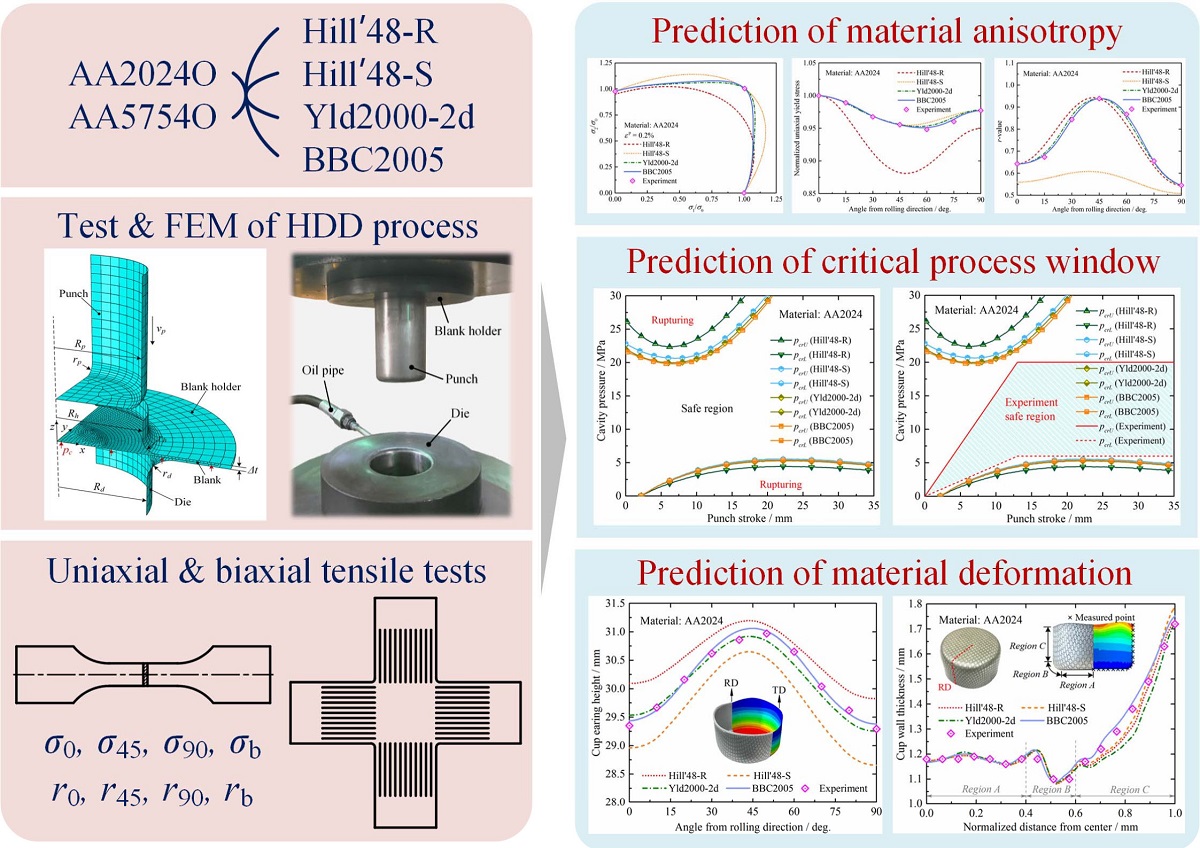

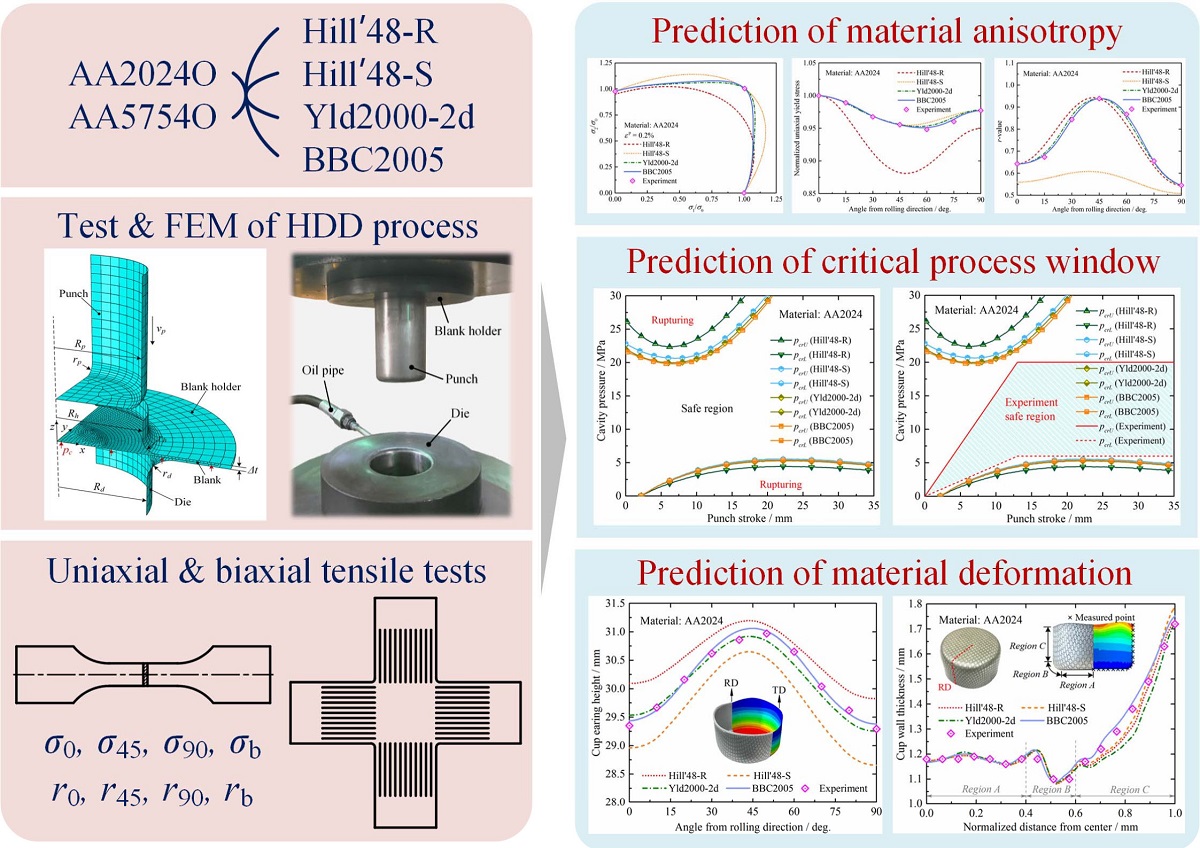

Owing to the reduction of rupture instability and the avoidance of wrinkle defect, hydrodynamic deep drawing (HDD) process is gradually becoming attractive for fabricating lightweight and complicated products. Meanwhile, since metallic material presents anisotropic deformation behavior, it is necessary to select an appropriate constitutive model for the prediction of plastic deformation behavior of applied material with high precision. In the present research, several anisotropic yield criteria namely, Hill’48, Yld2000-2d and BBC2005 are implemented to investigate the effect of yield functions on the prediction accuracy of the critical process window and deformation behavior for HDD process of 2024 and 5754 aluminum alloys. Material constants in the yield criteria are determined by applying uniaxial and equi-biaxial tension tests and optimizing an error-function by using the Levenberg-Marquardt algorithm. Furthermore, the process window diagram is computed utilizing the stress analytical model combined material properties with workpiece geometrical features. Numerical simulation results of predicted material anisotropic parameters, process window and HDD deformation for aluminum alloys are compared with the experimental data. Through the comparison of diverse yield criteria based on materials anisotropic coefficients, critical process window prediction, earing profile, and thickness distribution, it is revealed that the Yld2000-2d and the BBC2005 yield criteria can offer more precise models of material behavior in planar anisotropy properties for HDD process of 2024 and 5754 aluminum alloys.