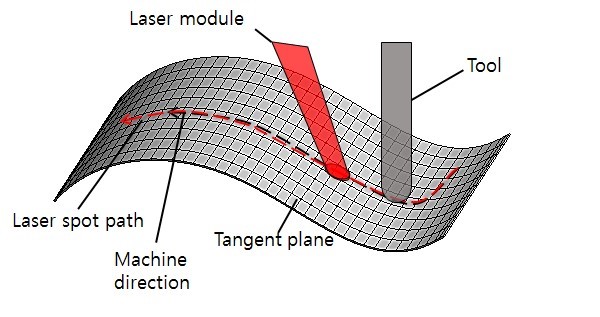

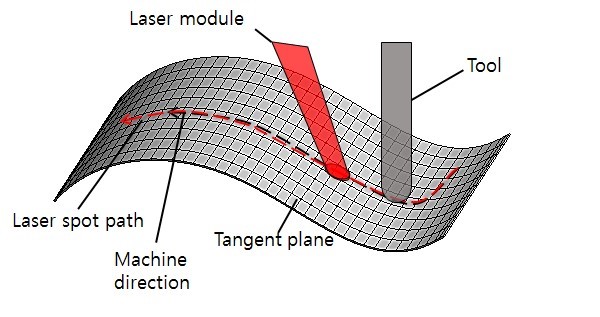

Difficult-to-cut materials are being increasingly used in many industries because of their superior properties, including high corrosion resistance, heat resistance and specific strength. However, these same properties make the materials difficult to machine using conventional machining techniques. Laser-assisted milling (LAM) is one of the effective methods for machining difficult-to-cut materials. In laser-assisted milling machining occur after the workpiece is locally preheated using a laser heat source. Laser assisted machining has been studied by many researchers on flat workpiece or micro end-milling. However, there is no research on the curved shape using laser assisted milling. This study investigated the use of laser assisted milling to machine a three-dimensional curved shape workpiece based on NURBS. A machining experiment was performed on Inconel 718 using different tool paths (ramping, contouring) under various machining conditions. Finite elements analysis was conducted to determine the depth of cut. Cutting force, specific cutting energy and surface roughness characteristics were measured, analyzed and compared for conventional and LAM machining. LAM significantly improved these machining characteristics, compared to conventional machining. There results can be applied to the laser-assisted machining of various three-dimensional shapes.