Submitted:

10 January 2023

Posted:

12 January 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Pyrolysis processing and technology of biomass

- when the temperature of the wood rises from 145 to 165 °C, water is released which is not chemically bound to the organic matter of the wood (absorbed water),

- with a further increase in temperature from 245 to 265 °C, water chemically bound in the cellulose structure and the release of CO2, CO, and small amounts of condensing acetic acid and methanol vapors, also begin to emit small amounts of wood tar,

- above 265 to 275 °C, the process becomes exothermic, with the strong release of methanol, acetic acid, acetone, lighter hydrocarbons, wood tar, and small amounts of hydrogen; the amount of CO2 and CO released decreases,

- The biofuels production in the pyrolysis processes

2.1. Pyrolytic gas

2.2. Pyrolitic oil

2.3. Biochar

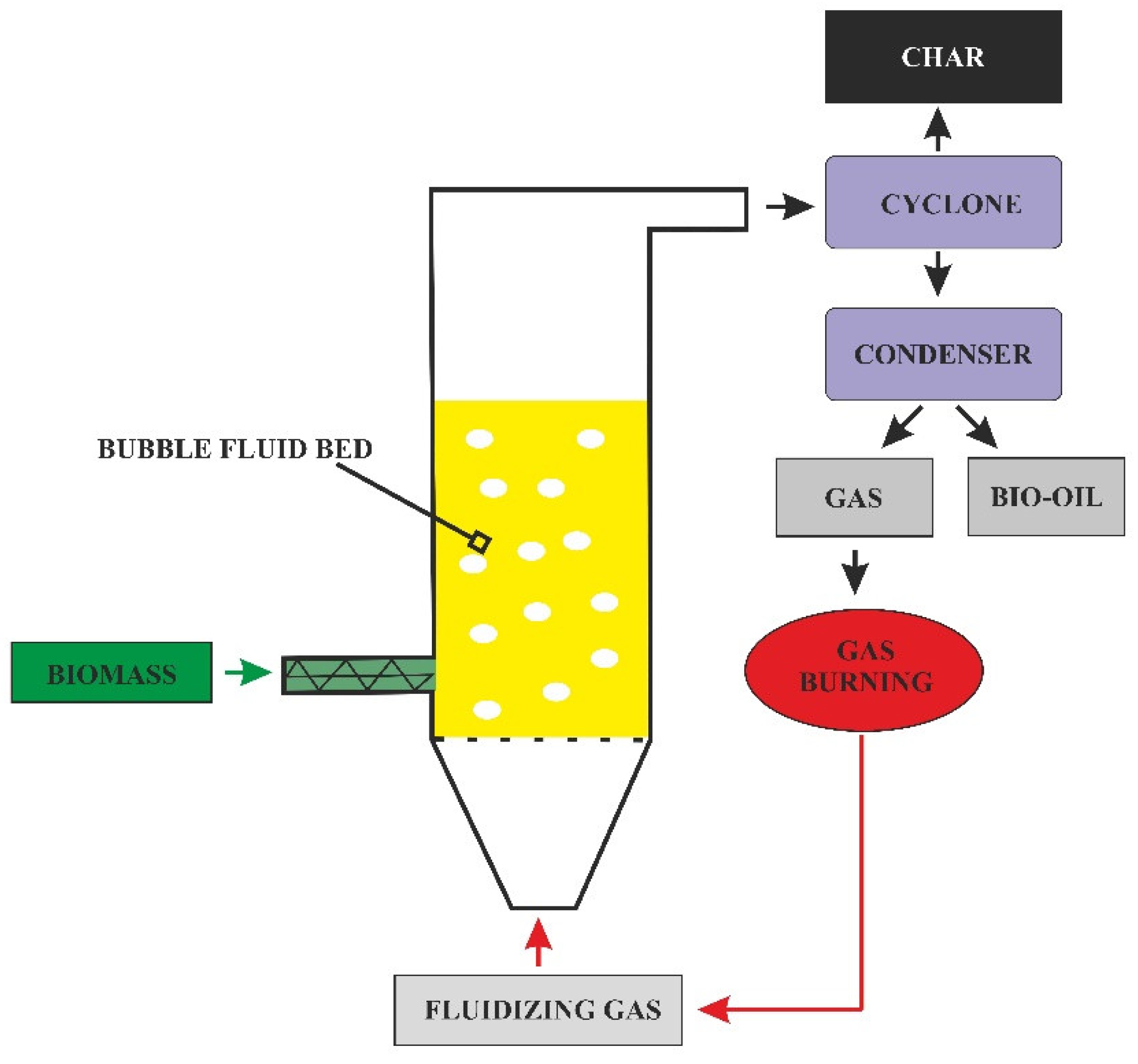

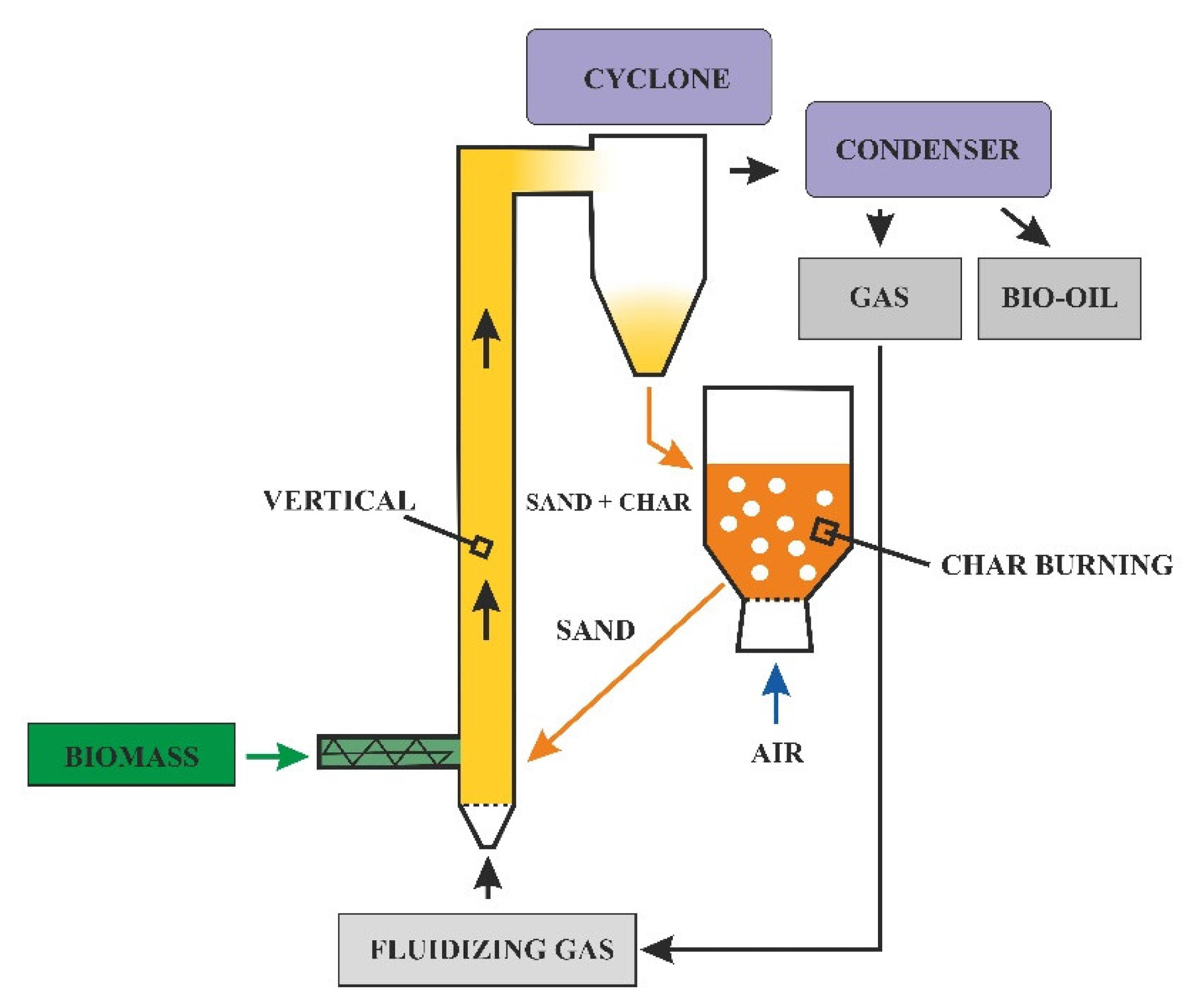

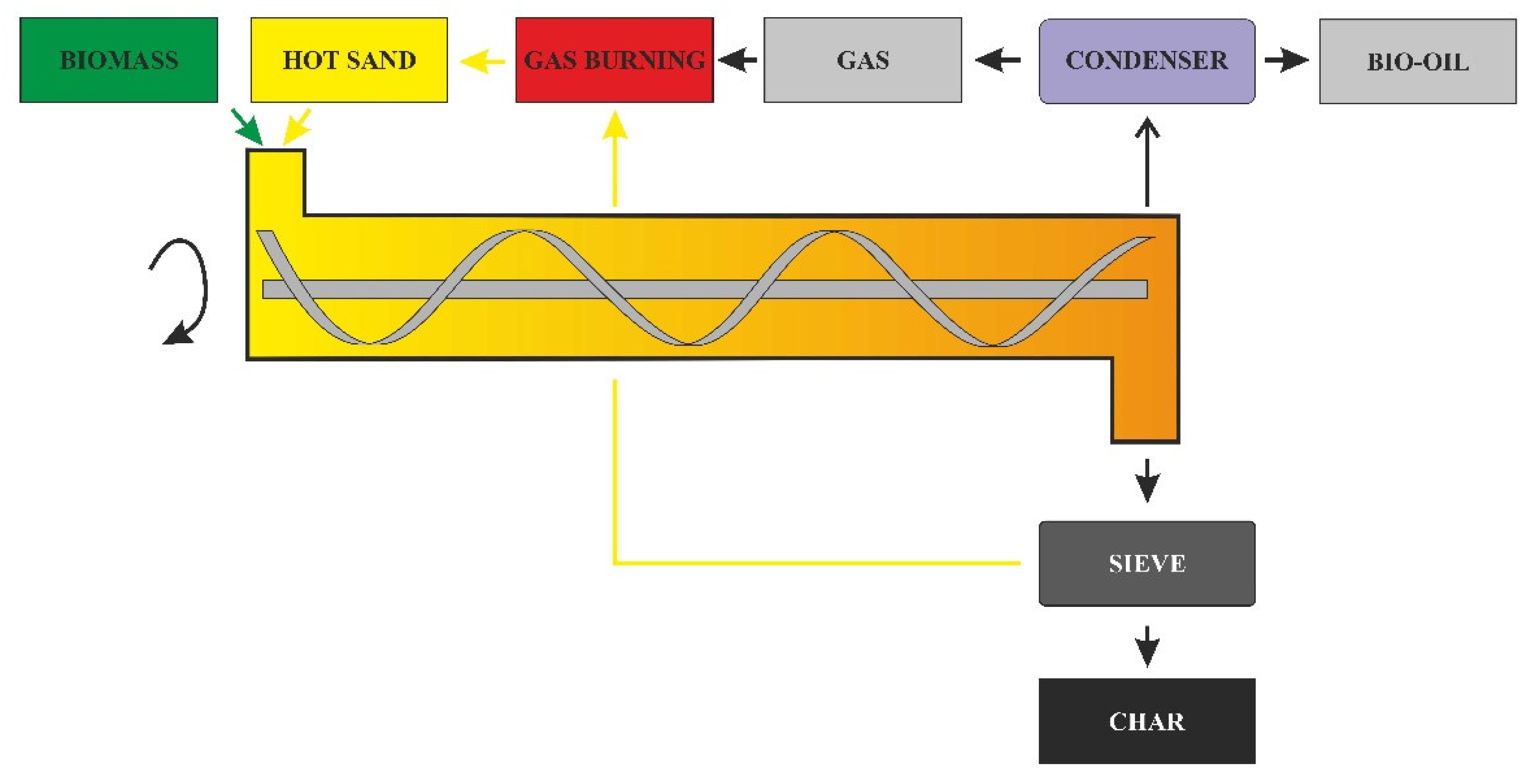

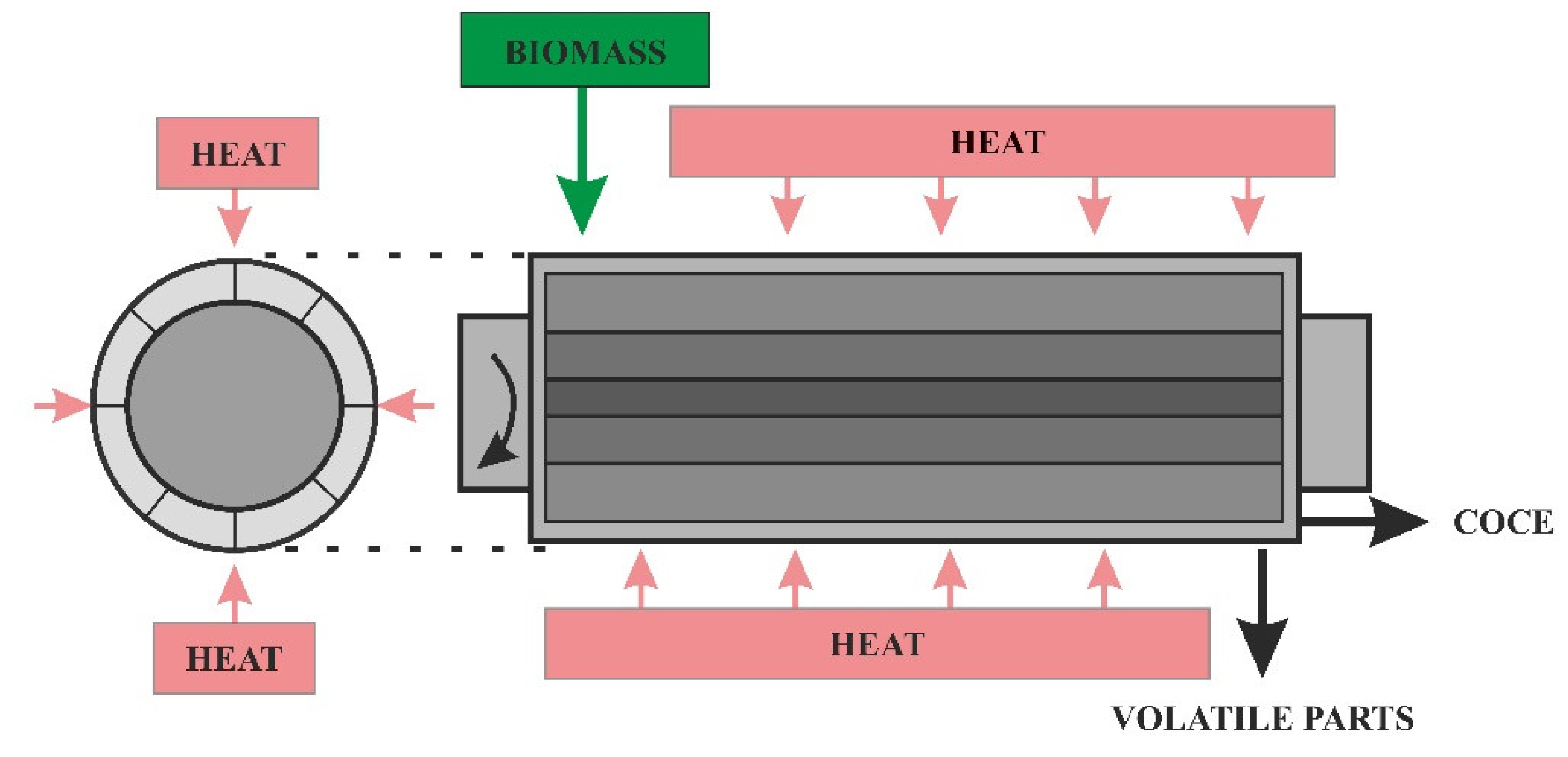

3. Pyrolitic reactors – the technical aspects and influence on the process

5.1. Reactor heating method

- the heat is transferred to the reactor by the heat carrier,

- from the carrier, the heat is transferred to the biomass to be pyrolyzed [46].

- heat exchange surfaces placed in appropriate places in the reactor,

- heating with fluidizing gas,

- removal and reheating of the bed (sand) in a separate reactor,

- adding some air, which can create hot spots and grow cracks leading to tar formation.

4. Prospects and developments in the pyrolysis technology

5. Conclusion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Igliński B.; Iglińska A.; Kujawski W.; Buczkowski R.; Cichosz M. Bioenergy in Poland. Renewable and Sustainable Energy Reviews 2012, 15, 2999-3007. [CrossRef]

- Igliński B.; Kiełkowska U.; Piechota G.; Skrzatek M.; Cichosz M.; Iwański P. Can energy self-sufficiency be achieved? Case study of Warmińsko-Mazurskie Voivodeship (Poland). Clean Technolology and Environonmental Policy 2021, 23, 2061-2081. https://link.springer.com/article/10.1007/s10098-021-02103-1.

- Baudry G.; Macharis C.; Vallée T. Can microalgae biodiesel contribute to achieve the sustainability objectives in the transport sector in France by 2030? A comparison between first, second and third generation biofuels through a range-based Multi-Actor. Multi-Criteria Analysis Energy 2018, 155, 1032-1046. [CrossRef]

- Kaczor Z.; Buliński Z.; Werle S. Modelling approaches to waste biomass pyrolysis: a review. Renewable Energy 2020, 159, 427-443. [CrossRef]

- Velmurugan V. Review of research and development on pyrolysis process. Materials Today: Proceedings 2022, 49, 3679-3686. [CrossRef]

- Liu R.; Liu G.; Yousaf B.; Niu Z.; Abbas Q. Novel investigation of pyrolysis mechanism and kinetics for functional groups in biomass matrix. Renewable and Sustainable Energy Reviews 2022, 153, 111761. [CrossRef]

- Zhang Y.; Cui Y.; Liu S.; Fan L.; Zhou N.; Peng P.; Wang Y.; Guo F.; Cheng Y.; Liu Y.; Lei H.; Chen P.; Li B.; Ruan R. Fast microwave-assisted pyrolysis of wastes for biofuels production – A revie. Bioresource Technology 2020, 297, 122480. [CrossRef]

- Du Y.; Ju T.; Meng Y.; Lan T.; Han S.; Jiang J. A review on municipal solid waste pyrolysis of different composition for gas production. Fuel Processing Technology 2021, 224, 107026. [CrossRef]

- Haghighat M.; Majidian N.; Hallajisani A.; Samipourgiri M. Production of bio-oil from sewage sludge: A review on the thermal and catalytic conversion by pyrolysis. Sustainable Energy Technologies and Assessments 2020, 42, 100870. [CrossRef]

- Fakayode O.A.; Aboagarib E.A.A.; Zhou C.; Ma H. Co-pyrolysis of lignocellulostic and macroalgae biomasses for the production of biochar – A review. Bioresource Technology 2020, 297, 122408. [CrossRef]

- Hu X.; Gholizaed M. Biomass pyrolysis: A review of the process development and challenges from initial researches up to the commercialisation stage. Journal of Green Chemistry 2019, 39, 109-143. [CrossRef]

- Wang G.; Dai Y.; Yang H.; Xiong Q.; Wang K.; Zhou J.; Li Y. Wang S. A review of recent advances in biomass pyrolysis. Energy Fuels 2020, 34, 15557-15578. [CrossRef]

- Stelmach S. Waste pyrolysis as an element of the circular economy. Publisher: Wydawnictwo Politechniki Śląskiej, 2019, Gliwice.

- Gonnella G.; Ischia G.; Fambri L.; Fiori L. Thermal analysis and kinetic modeling of pyrolysis and oxidation of hydrochars. Energies 2022, 15, 950. [CrossRef]

- Hu M.; Ye Q.; Xue Q.; Li Z.; Wang J., Pan Z. Towards understanding the chemical reactions between KOH and oxygen-containing groups during KOH-catalyzed pyrolysis of biomass. Energy 2022, 245, . [CrossRef]

- Liu Y.; Li K.; Guo J.; Xu Z. Impact of the operating conditions on the derived products and the reaction mechanism in vacuum pyrolysis treatment of the organic material in waste integrated circuits. Journal of Cleaner Production 2018, 197, 1488-1497. [CrossRef]

- Siddiqul M.N.; Redhwi H.H.; Antonakou E.V.; Achilias D.S. Pyrolysis mechanism and thermal degradation kinetics of poly(bisphenol A carbonate)-based polymers originating in waste electric and electronic equipment. Journal of Analytical and Applied Pyrolysis 2018, 132, 123-133. [CrossRef]

- Kan T.; Strezov V.; Evans T.; He J.; Kumar R.; Lu Q. Catalytic pyrolysis of lignocellulosic biomass: A review of variations in process factors and system structure. Renewable and Sustainable Energy Reviews 2020, 134, 110305. [CrossRef]

- Stančić H.; Manić N.; Stojiljiković, D.; Vujanović M.; Wang X.; Duić N. Thermogravimetric and kinetic analysis of biomass and polyurethane foam mixtures co-pyrolysis. Energy 2021, 237, 121592. [CrossRef]

- Lv P.; Bai Y.; Wang J.; Song X.; Su W.; Yu G.; Ma Y. Investigation into interaction of biomass waste with industrial solid waste during co-pyrolysis and the synergetic effect of its char gasification. Biomass and Bioenergy 2022, 159, 106414. [CrossRef]

- Zou J.; Hu H.; Xue Y.; Li C.; Li Y.; Yellezuome D.; He F.; Zhang X.; Rahman, M.M.; Cai J. Exploring kinetic mechanisms of biomass pyrolysis using a generalized logistic mixture model. Energy Conversion and Management 2022, 258, 115522. [CrossRef]

- Phuakpunk K.; Chalermsininsuwan B.; Assabumrungrat S. Pyrolysis kinetic parameters investigation of single and tri-component biomass: Models fitting via comparative model-free methods. Renewable Energy 2022, 182, 494-507. [CrossRef]

- Gouws S.M.; Carrier M.; Bunt J.R.; Neomagus H.W.J.P. Lumped chemical kinetic modeling of raw torrefied biomass under pressurized pyrolysis. Energy Conversion and Management 2022, 253, 115199. [CrossRef]

- Wang S.; Dai G.; Yang H.; Luo Z. Lignocellulosic biomass pyrolysis mechanism: A state-of-the-art review. Progess in Energy and Combustion Science 2017, 62, 33-86. [CrossRef]

- Zhang L.; Tan Y; Cai D.; Sun J.; Zhang Y.; Li L.; Zhang Q.; Zou G.; Song Z.; Bai Y. Enhanced pyrolysis of woody biomass under the interaction of microwave and needle-shaped metal and its production properties. Energy 2022, 249, 123667. [CrossRef]

- Ansari B.; Kamal B.; Beg S.; Khan M.A.W.; Khan M.S.; Al Mesfer M.K. Danish M. Recent development in investigating reaction chemistry and transport effects in biomass fast pyrolysis: A review. Renewable and Sustainable Energy Review 2021, 150, 111454. [CrossRef]

- Liu Z.; Li P.; Chang C.; Wang X.; Song J.; Fang S.; Pang S. Influence of metal chloride modified biochar on products characteristics from catalytic pyrolysis. Energy 2022, 250, 123776. [CrossRef]

- Igliński B.; Buczkowski R.; Cichosz M. Bioenergetics technologies. Publisher: Nicolaus Copernicus University, 2009, Toruń.

- Roy P.; Dias G. Prospects for pyrolysis technologies in the bioenergy sector: A review. Renewable and Sustainable Energy Reviews 2017, 77, 59-69. [CrossRef]

- Homagain K.; Shahi C.; Luckai N.; Sharma M. Biochar-based bioenergy and its environmental impact in Northwestern Ontario Canada: a review. Journal of Forest Research 2014, 25, 737-48. [CrossRef]

- Hornung A. Transformation of biomass: theory to practice. Publisher: John Wiley&Sons, 2014.

- Ahmad M.; Rajapaksha A.U.; Lim J.E.; Zhang M.; Bolan N.; Mohdan D. Biochar as a sorbent for contamined management in soil and water: a review. Chemosphere 2014, 99, 19-33. [CrossRef]

- Chintala V. Production, up-gradation and utilization of solar-assisted pyrolysis fuels from biomass – A technical review. Renewable and Sustainable Energy Reviews 2018, 90, 120-130. [CrossRef]

- Zhao B.; Schmidt S.; Qin W.; Li J.; Li G.; Zhang W.. Towards the circular economy – a global meta-analysis of composting technologies reveals much potential for mitigating nitrogen losses. Science of the Total Environment 2020, 704, 135401. [CrossRef]

- Retajczyk M.; Wróblewska A. Pyrolysis of biomass as a source of energy, Wiadomości Chemiczne 2018, 72(3-4), 127-146.

- Zaman C.Z.; Pal K.; Yehye W.A.; Sagadevan S.; Shah S.T.; Adebisi G.A.; Mariana, E.; Rafique R.F.; Johan R.B. Pyrolysis: a sustainable way to generate energy from waste. Pyrolysis, 2017. ISBN 978-953-51-3312-4, . [CrossRef]

- Zhang H.; Xiao R.; Wang D.; He G.; Shao S.; Zhang J.; Zhong Z. Biomass fast pyrolysis in a fluidized bed reactor under N2, CO2, CH4 and H2 atmospheres. Bioresource Technology 2021, 102, 4258-4264. [CrossRef]

- Gouws S.M.; Carrier M.; Bunt J.R.; Neomagus, H.W.J.P. Lumped chemical kinetic modeling of raw torrefied biomass under pressurized pyrolysis. Energy Conversion and Management 2022, 253, 115199. [CrossRef]

- Bieniek A.; Jerzak W.; Sieradzka M.; Mika Ł.; Sztekler K.; Magdziarz A. Intermediate pyrolysis of brewer’s spent grain: impact of gas atmosphere. Energies 2022, 15, 2491. [CrossRef]

- Xu X.; Gholizadeh M. Biomass pyrolysis: a review of the process development and challenges from initial researches up to the commercialization stage. Journal of Energy Chemistry 2019, 39, 109-143. [CrossRef]

- Niesler M.; Stecko J.; Stelmach S. The use of softwood char as a substitute fuel in the iron ore sintering process. Journal of Metallic Materials 2020, 2, 2-14.

- Li A.; Han H.; Hu S.; Zhu M.; Ren Q.; Wang Y.; Xu J.; Jiang L.; Su A.; Xiang J. A novel sludge pyrolysis and biomass gasification integrated method to enhance hydrogen-rich gas generation. Energy Conversion and Management 2022, 254, 115205. [CrossRef]

- Mariyam S.; Shahbaz M.; Al-Ansari T.; Mackey H.R.; A critical review on co-gasification and co-pyrolysis for gas production. Renewable and Sustainable Energy Reviews 2022, 161, 112349. [CrossRef]

- Zhang L.; Zhang S.; Hu X.; Gholizadeh M. Progress in the application of the pyrolytic lignin from pyrolysis of biomass. Chemical Engineering Journal 2021, 419, 129560. [CrossRef]

- Terry L.M.; Li C.; Chew J.J.; Aqsha A.; How B.S.; Loy A.C.M.; Chin B.L.F.; Khaerudini D.S.; Hameed N.; Guan G.; Sunarso J. Bio-oil production from pyrolysis of oil palm biomass and the upgrading technologies: A review. Carbon Resources Conversion 2021, 4, 239-250. [CrossRef]

- Wang C.; Wang R.; Chen T.; Zhu X. Visual experimental study on the effect of heat exchange area on the evaluation of biomass pyrolysis vapors in a vertical indirect condensing field. Bioresource Technolology 2022, 348, 126686. [CrossRef]

- Qiu B.; Tao X.; Wang J.; Liu Y.; Li S.; Chu H. Research progress in the preparation of high-quality liquid fuels and chemicals by catalytic pyrolysis of biomass: A review. Energy Conversion and Management 2022, 261, 115647. [CrossRef]

- Zhou, S.; Xue Y.; Cai J.; Cui C.; Ni Z.; Zhou Z. An understanding for improved biomass pyrolysis: Towards a systematic comparison of different acid pretreatments. Chemical Engineering Journal 2021, 411, 128513. [CrossRef]

- Nisar J.; Ahmad A.; Ali G.; Rehman N.U.; Shah A.; Shah I. Enhanced bio-oil yield from thermal decomposition of peanut shells using termite hill as the catalyst. Energies 2022, 15, 1891. [CrossRef]

- Shen Y.; Zhang N.; Zhang S. Catalytic pyrolysis of biomass with potassium compounds for co-production of high-quality biofuels and porous carbons. Energy 2020, 190, 116431. [CrossRef]

- Fan Y.; Zhao W.; Shao S.; Cai Y.; Chen Y.; Jin L. Promotion of the vapors from biomass vacuum pyrolysis for biofuels under Non-thermal Plasma Synergistic Catyalysis (NPSC) system. Energy 2018, 142, 462-472. [CrossRef]

- Kumar R.S.; Sivakumar S.; Joshuva A.; Deenadayalan G.; Vishnuvardhan R. Bio-fuel production from Martynia annua L. seeds using slow pyrolysis reactor and its effects on diesel engine performance, combustion and emission characteristics, Energy 2021, 217, 119327. [CrossRef]

- Armer MW, Alhesan JSA, Ibrahim S, Qussay G, Marshall M, Al-Aye, OS. Potential use of corn leaf waste for biofuel production in Jordan (physio-chemical study). Energy 2021, 214, 118863. [CrossRef]

- Zanzi R.; Sjöström E. Rapid pyrolisis of agricultural residues at high temperature. Biomass and Bioenergy 2022, 23, 357-366. [CrossRef]

- Zhang L.; Sun X. Influence of bulking agents of physical, chemical, and microbiological properties during the two-stage composting of green waste. Waste Management 2016, 48, 115-126. [CrossRef]

- Kim T.; Oh S.; Kim J.; Choi I.; Choi J.W. Study on the hydrodeoxygenative upgrading of crude bio-oil produced from woody biomass by fast pyrolysis. Energy 2014, 68, 437–43. [CrossRef]

- Wildschut J.; Mahfud F.H.; Venderbosch R.H.; Heeres H.J. Hydrotreatment of fast pyrolysis oil using heterogeneous noble-metal catalysts. Industrial and Engineering Chemistry Research 2009, 48, 10324-34. [CrossRef]

- Yin W.; Venderbosch R.H.; He S.; Bykova M.V.; Khromova S.A.; Yakovlev V.A.; Heeres H.J. Mono-, bi-, and tri-metallic Ni-based catalysts for the catalytic hydrotreatment of pyrolysis liquids. Biomass Conversion and Biorafinery 2017, 7, 361-76. [CrossRef]

- Boscagli C.; Raffelt K.; Grunwaldt J. Reactivity of platform molecules in pyrolysis oil and in water during hydrotreatment over nickel and ruthenium catalysts. Biomass and Bioenergy 2017, 106, 63-73. [CrossRef]

- Capunitan J.A.; Capareda S.C. Hydrotreatment of corn stover bio-oil using noble metal catalysts. Fuel Processing Technology 2014, 125, 190-9. [CrossRef]

- Zheng J.; Zhu X.; Guo Q.; Zhu Q. Thermal conversion of rice husks and sawdust to liquid fuel. Waste Management 2006, 26, 1430-5. [CrossRef]

- Weerachanchai P.; Tangsathitkulchai C.; Tangsathitkulchai M. Effect of reaction conditions on the catalytic esterification of bio-oil. Korean Journal of Chemistry Engineering 2012, 29, 182-189. [CrossRef]

- Cheng D.; Wang L.; Shahbazi A.; Xiu S.; Zhang B. Catalytic cracking of crude bio-oil from glycerol-assisted liquefaction of swine manure. Energy Conversion and Management 2014, 87, 378-84. [CrossRef]

- Tian Y.; Zuo W.; Ren Z.; Chen D. Estimation of a novel method to produce bio-oil from sewage sludge by microwave pyrolysis with the consideration of efficiency and safety. Bioresource Technology 2011, 102, 2053-2061. [CrossRef]

- Mushtaq F.; Channa A.S.; Mat R.; Ani F.N.. Microwave assisted pyrolysis of waste biomass resources for bio-oil production. Applied Mechanics and Material 2014, 554, 307-311. [CrossRef]

- Kuan W.H.; Huang Y.F.; Chang C.C.; Lo S.L. Catalytic pyrolysis of sugarcane bagasse by using microwave heating. Bioresouce Technololgy 2013, 146, 324-329. [CrossRef]

- Mushtaq F.; Abdullah T.A.T.; Mat R.; Ani F.N. Optimization and characterization of bio-oil produced by microwave assisted pyrolysis of oil palm shell waste biomass with microwave absorber. Bioresource Technology 2015, 190, 442-450. [CrossRef]

- Liu H.; Ma X.; Li L.; Hu Z.; Guo P.; Jiang Y. The catalytic pyrolysis of food waste by microwave heating. Bioresource Technology 2014, 166, 45-50. [CrossRef]

- Wang Y.; Zeng Z.; Tian X.; Dai L.; Jiang L.; Zhang S.; Wu Q.; Wen P.; Fu G.; Liu Y.; Ruan R. Production of bio-oil from agricultural waste by using a continuous fast microwave pyrolysis system. Bioresource Technology 2018, 269, 162-168. [CrossRef]

- Al-Rumaihi A.; Shahbaz M.; Mckay G.; Mackey H.; Al-Ansari T. A review of pyrolysis technologies and feedstock: A blending approach for plastic and biomass towards optimum biochar yield. Renewable and Sustainable Energy Reviews 2022, 167, 112715. [CrossRef]

- Li Y.; Xing B.; Ding Y.; Han X.; Wang S. A critical review of the production and advanced utilization of biochar via selective pyrolysis of lignocelluslosic biomass, Bioresource Technology 2020, 312, 1231614. [CrossRef]

- Shao S.; Liu C. Xiang X.; Liu X.; Zhang H.; Xiao R.; Ca Y. In situ catalytic fast pyrolysis over CeO2 catalyst: Impact of biomass source, pyrolysis temperature and metal ion. Renewable Energy 2021, 177, 1372-1381. [CrossRef]

- Składeczek F.; Głodek-Bucyk E. Research of using low-temperature pyrolysis for processing of waste biomass to biochar. Scientific Works of Institute of Ceramics and Building Materials 2017, 28, 50-61.

- Sieradzka M.; Kirczuk C.; Kalemba-Rec I.; Mlonka-Mędrala A.; Magdziarz A. Pyrolysis of biomass wastes into carbon materials. Energies 2022, 15, 1941. [CrossRef]

- Saint H.H.; Hussain A.; Bassyouni M.; Ali I.; Kanthasamy R.; Ayodele B.V.; Elhenawy Y. Hydrogen-rich syngas and biochair production by the non-catalytic valorization of date palm seeds. Energies 2022, 15, 2727. [CrossRef]

- Duan D.; Chen D.; Huang L.; Zhang Y.; Zhang Y.; Wang Q.; Xiao G.; Zhang W.; Lei H.; Ruan R. Activated carbon from lignocellulosic biomass as a catalyst: A review of the application in fast pyrolysis process. Journal of Analytical and Applied Pyrolysis 2021, 158, 105246. [CrossRef]

- Pallaréz J.; González-Cencerrado A.; Arazuro I. Production and characterization of activated carbon from barley straw by physical activation with carbon dioxide and steam. Biomass and Bioenergy 2017, 115, 54-73. [CrossRef]

- Köseoğlu C.; Akmil-Başar C. Preparation, structural evaluation and adsorptive properties of activated carbon from agricultural waste biomass. Advanced Powder Technoly 2015, 26, 811-818. [CrossRef]

- Tay T.; Ucar S.; Karagöz S.. Preparation and characterization of activated carbon from waste biomass. Journal of Hazard Materials 2009, 165, 481-485. [CrossRef]

- Sayğili H.; Güzel F. High surface area mesoporous activated carbon from tomato processing solid waste by zinc chloride activation: process optimization, characterization and dyes adsorption. Journal of Cleaner Production 2016, 113, 995-1004. [CrossRef]

- Duan D.; Feng Z.; Dong X.; Chen X.; Zhang Y.; Wan K.; Wang Y.; Wang Q.; Xiao G.; Liu H. Improving bio-oil quality from low-density polyethylene pyrolysis: Effects of varying activation and pyrolysis parameters. Energy 2021, 232, 121090. [CrossRef]

- Pan J.; Jiang J.; Xu R. Adsorption of Cr(III) from acidic solutions by crop straw derived biochars. Journal of Environmental Sciences (China) 2013, 25, 1957-1965. [CrossRef]

- Agrafioti E.; Kalderis D.; Diamadopoulos E. Arsenic and chromium removal from water using biochars derived from rice husk, organic solid wastes and sewage sludge. Journal of Environmental Management 2014, 133, 309-314. [CrossRef]

- Wnetrzak R.; Leahy J.J.; Chojnacka K.W.; Saeid A.; Novotny E.; Jensen L.S.; Kwapinski W. Influence of pig manure biochar mineral content on Cr(III) sorption capacity. Journal of Chemical Technology and Biotechnoly 2014, 89, 569-578. [CrossRef]

- Li H.; Dong X.; da Silva E.B.; de Oliveira L.M.; Chen Y.; Ma L.Q. Mechanisms of metal sorption by biochars: Biochar characteristics and modifications. Chemosphere 2017, 178, 466-478. [CrossRef]

- Piechota G.; Igliński B. Biomethane in Poland: current status, potential, perspective and development. Energies 2021, 14, 1-32. [CrossRef]

- Mierzawa-Hersztek M.; Gondek K.; Jewarz M.; Dziedzic K. Assessment of energy parameters of biomass and biochars, leachability of heavy metals and phytotoxicity of their ashes. Journal of Materials Cycles and Waste Management 2019, 21, 786-800. [CrossRef]

- Karhu K.; Mattila T.; Bergstrom I.; Regina K. Biochar addition to agricultural soil increased CH4 uptake and water holding capacity – Results from a short-term pilot field study. Agriculture, Ecosystems and Environment 2011, 140, 309-313. [CrossRef]

- Zhang P.; Sun H.; Yu L.; Sun T. Adsorption and catalytic hydrolysis of carbaryl and atrazine on pig manure-derived biochars: impact of structural properties of biochars. Journal of Hazardous Materials 2013, 244-245, 217-224. [CrossRef]

- Qiu M.; Ling Q.; Cai Y.; Yu S.; Wang S.; Fu D.; Hu B.; Wang X. Biochar for the removal of contaminants from soil and water: a review. Biochar 2022, 4, 19. [CrossRef]

- Luo J.; Sun S.; Chen X.; Lin J.; Ma R.; Zhang R.; Fang L. In-depth exploration of the Energy utilization and pyrolysis mechanism of advanced continuous microwave pyrolysis. Applied Energy 2021, 292, 116941. [CrossRef]

- Ren X.; Ghazani M.S.; Zhu H.; Ao W.; Zhang H.; Moreside E.; Zhu J.; Yang P.; Zhong N.; Bi X. Challenges and opportunities in microwave-assisted catalytic pyrolysis of biomass: A review. Applied Energy 2022, 315, 118970. [CrossRef]

- Sait H.H.; Hussain A.; Bassyouni M.; Ali I.; Kanthasamy R.; Ayodele B.V.; Elhenawy Y. Hydrogen-rich syngas and biochar production by the non-catalytic valorization of date palm seeds. Energies 2022, 15, 2727. [CrossRef]

- Li P.; Shi X.; Wang X.; Song J.; Fang S.; Bai J.; Zhang G.; Chang C.; Pang S. Bio-oil from biomass fast pyrolysis: yields, related properties and energy consumption analysis of pyrolysis system. Journal of Cleaner Production 2021, 328, 129613. [CrossRef]

- Ringer M.; Putsche V.; Scahill J. Large-scale pyrolysis oil production: a technology assessment and economic analysis. National Renewable Energy Laboratory. Technical report, 2006. www.nrel.gov/docs/fy07osti/37779.pdf.

- Jaworski T.J. Waste and biomass pyrolysis reactors. Piece i Kotły 2017, 1, 1-7.

- Li X,; Peng B.; Liu Q.; Zhang H. Microwave pyrolysis coupled with conventional pre-pyrolysis of the stalk for syngas and biochar. Bioresource Technology 2022, 348, 126745. [CrossRef]

- Bridgwater A.V. Review of fast pyrolysis of biomass and product upgrading. Biomass and Bioenergy 2012, 38, 68-94. [CrossRef]

- Gao A.; Wang Y.; Lin G.; Liu B.; Hu X.; Huang Y.; Zhang S.; Zhang H. Volatile-char interactions during biomass pyrolysis: Reactor design toward product control. Renewable Energy 2022, 185, 1-7. [CrossRef]

- Alves V.R.D. Advances in the pyrolysis process and the generation of bioenergy. Recent Perspectives in Pyrolysis Research, 2021. ISBN978-1-83969-915-3.

- Hasan M.M.; Rasul M.G.; Khan M.M.K.; Ashwath N.; Jahirul M.I. Energy recovery from municipal solid waste using pyrolysis technology: A review on current status and developments. Renewable and Sustainable Energy Reviews 2021, 145, 111073. [CrossRef]

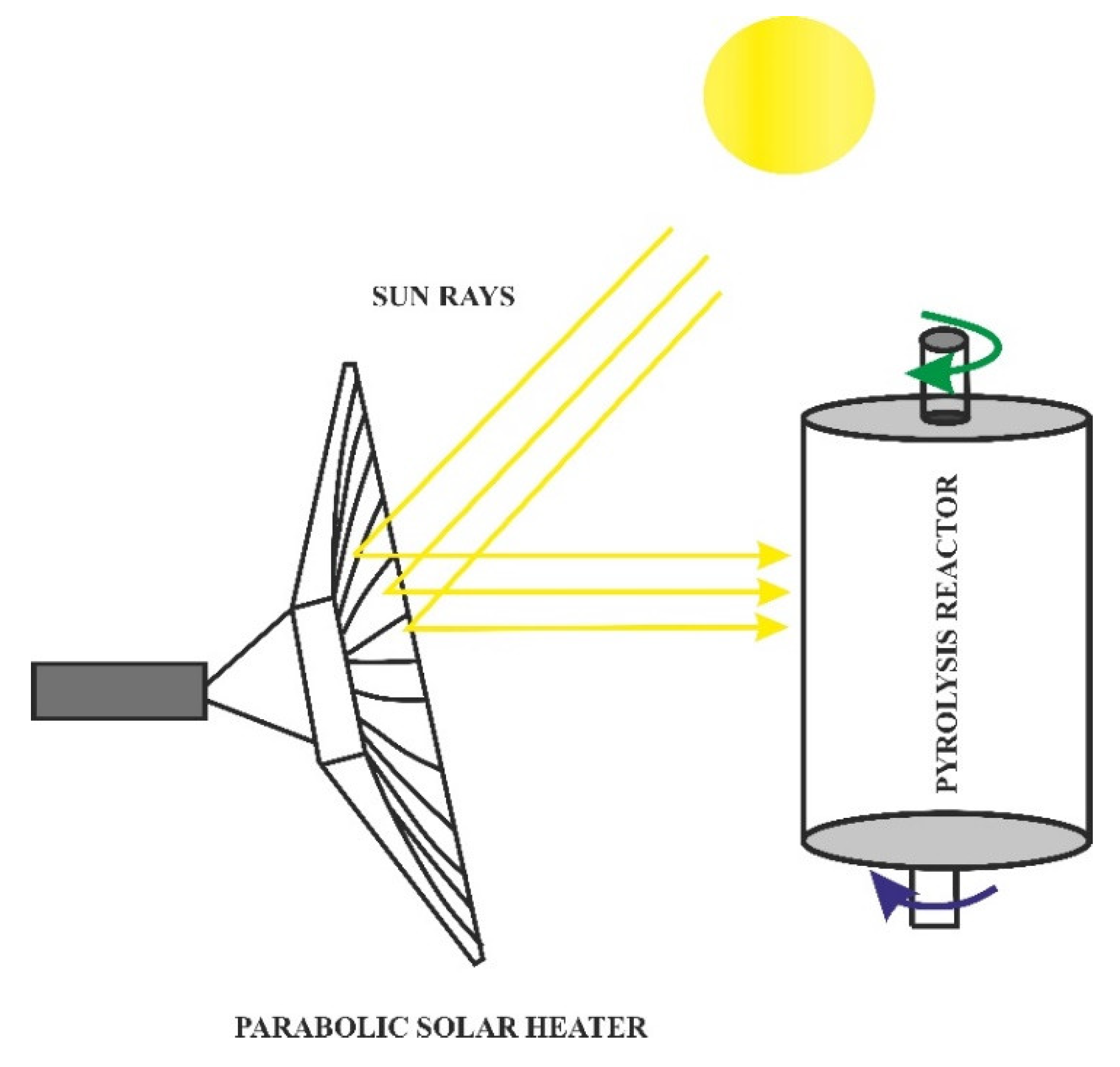

- Rahman M.A.; Parvej A.M.; Aziz M.., Concentrating technologies with reactor integration and effect of process variables on solar assisted pyrolysis: A critical review. Thermal Science and Engineering Progress 2021, 25, 100957. [CrossRef]

- Jahirul M.I.; Rasul M.G.; Chowdhury A.A.; Ashwath N. Biofuels production through biomass pyrolysis – a technological review. Energies 2021, 12, 4952-5001. [CrossRef]

- Garcia-Nunez J.A. Pelaez-Samaniego M.R.; Garcia-Perez M.E.; Fonts I.; Abrego J.; Westerhof J.M.; Garcia-Perez M. Historical developments of pyrolysis reactors: a review. Energy Fuels 2017, 31, 5751-5775. [CrossRef]

- Parthasarathy P.; Al-Ansari T.; Mackey H.R.; Narayanan K.S.; McKay G. A review on prominent animal and municipal wastes as potential feedstocks for solar pyrolysis for biochar production. Fuel 2022, 316, 123378. [CrossRef]

- Ndukwu M.C.; Horsfall I.T.; Ubouh E.A.; Orji F.N.; Ekop I.E.; Ezejiofor N.R. Review of solar-biomass pyrolysis systems: Focus on the configuration of thermal-solar systems and reactor orientation. Journal of King Saud Univerisity – Engineering Sciences 2021, 33, 413-423. [CrossRef]

- Sobek S.; Werle S. Solar pyrolysis of waste biomass: Part 2 kinetic modeling and methodology of the determination of the kinetic parameters for solar pyrolysis of sewage sludge. Renewable Energy 2020, 153, 962-974. [CrossRef]

- Boutin O.; Lede J.; Olalde G.; Ferriere A. Solar flash pyrolysis of biomass direct measurement of the optical properties of biomass components. Journal of Physique Archives, 1999, 9. [CrossRef]

- Rony A.H.; Daniel M.; Zhao S.; Dengfeng Q.; Yuan Z.; John H.B.; Maohong F. 2018. A novel solar powered biomass pyrolysis reactor for producing fuels and chemicals. Journal of Analitycal and Applied Pyrolysis 2018, 132, 19-32, . [CrossRef]

- Sobek S.; Werle S. Solar pyrolysis of waste biomass: Part 1 reactor design. Renewable Energy 2019, 143, 1939-1948. [CrossRef]

- Su G.; Zulkifli N.W.M.; Ong H.C.; Ibrahim S.; Bu Q.; Zhou R. Pyrolysis of oil palm wastes for bioenergy in Malaysia: A review. Renewable and Sustainable Energy Reviews 2022, 164, 112554. [CrossRef]

- Du Z.; Li Y.; Wang X.; Wan Y.; Chen Q.; Wang C.; Lin X.; Liu Y.; Chen P.; Ruan R. Microwave-assisted pyrolysis of microalgae for biofuel production, Bioresource Technolology, 2011, 102, 4890-4896. [CrossRef]

- Sekar M.; Mathimani T.; Alagumalai A.; Chi N.T.L.; Duc P.A.; Bhatia S.K.; Brindhadevi K.; Pugazhendhi A. A review on the pyrolysis of algal biomass for biochar and bio-oil – Bottlenecks and scope. Fuel 2021, 283, 119190. [CrossRef]

- Michalak I.; Ba´slady´nska S.; Mokrzycki J.; Rutkowski P. Biochar from a freshwater macroalga as a potential biosorbent for wastewater treatment. Water (Switzerland) 2019, 11, 4-6.

- Wang H.E.; Wang H.; Zhao H.; Yan Q. Adsorption and Fenton-like removal of chelated nickel from Zn-Ni alloy electroplating wastewater using activated biochar composite derived from Taihu blue algae. Chemical Engineering Journal 2020, 379, 122372. [CrossRef]

- Cheng B-H.; Zeng R.J.; Jiang H. Recent developments of post-modification of biochar for electrochemical energy storage. Bioresource Technology 2017, 246, 224-233. [CrossRef]

- Zhou Y.; Zhang H.; Cai L.; Guo J.; Wang Y.; Ji L.; Song W. Preparation and characterization of macroalgae biochar nanomaterials with highly efficient adsorption and photodegradation ability. Materials 2018, 11, 1709. [CrossRef]

- Pourhosseini S.E.M.; Norouzi O.; Naderi H.R. Study of micro/macro ordered porous carbon with olive-shaped structure derived from Cladophora glomerata macroalgae as efficient working electrodes of supercapacitors. Biomass Bioenergy 2017, 107, 287-298. [CrossRef]

- Pourhosseini S.E.M.; Norouzi O.; Salimi P.; Naderi H.R. Synthesis of a novel interconnected 3D pore network algal biochar constituting iron nanoparticles derived from a harmful marine biomass as high-performance asymmetric supercapacitor electrodes. ACS Sustainable Chemistry and Engineering 2018, 6, 4746-4758. [CrossRef]

- Ren M.; Jia Z.; Tian Z.; Lopez D.; Cai J.; Titirici M.-M.; Jorge A.B. High performance n-doped carbon electrodes obtained via hydrothermal carbonization of macroalgae for supercapacitor applications. ChemElectroChem 2018, 5, 2686-2693. [CrossRef]

- Zeng J.; Wei L.U.; Guo X. Bio-inspired high-performance solid-state supercapacitors with the electrolyte, separator, binder and electrodes entirely from: kelp. Journal of Materials Chemistry A 2017, 48, 25282-25292.

- Zhou M.; Catanach J.; Gomez J.; Richins S.; Deng S.. Effects of Nanoporous Carbon Derived from Microalgae and Its CoO Composite on Capacitance. ACS Applied Materials and Interfaces 2017, 9, 4362-4373. [CrossRef]

- Chaudhary J.P.; Gupta R.; Mahto A.; Vadodariya N.; Dharmalingm K.; Sanna Kotrappanavar N.; Meena R. Self-doped interwoven carbon network derived from Ulva fasciata for all-solid supercapacitor devices: Solvent-free approach to a scalable synthetic route. ACS Applied Materials and Interfaces 2019, 7, 174-186. [CrossRef]

- Kang D.; Liu Q.; Gu J.; Su Y.; Zhang W.; Zhang D.I. “Egg-Box” – assisted fabrication of porous carbon with small mesopores for high-rate electric double layer Capacitors. ACS Nano 2015, 9, 11225-11233. [CrossRef]

- Zhang H.; Luo B.; Wu K.; Zhao B.; Yu J.; Wang S.; Tao Y, 2022. Ex-situ catalytic pyrolysis of lignin using lignin-carbon (LG) catalyst combined with HZSM-5 to improve the yield of high-quality liquid fuels. Fuel 318, 123635. [CrossRef]

- Sun J.; Luo J.; Lin J.; Ma R.; Sun S.; Fang L.; Li H. Study of co-pyrolysis endpoint and product conversion of plastic and biomass using microwave thermogravimetric technology. Energy 2022, 247, 123547. [CrossRef]

- Ayala-Cortés A.; Lobato-Peralta R.; Arreola-Ramos C.E.; Martínez-Casillas C.; Pacheno-Catalán D.E.; Curntas-Gallegos A.K.; Arancibia-Bulnes C.A.; Villafán-Vidales H.I. Exploring the influence of solar pyrolysis operation parameters on characteristics of carbon materials. Journal of Analytical and Applied Pyrolysis 2019, 140, 290-298. [CrossRef]

- Wang Z.; Burra K.G.; Lei T.; Gupta A.K.; Co-pyrolysis of waste plastic and solid biomass for synergistic production of biofuels and chemicals – A review. Progress on Energy and Combustion Science 2021, 84, 100899. [CrossRef]

- Haeldermans T.; Campion L.; Kuppens T.; Vanreppelen K.; Cuypers A.; Schreurs S. A comparative techno-economic assessment of biochar production from different residue streams using conventional and microwave pyrolysis. Bioresource Technology 2020, 318, 124083. [CrossRef]

- Ly H.V.; Lee B.; Sim J.W.; Tran Q.K.; Kim S.-S.; Kim J.; Brigljević B.; Hwang H.T.; Lim H. Catalytic pyrolysis of spent coffee waste for upgrading sustainable bio-oil in bubbing fluidized-bed reactor: Experimental and techno-economic analysis. Chemical Engineering Journal 2022, 427, 130956. [CrossRef]

- Wang L.; Lei H.; Ruan R. Techno-economic analysis of microwave-assisted pyrolysis for production of biofuels. In: Fang Z.; Smith J.R.L.; Qi X. (editors). Production of biofuels and chemicals with microwave. Dordrecht: Springer Netherlands 2015, 251-63.10.1007/978-94-017-9612-5_12.

- Li H.; Xu J.; Nyambura S.M.; Wang J.; Li C.; Zhu X.; Feng X.; Wang Y. Food waste pyrolysis by traditional heating and microwave heating: A review. Fuel 2022, 324, 124574. [CrossRef]

- Malińska K.; Dach J. Potential applications of biochar for composting, Inżynieria Ekologiczna 2014, 36, 28-39.

| Type of pyrolysis | Duration | Heating speed | Temperature [°C] | Products | Ref. |

| Slow charring | several days | very slow | 400 | charcoal | [28] |

| Slow | hours/days | slow | 400 | charcoal, gas | [28] |

| Slow conventional | 5-30 min. | slow | 600 | charcoal, oils, gas | [30] |

| Intermediate Fast |

10 min. 0,5-5 s |

intermediate very fast |

300-450 300-1000 |

charcoal, oils, gas charcoal, oils, gas |

[31] [32] |

| Instant liquid | < 1 s | fast | < 650 | oils | [28] |

| Instant gas | < 1 s | fast | < 650 | chemicals, gas | [28] |

| Ultra lightning fast | < 0,5 s | very fast | 1000 | chemicals, gas | [28] |

| Vacuum | 2-30 s | medium | 400 | oils | [28] |

| Hydro-pyrolysis | < 10 s | medium | < 500 | oils | [28] |

| Methane-pyrolysis | < 10 s | medium | >700 | chemicals | [28] |

| Component | Content in bio-oil [%] |

| Hydroxyacetic aldehyde Acetic acid Formic acid Acetaldehyde Hydroxyacetone Isoeugenol Furfuryl alcohol 2,6 - dimethyloxyphenol Etandial Phenol Formic aldehyde Acetone Eugenol Ethylene glycol 1,4 - dihydroxybenzene Cellobiose 1,6 - anhydroglycofuran Fructose Levoglucosan Glucose |

0.9-13.0 0.5-12.0 0.3-9.1 0.1-8.5 0.7-7.4 0.1-7.2 0.1-5.2 0.7-4.8 0.9-4.6 0.1-3.8 0.1-3.3. 2.8 0.1-2.3 0.7-2.0 0.1-1.9 0.6-3.2 3.1 0.7-2.9 0.4-1.4 0.4-1.3 |

| Feedstock | Reaction condition | Catalyst | Oil yield | References |

| Peanut shells Martynia annua seed Corn leaf waste Poplar wood |

3-30°C/min, 30-800°C 650 °C, 3 h 300-450 °C, constant flow rate of nitrogen 350°C, 90 min |

termite hill - - Pd/C |

max. 57 30.77% of BTE 57–73% of diesel fracttion 23.6 |

[49] [52] [53] [56] |

| Beech wood | 450°C, 4 h, 35 MPa H2 | Ru/C | 60 | [57] |

| Pine wood | 350°C, 4 h, 14 MPa H2 | NiMo/ SiO2-Al2O3 | 42.4 | [58] |

| Wheat straw | 340°C, 1.6 h, 8 MPa H2 | NiW/AC | 18.2 | [59] |

| Wheat straw | 340°C, 1.6 h, 8 MPa H2 | Ni/TiO2 | 76.8 | [60] |

| Corn stover | 300°C, 4 h, 12.5 MPa H2 | Ru/C | 54.4 | [61] |

| Rice husks | 465°C, 30 min | SO42-/ZrO2 | 56 | [62] |

| Palm shell | 700°C, 20 min | Amberlyst15 | 86.87 | [63] |

| Swine manure | 400°C, 30 min, 0.69 MPa N2 | Modified zeolite | 45 | [64] |

| Sewage sludge | 330-1200 °C | Graphite | 7.16-49.79 | [65] |

| Bagasse | 300 W | Activated carbon (35%, 55%, 75%), | 13.95-18.95 | [66] |

| Sugarcane bagasse | 493-532 °C | NiO, CuO, CaO, MgO | 18.4-35 | [67] |

| Oil palm shell | 180-720 W | Activated carbon (18.8–91.2%), | 16.43-36.75 | [68] |

| Food waste | 300-600 W | CaO, MgO, CuO, Fe2O3, MnO2, CuCl2 | 10-36 | [69] |

| Agricultural waste | 400-600 °C | SiC | 14.56-31.86 | [70] |

| Raw biomass | Agent | Temperature [°C] | Time [min] | Surface [m2/g] | Micropore valume [cm3/g] | Ref. |

| Barley straw | Steam | 700 | 60 | 552 | 0.2304 | [78] |

| Barley straw | Steam | 800 | 60 | 534 | 0.2186 | [79] |

| Barley straw | CO2 | 700 | 60 | 211 | 0.0830 | [80] |

| Orange peels | K2CO3 | 700 | 60 | 477 | 0.21 | [81] |

| Orange peels | K2CO3 | 950 | 60 | 1352 | 0.22 | [81] |

| Orange peels | ZnCl2 | 700 | 60 | 822 | 0.09 | [81] |

| Soybean oil cake | K2CO3 | 600 | 60 | 643 | 0.272 | [82] |

| Soybean oil cake | KOH | 600 | 60 | 600 | 0.213 | [82] |

| Soybean oil cake | KOH | 800 | 60 | 619 | 0.143 | [82] |

| Tomato | ZnCl2 | 400 | 60 | 648 | 0.086 | [83] |

| Tomato | ZnCl2 | 600 | 60 | 1093 | 0.129 | [83] |

| Tomato | ZnCl2 | 800 | 60 | 492 | 0.058 | [83] |

| Chesnut Shell | H3PO4 | 750 | 20 | 1138 | 0.424 | [84] |

| Chesnut Shell | H3PO4 | 850 | 20 | 1413 | 0.562 | [84] |

| Raw material | Pyrolysis temperature [°C] | Initial concentration Cr(III) | Sorption capacity | References |

| The husk of rice | 300 | 185 [μg/dm3] | 15.1 [μg/dm3] | [37] |

| Soybean stalks | 400 | 260 [mg/dm3] | 14.6 [mg/dm3] | [50] |

| Slurry | 600 | 300 [mg/dm3] | 40.0 [mg/dm3] | [17] |

| Wood of conifers | 700 | 650 [mg/dm3] | 32.0 [mg/dm3] | [75] |

| Biomass | Reactor | Concentrator | Light source | References |

| Wood | Quartz tube | Direct concentration | 5 kWarc Xenon bulb | [106] |

| Waste biomass | Indirect (conduction) | Elliptical reflector | 1.6 kW Xenon arc lamp |

[107] |

| Mixed biomass components |

Integrated sphere | Converging lenses | A xenon lamp | [108] |

| Pine sawdust | Cylindrical quartz reactor | Deep-dish Parabolic concentrator |

5 kW Xenon arc lamps |

[109] |

| Chicken-litter | Copper, Indirect (conduction) | Elliptical reflector | 0.6 kW Xenon arc lamp | [110] |

| Algae | Specific surface area [m2/g] | Energy density [Wh /kg] | Cycle stability | Cycle stability percent [%] | References |

| Chlorella | 1337.9 | 20 | 10,000 | 92 | [118] |

| Cladophora glomerata | 354 | 42.4 | 5000 | 99.2 | [119] |

| Cladophora glometa | 957 | 41.5 | 10,000 | 93.1 | [120] |

| Enteromorpha prolifera | 2000 | 7 | 10,000 | 96 | [121] |

| Kelp | 4425 | 8 | 20,000 | 92 | [122] |

| Nannochloropsis salina | 1784 | 26.1 | 5000 | 83 | [123] |

| Ulva fasciata | 376.82 | 46.1 | 5000 | 97.5 | [124] |

| Undaria pinnatifida | 3270 | 42 | 10,000 | 94 | [125] |

| Fraction yield [%] | Heating power [W] | |||

| 500 | 750 | 1000 | 1250 | |

| Oil fraction | 26 | 28.5 | 25 | 17 |

| Water fraction | 21 | 20 | 20 | 22 |

| Carbonizate | 28 | 24 | 25 | 25 |

| Gaseous fraction | 24 | 26.5 | 29 | 35 |

| Costs | Traditional heating pyrolysis | Microwave pyrolysis |

| Capital costs details |

+++ |

+++ Electrical panels, magnetron, reactor design |

| Production costs details |

++ High throughput |

++ Low pyrolysis temperature and time |

| Revenues details |

+ |

++ High-quality products |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).