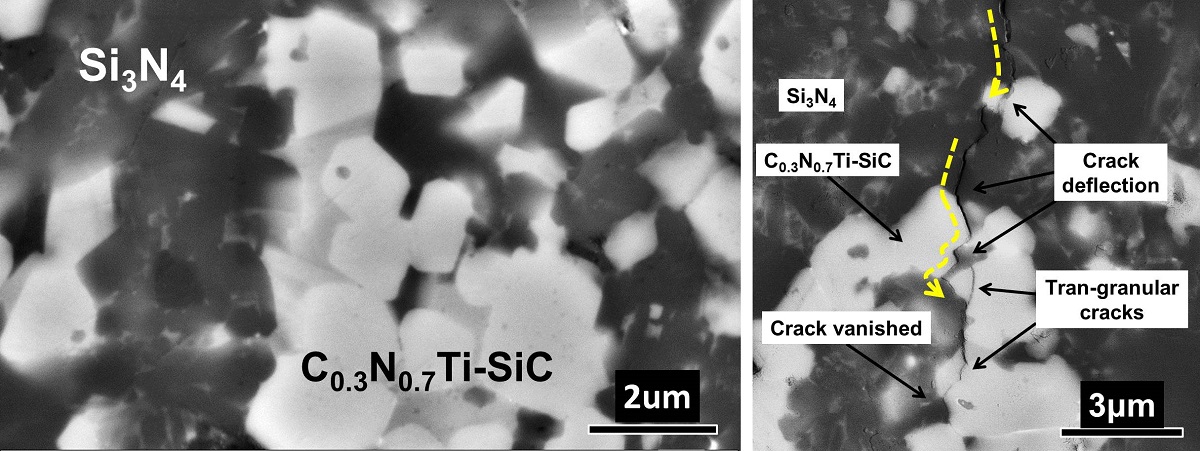

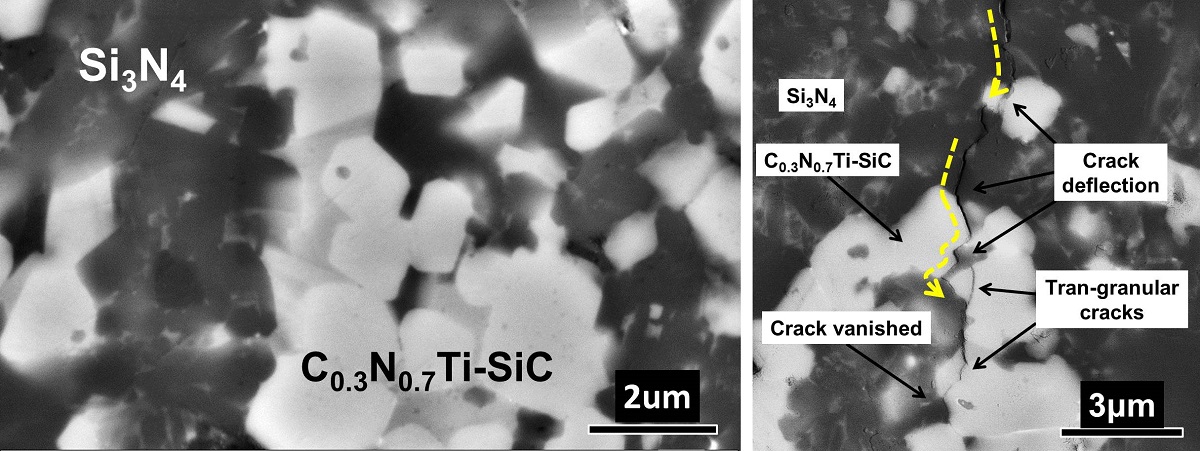

In-situ grown C0.3N0.7Ti and SiC, which derived from non-oxide additives Ti3SiC2, are proposed to densify silicon nitride (Si3N4) ceramics with enhanced mechanical performance. Remarkable increase of density from 79.20% to 95.48% could be achieved for Si3N4 ceramics with 5vol% Ti3SiC2. The capillarity of decomposed Si from Ti3SiC2, and in-situ reaction between nonstoichiometric TiCx and Si3N4 were believed to be responsible for densification of Si3N4 ceramics. An obvious enhancement of flexural strength and fracture toughness for Ti3SiC2 doped Si3N4 ceramics was observed. The maximum flexural strength of 795 MPa for Si3N4 composites with 5vol% Ti3SiC2 and maximum fracture toughness of 6.97 MPa.m1/2 for Si3N4 composites with 20vol% Ti3SiC2 are achieved when mixed powders are hot-press sintered at 1700℃. Pull out of elongated Si3N4 grains, crack bridging, crack branching and crack deflection were demonstrated to dominate enhance fracture toughness of Si3N4 composites.