1. Introduction

Highly populated cities make the market share of transportation and product deliveries for urban mobility extremely attractive by going into the third dimension (vertically). The demand for fast relocation is met by (electrified) vertical take-off and landing vehicles for passenger transport, and drones possibly deliver goods in the future. It is evident that this scenario poses an extraordinary challenge for the community issuing regulations (ICAO Annex 16 [

1]) and the stakeholders of such operating systems due to possible noise emissions that must be classified, analyzed and reduced to an acceptable minimum [

2]. The article revisits the usefulness of a measurement procedure to gain first insights into such propulsion units associated with new disruptive technologies and outlines how to start with noise mitigation at the early prototyping stage affordably and within a short time.

Electric propulsion has become a vital part of the aviation sector among electrically powered vertical take-off and landing (eVTOL) aircraft. Noise emissions of those eVTOL aircraft are mainly produced by the propulsion and lifting units and are of major concern during certification. During vertical flight operation, usually performed in urban and rural areas, the propulsion units’ thrust generates lift forces [

3,

4] and, simultaneously, a substantial amount of noise emissions. One type of an electric propulsion system is an EDF.

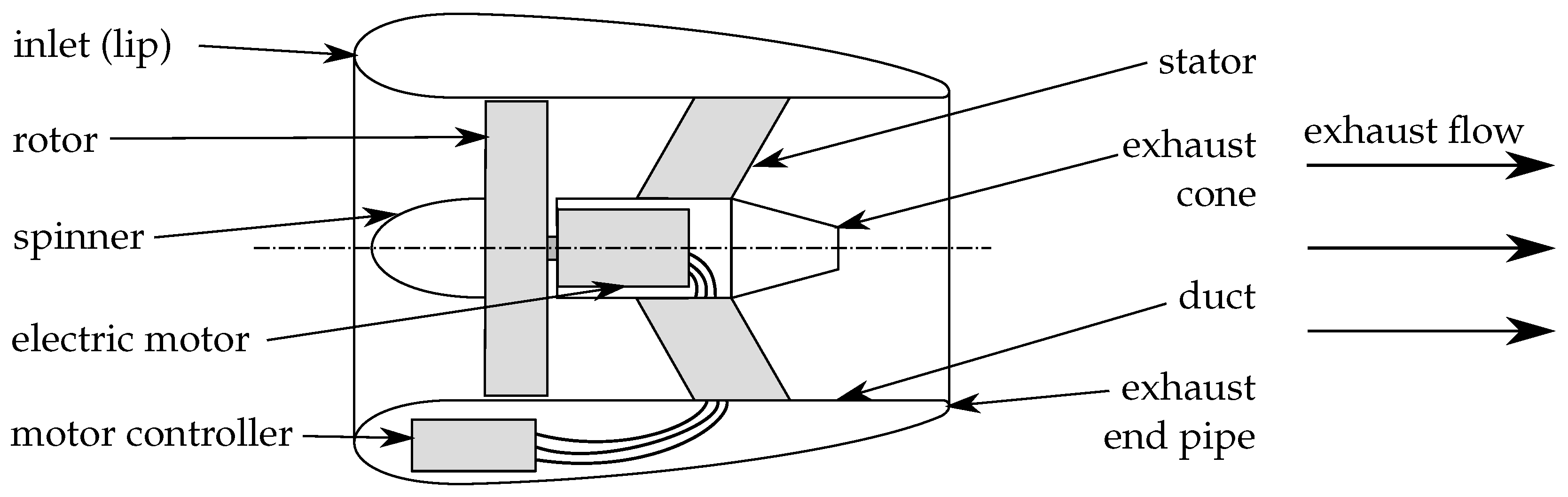

Figure 1 shows a schematic of the EDF based on a single-stage axial fan and its aerodynamic and electric components. Such an EDF is the subject of this study on acoustic characterization in early prototyping.

Similar types of electric aero-engines [

6,

7,

8,

9,

10] have been studied for small-scale aircrafts aerodynamically [

11]. Typically, the rotors are driven at high angular velocities (like 8000 revolutions per minute) and relatively low Reynolds numbers (10.000 to 100.000) compared to large aircraft engines. Both the positioning of multiple propulsion units as well as the in-duct placement of the rotors is a challenge for flight control and noise [

4,

11] but offers a high potential for optimization of fuel consumption, emission, noise reduction [

12,

13,

14], and operational flexibility [

15]. Although the whole aircraft offers acoustic shielding effects, in early prototyping, a component-based evaluation is of significant importance to detect design errors upfront [

16] and gain experience with electric propulsion units [

17].

Concerning this need for structured experimental assessment of preliminary design at low cost, this case study on the electric ducted fan unit provides valuable insights for conducting such evaluation with relatively few resources and within a stringent timeframe. In contrast to well-tailored and detailed experimental studies concerning electric ducted fan noise [

18,

19] of the past hosted inside expensive facilities, the study concentrates on the overall aspects and an easy-to-realize and affordable method also during the starting phase of a new idea with a limited budget. In [

18], the aeroacoustic aspects of the design, construction, and testing of an all-electric ducted fan propulsion unit inside a large anechoic test chamber are presented. In general, ducted fan configurations potentially reduce noise emissions significantly [

19,

20,

21]. These options include incorporating acoustic liners to the ducted walls [

22] and designing the ratio of stator vanes to rotor blades so that specific blade passing frequency harmonics are cut-off [

23]. Recently, studies showed insignificant or even noise amplification can occur when incorporating simple ducts into an existing propeller unit [

11,

12]. The duct as a design concept having both a potential to lower or increase the sound emission is critical; possible erroneous designs can be sorted out early with the proposed method since keeping them in the development process is very costly. Furthermore, the method can be combined with computational models [

24,

25] to gain further insight into the mechanism and serve as a plausible baseline for the simulation.

Another important aspect of the noise generation of electric ducted fans is the excitation of electric motor forces and a possible attenuation by structural modes [

26]. Additionally, the authors of [

22] reported high-frequency noise of the electronic switching since the frequencies can be close to natural frequencies of the structure, especially when placed inside the fan’s duct. Typically, this switching noise occurs around a base switching frequency, and both increasing and falling harmonics arise during operation [

26,

27,

28]. Common strategies for avoiding this source of sound are placing them outside the human hearing range or by advanced switching algorithms [

27]. For instance, such a parasitic side effect is an exemplary motivation for this article by the underlying data showing unexpected effects of the electric drive of the electric ducted fan unit.

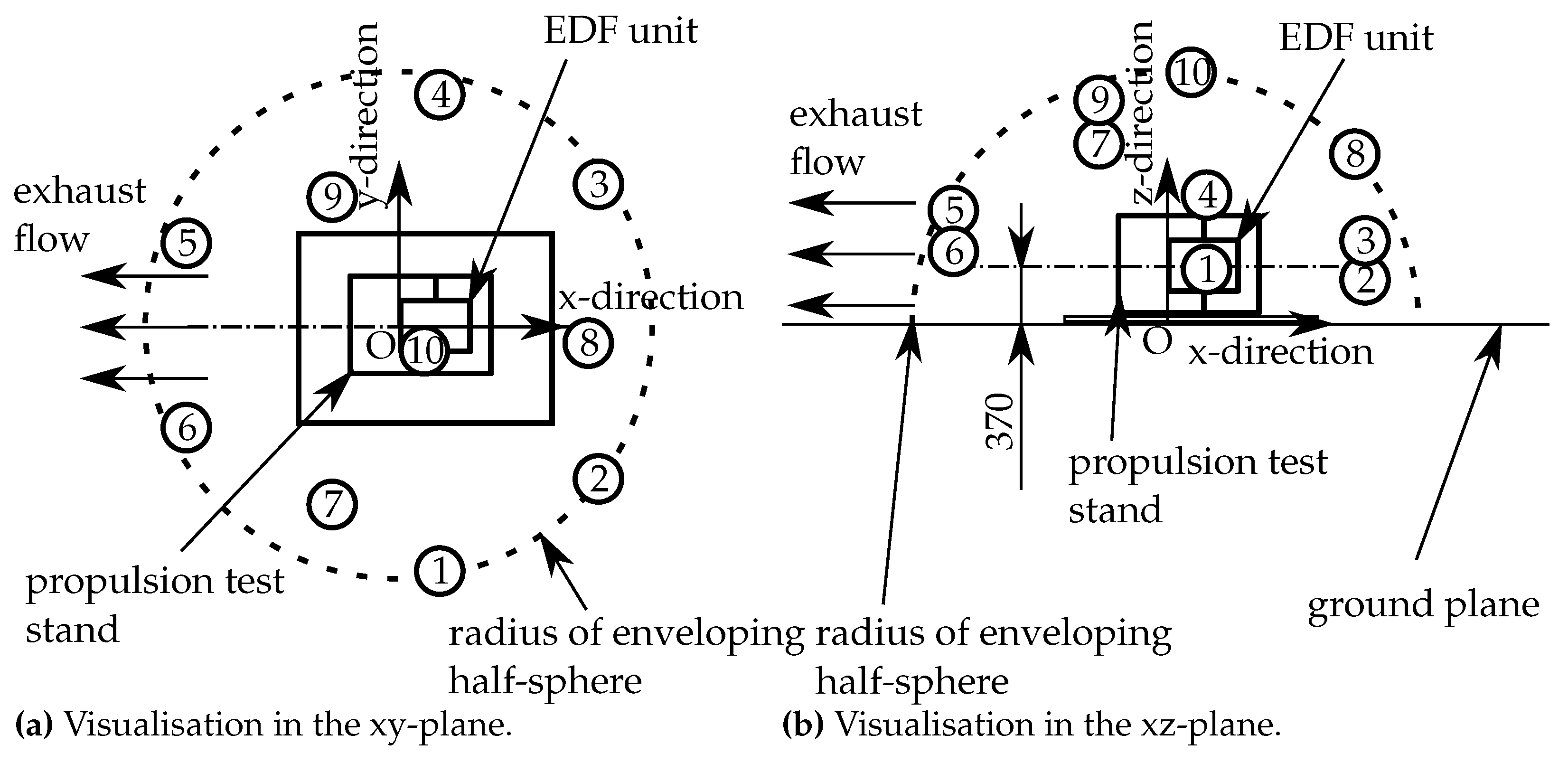

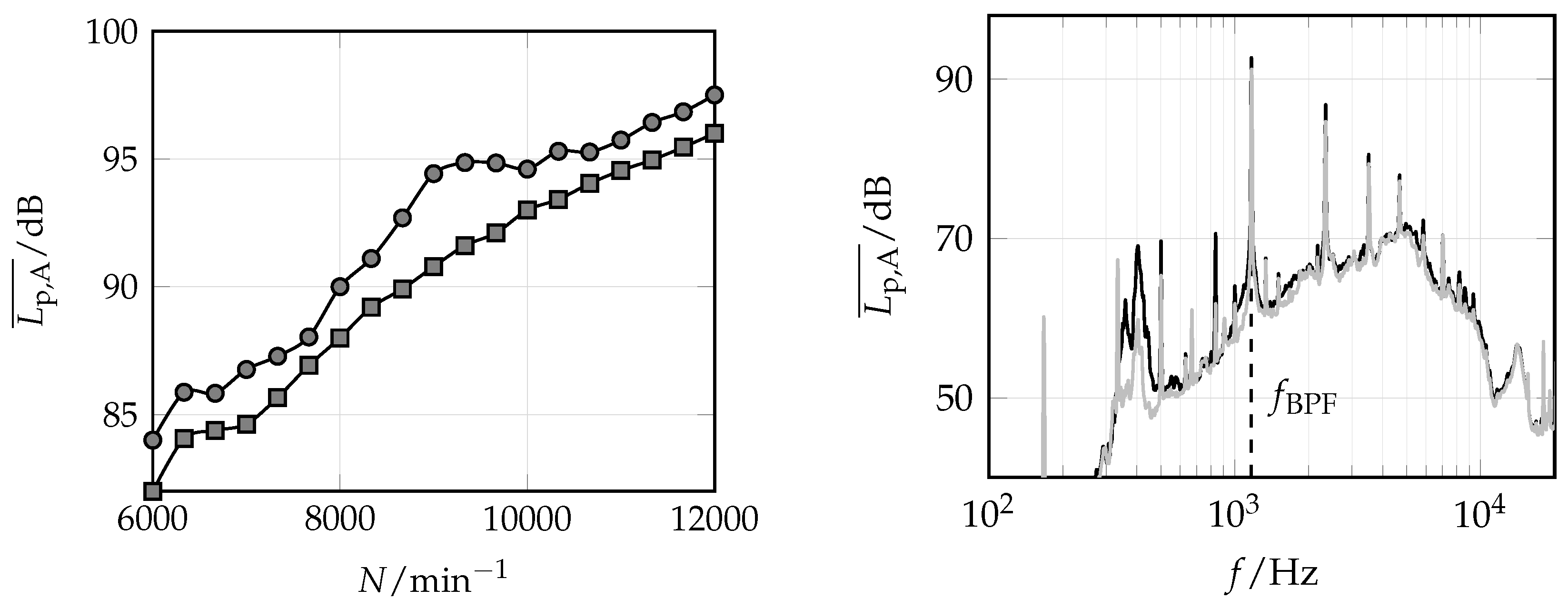

Based on the proposed enveloping surface of the international standard

DIN EN ISO 3744:2011-02, ten microphones were positioned around the electric ducted fan unit. The fan’s sound emissions are subject to the following investigation at different operating points. The total sound power of the operating EDF unit was measured at different operation points. In doing so, far-field measurements of the unit’s electric powertrain with and without load were conducted, which showed significant noise emissions at the blade passing frequencies. We investigate acoustically the electric powertrain, consisting of an electronically commutated brushless DC motor (ECM) and the motor controller without load and found significant contributions from the periodic electromagnetic forces and the motor controller electronics. After processing the insights gained from the measuring campaign, a secondary noise reduction measure was designed. By considering several options for noise mitigation, a micro-perforated plate liner configuration after the fan was placed inside the duct with an optimally designed back volume. The noise was evaluated using an A-weighting to account for human perception. This paper is an extended version of an article published in the AIAA Aviation Forum 2021, Virtuell, USA, 2 Aug 2021-6 Aug 2021 [

22].

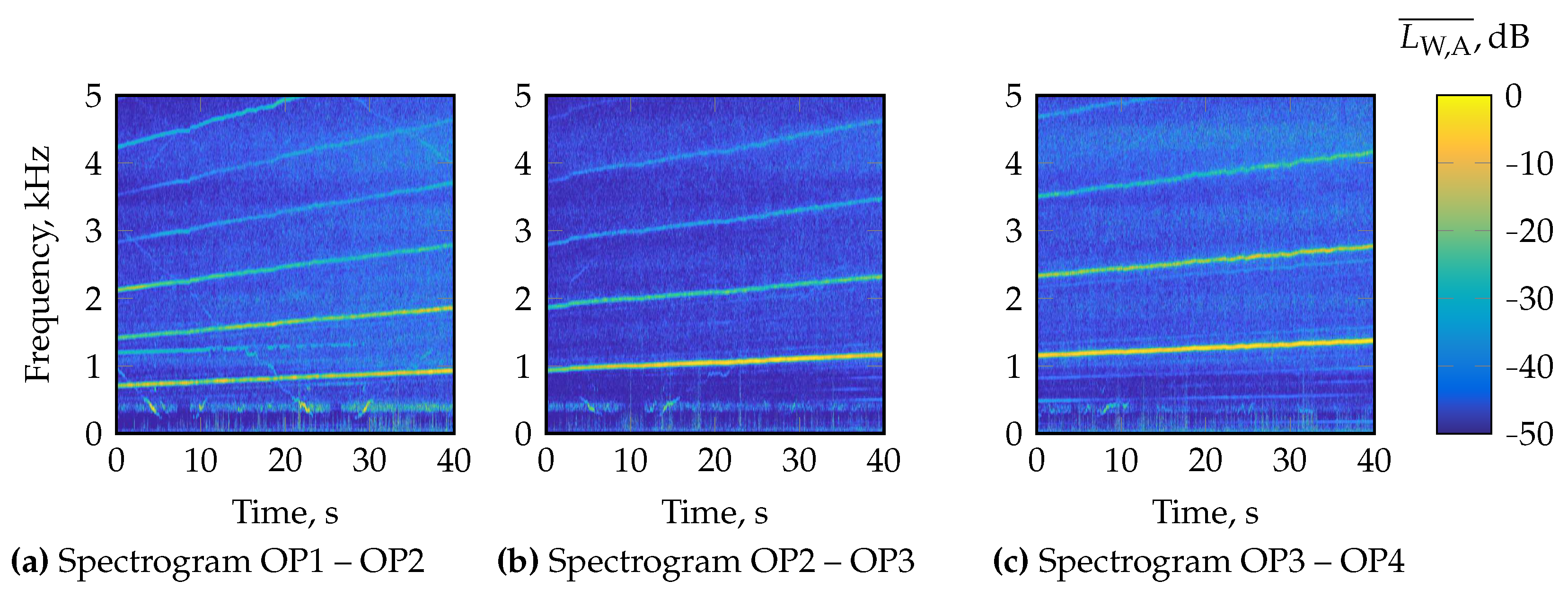

The article is structured as follows. The electric ducted fan unit and the upfront noise mitigation measures are presented. Followed by the setup of the measurement campaign designed for early prototyping studies of electric ducted fan units. The limitation of the enveloping surface method regarding this application is discussed. Based on this initial measurement campaign, the results are analyzed, and conclusions for improvements are drawn in a structured way. The results indicate two interesting issues for further analysis. Firstly, at 9000 revolutions per minute, a hump in the overall sound pressure level was found and further investigated within the means of the method. Secondly, the characteristics of the far-field noise of the EDF unit’s electric powertrain, consisting of a brushless DC motor and electronic speed controller, without load were analyzed. After processing the insights gained from the measuring campaign with accompanying duct mode simulations, a secondary noise reduction measure was designed and evaluated.

2. Application and device under test

The device under test is a subsonic, subscale 1:2, single-stage, axial-flow EDF unit.

Figure 2 shows how the axil-flow EDFs are mounted at the APELEON X1 and provides a detailed picture of the EDF unit mounted on the propulsion test rig during the measurement setup of the enveloping surface method.

Figure 1 schematically shows the structure of the EDF unit under test. The primary parts of the EDF unit are the rotor, consisting of 7 blades, the spinner, the electric motor, the stator with four guide vanes vectorizing the flow and connecting the brushless DC motor (7 pole pairs) with the motor controller, which is assembled inside the duct hub and the duct with a curved inlet lip. Further geometrical details can be found in [

5].

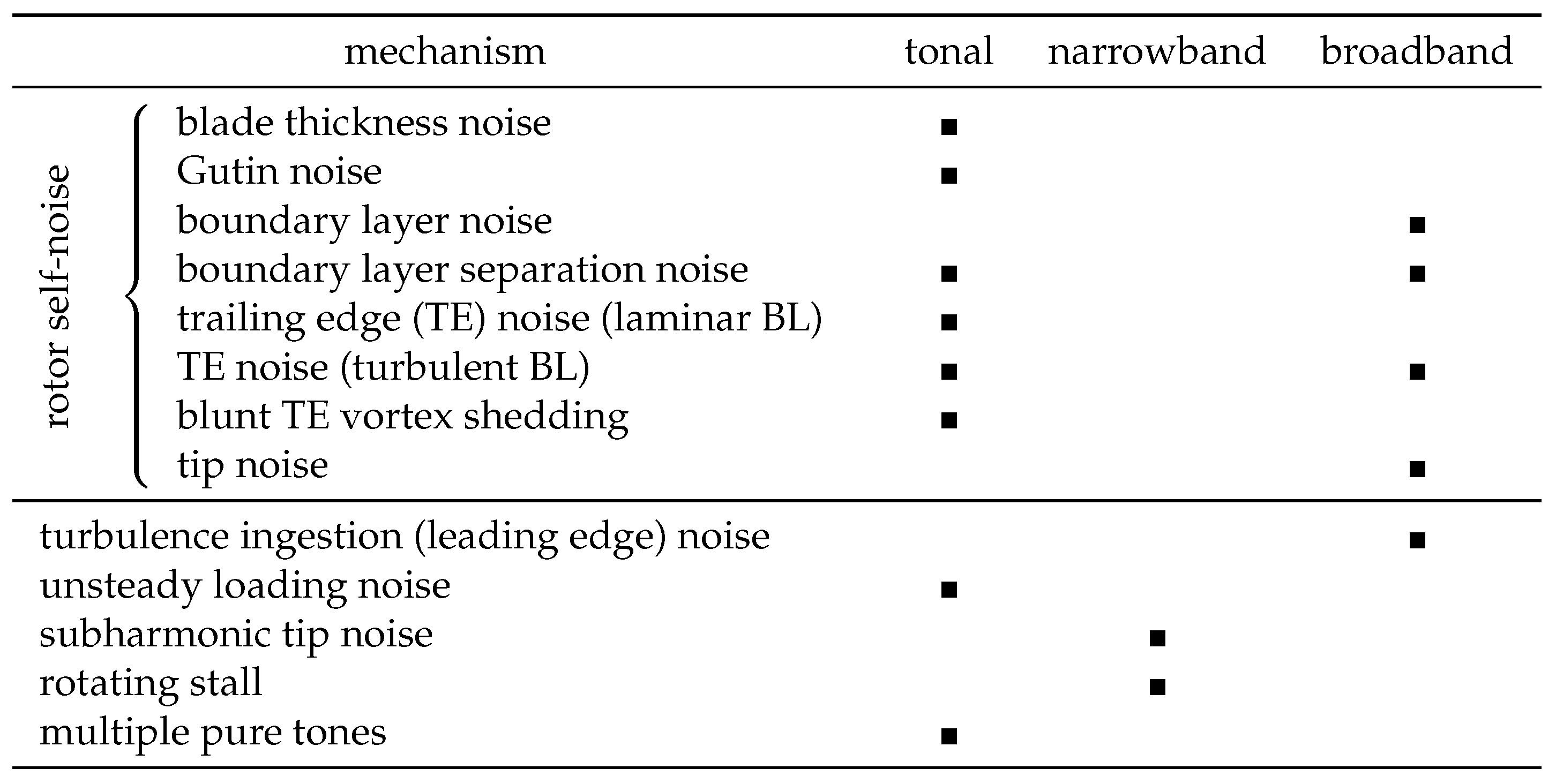

2.1. Revisiting basic acoustic emissions of EDF units

This EDF unit generates aeroacoustic sound that is characteristic for axial fans [

29] and summarized in

Table 1.

According to [

23], the primary noise emissions of axial fans stem from aerodynamic excitation. Rotor self-noise and noise generated by the interaction between the rotor and stator flow generate tonal noise at the blade passing frequency (BPF) [

30,

31]

and its harmonic frequencies

, with

B being the number of rotor blades,

the rotational speed, and

n the harmonic multiplicity. The noise origin at the BPF and its harmonics is anticipated to be from the rotor-stator interactions for subsonic rotor-self mechanisms inside circular ducts [

30].

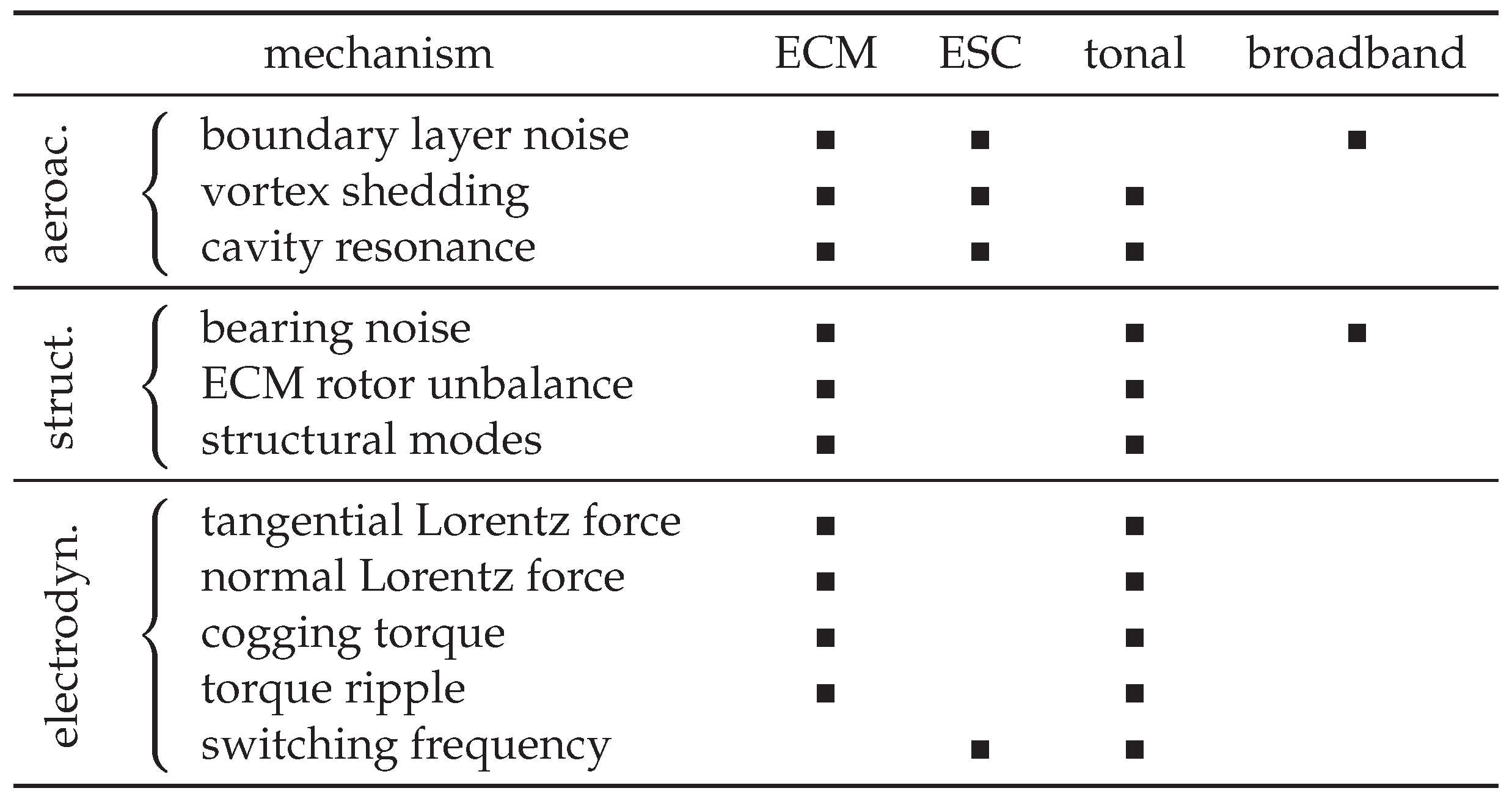

In addition, the EDFs electric powertrain emits noise.

Table 2 summarizes possible source and attenuation mechanisms related to the electric motor placement inside the duct. The individual mechanisms are classified into tonal and broadband representation inside a measured spectrum. Furthermore, the excitation is classified as aeroacoustic, structurally related, and electrodynamic. In addition, the electric drive parts, electronic commutate motor (ECM), and electronic speed controller (ESC), responsible for the acoustic emission, are also provided.

The noise emissions of an ECM are a result from electromagnetic force and torque ripples during operation [

32,

33,

34,

35]. The fundamental frequency of the electromagnetic force forces is

and its harmonic frequencies are

The frequencies can be computed using the number of motor pole pairs

p [

32,

34,

35].

2.2. Noise mitigation strategies

Since future small aircraft should operate and be tolerated in urban and rural environments, noise reduction is relevant, even on the component level. Therefore, propulsion noise should be considered early, indicating a motivation for this investigation at the conceptual design stage [

15]. For instance, the ducted fan offers the potential of combining a variety of rotor blade and stator vane designs to minimize noise, offers noise shielding options, and the placement of acoustic liners [

36,

37].

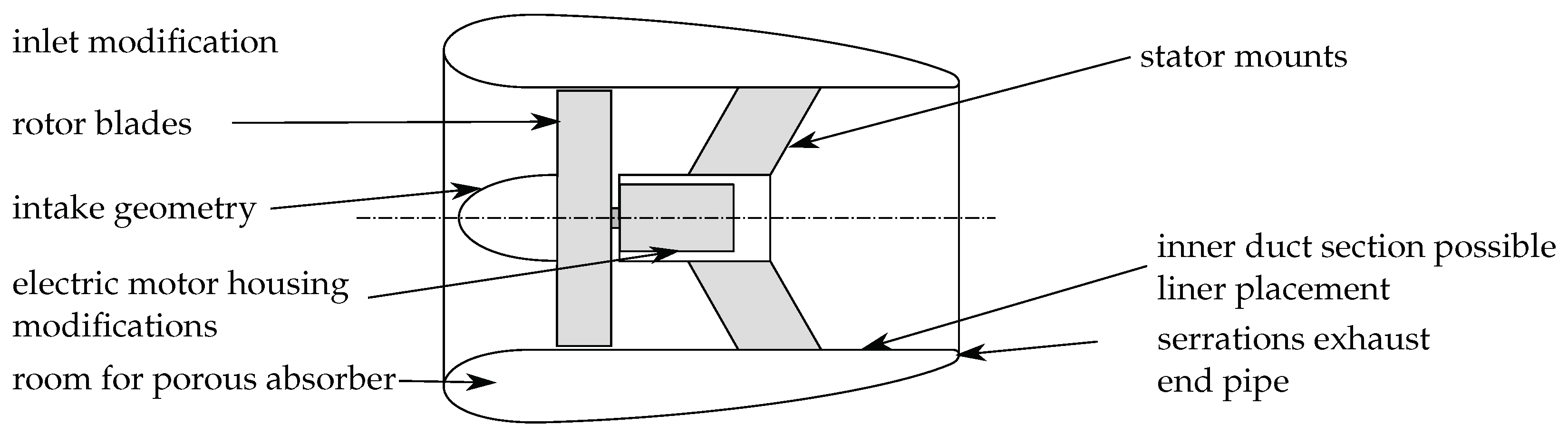

Figure 3 shows possible locations to apply noise mitigation measures.

In the current design, the stator is placed downstream, as so-called outlet guide vanes, to significantly lower sound pressure levels (SPL) for the resulting rotor-stator interaction compared to upstream stator installations [

38]. The guide vanes are swept to decrease the noise emissions further. No special care was taken in the current configuration by selecting the rotor blade number and the guide vane number to cut off lower harmonic duct modes. Also, no modifications of the leading and trailing edge serrations [

39] or forward and backward skew [

40] were applied to the fan blades.

A possible noise amplification effect that is important to be investigated is that the manufactured EDF unit number of electric motor pole pairs equals the rotor blades . As a consequence, the excitation frequency of the electromagnetic forces matches the second harmonic of the BPF of the EDF unit. Changing this attribute can reduce the emitted sound regarding the overall sound level.

Finally, the electric motor controller cooling fins reach into the air stream inside the duct to achieve the required cooling. This placement impacts the overall aerodynamic sound generation. Furthermore, the structural sound of the switching currents may be transmitted inside the duct and possibly amplified. In the case of occurring switching noise, advanced switching routines can reduce the noise emissions drastically.

2.3. Design constraints for noise mitigation measures

Regarding this study, being executed in early prototyping, the primary and fundamental principles behind the noise generation are essential to gain a first insight into the aeroacoustic properties of the device [

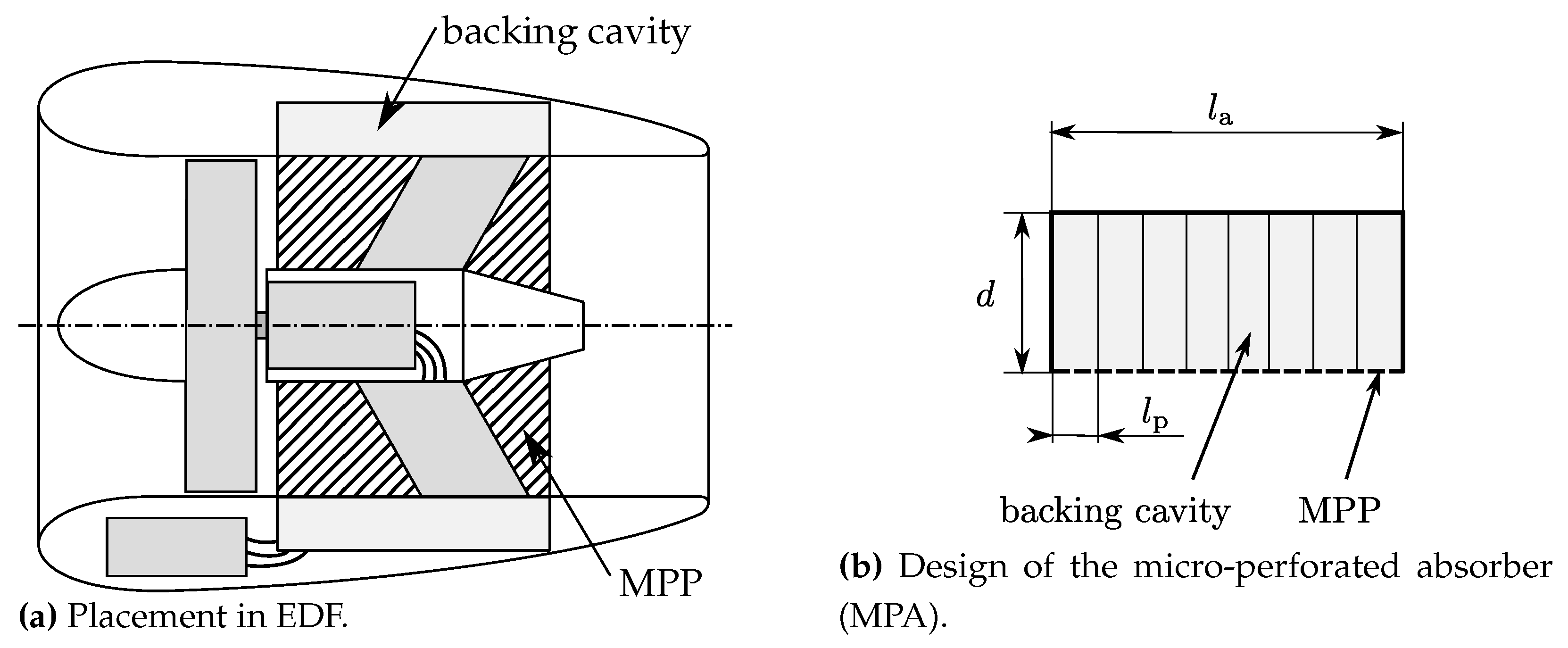

15]. In reality, the design space of possible noise mitigation structures was limited by the current design of the EDF unit. No alternation of the housing and dimensions of the duct with a length of 250 mm, a duct diameter of 201.3 mm, the number of stator blades and the number of rotor blades, and the rotor diameter of 200 mm was in the scope of possibilities. Furthermore, the influence of a possible treatment on the aerodynamic characteristics of the fan and the EDF unit must be kept to a minimum. Additionally, the position of the motor controller electronics must stay at the same place due to the cooling requirements. These constraints fundamentally reduced the design space for noise mitigation strategies. After an initial measurement campaign, an acoustic liner treatment to partly cover the inner duct side was applied for the first reduction measure for the acoustic emissions (see

Figure 4). We selected to use micro-perforated (MASH of the company

fteu) liners with back volume, among other treatments, since minor changes in the aerodynamic properties are expected and currently unused volume in the duct can provide value.

The micro-perforated face sheet of the liner has a perforation rate

and thickness

mm. The perforations are slit-shaped. The absorber liner uses a backing cavity depth of

mm, which already pushed the geometric limits of the fan unit’s aerodynamic shell. The extent is also limited towards the inlet lip due to the avoidance of absorbers in the rotor plane, which would reduce the fan’s aerodynamic efficiency [

41]. The computed absorption maximum [

42] in the lower frequency range at 1800 Hz is close to the fan unit’s BPF at OP4 (see

Table 3), which represents the maximum tonal SPL for the examined operating range. The highest broadband SPL will also be partially absorbed by the absorber designed, as the second maximum of the absorption coefficient occurs at 5500 Hz. As shown in

Figure 4, the backing cavity of the absorber linings designed is partitioned to increase the absorption of random incident sound pressure waves. A partitioning resulted in the rectangular segment cross-sections, which were dimensioned according to former research insights [

43]. The absorber linings were placed in the stators guide vane section duct to not disturb the aerodynamics at the rotor tip section. This placement resulted in a relative absorption area of 16.6% of the total inner duct area.

3. Measurement campaign for early prototyping

One of the most important acoustic indicators to determine a machine’s acoustic emissions is the acoustic power level, which can be quantified by the enveloping surface method (ESM) to determine the sound power level of an acoustic source using an anechoic measuring room. The international standard

DIN EN ISO 3745 contains all the necessary information and procedures to conduct the measurements needed for accuracy class 1. As the claims to the anechoic room have to be proven according to

ISO 26101 and are very restrictive, measurements for accuracy class 1 cannot be taken without unreasonable effort and are contradictory to the motivation of the study in providing an affordable experimental setup. However, a measuring method with the lower accuracy class 2 is described in the international standard

DIN EN ISO 3744 and can be conducted with fewer resources. The criteria of 15dB difference between external noise and the measured sound is met at all narrowband measurements [

5].

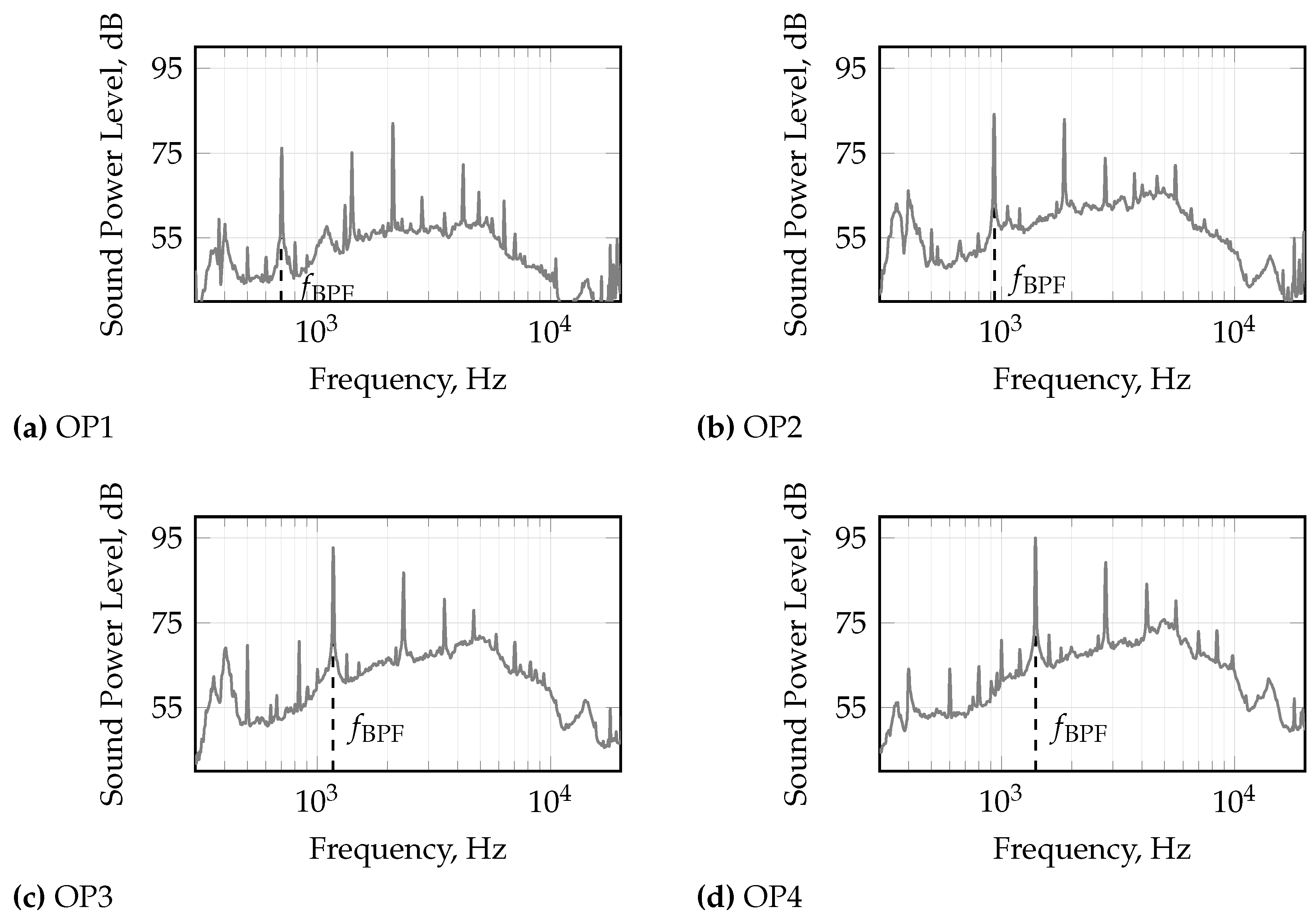

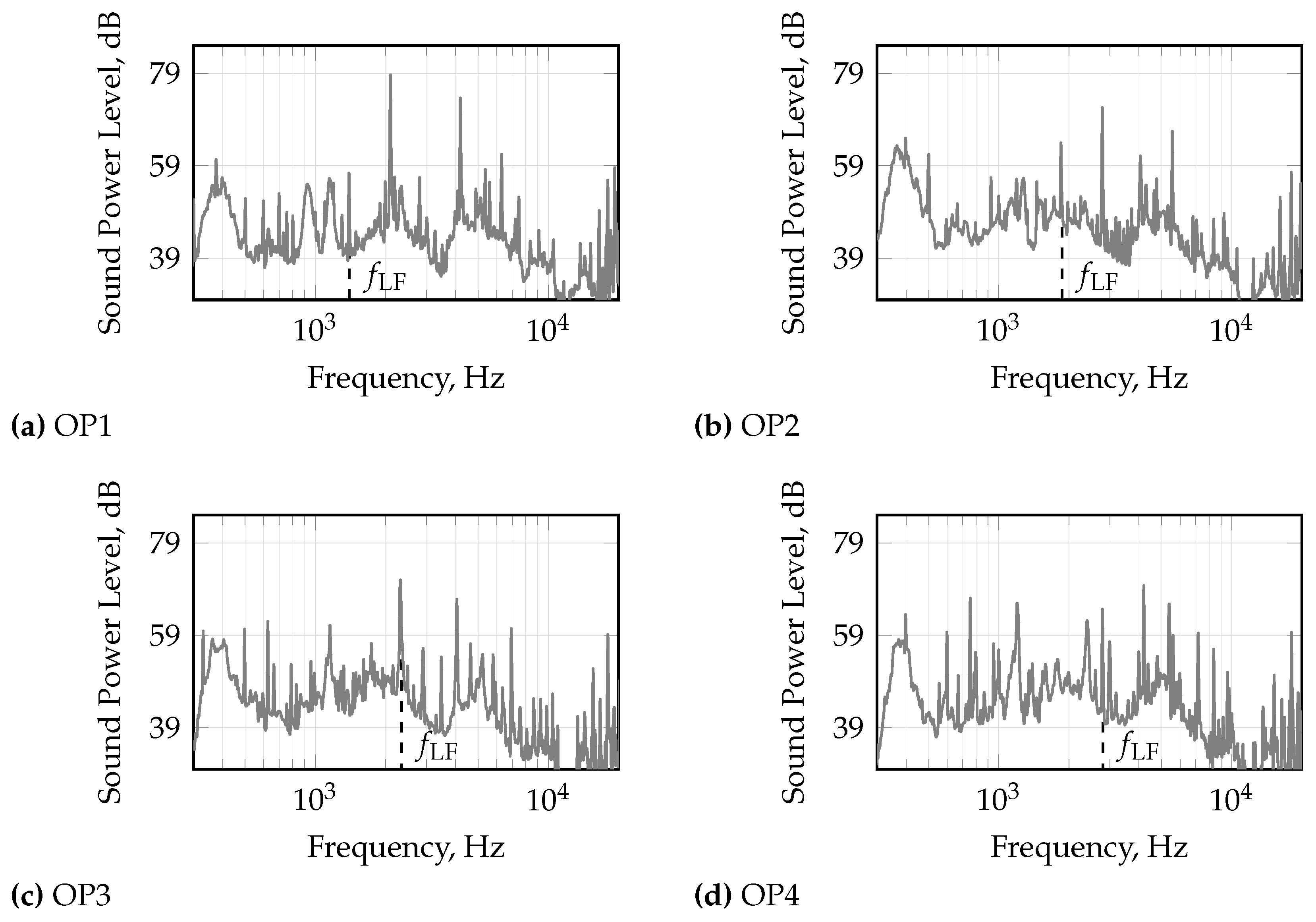

3.1. Operation condition

The EDF units’ acoustic emissions are studied at four operating points, defined in

Table 3.

The subsonic behavior of the observed EDF unit is evident when looking at the rotor blades’ tip Mach number

. The temperature was about 26°C, the relative humidity 30%, and the atmospheric pressure was 98 kPa during the calibration and measurement. The microphones were calibrated according to the procedure described in [

44]. The EDF is mounted at a fixed location inside a measurement room.

3.2. Measurement facility

Sound power measurements based on

DIN EN ISO 3744:2011-02 were carried out in a fully equipped low-reflection room with a reflecting floor [

45].

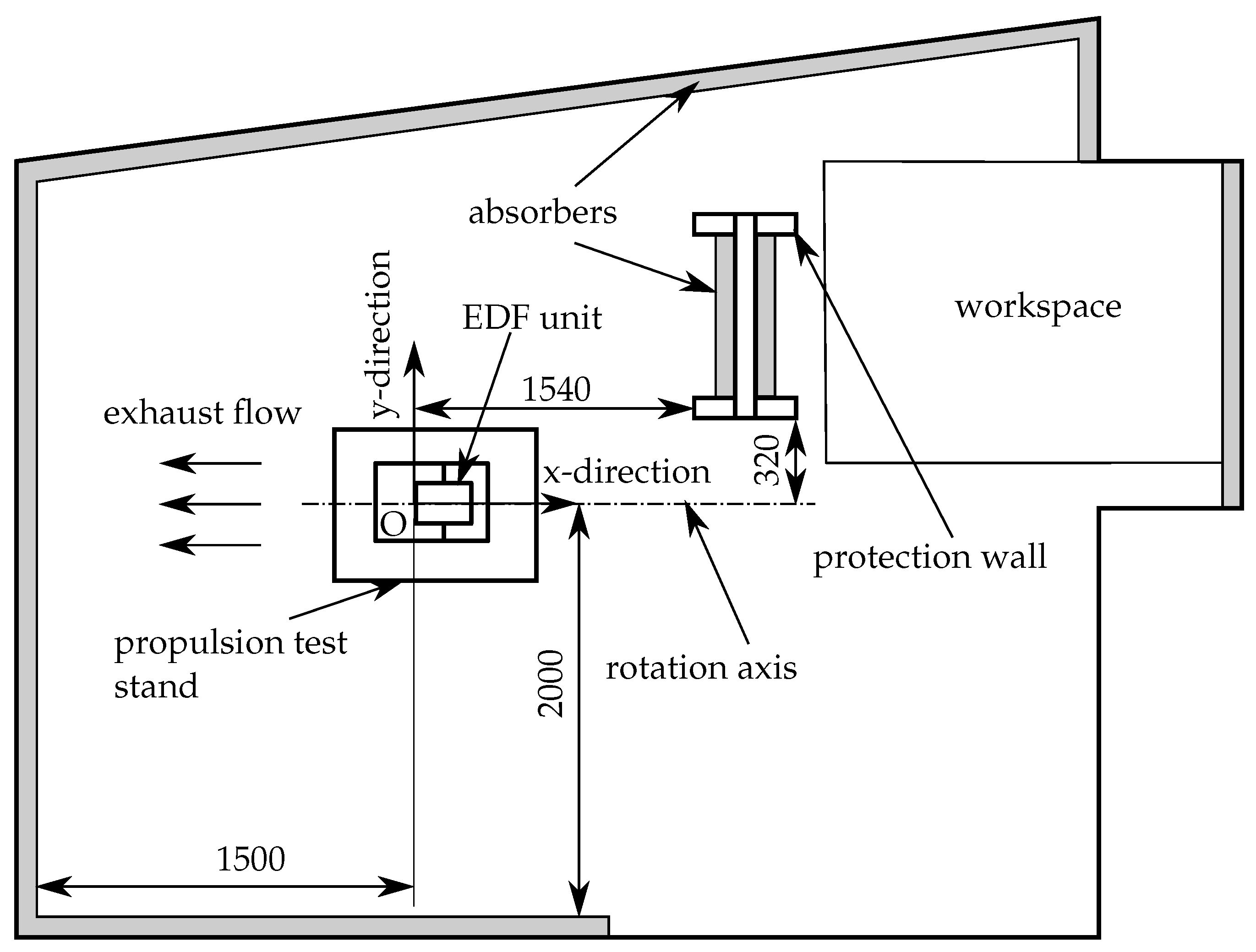

Figure 5.

Setup and spatial dimensions of the experimental facility and positioning of the EDF unit on a propulsion test bench inside the measuring room. Adapted from [

5].

Figure 5.

Setup and spatial dimensions of the experimental facility and positioning of the EDF unit on a propulsion test bench inside the measuring room. Adapted from [

5].

A porous absorber (Baso Plan 100) is attached to approximately 50% of the room’s walls and ceiling to produce relatively cheap, easy-to-install, and effective absorption characteristics. Mobile protection walls were needed to be put up to ensure safety for the people present in the measuring room during the EDF unit’s operation. The acoustic properties of the facility limit the reliable experiments to frequencies above 300 [

45]. The room was characterized by reverberation time measurements in [

5,

44].

Ten microphones envelop the EDF unit by spanning a half-sphere surface around it [

45] (see

Figure 6).

The EDF unit was mounted on a thrust measurement test rig.

Figure 5 shows the EDF unit positioned inside the middle of the room to minimize the effects of flow interaction with the surrounding walls. In the current setup, no free flow conditions could be realized. The exhaust flow hits the rear wall, covered by acoustic absorber material, at a distance of 1.5 m. No avoiding measures to reduce the impinging jet on the room walls were used during the experiments. The measurement campaign produced reliable results since the goal was to understand the noise mechanisms and a possible mitigation strategy by comparing two manufactured variants.

The measurement concept followed the data processing presented in [

44]. Pre-polarised back-electret condenser microphones (Sennheiser KE 4-211-2) with windscreens recorded the acoustic signal. According to the manufacturer, the capsule has high long-term stability and a constant sensitivity in the frequency range from 20 to 20000 Hz (within a deviation 3 dB). The signals emitted by the microphone capsules pass through the microphone-integrated preamplifier to the main amplifier (in-house developed amplifier, so-called FlexAmplifier), in which the signals can be amplified by a factor of 55 to 430, depending on the setting. The signals are amplified to achieve the recommended output level of the A/D converter (RM M32 AD). The digitized data is transferred to the MADIface (MADIface XT) via a fiber optic cable (LWL), where the signal is converted into the MADI format. The MADIface is connected to the computer via USB. Finally, the data is read and processed in

MATLAB using the ASIO driver.

The measurements were sampled at a frequency of

. Each operating point was measured for 20

. The data is further processed by the Matlab-based AcouCam-Software [

44]. The measurement results were corrected with the measuring room’s reverberation characteristics and the individual microphones’ frequency-dependent sensitivities based on the data generated in [

44]. Finally, the A-weighted sound power level spatially averaged across all microphone positions

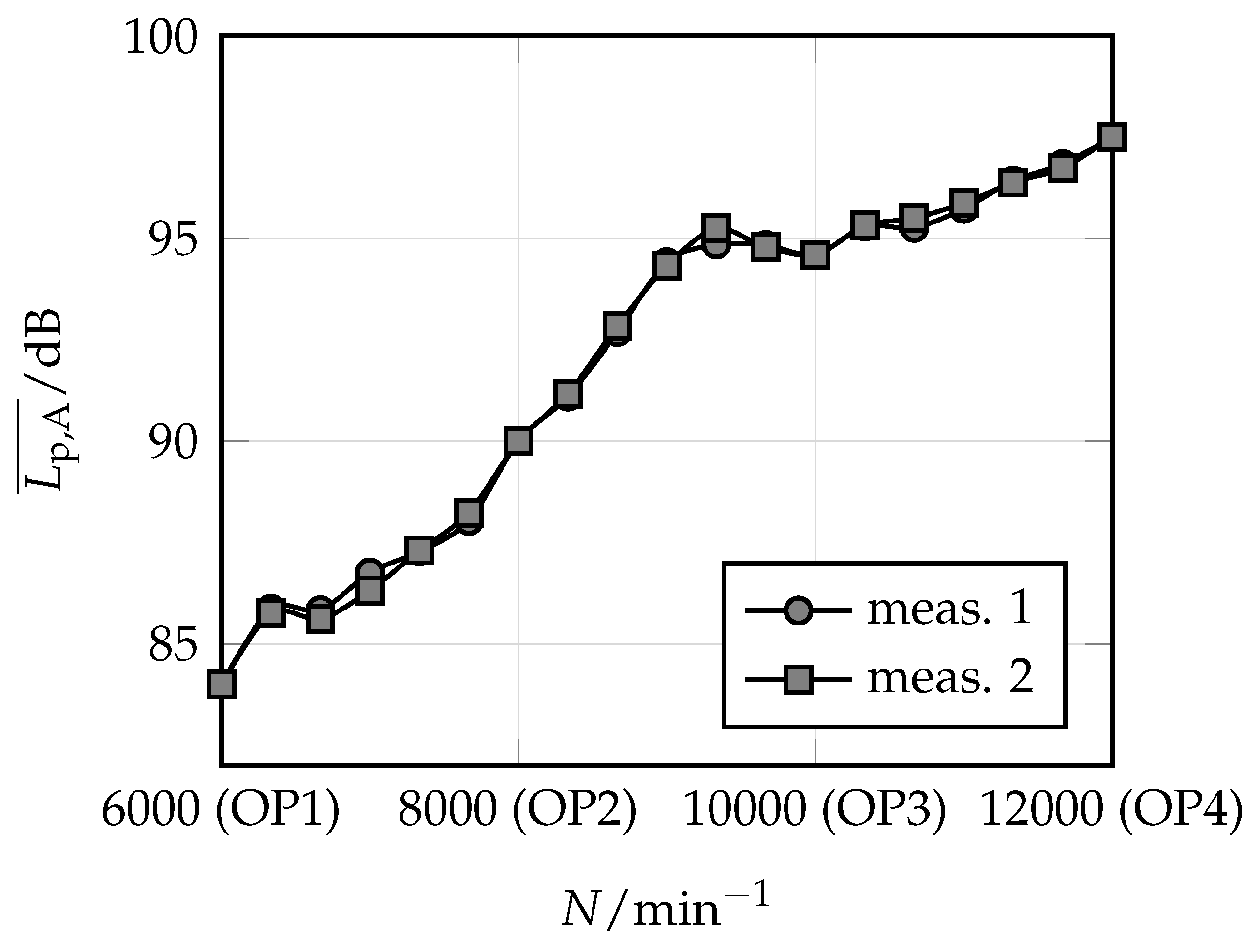

is computed.

3.3. Limitations and improvements

As already discussed above, this section additionally highlights possible limitations of the study in order to generate awareness and that the purpose of this study was not to tailor the measurements towards the highest accuracy but to stay within a minimal budget and to compare different configurations of the same EDF unit with an identical setup. The reproducibility was therefore tested during the experimental investigations and found to be the case within 1 dB(A) range.

A major improvement to the current study would be to perform countermeasures to the impinging jet on the room’s walls and avoid large recirculations. Mitigating this was not possible in the available measurement facilities. The microphone positions were selected such that the influence of the airflow was kept to a minimum. Moreover, recirculations can affect the acoustic measurement and should be avoided using a relatively large room [

15].

The authors are aware of the influence of ingested external disturbances, as they could strongly affect acoustic behavior. The problems first arose when comparing the acoustic data of jet engines gathered through ground tests and in-flight measurements with different inflow conditions. When ground vortices, atmospheric turbulences, or other flow disturbances are ingested, they are experienced by the rotor for several revolutions due to the elongation of the flow medium in a streamlined direction. In conclusion, broadband noise and tonal noise components result from ingested external disturbances interacting with the rotor [

46,

47]. In the ground testing stage of the study, mitigating this effect is subject to more advanced testing.

Furthermore, the directivity of the EDF unit’s acoustic emissions was considered unidirectional. Several publications mentioned that the radiation is not unidirectional and varies with frequency (e.g., see in [

15,

25]). Since the setup’s directivity was not clear upfront in this very early prototyping study, the benefit of knowing the directivity of a possible setup not being put into further production may be too early in the design process. We recommend studying the directivity and adapting the measurement positions for a second follow-up study of an EDF unit passing this presented preliminary study.

Finally, the measurement facility has no option to emulate a dismounted fan configuration’s load onto the electric motor during measurements without a fan. Emulating the reactions from the fan would be necessary for a very reliable experimental study of the electric motor and the electronics. Again, within this limited budget and the facilities available, this was not possible in the scope of the work, and it was decided to drive the electric motor without fan loading to gain at least some information about the electric drive system. For following up on this topic, it is recommended to emulate the fan loading by a second electric motor connected to the propeller shaft.

5. Conclusion and Suggestions

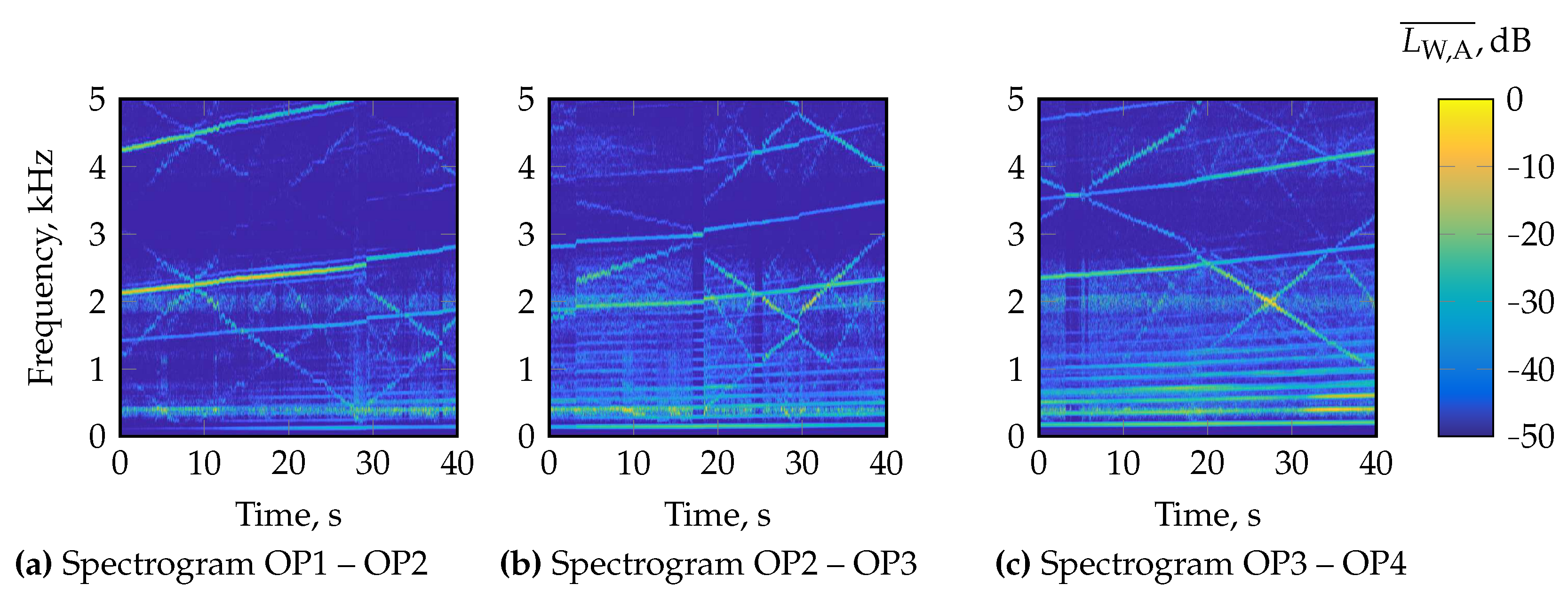

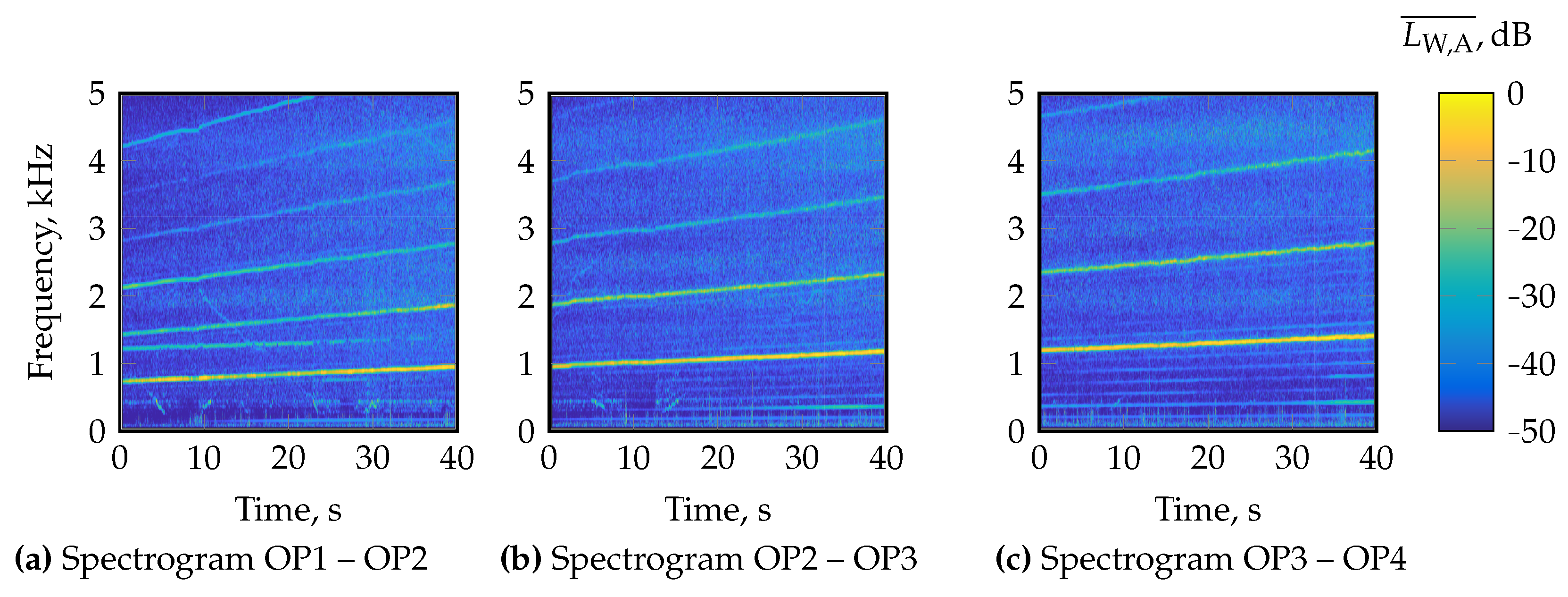

In this acoustic measurement campaign for early prototyping, we showed how to achieve reliable results within a limited budget and timeframe. The study of the EDF unit’s noise emissions in the investigated operating range has shown expected tonal components at the BPF and its harmonics. Aerodynamic reasons caused the highest measured sound power levels. An unexpected excitation and duct mode frequency match caused specific humps on the overall sound power level measurements.

In contrast, minor sound power level characteristics in the spectrogram could be attributed to the electric powertrain and its components. The fundamental frequency of the ECM’s electromagnetic forces caused tonal noise emissions of the electric powertrain with a dismounted axial fan. X-shaped dependence on the rotational speed of tonal noise emissions in spectrograms was found for transient measurements of the electric powertrain. The behavior was assigned to the switching currents of the electric powertrain. Regarding the measurement results of the electric powertrain in contrast to the entire EDF unit, a study using an artificial loading to account for the original fan load would be interesting to make the results comparable. Furthermore, the next measurement campaign is motivated to adjust the test rig to analyze the electric powertrain’s effects. In the future, a detailed analysis of the electric powertrain would also involve measurement of the individual single motor phases and currents supplied to the motor. These correlations could be drawn to understand the powertrains’ noise emissions better.

Given the EDF’s acoustic characteristics findings, perforate absorber linings were laid out to effectively absorb the sound pressure waves with the highest amplitude, which the BPF represents. After designing and manufacturing the absorber linings, the modified EDF was measured again and a resulting reduction in the SPL was noticed. The A-weighted OSPL was reduced by 2-4 dB across the EDF operating range, whereas the dominant BPF and the harmonics were attenuated by up to 10 dB. Although discussed limitations to the affordable measurement campaign apply, gaining first insight in early prototyping is valuable and can be combined with more detailed computational or experimental studies. The value of the method was proven by identifying the EDF’s noise characteristics of an improved design version and lowering the overall noise signature by several dB across a wide operating range.