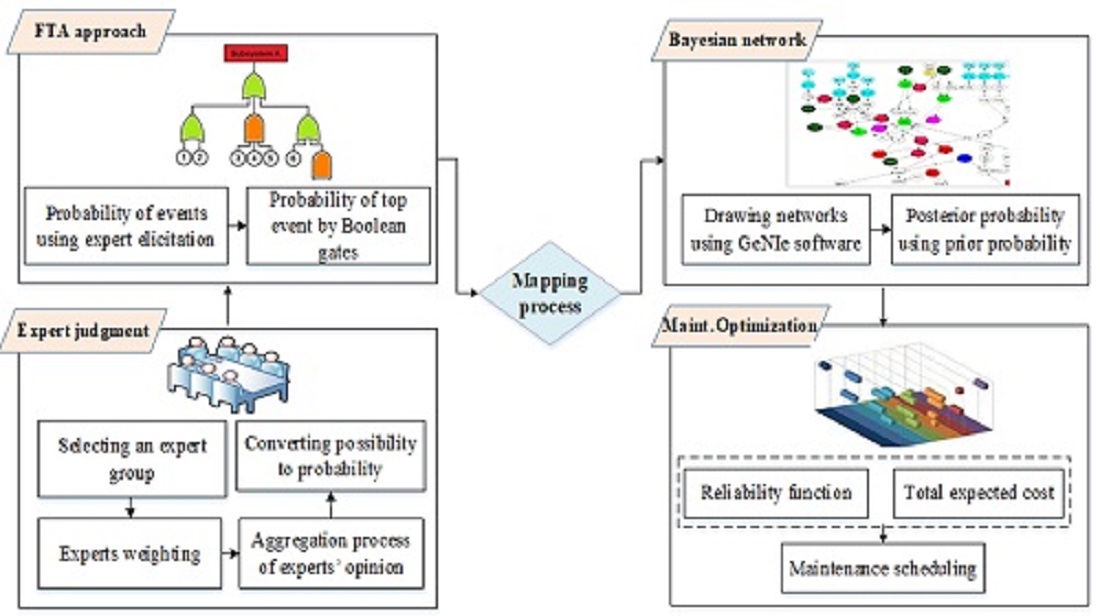

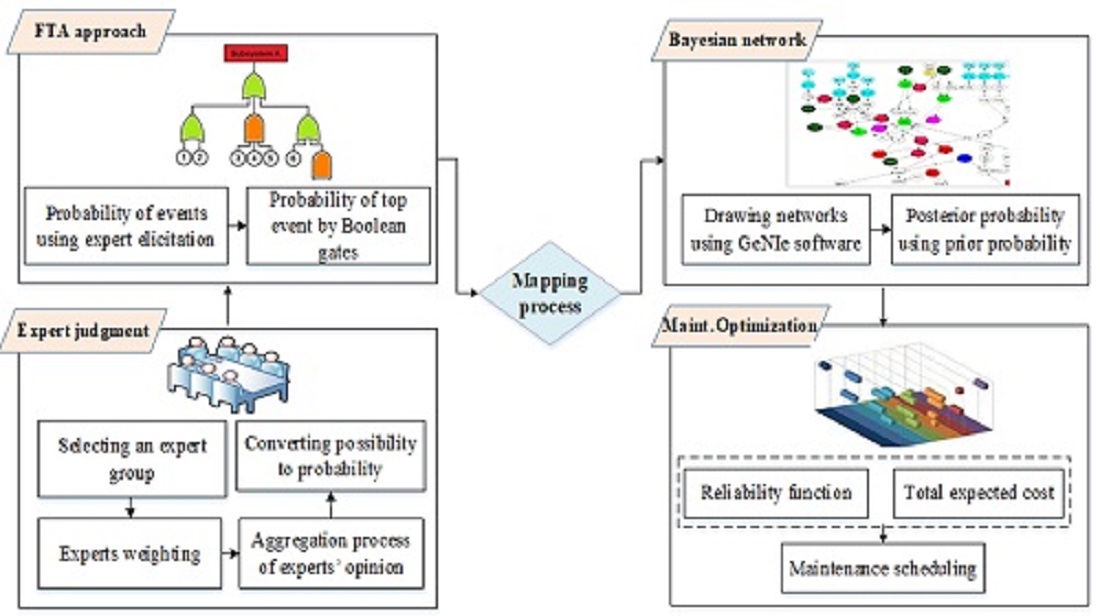

Knowledge-based approaches are useful alternatives to predict the Failure Probability (FP) coping with the insufficient data, process integrity, and complexity issue in manufacturing systems. This study proposes a Fault Tree Analysis (FTA) approach as proactive knowledge-based technique to estimate the FP based maintenance planning with subjective information from domain experts. However, the classical-FTA still suffers from uncertainty and static structure limitations which poses a substantial dilemma in predicting FP. To deal with the uncertainty issues, a Fuzzy-FTA (FFTA) model was developed by statistical analysing the effective attributes such as experts' trait impacts, scales variation and, assorted membership and defuzzification functions. Besides, a Bayesian Network (BN) theory was conducted to overcome the static limitation of classical-FTA. The results of FFTA model revealed that the changes in decision attributes were not statistically significant on FP variation while BN model considering conditional rules to reflect the dynamic relationship between events had more impact on predicting FP. After all, the integrated FFTA-BN model was used in the optimization model to find the optimal maintenance intervals according to estimated FP and the total expected cost. As a practical example, the proposed model was implemented in a semi-automatic filling system in an automotive production line. The outcomes could be useful for upgrading the availability and safety of complex equipment in manufacturing systems.