Submitted:

10 January 2023

Posted:

11 January 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

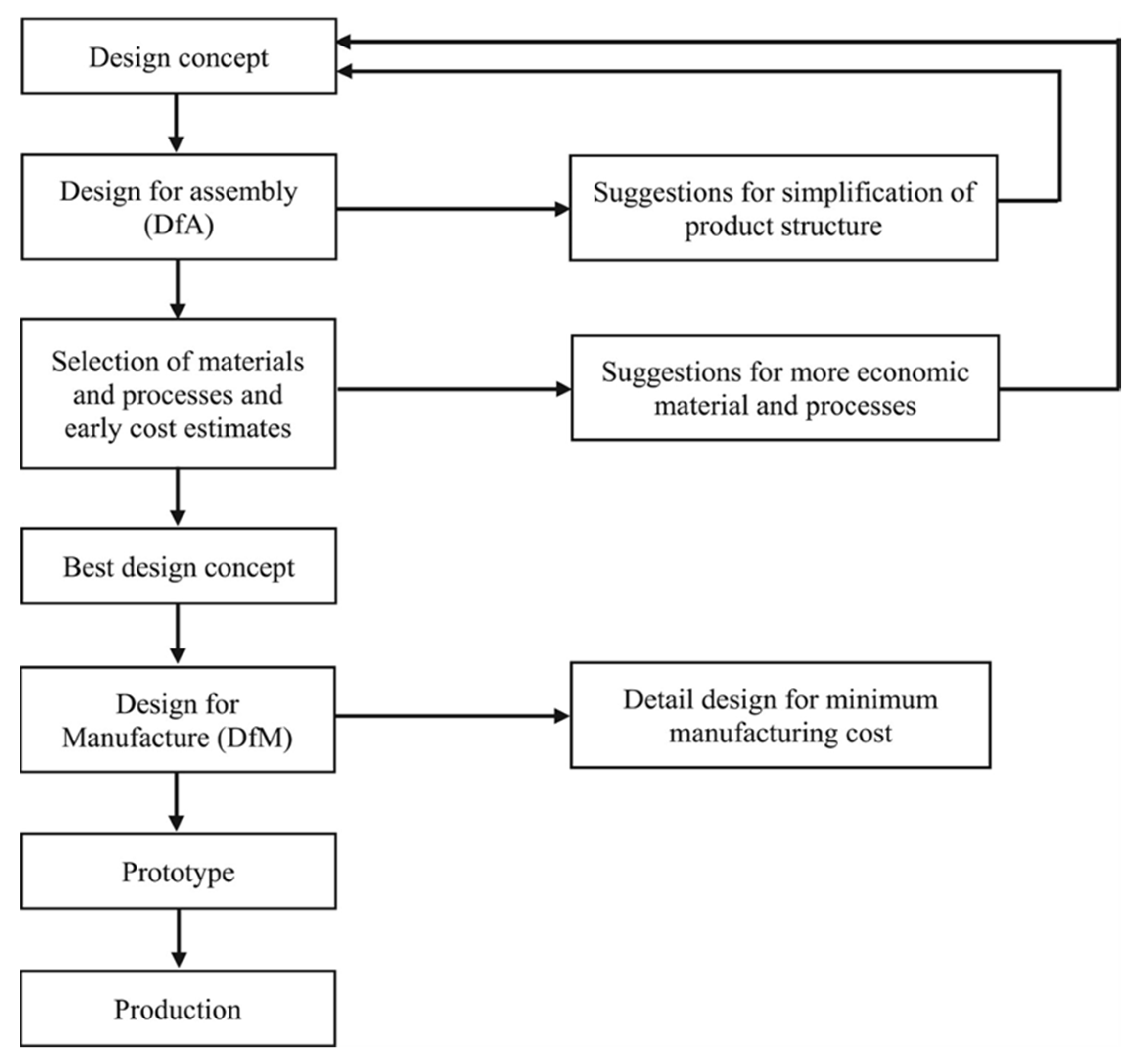

2. Concept of DfMA

3. Fundamental DfMA aspects in construction

- [1]

- The design team reduced the product's structure to save manufacturing and assembly expenses. Moreover, the product structure enhancements were quantified.

- [2]

- A tool for evaluating items that quantifies issues in their manufacture and assembly was developed.

- [3]

- A tool for reducing costs and negotiating contracts with suppliers was also created

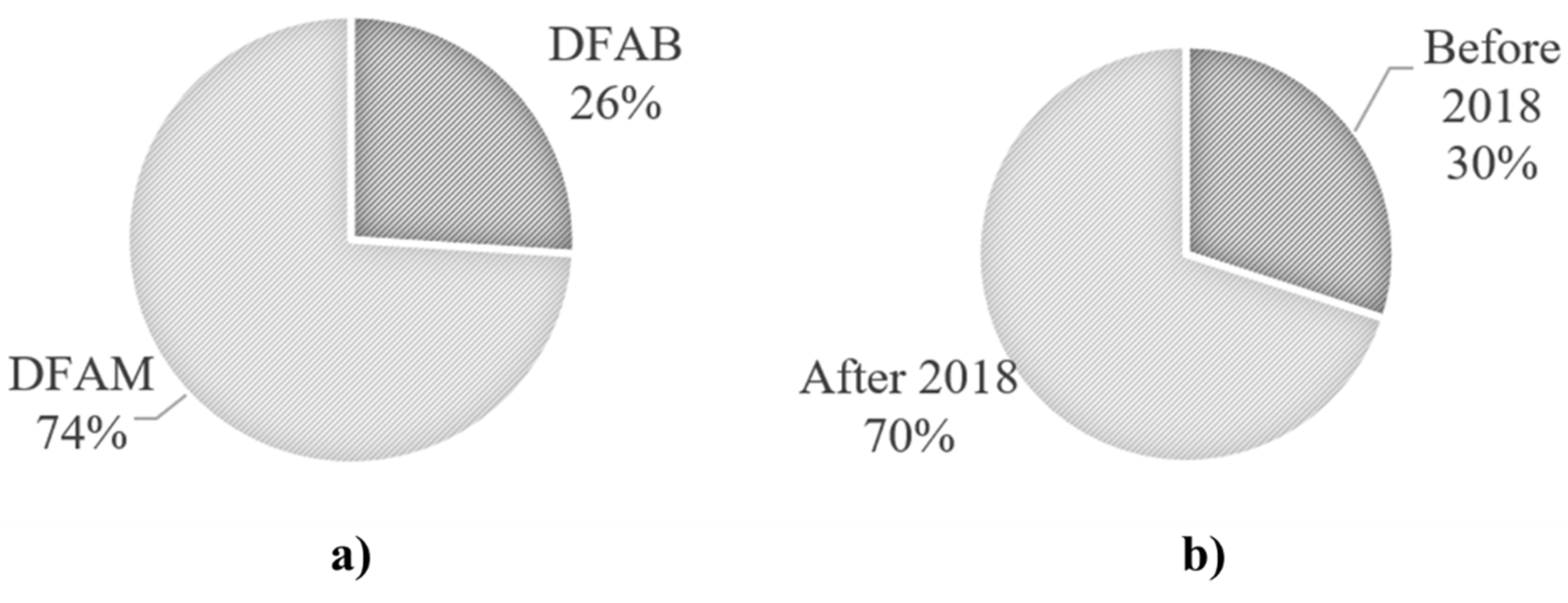

4. DfMA for Digital fabrication (Dfab) and AM (DfAM)

4.1. DfMA for Dfab

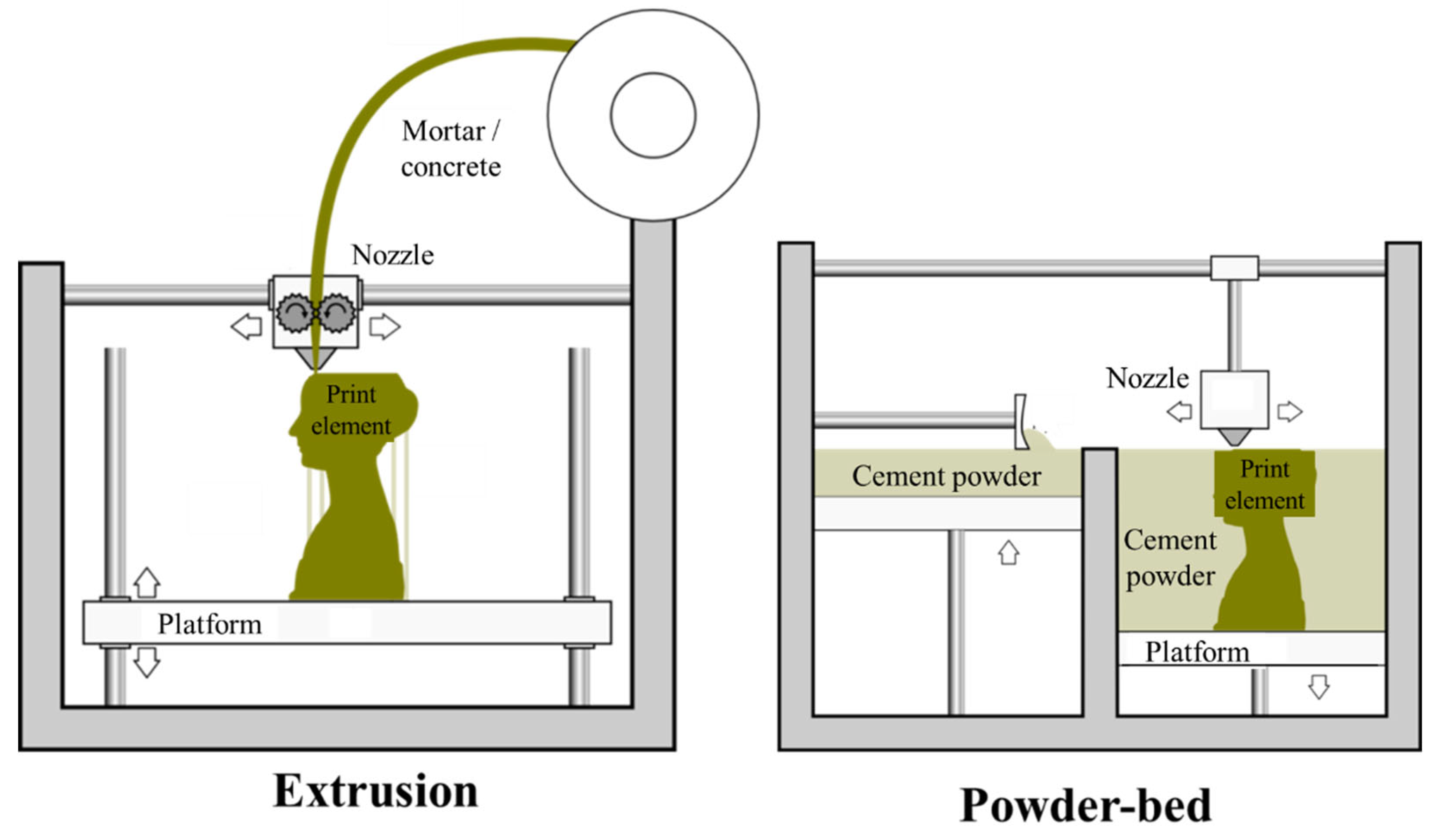

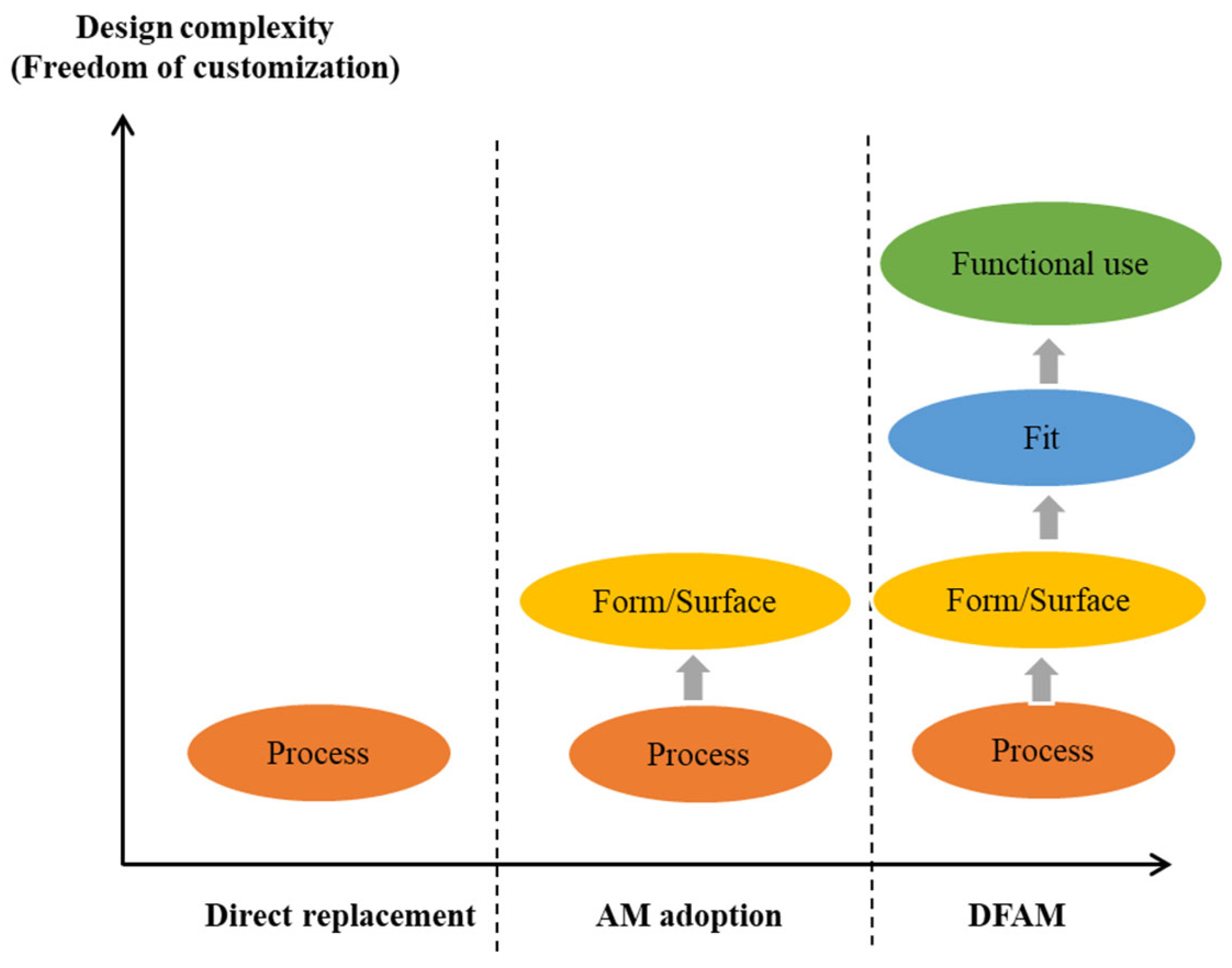

4.2. DfMA for DfAM

- Layerwise operational characteristics and direct CAD model production extend part design creativity.

- Parts could be created as modular 3D puzzles incorporating small modules.

- As AM materials may be treated point-by-point or layer-by-layer, complicated material compositions and property gradients are possibly adopted.

- AM allows for the fabrication of hierarchically complicated, long-scale building designs.

- The layer-by-layer or point-by-point nature of AM makes it easier to combine parts and embed them. Most applications can be put into two groups: those that use operational mechanisms and those that use embedded components. In the case of operational mechanisms, if two or more parts need to be able to move in relation to each other, AM can build these parts already put together. For this type of non-assembly mechanism, one of the most crucial factors was joint clearance [121]. The joint clearance could reform the way the mechanism works. Besides, in the case of embedded components, it is often essential in building a functional prototype by putting components into a part. This can improve the performance of the holistical system.

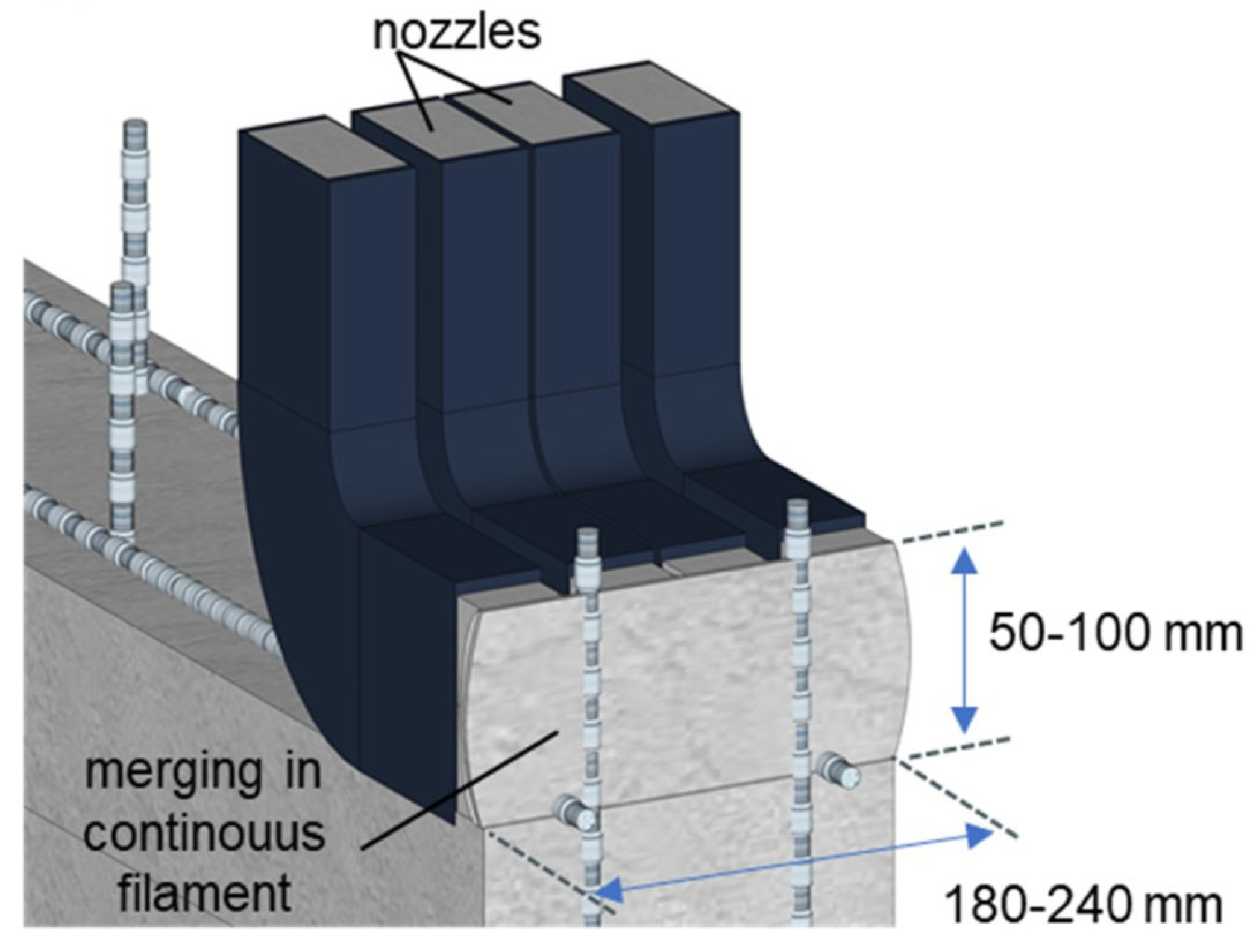

- AM is a good way to fabricate structure with more than one material. The use of more than one material in AM can be done to improve functionality of the printed element. The multiple nozzle heads of extrusion AM has been examined [19,122,123]. Classen et al. [95] made fork-shaped, multi-nozzle extrusion heads for layer thicknesses of 50–100 mm and filament widths of 180–240 mm, as illustrated in Figure 7. The goal was to set up a fully automated, high-speed process for making continuously steel-reinforced concrete walls. Khoshnevis et al. [124] introduced supporting material, such as wax and sand, along with the concrete nozzle. This can be adopted for better buildability and can be built as the roof structure. Aside from these, multi-nozzle AM can produce complicated structures such as concrete extruded nozzles and spraying nozzles for smoothing the surface of the structure and creating a range of surface textures.

5. Joints design for AM structure

6. Machine learning for DfAM

7. Implication

8. Conclusion, implication, and suggested future works

- AM using concrete materials also applies to the DfM and DfA principles suitably.

- Increasingly advanced technical developments in construction, such as AM and DfMA in particular, new entrance prospects for manufacturing technology, and improvements in production efficiency.

- Majority of research (70%) has been investigated within this 5-year period.

- DfAM allows for a greater degree of design complexity as well as a larger range of freedoms in terms of customization. It consists of four stages: process, form/surface, assembly, and functional usage.

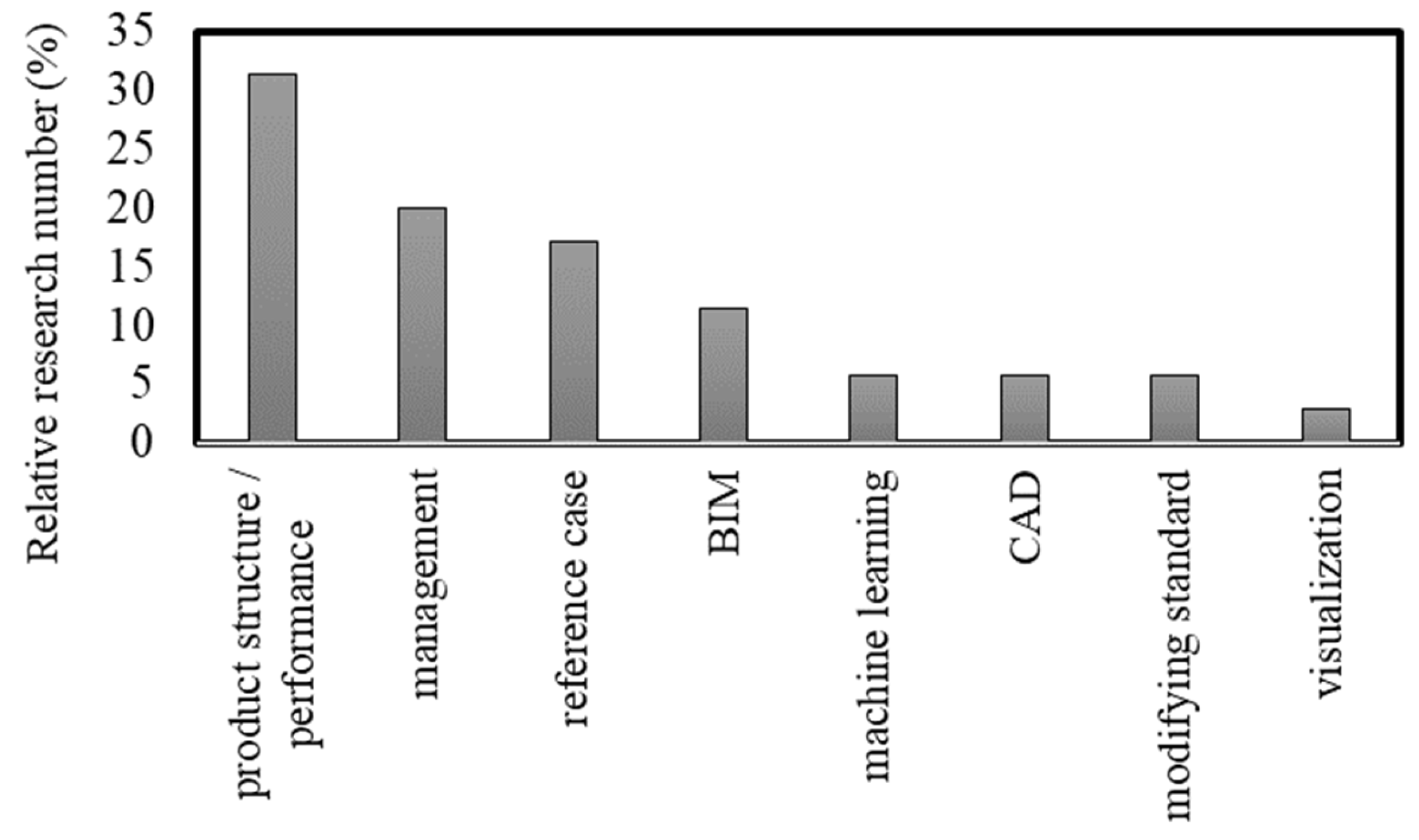

- Existing knowledge is still applied to the product structure/performance, management, and BIM integration domains.

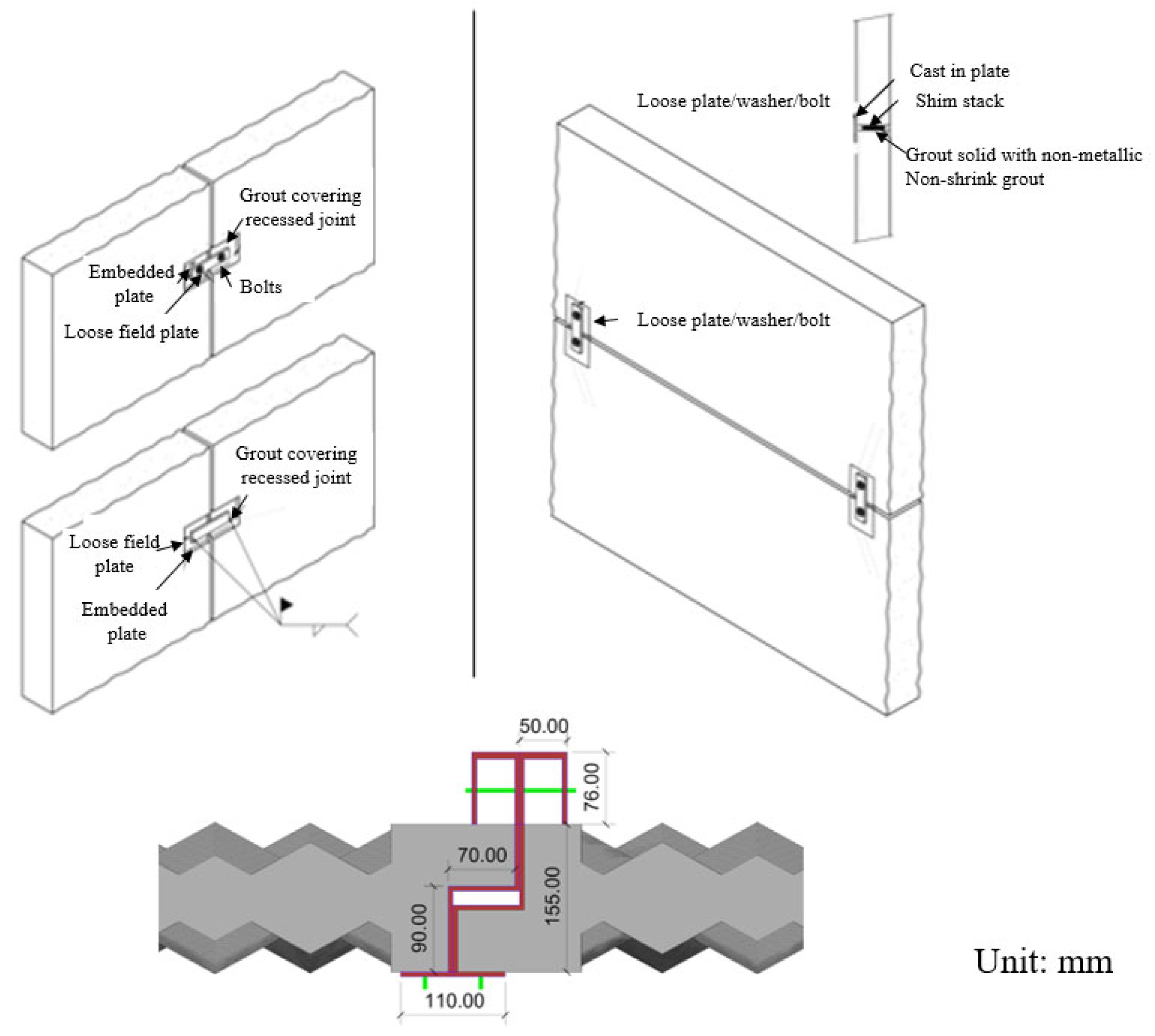

- Anchor bolt and stud fabrication is a viable option for achieving joints design in an AM wall structure. Additionally, the DfMA of AM wall structure can be designed as like manner to the precast wall system. More practices are required for validating these techniques.

- Although many machine learning methods for DfAM has been studied in a variety of applications, only one or two research programs have been conducted in the building industry.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- ElMaraghy, W.; ElMaraghy, H.; Tomiyama, T.; Monostori, L. Complexity in engineering design and manufacturing. CIRP Ann. 2012, 61, 793–814. [Google Scholar] [CrossRef]

- Cardin, M.-A.; Kolfschoten, G.L.; Frey, D.D.; de Neufville, R.; de Weck, O.L.; Geltner, D.M. Empirical evaluation of procedures to generate flexibility in engineering systems and improve lifecycle performance. Res. Eng. Des. 2012, 24, 277–295. [Google Scholar] [CrossRef]

- Hannibal, M.; Knight, G. Additive manufacturing and the global factory: Disruptive technologies and the location of international business. Int. Bus. Rev. 2018, 27, 1116–1127. [Google Scholar] [CrossRef]

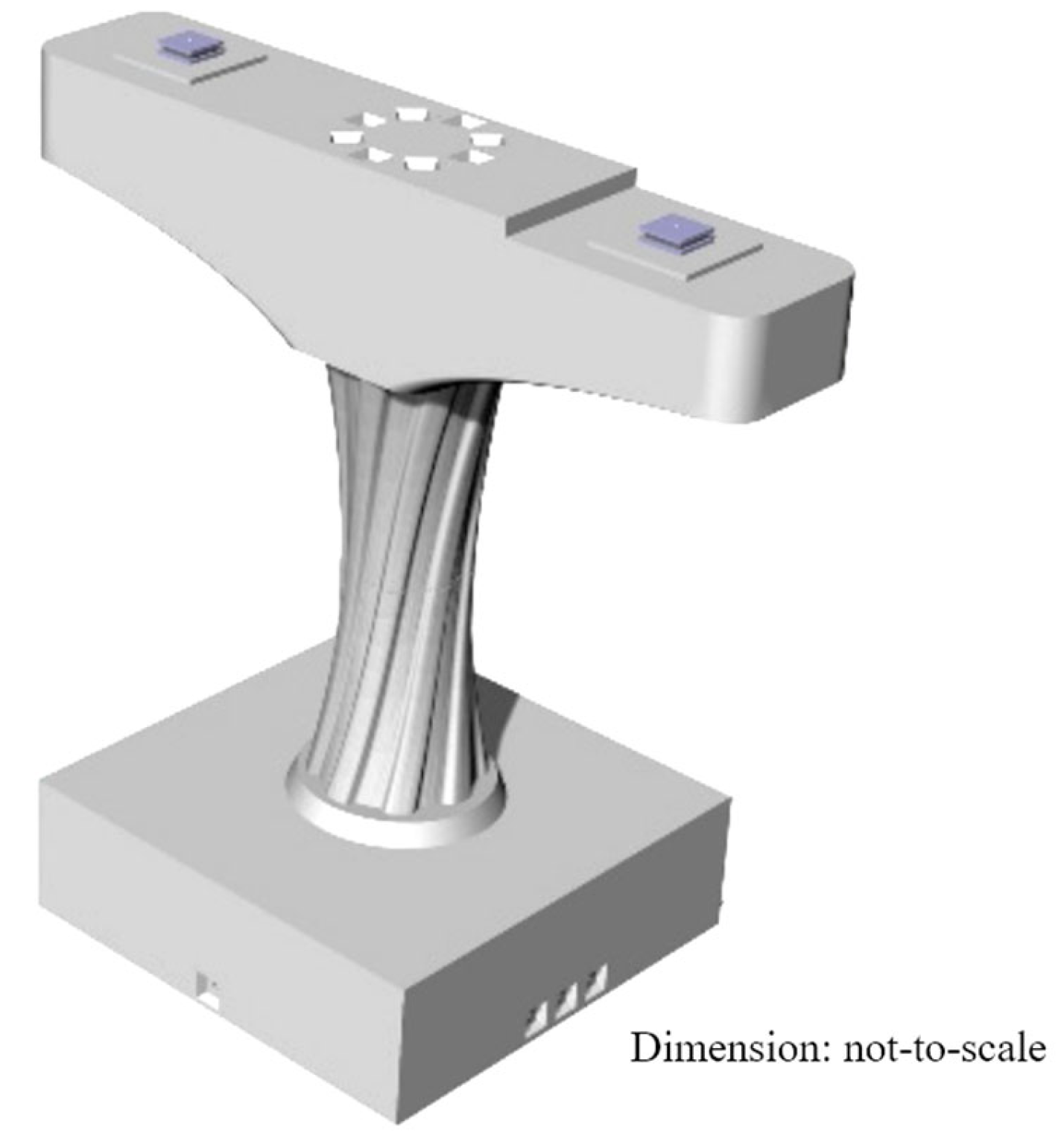

- Nguyen, D. and C. Shim, Digital Fabrication for DfMA of a Prefabricated Bridge Pier, in The 17th East Asia-Pacific Conference on Structural Engineering & Construction (EASEC17). 2022: Singapore.

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- de Soto, B.G. , et al., Productivity of digital fabrication in construction: Cost and time analysis of a robotically built wall. Automation in construction, 2018. 92: p. 297-311.

- Buswell, R.; Soar, R.; Gibb, A.; Thorpe, A. Freeform Construction: Mega-scale Rapid Manufacturing for construction. Autom. Constr. 2007, 16, 224–231. [Google Scholar] [CrossRef]

- Lloret, E. , et al., Complex concrete structures: Merging existing casting techniques with digital fabrication. Computer-Aided Design, 2015. 60: p. 40-49.

- Prakash, K.S.; Nancharaih, T.; Rao, V.S. Additive Manufacturing Techniques in Manufacturing -An Overview. Mater. Today: Proc. 2018, 5, 3873–3882. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Standardization, I.O.f. , Additive Manufacturing: General: Principles: Terminology. 2015: ISO.

- Ali, M., A. Abilgaziyev, and D. Adair, 4D printing: a critical review of current developments, and future prospects. The International Journal of Advanced Manufacturing Technology, 2019. 105(1): p. 701-717.

- Hull, C.W. , The birth of 3D printing. Research-Technology Management, 2015. 58(6): p. 25-30.

- Pegna, J. Exploratory investigation of solid freeform construction. Autom. Constr. 1997, 5, 427–437. [Google Scholar] [CrossRef]

- Chung, J.; Lee, G.; Kim, J.-H. Framework for technical specifications of 3D concrete printers. Autom. Constr. 2021, 127, 103732. [Google Scholar] [CrossRef]

- Sun, J.; Xiao, J.; Li, Z.; Feng, X. Experimental study on the thermal performance of a 3D printed concrete prototype building. Energy Build. 2021, 241, 110965. [Google Scholar] [CrossRef]

- Lyu, F.; Zhao, D.; Hou, X.; Sun, L.; Zhang, Q. Overview of the Development of 3D-Printing Concrete: A Review. Appl. Sci. 2021, 11, 9822. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Sakdanaraseth, T.; Horayangkura, V. Design and Construction Method of a 3D Concrete Printing Self-Supporting Curvilinear Pavilion. J. Arch. Eng. 2021, 27, 05021006. [Google Scholar] [CrossRef]

- De Schutter, G. , et al., Vision of 3D printing with concrete—Technical, economic and environmental potentials. Cement and Concrete Research, 2018. 112: p. 25-36.

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: a review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Prasittisopin, L. , et al., Lean manufacturing and thermal enhancement of single-layer wall with an additive manufacturing (AM) structure. ZKG Intern, 2019. 4: p. 64-74.

- Goulding, J.; Pour Rahimian, F.; Arif, M. ; Sharp New offsite production and business models in construction: priorities for the future research agenda. Arch. Eng. Des. Manag. 2014, 11, 163–184. [Google Scholar] [CrossRef]

- Pan, W.; Goodier, C. House-Building Business Models and Off-Site Construction Take-Up. J. Arch. Eng. 2012, 18, 84–93. [Google Scholar] [CrossRef]

- Maxwell, D. and I. Kuzmanovska, A blended approach to concept transfer: Building platform-based Design for Manufacture and Assembly (DfMA), in Structures and Architecture A Viable Urban Perspective? 2022, CRC Press. p. 713-720.

- Arif, M.; Goulding, J.; Pour Rahimian, F. Promoting Off-Site Construction: Future Challenges and Opportunities. J. Arch. Eng. 2012, 18, 75–78. [Google Scholar] [CrossRef]

- Goodier, C.; Gibb, A. Future opportunities for offsite in the UK. Constr. Manag. Econ. 2007, 25, 585–595. [Google Scholar] [CrossRef]

- Blismas, N.; Pasquire, C.; Gibb, A. Benefit evaluation for off-site production in construction. Constr. Manag. Econ. 2006, 24, 121–130. [Google Scholar] [CrossRef]

- Blismas, N.G.; Pendlebury, M.; Gibb, A.; Pasquire, C. Constraints to the Use of Off-site Production on Construction Projects. Arch. Eng. Des. Manag. 2005, 1, 153–162. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Pan, W.; Ye, K. Major Barriers to Off-Site Construction: The Developer’s Perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- Fox, S., L. Marsh, and G. Cockerham, Design for manufacture: A strategy for successful application to buildings. Construction Management and Economics, 2001. 19(5): p. 493-502.

- Winch, G.; Usmani, A.; Edkins, A. Towards total project quality: a gap analysis approach. Constr. Manag. Econ. 1998, 16, 193–207. [Google Scholar] [CrossRef]

- Boothroyd, G. Assembly Automation and Product Design, 2nd ed.; Taylor & Francis: Boca Raton, FL, USA, 2005; pp. 29–45. [Google Scholar]

- Gatenby, D.A. and G. Foo, Design for X (DFX): key to competitive, profitable products. AT&T Technical Journal, 1990. 69(3): p. 2-13.

- Bock, T. and T. Linner, Robot oriented design. 2015: Cambridge university press.

- Linner, T. , Automated and robotic construction: integrated automated construction sites. 2013, Technische Universität München.

- Thompson, M.K.; Jespersen, I.K.J.; Kjærgaard, T. Design for manufacturing and assembly key performance indicators to support high-speed product development. Procedia CIRP 2018, 70, 114–119. [Google Scholar] [CrossRef]

- Gerth, R.; Boqvist, A.; Bjelkemyr, M.; Lindberg, B. Design for construction: utilizing production experiences in development. Constr. Manag. Econ. 2013, 31, 135–150. [Google Scholar] [CrossRef]

- El-Nounu, A.; Popov, A.; Ratchev, S. Redesign methodology for mechanical assembly. Res. Eng. Des. 2017, 29, 107–122. [Google Scholar] [CrossRef] [PubMed]

- Kuo, T.-C., S. H. Huang, and H.-C. Zhang, Design for manufacture and design for ‘X’: concepts, applications, and perspectives. Computers & industrial engineering, 2001. 41(3): p. 241-260.

- Boothroyd, G. , Design for assembly—the key to design for manufacture. The International Journal of Advanced Manufacturing Technology, 1987. 2(3): p. 3-11.

- Swift, K. and A. Redford, Design for assembly-analysis of a design can cut assembly costs. Engineering, 1980. 220(7): p. 799-802.

- Emmatty, F.J.; Sarmah, S.P. Modular product development through platform-based design and DFMA. J. Eng. Des. 2012, 23, 696–714. [Google Scholar] [CrossRef]

- Stoll, H.W. Design for Manufacture: An Overview. Appl. Mech. Rev. 1986, 39, 1356–1364. [Google Scholar] [CrossRef]

- Wasim, M., P. Vaz Serra, and T.D. Ngo, Design for manufacturing and assembly for sustainable, quick and cost-effective prefabricated construction–a review. International Journal of Construction Management, 2020: p. 1-9.

- Oh, Y.; Zhou, C.; Behdad, S. Part decomposition and assembly-based (Re) design for additive manufacturing: A review. Addit. Manuf. 2018, 22, 230–242. [Google Scholar] [CrossRef]

- Robinson, T.; Friel, I.; Armstrong, C.G.; Murphy, A.; Butterfield, J.; Price, M.; Marzano, A. Computer-aided design model parameterisation to derive knowledge useful for manufacturing design decisions. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 2017, 232, 621–628. [Google Scholar] [CrossRef]

- Urban, M.; Manlig, F. DEVELOPMENT OF PRODUCT WHILE CONSIDERING MATERIAL FLOW IN A PRODUCT’S LIFE. MM Sci. J. 2018, 2018, 2313–2318. [Google Scholar] [CrossRef]

- Gokul Kumar, K. and C. Naiju, Early cost estimation of hand pressure mop using design for manufacture & assembly (DFMA). Int J Mech Eng Technol, 2017. 8(9): p. 167-172.

- Anyfantis, K.; Stavropoulos, P.; Foteinopoulos, P.; Chryssolouris, G. An approach for the design of multi-material mechanical components. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 2018, 233, 960–974. [Google Scholar] [CrossRef]

- Favi, C., M. Germani, and M. Mandolini, Multi-objective conceptual design: an approach to make cost-efficient the design for manufacturing and assembly in the development of complex products, in Advances on Mechanics, Design Engineering and Manufacturing. 2017, Springer. p. 63-70.

- Ashley, S. , Cutting costs and time with DFMA. Mechanical Engineering, 1995. 117(3): p. 74-77.

- O’Driscoll, M. , Design for manufacture. Journal of materials processing technology, 2002. 122(2-3): p. 318-321.

- RIBA, RIBA Plan of Work 2013: Designing for Manufacture and Assembly. 2013, Royal Institute of British Architects (RIBA) London.

- Robinson, M. , File-to-Factory: Transferring Design Intent to Manufacture. 2020.

- Constance, J. , DFMA: learning to design for manufacture and assembly. Mechanical Engineering, 1992. 114(5): p. 70.

- Boothroyd, G., P. Dewhurst, and W.A. Knight, Product design for manufacture and assembly. 2010: CRC press.

- Bogue, R. Design for manufacture and assembly: background, capabilities and applications. Assem. Autom. 2012, 32, 112–118. [Google Scholar] [CrossRef]

- Stoll, H.W. , Design for manufacture. Manufacturing Engineering, 1988. 100(1): p. 67-73.

- Kim, M.-K.; McGovern, S.; Belsky, M.; Middleton, C.; Brilakis, I. A Suitability Analysis of Precast Components for Standardized Bridge Construction in the United Kingdom. Procedia Eng. 2016, 164, 188–195. [Google Scholar] [CrossRef]

- Jung, S.; Yu, J. Design for Manufacturing and Assembly (DfMA) Checklists for Off-Site Construction (OSC) Projects. Sustainability 2022, 14, 11988. [Google Scholar] [CrossRef]

- Banks, C.; Kotecha, R.; Curtis, J.; Dee, C.; Pitt, N.; Papworth, R. Enhancing high-rise residential construction through design for manufacture and assembly – a UK case study. Proc. Inst. Civ. Eng. - Manag. Procure. Law 2018, 171, 164–175. [Google Scholar] [CrossRef]

- Bao, Z.; Laovisutthichai, V.; Tan, T.; Wang, Q.; Lu, W. Design for manufacture and assembly (DfMA) enablers for offsite interior design and construction. Build. Res. Inf. 2021, 50, 325–338. [Google Scholar] [CrossRef]

- Laovisutthichai, V. and W. Lu, Architectural design for manufacturing and assembly for sustainability, in Design and Technological Applications in Sustainable Architecture. 2021, Springer. p. 219-233.

- Serra, P.V., G. Marfella, and S. Egglestone, Implications of Flat-Pack Plumbing Systems For High-Rise Construction Efficiency. CTBUH Journal, 2019(3).

- Wasim, M.; Han, T.M.; Huang, H.; Madiyev, M.; Ngo, T.D. An approach for sustainable, cost-effective and optimised material design for the prefabricated non-structural components of residential buildings. J. Build. Eng. 2020, 32, 101474. [Google Scholar] [CrossRef]

- Alfieri, E.; Seghezzi, E.; Sauchelli, M.; Di Giuda, G.M.; Masera, G. A BIM-based approach for DfMA in building construction: framework and first results on an Italian case study. Arch. Eng. Des. Manag. 2020, 16, 247–269. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Y.; Lei, Z.; Li, H.X.; Han, S. Design for Manufacturing and Assembly: A BIM-Enabled Generative Framework for Building Panelization Design. Adv. Civ. Eng. 2021, 2021, 1–14. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Ng, M.S.; Graser, K.; Hall, D.M. Digital fabrication, BIM and early contractor involvement in design in construction projects: a comparative case study. Arch. Eng. Des. Manag. 2021, 19, 39–55. [Google Scholar] [CrossRef]

- Ng, M.S.; Chen, Q.; Hall, D.M.; Hackl, J.; Adey, B.T. Designing for Digital Fabrication: An Empirical Study of Industry Needs, Perceived Benefits, and Strategies for Adoption. J. Manag. Eng. 2022, 38, 04022052. [Google Scholar] [CrossRef]

- Abrishami, S.; Martín-Durán, R. BIM and DfMA: A Paradigm of New Opportunities. Sustainability 2021, 13, 9591. [Google Scholar] [CrossRef]

- Rehman, S.U., S. Ryu, and I. Kim. An Analysis and Consolidation of DfMA Based Construction Guidelines and Its Validation Through a Korean Case Study. in International Conference on Geometry and Graphics. 2023. Springer.

- Williams, N.; Stehling, H.; Scheurer, F.; Oesterle, S.; Kohler, M.; Gramazio, F. A Case Study of a Collaborative Digital Workflow in the Design and Production of Formwork for ‘Non-Standard’ Concrete Structures. Int. J. Arch. Comput. 2011, 9, 223–240. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Shou, W.; Xu, B. Integrating BIM and augmented reality for interactive architectural visualisation. Constr. Innov. 2014, 14, 453–476. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, Y.F. Additive manufacturing-enabled design theory and methodology: a critical review. Int. J. Adv. Manuf. Technol. 2015, 80, 327–342. [Google Scholar] [CrossRef]

- Tang, Y.; Zhao, Y.F. A survey of the design methods for additive manufacturing to improve functional performance. Rapid Prototyp. J. 2016, 22, 569–590. [Google Scholar] [CrossRef]

- Tang, Y., S. Yang, and Y.F. Zhao, Sustainable design for additive manufacturing through functionality integration and part consolidation, in Handbook of sustainability in additive manufacturing. 2016, Springer. p. 101-144.

- Krimi, I.; Lafhaj, Z.; Ducoulombier, L. Prospective study on the integration of additive manufacturing to building industry—Case of a French construction company. Addit. Manuf. 2017, 16, 107–114. [Google Scholar] [CrossRef]

- Arashpour, M.; Miletic, M.; Williams, N.; Fang, Y. Design for Manufacture and Assembly in Off-Site Construction: Advanced Production of Modular Façade Systems. 34th International Symposium on Automation and Robotics in Construction. LOCATION OF CONFERENCE, TaiwanDATE OF CONFERENCE; pp. 216–221.

- Durakovic, B. , Design for additive manufacturing: Benefits, trends and challenges. Periodicals of Engineering and Natural Sciences (PEN), 2018. 6(2): p. 179-191.

- Ng, M.S. and D. In M. Hall. Toward lean management for digital fabrication: A review of the shared practices of lean, DfMA and dfab. in Proceedings of the 27th Annual Conference of the International Group for Lean Construction (IGLC), Dublin, Ireland. 2019. [Google Scholar]

- Dörfler, K. , et al., Mobile robotic fabrication beyond factory conditions: Case study Mesh Mould wall of the DFAB HOUSE. Construction robotics, 2019. 3(1): p. 53-67.

- Hinchy, E.P. , Design for Additive Manufacturing, in Polymer-Based Additive Manufacturing. 2019, Springer. p. 23-50.

- Medellin-Castillo, H.I.; Zaragoza-Siqueiros, J. Design and Manufacturing Strategies for Fused Deposition Modelling in Additive Manufacturing: A Review. Chin. J. Mech. Eng. 2019, 32, 53. [Google Scholar] [CrossRef]

- Ng, M.S.; Bonanomi, M.M.; Hall, D.M.; Hackl, J. Design for Digital Fabrication: an Industry needs Analysis of Collaboration Platforms and Integrated Management Processes. 37th International Symposium on Automation and Robotics in Construction. LOCATION OF CONFERENCE, JapanDATE OF CONFERENCE; pp. 318–325.

- Alfaify, A.; Saleh, M.; Abdullah, F.; Al-Ahmari, A. Design for Additive Manufacturing: A Systematic Review. Sustainability 2020, 12, 7936. [Google Scholar] [CrossRef]

- Nguyen, D. and C. Shim, Digital Fabrication for DfMA of a Prefabricated Bridge Pier.

- Ghaffar, S.H., J. Corker, and P. Mullett, The potential for additive manufacturing to transform the construction industry, in Construction 4.0. 2020, Routledge. p. 155-187.

- Gibson, I. , et al., Design for additive manufacturing, in Additive manufacturing technologies. 2021, Springer. p. 555-607.

- Frascio, M.; Marques, E.A.d.S.; Carbas, R.J.C.; da Silva, L.F.M.; Monti, M.; Avalle, M. Review of Tailoring Methods for Joints with Additively Manufactured Adherends and Adhesives. Materials 2020, 13, 3949. [Google Scholar] [CrossRef] [PubMed]

- Ng, C. and D. Hall. Teaching Target Value Design for Digital Fabrication in an Online Game: Overview and Case Study. in Proceedings 29th Annual Conference of the International Group for Lean Construction (IGLC). 2021. International Group for Lean Construction.

- Graser, K.; Kahlert, A.; Hall, D.M. DFAB HOUSE: implications of a building-scale demonstrator for adoption of digital fabrication in AEC. Constr. Manag. Econ. 2021, 39, 853–873. [Google Scholar] [CrossRef]

- Ghiasian, S.E. , The Development of Intelligent Assessment and Re-design Recommender Systems for Additive Manufacturing. 2021, State University of New York at Buffalo.

- Classen, M.; Ungermann, J.; Sharma, R. Additive Manufacturing of Reinforced Concrete—Development of a 3D Printing Technology for Cementitious Composites with Metallic Reinforcement. Appl. Sci. 2020, 10, 3791. [Google Scholar] [CrossRef]

- Vu, B.N.; Wein, F.; Stingl, M. Two-Scale Optimization and Generation of Anisotropic Cellular Designs in the Context of Additive Manufacturing. Comput. Des. 2021, 140, 103073. [Google Scholar] [CrossRef]

- Rankohi, S.; Carbone, C.; Iordanova, I.; Bourgault, M. Design-for-Manufacturing-and-Assembly (DfMA) for the construction industry: A review. Modul. Offsite Constr. (moc) Summit Proc. [CrossRef]

- Sadakorn, W., S. Prasertsuk, and L. Prasittisopin, 3D Cement Printing: DFMA Guideline of Patterned Load-bearing Walls for Small Residential Units, in 5th International Conference on Civil Engineering and Architecture (ICCEA 2022). 2022, Dec 16-18: Hanoi, VN.

- Spuller, J. , Additive Manufacturing Design Methods in Construction Industry. 2022.

- Song, X.T., J. -Y. Kuo, and C.-H. Chen, Design methodologies for conventional and additive manufacturing, in Digital Manufacturing. 2022, Elsevier. p. 97-143.

- Qin, J.; Hu, F.; Liu, Y.; Witherell, P.; Wang, C.C.; Rosen, D.W.; Simpson, T.W.; Lu, Y.; Tang, Q. Research and application of machine learning for additive manufacturing. Addit. Manuf. 2022, 52, 102691. [Google Scholar] [CrossRef]

- Sass, L.; Oxman, R. Materializing design: the implications of rapid prototyping in digital design. Des. Stud. 2006, 27, 325–355. [Google Scholar] [CrossRef]

- Bak, D. Rapid prototyping or rapid production? 3D printing processes move industry towards the latter. Assem. Autom. 2003, 23, 340–345. [Google Scholar] [CrossRef]

- Bridgewater, C. Principles of design for automation applied to construction tasks. Autom. Constr. 1993, 2, 57–64. [Google Scholar] [CrossRef]

- Bonwetsch, T. Robotic Assembly Processes as a Driver in Architectural Design. Nexus Netw. J. 2012, 14, 483–494. [Google Scholar] [CrossRef]

- Martínez, S.; Jardón, A.; Victores, J.; Balaguer, C. Flexible field factory for construction industry. Assem. Autom. 2013, 33, 175–183. [Google Scholar] [CrossRef]

- Montali, J.; Overend, M.; Pelken, P.M.; Sauchelli, M. Knowledge-Based Engineering in the design for manufacture of prefabricated façades: current gaps and future trends. Arch. Eng. Des. Manag. 2017, 14, 78–94. [Google Scholar] [CrossRef]

- Gomes Miron, L., A. Kaushik, and L. Koskela, Target value design: The challenge of value generation. 2015, IGLC. net.

- Silveira, S.S. and T.d.C. Alves, Target value design inspired practices to deliver sustainable buildings. Buildings, 2018. 8(9): p. 116.

- Ng, M.S.; Hall, D.; Schmailzl, M.; Linner, T.; Bock, T. Identifying enablers and relational ontology networks in design for digital fabrication. Autom. Constr. 2022, 144. [Google Scholar] [CrossRef]

- Garcia De Soto, B. , et al. Rethinking the roles in the AEC industry to accommodate digital fabrication. in Creative Construction Conference 2018. 2018. Budapest University of Technology and Economics.

- Graser, K. , et al., DFAB HOUSE—A Comprehensive Demonstrator of Digital Fabrication in Architecture. Fabricate 2020: making resilient architecture, 2020. 4(2020): p. 130-139.

- Barbosa, G.F.; Carvalho, J. Guideline tool based on design for manufacturing and assembly (DFMA) methodology for application on design and manufacturing of aircrafts. J. Braz. Soc. Mech. Sci. Eng. 2013, 36, 605–614. [Google Scholar] [CrossRef]

- Rekola, M.; Kojima, J.; Mäkeläinen, T. Towards Integrated Design and Delivery Solutions: Pinpointed Challenges of Process Change. Arch. Eng. Des. Manag. 2010, 6, 264–278. [Google Scholar] [CrossRef]

- Puttonen, T. , Design of an elevator button assembly for additive manufacturing. 2017.

- Bralia, J.G. , Handbook of product design for manufacturing: a practical guide to low-cost production. McGraw-Hill Book Company, 1986, 1986: p. 1120.

- Mueller, B. Additive Manufacturing Technologies – Rapid Prototyping to Direct Digital Manufacturing. Assem. Autom. 2012, 32. [Google Scholar] [CrossRef]

- Furet, B.; Poullain, P.; Garnier, S. 3D printing for construction based on a complex wall of polymer-foam and concrete. Addit. Manuf. 2019, 28, 58–64. [Google Scholar] [CrossRef]

- Nguyen, D.-C., S. -J. Park, and C.-S. Shim, Digital engineering models for prefabricated bridge piers. SMART STRUCTURES AND SYSTEMS, 2022. 30(1): p. 35-47.

- Mavroidis, C.; DeLaurentis, K.J.; Won, J.; Alam, M. Fabrication of Non-Assembly Mechanisms and Robotic Systems Using Rapid Prototyping. J. Mech. Des. 2000, 123, 516–524. [Google Scholar] [CrossRef]

- Chen, Y.; Zhezheng, C. Joint analysis in rapid fabrication of non-assembly mechanisms. Rapid Prototyp. J. 2011, 17, 408–417. [Google Scholar] [CrossRef]

- Paul, S.C.; van Zijl, G.P.; Tan, M.J.; Gibson, I. A review of 3D concrete printing systems and materials properties: current status and future research prospects. Rapid Prototyp. J. 2018, 24, 784–798. [Google Scholar] [CrossRef]

- Cui, H.; Li, Y.; Cao, X.; Huang, M.; Tang, W.; Li, Z. Experimental Study of 3D Concrete Printing Configurations Based on the Buildability Evaluation. Appl. Sci. 2022, 12, 2939. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Bukkapatnam, S.; Kwon, H.; Saito, J. Experimental investigation of contour crafting using ceramics materials. Rapid Prototyp. J. 2001, 7, 32–42. [Google Scholar] [CrossRef]

- Frizziero, L.; Donnici, G.; Liverani, A.; Dhaimini, K. Design for Additive Manufacturing and Advanced Development Methods Applied to an Innovative Multifunctional Fan. Int. J. Manuf. Mater. Mech. Eng. 2019, 9, 1–32. [Google Scholar] [CrossRef]

- EL Mesbahi, J.; Buj-Corral, I.; EL Mesbahi, A. Use of the QFD method to redesign a new extrusion system for a printing machine for ceramics. Int. J. Adv. Manuf. Technol. 2020, 111, 227–242. [Google Scholar] [CrossRef]

- Nguyen, D.S. and F. Vignat. Topology optimization as an innovative design method for additive manufacturing. in 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM). 2017. IEEE.

- Morin, R. and I.Y. Kim, Topology Optimization for DfAM with Build Area Constraints.

- Karadeniz, Z.H. and M. Toksoy, 3D printing of HVAC systems. REHVA Journal, 2017: p. 18-22.

- Samuel, A.L. Some Studies in Machine Learning Using the Game of Checkers. II-Recent Progress. In Computer Games I; Levi, D.N.L., Ed.; Springer: New York, NY, USA, 1988; pp. 366–400. [Google Scholar] [CrossRef]

- Yuliarty, P.; Ardiwijayanta, H. The design of front and back grille of KAD-927 B fan with Nigel Cross Approach at PT. X (A Manufacturer of Household Appliances). IOP Conf. Series: Mater. Sci. Eng. 2018, 453, 012035. [Google Scholar] [CrossRef]

- Donnici, G.; Frizziero, L.; Liverani, A.; Buscaroli, G.; Raimondo, L.; Saponaro, E.; Venditti, G. A New Car Concept Developed with Stylistic Design Engineering (SDE). Inventions 2020, 5, 30. [Google Scholar] [CrossRef]

- R. Jacobs and R. B. Chase, Operations Management. Production and Supply Chain, 15th ed. M: Mexico, 2018.

- S. Kalpakjian and S. Schmid, Manufactura, Ingeniería y Tecnología. 2008.

- Ferreira, R.d.S.B.; Sabbaghi, A.; Huang, Q. Automated Geometric Shape Deviation Modeling for Additive Manufacturing Systems via Bayesian Neural Networks. IEEE Trans. Autom. Sci. Eng. 2019, 17, 584–598. [Google Scholar] [CrossRef]

- Haruna, A.; Jiang, P. Adaptability analysis of design for additive manufacturing by using fuzzy Bayesian network approach. Adv. Eng. Informatics 2022, 52. [Google Scholar] [CrossRef]

- Sun, H.; Pedrielli, G.; Zhao, G.; Zhou, C.; Xu, W.; Pan, R. Cyber coordinated simulation for distributed multi-stage additive manufacturing systems. J. Manuf. Syst. 2020, 57, 61–71. [Google Scholar] [CrossRef]

- Elhoone, H.; Zhang, T.; Anwar, M.; Desai, S. Cyber-based design for additive manufacturing using artificial neural networks for Industry 4.0. Int. J. Prod. Res. 2020, 58, 2841–2861. [Google Scholar] [CrossRef]

- Ding, L.; Tan, S.; Chen, W.; Jin, Y.; Sun, Y.; Zhang, Y. Development of a manufacturability predictor for periodic cellular structures in a selective laser melting process via experiment and ANN modelling. Virtual Phys. Prototyp. 2022, 17, 948–965. [Google Scholar] [CrossRef]

- Nagarajan, H.P.N.; Mokhtarian, H.; Jafarian, H.; Dimassi, S.; Bakrani-Balani, S.; Hamedi, A.; Coatanéa, E.; Wang, G.G.; Haapala, K.R. Knowledge-Based Design of Artificial Neural Network Topology for Additive Manufacturing Process Modeling: A New Approach and Case Study for Fused Deposition Modeling. J. Mech. Des. 2018, 141. [Google Scholar] [CrossRef]

- Xiong, Y.; Duong, P.L.T.; Wang, D.; Park, S.-I.; Ge, Q.; Raghavan, N.; Rosen, D.W. Data-Driven Design Space Exploration and Exploitation for Design for Additive Manufacturing. J. Mech. Des. 2019, 141, 1–46. [Google Scholar] [CrossRef]

- Jiang, J.; Xiong, Y.; Zhang, Z.; Rosen, D.W. Machine learning integrated design for additive manufacturing. J. Intell. Manuf. 2020, 33, 1073–1086. [Google Scholar] [CrossRef]

- Prabhu, R.; Miller, S.R.; Simpson, T.W.; Meisel, N.A. Exploring the Effects of Additive Manufacturing Education on Students' Engineering Design Process and its Outcomes. J. Mech. Des. 2019, 142, 1–37. [Google Scholar] [CrossRef]

- Hamulczuk, D.; Isaksson, O. Data analysis as the basis for improved design for additive manufacturing(DfAM). Proc. Des. Soc. 2021, 1, 811–820. [Google Scholar] [CrossRef]

- Page, T.D., S. Yang, and Y. F. Zhao. Automated candidate detection for additive manufacturing: a framework proposal. in Proceedings of the design society: international conference on engineering design. 2019. Cambridge University Press. [Google Scholar]

- Chang, J. , et al. Bundle recommendation with graph convolutional networks. in Proceedings of the 43rd international ACM SIGIR conference on Research and development in Information Retrieval. 2020.

- Huang, J.; Kwok, T.-H.; Zhou, C.; Xu, W. Surfel convolutional neural network for support detection in additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 105, 3593–3604. [Google Scholar] [CrossRef]

- Zhu, Z.; Anwer, N.; Huang, Q.; Mathieu, L. Machine learning in tolerancing for additive manufacturing. CIRP Ann. 2018, 67, 157–160. [Google Scholar] [CrossRef]

- Woo, Y.-J.; Nam, D.-H.; Lee, S.-R.; Kim, E.-A.; Lee, W.-J.; Yang, D.-Y.; Yu, J.-H.; Park, Y.-H.; Lee, H.-S. High-Efficiency Cooling System Using Additive Manufacturing. Arch. Met. Mater. 2021, 66, 689–693. [Google Scholar] [CrossRef]

- Alshare, A.A.; Calzone, F.; Muzzupappa, M. Hydraulic manifold design via additive manufacturing optimized with CFD and fluid-structure interaction simulations. Rapid Prototyp. J. 2019, 25, 1516–1524. [Google Scholar] [CrossRef]

- Desai, P.S.; Higgs, C.F. Spreading Process Maps for Powder-Bed Additive Manufacturing Derived from Physics Model-Based Machine Learning. Metals 2019, 9, 1176. [Google Scholar] [CrossRef]

- Chu, C.; Graf, G.; Rosen, D.W. Design for Additive Manufacturing of Cellular Structures. Comput.-Aided Des. Appl. 2008, 5, 686–696. [Google Scholar] [CrossRef]

- Maiyar, L.M.; Singh, S.; Prabhu, V.; Tiwari, M.K. Part segregation based on particle swarm optimisation for assembly design in additive manufacturing. Int. J. Comput. Integr. Manuf. 2019, 32, 705–722. [Google Scholar] [CrossRef]

- As, I.; Pal, S.; Basu, P. Artificial intelligence in architecture: Generating conceptual design via deep learning. Int. J. Arch. Comput. 2018, 16, 306–327. [Google Scholar] [CrossRef]

- Yigit, S. A machine-learning-based method for thermal design optimization of residential buildings in highly urbanized areas of Turkey. J. Build. Eng. 2021, 38, 102225. [Google Scholar] [CrossRef]

- Huang, J.; Algahtani, M.; Kaewunruen, S. Energy Forecasting in a Public Building: A Benchmarking Analysis on Long Short-Term Memory (LSTM), Support Vector Regression (SVR), and Extreme Gradient Boosting (XGBoost) Networks. Appl. Sci. 2022, 12, 9788. [Google Scholar] [CrossRef]

- Lin, Y.; Zhao, L.; Liu, X.; Yang, W.; Hao, X.; Tian, L. Design Optimization of a Passive Building with Green Roof through Machine Learning and Group Intelligent Algorithm. Buildings 2021, 11, 192. [Google Scholar] [CrossRef]

- Sresakoolchai, J. and S. Kaewunruen, Integration of building information modeling (BIM) and artificial intelligence (AI) to detect combined defects of infrastructure in the railway system, in Resilient Infrastructure. 2022, Springer. p. 377-386.

- Kittinaraporn, W.; Tuprakay, S.; Prasittisopin, L. Effective Modeling for Construction Activities of Recycled Aggregate Concrete Using Artificial Neural Network. J. Constr. Eng. Manag. 2022, 148, 04021206. [Google Scholar] [CrossRef]

- Sresakoolchai, J.; Kaewunruen, S. Integration of Building Information Modeling and Machine Learning for Railway Defect Localization. IEEE Access 2021, 9, 166039–166047. [Google Scholar] [CrossRef]

- Goh, G.D.; Sing, S.L.; Yeong, W.Y. A Review on Machine Learning in 3D Printing: Applications, Potential, and Challenges; Springer: Netherlands, 2021; Volume 54, ISBN 0123456789. [Google Scholar]

- Kumke, M.; Watschke, H.; Vietor, T. A new methodological framework for design for additive manufacturing. Virtual Phys. Prototyp. 2015, 11, 3–19. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Lao, W.; Li, M.; Wong, T.N.; Tan, M.J.; Tjahjowidodo, T. Improving surface finish quality in extrusion-based 3D concrete printing using machine learning-based extrudate geometry control. Virtual Phys. Prototyp. 2020, 15, 178–193. [Google Scholar] [CrossRef]

- Ko, H.; Witherell, P.; Lu, Y.; Kim, S.; Rosen, D.W. Machine learning and knowledge graph based design rule construction for additive manufacturing. Addit. Manuf. 2020, 37, 101620. [Google Scholar] [CrossRef]

- Nadhim, E.A.; Hon, C.; Xia, B.; Stewart, I.; Fang, D. Falls from Height in the Construction Industry: A Critical Review of the Scientific Literature. Int. J. Environ. Res. Public Heal. 2016, 13, 638. [Google Scholar] [CrossRef] [PubMed]

- Flatt, R.J.; Wangler, T. On sustainability and digital fabrication with concrete. Cem. Concr. Res. 2022, 158. [Google Scholar] [CrossRef]

- Ranaudo, F.; Van Mele, T.; Block, P. A low-carbon, funicular concrete floor system: design and engineering of the HiLo floors. IABSE Congress, Ghent 2021: Structural Engineering for Future Societal Needs. LOCATION OF CONFERENCE, BelgiumDATE OF CONFERENCE; pp. 2016–2024.

- Sereewatthanawut, I.; Prasittisopin, L. Environmental evaluation of pavement system incorporating recycled concrete aggregate. Int. J. Pavement Res. Technol. 2020, 13, 455–465. [Google Scholar] [CrossRef]

- Luhar, S.; Suntharalingam, T.; Navaratnam, S.; Luhar, I.; Thamboo, J.; Poologanathan, K.; Gatheeshgar, P. Sustainable and Renewable Bio-Based Natural Fibres and Its Application for 3D Printed Concrete: A Review. Sustainability 2020, 12, 10485. [Google Scholar] [CrossRef]

- Walsh, N. P. , AI SpaceFactory Wins NASA's 3D-Printed Mars Habitat Challenge, Arch daily, 2019. Accessed 14 Dec 2022. https://www.archdaily.com/916888/ai-spacefactory-wins-nasas-3d-printed-mars-habitat-challenge.

| PICO component | Explanation |

|---|---|

| Problem | Review current knowledge of DfMA for Dfab and AM process |

| Intervention | Examine the effective methods and applications of DfMA for Dfab and AM process |

| Comparison | Compare DfMA of prefabrication and precast construction |

| Outcome | DfMA knowledge for Dfab and AM is currently under development and seemingly adopted similarly to prefabrication construction. The knowledge now highly emphasizes on performance and functionality |

| Stage | Explanation | |

|---|---|---|

| 1 | Functional analysis | Any material not qualifying for characteristics like relative movement need and adjustment is excluded from the system. |

| 2 | Manufacturing process | Selection of materials, quantities, complexity, process, and cost for improved manufacturing. |

| 3 | Handling/feeding | A part's ease of manual or automatic assembly is evaluated (termed as feeding). |

| 4 | Assembly/jointing | Identifies and scores insertion, fastening, and gripping portions. This examination examines the ease of inserting and connecting pieces. Avoid fasteners. |

| 5 | Product group | A product's similar parts, assembly procedure, and routine feedings differentiate it from others. |

| 6 | Product structure | Structured information on manufacturing process description, materials selection, process variation for production, economics, design elements, size configurations, and process capabilities for tolerance and surface polish. |

| 7 | Component design | The designer is given information on insertion and fastening assembly processes, process capability data, component models, and assembly cost. |

| 8 | DfA heuristics | These are usually offered in pairs of "good practice" and "poor practice" examples. Graphically presented heuristic examples are simple to understand. |

| 9 | Evaluation assemblies | Two approaches to lower the overall number of components are presented, followed by a full investigation of fitting, handling/feeding, and fixing. Each component/part and assembly procedure is scored to demonstrate complexity. |

| Year | Author | Process | Discussion | Reference |

| 2011 | Williams et al. | DfAM | Design system focuses on three aspects: identifying essential use-cases, defining formwork systems, and defining software element communication to facilitate expert user cooperation. | [1] |

| 2014 | Wang et al. | DfAM | Integration of 3D printing, BIM, and augmented reality is needed to improve architectural visualization in building life cycle. | [2] |

| 2015 | Bock & Linner | Dfab | Product structures and information aspects required manufacturing technology for full capability | [3] |

| 2015 | Yang&Zhao | DfAM | General Design Theory and Methodology (DTM) cannot take use of the enhanced design freedom and process options. Modifying standard DTM and DfAM can help designers effectively use AM in designs. | [4] |

| 2016 | Wu et al. | DfAM | BIM and 3Dprinting synergize to provide new DfMA possibilities in the building business. BIM can create an accurate 3D integrated information model for building design and 3D printing. | [5] |

| 2016 | Tang&Zhao | DfAM | Few product-level design approaches exist for both functionality and assembly, and some current design methods are challenging to execute due to an unfitted CAD software. | [6] |

| 2016 | Tang et al. | DfAM | Establishes the basis for sustainable AM design through functionality integration and component consolidation. DfMA offers designs with fewer parts and less material without sacrificing functionality. | [7] |

| 2016 | Kim et al. | Dfab | An interview determines the acceptability of precast bridge components based on DfMA requirements. A case study on a newly completed highway bridge identifies the possibility of precast components selected from suitability analysis. | [8] |

| 2017 | Krimi et al. | DfAM | 3D printing provides design flexibility and cost savings to build complicated forms, not the time saving. | [9] |

| 2018 | Arashpour et al. | DfAM | In advanced façade manufacturing, a substantial portion of the expenditure is for equipment like CNC machines and 3D printers which can be significantly reduced by DfMA. | [10] |

| 2018 | Durakovic | DfAM | Most 3D printing studies are still in early stage. This method lacks numerous technologies; therefore, maturity will take time. | [11] |

| 2019 | Ng&Hall | Dfab | LEAN, DfMA, and Dfab share design to target value and concurrent engineering. | [12] |

| 2019 | Dorfler et al. | Dfab | Mesh Mould is a novel construction technology for non-standard reinforced concrete buildings employing a mobile robot on site. | [13] |

| 2019 | Hinchy | DfAM | 3D printing is ideal for low-volume, sophisticated components, hence it should be selected over traditional methods. Build orientation and support structures effect manufacturing cost, time, post-processing, and final component mechanical characteristics. | [14] |

| 2019 | Medelling-Castillo&Zaragoza-Siqueiros | DfAM | Build orientation affects component stability during construction by determining the part's support surface on the building platform. | [15] |

| 2020 | Ng et al. | Dfab | Dfab manager and Dfab BIM coordinators are needed early in the design process. | [16] |

| 2020 | Alfaify et al. | DfAM | The suggested DfAM solutions include cellular structures, component consolidation and assembly, materials, support structures, build orientation, part complexity, and product sustainability. | [17] |

| 2020 | Vaneker et al. | DfAM | DfMA attempts to optimize product design to deal with complicated production processes while specifying 3D printed product advantages throughout its consumption phases. | [18] |

| 2020 | Ghaffar et al. | DfAM | Collaboration across materials science, architecture/design, computer, and robotics is important to developing and implementing 3D printing. | [19] |

| 2021 | Gibson et al. | DfAM | Modern 3D printing has led to more emphasis on DfAM training. | [20] |

| 2020 | Frascio et al. | DfAM | This solution tackles the exponential link between construction volume and printer cost and improves efficiency by deploying many 3D printers simultaneously. | [21] |

| 2021 | Ng et al. | Dfab | Three design practices were identified: post-rationalization, mass customization, and modularization. | [22] |

| 2021 | Graser et al. | Dfab | Three theoretical factors for using Dfab house projects: full-scale projects are an effective Dfab strategy in AEC; large-scale implementation promotes Dfab's acceptability in AEC; and projects help develop a new Dfab paradigm. | [23] |

| 2021 | Ghiasian | DfAM | Intelligent machine learning-based recommender system that identifies part candidates and addresses AM infeasibilities unexisting component designs. | [24] |

| 2021 | Prasittisopin et al. | DfAM | Small modules for 3D-printed pavilions cab be attached together using bolt-nut designs | [25] |

| 2021 | Morin and Kim | DfAM | The optimization scheme's effectiveness in breaking a cantilever beam structure into components that fulfill the AM build plate's geometric restrictions while reducing the structural impact of joints. | [26] |

| 2021 | Vu et al. | DfAM | DfMA framework entails three main elements: Structure, Property and Process. | [27] |

| 2022 | Ng et al. | Dfab | Proposed seven strategy propositions to achieve the benefits of adopting Dfab system. | [28] |

| 2022 | Rankohi et al. | DfAM | Integration of 3D printing, DfMA, and BIM can boost automation and productivity even with present labor difficulties. | [29] |

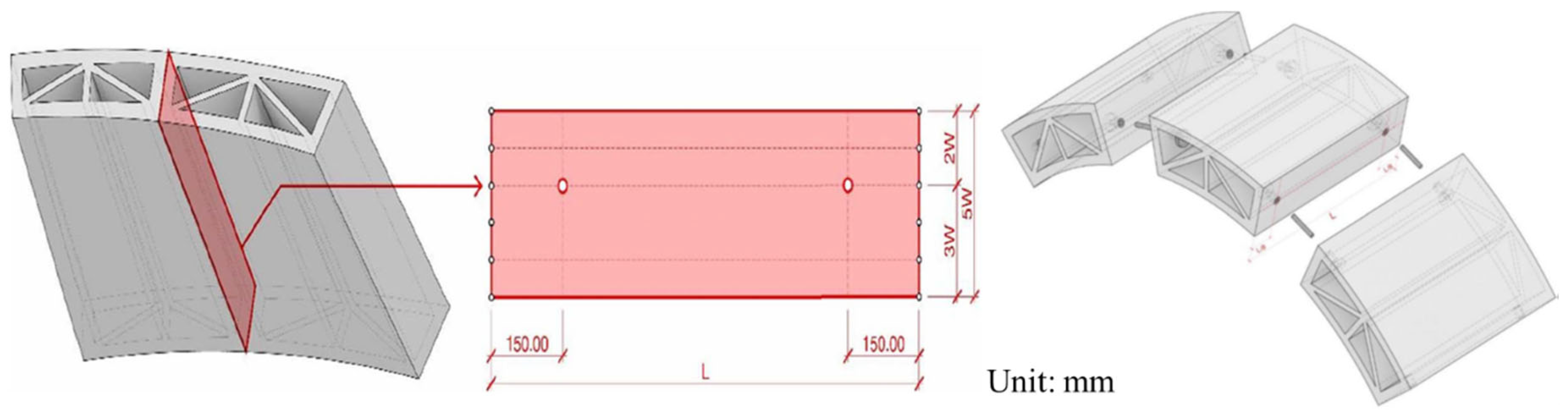

| 2022 | Sadakorn et al. | DfAM | Similar to the precast method, the jointing can be executed in dry process. | [30] |

| 2022 | Nguyen et al. | DfAM | Parametric model for bridge pier improved industrial output. | [31] |

| 2022 | Spuller | DfAM | Unlike product design application, construction occasionally uses DfAM. | [32] |

| 2022 | Song et al. | DfAM | New DfAM knowledge must be organized into general frameworks to assist practitioners throughout the product design process and to properly leverage present AM capabilities and developing potentials. | [33] |

| 2022 | Qin et al. | DfAM | Machine learning has contributed significantly to DfAM and has the potential to revolutionize AM. | [34] |

| 2023 | Rehman et al. | Dfab | Two most important liability factors are management capability and BIM. | [35] |

| Workflow | Discussion |

|---|---|

| Pre-testing | Set up nozzle experiments and perform experiments |

| ANN model | Optimize topology, train, and validate |

| Establish database | Generate sufficient volume randomly and predict extrudate shape |

| Target extrudate cross-sectional shapes | Analyze target shape, find nozzle shape, and perform printing |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).