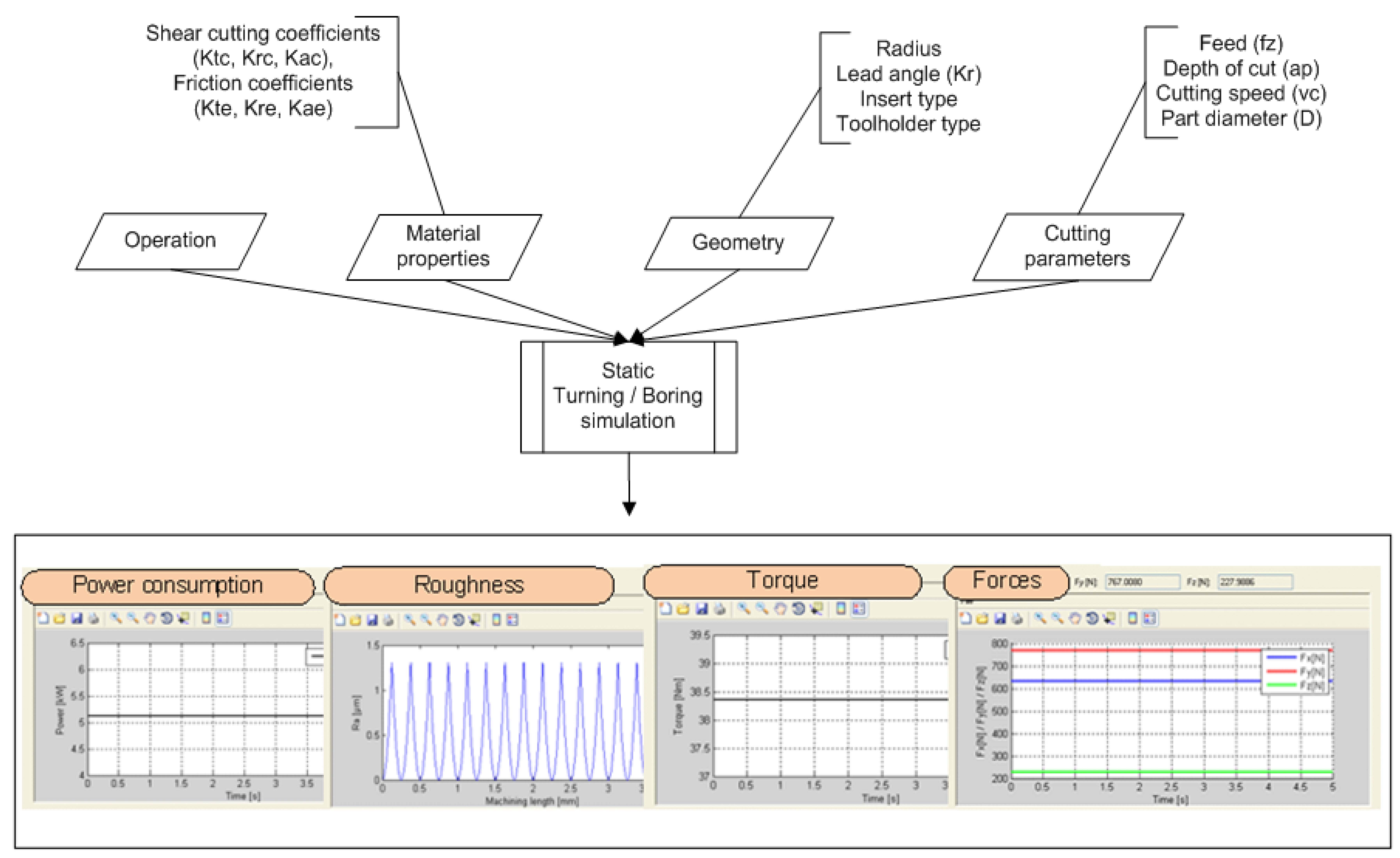

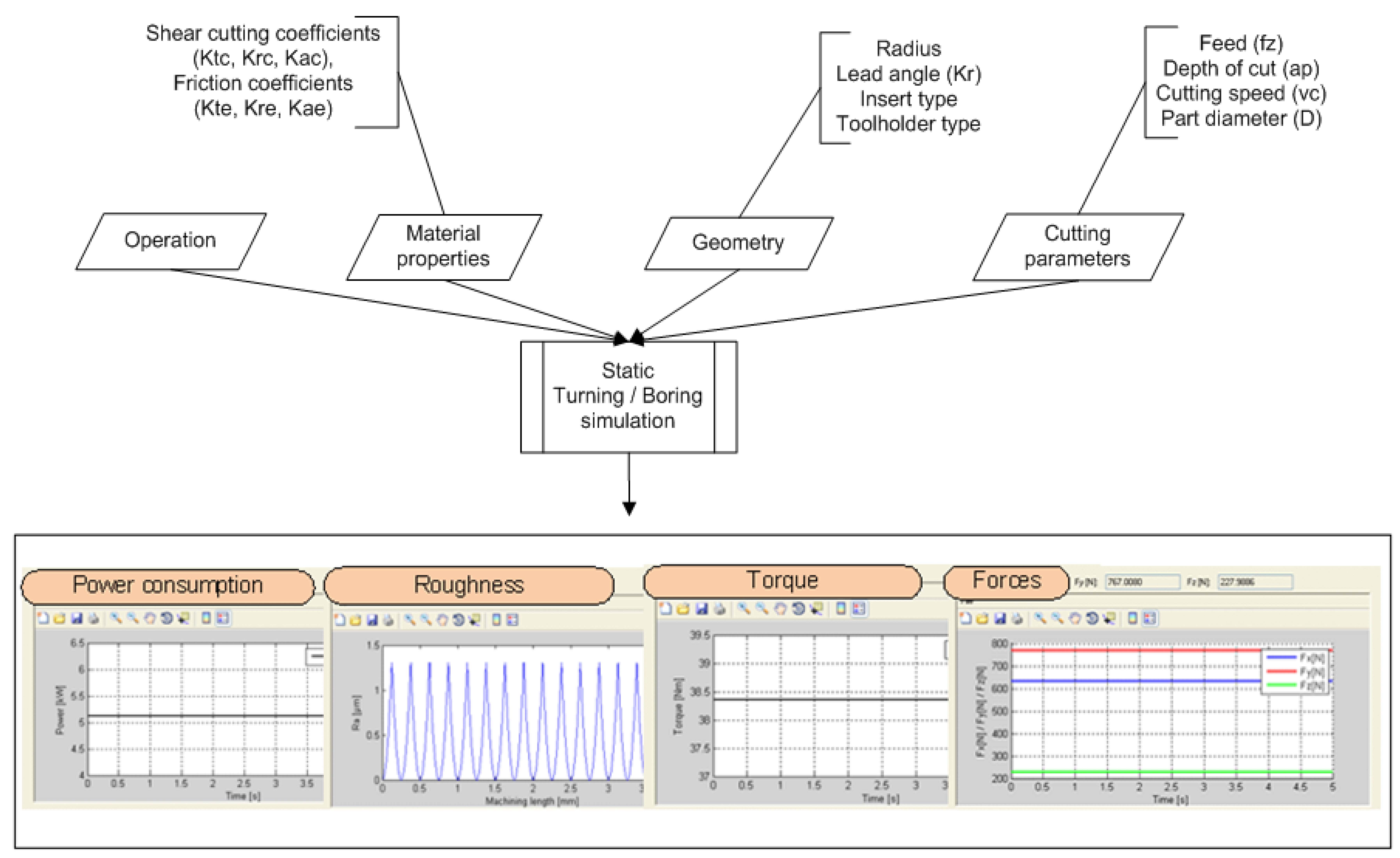

The future of machine tools will be dominated by highly flexible and interconnected systems, in order to achieve the required productivity, accuracy and reliability. Nowadays, distortion and vibration problems are easily solved in labs for the most common machining operations by using models based on equations describing the physical laws of the machining processes; however additional efforts are needed to overcome the gap between scientific research and the real manufacturing problems. In fact, there is an increasing interest in developing simulation packages based on “deep-knowledge and models” that aid machine designers, production engineers or machinists to get the best of the machine-tools. This article proposes a methodology to reduce problems in machining by means of a simulation utility, which uses the main variables of the system&process as input data, and generates results that help in the proper decision-making and machining planification. Direct benefits can be found in a) the fixture/clamping optimal design, b) the machine tool configuration, c) the definition of chatter-free optimum cutting conditions and d) the right programming of cutting toolpaths at the Computer Aided Manufacturing (CAM) stage. The information and knowledge-based approach showed successful results in several local manufacturing companies and are explained in the paper.