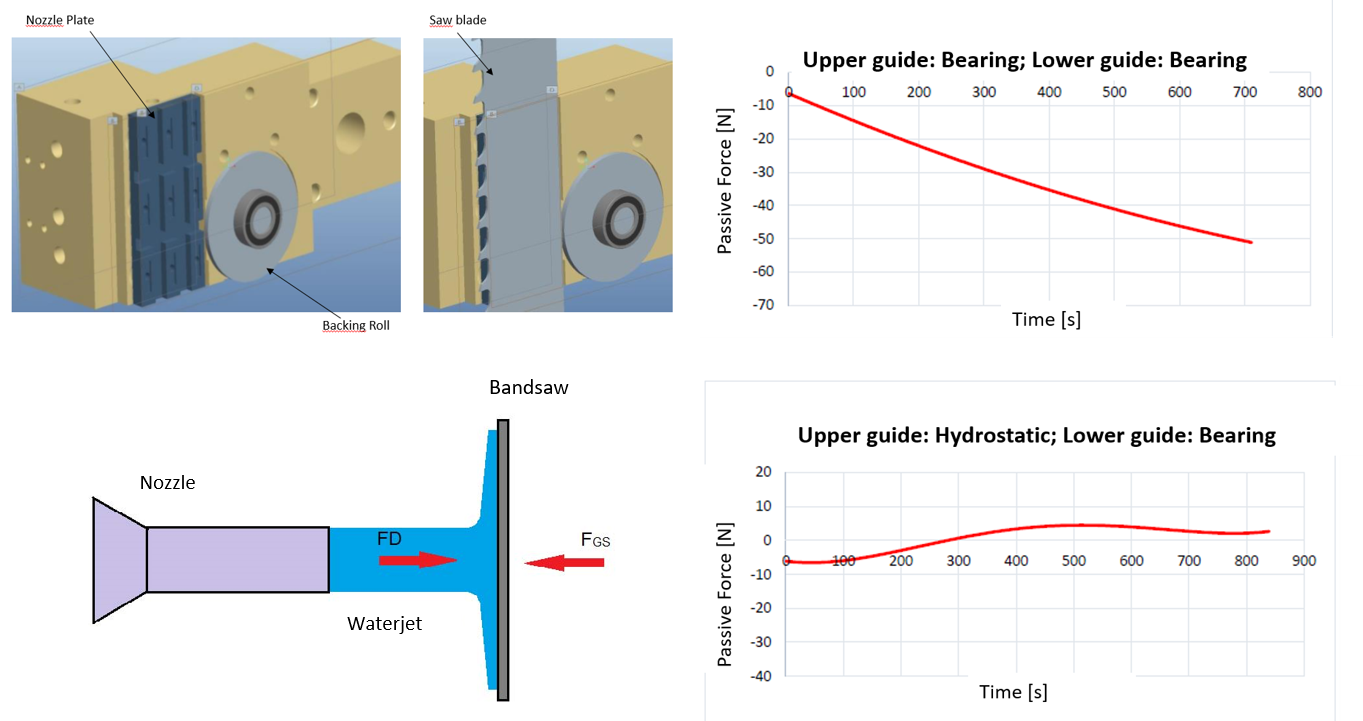

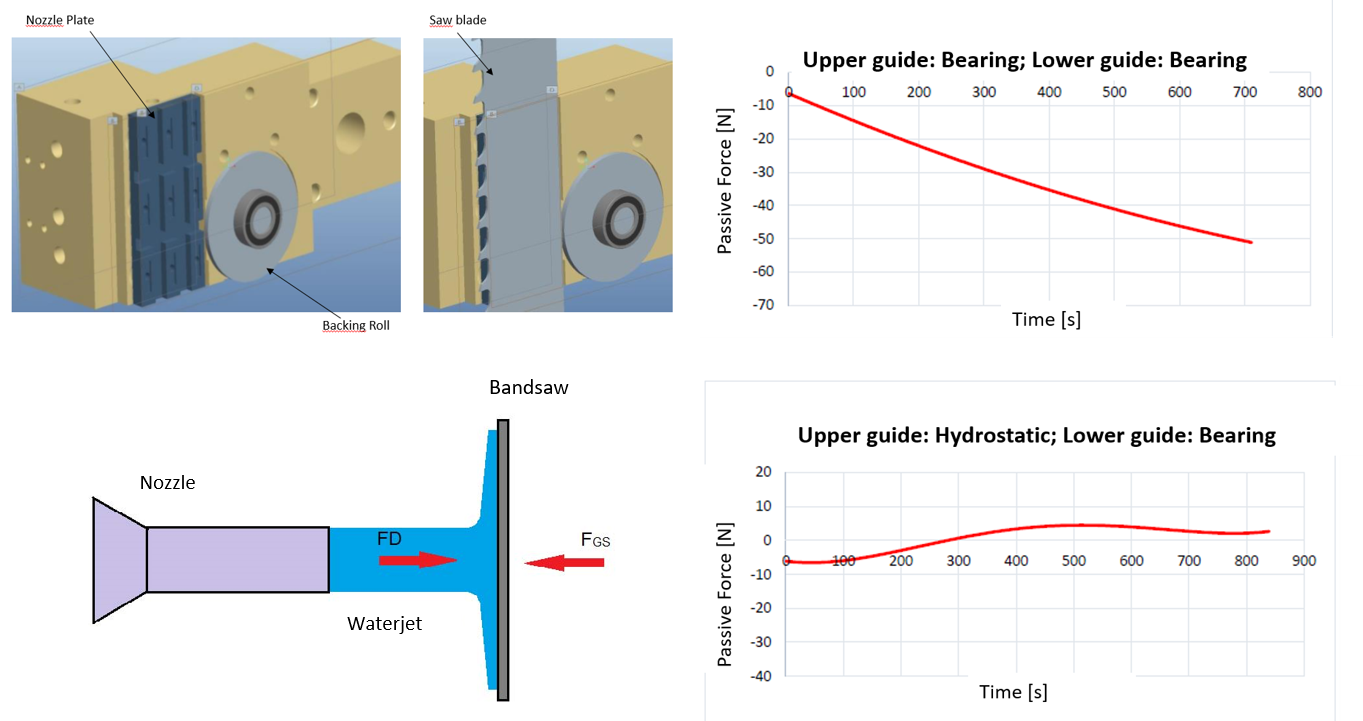

Bandsaws either use fibre or ceramic block or sealed bearings as blade guides. This works well for cutting metals, wood and plastics. However, highly abrasive particles generated while cutting stones, settle between the contacts of the blade and the guides causing wear and premature failure. Hydrostatic guide system as presented in this work, is a contactless blade guiding method that uses force of several pressurized water jets to keep the blade cutting in a straight line. For this investigation, cutting tests were performed on a marble block using a galvanic diamond coated bandsaw blade with the upper roller guides replaced by hydrostatic guides. The results show that the hydrostatic guides help to reduce the passive force to a constant near zero in contrast to the bearing guides. This also resulted in reduced surface roughness of the stone plates that were cut. Additionally, it has also been shown that using hydrostatic guides the bandsaw blade can be tilted to counter the bandsaw drift. This original research work has shown that the hydrostatic guide systems are capable of replacing and in fact perform better than the state of the art bearing or block guides specially for stone cutting applications.