1. Introduction

Additive manufacturing (AM) technologies, laser powder bed fusion (LPBF) in particular, are of extraordinary interest for the aerospace industry. Advantages of these technologies include a large increase in geometrical freedom and potential savings of material and overall production cost [

1]. They are especially useful when looking into load bearing applications, however, they require a deep understanding of mechanical properties and their influencing factors. In order to understand the effect of as-built LPBF surface quality on cyclic loading, it is important to look into specimens with different surfaces but comparable bulk properties.

Considering the correlation of surface texture and fatigue for metal additive parts, mainly studies on different surface states obtained from post-processing or from variation of build orientation are found in literature [

2,

3,

4], with the latter resulting in the assessment of a combined bulk and surface effect.

Thus, this work aims at creating these specimens and confirming the comparability of bulk quality by density measurements and tensile testing, as well as the difference of as-built surface quality, described by areal arithmetic mean profile height Sa and core height from the material ratio curve Sk.

2. Materials and Methods

2.1. Manufacturing

The evaluated samples were manufactured in an LPBF process on a Trumpf TruePrint 1000 from AlSi7Mg0.6 aluminium alloy powder. Specifications of geometries and manufacturing settings are given subsequently.

Figure 1.

Top view: sample orientation w.r.t. coater (top left), example of build job layout (bottom left), individual tested sample (middle) and finished build job on platform (right).

Figure 1.

Top view: sample orientation w.r.t. coater (top left), example of build job layout (bottom left), individual tested sample (middle) and finished build job on platform (right).

Figure 2.

Exposure strategy for bulk and contour scan: Bulk scan direction is rotated by (schematic representation, not true to scale) after each powder layer application.

Figure 2.

Exposure strategy for bulk and contour scan: Bulk scan direction is rotated by (schematic representation, not true to scale) after each powder layer application.

2.1.1. Sample Geometry

There were two kinds of samples used in this work: Cuboids (height 10 mm, width 10 mm, thickness 5 mm) and fatigue specimens according to ASTM 466-15 [

5] (height 80 mm, smallest cross section 6 mm, thickness 3mm). The latter type is shown in

Figure 1.

2.1.2. Manufacturing Parameters

Powder layers were exposed to the laser by a pattern of parallel stripes in the bulk, changing direction by after each layer, and a continous scan of the geometric contour. Sky writing was applied to ensure the laser source was moving at the chosen speed prior to exposure.

The samples were placed on the build platform at a

angle w.r.t. coater and gas flow, as shown in

Figure 1. Bulk scan parameters were identical for all samples, as specified in

Table 1 and originate from a previous density optimisation study.

The contour scan parameters were varied, intending to achieve a variation of surface properties. Maintaining layer thickness, hatch distance and laser power, the scan speed was modified between 300 mm/s and 1800 mm/s, paired with the settings with and without additional pre-sinter at 50% laser power, resulting in a total of ten manufacturing parameter combinations.

The samples with identical parameter combinations were named by a designated letter according to

Table 3 with consecutive numbering, e.g.: A1 → Contour parameter set A (scan speed 300 mm/s, with pre-sinter), mechanical testing sample No. 1.

2.2. Characterisation and Testing

2.2.1. Density

The first step toward the assessment of bulk quality was the measurement of part density. For this purpose, the cuboid samples (3 samples for each of the 10 different manufacturing parameter sets) were weighed in air and ethanol and the density was calculated according to Archimedes ([

6]). Each measurement was performed three times and the final density result reported per sample was the respective mean value.

2.2.2. Surface Texture

The surfaces were measured using a Keyence VR3200 fringe projection system. The micro camera setting at a magnification of 40x was applied, resulting in a lateral resolution of 7.4 µm. For the cuboid samples, selected ISO 25178 areal parameters were evaluated for a square area with an 8 mm length, measured perpendicular to the build direction on the side facing away from the coater, as indicated in

Figure 1. A linear level operation, an S-filter of 20 µm and an L-filter of 0.25 mm were applied.

The chosen areal surface texture parameters to assess surface quality are Sa, the arithmetic mean height, and Sk, the core height from the material ratio curve. Sa was selected due to it’s common use in research and industry [

7]. Sk is used because it gives a more distinctive information on the surface texture (for more information, please refer to ([

8], p.56).

2.2.3. Tensile Testing

The tensile strength was tested using a ZWICK/Z050 in accordance with ASTM E8M [

9]. A preloading of 35 N and a speed setting of 0.48 mm/min were selected.

The required cross sectional areas of the tested specimens were obtained from a digital caliper.

2.3. Workflow Summary

Figure 3 gives a summary of this work’s process steps.

At the first manufacturing stage, 30 cuboid samples were made. All of these were made with identical bulk scan parameters, paired with 10 variations of contour scan parameters, resulting in 3 cuboid samples per parameter set combination.

Table 3.

Naming of sample groups based on contour scan variation.

Table 3.

Naming of sample groups based on contour scan variation.

| Scan Speed in mm/s |

300 |

600 |

900 |

1200 |

1800 |

| Pre-sinter |

A |

C |

E |

G |

I |

| No Pre-sinter |

B |

D |

F |

H |

J |

Afterwards, the cuboids’ densities and surfaces were measured in order to get a first assessment of bulk quality on one hand and rating based on the surface quality on the other hand. Based on these evaluations, parameter sets were chosen to produce samples for mechanical testing. Details on the selection process can be found in

Section 3.2.

For seven manufacturing parameter sets chosen based on the cuboid assessment, six samples each were made for mechanical testing.

As a final part of this work, tensile testing according ASTM E8M [

9] was performed.

In subsequent studies, fatigue performance was investigated for a selection of the manufacturing parameter sets. A part of these studies is already published [

10].

3. Results and Discussion

3.1. Density

Density was measured in order to get a first impression of the bulk quality and confirm that it is not influenced significantly by the variation of contour scan parameters.

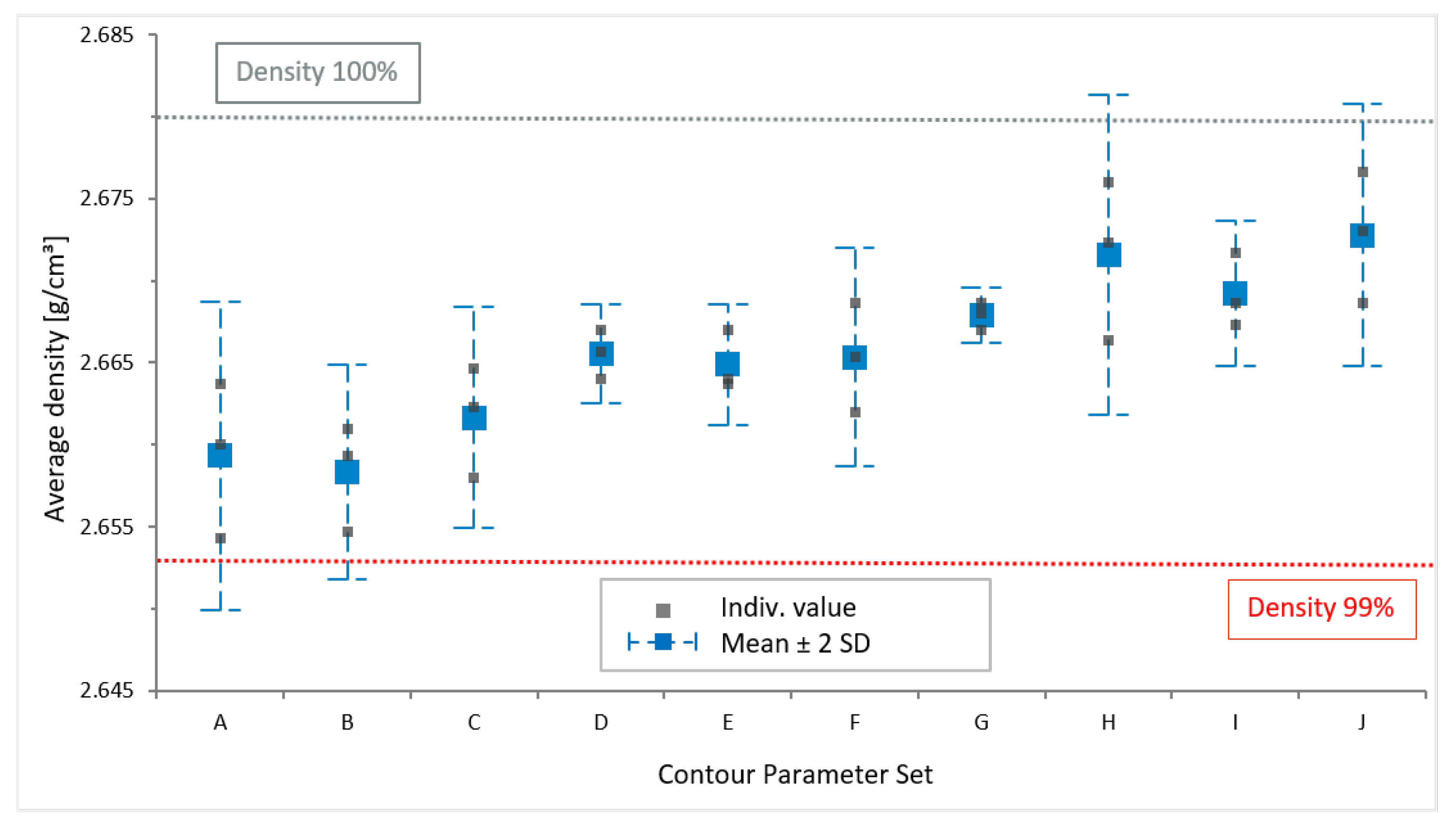

The data shown in

Figure 4 confirm a density of over 99% for all of the measured samples with a reference density of 2.68 g/cm³ (theoretical maximum). Taking a 95% confidence interval into account, data sets A and B are below that 99% value. Data set A has a lower boundary value at 98.84%, which is also the lowest overall value.

Considering all the data sets, the only statistically distinctive sets are B and G. However, they cannot be distinct from all remaining data sets.

It can be concluded from the performed Archimedes density measurements, that there is no statistically significant influence of the variation of contour scan parameters on the bulk quality.

3.2. Surface texture

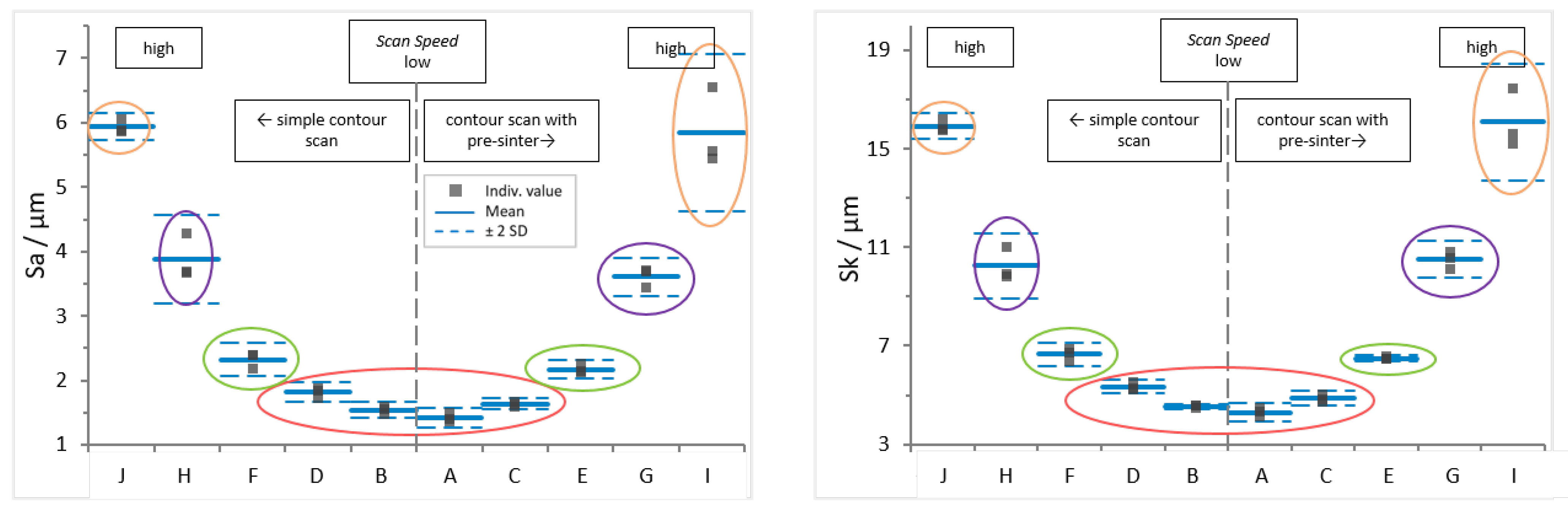

The purpose of this section is to confirm that the created samples with different contour scan parameters show a variation and are distinguishable by means of the selected areal surface texture parameters Sa and Sk.

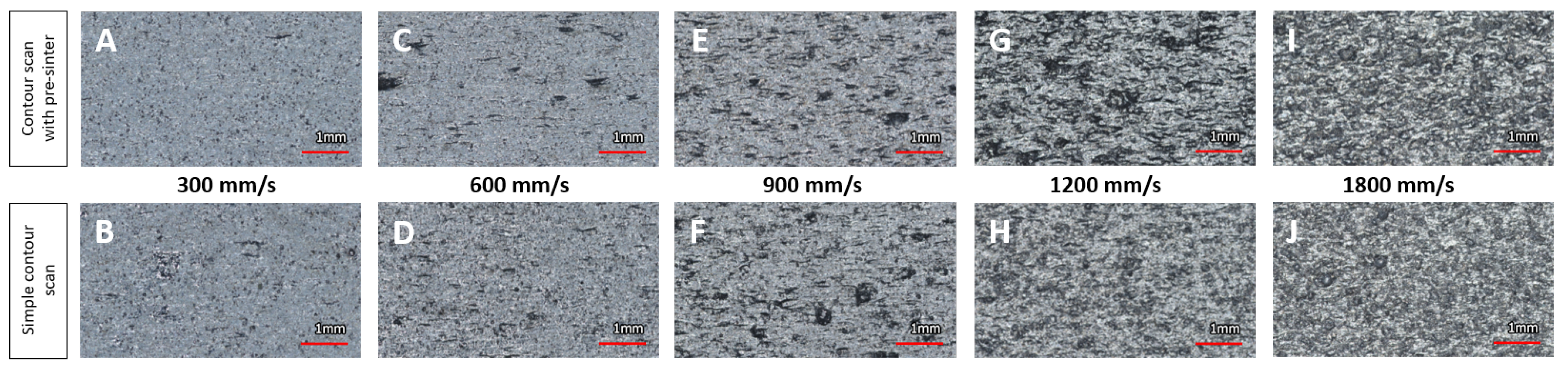

From visual inspection of the microscopic images in

Figure 5 it can be observed that at first sight, there was a variety of as-built surface conditions achieved. The A and B conditions look mostly smooth with small dots and few linear defects (length below 1 mm, oriented parallel to the layers). Increasing the contour scan speed, surfaces appear to have more and bulkier linear defects (C and D). The D image also seems a little blurry, which is a sign of increasing height variation on the surface. This effect becomes more clear when increasing scan speed even further (E and F). On surface F there are a few circular shadows present, which may be spatter or local accumulations of powder particles. Surfaces G to J are hardly distinguishable visually. All show circular shadows of different sizes, which are mostly particle agglomerations and accumulations, and an underlying irregular structure. G shows some darker areas, which may be an issue of different lighting conditions or height differences on the surface itself.

Figure 6 shows Sa (left) and Sk (right) values. The surface conditions are sorted by contour scan parameters. To the right, results for sample sets exposed to pre-sinter are presented, to the left of each graph, results for simple contour scans are shown. The scan speed increases from the middle to the edge. This representation is chosen to view the effect of both scan settings separately while giving a direct comparison, as this setting presumably influences the mechanical performance under cyclic loading due to its impact on near surface defects.

The graphs give the mean (blue line) ± two standard deviations (SD, dashed blue line). Colours mark the surface conditions which can be distinct by the selected parameters at 95% confidence level (±2SD). The first group (red), includes surface conditions A to D, conditions E and F form the second group (green), conditions G and H (purple) are the third group, and finally, the fourth group (orange) comprises conditions I and J.

Especially looking at the Sk graph, it can be seen that the 2SD lines of D and A/B not overlap, while all three conditions have overlap with C. Conditions E and F show comparable mean values for Sa and Sk and it was decided to keep set E, as it was the original starting point of the variation, and discard condition F.

Parameter set J is chosen as the set with the highest mean value for Sa. From the low Sa / Sk group (red), A was chosen as set with the lowest mean values, C and D were selected to compare the possible impact of pre-sinter with otherwise identical process settings (see

Table 3). G and H will be considered for the same reason as conditions with higher Sa / Sk.

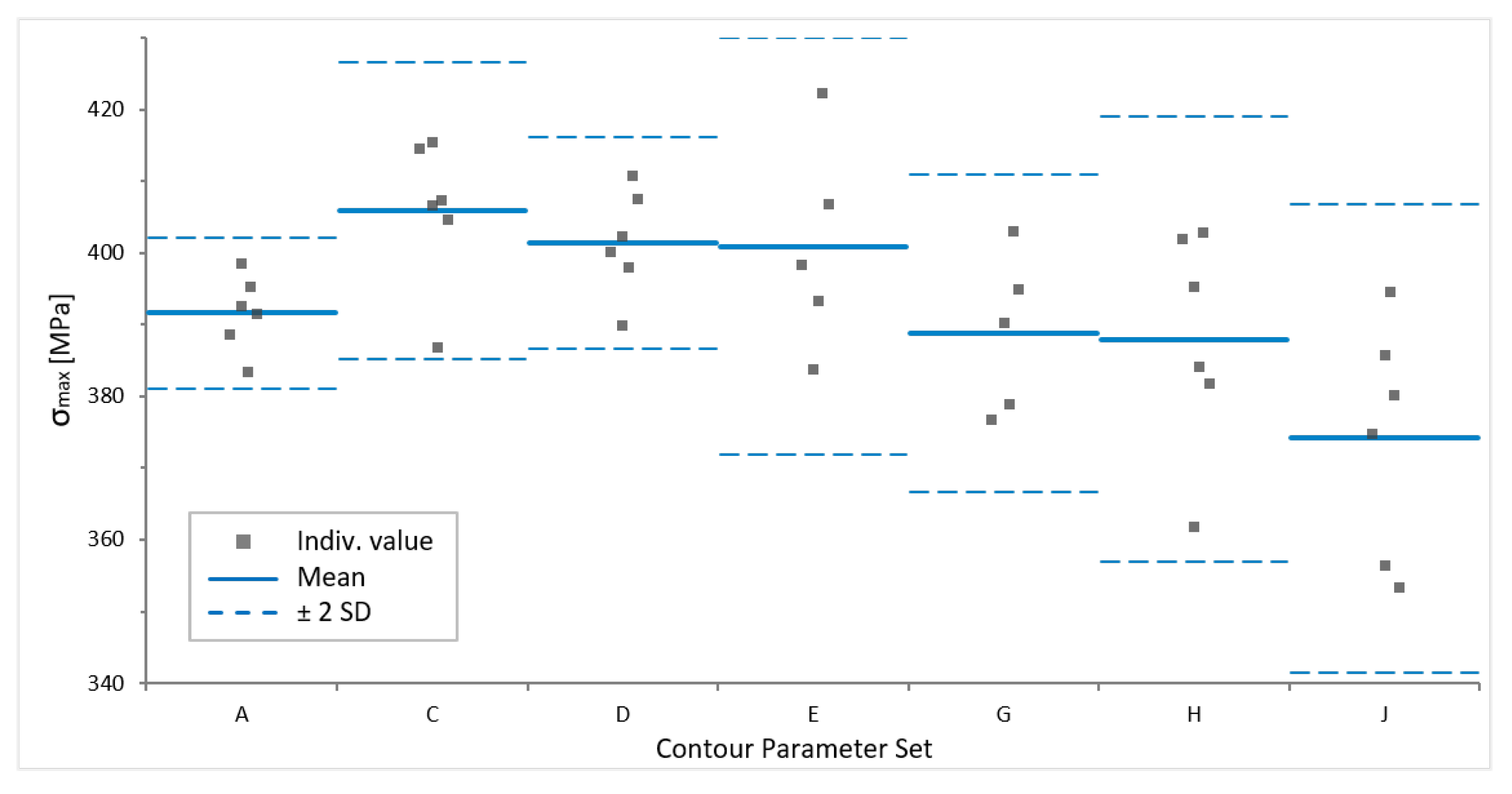

3.3. Tensile testing

Figure 7 shows the tensile testing results for longitudinal specimens manufactured using the contour parameters sets selected according to the previous surface texture characterisation (A, C, D, E, G, H, J). Density values for the mechanical testing samples, alongside with all numerical data presented in

Figure 7, are included in

Appendix A.

Similar to the results from density determination, there is no statistically significant difference in ultimate tensile strength. The mean values of the individual surface conditions are between 374 and 406 N/mm², which is equal to a variation of less than 8%.

For context, reported values in literature for as-built of the same material and build direction, vary between 300 N/mm² [

11] and over 400 N/mm² [

12,

13,

14]. For the cast alloy with T6 heat treatment, typically values of ultimate tensile strength between 320 and 360 N/mm² are reported [

14]. Hence, the tested samples perform equally well as or better than other as-built LPBF AlSi7Mg0.6 specimens and mostly exceed the strength of the cast material.

From the graph it can be observed, that the standard deviation seems to be increasing for rougher surface texture. A possible explanation is its influence on the caliper cross section measurement. Since the ultimate tensile strength does depend on the cross sectional area. The caliper may be locked by protruding features, leading to a variation of measured cross section.

From the tensile testing results, in combination with those from density and surface texture characterisation, it can be concluded that creating samples with comparable bulk quality and different surfaces by means of variation of contour scan parameters was achieved.

4. Summary and Future Work

This work aimed at producing samples with identical bulk and different surface quality for future fatigue investigations. The variation of surface texture could be achieved by variation of contour scan speed and was assessed by optical fringe projection measurements. The comparable bulk quality was confirmed by means of Archimedes’ density and tensile testing.

The following conclusions can be derived from the previously presented work:

Contour parameter variation has a small influence on bulk quality (i.e., density and tensile strength) of tested samples

Rougher surfaces show the tendency for larger spread of ultimate tensile strength across the tested samples (possible caliper influence)

Manufactured samples are considered suitable for subsequent work on surface texture and fatigue [

10].

Ongoing work and partially published work based on this study includes investigations on fatigue and surface texture [

10,

15] and alternative surface texture parameters [

10,

16]. The latter comprises parameters derived from the material ratio curve as well as selected surface feature parameters, both defined in ISO 25178 [

17]. Furthermore, LPBF-specific surface features for a part of the samples presented in this work are evaluated using commercial software [

18].

In upcoming work, further investigations on surface texture, surface features and their influence on fatigue and corrosion will be addressed.

Author Contributions

Conceptualisation, T.B.; methodology, T.B., M.A. and H.B.; formal analysis, T.B.; investigation, T.B.; resources, M.A., H.B. and B.M.; data curation, T.B.; writing—original draft preparation, T.B.; writing—review and editing, M.A., H.B. and B.M.; visualisation, T.B.; funding acquisition, M.A., H.B. and B.M.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data is available from the authors upon request.

Acknowledgments

The authors thank Inga Meyenborg for manufacturing the samples and performing density measurements and Anette Schwingen for tensile testing.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AM |

Additive Manufacturing |

| LPBF |

Laser Powder Bed Fusion |

| SD |

Standard Deviation |

| Sa |

Arithmetic mean height [µm] |

| Sk |

Core height, derived from material ratio curve [µm] |

|

Ultimate tensile strength [N/mm²] |

Appendix A

Table A1.

Sa and Sk for cuboid samples, 10 surface conditions L-filter 0.25 mm, S-filter 20µm. With pre-sinter (right), without pre-sinter (left).

Table A1.

Sa and Sk for cuboid samples, 10 surface conditions L-filter 0.25 mm, S-filter 20µm. With pre-sinter (right), without pre-sinter (left).

Table A2.

Ultimate tensile strength and relative density of tensile samples. Reference density 2.68 g/cm³. 7 surface conditions.

Table A2.

Ultimate tensile strength and relative density of tensile samples. Reference density 2.68 g/cm³. 7 surface conditions.

| Parameter Set |

A |

C |

D |

E |

G |

H |

J |

| N |

6 |

6 |

6 |

6 |

6 |

5 |

5 |

|

/ MPa, Mean |

374.21 |

387.96 |

401.42 |

391.63 |

405.90 |

400.87 |

388.79 |

|

/ MPa, SD |

16.33 |

15.55 |

7.37 |

5.26 |

10.33 |

14.54 |

11.04 |

| Relative Density / %, Mean |

99.85 |

99.68 |

99.52 |

99.61 |

99.69 |

99.58 |

99.74 |

| Relative Density / %, SD |

0.17 |

0.15 |

0.18 |

0.11 |

0.17 |

0.28 |

0.20 |

References

- Uriondo, A.; Esperon-Miguez, M.; Perinpanayagam, S. The present and future of additive manufacturing in the aerospace sector: A review of important aspects. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering 2015, 229, 2132–2147. [Google Scholar] [CrossRef]

- Bagehorn, S.; Wehr, J.; Maier, H. Application of mechanical surface finishing processes for roughness reduction and fatigue improvement of additively manufactured Ti-6Al-4V parts. International Journal of Fatigue 2017, 102, 135–142. [Google Scholar] [CrossRef]

- Nicoletto, G.; Konečná, R.; Frkáň, M.; Riva, E. Surface roughness and directional fatigue behavior of as-built EBM and DMLS Ti6Al4V. International journal of fatigue 2018, 116, 140–148. [Google Scholar] [CrossRef]

- Zerbst, U.; Bruno, G.; Buffiere, J.Y.; Wegener, T.; Niendorf, T.; Wu, T.; Zhang, X.; Kashaev, N.; Meneghetti, G.; Hrabe, N.; others. Damage tolerant design of additively manufactured metallic components subjected to cyclic loading: State of the art and challenges. Progress in materials science 2021, 121, 100786. [Google Scholar] [CrossRef] [PubMed]

- ASTM E466-15: Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials, 2015. [CrossRef]

- Winkler, F. Taschenbuch Kunststoff-Prüftechnik. Von RP BROWN. Deutsche Ausgabe hg. von B. CARLOWITZ. München/Wien: Carl 217 Hanser Verlag 1984. XIV, 485 S., Plasteinband, DM 118,–; Vol. 36, Wiley Online Library, 1985; pp. 519–519.

- Townsend, A.; Senin, N.; Blunt, L.; Leach, R.; Taylor, J. Surface texture metrology for metal additive manufacturing: a review. Precision Engineering 2016, 46, 34–47. [Google Scholar] [CrossRef]

- Steinhilper, W.; Sauer, B.; Feldhusen, J. Konstruktionselemente des Maschinenbaus 1: Grundlagen der Berechnung und Gestaltung von Maschinenelementen; Springer-Verlag, 2008.

- ASTM E8M: Standard Test Methods for Tension Testing of Metallic Materials, 2016. [CrossRef]

- Buchenau, T.; Amkreutz, M.; Brüning, H. Surface texture and high cycle fatigue of as-built metal additive AlSi7Mg0. 6. Journal of Additive Manufacturing Technologies 2021, 1, 531–531. [Google Scholar] [CrossRef]

- Bassoli, E.; Denti, L.; Comin, A.; Sola, A.; Tognoli, E. Fatigue Behavior of As-Built L-PBF A357.0 Parts. Metals 2018, 8. [Google Scholar] [CrossRef]

- Mauduit, A.; Gransac, H.; Auguste, P.; Pillot, S. Study of AlSi7Mg0.6 Alloy by Selective Laser Melting: Mechanical Properties, Microstructure, Heat Treatment. Journal of Casting & Materials Engineering 2019, 3, 1. [Google Scholar] [CrossRef]

- Grande, A.; Cacace, S.; Demir, A.G.; Sala, G. Fracture and fatigue behaviour of AlSi7Mg0.6 produced by Selective Laser Melting: effects of thermal-treatments. In Proceedings of the 25th International Congress; Italian Association of Aeronautics and Astronautics: Rome, Italy, 2019. [Google Scholar]

- Rao, J.H.; Zhang, Y.; Fang, X.; Chen, Y.; Wu, X.; Davies, C.H. The origins for tensile properties of selective laser melted aluminium alloy A357. Additive Manufacturing 2017, 17, 113–122. [Google Scholar] [CrossRef]

- Buchenau, T.; Cersullo, N.; Mardaras, J.; Emile, P.; Lafue, V.; Brüning, H.; Amkreutz, M.; Hühne, C. Fatigue and surface texture of post-processed metal additive Ti-6Al-4V. In Proceedings of the 17th European Conference on Spacecraft Structures, Materials and Environmental Testing; CNES: Toulouse, France, 2023. [Google Scholar]

- Buchenau, T.; Brüning, H.; Amkreutz, M. Feature Parameters for Metal Additive Surface Texture Characterization. In Proceedings of the 40. Vortrags- und Diskussionstagung Werkstoffprüfung; DGM: Dresden, Germany, 2022. [Google Scholar]

- ISO 25178: Geometric Product Specifications (GPS) – Surface texture: areal – Part 2: Terms, definitions and surface texture parameters, 2022.

- Buchenau, T.; Thompson, A.; Brüning, H.; Amkreutz, M.; Mayer, B.; Piano, S. Surface features of as-built metal aditive AlSi7Mg0.6. In Proceedings of the 17th European Conference on Spacecraft Structures, Materials and Environmental Testing; CNES: Toulouse France, 2023. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).