Submitted:

12 January 2026

Posted:

13 January 2026

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. AI Applications in Textile Design

1.2. Application of Semantic Differential Scale

2. Objects of Research

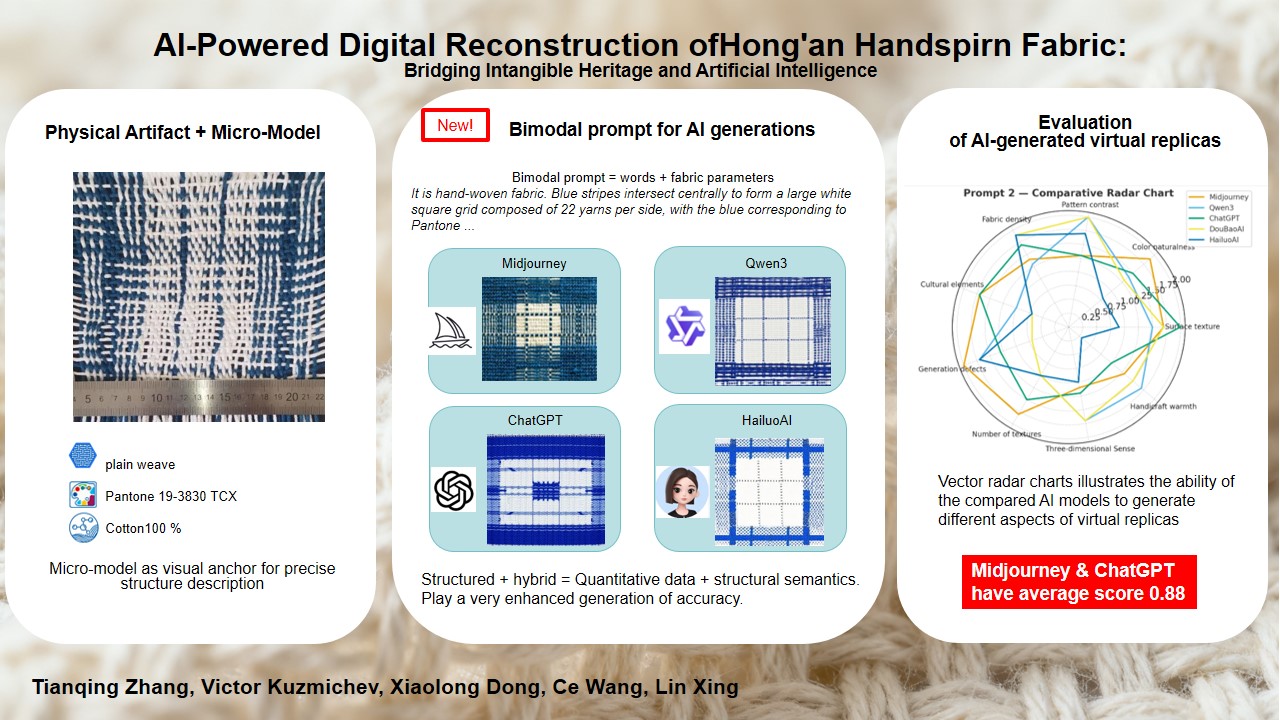

3. Methods of Research and Tools

3.1. Micro-Models of Fabric

3.2. AI Types

3.2.1. Basic One Modal Prompt

3.2.2. Improved Bimodal Prompts

3.3. Mat

Semantic Differential Method for an Images Validation

4. Results Obtained

5. Discussion

5.1. Analyze AI's Understanding of Basic One Modal Prompts

5.2. Analyze AI's Understanding of Improved Bimodal Prompts

5.3. Comparison Basic and Improved Prompts

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hong'an County Chronicles Compilation Committee. (1992). Hong'an County Chronicles. Shanghai People's Publishing House. Unregistered DOI. http://rendezixun.com/m/product/huazhong/1238.html.

- Xu, Y., Ye, H., & Zhao, H. Research on the development of non-heritage derivatives of Hong'an dabu clothing. Tianjin Textile Science & Technology. (2019), (05), 1–4. [CrossRef]

- Xu, Y. M., Ye, H. G., & Zhao, H. (2019). Research on the development of intangible cultural heritage derivatives of Hong'an Dabu clothing. Tianjin Textile Science & Technology, (05), 1–4. [CrossRef]

- Erdelez, S. (1997). Information encountering: a conceptual framework for accidental information discovery. In Proceedings of an international conference on Information seeking in context (pp. 412–421).:Unregistered DOI. http://www.shurl.cc/5bd18c05dc86a5c02e9c7f6d79320e60.

- Gangadharbatla, H. (2022). The role of AI attribution knowledge in the evaluation of artwork. Empirical Studies of the Arts, 40(2), 125–142. [CrossRef]

- Turkmen, B. G., Celik, P., Sehit, H., & Ute, T. B. (2024). Investigation of the effects of hollow yarn structure and woven fabric construction on fabric performance: Mechanical properties. The Journal of The Textile Institute, 115, 490–503. [CrossRef]

- Kim, H., Kim, S., & Park, C. K. (2023). Prediction of fabric drape coefficient using simple measurement method. Journal of Engineering Fibers and Fabrics, 18. [CrossRef]

- Kenkare, N. (2005). Fabric Drape Measurement: A Modified Method Using Digital Image Processing. Journal of Textile and Apparel, Technology and Management, 4(3), 1–8.http://www.tx.ncsu.edu/jtatm.

- Elkateb, S. N. (2022). Prediction of Mechanical Properties of Woven Fabrics by ANN. Fibres and Textiles in Eastern Europe, 30(4), 54–59. [CrossRef]

- Metin, A., & Bilgin, T. T. (2024). Automated machine learning for fabric quality prediction: A comparative analysis. PeerJ Computer Science, 10. [CrossRef]

- Youn, S., West, A., & Mathur, K. (2024). Evaluation of a new artificial intelligence-based textile digitization using fabric drape. Textile Research Journal, 94(17), 2001–2018. [CrossRef]

- Seçkin, M., Seçkin, A. Ç., Demircioglu, P., & Bogrekci, I. (2023). FabricNET: A Microscopic Image Dataset of Woven Fabrics for Predicting Texture and Weaving Parameters through Machine Learning. Sustainability, 15(21). [CrossRef]

- Booth, A., Papaioannou, D., & Sutton, A. (2012). Systematic Approaches to a Successful Literature Review. SAGE Publications Ltd.Unregistered DOI. ISBN (9780857021342).

- Ouyang, W., Xu, B., Hou, J., & Yuan, X. (2019). Fabric Defect Detection Using Activation Layer Embedded Convolutional Neural Network. IEEE Access, 7. [CrossRef]

- Arshad, S. R., & Shahzad, M. K. (2024). Deep Learning Based Fabric Defect Detection. Research Reports on Computer Science, 3(1), 1–11. [CrossRef]

- Makarama, O., Van, H., Hong,M.(2023). Video Classification of Cloth Simulations: Deep Learning and Position-Based Dynamics for Stiffness Prediction.Applied Sciences 2023, 13(9), 5521. [CrossRef]

- Rasouli, M., Chen, Y., Basu, A., Kukreja, S. L., & Thakor, N. V. (2018). An Extreme Learning Machine-Based Neuromorphic Tactile Sensing System for Texture Recognition. IEEE Transactions on Biomedical Circuits and Systems, 12(2), 313–325. [CrossRef]

- Xue, Z., Zeng, X., & Koehl, L. (2017). Development of a method based on fuzzy comprehensive evaluation and genetic algorithm to study relations between tactile properties and total preference of textile products. The Journal of The Textile Institute, 108. [CrossRef]

- Xue, Z., Zeng, X., Koehl, L., & Shen, L. (2015). Development of an Intelligent Model to Predict Tactile Properties from Visual Features of Textile Products. In 2015 10th International Conference on Intelligent Systems and Knowledge Engineering (ISKE), 229–236. [CrossRef]

- Gültekin, E., Çelik, H. I., Nohut, S., & Elma, S. K. (2020). Predicting air permeability and porosity of nonwovens with image processing and artificial intelligence methods. The Journal of The Textile Institute, 111(11), 1641–1651. [CrossRef]

- Menéndez-Benito, V., & Schwenter, S. A. (2019). Loanwords as a window into cultural contact and diffusion: A cross-linguistic study. Language Sciences, 73, 101–116. [CrossRef]

- Pokorny, J. (1959–1969). Indogermanisches Etymologisches Wörterbuch (Vols. 1–2).Unregistered DOI. https://indo-european.info/pokorny-etymological-dictionary/indogermanisches-etymologisches-woerterbuch.htm.

- Lombardini, L. (2012). Textiles: An Introduction. Berg Publishers.Unregistered DOI.https://www.bloomsbury.com/uk/textiles-an-introduction-9781847888728/.

- Gaspa, S., Michel, C., & Nosch, M. L. (2017). Remarks on the Interpretation of Some Ambiguous Greek Textile Terms. In Textile Terminologies from the Orient to the Mediterranean and Europe, 1000 BC to 1000 AD (pp. 202–211). Zea Books. [CrossRef]

- Nosch, M. L., & Michel, C. (Eds.). (n.d.). Textile Terminologies in the Ancient Near East and Mediterranean from the Third to the First Millennnia BC. Oxbow Books.ISBN(9781842179758).

- Qwen AI. (n.d.). Qwen Chat. Retrieved September 20, 2025, from https://chat.qwen.ai.

- ChatGPT (n.d.).ChatGPTHomepage. Retrieved September 20, 2025, from https://chat.openai.com/.

- Midjourney. (n.d.). Midjourney Homepage. Retrieved September 20, 2025, from https://www.midjourney.com/account.

- Doubao. (n.d.). Doubao AI. Retrieved September 20, 2025, from https://www.doubao.com/.

- Hailuo AI. (n.d.). Hailuo AI Video Creation. Retrieved September 20, 2025, from https://hailuoai.video/create.

| No. | Steps | Detailed description |

|---|---|---|

| 1 | Data collection and processing | Physical characteristics: Collect data on the physical properties of various fabrics, such as fiber composition, thickness, weight, and elasticity. These quantitative data are obtained through laboratory measurements—for example, determining fiber composition using a fiber analyzer and measuring fabric thickness with a thickness gauge. |

| Visual features: High-resolution images of fabric samples can be analyzed to extract critical visual attributes, such as color and texture. Color features can be quantified by Pantone color, and texture features can be extracted with the help of image processing algorithms. | ||

| 2 | Semantic data collection | The semantic difference scale is employed to systematically quantify subjective user perceptions of textile materials. design a carefully curated set of bipolar adjective pairs (e.g., “soft-hard”) that comprehensively capture tactile, visual and functional fabric attributes. |

| 3 | Data processing | The abnormal values and abnormal expressions in the understanding of collected fabric feature data are removed through preliminary AI experiments. For numerical fabric feature data and semantic data, standardize processing to make them have a unified dimension. |

| 4 | Feature selection and extraction | The preprocessed fabric characteristic data undergoes rigorous feature selection and extraction to effectively reduce the dimensionality of irrelevant descriptors and retain the most representative features. These optimized features are used as input variables for subsequent attribution analysis. |

| 5 | Attribution evaluation and optimization | The trained model establishes mapping relationships between fabric characteristics and user semantic perceptions. For instance, the model may learn positive correlations between specific fiber compositions and perceptual descriptors like “softness”. The constructed prompt words are evaluated to measure the model performance with indicators such as accuracy and error. Based on the evaluation results, adjust the parameters or structure of the prompt words to optimize AI performance to ensure that the AI can accurately attribute the relationship between fabric features and user semantic perception. |

| Characteristic | Value | |||

|---|---|---|---|---|

| sample 1 | sample 2 | sample 3 | ||

| 1 | Interweave Type | plain weave | plain weave | plain weave |

| 2 | Density, yarns/1 cm: wrap weft |

21 17 |

18 15 |

22 22 |

| 3 | Strength | high | medium | medium |

| 4 | Relief | smooth | smooth | textured |

| 5 | Pantone code | 19-3830TCX | 19-3830TCX. | 19-3830 TCX |

| 6 | Cotton content, % | 100 | 100 | 100 |

| Comparison dimensions | Basic one modal prompt | Improved bimodal prompt |

|---|---|---|

| Degree of information quantification | There is no quantitative data, only qualitative descriptions such as "thin stripes" and "large checks" | Use a large number of specific numbers (such as the number of yarns, stripe width) to precisely define the size and distribution |

| Pattern structure disassembly | Only describe the overall pattern shape (such as "forming a nine - grid", "grid - like structure"), without regional subdivision | Divide the pattern into specific areas (four corners and quadrants, left and right sides), and clarify the yarn composition and interweaving rules of each area. |

| Depth of Process Details | Only mention "warp and weft interweaving" and "handmade", without specific description of the weaving method | Supplement the alternating interweaving methods of weft and warp yarns, as well as the yarn connection logic (such as dot - shaped yarn connection), and clarify the process types such as "plain weave". |

| Expression logic and framework | The information is fragmented. Simply list it according to "fabric - pattern - shooting - texture" | The structure is clear. First, disassemble the composition details of each part of the fabric, and then explain the shooting and visual conditions to form a logical chain of "part - whole". |

| Design concept extraction | There is no clear design concept, only vague associations such as "similar to traditional Chinese geometric patterns" are mentioned. | Put forward structured concepts such as "symmetric grid" to strengthen the systematicness and regularity of the design. |

| Sample | Basic one modal prompt | Improved bimodal prompt |

|---|---|---|

| 1 | Hand-woven fabric. The fine blue stripes cross the middle to form a large white lattice, Blue is Pantone 19-4053 TCX. and there are two horizontal lines and two longitudinal indigo yarns in the large white lattice, forming nine checks within the white lattice. The blue yarn weave pattern is dotted and the blue and white weave check. The texture is delicate, the vertical shooting angle is uniform, and the light is uniform. It can be seen that the warp and weft are intertwined, with handmade natural imperfections. | It is hand-woven fabric. Blue stripes intersect centrally to form a large white square grid composed of 22 yarns per side, with the blue corresponding to Pantone 19-4053 TCX. The large white grid incorporates two horizontally aligned blue yarns and two vertically aligned blue yarns, systematically distributed to form a nine-cell matrix. The corner square patterns of this matrix are structured as follows. Upper-left quadrant is composed of three vertical white yarns interspersed with four vertical dark blue yarns. Upper-right quadrants composed of three horizontal white yarns. Lower-left quadrant is composed of three horizontal white yarns. Lower-right quadrant is composed of three vertical white yarns separated by four vertical dark blue yarns. Each weft yarn interlaces alternately over and under individual warp yarns. The corner square patterns are interconnected by dotted-line configured yarns. Balanced yarn thickness ensures chromatic presentation in a symmetrical grid formation. Imaged from a vertical downward perspective under even illumination, the fabric reveals meticulously interlaced warp and weft threads, preserving artisanal imperfections inherent to hand-weaving techniques. |

| 2 | The linen fabric has vertical stripes in deep indigo and white, and the pattern is an intricate weave of different shades of blue lines. Blue is Pantone 19-4053TCX. Each blue stripe has regularly spaced black dot braided holes that form a dotted pattern that removes color from the material to create a negative space design. There is also a pinstripe on each side of the main stripe. The fabric is laid flat. Shoot vertically downwards with even lighting. It can be seen that the warp and weft are intertwined, with handmade natural imperfections. | A handcrafted plain white cotton fabric serves as the base, featuring a vertical blue stripe with a width of 9 warp yarns. At the center of this blue stripe, a black-and-white dotted line is formed by interwoven black yarns. On both sides of the blue stripe, spaced 3 white warp yarns apart, there are thin blue lines each with a width of 2 warp yarns, resulting in three vertical blue lines in total. The white and blue colors (Pantone 19-4053TCX) are woven using warp and weft yarns of identical thickness. Balanced yarn thickness ensures chromatic presentation in a “symmetrical grid” formation. Imaged from a vertical downward perspective under even illumination, the fabric reveals meticulously interlaced warp and weft threads, preserving artisanal imperfections inherent to hand-weaving techniques. |

| 3 | A two-tone weave pattern in dark blue and gray with lines in different directions, The dark blue color is Pantone 19-3831 TCX. A small square pattern, three vertical and three horizontal gray yarns are intertwined to form a checkerboard-like staggered distribution, with dark blue as the base color. Soft light creates soft shadows on the surface, accentuating its intricate design. The top-down view captures the complete distribution across the entire canvas, showing a seamless arrangement of threads in a symmetrical manner. It can be seen that the warp and weft are intertwined, with handmade natural imperfections | The handmade plain weave pattern consists of four parts, the upper left is composed of three vertical white warp yarns spaced by four vertical dark blue warp threads, the upper right is composed of three horizontal white warp yarns spaced by four horizontal dark blue weft yarns, the lower left is composed of three horizontal white warp yarns interspersed with four horizontal dark blue warp yarns, and the lower right is composed of three vertical white warp yarns composed of four vertical dark blue warp intervals. The shooting angle is vertically downward, and the light is evenly balanced. It can be seen that the warp and weft are intertwined, with handmade natural imperfections. |

| Evaluation Dimension | Severely Inconsistent | Obvious Defect | Basic Compliance | Good Performance | Perfect Restore |

| -2 | -1 | 0 | +1 | 2 | |

| A. Visual effects | |||||

| 1. Surface Texture | Smooth as silk, without three-dimensional sense | Slight sense of concavity and convexity (concavity-convexity), similar to cheap cotton fabric | Shallow grooves visible, but without "roughness" | Clear nodules, occasional traces of hand-spun yarn | Strong "bark-like" concave and convex with deep grooves and knots prominent |

| 2. Color Naturalness | Dazzling fluorescent blue/false black | Oversaturated indigo or grayish black | Close to Pantone standard but with a plastic-like feel | Natural dye tones, slight color spots | The earth tone of indigo is the same as the Pantone color number, and there is a natural transition between black and white |

| 3. Pattern Contrast | Stripes blurred and difficult to distinguish | Blurred boundaries (>1mm transition zone) | Clear demarcation but without sharpness | Sharp edges, excessive is more natural | Knife-like precision of color block demarcation |

| 4. Fabric Density | Translucent to see the background (sparse like a net) | Local yarn gaps visible | Minimum gaps (similar to denim) | Tightly knitted, unevenly distributed locally | The structure is compact and evenly distributed |

| 5. Cultural Elements | Abstract patterns, irrelevant to Hong’an homespun | Stripes with distorted proportions | Basic patterns correct but without cultural details | Traditional stripes/grids + hints of weaving tools | Typical pattern background element |

| 6. Generation Defects | Obvious repeated patterns/digital noise | Local deformation or blurring | Slight edge defects | 1-2 minor flaws | Zero defects |

| B. Structure | |||||

| 7. Number of textures | The number of textures varies greatly from the number needed | The number of textures is quite different from the number required | The number of textures varies quite a bit from the number needed | The number of textures is less than what is needed | The number of textures is the same as the required number |

| C. Properties | |||||

| 8. Three-dimensional Sense | Completely flat 2D effect | Faint shadows visible when magnified | Medium depth, main grooves with shadows | Strong yarn projection under side light | 3D tactile "on paper" |

| 9. Handicraft Warmth | Industrial perfectionism (flawless) | Excessively regular, mechanical symmetry | Slight changes in yarn thickness | Visible hand-knotted nodules/asymmetric beauty | Vivid irregularities: burrs, uneven dyeing, etc |

| Criteria | Sample | Scores | Average score | ||||

| Midjourney | Qwen3 | ChatGPT | DouBaoAI | HailuoAI | |||

| 1.Surface texture | 1 | 1 | 1 | 1 | 1 | 0 | 1 |

| 2 | 2 | 1 | 1 | 1 | 0 | ||

| 3 | 0 | 1 | 2 | 2 | 1 | ||

| average score | 1 | 1 | 1.3 | 1.3 | 0.3 | ||

| 2.Color naturalness | 1 | 1 | 1 | 1 | 1 | 0 | 0.8 |

| 2 | 0 | 1 | 0 | 0 | 1.5 | ||

| 3 | 1.5 | 1 | 1.5 | 1 | 0 | ||

| average score | 0.8 | 1 | 0.8 | 0.7 | 0.5 | ||

| 3.Pattern contrast | 1 | 1 | 1 | 1 | 1 | 1 | 1.2 |

| 2 | 2 | 1 | 1 | 1 | 1.5 | ||

| 3 | 0 | 0 | 1.5 | 1 | 1 | ||

| average score | 1 | 0.7 | 1.2 | 1 | 1.2 | ||

| 4.Fabric density | 1 | 1 | 0.5 | 1 | 2 | 2 | 11.2 |

| 2 | 1 | 1 | 2 | 1 | 2 | ||

| 3 | 1 | 0 | 0 | 2 | 1 | ||

| average score | 1 | 0.5 | 1 | 1.7 | 1.7 | ||

| 5.Cultural elements | 1 | 1 | 0 | 1 | 0 | -1 | 0.2 |

| 2 | 1 | 0 | 0 | 0 | 0 | ||

| 3 | 0 | 0 | 1 | 0 | -1 | ||

| average score | 0.7 | 0 | 0.7 | 0 | -0.6 | ||

| 6.Generation defects | 1 | 0 | 0 | 1 | 0 | 1 | 0.3 |

| 2 | 1 | 0 | 0 | -1 | 0 | ||

| 3 | 1 | 0 | 1 | -1 | 1 | ||

| average score | 0.7 | 0 | 0.7 | -0.7 | 0.7 | ||

| 7. Number of textures | 1 | 2 | -1 | 1 | 0 | 1 | 0.4 |

| 2 | 1 | 0 | 1 | 0 | 1 | ||

| 3 | 0.5 | 0 | 0.5 | -1 | 0 | ||

| average score | 1.2 | -0.3 | 0.8 | -0.3 | 0.7 | ||

| 8.Three-dimensional Sense | 1 | 1 | 2 | 1 | 2 | -1 | 1 |

| 2 | 1.5 | 1 | 0 | 1 | -2 | ||

| 3 | 0 | 2 | 2 | 2 | 0 | ||

| average score | 0.8 | 1.7 | 1 | 1.7 | -1 | ||

| 9.Handicraft warmth | 1 | 1 | 0 | -1 | 1 | 0 | 0.2 |

| 2 | 1 | 1 | 0 | 1 | -1 | ||

| 3 | 0 | 0 | 0 | 1 | 0 | ||

| average score | 0.3 | 0.3 | -0.3 | 1 | -0.3 | ||

| Average score | 0.8 | 0.5 | 0.8 | 0.7 | 0.4 | 0.6 | |

| AI | Comprehensive average score | Strong ability | Weak ability |

|---|---|---|---|

| Midjourney | 0.8 | Surface Texture, Pattern Contrast, Cultural Elements | Three-Dimensional Sense, Handmade Texture |

| ChatGPT | 0.8 | Color Naturalness, Texture Quantity, Cultural Elements | Pattern Contrast, Three-Dimensional Sense |

| DouBaoAI | 0.7 | Fabric Density, Generation Defect Control | Cultural Elements, Handmade Texture, Texture Quantity |

| Qwen3 | 0.7 | Three-Dimensional Sense, Generation Defect Control | Fabric Density, Cultural Elements |

| HailuoAI | 0.4 | Pattern Contrast, Fabric Density | Generation Defects, Texture Quantity, Three-Dimensional Sense |

| AI | Comprehensive Average Score | Strong ability | Weak ability |

|---|---|---|---|

| ChatGPT | 1.5 | Surface Texture, Pattern Contrast, Cultural Elements | Three-Dimensional Sense, Handmade Texture |

| Midjourney | 1.6 | Color Naturalness, Texture Quantity, Cultural Elements | Pattern Contrast, Three-Dimensional Sense |

| DouBaoAI | 1.4 | Fabric Density, Generation Defect Control | Cultural Elements, Handmade Texture, Texture Quantity |

| Qwen3 | 1.5 | Three-Dimensional Sense, Generation Defect Control | Fabric Density, Cultural Elements |

| HailuoAI | 1.1 | Pattern Contrast, Fabric Density | Generation Defects, Texture Quantity, Three-Dimensional Sense |

| Prompt element | An example/writing guide |

|---|---|

| positive prompt (what should be included) | |

| Fundamental description | Seamless textile surface with a pattern based on the provided repeat unit image. Photorealistic macro shot. |

| Condition | maintain the composition from the micro-model. |

| Fabric type | satin silk, 3/1 twill (denim-like texture), herringbone wool tweed, twill 3/1, satin 5-harness, herringbone, basket weave, jacquard. |

| Colors and color ratios | deep indigo blue (#0A1E6B) and natural off-white (#F9F9F4). Exact color relationships: [color 1] and [color 2/3]. |

| Weave structure | 3/1 twill weave, 5-harness satin weave, herringbone, basket weave, jacquard. Repeat structure by quadrants (2x2) with alternating stripe orientation: vertical warp stripes in three quadrants, horizontal weft stripes in one quadrant. |

| Fabric parameters | Density: ~5–7 threads per cm, clear geometric rhythm. |

| Surface texture | Texture character: [light nap/silky sheen/matte graininess], [S or Z twist], micro-fibers, slightly uneven thickness, natural crossings and overlaps. [If needed: pronounced diagonal ridges for twill / V-shaped 'herringbones' / smooth mirror-like surface for satin / raised patterns for jacquard]. Controlled shadows between threads, readable over-under intersections. |

| Weave characteristics | Plain weave with visible thread interlacing, minor manual irregularities in thread thickness and tension |

| Lighting | [soft/hard] [direction] light, natural color rendition, shallow depth of field, muted background in highlights. |

| Final appearance | Square repeat unit laid flat, symmetrical, with clear edges, no folds, no imitation of fabric draping, and no background interference |

| negative prompt (what should be excluded) | |

| Exclude the following elements and styles: cartoon or illustrative style, vector graphics, 3D render, plastic look, glossy tubes, wireframe models, perfectly even lines, flat fills, embroidery, knitting or stitching effects, text, logos, watermarks, visible pattern seams, excessive sharpness, digital noise, blurriness, and low resolution | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).