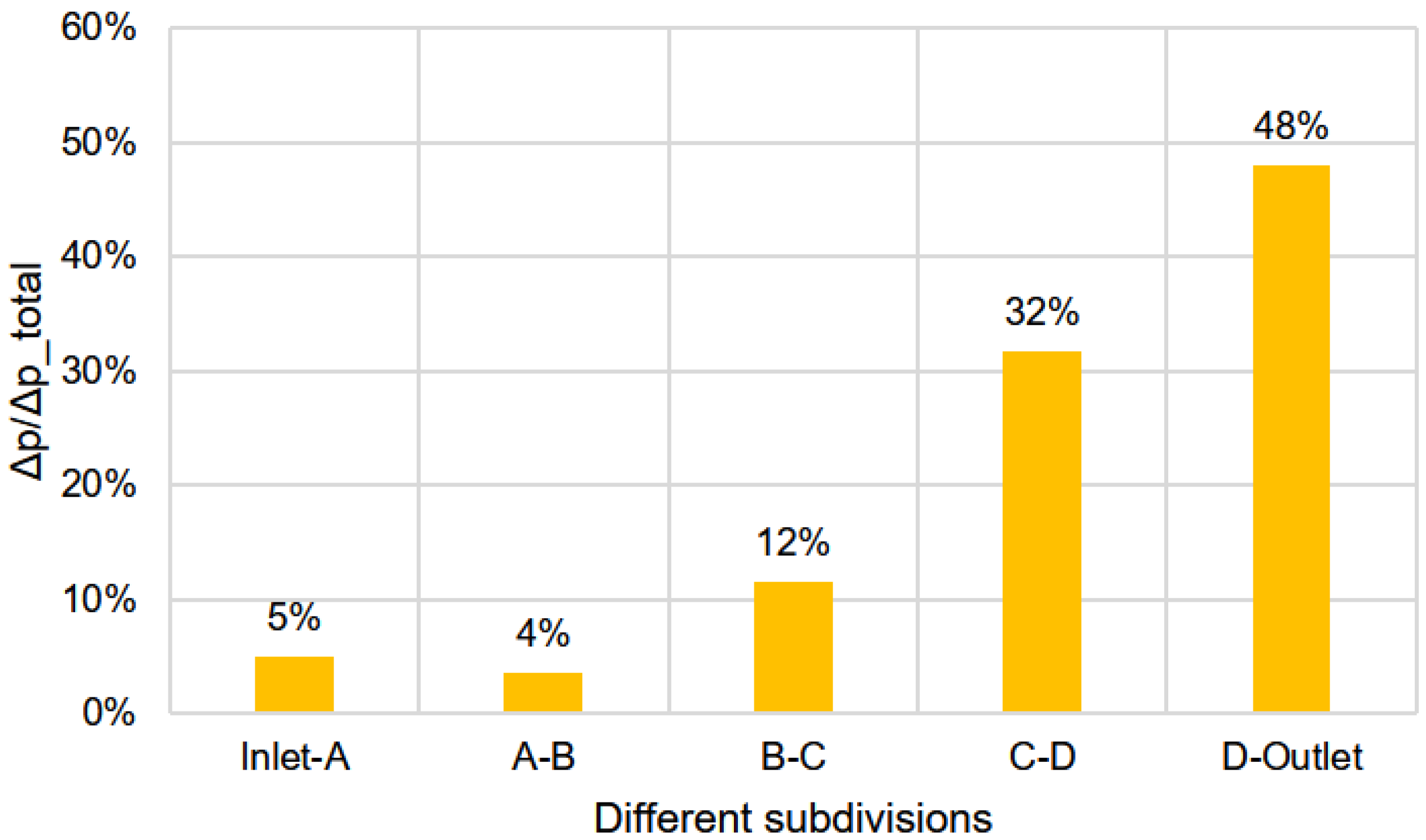

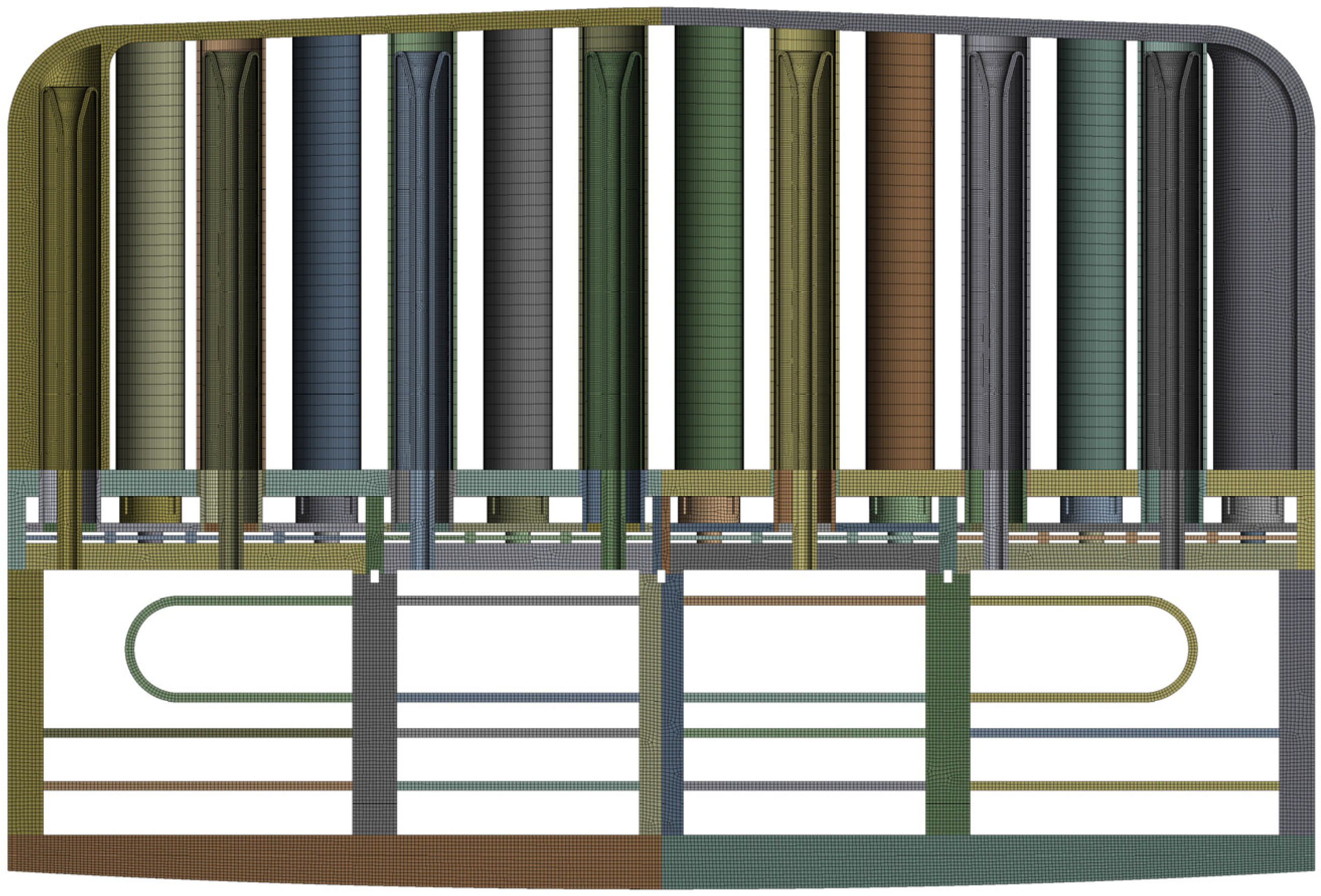

3.2. Thermal hydraulic analyses

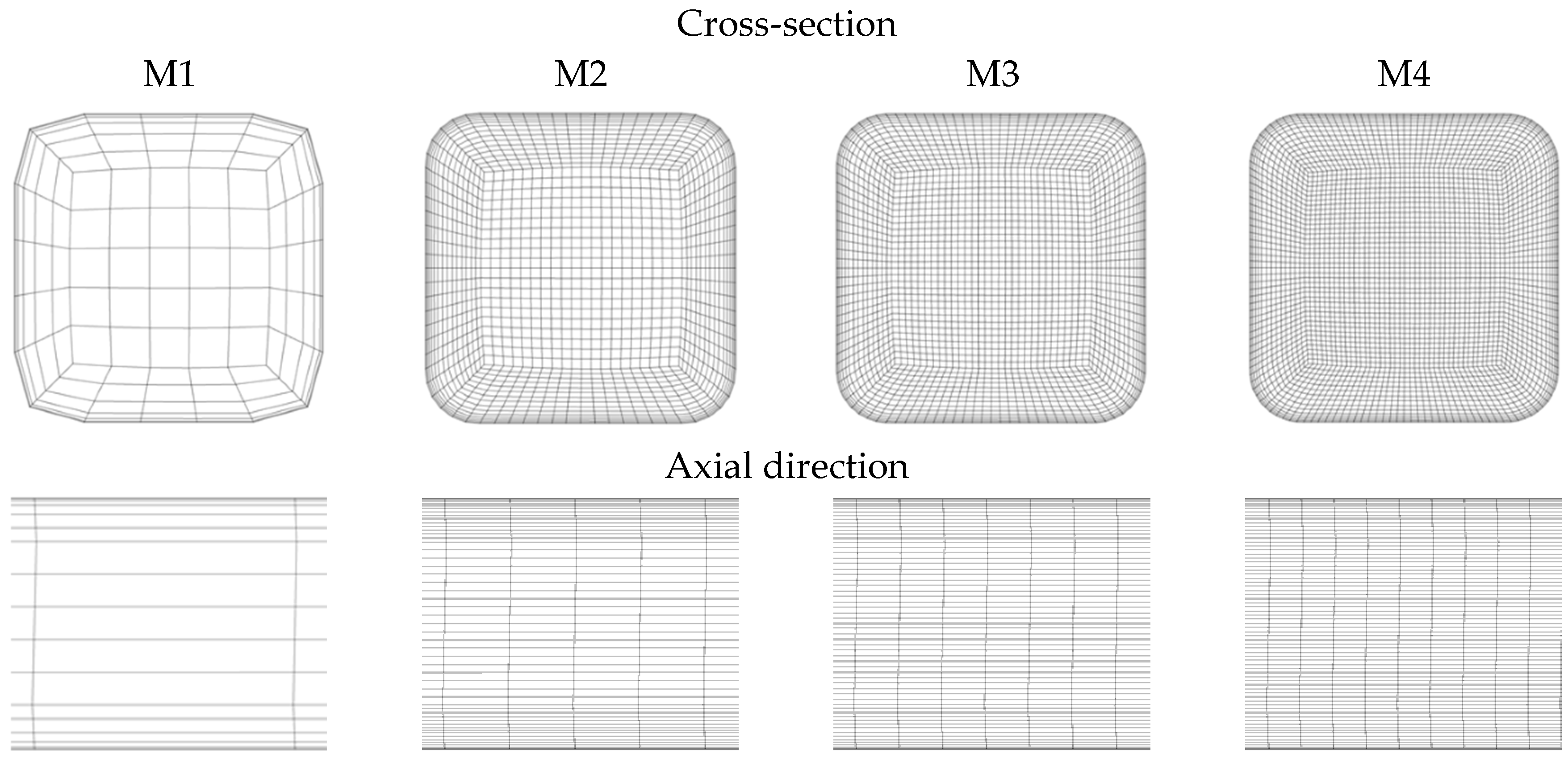

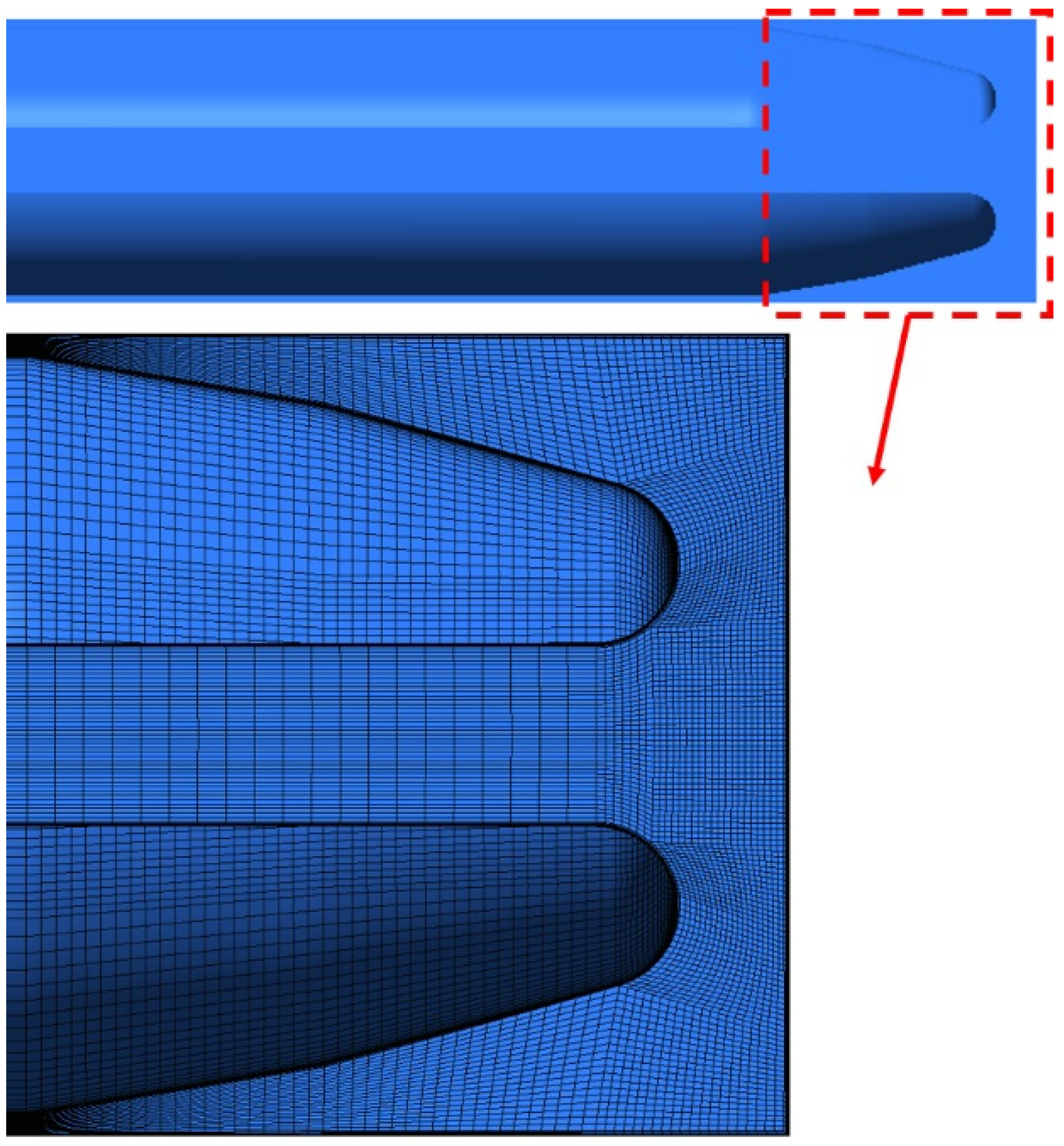

3.2.1. Mesh independence analysis

| M1 | M2 | M3 | M4 | |

|---|---|---|---|---|

| Mesh nodes | 37 944 | 1 603 119 | 4 054 018 | 8 003 677 |

| Mesh elements | 35 060 | 1 560 800 | 3 960 900 | 7 840 000 |

| Number of mesh nodes | Pressure drop [Pa] | Difference from M5 [%] | |

|---|---|---|---|

| M1 | 37 944 | 37 740 | -4.259 |

| M2 | 1 603 119 | 36 020 | 0.493 |

| M3 | 4 054 018 | 36 112 | 0.24 |

| M4 | 8 003 677 | 36 199 | 0 |

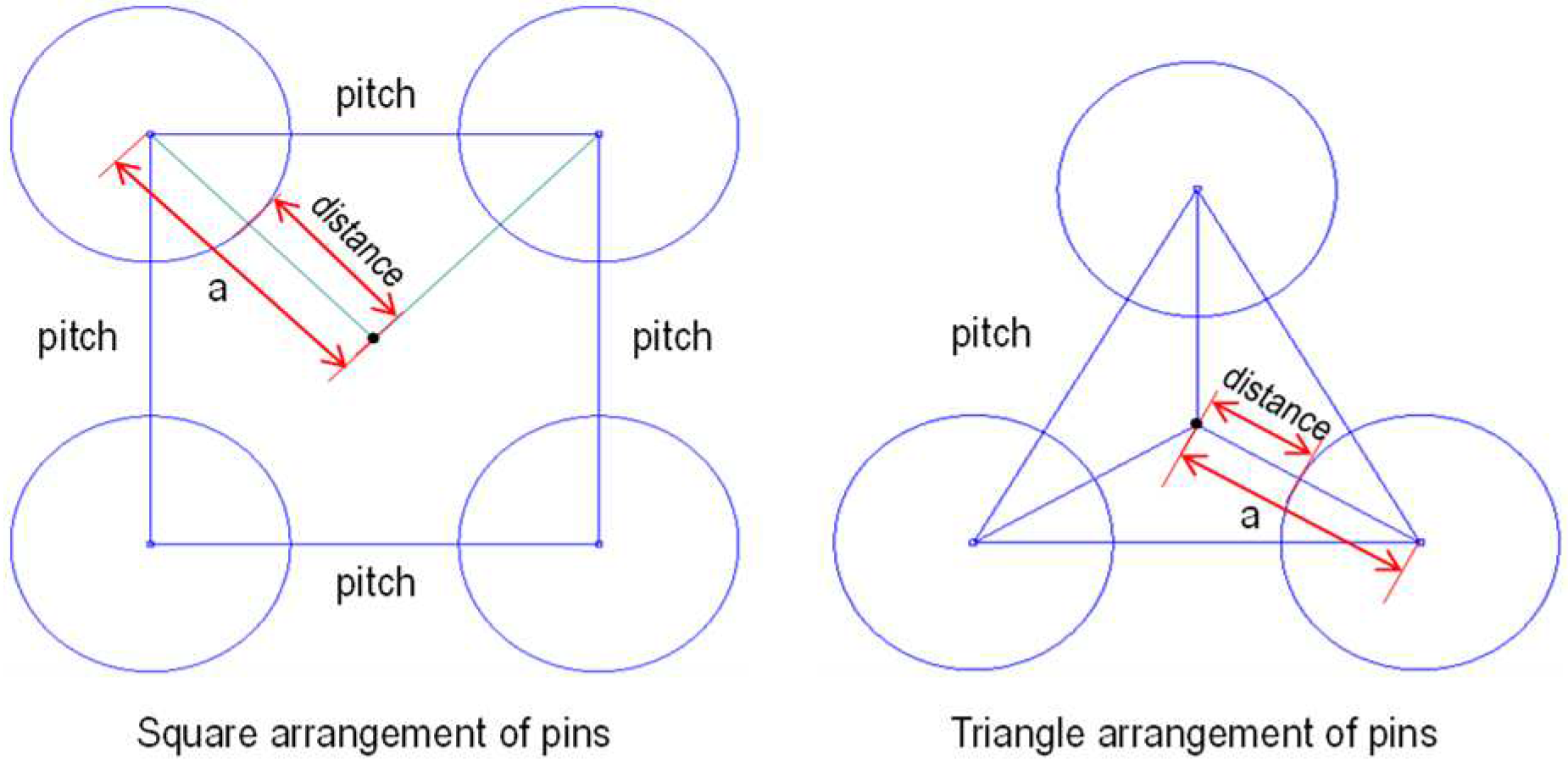

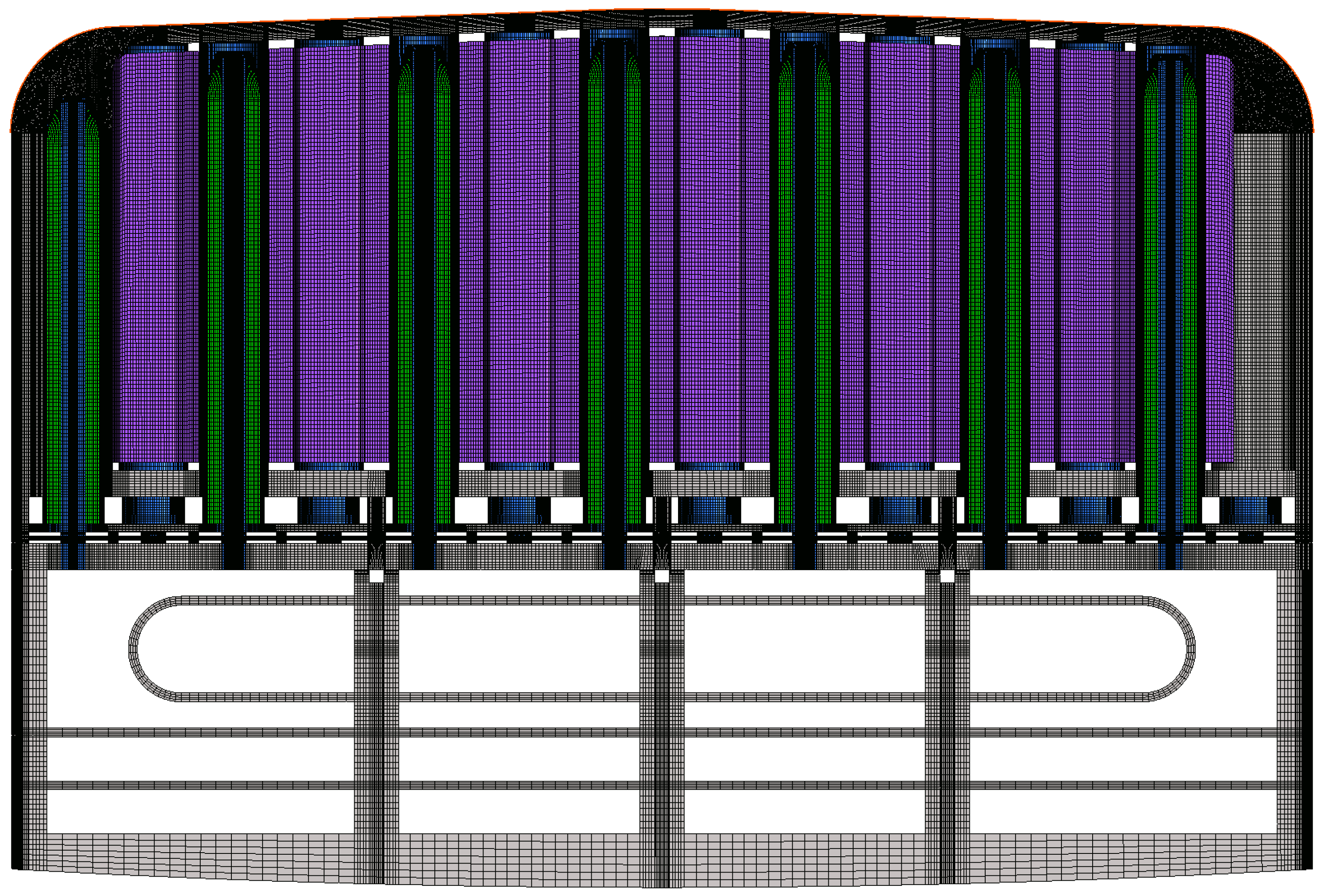

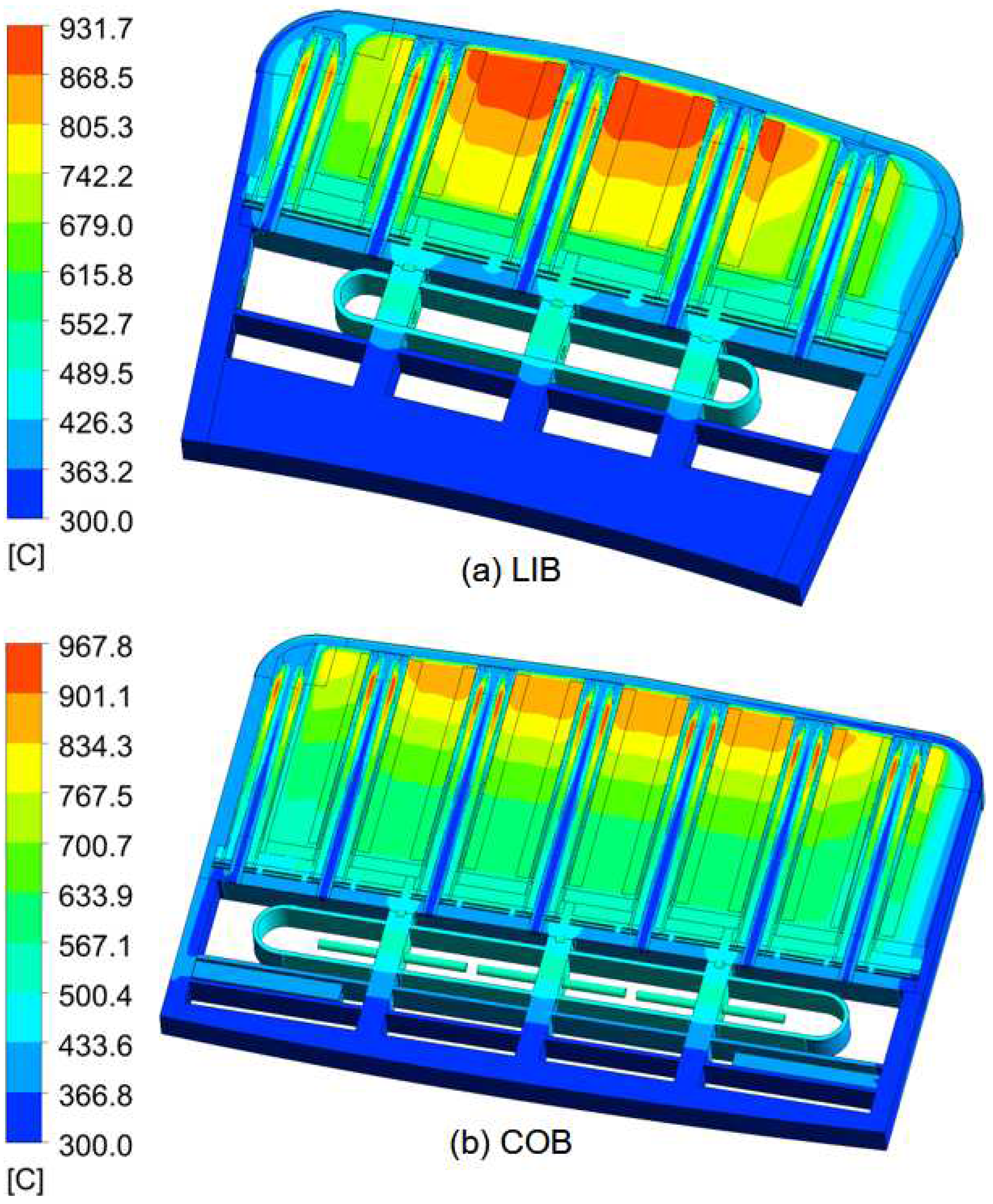

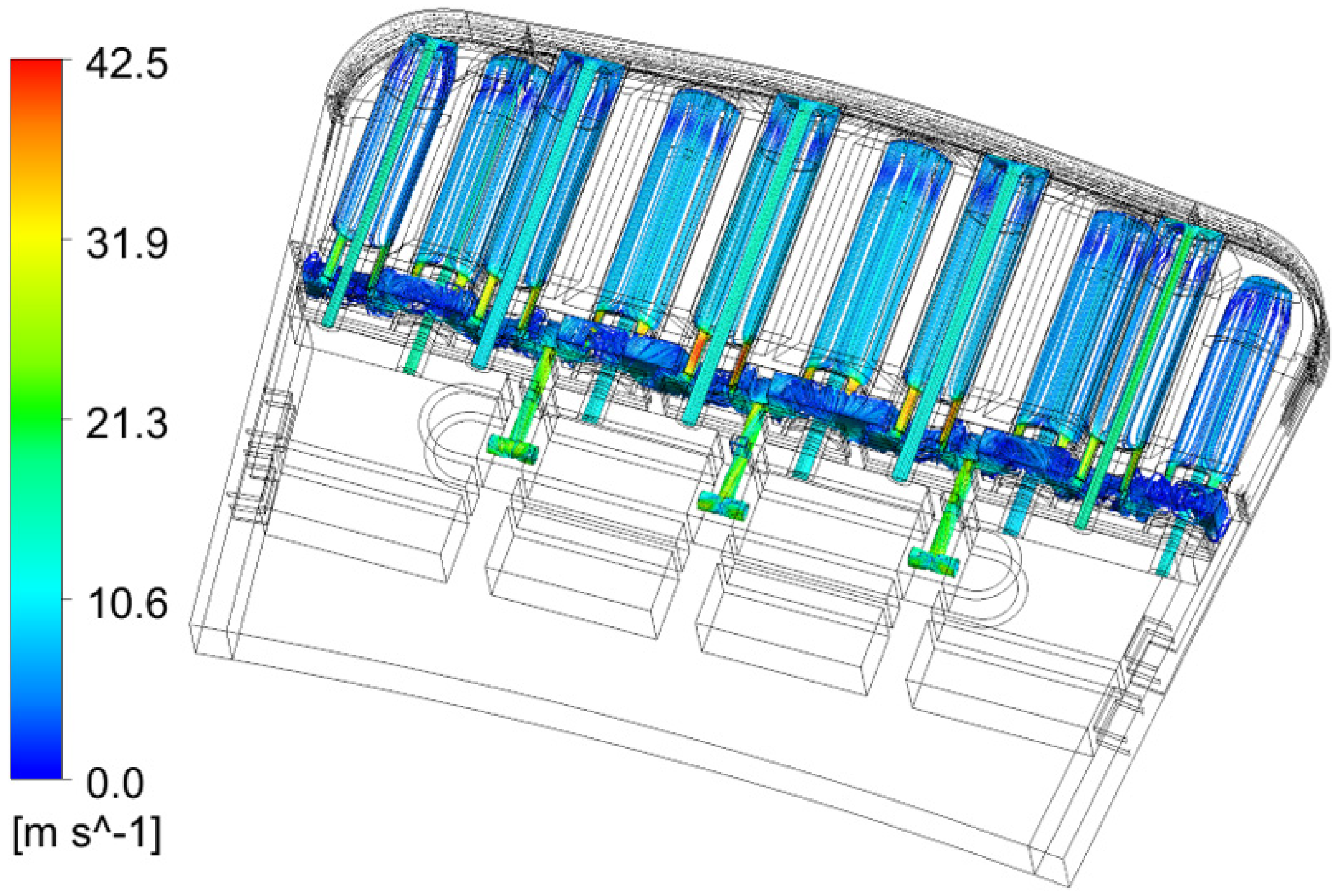

3.2.2. Detailed CFD analysis on the representative unit slice

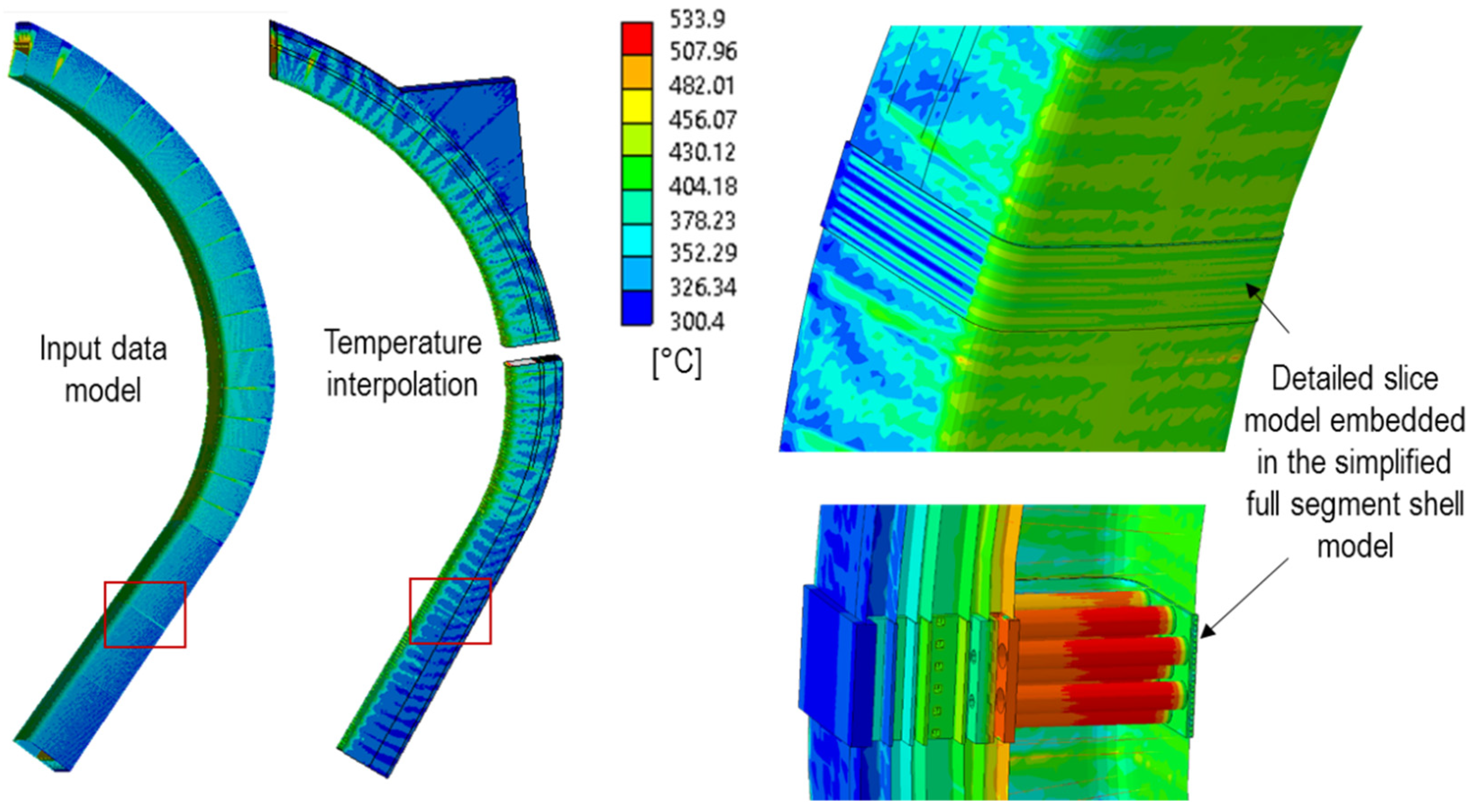

3.3. Thermal mechanical analyses

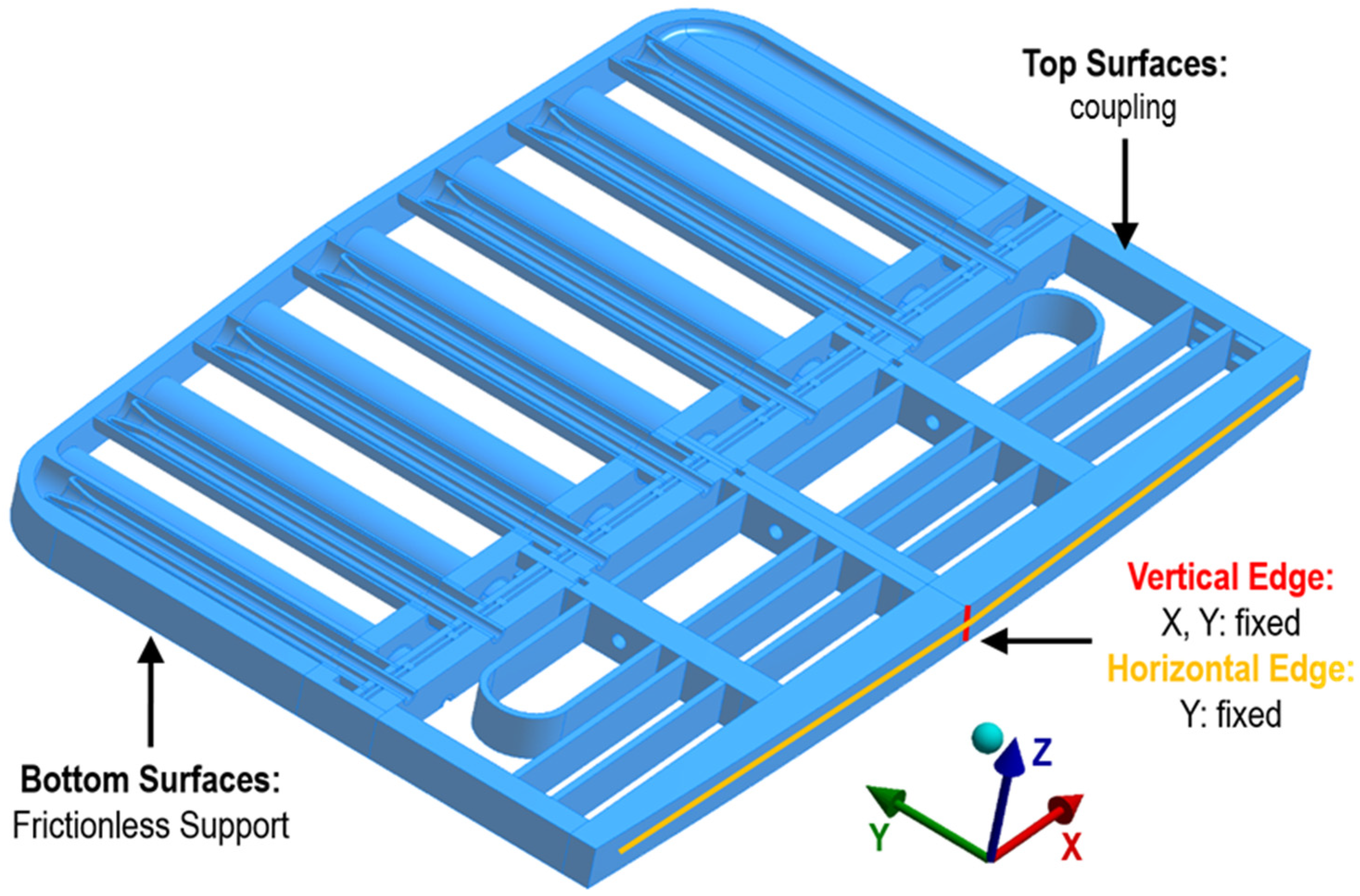

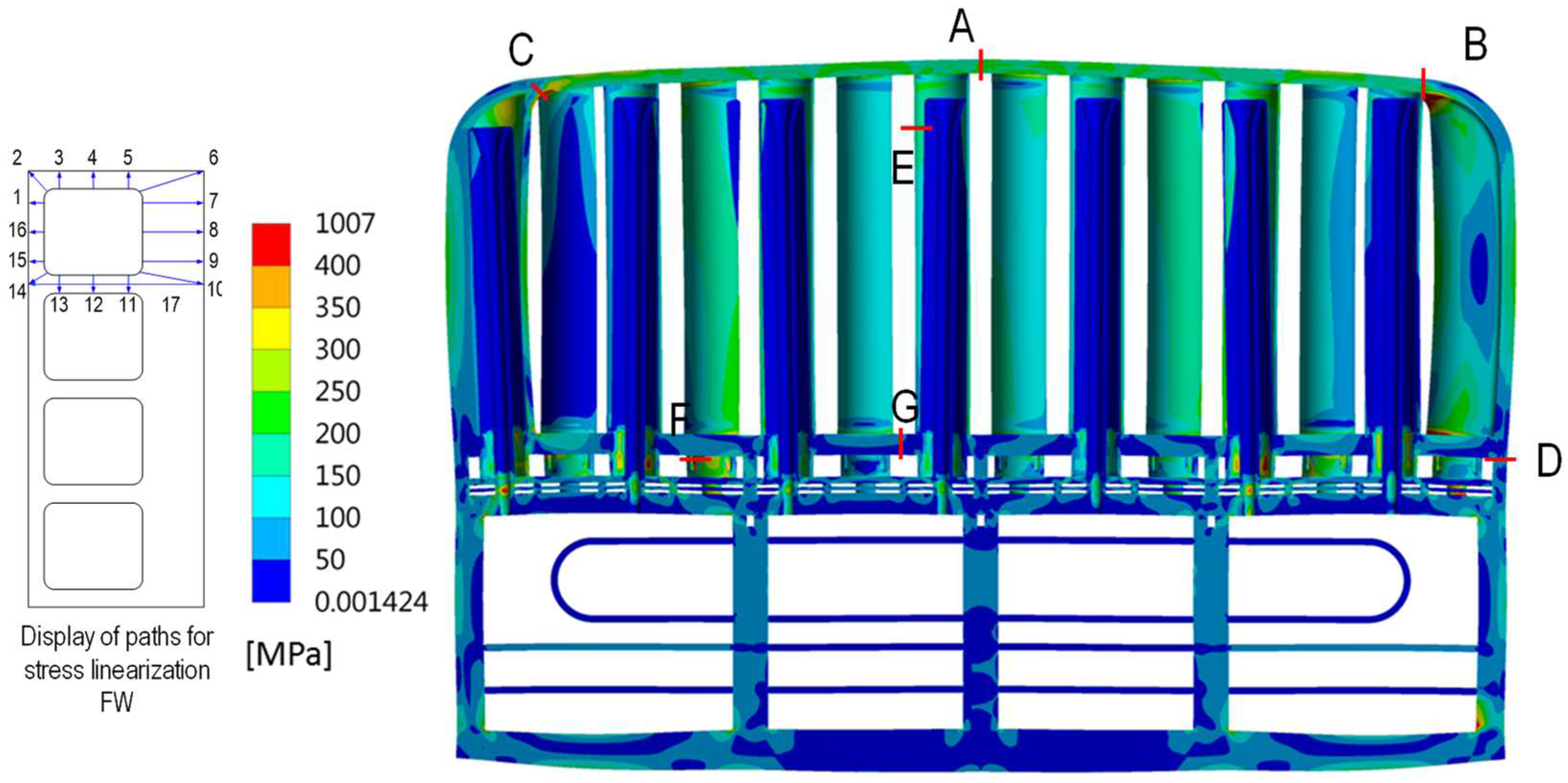

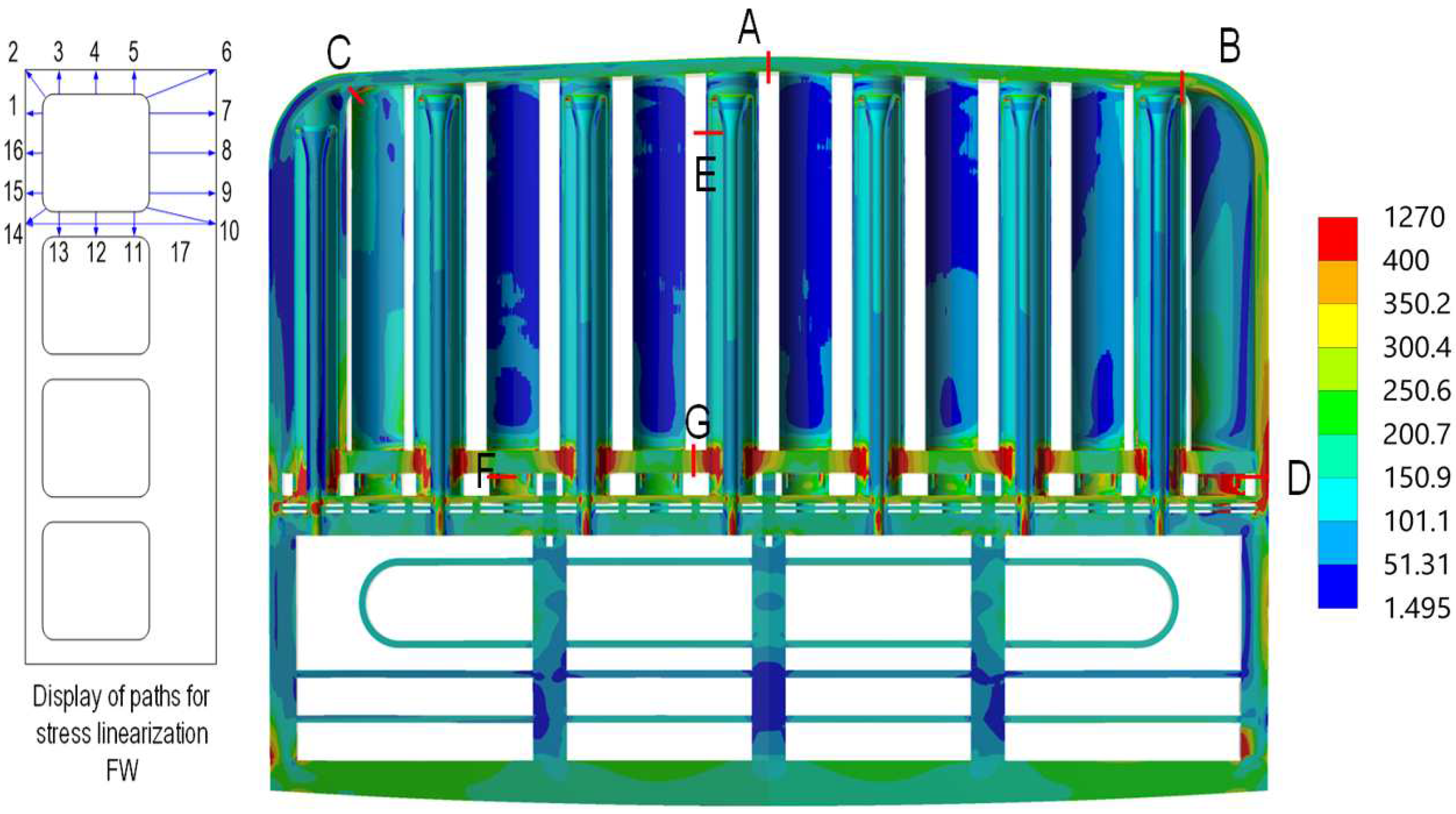

3.3.1. Elastic analyses on a detailed unit slice

| IPI | IPFL | ||||||

|---|---|---|---|---|---|---|---|

| Path | Path average temp. | Linearized stress value | Stress limit | Φ | Linearized stress value | Stress limit | Φ |

| A1 | 480.0 | 210.8 | 286.2 | 50.9% | 321.0 | 455.0 | 29% |

| A2 | 480.8 | 205.3 | 285.7 | 52.1% | 317.8 | 453.1 | 30% |

| A3 | 476.3 | 200.2 | 288.3 | 53.7% | 329.8 | 463.8 | 29% |

| A4 | 448.0 | 221.8 | 304.8 | 51.5% | 384.0 | 529.9 | 28% |

| A5 | 431.6 | 215.9 | 312.6 | 53.9% | 400.6 | 559.4 | 28% |

| A6 | 431.7 | 230.6 | 312.5 | 50.8% | 363.7 | 559.2 | 35% |

| A7 | 455.8 | 217.7 | 300.4 | 51.7% | 366.3 | 512.5 | 29% |

| A8 | 456.7 | 221.6 | 299.9 | 50.7% | 361.1 | 510.3 | 29% |

| A9 | 457.3 | 216.7 | 299.5 | 51.8% | 358.5 | 508.9 | 30% |

| A10 | 458.2 | 212.5 | 299.0 | 52.6% | 353.6 | 506.8 | 30% |

| A11 | 459.5 | 214.8 | 298.2 | 52.0% | 377.1 | 503.7 | 25% |

| A12 | 438.1 | 212.6 | 309.5 | 54.2% | 374.9 | 547.7 | 32% |

| A13 | 437.3 | 212.8 | 309.8 | 54.2% | 312.4 | 549.1 | 43% |

| A14 | 451.9 | 200.1 | 302.7 | 55.9% | 304.5 | 521.7 | 42% |

| A15 | 479.4 | 206.9 | 286.5 | 51.9% | 318.7 | 456.4 | 30% |

| A16 | 481.5 | 213.6 | 285.3 | 50.1% | 315.2 | 451.4 | 30% |

| A17 | 456.9 | 216.4 | 299.7 | 51.9% | 339.6 | 509.9 | 33% |

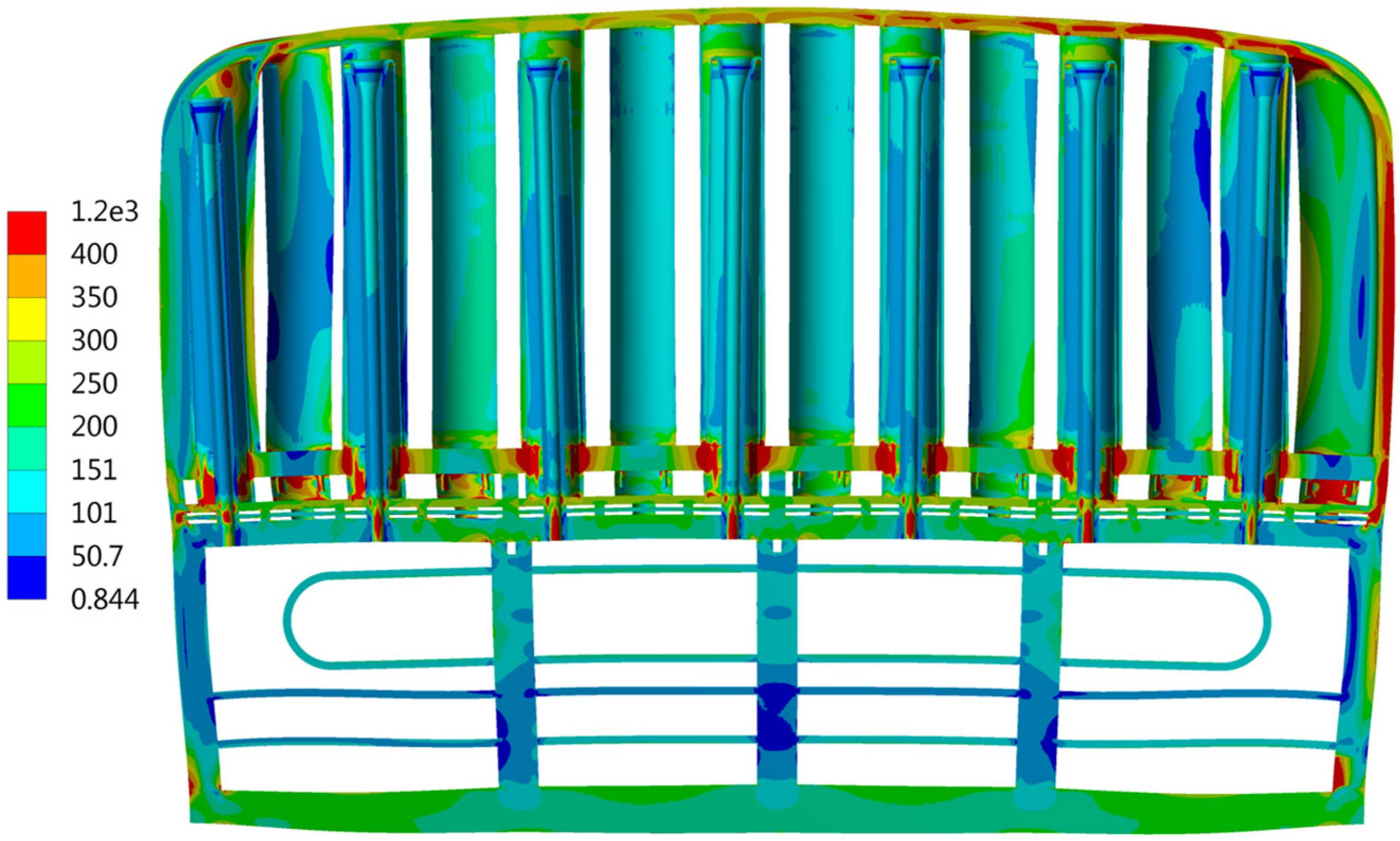

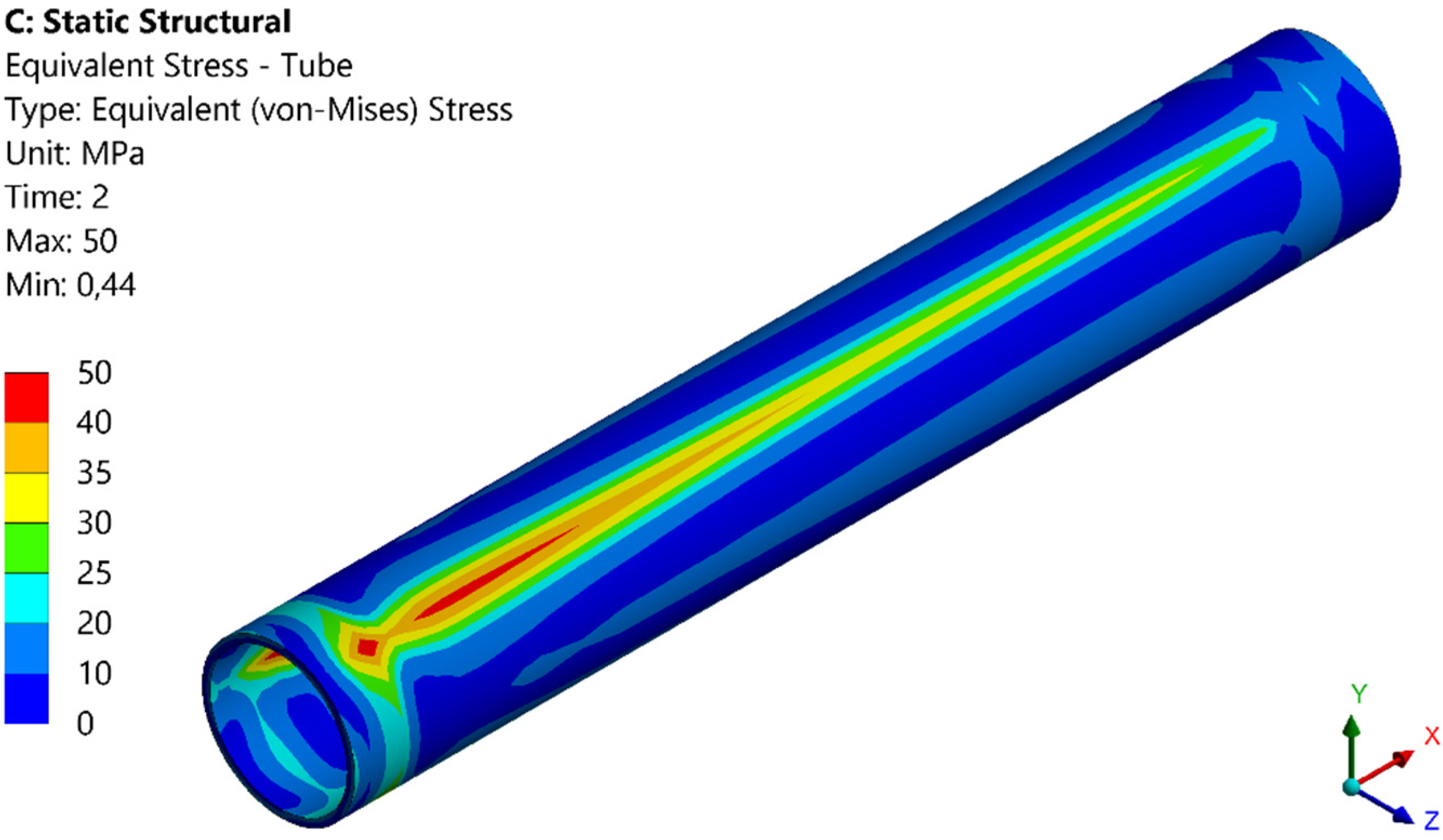

3.3.2. Inelastic analyses on the cap region of HCPB BB

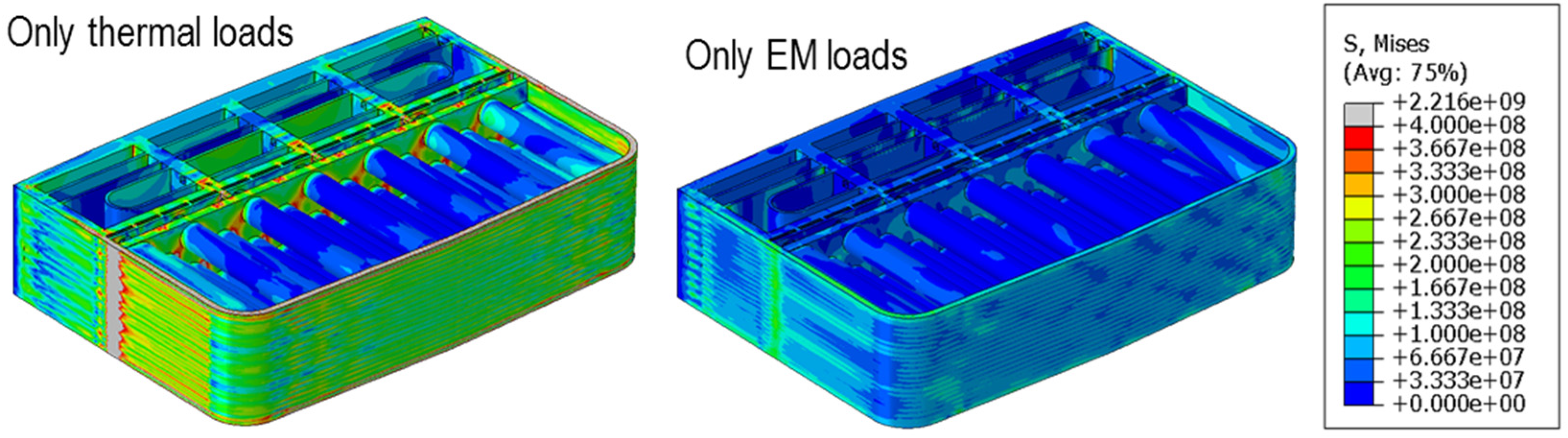

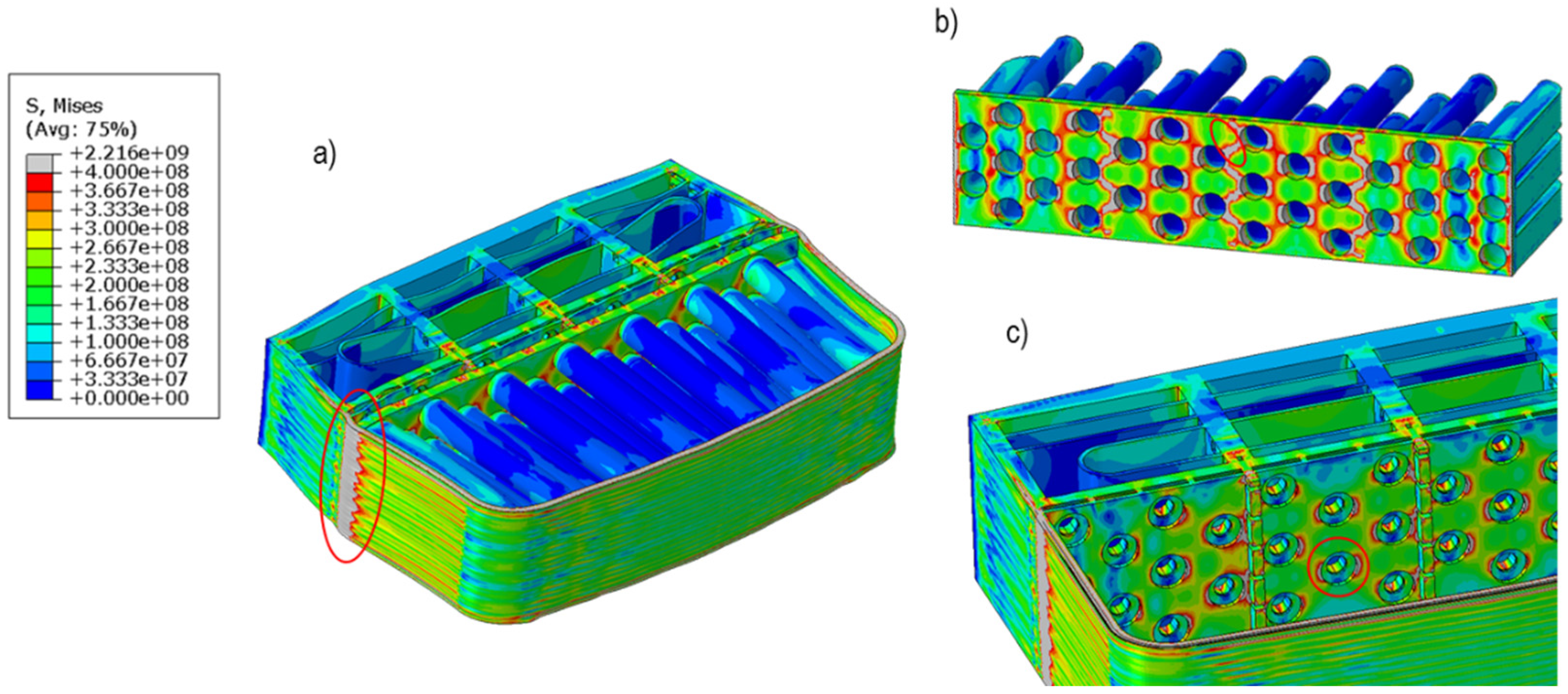

3.3.3. Global elastic analyses of blanket segment

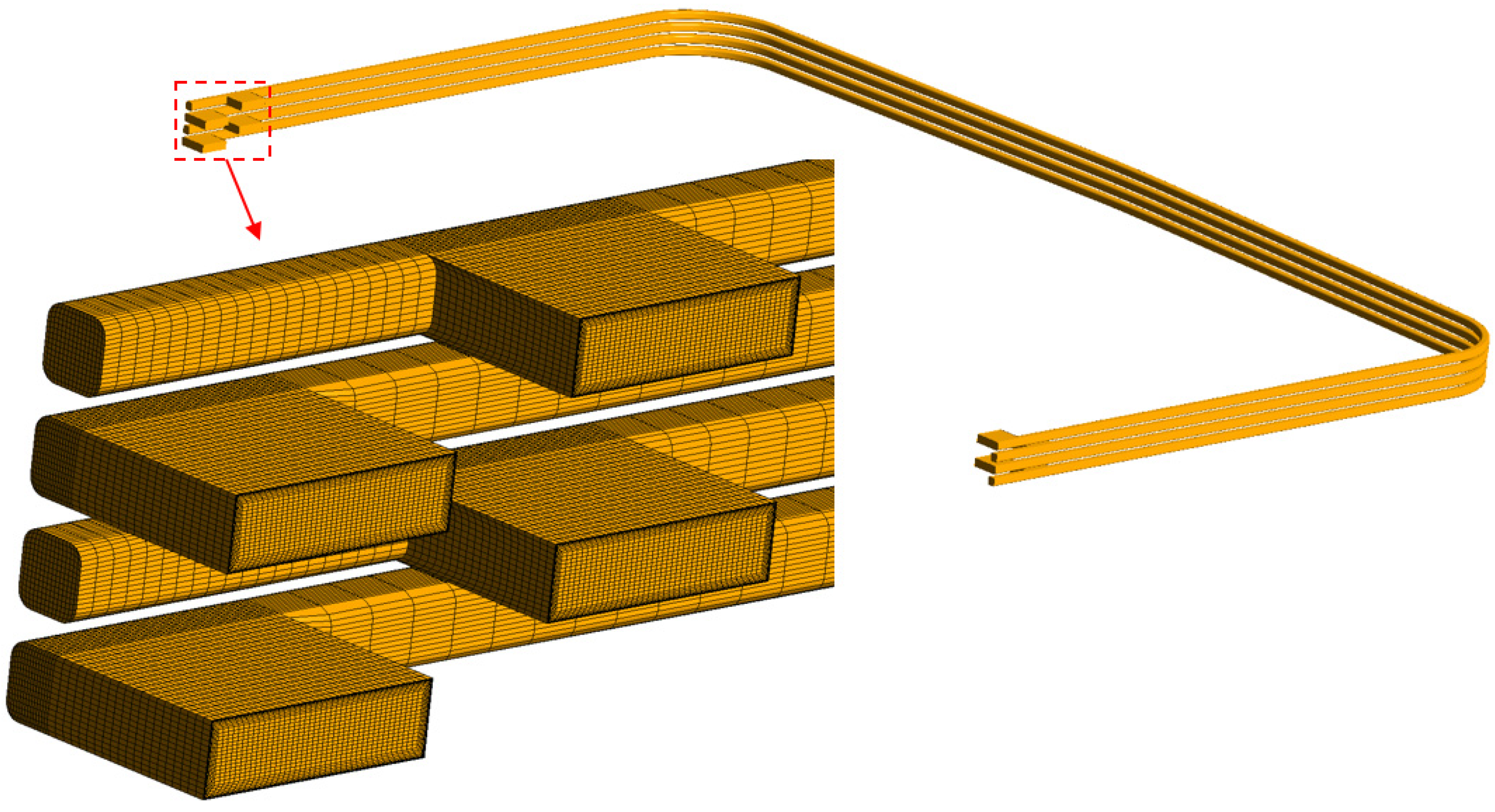

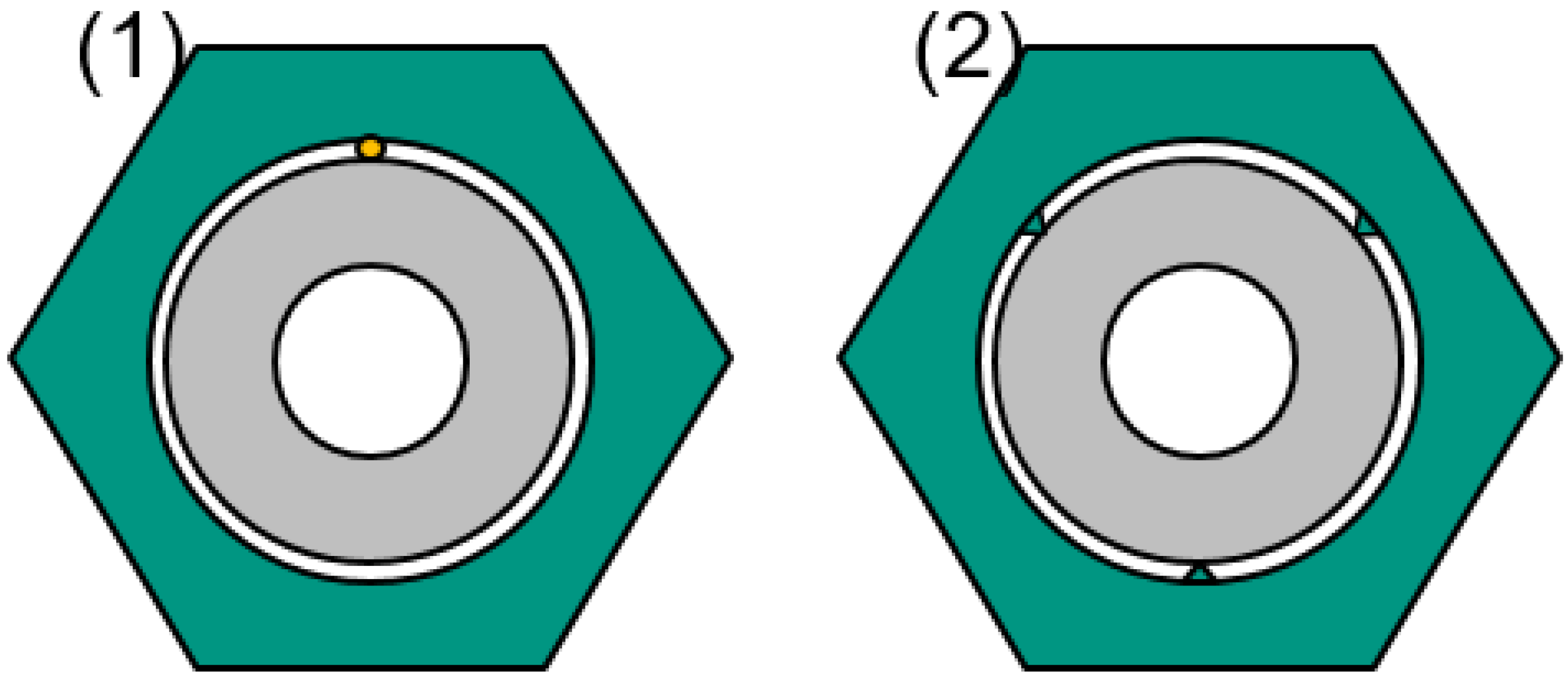

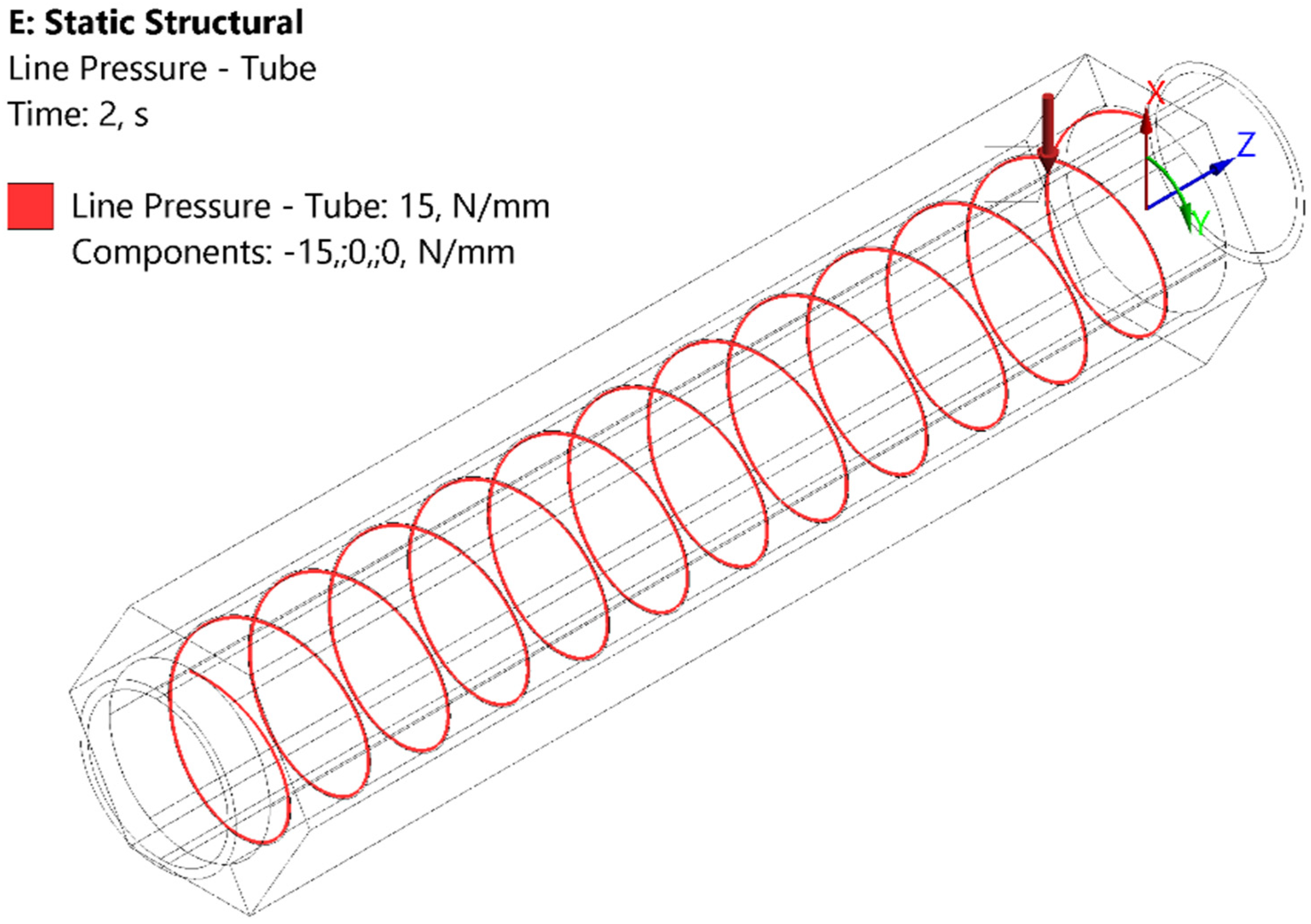

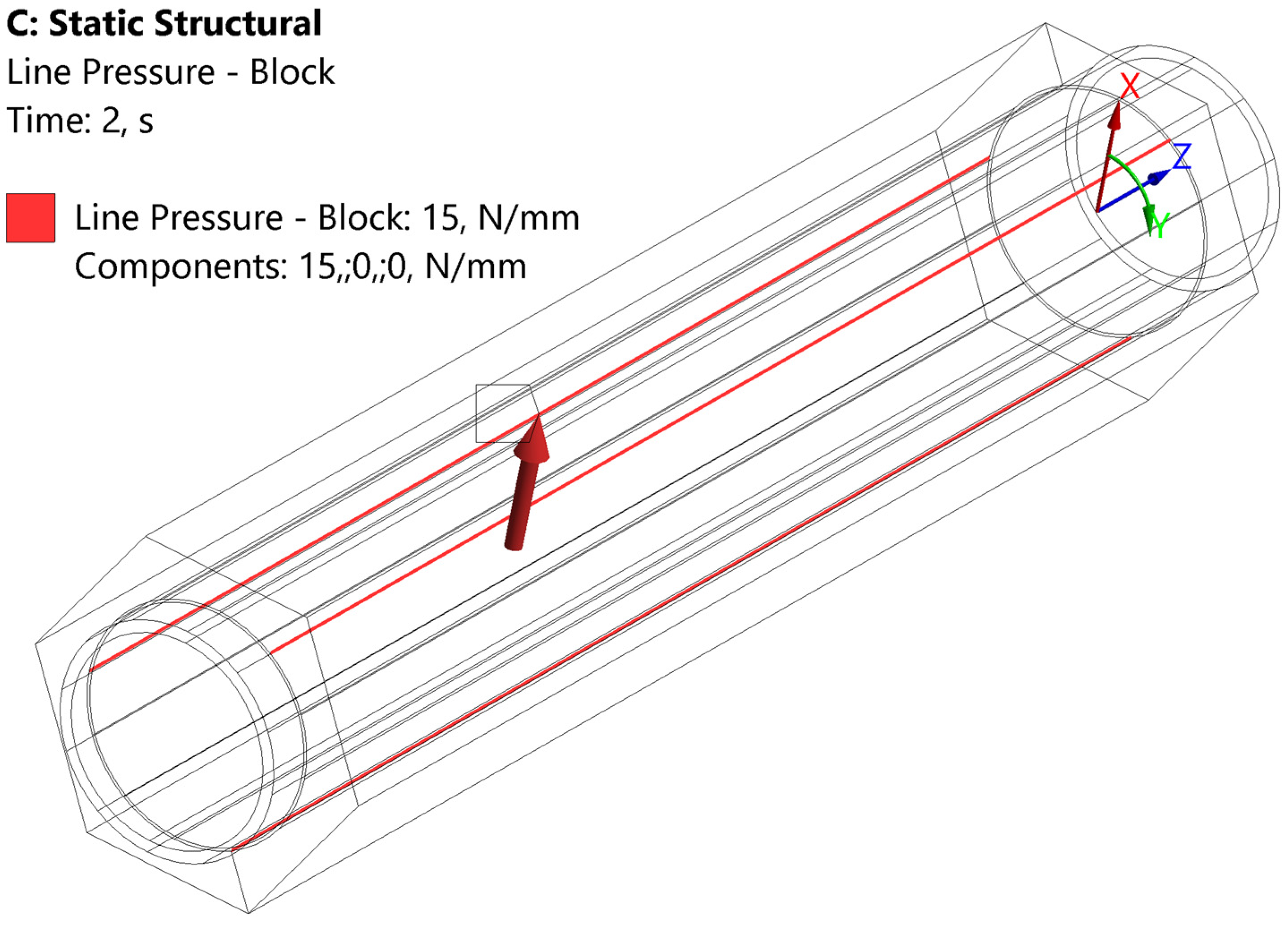

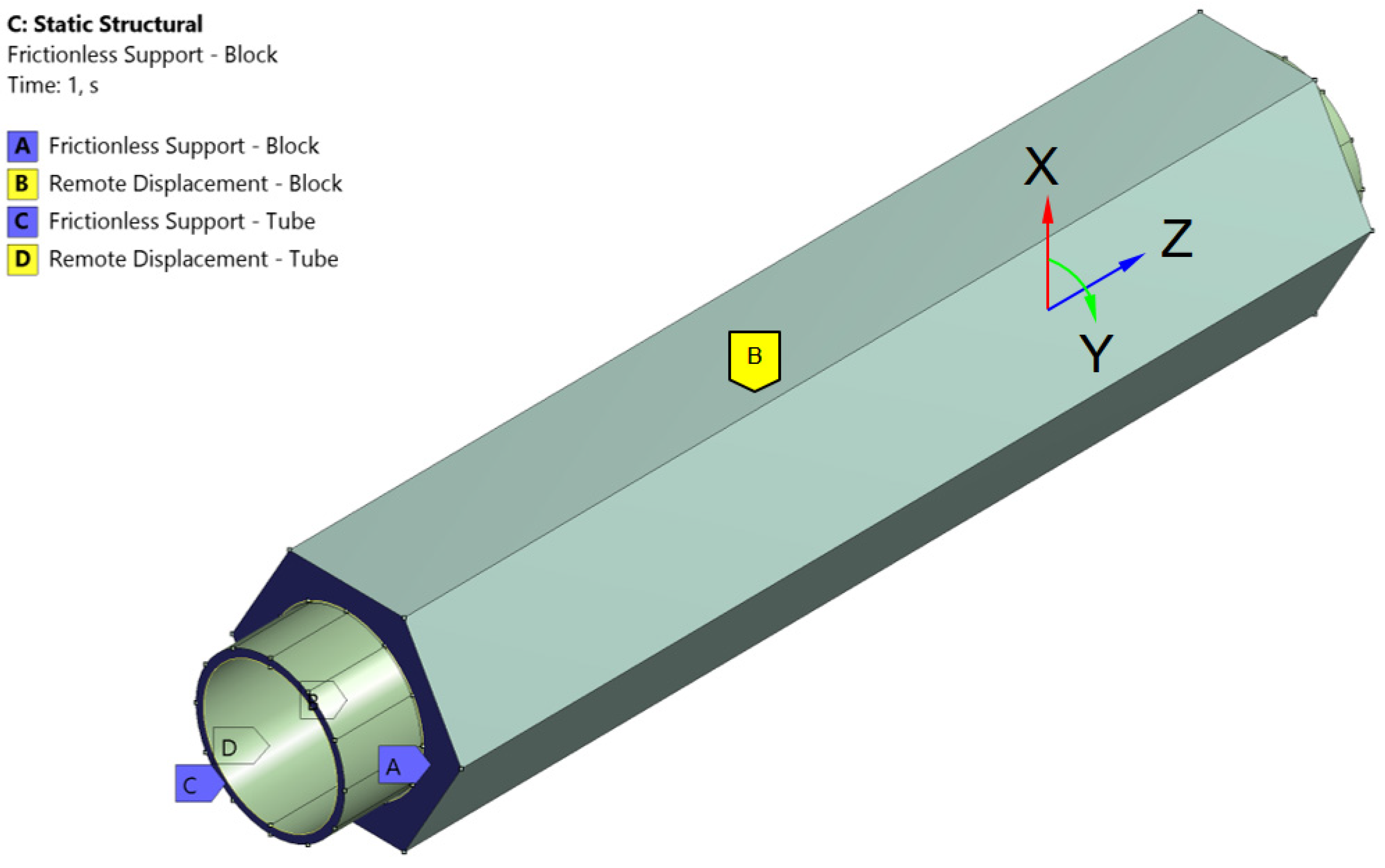

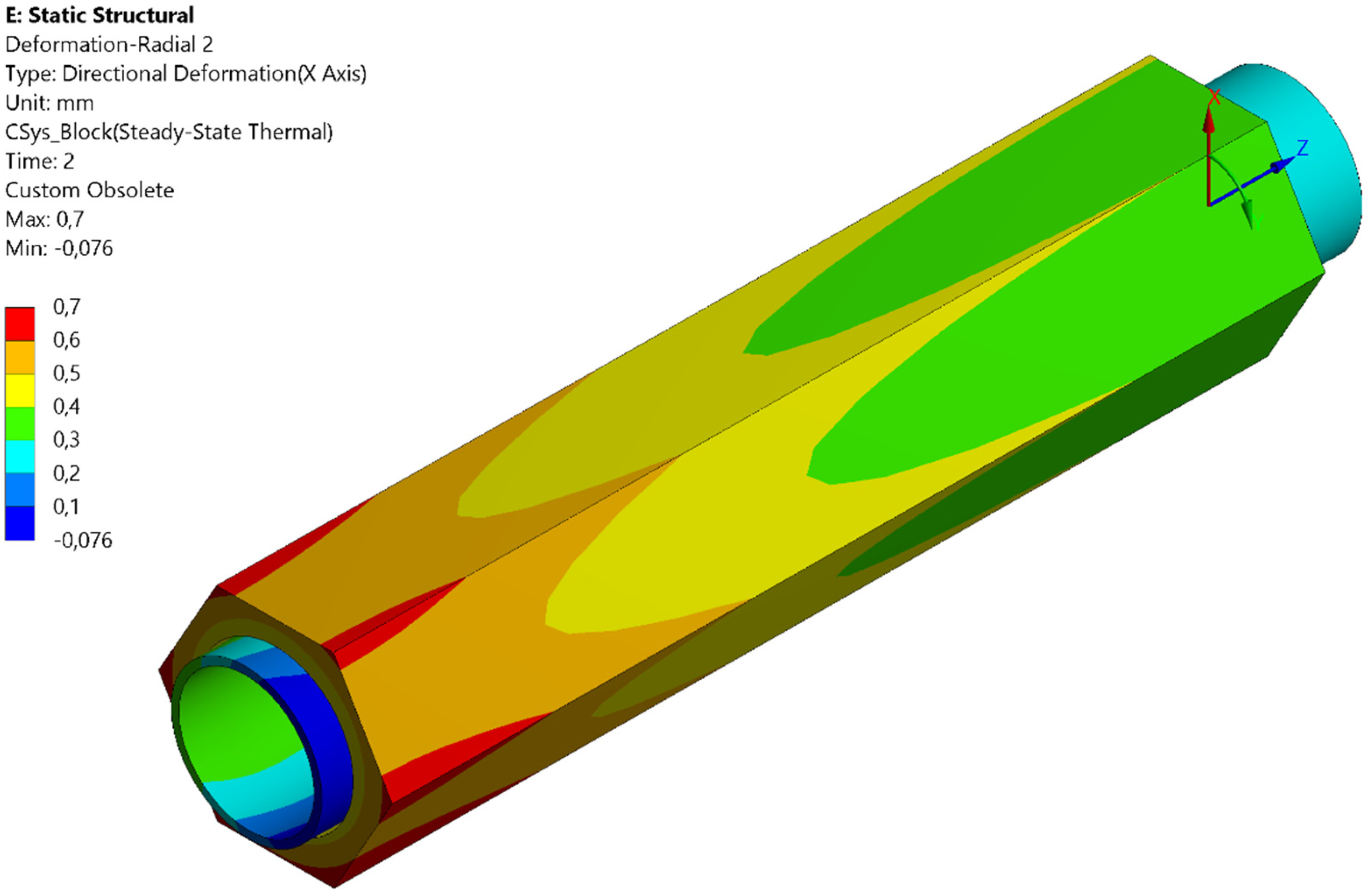

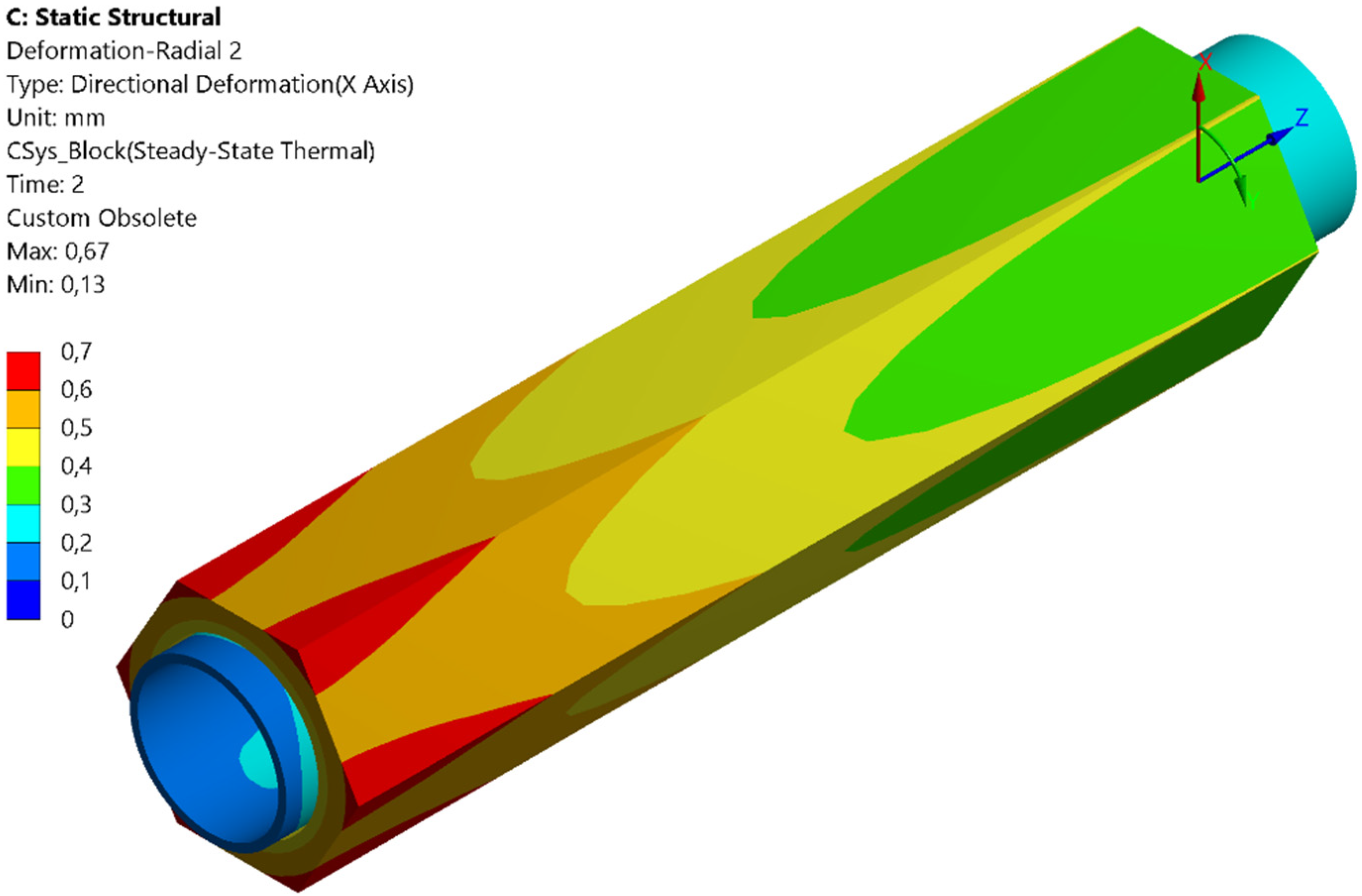

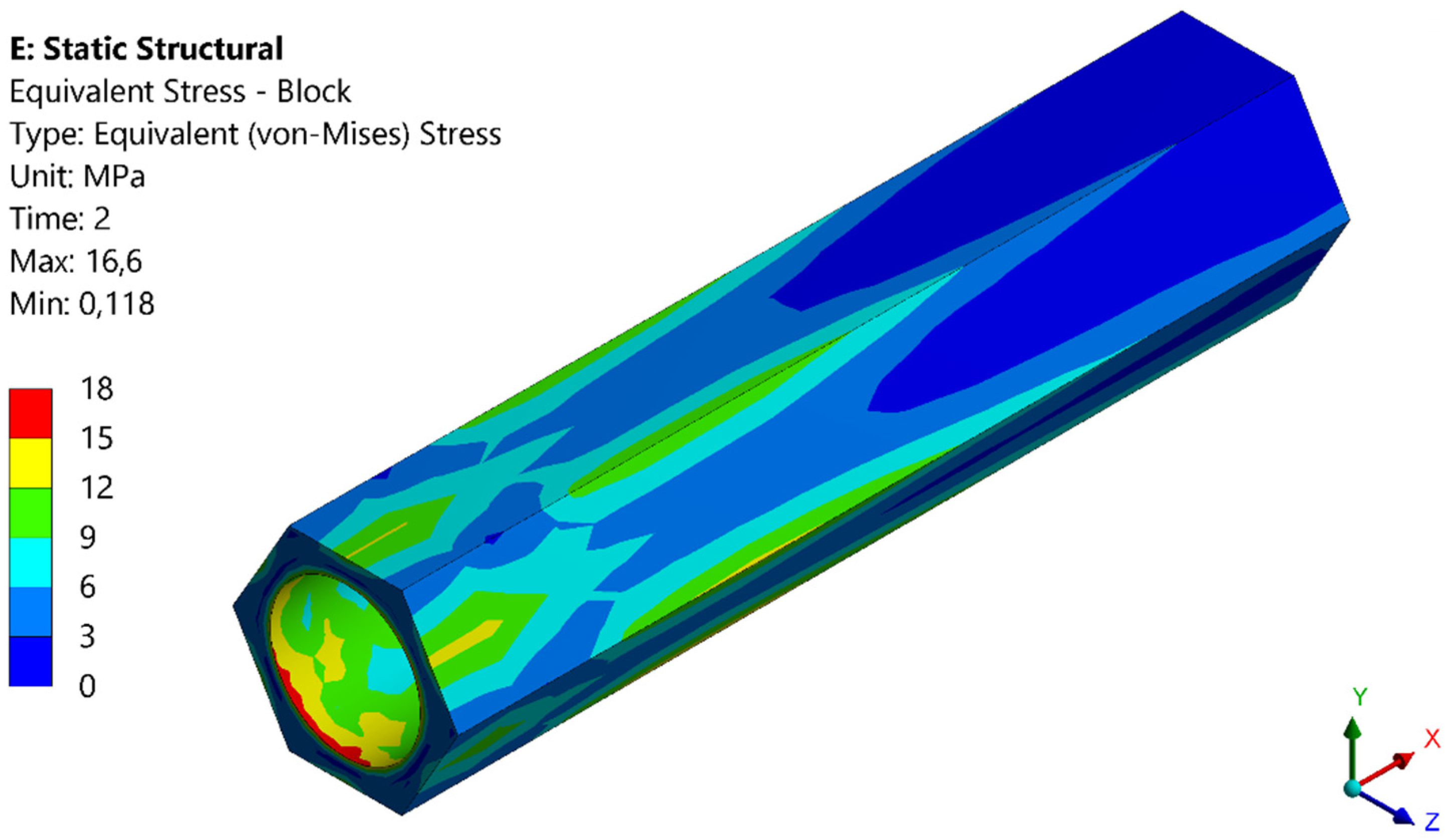

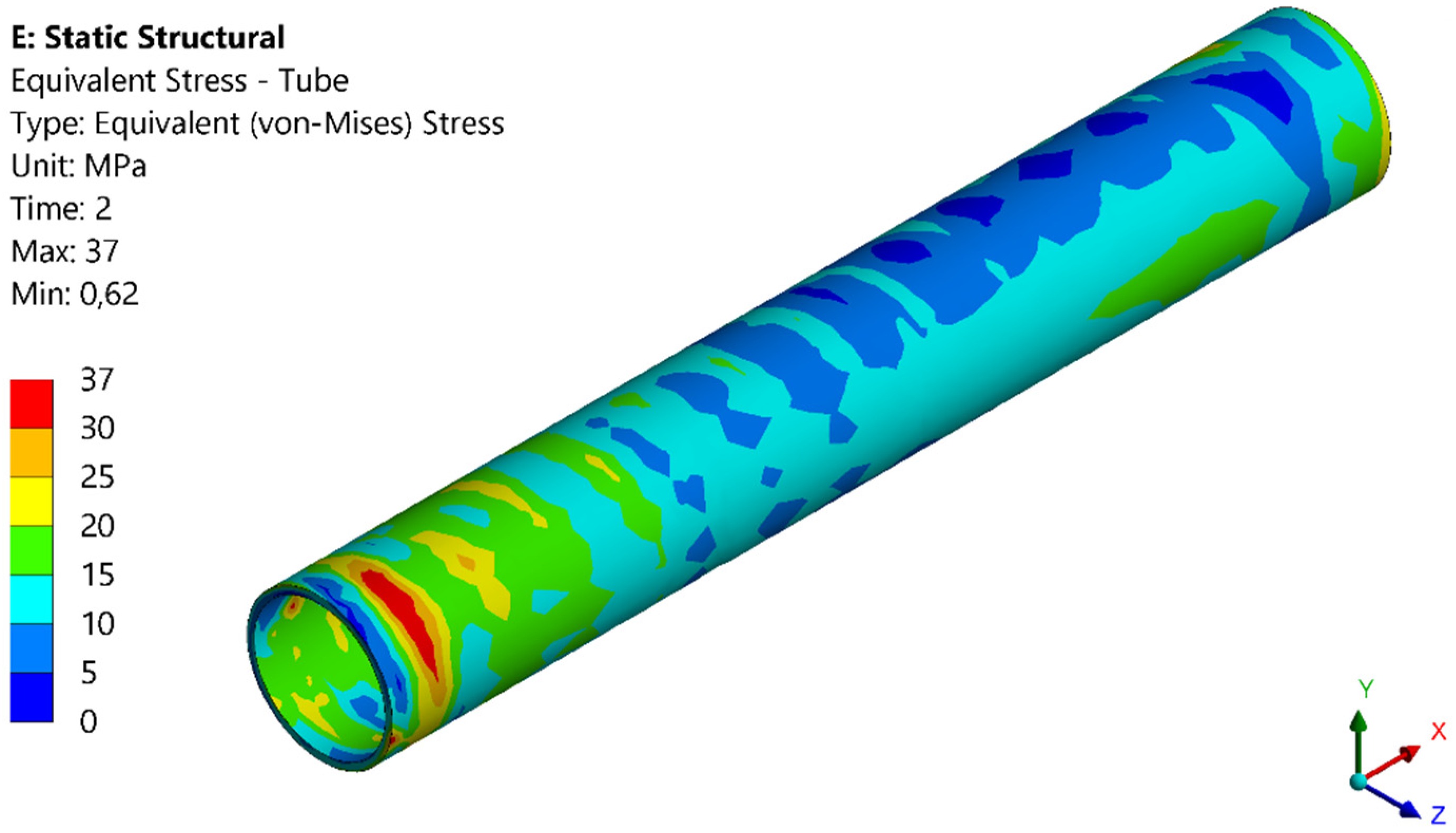

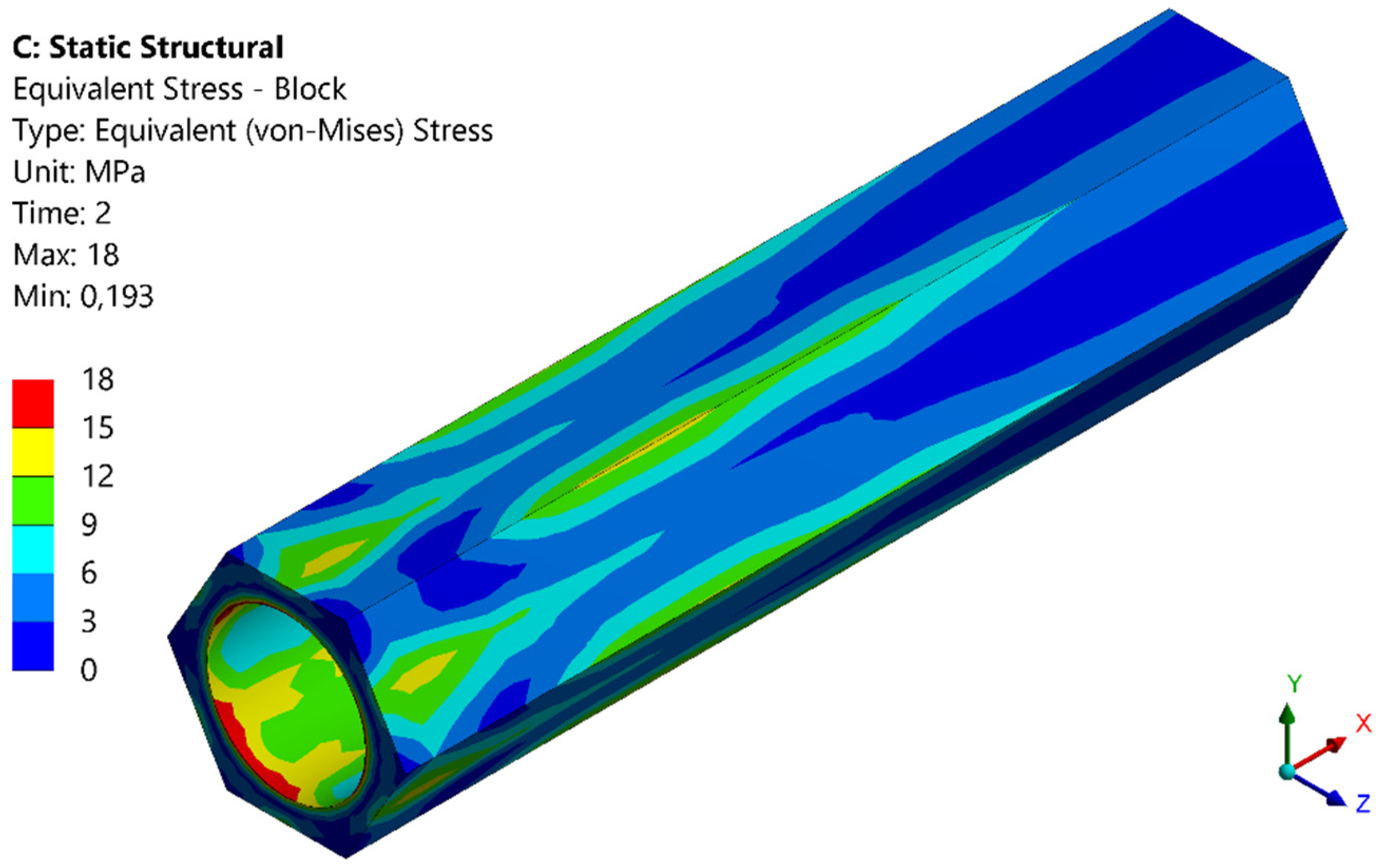

3.3.4. First thermal mechanical analyses of a single beryllide block

3.4. Tritium transport analysis

4. Alternative breeding blanket concepts

4.1. CO2 Cooled Pebble Bed (CCPB) concept

| Coolant | Density | Cp | Dynamic viscosity | Thermal conductivity |

|---|---|---|---|---|

| kg/m3 | J/kg*K | Pa*s | W/m*K | |

| He | 5.6376 | 5188.7 | 3.50E-05 | 0.27759 |

| CO2 | 63.09 | 1159.6 | 3.15E-05 | 0.049073 |

4.2. Helium cooled Molten Lead Ceramic Breeder (MLCB) concept

4.3. Water cooled Lead Ceramic Breeder (WLCB) concept

5. Summary and outlook

- C1.

- Low reliability of BB system under DEMO conditions due to welds failure

- C2.

- Loss of structural integrity of beryllide blocks

- C3.

- High pressure drops in coolant loop contributing to total high pumping power

- C4.

- Large tritium permeation rates at the interface of breeder-coolant loop

- C5.

- Low BB shielding capability

- C6.

- High EM loads due to disruption events

- C7.

- Degradation of Eurofer97 at contact with pebbles in purge gas environment

- S1.

- Equalize purge gas and coolant to eliminate in-box LOCA welds, hence improving reliability

- S2.

- New shaping of block to reduce cracking of beryllide

- S3.

- Increase temperature difference between outlet and inlet, hence reducing flow velocity & pressure drop

- S4.

- Different purge gas schemes (add steam to purge gas and counter-permeation) to reduce permeation

- S5.

- Explore more efficient shielding materials

- S6.

- Insulate the connection between BB and VV

- S7.

- Make the pebble container have no structural function

- T1.

- Demonstrate high heat flux capability with augmented structure

- T2.

- Increase the scalability of beryllide block fabrication to DEMO scale

- T3.

- Demonstrate reaction of beryllide with water at high temperature is not critical

- T4.

- Select suitable supplier or different fabrication route to have low U impurity to eliminate the activation issue

- T5.

- Demonstrate industrial production of the KALOS ceramic breeder pebble

- T6.

- Demonstrate feasibility of manufacturing a full blanket segment at DEMO scale

- T7.

- Reduce tritium permeation by trying different purge gas schemes and demonstrate the selected scheme causes no additional issue

- T8.

- Develop & validate advanced tritium transport tools to increase confidence on tritium transport modelling

- T9.

- Develop reliable tools of pebble bed and validate tools with experiments

- T10.

- Develop suitable Li-6 enrichment process to ensure lower costs

- T11.

- Demonstrate feasibility of recycling functional materials

- T12.

- Irradiate the structural and function materials, conduct post-irradiation examination, to evaluate characteristics & properties to understand their irradiation behaviours

- T13.

- Establish a reproducible route of coating the FW with tungsten on large components

- T14.

- Age Eurofer97 in controlled environment at DEMO conditions and understand the degradation level of Eurofer97

- T15.

- Test the components of HCPB BB at prototypical scale to increase the maturity level of HCPB BB

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Donné, A.J.H. The European Roadmap towards Fusion Electricity. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences 2019, 377, 20170432. [Google Scholar] [CrossRef] [PubMed]

- Federici, G.; Bachmann, C.; Barucca, L.; Baylard, C.; Biel, W.; Boccaccini, L.V.; Bustreo, C.; Ciattaglia, S.; Cismondi, F.; Corato, V.; et al. Overview of the DEMO Staged Design Approach in Europe. Nucl. Fusion 2019, 59, 066013. [Google Scholar] [CrossRef]

- EUROfusion official website: https://www.euro-fusion.

- Federici, G.; Baylard, C.; Beaumont, A.; Holden, J. The Plan Forward for EU DEMO. Fusion Engineering and Design 2021, 173, 112960. [Google Scholar] [CrossRef]

- Hernández, F.A.; Pereslavtsev, P.; Zhou, G.; Kang, Q.; D’Amico, S.; Neuberger, H.; Boccaccini, L.V.; Kiss, B.; Nádasi, G.; Maqueda, L.; et al. Consolidated Design of the HCPB Breeding Blanket for the Pre-Conceptual Design Phase of the EU DEMO and Harmonization with the ITER HCPB TBM Program. Fusion Engineering and Design 2020, 157, 111614. [Google Scholar] [CrossRef]

- Arena, P.; Del Nevo, A.; Moro, F.; Noce, S.; Mozzillo, R.; Imbriani, V.; Giannetti, F.; Edemetti, F.; Froio, A.; Savoldi, L.; et al. The DEMO Water-Cooled Lead–Lithium Breeding Blanket: Design Status at the End of the Pre-Conceptual Design Phase. Applied Sciences 2021, 11, 11592. [Google Scholar] [CrossRef]

- Federici, G.; Boccaccini, L.; Cismondi, F.; Gasparotto, M.; Poitevin, Y.; Ricapito, I. An Overview of the EU Breeding Blanket Design Strategy as an Integral Part of the DEMO Design Effort. Fusion Engineering and Design 2019, 141, 30–42. [Google Scholar] [CrossRef]

- Dalle Donne, M.; et al. Conceptual design of two helium cooled fusion blankets (ceramic and liquid breeder) for INTOR. KfK-3584. 1983 Kernforschungszentrum Karlsruhe.

- Dalle Donne, M.; Anzidei, L.; Kwast, H.; Moons, F.; Proust, E. Status of EC Solid Breeder-Blanket Designs and R&D for DEMO Fusion Reactors. Fusion Engineering and Design 1995, 27, 319–336. [Google Scholar] [CrossRef]

- Boccaccini, L.V.; Bekris, N.; Chen, Y.; Fischer, U.; Gordeev, S.; Hermsmeyer, S.; Hutter, E.; Kleefeldt, K.; Malang, S.; Schleisiek, K.; et al. Design Description and Performance Analyses of the European HCPB Test Blanket System in ITER Feat. Fusion Engineering and Design 2002, 61–62, 339–344. [Google Scholar] [CrossRef]

- Carloni, D.; Kang, Q.; Bitz, O.; Hernandez, F.; Zeile, C.; Maione, I.A.; Norajitra, P.; Boccaccini, L.V. Advancement in HCPB DEMO Blanket Design. 28th Symposium on Fusion Technology (SOFT 2014); San Sebastian, Spain, 2014.

- Hernández, F.A.; Arbeiter, F.; Boccaccini, L.V.; Bubelis, E.; Chakin, V.P.; Cristescu, I.; Ghidersa, B.E.; González, M.; Hering, W.; Hernández, T.; et al. Overview of the HCPB Research Activities in EUROfusion. IEEE Transactions on Plasma Science 2018, 46, 2247–2261. [Google Scholar] [CrossRef]

- Hernández, F.; Pereslavtsev, P.; Kang, Q.; Norajitra, P.; Kiss, B.; Nádasi, G.; Bitz, O. A New HCPB Breeding Blanket for the EU DEMO: Evolution, Rationale and Preliminary Performances. Fusion Engineering and Design 2017, 124, 882–886. [Google Scholar] [CrossRef]

- Zhou, G.; Hernández, F.; Boccaccini, L.V.; Chen, H.; Ye, M. Preliminary Structural Analysis of the New HCPB Blanket for EU DEMO Reactor. International Journal of Hydrogen Energy 2016, 41, 7053–7058. [Google Scholar] [CrossRef]

- Zhou, G.; Hernández, F.; Boccaccini, L.V.; Chen, H.; Ye, M. Design Study on the New EU DEMO HCPB Breeding Blanket: Thermal Analysis. Progress in Nuclear Energy 2017, 98, 167–176. [Google Scholar] [CrossRef]

- Hernández, F.A.; Pereslavtsev, P.; Zhou, G.; Kiss, B.; Kang, Q.; Neuberger, H.; Chakin, V.; Gaisin, R.; Vladimirov, P.; Boccaccini, L.V.; et al. Advancements in the Helium-Cooled Pebble Bed Breeding Blanket for the EU DEMO: Holistic Design Approach and Lessons Learned. Fusion Science and Technology 2019, 75, 352–364. [Google Scholar] [CrossRef]

- Boccaccini, L.V.; Aiello, A.; Bede, O.; Cismondi, F.; Kosek, L.; Ilkei, T.; Salavy, J.-F.; Sardain, P.; Sedano, L. Present Status of the Conceptual Design of the EU Test Blanket Systems. Fusion Engineering and Design 2011, 86, 478–483. [Google Scholar] [CrossRef]

- Zhou, G.; Hernández, F.A.; Zeile, C.; Maione, I.A. Transient Thermal Analysis and Structural Assessment of an Ex-Vessel LOCA Event on the EU DEMO HCPB Breeding Blanket and the Attachment System. Fusion Engineering and Design 2018, 136, 34–41. [Google Scholar] [CrossRef]

- Federici, G.; Bachmann, C.; Barucca, L.; Biel, W.; Boccaccini, L.; Brown, R.; Bustreo, C.; Ciattaglia, S.; Cismondi, F.; Coleman, M.; et al. DEMO Design Activity in Europe: Progress and Updates. Fusion Engineering and Design 2018, 136, 729–741. [Google Scholar] [CrossRef]

- Knitter, R.; Chaudhuri, P.; Feng, Y.J.; Hoshino, T.; Yu, I.-K. Recent Developments of Solid Breeder Fabrication. Journal of Nuclear Materials 2013, 442, S420–S424. [Google Scholar] [CrossRef]

- Vladimirov, P.V.; Chakin, V.P.; Dürrschnabel, M.; Gaisin, R.; Goraieb, A.; Gonzalez, F.A.H.; Klimenkov, M.; Rieth, M.; Rolli, R.; Zimber, N.; et al. Development and Characterization of Advanced Neutron Multiplier Materials. Journal of Nuclear Materials 2021, 543, 152593. [Google Scholar] [CrossRef]

- Zhou, G.; Ghidersa, B.-E.; Hernández, F.A.; Kang, Q.; Neuberger, H. Design of Two Experimental Mock-Ups as Proof-of-Concept and Validation Test Rigs for the Enhanced EU DEMO HCPB Blanket. Fusion Science and Technology 2019, 75, 1016–1023. [Google Scholar] [CrossRef]

- Mitteau, R.; Stangeby, P.; Lowry, C.; Firdaouss, M.; Labidi, H.; Loarte, A.; Merola, M.; Pitts, R.; Raffray, R. A Shaped First Wall for ITER. Journal of Nuclear Materials 2011, 415, S969–S972. [Google Scholar] [CrossRef]

- Bachmann, C.; Ciattaglia, S.; Cismondi, F.; Eade, T.; Federici, G.; Fischer, U.; Franke, T.; Gliss, C.; Hernandez, F.; Keep, J.; et al. Overview over DEMO Design Integration Challenges and Their Impact on Component Design Concepts. Fusion Engineering and Design 2018, 136, 87–95. [Google Scholar] [CrossRef]

- Zhou, G.; Kang, Q.; Hernández, F.A.; D’Amico, S.; Kiss, B. Thermal Hydraulics Activities for Consolidating HCPB Breeding Blanket of the European DEMO. Nucl. Fusion 2020, 60, 096008. [Google Scholar] [CrossRef]

- CANDU 6 Program Team, CANDU® 6 Technical Summary, 2005.

- Smoluchowski, M. Über den Temperatursprung bei Wärmeleitung in Gasen. Pisma Mariana Smoluchowskiego 1924, 1, 113–138. [Google Scholar]

- Pupeschi, S.; Knitter, R.; Kamlah, M. Effective Thermal Conductivity of Advanced Ceramic Breeder Pebble Beds. Fusion Engineering and Design 2017, 116, 73–80. [Google Scholar] [CrossRef]

- Cristescu, I.; Draghia, M. Developments on the Tritium Extraction and Recovery System for HCPB. Fusion Engineering and Design 2020, 158, 111558. [Google Scholar] [CrossRef]

- Brown, F.; et al. 2010 MCNP5-1.60 Release Notes. LA-UR-10-06235. Los Alamos National Laboratory.

- Plompen, A.J.M.; Cabellos, O.; De Saint Jean, C.; Fleming, M.; Algora, A.; Angelone, M.; Archier, P.; Bauge, E.; Bersillon, O.; Blokhin, A.; et al. The Joint Evaluated Fission and Fusion Nuclear Data Library, JEFF-3.3. Eur. Phys. J. A 2020, 56, 181. [Google Scholar] [CrossRef]

- Tsige-Tamirat, H.; Fischer, U. CAD interface for Monte Carlo particle transport codes. The Conference of the Monte Carlo method: versatility unbounded in a dynamic computing world, Chattanooga, Tennessee, April 17–21, 2005 American Nuclear Society. 17 April.

- Lu, L.; et al. Improved solid decomposition algorithms for the CAD-to-MC conversion tool McCad. Fusion Eng. Des. 2017, 124, 1269–1272. [Google Scholar] [CrossRef]

- Pereslavtsev, P.; et al. Nuclear analyses of solid breeder blanket options for DEMO: status, challenges and outlook. Fusion Eng. Des. 2019, 146, 563–567. [Google Scholar] [CrossRef]

- Pereslavtsev, P.; Cismondi, F.; Hernández, F.A. Analyses of the Shielding Options for HCPB DEMO Blanket. Fusion Engineering and Design 2020, 156, 111605. [Google Scholar] [CrossRef]

- Guirao, J.; Walsh, M.J.; Udintsev, V.S.; Iglesias, S.; Giacomin, T.; Bertalot, L.; Shigin, P.; Kochergin, M.; Alexandrov, E.; Zvonkov, A.; et al. Standardized Integration of ITER Diagnostics Equatorial Port Plugs. Fusion Engineering and Design 2019, 146, 1548–1552. [Google Scholar] [CrossRef]

- Park, J.H.; Pereslavtsev, P. Comparative Activation Analyses for the HCPB Breeding Blanket in DEMO. Fusion Engineering and Design 2021, 167, 112338. [Google Scholar] [CrossRef]

- D’Amico, S.; Di Maio, P.A.; Jin, X.Z.; Hernández Gonzalez, F.A.; Moscato, I.; Zhou, G. Preliminary Thermal-Hydraulic Analysis of the EU-DEMO Helium-Cooled Pebble Bed Fusion Reactor by Using the RELAP5-3D System Code. Fusion Engineering and Design 2021, 162, 112111. [Google Scholar] [CrossRef]

- Ghidersa, B.-E.; Gonfiotti, B.; Kunze, A.; Di Marcello, V.; Ionescu-Bujor, M.; Jin, X.Z.; Stieglitz, R. Experimental Investigation of a Helium-Cooled Breeding Blanket First Wall under LOFA Conditions and Pre-Test and Post-Test Numerical Analysis. Applied Sciences 2021, 11, 12010. [Google Scholar] [CrossRef]

- Di Marcello, V.; Ghidersa, B.-E.; Jin, X.Z.; Abou-Sena, A.; Stieglitz, R. Development and Validation of the Blanket First Wall Mock-up Model in RELAP5-3D. Fusion Engineering and Design 2018, 136, 1534–1539. [Google Scholar] [CrossRef]

- Angelucci, M.; Gonfiotti, B.; Ghidersa, B.-E.; Jin, X.Z.; Ionescu-Bujor, M.; Paci, S.; Stieglitz, R. Post-Test Numerical Analysis of a Helium-Cooled Breeding Blanket First Wall under LOFA Conditions with the MELCOR Fusion Code. Applied Sciences 2022, 12, 187. [Google Scholar] [CrossRef]

- Zhou, G.; Rey, J.; Hernández, F.A.; Abou-Sena, A.; Lux, M.; Arbeiter, F.; Schlindwein, G.; Schwab, F. Engineering Design of the European DEMO HCPB Breeding Blanket Breeder Zone Mockup. Applied Sciences 2023, 13, 2081. [Google Scholar] [CrossRef]

- Abou-Sena, A.; Ghidersa, B.-E.; Zhou, G.; Rey, J.; Hernández, F.A.; Lux, M.; Schlindwein, G. Experimental Thermal–Hydraulic Testing of a Mock-Up of the Fuel-Breeder Pin Concept for the EU-DEMO HCPB Breeding Blanket. Journal of Nuclear Engineering 2023, 4, 11–27. [Google Scholar] [CrossRef]

- RCC-MRx: Design and Construction Rules for mechanical components of nuclear installations. Addenda included: n° 1 (2013).

- Aiello, G.; Aktaa, J.; Cismondi, F.; Rampal, G.; Salavy, J.F.; Tavassoli, F. Assessment of Design Limits and Criteria Requirements for Eurofer Structures in TBM Components. Journal of Nuclear Materials 2011, 414, 53–68. [Google Scholar] [CrossRef]

- Retheesh, A.; Hernández, F.A.; Zhou, G. Application of Inelastic Method and Its Comparison with Elastic Method for the Assessment of In-Box LOCA Event on EU DEMO HCPB Breeding Blanket Cap Region. Applied Sciences 2021, 11, 9104. [Google Scholar] [CrossRef]

- Maione, I.A.; Roccella, M.; Hernández, F.A.; Lucca, F. Update of Electromagnetic Loads on HCPB Breeding Blanked for DEMO 2017 Configuration. Fusion Engineering and Design 2020, 156, 111604. [Google Scholar] [CrossRef]

- Carella, E.; Moreno, C.; Urgorri, F.R.; Rapisarda, D.; Ibarra, A. Tritium Modelling in HCPB Breeder Blanket at a System Level. Fusion Engineering and Design 2017, 124, 687–691. [Google Scholar] [CrossRef]

- Franza, F.; Boccaccini, L.V.; Ciampichetti, A.; Zucchetti, M. Tritium Transport Analysis in HCPB DEMO Blanket with the FUS-TPC Code. Fusion Engineering and Design 2013, 88, 2444–2447. [Google Scholar] [CrossRef]

- Pasler, V.; Arbeiter, F.; Klein, C.; Klimenko, D.; Schlindwein, G.; von der Weth, A. Development of a Component-Level Hydrogen Transport Model with OpenFOAM and Application to Tritium Transport Inside a DEMO HCPB Breeder. Applied Sciences 2021, 11, 3481. [Google Scholar] [CrossRef]

- Carella, E.; Moreno, C.; Urgorri, F.R.; Demange, D.; Castellanos, J.; Rapisarda, D. Tritium Behavior in HCPB Breeder Blanket Unit: Modeling and Experiments. Fusion Science and Technology 2017, 71, 357–362. [Google Scholar] [CrossRef]

- Klimenko, D.; Arbeiter, F.; Pasler, V.; Schlindwein, G.; von der Weth, A.; Zinn, K. Definition of the Q-PETE Experiment for Investigation of Hydrogen Isotopes Permeation through the Metal Structures of a DEMO HCPB Breeder Zone. Fusion Engineering and Design 2018, 136, 563–568. [Google Scholar] [CrossRef]

- Wang, S.; Hernández, F.A.; Bubelis, E.; Chen, H. Comparative Analysis of the Efficiency of a CO2-Cooled and a He-Cooled Pebble Bed Breeding Blanket for the EU DEMO Fusion Reactor. Fusion Engineering and Design 2019, 138, 32–40. [Google Scholar] [CrossRef]

- Wang, S.; Hernández, F.A.; Zhou, G.; Chen, H. First Thermal-Hydraulic Analysis of a CO2 Cooled Pebble Bed Blanket for the EU DEMO. Fusion Engineering and Design 2019, 146, 2218–2221. [Google Scholar] [CrossRef]

- Wang, S.; Hernández, F.A.; Chen, H.; Zhou, G. Thermal-Hydraulic Analysis of the First Wall of a CO2 Cooled Pebble Bed Breeding Blanket for the EU-DEMO. Fusion Engineering and Design 2019, 138, 379–394. [Google Scholar] [CrossRef]

- Hernández, F.A.; Pereslavtsev, P. First Principles Review of Options for Tritium Breeder and Neutron Multiplier Materials for Breeding Blankets in Fusion Reactors. Fusion Engineering and Design 2018, 137, 243–256. [Google Scholar] [CrossRef]

- Zhou, G.; Hernández, F.A.; Kang, Q.; Pereslavtsev, P. Progress on the Helium Cooled Molten Lead Ceramic Breeder Concept, as a near-Term Alternative Blanket for EU DEMO. Fusion Engineering and Design 2019. [Google Scholar] [CrossRef]

- Zhou, G.; Lu, Y.; Hernández, F.A. A Water Cooled Lead Ceramic Breeder Blanket for European DEMO. Fusion Engineering and Design 2021, 168, 112397. [Google Scholar] [CrossRef]

- Lu, Y.; Ye, M.; Zhou, G.; Hernández, F.A.; Leppänen, J.; Hu, Y. Exploratory Tritium Breeding Performance Study on a Water Cooled Lead Ceramic Breeder Blanket for EU DEMO Using Serpent-2. Nuclear Materials and Energy 2021, 28, 101050. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).