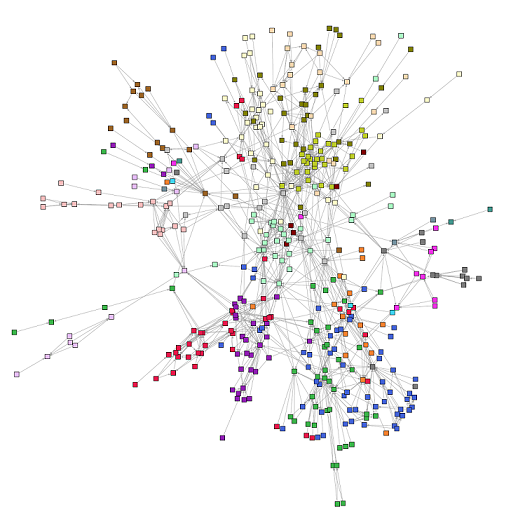

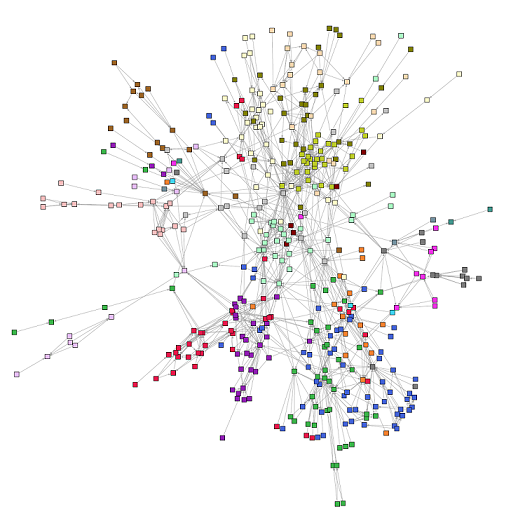

The production of lithium-ion battery cells is characterized by a high degree of complexit due to numerous cause-effect relationships between process characteristics. Knowledge about the multi-stage production is spread among several experts, rendering tasks such as failure analysis challenging. In this paper, a method is presented, which includes expert knowledge acquisition in production ramp-up by combining Failure Mode and Effects Analysis (FMEA) with a Bayesian Network. We show the effectiveness of this holistic method by building up a large scale, cross-process Bayesian Failure Network in lithium-ion battery production. Using this model, we are able to conduct root cause analyses as well as analyses of failure propagation. The former support operators in identifying root causes once a cell possesses a specific failure by calculating most-probable explanations matched to the individual battery cell data. The latter enable us to analyze propagation of failures and deviations in the production chain and thus provide support for placement of quality gates, leading to a significant reduction in scrap rate. Moreover, it gives an insight into which process steps are key drivers for which final product characteristics.