Submitted:

04 April 2023

Posted:

06 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

- a)

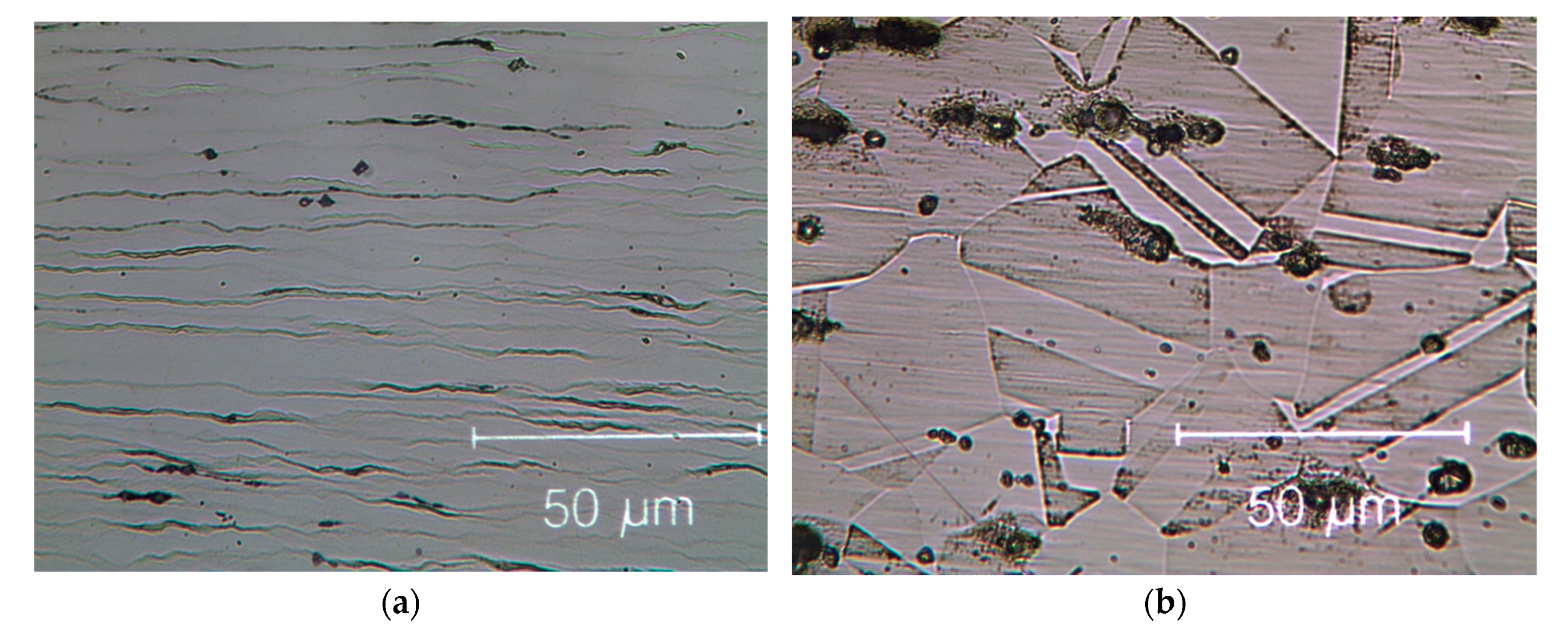

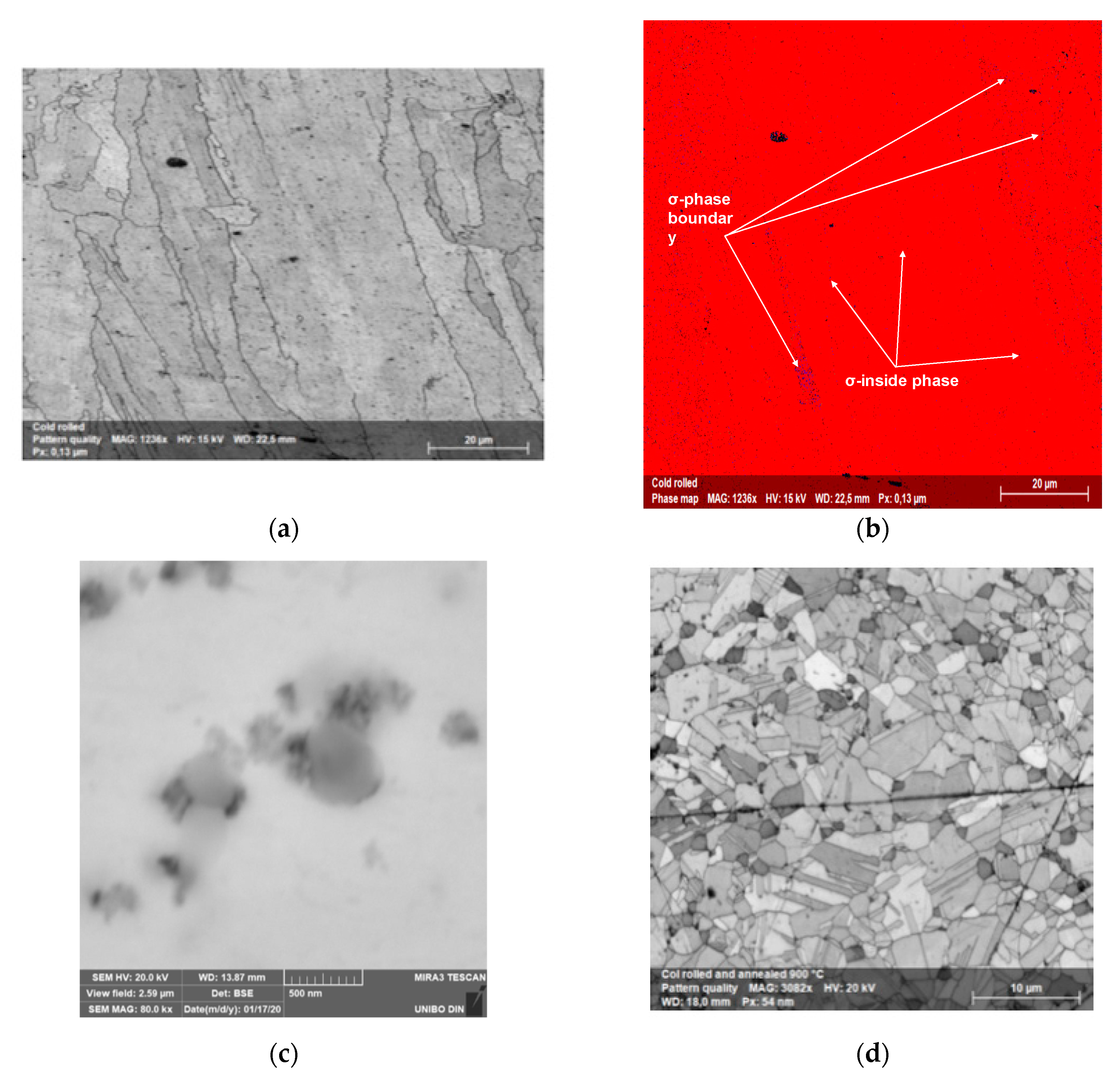

- Micro-structural investigations. They were performed by optical microscopy with an Olympus GX71 (Tokyo, Japan) and electron microscopy using a Tescan MIRA3 (Brno, Czech Republic) equipped with EDS (energy dispersive spectroscopy) microanalyzer by Bruker Quantax (Billerica, MA, USA). Specimens used for these analyses were polished and chemically etched (glyceregia solution composed of 1 HNO3 + 3 HCl + 3 Glycerol). Crystallographic orientation and grain size were analyzed by electron backscattered diffraction (EBSD). EBSD maps were conducted with Quantax EBSD detector on as built, cold deformed, annealed and re-crystallized samples to document the FCC matrix alloy and the precipitation of secondary phases. The EBSD data were recorded and analysed using the Bruker Esprit software.

- b)

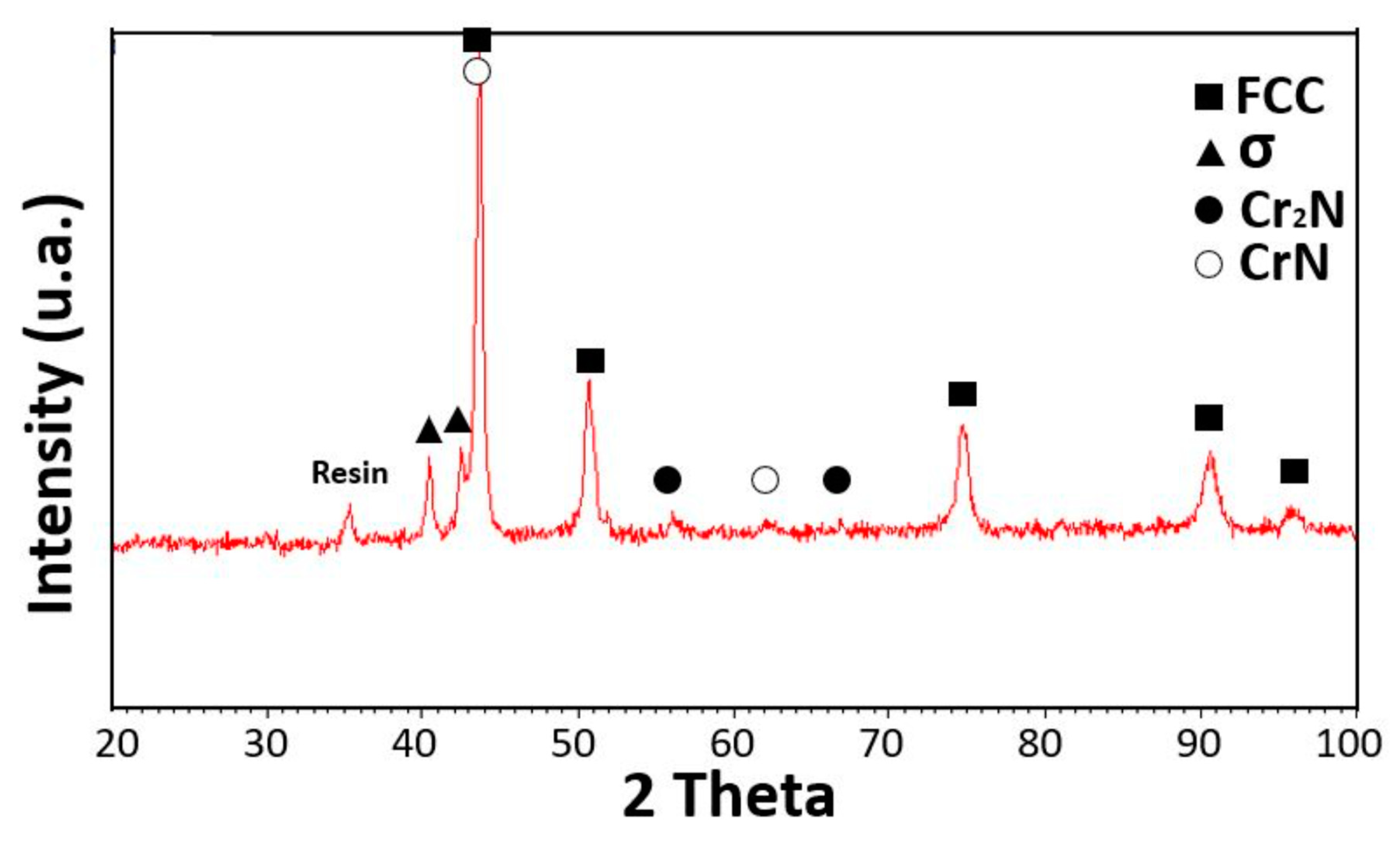

- X-ray Diffraction (XRD). In order to determine the crystal structure, a Q/2Q scan was performed in the 2Q range from 35 to 100 degrees using a Panalytical X’Pert PRO diffractometer equipped with a gas proportional detector (Malvern, UK). A parallel beam configuration was applied, including an X-ray mirror (incident beam optics) coupled with a long soller slit and a flat monochromator (diffracted beam optics). Hence, sample displacement errors were avoided, and a correct determination of the unit cell from peak positions could be performed.

- c)

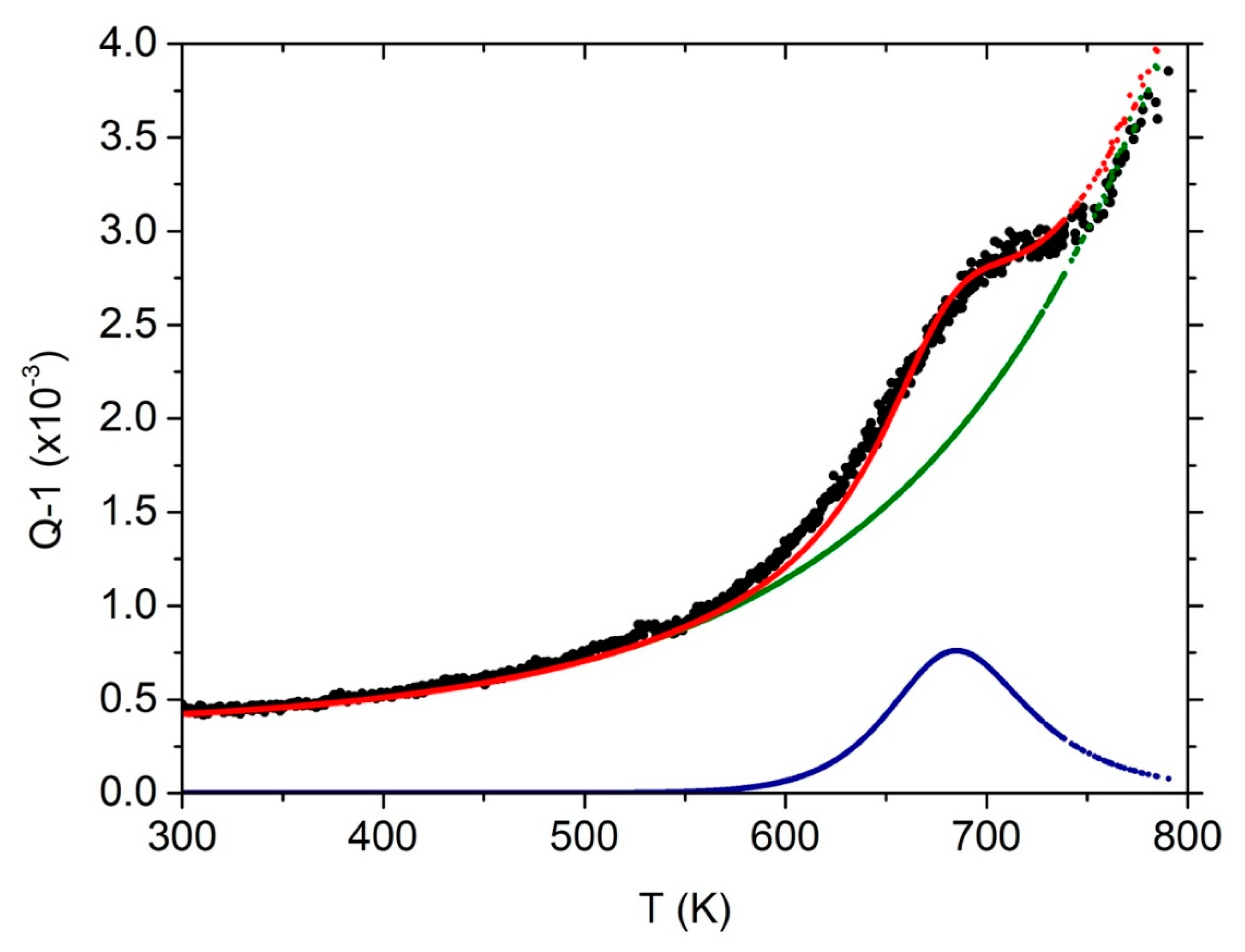

- Mechanical spectroscopy. Damping and dynamic modulus measurements were performed in a vacuum by means of the mechanical analyser VRA 1604 [26,27]. In the VRA apparatus, specimens are mounted in free-clamped mode and excited by flexural vibrations. Specimens were kept into resonance while temperature changed at the selected rate. The resonance frequency of all specimens was in the 300 to 1000 Hz range; the strain amplitude was about 10−5. Specimens were heated from room temperature up to a maximum temperature of 800 K at 1.5 K/min rate. The reeds were put into resonance by an electrostatic excitation and the damping parameter (usually referred to as Q−1) has been determined from the logarithmic decay of the flexural vibrations when excitation was turned off:being An and An+m the amplitudes of the n-th and (n + m)-th oscillation. The dynamic modulus E was obtained from the resonance frequency f, by:where m is a constant (m = 1.875), Ρ the material density, L and h the length and thickness of the sample. Debye relaxation peaks occur when the following condition is satisfied:being ω = 2πf, τ the relaxation time, τ0 its pre-exponential factor, H the activation energy of the physical process originating the peak, k the Boltzmann constant and T the temperature.

3. Results

4. Discussion

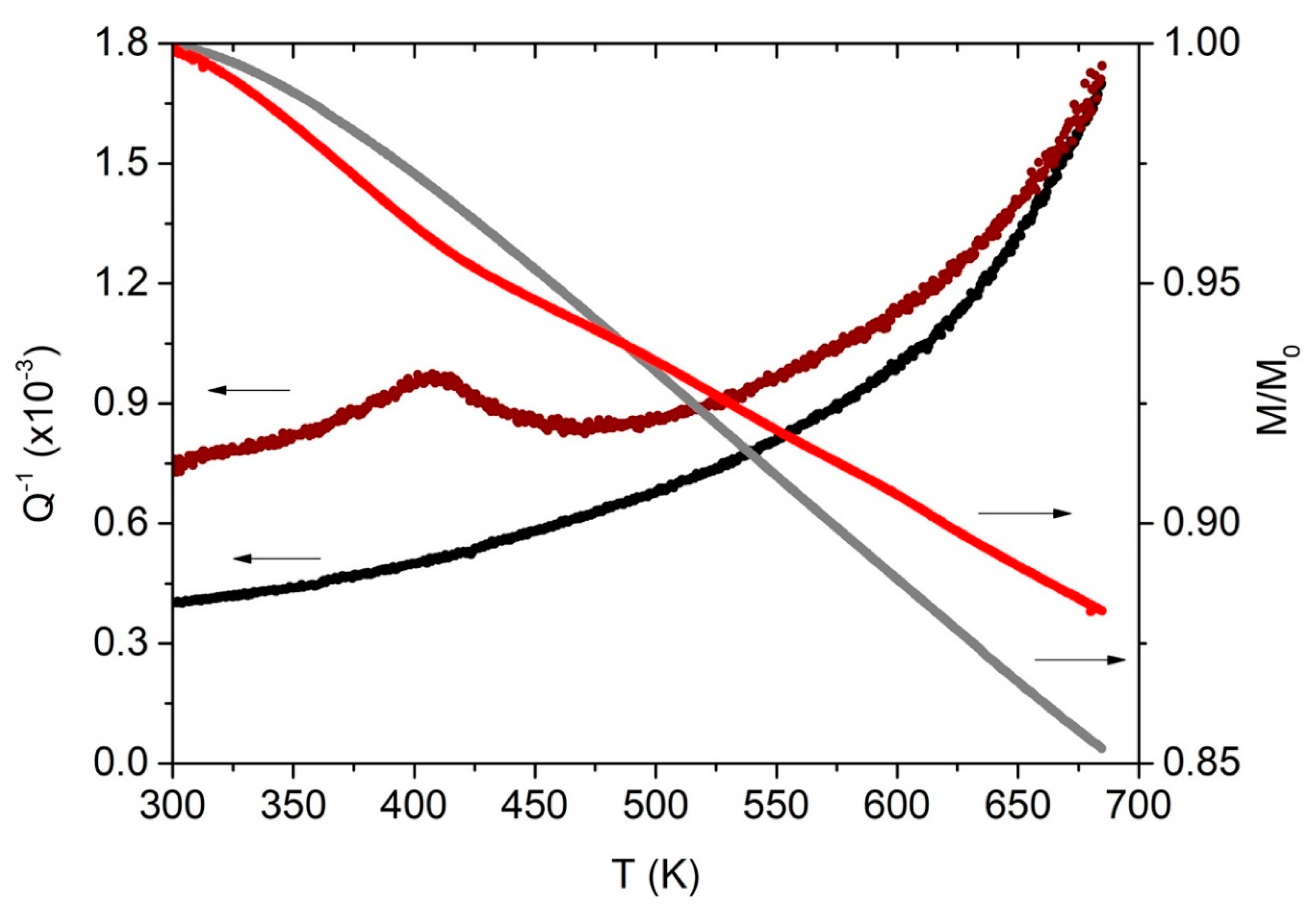

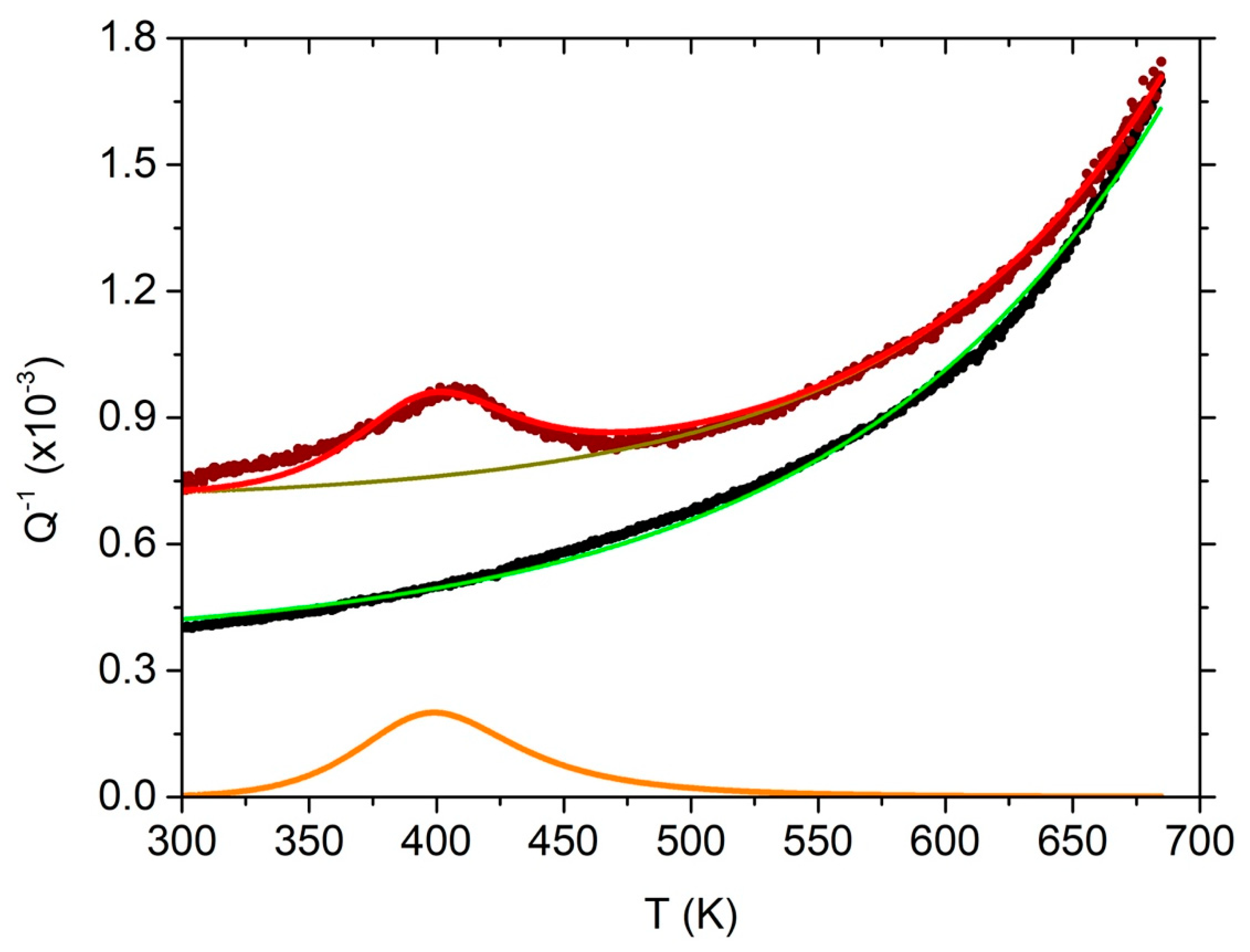

4.1. Low temperature peak of CoCrFeMnNi alloy after cold rolling, without re-crystallization.

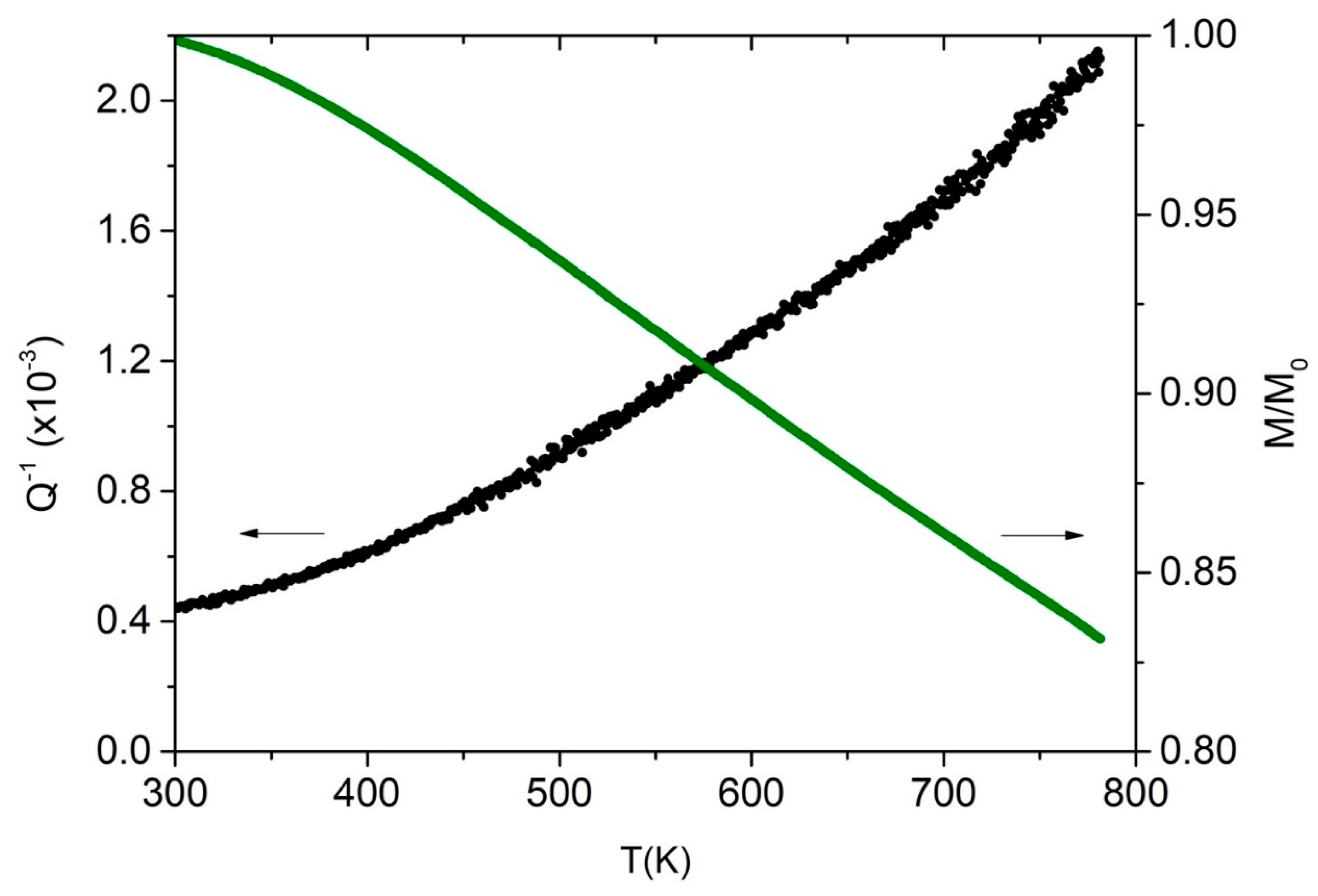

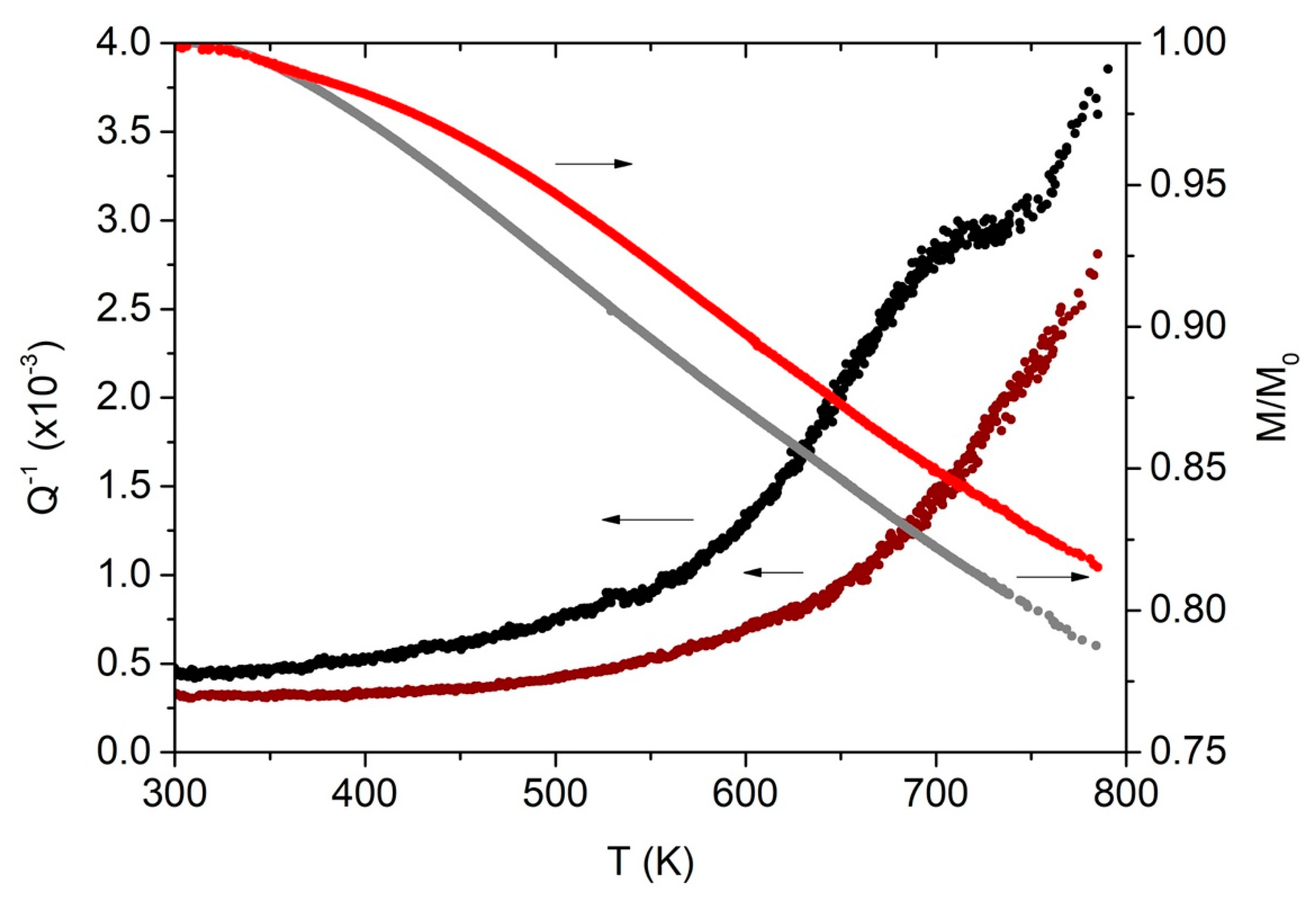

4.1. High temperature peak of CoCrFeMnNi alloy produced by SLM after cold rolling and re-crystallization.

4. Conclusions

- In this work, a mechanical spectroscopy study of two CrNiFeCoMn Cantor’s alloys obtained by induction melting (standard) and by selective laser melting (SLM), with the same lattice structure (FCC), was performed.

- Both types of alloys, cold-deformed by rolling, showed damping peaks in the 300-800 K temperature range.

- Cold-worked samples exhibited a damping peak at 400 K with relaxation strength 2 ⋅10-4 and apparent activation energy of 48 kJ/mol. The peak was tentatively attributed to a Bordoni relaxation, that is to dislocation motion. It disappeared after a thermal treatment above 700 K.

- SLM alloys samples exhibited a damping peak at 685 K with relaxation strength 7.6 ⋅10-4 and apparent activation energy of 127 kJ/mol. The peak was tentatively attributed to grain boundary sliding controlled by precipitates (nitride and σ phase). The peak disappeared after a re-crystallization treatment.

- An exponentially growing damping background was measured in both standard and SLM samples, with typical values of about 3-5⋅10-4 at 300 K and 20⋅10-4 at 800 K.

- The dynamic Young’s Modulus of SLM samples was rather low, (90±10) GPa, in the not-recrystallized case, due to porosity. It grew to (170±10) GPa after re-crystallization.

Author Contributions

Funding

Conflicts of Interest

References

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Chen, S.K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N.; Wilks, J. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Cantor, B. Multicomponent high-entropy Cantor alloys. Prog. Mater. Sci. 2021, 120, 100754. [Google Scholar] [CrossRef]

- Kao, Y.-F.; Chen, T.-J.; Chen, S.-K.; Yeh, J.-W. Microstructure and mechanical property of as-cast, -homogenized, and -deformed AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys. J. Alloys. Compd. 2009, 488, 57–64. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Tabachnikova. ; Podolskiy,.; Laktionova, M.; Bereznaia, N.; Tikhonovsky, M.; Tortika, A. Mechanical properties of the CoCrFeNiMnVx high entropy alloys in temperature range 4.2–300 K. J. Alloy. Compd. 2017, 698, 501–509. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Bhattacharjee, P.P.; Sathiaraj, G.D.; Zaid, M.; Gatti, J.R.; Lee, C.; Tsai, C.W.; Yeh, J.W. Microstructure and texture evolution during annealing of equiatomic CoCrFeMnNi high-entropy alloy. J. Alloys Compd. 2014, 587, 544–552. [Google Scholar] [CrossRef]

- Liu, W.; Lu, Z.; He, J.; Luan, J.; Wang, Z.; Liu, B.; Liu, Y.; Chen, M.; Liu, C. Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases. Acta Mater. 2016, 116, 332–342. [Google Scholar] [CrossRef]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- Gludovatz, B.; George, E.P.; Ritchie, R.O. Processing, Microstructure and Mechanical Properties of the CrMnFeCoNi High-Entropy Alloy. JOM 2015, 67, 2262–2270. [Google Scholar] [CrossRef]

- Haglund, A.; Koehler, M.; Catoor, D.; George, E.; Keppens, V. Polycrystalline elastic moduli of a high-entropy alloy at cryogenic temperatures. Intermetallics 2015, 58, 62–64. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, X.; Qi, W.; Li, Y.; Wang, W.; Chen, Y.; Li, J.; Li, L. Effect of Co on phase stability and mechanical behavior of CoxCrFeNiMnAl0.3 high entropy alloys with micro/nano hierarchical structure. Mater. Des. 2022, 215, 110442. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Horst, O.M.; Eggeler, G.; George, E.P. Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2016, 118, 152–163. [Google Scholar] [CrossRef]

- Zaddach, A.J.; Niu, C.; Koch, C.C.; Irving, D.L. Mechanical Properties and Stacking Fault Energies of NiFeCrCoMn High-Entropy Alloy. JOM 2013, 65, 1780–1789. [Google Scholar] [CrossRef]

- George, E.P.; Curtin, W.A.; Tasan, C.C. High Entropy Alloys: A Focused Review of Mechanical Properties and Deformation Mechanisms. Acta Mater. 2020, 188, 435–474. [Google Scholar] [CrossRef]

- Nowick, A.S.; Berry, B.S.; Katz, J.L. Anelastic Relaxation in Crystalline Solids, (Academic Press, New York, 1972).

- Blanter, M.S.; Golovin, I.S.; Neuhäuser, H.; Sinning, H.-R. Internal Friction in Metallic Glasses, Springer Series in Materials Science, January, 2007.

- Biswas, M.R.; Alzubaidi, M.S.; Shah, U.; Abd-Alrazaq, A.A.; Shah, Z. The Effect of Zr Addition on Melting Temperature, Microstructure, Recrystallization and Mechanical Properties of a Cantor High Entropy Alloy. Materials 2021, 14, 5994. [Google Scholar] [CrossRef]

- Campari, E.G.; Casagrande, A. Microstructural Study of CrNiCoFeMn High Entropy Alloy Obtained by Selective Laser Melting. Materials 2022, 15, 5544. [Google Scholar] [CrossRef] [PubMed]

- Olakanmi, E.O.T.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477, ISSN 0079-6425. [Google Scholar] [CrossRef]

- Rao, H.; Giet, S.; Yang, K.; Wu, X.; Davies, C.H. The influence of processing parameters on aluminium alloy A357 manufactured by Selective Laser Melting. Mater. Des. 2016, 109, 334–346. [Google Scholar] [CrossRef]

- Carter, L.N.; Martin, C.; Withers, P.J.; Attallah, M.M. The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. J. Alloy. Compd. 2014, 615, 338–347. [Google Scholar] [CrossRef]

- Bonetti, E.; Campari, E.G.; Pasquini, L.; Savini, L. Automated resonant mechanical analyzer. Rev. Sci. Instruments 2001, 72, 2148–2152. [Google Scholar] [CrossRef]

- Amadori, S.; Campari, E.; Fiorini, A.; Montanari, R.; Pasquini, L.; Savini, L.; Bonetti, E. Automated resonant vibrating-reed analyzer apparatus for a non-destructive characterization of materials for industrial applications. Mater. Sci. Eng. A 2006, 442, 543–546. [Google Scholar] [CrossRef]

- Norton, R.L. Machine Design—an Integrated Approach (Pearson Education Asia, 2nd edition, 2010).

- Li, S.; Deng, L.; Wu, X. The mechanism investigation of deep cryogenic treatment on high alloy martensitic steel by low frequency internal friction. Cryogenics 2010, 50, 433–438. [Google Scholar] [CrossRef]

- Rivière, A. Analysis of the low frequency damping observed at medium and high temperatures. Mater. Sci. Eng. A 2004, 370, 204–208. [Google Scholar] [CrossRef]

- Povolo, F.; Hermida, E.B. On the Frequency Dependence of the High Temperature Background. 1996, 06, C8–227. [CrossRef]

- Szenes, G.; Havancsák, K.; Nagy, E. Young's modulus change during recrystallization. Phys. Status solidi (a) 1974, 22, 125–132. [Google Scholar] [CrossRef]

- Boccaccini, A.; Ondracek, G.; Mazilu, P.; Windelberg, D. On the Effective Young's Modulus of Elasticity for Porous Materials: Microstructure Modelling and Comparison Between Calculated and Experimental Values. J. Mech. Behav. Mater. 1993, 4, 119–128. [Google Scholar] [CrossRef]

- Kováčik, J. Correlation between Young's modulus and porosity in porous materials. J. Mater. Sci. Lett. 1999, 18, 1007–1010. [Google Scholar] [CrossRef]

- Seeger, A. Progress and problems in the understanding of the dislocation relaxation processes in metals. Mater. Sci. Eng. A 2004, 370, 50–66. [Google Scholar] [CrossRef]

- Suresh, N.; Ramamurty, U. Aging response and its effect on the functional properties of Cu–Al–Ni shape memory alloys. J. Alloy. Compd. 2008, 449, 113–118. [Google Scholar] [CrossRef]

- Zener, C. Theory of the Elasticity of Polycrystals with Viscous Grain Boundaries. Phys. Rev. 1941, 60, 906–908. [Google Scholar] [CrossRef]

- Povolo, F.; Molinas, J.B. Present State of the Controversy about the Grain Boundary Relaxation. Il Nuovo Cimento, 1992, 14, 287–332. [Google Scholar] [CrossRef]

- Mosher, D.; Raj, R. Use of the internal friction technique to measure rates of grain boundary sliding. Acta Met. 1974, 22, 1469–1474. [Google Scholar] [CrossRef]

| Alloy | H (eV) | (10-4) | Tp (K) | A (10-4) | B (10-6) | C |

|---|---|---|---|---|---|---|

| standard | 0.5 | 2.0 | 400 | 7 | 1.2 | 102 |

| SLM | 1.3 | 7.6 | 685 | 3.5 | 6.3 | 124 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).