Submitted:

24 April 2023

Posted:

24 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgements

References

- Puttaswamy, K.; Loh, G.H. Thermal Analysis of a 3D Die-Stacked High-Performance Microprocessor. In Proceedings of the Proceedings of the 16th ACM Great Lakes symposium on VLSI; 2006; pp. 19–24.

- Nada, S.; Alshaer, W. Comprehensive Parametric Study of Using Carbon Foam Structures Saturated with PCMs in Thermal Management of Electronic Systems. Energy Convers. Manag. 2015, 105, 93–102. [CrossRef]

- Mathew, J.; Krishnan, S. A Review on Transient Thermal Management of Electronic Devices. J. Electron. Packag. 2022, 144. [CrossRef]

- Brooks, D.; Martonosi, M. Dynamic Thermal Management for High-Performance Microprocessors. In Proceedings of the Proceedings HPCA Seventh International Symposium on High-Performance Computer Architecture; IEEE, 2001; pp. 171–182.

- Haywood, A.M.; Sherbeck, J.; Phelan, P.; Varsamopoulos, G.; Gupta, S.K. The Relationship among CPU Utilization, Temperature, and Thermal Power for Waste Heat Utilization. Energy Convers. Manag. 2015, 95, 297–303. [CrossRef]

- Su, Y.; Zhang, M.; Chitrakar, B.; Zhang, W. Effects of Low-Frequency Ultrasonic Pre-Treatment in Water/Oil Medium Simulated System on the Improved Processing Efficiency and Quality of Microwave-Assisted Vacuum Fried Potato Chips. Ultrason. Sonochem. 2020, 63, 104958. [CrossRef]

- Moscoso, W.; Olgun, E.; Compton, W.D.; Chandrasekar, S. Effect of Low-Frequency Modulation on Lubrication of Chip-Tool Interface in Machining. J Trib 2005, 127, 238–244. [CrossRef]

- Cebrián, J.M.; Natvig, L.; Meyer, J.C. Performance and Energy Impact of Parallelization and Vectorization Techniques in Modern Microprocessors. Computing 2014, 96, 1179–1193. [CrossRef]

- Bowman, K.A.; Alameldeen, A.R.; Srinivasan, S.T.; Wilkerson, C.B. Impact of Die-to-Die and within-Die Parameter Variations on the Clock Frequency and Throughput of Multi-Core Processors. IEEE Trans. Very Large Scale Integr. VLSI Syst. 2009, 17, 1679–1690. [CrossRef]

- Le Sueur, E.; Heiser, G. Dynamic Voltage and Frequency Scaling: The Laws of Diminishing Returns. In Proceedings of the Proceedings of the 2010 international conference on Power aware computing and systems; 2010; pp. 1–8.

- Suszko, A.; El-Genk, M.S. Thermally Anisotropic Composite Heat Spreaders for Enhanced Thermal Management of High-Performance Microprocessors. Int. J. Therm. Sci. 2016, 100, 213–228. [CrossRef]

- Kong, J.; Chung, S.W.; Skadron, K. Recent Thermal Management Techniques for Microprocessors. ACM Comput. Surv. CSUR 2012, 44, 1–42. [CrossRef]

- Li, Y.; Gong, L.; Ding, B.; Xu, M.; Joshi, Y. Thermal Management of Power Electronics with Liquid Cooled Metal Foam Heat Sink. Int. J. Therm. Sci. 2021, 163, 106796. [CrossRef]

- Laloya, E.; Lucia, O.; Sarnago, H.; Burdio, J.M. Heat Management in Power Converters: From State of the Art to Future Ultrahigh Efficiency Systems. IEEE Trans. Power Electron. 2015, 31, 7896–7908. [CrossRef]

- Shatikian, V.; Ziskind, G.; Letan, R. Numerical Investigation of a PCM-Based Heat Sink with Internal Fins. Int. J. Heat Mass Transf. 2005, 48, 3689–3706. [CrossRef]

- Lee, Y.J.; Singh, P.K.; Lee, P.S. Fluid Flow and Heat Transfer Investigations on Enhanced Microchannel Heat Sink Using Oblique Fins with Parametric Study. Int. J. Heat Mass Transf. 2015, 81, 325–336. [CrossRef]

- Qi, Z. Advances on Air Conditioning and Heat Pump System in Electric Vehicles–A Review. Renew. Sustain. Energy Rev. 2014, 38, 754–764. [CrossRef]

- Jin, X.; Ma, E.W.; Cheng, L.L.; Pecht, M. Health Monitoring of Cooling Fans Based on Mahalanobis Distance with MRMR Feature Selection. IEEE Trans. Instrum. Meas. 2012, 61, 2222–2229. [CrossRef]

- Leroy, A.; Bhatia, B.; Kelsall, C.C.; Castillejo-Cuberos, A.; Di Capua H, M.; Zhao, L.; Zhang, L.; Guzman, A.; Wang, E. High-Performance Subambient Radiative Cooling Enabled by Optically Selective and Thermally Insulating Polyethylene Aerogel. Sci. Adv. 2019, 5, eaat9480. [CrossRef]

- Xiang, X.; Yang, J.; Fan, A.; Liu, W. A Comparison between Cooling Performances of Water-Based and Gallium-Based Micro-Channel Heat Sinks with the Same Dimensions. Appl. Therm. Eng. 2018, 137, 1–10. [CrossRef]

- Khan, Y.; Sarowar, M.T.; Mobarrat, M.; Rahman, M.H. Performance Comparison of a Microchannel Heat Sink Using Different Nano-Liquid Metal Fluid Coolant: A Numerical Study. J. Therm. Sci. Eng. Appl. 2022, 14, 091014. [CrossRef]

- Muhammad, A.; Selvakumar, D.; Iranzo, A.; Sultan, Q.; Wu, J. Comparison of Pressure Drop and Heat Transfer Performance for Liquid Metal Cooled Mini-Channel with Different Coolants and Heat Sink Materials. J. Therm. Anal. Calorim. 2020, 141, 289–300. [CrossRef]

- Li, M.; Wei, J.; Tao, W. Numerical Simulation of Dropwise Condensation on Rough Structures in the Presence of Non-Condensable Gas Using LBM. Numer. Heat Transf. Part Appl. 2021, 79, 450–462. [CrossRef]

- Sivasamy, P.; Devaraju, A.; Harikrishnan, S. Review on Heat Transfer Enhancement of Phase Change Materials (PCMs). Mater. Today Proc. 2018, 5, 14423–14431. [CrossRef]

- Yang, L.; Jin, X.; Zhang, Y.; Du, K. Recent Development on Heat Transfer and Various Applications of Phase-Change Materials. J. Clean. Prod. 2021, 287, 124432. [CrossRef]

- Wu, Y.; Zhang, X.; Xu, X.; Lin, X.; Liu, L. A Review on the Effect of External Fields on Solidification, Melting and Heat Transfer Enhancement of Phase Change Materials. J. Energy Storage 2020, 31, 101567. [CrossRef]

- Wang, X.; Luo, L.; Xiang, J.; Zheng, S.; Shittu, S.; Wang, Z.; Zhao, X. A Comprehensive Review on the Application of Nanofluid in Heat Pipe Based on the Machine Learning: Theory, Application and Prediction. Renew. Sustain. Energy Rev. 2021, 150, 111434. [CrossRef]

- Tang, H.; Tang, Y.; Wan, Z.; Li, J.; Yuan, W.; Lu, L.; Li, Y.; Tang, K. Review of Applications and Developments of Ultra-Thin Micro Heat Pipes for Electronic Cooling. Appl. Energy 2018, 223, 383–400. [CrossRef]

- Zhu, L.; Tan, H.; Yu, J. Analysis on Optimal Heat Exchanger Size of Thermoelectric Cooler for Electronic Cooling Applications. Energy Convers. Manag. 2013, 76, 685–690. [CrossRef]

- Byon, C. Heat Pipe and Phase Change Heat Transfer Technologies for Electronics Cooling. Electron. Cool. 2016. [CrossRef]

- Abdelkareem, M.A.; Maghrabie, H.M.; Sayed, E.T.; Kais, E.-C.A.; Abo-Khalil, A.G.; Al Radi, M.; Baroutaji, A.; Olabi, A. Heat Pipe-Based Waste Heat Recovery Systems: Background and Applications. Therm. Sci. Eng. Prog. 2022, 101221. [CrossRef]

- Baby, R.; Balaji, C. Thermal Management of Electronics Using Phase Change Material Based Pin Fin Heat Sinks. In Proceedings of the Journal of Physics: Conference Series; IOP Publishing, 2012; Vol. 395, p. 012134. [CrossRef]

- Goharshadi, E.; Ahmadzadeh, H.; Samiee, S.; Hadadian, M. Nanofluids for Heat Transfer Enhancement-a Review. 2013. [CrossRef]

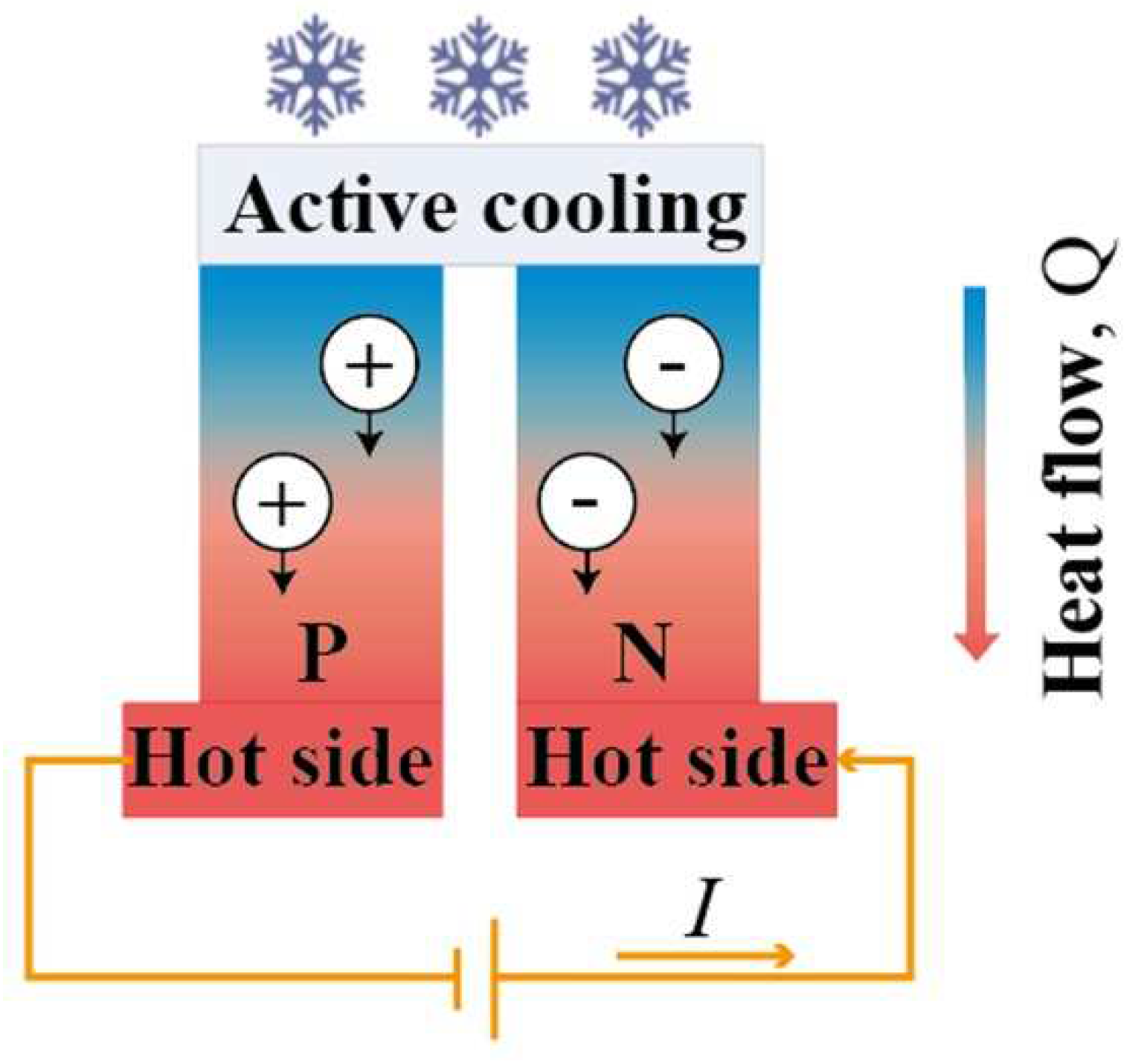

- Zhao, D.; Tan, G. A Review of Thermoelectric Cooling: Materials, Modeling and Applications. Appl. Therm. Eng. 2014, 66, 15–24. [CrossRef]

- Enescu, D.; Virjoghe, E.O. A Review on Thermoelectric Cooling Parameters and Performance. Renew. Sustain. Energy Rev. 2014, 38, 903–916. [CrossRef]

- Chen, W.; Shi, X.; Zou, J.; Chen, Z. Thermoelectric Coolers: Progress, Challenges, and Opportunities. Small Methods 2022, 6, 2101235. [CrossRef]

- Pourkiaei, S.M.; Ahmadi, M.H.; Sadeghzadeh, M.; Moosavi, S.; Pourfayaz, F.; Chen, L.; Yazdi, M.A.P.; Kumar, R. Thermoelectric Cooler and Thermoelectric Generator Devices: A Review of Present and Potential Applications, Modeling and Materials. Energy 2019, 186, 115849. [CrossRef]

- Bansal, P.; Martin, A. Comparative Study of Vapour Compression, Thermoelectric and Absorption Refrigerators. Int. J. Energy Res. 2000, 24, 93–107. [CrossRef]

- Liang, K.; Li, Z.; Chen, M.; Jiang, H. Comparisons between Heat Pipe, Thermoelectric System, and Vapour Compression Refrigeration System for Electronics Cooling. Appl. Therm. Eng. 2019, 146, 260–267. [CrossRef]

- Chougule, S.S.; Sahu, S. Thermal Performance of Nanofluid Charged Heat Pipe with Phase Change Material for Electronics Cooling. J. Electron. Packag. 2015, 137, 021004. [CrossRef]

- Zhang, W.; Shen, L.; Yang, Y.; Chen, H. Thermal Management for a Micro Semiconductor Laser Based on Thermoelectric Cooling. Appl. Therm. Eng. 2015, 90, 664–673. [CrossRef]

- Shen, L.; Chen, H.; Xiao, F.; Yang, Y.; Wang, S. The Step-Change Cooling Performance of Miniature Thermoelectric Module for Pulse Laser. Energy Convers. Manag. 2014, 80, 39–45. [CrossRef]

- Singh, V.; Sisodia, S.; Patel, A.; Shah, T.; Das, P.; Patel, R.; Bhavsar, R. Thermoelectric Cooler (TEC) Based Thermal Control System for Space Applications: Numerical Study. Appl. Therm. Eng. 2023, 224, 120101. [CrossRef]

- Gillott, M.; Jiang, L.; Riffat, S. An Investigation of Thermoelectric Cooling Devices for Small-Scale Space Conditioning Applications in Buildings. Int. J. Energy Res. 2010, 34, 776–786. [CrossRef]

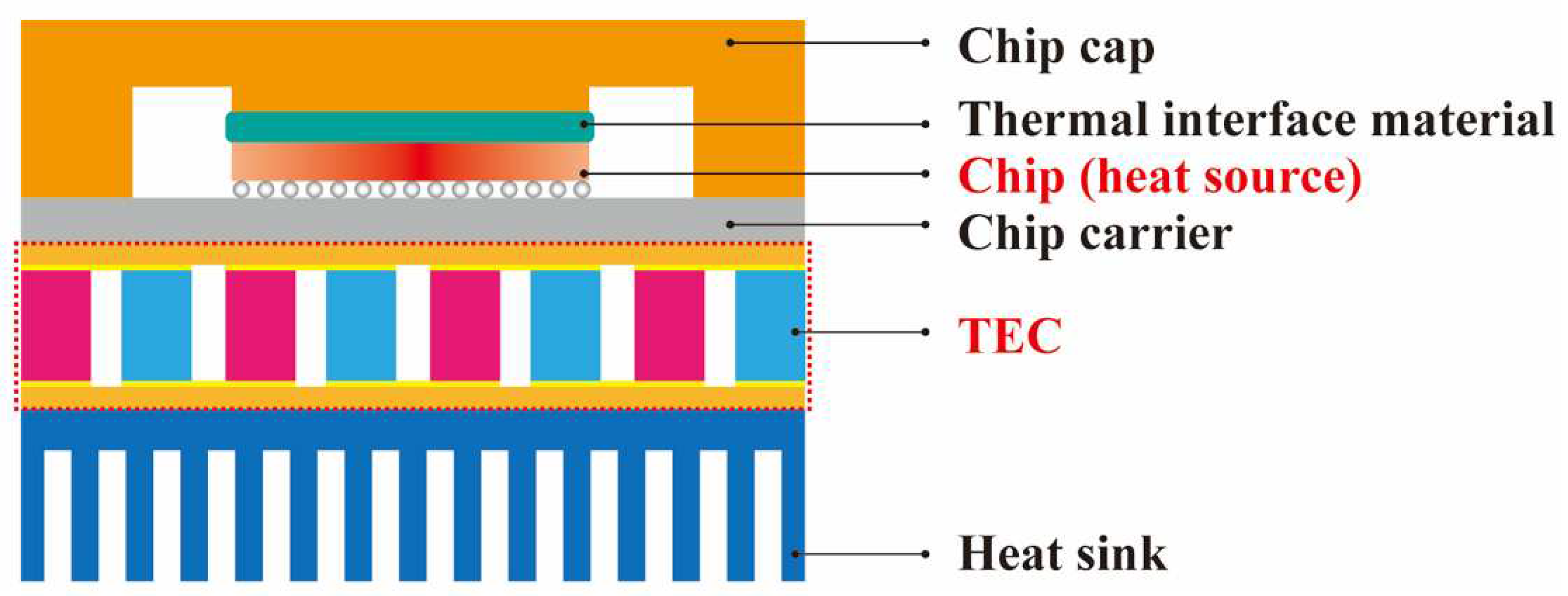

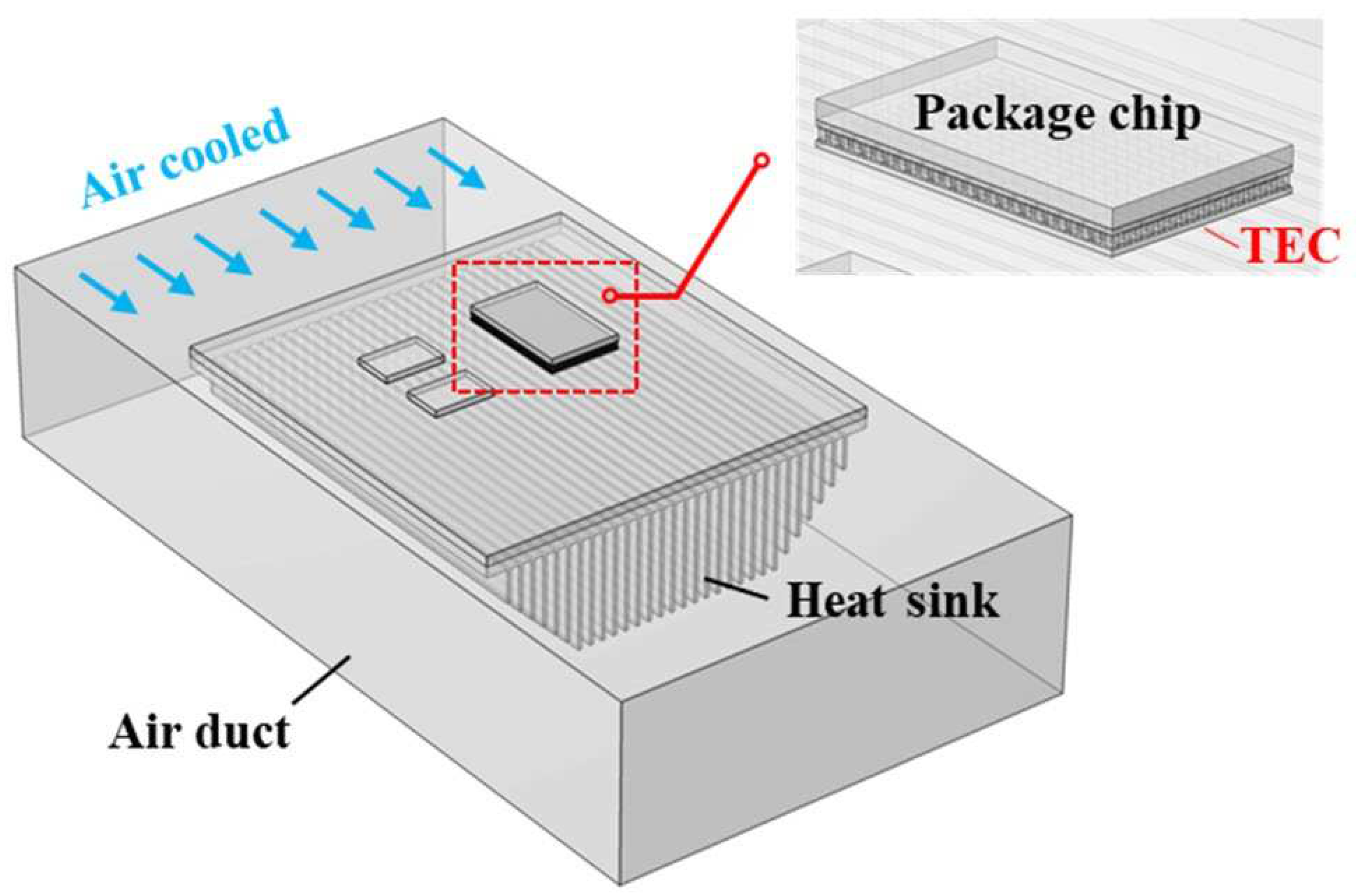

- Cai, Y.; Wang, Y.; Liu, D.; Zhao, F.-Y. Thermoelectric Cooling Technology Applied in the Field of Electronic Devices: Updated Review on the Parametric Investigations and Model Developments. Appl. Therm. Eng. 2019, 148, 238–255. [CrossRef]

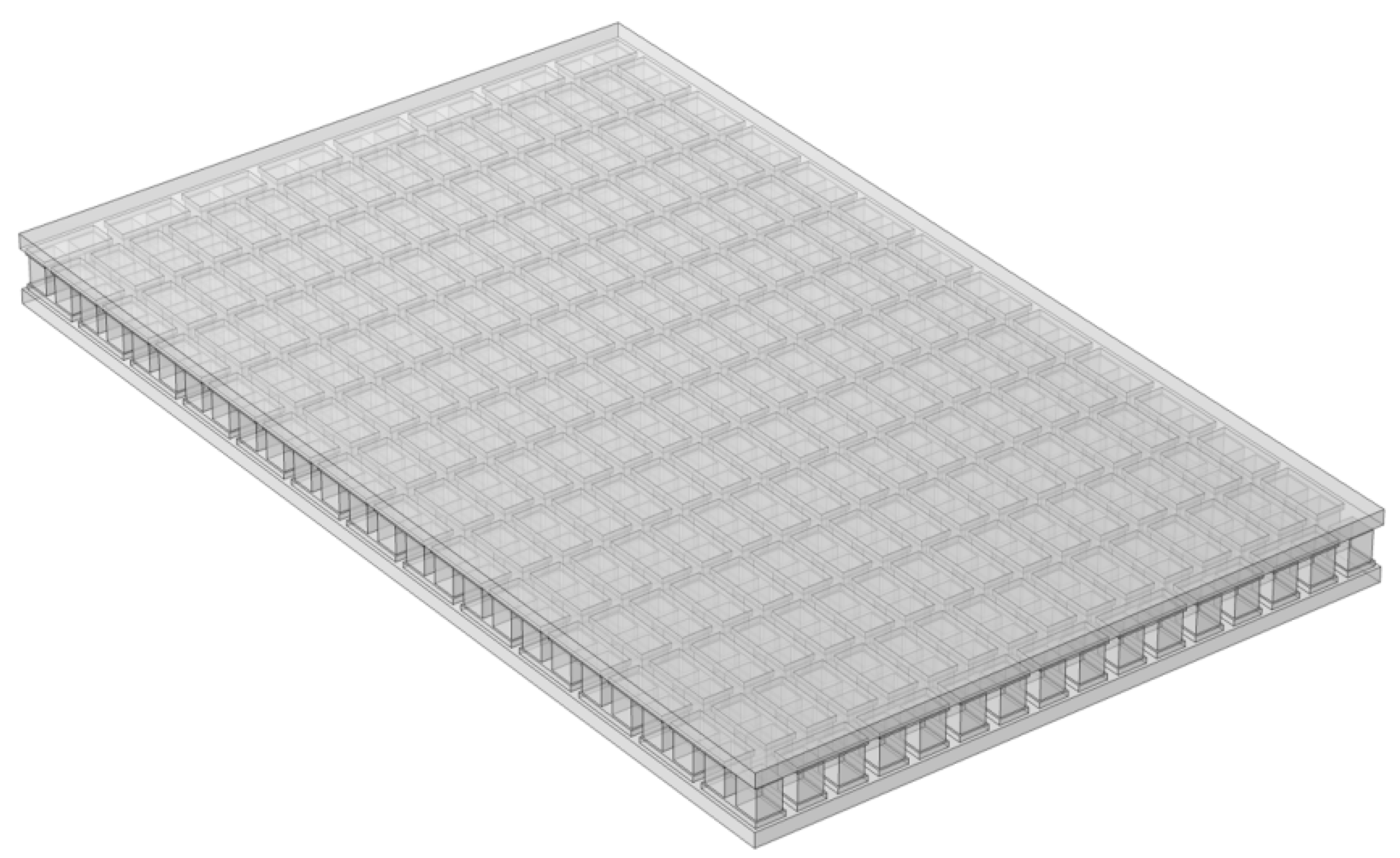

- Chen, W.-Y.; Shi, X.-L.; Zou, J.; Chen, Z.-G. Thermoelectric Coolers for On-Chip Thermal Management: Materials, Design, and Optimization. Mater. Sci. Eng. R Rep. 2022, 151, 100700. [CrossRef]

- Moazzez, A.F.; Najafi, G.; Ghobadian, B.; Hoseini, S.S. Numerical Simulation and Experimental Investigation of Air Cooling System Using Thermoelectric Cooling System. J. Therm. Anal. Calorim. 2020, 139, 2553–2563. [CrossRef]

- Al-Shehri, S.A. Cooling Computer Chips with Cascaded and Non-Cascaded Thermoelectric Devices. Arab. J. Sci. Eng. 2019, 44, 9105–9126. [CrossRef]

- Li, S.; Liu, J.; Ding, L.; Liu, J.; Xu, J.; Peng, Y.; Chen, M. Active Thermal Management of High-Power LED Through Chip on Thermoelectric Cooler. IEEE Trans. Electron Devices 2021, 68, 1753–1756. [CrossRef]

- Teng, T.-P.; Mo, H.-E.; Lin, H.; Tseng, Y.-H.; Liu, R.-H.; Long, Y.-F. Retrofit Assessment of Window Air Conditioner. Appl. Therm. Eng. 2012, 32, 100–107. [CrossRef]

- Said, M.; Hassan, H. Impact of Energy Storage of New Hybrid System of Phase Change Materials Combined with Air-Conditioner on Its Heating and Cooling Performance. J. Energy Storage 2021, 36, 102400. [CrossRef]

- Ma, K.; Zuo, Z.; Wang, W. Design and Experimental Study of an Outdoor Portable Thermoelectric Air-Conditioning System. Appl. Therm. Eng. 2023, 219, 119471. [CrossRef]

- Seyednezhad, M.; Najafi, H. Numerical Analysis and Parametric Study of a Thermoelectric-Based Radiant Ceiling Panel for Building Cooling Applications. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers, 2020; Vol. 84560, p. V008T08A030.

- Manikandan, S.; Selvam, C.; Pavan Sai Praful, P.; Lamba, R.; Kaushik, S.; Zhao, D.; Yang, R. A Novel Technique to Enhance Thermal Performance of a Thermoelectric Cooler Using Phase-Change Materials. J. Therm. Anal. Calorim. 2020, 140, 1003–1014. [CrossRef]

- Venkatesan, K.; Venkataramanan, M. Experimental and Simulation Studies on Thermoelectric Cooler: A Performance Study Approach. Int. J. Thermophys. 2020, 41, 1–23. [CrossRef]

- Hu, K.; Yang, D.; Hui, Y.; Zhang, H.; Song, R.; Liu, Y.; Wang, J.; Wen, P.; He, D.; Liu, X.; et al. Optimized Thermal Design for Excellent Wearable Thermoelectric Generator. J. Mater. Chem. A 2022, 10, 24985–24994. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).