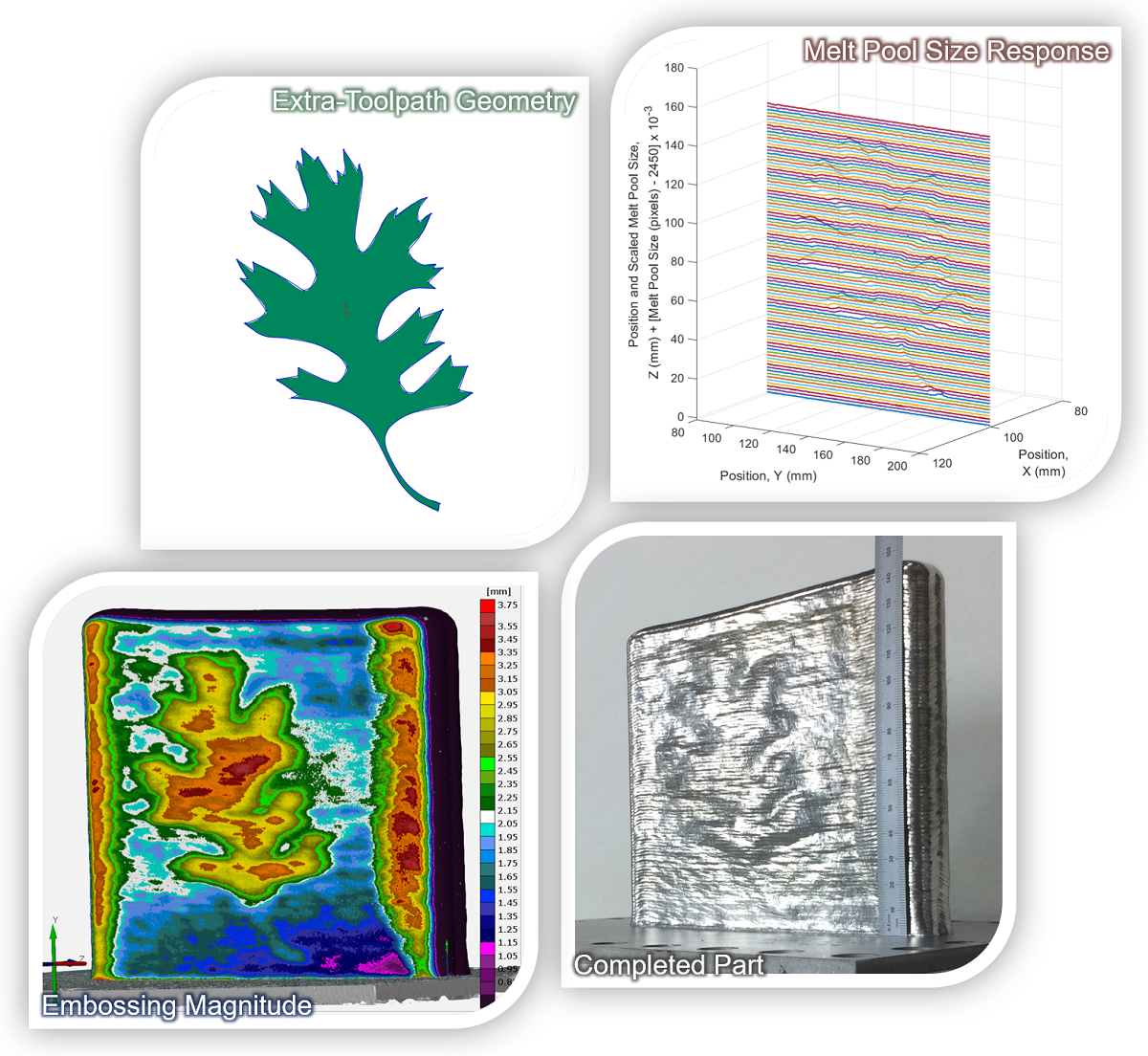

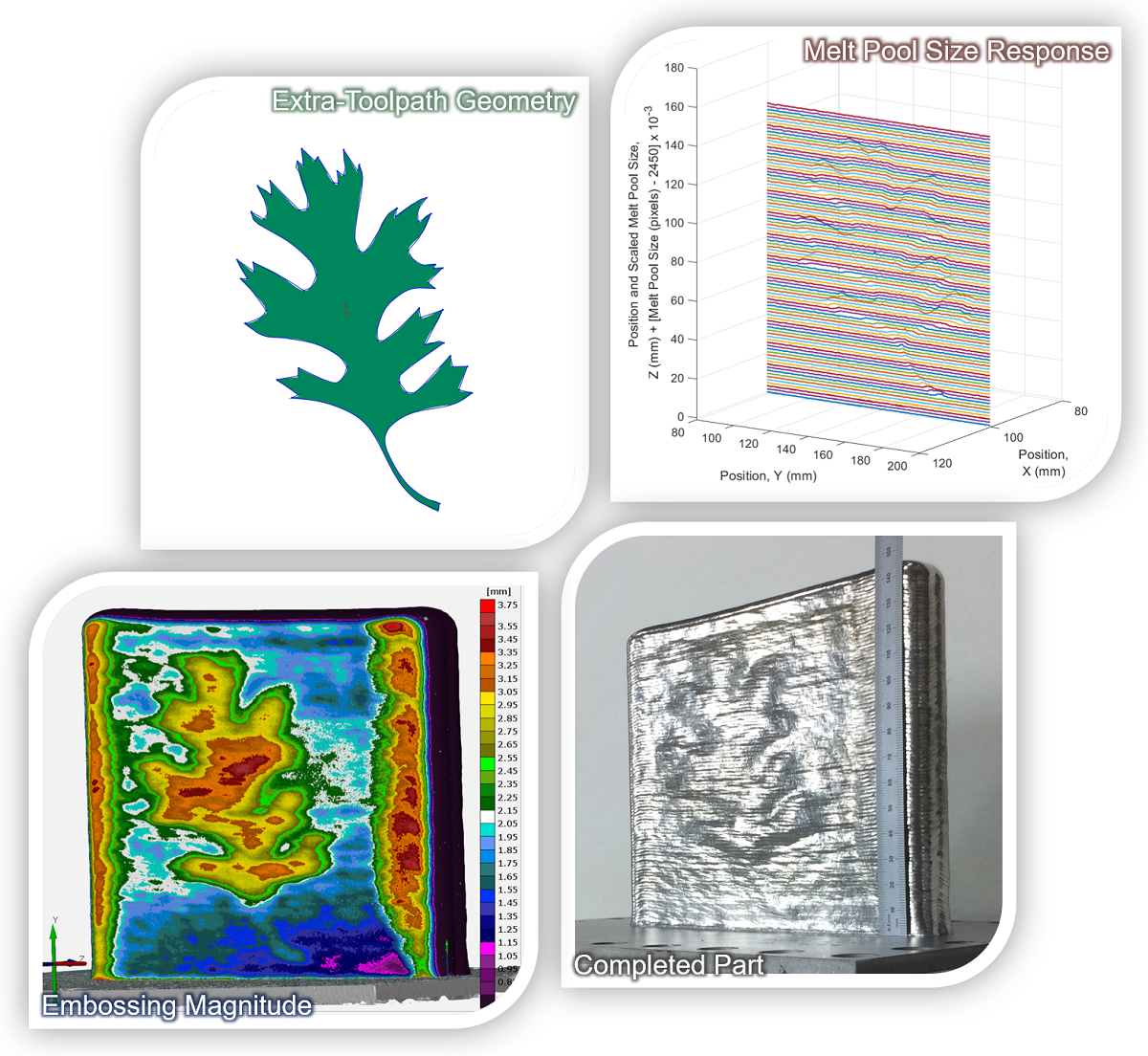

A variety of techniques have been utilized in metal additive manufacturing (AM) for melt pool size management, including modeling and feed-forward approaches. In a few cases, closed-loop control has been demonstrated. In this research, closed-loop melt pool size control for large-scale, laser-wire based Directed Energy Deposition is demonstrated with a novel modification: site-specific changes to the controller set-point were commanded at trigger points, the locations of which were generated by the projection of a secondary geometry onto the primary 3D-printed component geometry. The present work shows that, through this technique, it is possible to print a specific geometry that occurs beyond the actual toolpath of the print head. This is denoted as an extra-toolpath geometry and is fundamentally different from other methods of generating component features in metal AM. A proof-of-principle experiment is presented in which a complex oak leaf geometry was embossed on an otherwise ordinary double-bead wall made from Ti-6Al-4V. The process is introduced and characterized primarily from a controls perspective with reports on the performance of the control system, the melt pool size response, and the resulting geometry. The implications of this capability, which extend beyond localized control of bead geometry to the potential mitigations of defects and functional grading of component properties, are discussed.