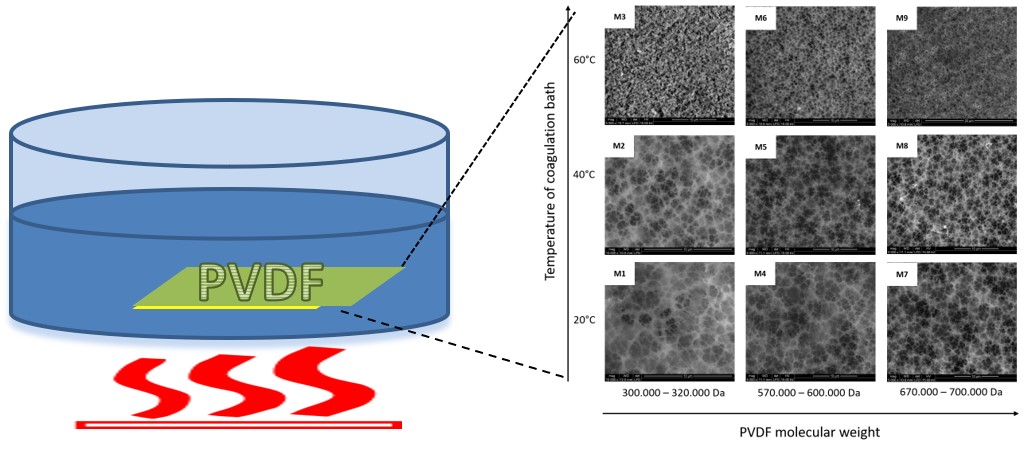

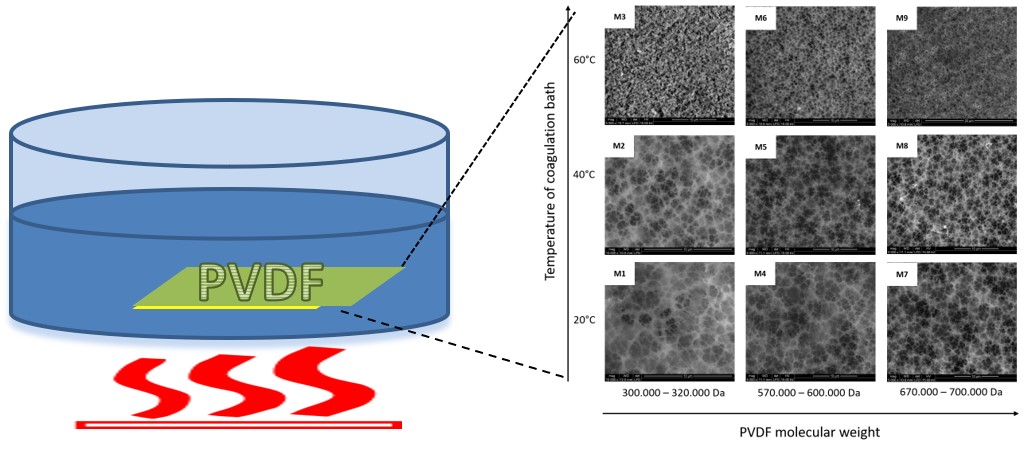

The global polyvinyldene flouride market is estimated to reach $937,278.5 thousand by 2019, therefore to develop new membranes and gain pioneering ideas, which could create innovative business opportunities, a fundamental knowledge about membrane properties fabricated from recent commercially available PVDF polymers is highly mandatory. In this study, we successfully prepared nine non-woven supported PVDF membranes using a phase inversion precipitation method starting from a 15 wt% PVDF solution in N-methyl-2-pyrrolidone. Various membrane morphologies were obtained by using (1) PVDF polymers with diverse molecular weight in a range from 300.000 Da to 700.000 Da and (2) different temperatures of the coagulation bath (20, 40, and 60 ±2°C) used for the films precipitation. Environmental Scanning Electron Microscope (ESEM) was used for surface and cross-section morphologies characterization. Atomic Force Microscope (AFM) was employed to investigate surface roughness, while Contact Angle (CA) instrument was used for membranes wettability studies. Fourier Transform Infrared Spectroscopy (FTIR) results show that the fabricated membranes are formed by a mixture of TGTG’ chains in α phase crystalline domains and all-TTTT trans planar zigzag chains characteristic to β phase. Moreover, generated results indicate that the phases content and membrane morphologies depend on the polymer molecular weight and conditions used for the membranes preparation. The diversity of fabricated membranes could be applied by the End User Industries for different applications.