1. Introduction

Grey Squirrels (Sciurus carolinensis) compete with local bird populations for supplementary feeding resources in urban areas, resulting in about 98% reduction in bird resource and an alteration in the effectiveness of supplementary feeding programs for birds, necessitating the use of squirrel-proof feeders to mitigate these effects [

1,

2]. In the UK, studies indicated that Grey Squirrels reduce the availability of supplementary food to wild birds and squirrels appear to keep away birds from bird feeders with their presence [

3,

4]. By design, bird feeders in gardens and parks are for feeding birds, but they attract squirrels in urban areas during winter period when food resources become scarce in forest habitats. This brings them into competition with birds over the bird seeds.

Like birds, there are feeding practices for squirrels. Jokimäki et al. [

5] found that squirrel abundance was approximately twice as high in urban habitats than in forests when feeding sites such as artificial feeding and planting spruce trees in urban environments were available. As such, understanding feeding and predation patterns may assist in designing conservation strategies for birds. In a recent study in Finland, Deshpande et al. [

6] found out that annual amount of food provided for birds in rural areas has increased but the number of bird feeding sites have declined over the past 40 years due to government regulation and concerns about attracting pests. A study in 2023 estimated that about 1300 –1500 bird species have gone extinct since the late Pleistocene, and many are currently endangered [

7]. Biodiversity remains a crucial factor in a resilient and effective functioning ecosystem because plants and animals, which have rare traits and functions, need to be prevented from becoming extinct [

8,

9]. Birds perform some roles in a functioning ecosystem as they pollinate plants and feed on pests that destroy vegetations. Birds are delightful to watch for leisure and wellbeing by nature lovers, and it may be connected to myths and customs [

10]. Ornithologists study birds to understand ecology, conservation and species [

11]. So, there is an ecological value in birds’ conservation, particularly rare birds or those endangered through competition or predation by other stronger animals.

Bird feeders are popular in households with garden views, as they attract various species of bird [

12]. There are some parks that use bird feeders to enhance food availability for birds. The problem of this study is based on an observation that squirrels frequently target bird feeders as a food source and waste large amounts of bird seeds. This increases cost of bird feeding as squirrels reduce the quantity of food available to birds due to competition for the scare resources during winter. In addition to the competition for food between birds and squirrels in an ecosystem where they co-exist [

13], the risks to the survival of rare birds are being fuelled by anthropogenic activities such as urbanisation and industrialisation, as well as environmental pressures from climate change such as drought, desertification, wildfire and extreme hot temperatures [

14]. Unlike conservation efforts for plants that can be realised over time through afforestation [

15], it is difficult to recreate animal species that have gone extinct [

16]. Thus, adopting birdfeeders as preventive approach to conservation of birds rather than corrective approach remains a theme of study.

Squirrels weigh more than garden birds. Grey squirrels females can weigh between 400 g and 720 g, and males can weigh between 440 g and 650 g [

17]. The mass of common garden bird species such as the Great Tit, the Gold Finch and the Chaffinch is between 18 g and 29 g [

18]. Bird feeders are good examples of how to feed and conserve garden birds as they keep returning because of the food resources. There are different designs in the market although many bird feeders cannot stop squirrels from gaining access to the bird seeds. The authors reviewed the major designs of bird feeders out there given that we are approaching the problem of squirrel feeding from current bird feeders as a design failure of the current solutions because the design intent was ab initio to deter squirrels from accessing the seeds. Therefore, a design and engineering solution is at the core of our approach to the problem of study.

There has been a bird feeder with a dome overhang baffle to prevent squirrels from climbing onto the feeder from above [

19]. A wide cylindrical baffle can be placed on a pole supporting a feeder to prevent squirrels from climbing onto the feeder. Whilst these designs block access from above and below the feeder, squirrels can jump onto feeders from elevated objects such as a tree branch or a fence. They can jump up to 2.5 m sideways, 1.2 m up and 4.5 m down; thus, requiring a feeder to be placed at least 3.0 to 4.5 m away from trees, or other elevated objects to reduce access [

20]. This eventual access to bird seeds by squirrel through consistent maneuvering using trial-and-error is the main problem of study this project seeks to address using engineering design solution.

Many feeders use static structures. However, squirrels easily outsmart static structures. For instance, if a squirrel passes static structures, there is nothing else to protect the bird seeds. Christopher et al. [

21] used two concentric cylindrical housings at the base of the feeder, with openings on the side walls to allow the bird to access the birdseed. When activated, a compression spring biases the outer cylinder to its upper position and aligns the holes to allow birds to have access to the bird seed. When the heavier squirrel’s weight is applied to the outer cylinder, it pulls the outer cylinder downwards to misalign the holes on each cylinder, blocking access to the birdseed. The design limitation is that the squirrel must place its weight at the base for the holes to misalign. Another design by [

22] used concentric cylinders as a cage. When a squirrel’s weight is exerted, the outside cage displaces downwards, causing a finer mesh on the cage to cover the feeding ports. Squirrels can grip onto the top of feeders with their back legs and lean over to eat the bird seed. With this technique, a squirrel could outsmart these designs and access the birdseed.

The mechanism of the squirrel-proof bird feeder is such that displacements due to applied force must return to its original state when the force is removed [

22]. Our design goal is to propose an engineering design solution to cause the bird feeder to close wherever the weight of a squirrel is exerted on the bird feeder to improve the existing dynamic design solutions that require the squirrel to exert its weight at a specific location (base or side) of the bird feeder. We hypothesize that the weight-induced self-protection mechanism of the proposed engineering design solution can be based on the weight difference between squirrels and birds which can be implemented using spring in accordance with Hooke’s law and systems dynamics.

Overall, the aim of this work was to design, prototype and test a squirrel-proof bird feeder which is capable of self-protection regardless of the part of the bird feeder on which a squirrel exerts its weight whilst allowing birds to feed from it. To realise the overall aim in a systematic manner, the following objectives were pursued:

Create conceptual and engineering designs for a squirrel-proof birdfeeder.

Perform Failure Mode and Effect Analysis (FMEA) to gain design insights on possible scenarios that the bird feeder could fail, which would allow a squirrel to gain access to bird seeds.

Perform Finite Element Analysis (FEA) using NX12 to optimise the engineering design solution.

Manufacture a prototype using additive manufacturing.

Test to validate the squirrel-proof birdfeeder in a real-world environment.

Engineering design solutions are valuable process for realising physical products and configuring service delivery to solve specific problems [

23,

24]. Scientific approach has been applied in this study to contrive an engineering design solution to the current problem of squirrels feeding on bird seeds. This contributes to the conservation of biodiversity through human interventions that promote bird species richness and abundance [

25]. Self-protecting bird feeders can be used where birds and squirrels co-exist. This study is presented to enhance reproducibility and adaptability. The study explains how the bird feeder can be manufactured using rapid production capabilities of additive manufacturing process. Henceforth, the design concepts are presented in section 2.

Section 3 presents the physics and engineering design process while Section 4 presents the materials and manufacturing process selection. The manufacturing processes applied in the study are presented in Section 5 while the testing results are presented in Section 6. Lastly, the conclusions from the study are presented in Section 7.

2. Research Methodology

This study went beyond observation of the squirrels and garden birds to proffer solutions based on product design and engineering. Therefore, the project management methodology implemented included problem identification, project initiation, planning, execution, testing and reporting

. Engineered solutions, whether simple or complex systems, often start with conceptual designs, development activities and optimisation of the final designs [

26]. Based on the insights from the review of literature and the designs of birdfeeders in the market, four design ideas were generated to address the competitions between garden birds and Grey Squirrels in Loughborough, United Kingdom. Two concentric cylinders were aligned to control access to the feeding holes. The outside cylinder displaces downwards to close the access to the bird seeds when the weight of a squirrel is exerted on it. The four conceptual designs were critically accessed using Pugh Matrix to down select the best design based on six criteria analysed using domain-based systems thinking [

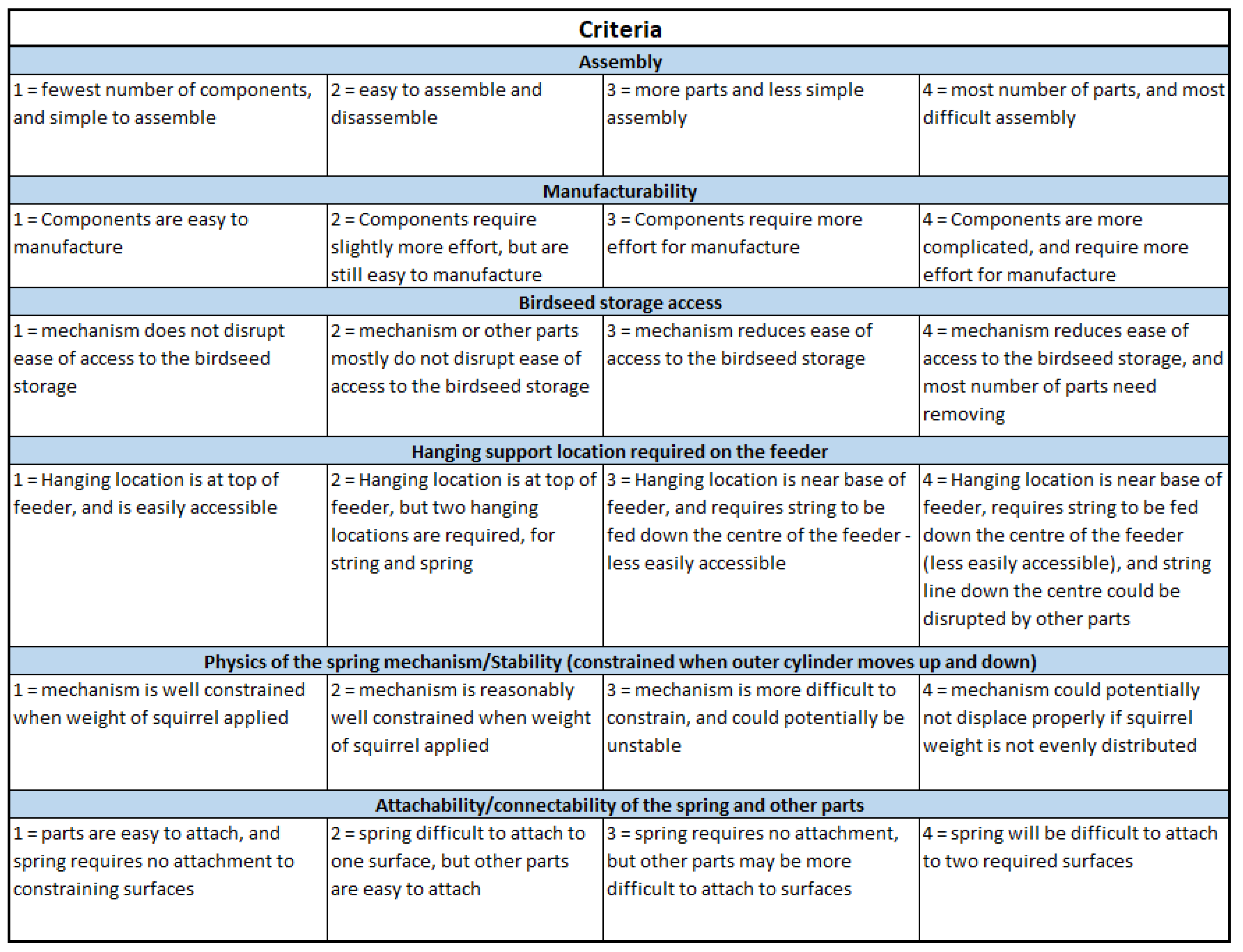

27].

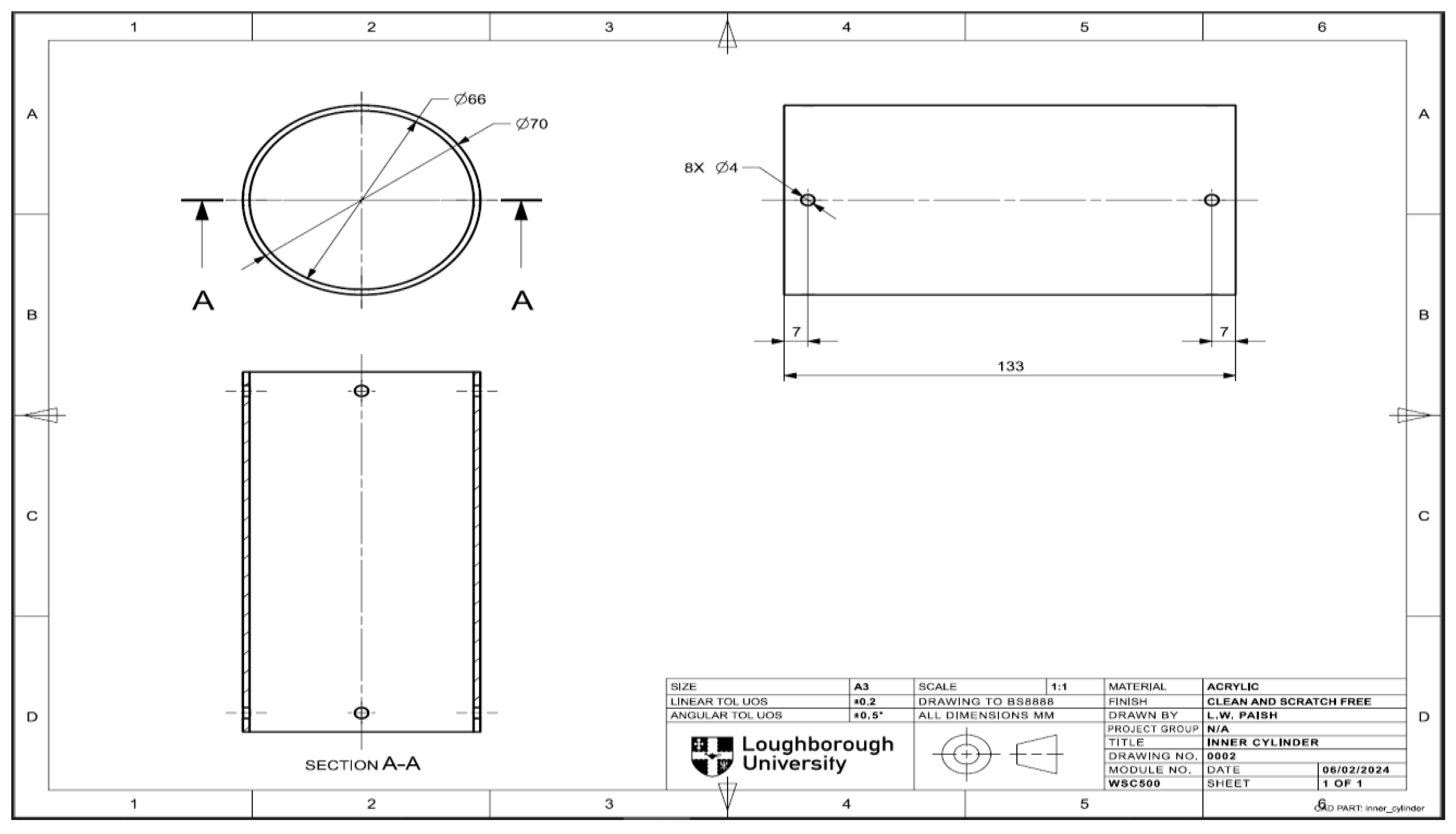

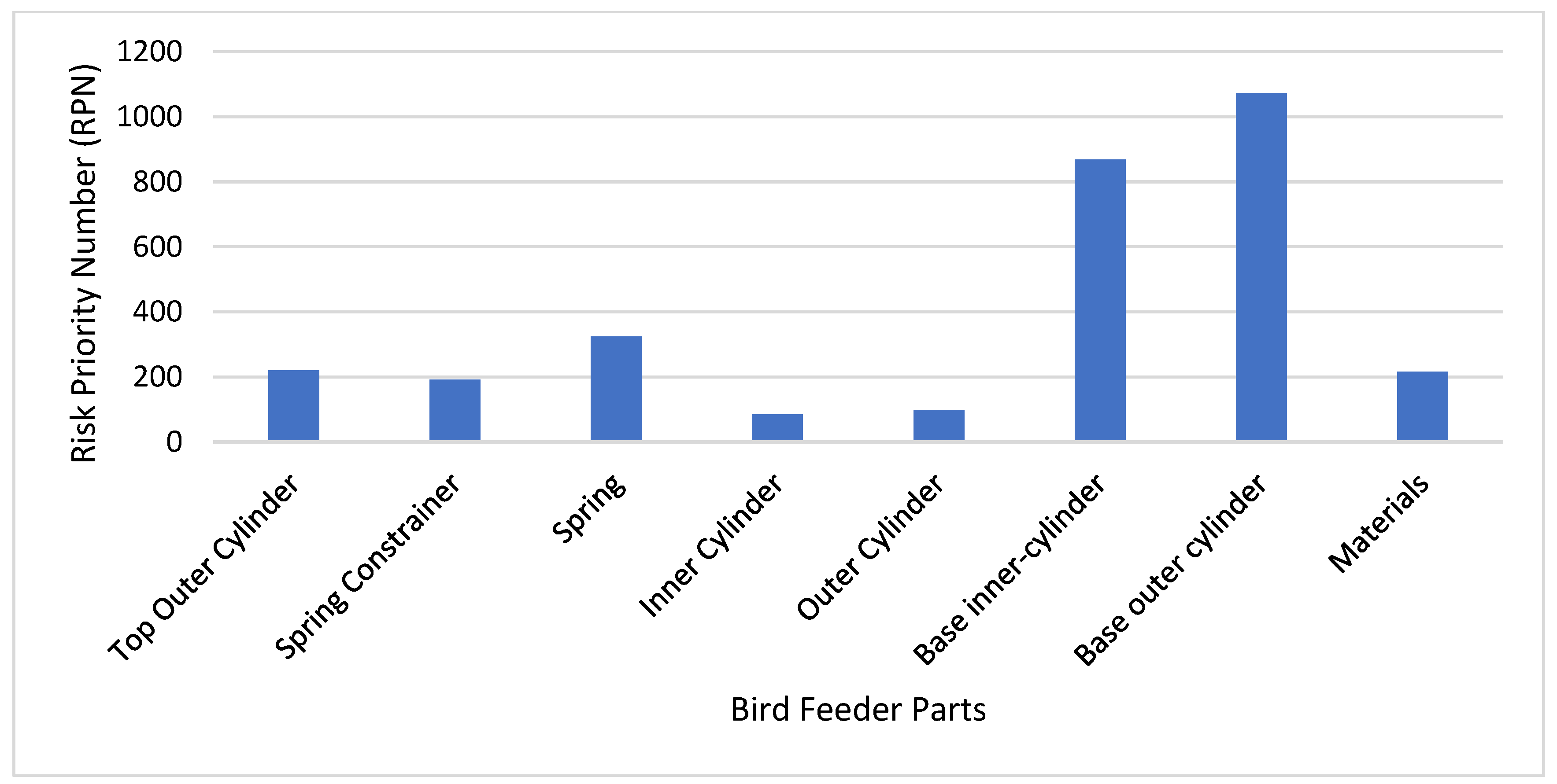

To optimise conceptual design features, failure mode and effect analysis (FMEA) was used to predict potential failures and in order to optimize the design to prevent such failures, thereby reducing the risk of squirrels gaining access to bird seeds. Risk Priority Number (RPN) was calculated to estimate the level of risk each failure pose [

28] For each part of the feeder, various failure modes and its effects on the system were identified, and each mode was ranked in terms of its severity on the system (S), how likely it was to occur (O), and the detectability of the failure (D). The parts suspected to be prone to failure were analysed and optimised using finite element analysis (FEA). An experiment was performed to select the spring constants for the system based on Hooke’s law.

A morphology matrix was used to determine the materials and manufacturing processes that can facilitate rapid prototyping and rapid production of the parts using additive manufacturing. Light materials were considered to ensure that the initial deflection of the spring will be minimal. Thus, the remaining displacement will be induced by the weight of the squirrel. Materials prone to rusting when subjected to harsh weather under use were excluded. Cheap materials were used to reduce cost of the bird feeder. Additive manufacturing was used to produce low-cost plastics parts of the prototype [

29]. The parts were assembled and the protype was tested at two different locations to validate the concept. Data was collected using direct observation and video recorder to enable continuous improvement of the design.

3. Results and Discussion

3.1. Conceptual Designs Considerations for Squirrel-Proof Bird Feeder

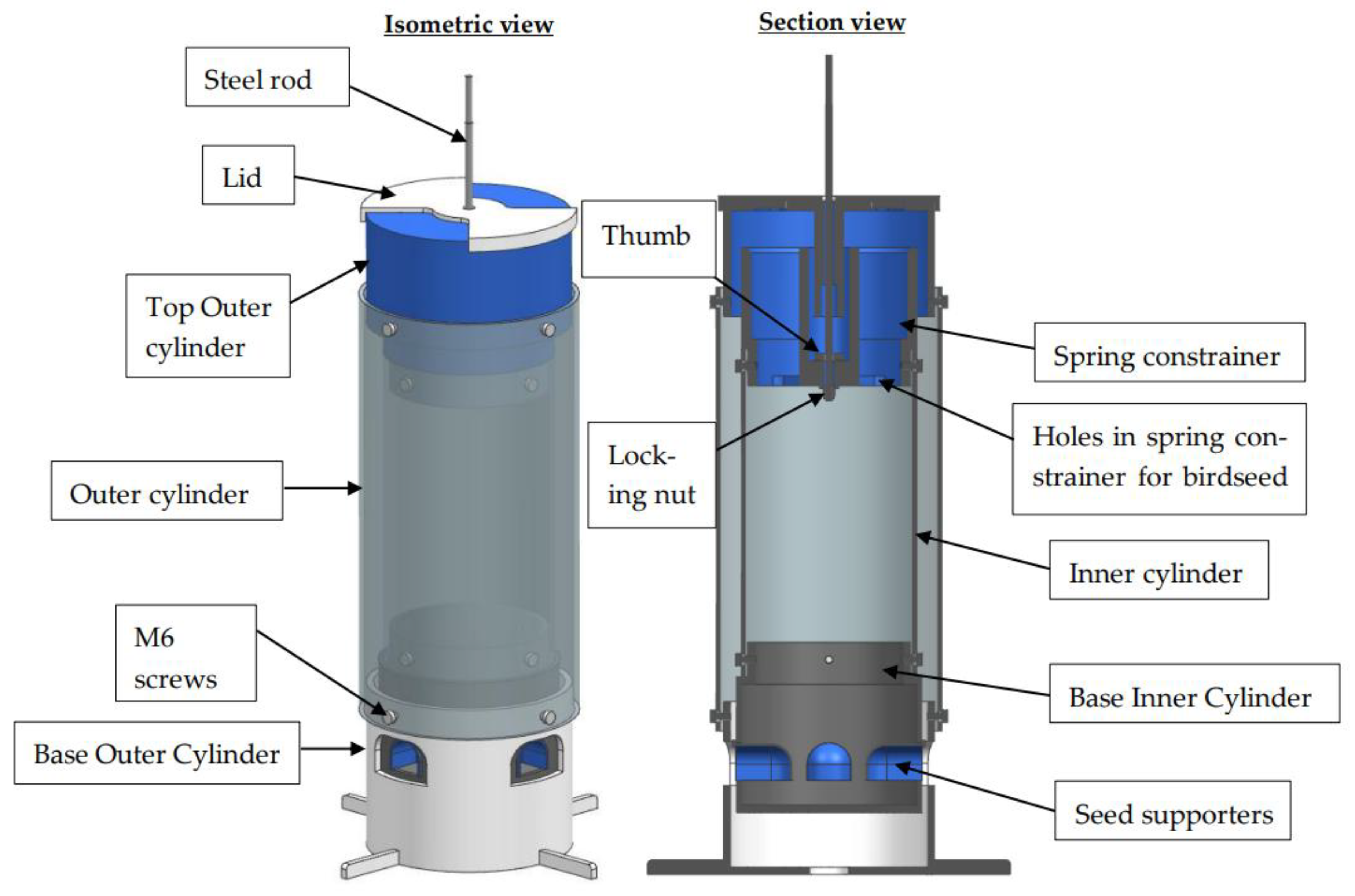

The design criteria included ease of assembly, manufacturability, ease of access to bird seeds, ease of attachment to support, physics of the spring to ensure reliability and attachability of the spring to ensure recoverable weight-induced displacement (see Appendix A). The conceptual design down selected based on Product Design Specifications (PDS) in Appendix B uses compression spring placed at the top of the feeder such that it can be compressed by the top component of the outside surface whenever weight beyond a limit of compression is applied anywhere on the outside surface and the base. Detailed engineering drawing was done using NX software including manufacturing drawings based on BS8888 (see Appendix C). All parts of the feeder were successfully designed and assembled as shown in

Figure 1.

3.2. Physics of the Bird Feeder

This discusses how the dynamic behaviour of the bird feeder was engineered to enable it to self-protect itself from squirrel. All equations cited can be found in Appendix D. The mass of the grey squirrel ranges from 400 – 700 g [

22]. Hence 400 g was taken as the mass to deflect the spring 15 – 20 mm. The desired spring constant was from 196 N/m – 262 N/m. The free length of each spring and the corresponding displacements from neutral position at every 100 g increment were measured, up to 400 g. The experimental data to determine the spring constant was recorded, and the approximate spring constant was calculated using equation (2) and quantified in equations (3) and (4). The value of

was taken as the spring displacement at 400 g since the spring displacement varied linearly with the applied weight. The maximum possible displacement of the spring should displace more at masses over 400 g to allow greater coverage of the feeding holes. At the end of spring selection process, a spring with dimensions of 5.5 mm in diameter and 38 mm in length, with a spring constant of 212 N/m was selected.

Platforms for birds were included at the base outer cylinder. Each platform acted as a cantilever beam, suspended at one end, but needed to withstand the stress from the bending moment induced by the weight of any squirrel. Under the assumption of a worst-case scenario, the squirrel will exert its weight on the end of the beam, inducing the largest bending moment possible. From equation (5), the larger the second moment of area , the smaller the induced stress . In equation (6) , increasing the height of the cross-sectional area will significantly increase the value of . Therefore, the platforms were designed with a larger height to width ratio to reduce the bending stress applied from a squirrel’s weight. Using equations (5), (6) , and (7) , the platforms were designed with a width of 0.003 m, a height of 0.006 m, and a length of 0.03 m. This would give a value of maximum normal stress of 16.67 MPa, which was well below the Yield strength value for PLA at 50 MPa. This was predicted to be sufficient to hold both the bird’s and squirrel’s weight but allow the feeding holes to remain open for the birds while they remained closed to the squirrels. Once the weight of the squirrel was removed, the spring returns the outer cylinder to the initial position for the birds to feed. This differential mass mechanism can be applied in engineering systems that require selective activation based on weight.

3.2. Failure Mode and Effects Analysis (FMEA)

Appendix E presents the results of the FMEA. This approach was useful in critical analysis of potential failure modes and their effects. Addressing the effect of critical risks was focused on engineering the system never to allow squirrels to access the bird seeds regardless of any kind of maneuver they perform. To identify which parts were most at risk of failure, the total RPN for each part was calculated and presented in a bar graph shown in

Figure 2. The insights from the FMEA were used to optimize the design to improve the reliability of the system.

The first risk was the likelihood of jamming of the two concentric cylinders which will cause the system to lose its dynamic behaviours and remain static, which the squirrel can easily maneuver to access the bird seeds. To address this risk, a diametral clearance was introduced between the two concentric cylinders to prevent jamming, whilst allowing the inner feeding holes to be within the reach of birds considering the short breaks of garden birds. Thinking about the feeding holes, the second risk of bird seeds falling off was identified. To address this, the feeding holes were sized to be large enough for the bird seeds not to fall off, assuming that the squirrels chose to forcefully shake and dangle the bird feeder. Small seeds could pour out from large gap in the feeder without additional support. In this design, the feeder was filled with larger nuts and peanuts, which could not fall off from small gaps due to their larger size. A cage-like structure covered the feeding holes at the base inner cylinder, with openings large enough for birds to feed from, but small enough that peanuts would not pour out the holes.

The third risk was a possible breaking of the platform attached to the base outer cylinder under the weight of a squirrel since a squirrel could jump onto the feeder from a greater height of up to 4.5 m, resulting in a much larger force being exerted on the platforms. To reduce this risk, the second base outer cylinder was designed without protruding platforms for the birds. Instead, a ladder-like structure for the birds to grip onto was created. It was thought that these would be less exposed to squirrel; hence, unlikely to receive a large force of a falling squirrel as well as increasing the difficulty for the squirrel to grip onto the base. After testing, it was realized that the birds found the ladder-like structure uncomfortable. The based design was reverted to have protruding structure. However, FEA approach was used to analysis the structure to ensure that the structure was strong enough to withstand the weight of squirrels.

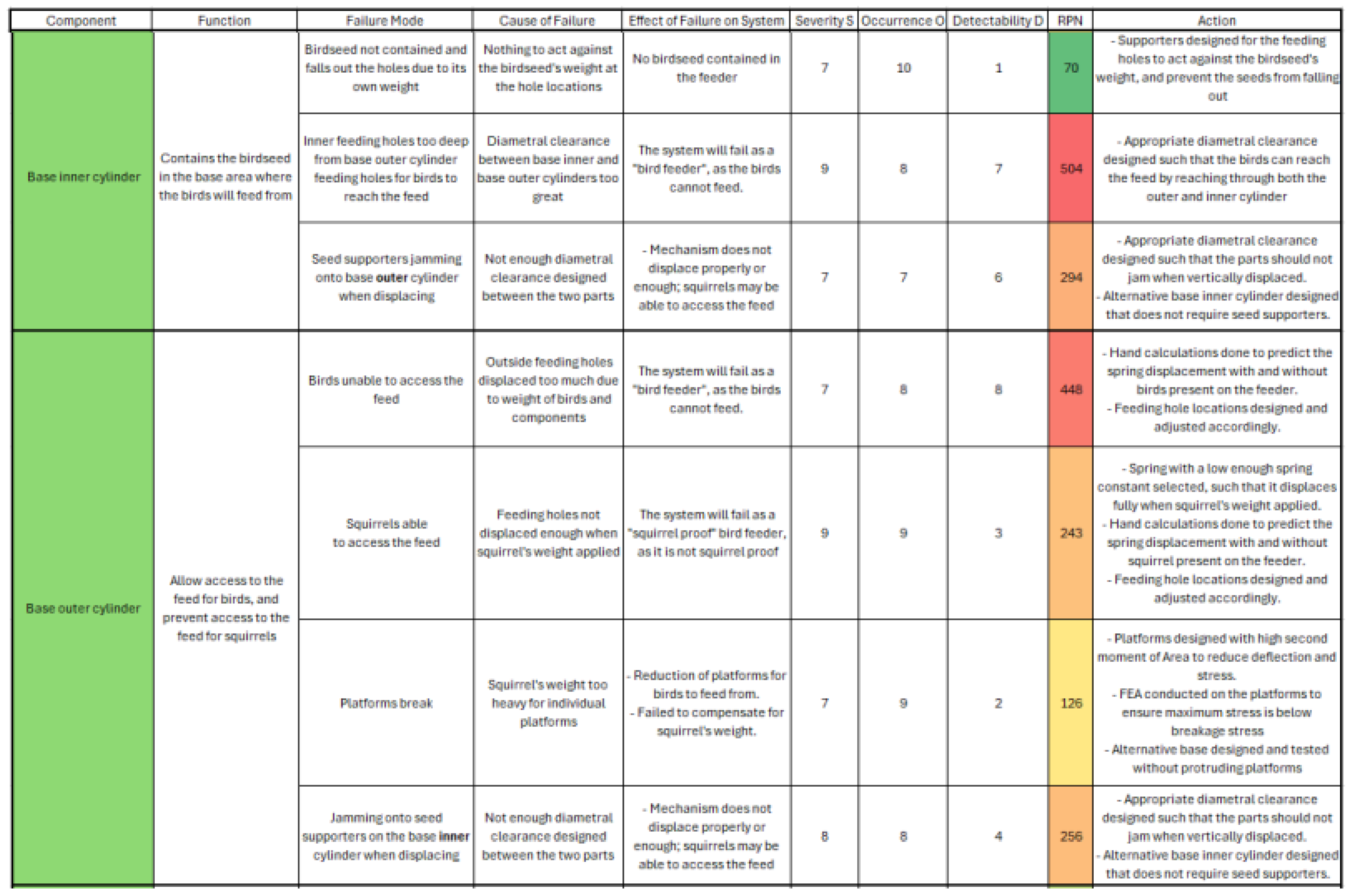

3.4. Design Optimisation Using Finite Element Analysis

The top outer cylinder should engage the spring constrainer when displaced downwards by the squirrel’s weight, hence exerting a force equal to the squirrel’s weight on each part. FEA ensured they could withstand this contact force. The base outer cylinder design contained specific areas for the squirrels to hold onto directly. Thus, the squirrel could place its whole weight on a small area which induces a higher stress on these parts.

A fixed constraint was applied to the surface of the central pillar that would meet the spring constrainer. Loads were applied to the surrounding holes, as this was where the force would be applied if the squirrel were to hang from the parts at the base. The yield strength of PLA is 50 MPa and the maximum stress experienced by this part was 0.22 MPa. This stress was significantly below the yield strength, meaning the part will likely not fail under the applied force. The spring constrainer was constrained at its base where it would be supported by the steel rod and a nut. The 10 N load was applied to the surface which the central pillar of the Top Outer Cylinder. The maximum stress experienced in the spring constrainer was 0.569 MPa, significantly below the yield strength of 50 MPa, meaning the part would not fail under the applied force.

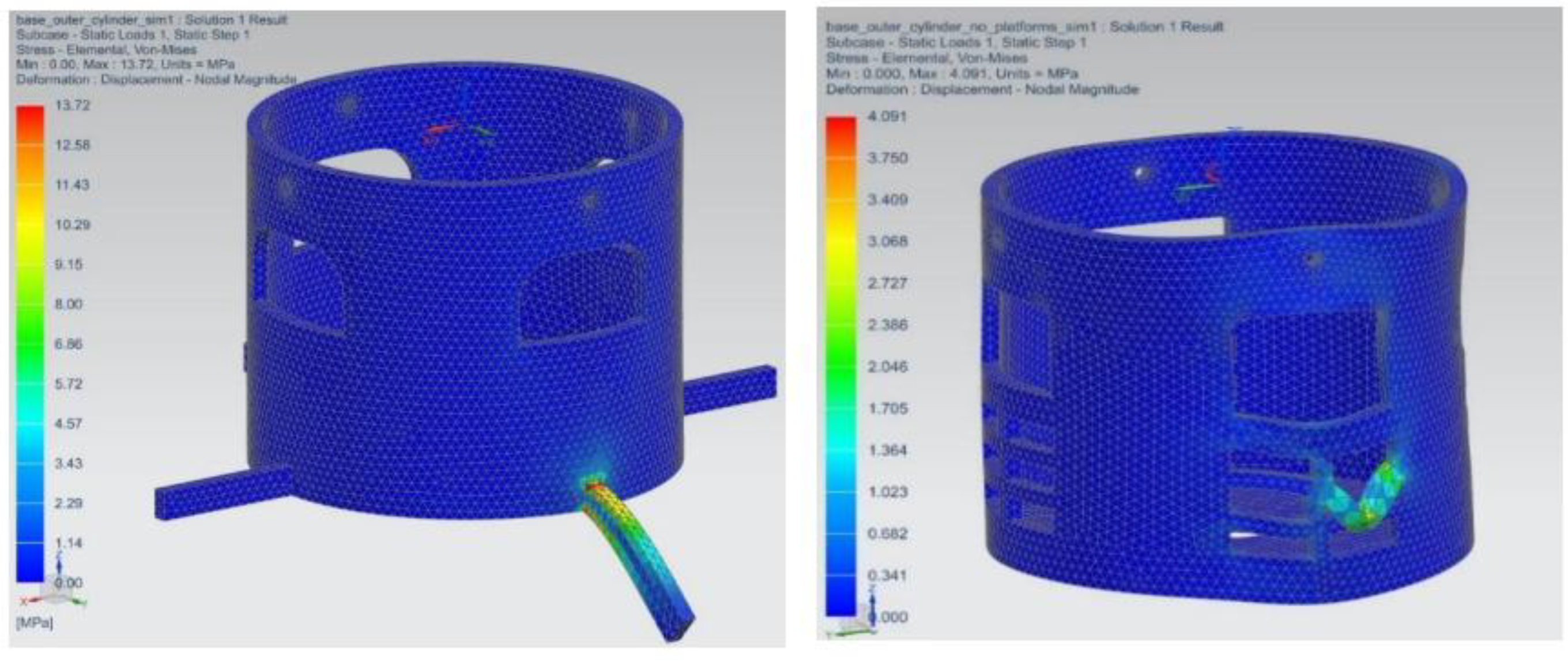

On the initial cylinder design, the load was applied to the end of one of the platforms to simulate the maximum bending moment that could be applied if the squirrel were to hang from a platform. The load was also applied to the centre of a horizontal beam in the ladder-like structure to simulate the maximum possible stress if the squirrel were to hang from this beam. The loads and constraints for the initial and improved base outer cylinders and the resulting stresses are shown in

Figure 3.

The maximum stress experienced by the base outer cylinder for the protruding cantilever was 13.72 MPa while the maximum stress experienced by the base outer cylinder for the ladder-like support was 4.091 MPa, which was significantly lower than the yield strength of 50 MPa. Reflecting on the design and development decisions after manufacturing and testing, having protruded base makes it easier for birds to ergonomically perch compared to the ladder-like design. Thus, the findings from the FMEA and FEA assisted to improve the alignment of the inner and outer cylinders, prevention of access to squirrels and comfortable access to bird seeds by birds.

3.5. Materials Selection for the Bird Feeder

Plastic screws were used because they have higher coefficient of thermal expansion than metal under various temperatures. Furthermore, metals corrode, become weaker and cause failure as the years pass by [

30].

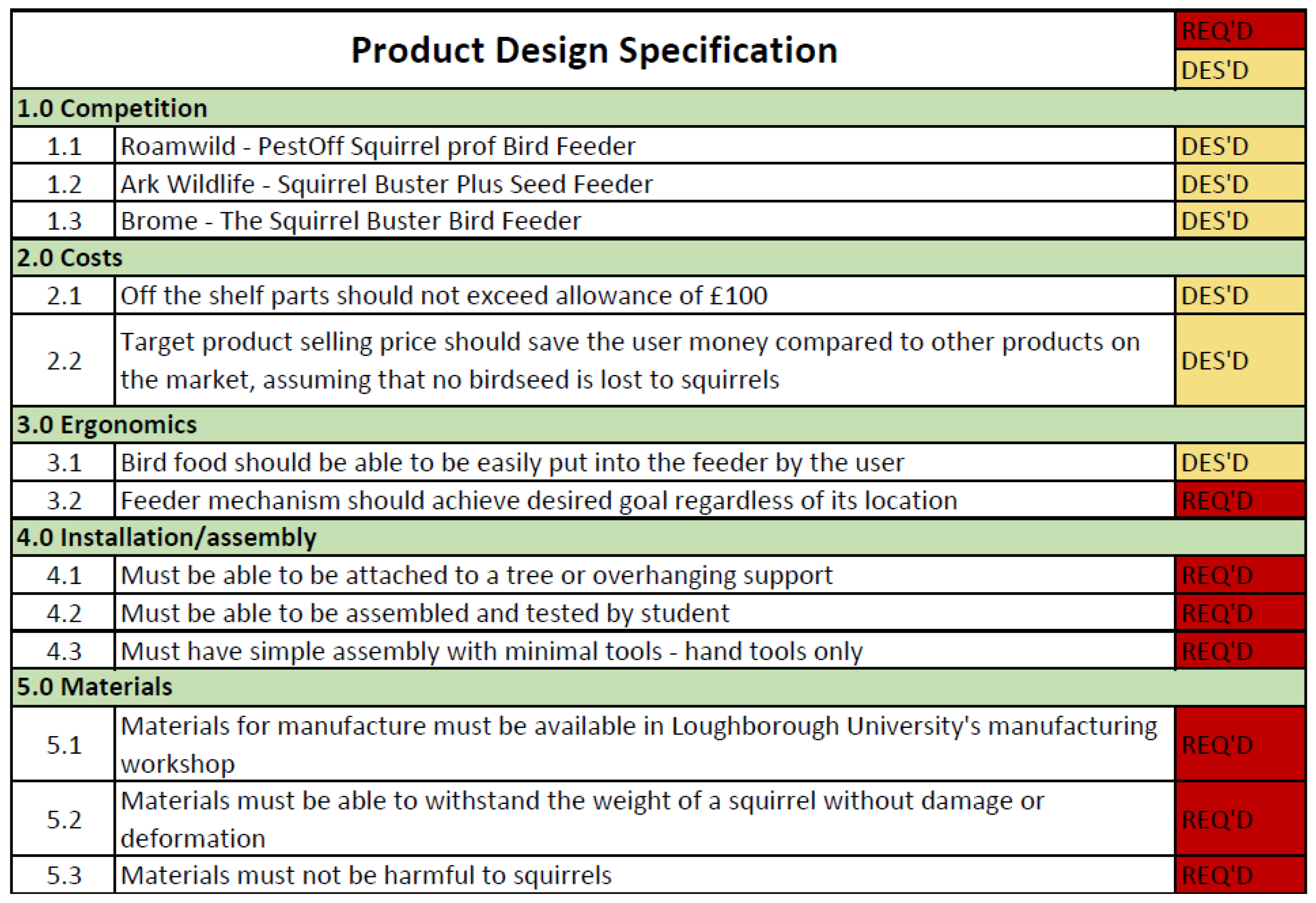

The inner and outer central cylinders were made of transparent material so that the birds can see the bird seeds from far distance. The spring and central rod were made of steel and purchased off-the-shelf. The height of the Acrylic inner cylinder was 133 mm, and an outer cylinder of height was 180 mm combined with a 140 mm steel rod. This resulted in a total vertical distance of 280 mm. Polylactic acid (PLA

) [

31,

32] and Acrylonitrile Butadiene Styrene (ABS) [

33] were considered for manufacturing the prototype. PLA was denser and heavier than ABS, and it has a yield strength (50 MPa), tensile strength (70 MPa), and a Young’s modulus (3600 MPa), compared to ABS with a yield strength (31 MPa), tensile strength (40 MPa), and a Young’s modulus (2000 MPa) [

34]. This meant that PLA could withstand higher stress and a higher resistance to deformation under a load. The inner and outer central cylinders were made of acrylic tubes to make the bird seeds readily visible and attractive to birds from a far distance. Tubes with diameters of 70 mm and 90 mm with 2 mm thicknesses were used, as this provided a suitable size for the bird seed container, whilst providing enough clearance between the cylinders.

3.6. Manufacturing Processes for the Bird Feeder

Manufacturing is the practical way to realise any physical product regardless of the sector of application [

35]. In this study, majority of the components were produced using additive manufacturing (or 3D printing) except the acrylic tubes for the inner and outer cylinders and spring that were purchased off-the-shelf. Ultimaker 3D printers with a nozzle diameter of 0.4 mm and PLA were used. All parts were given a two-layer wall thickness and a 20% infill density and a triangular pattern to give the polymeric parts sufficient strength whilst keeping them light. Support material was used in the prints where necessary, and this was carefully removed after printing. After printing all the plastic components, the bird feeder was assembled.

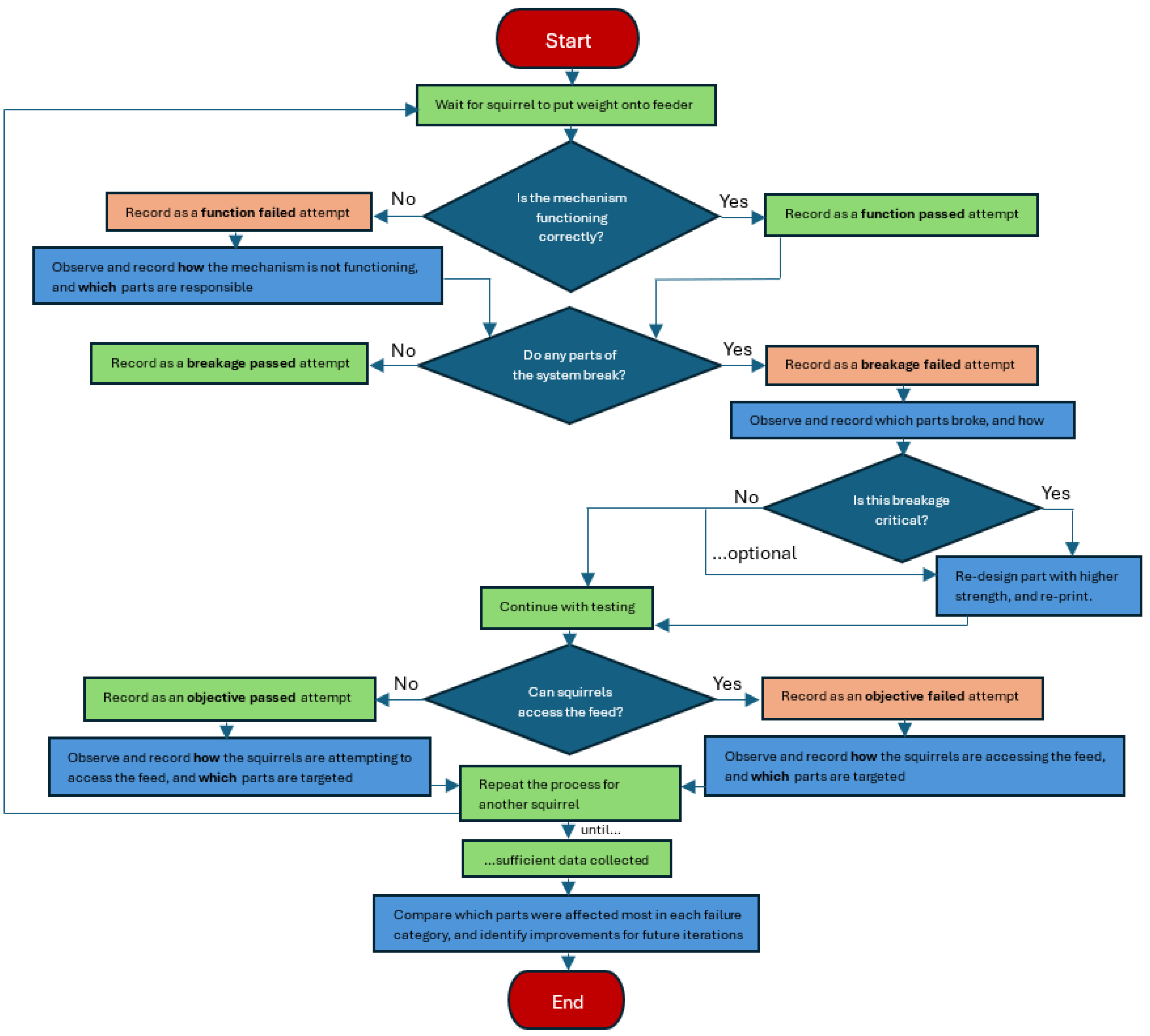

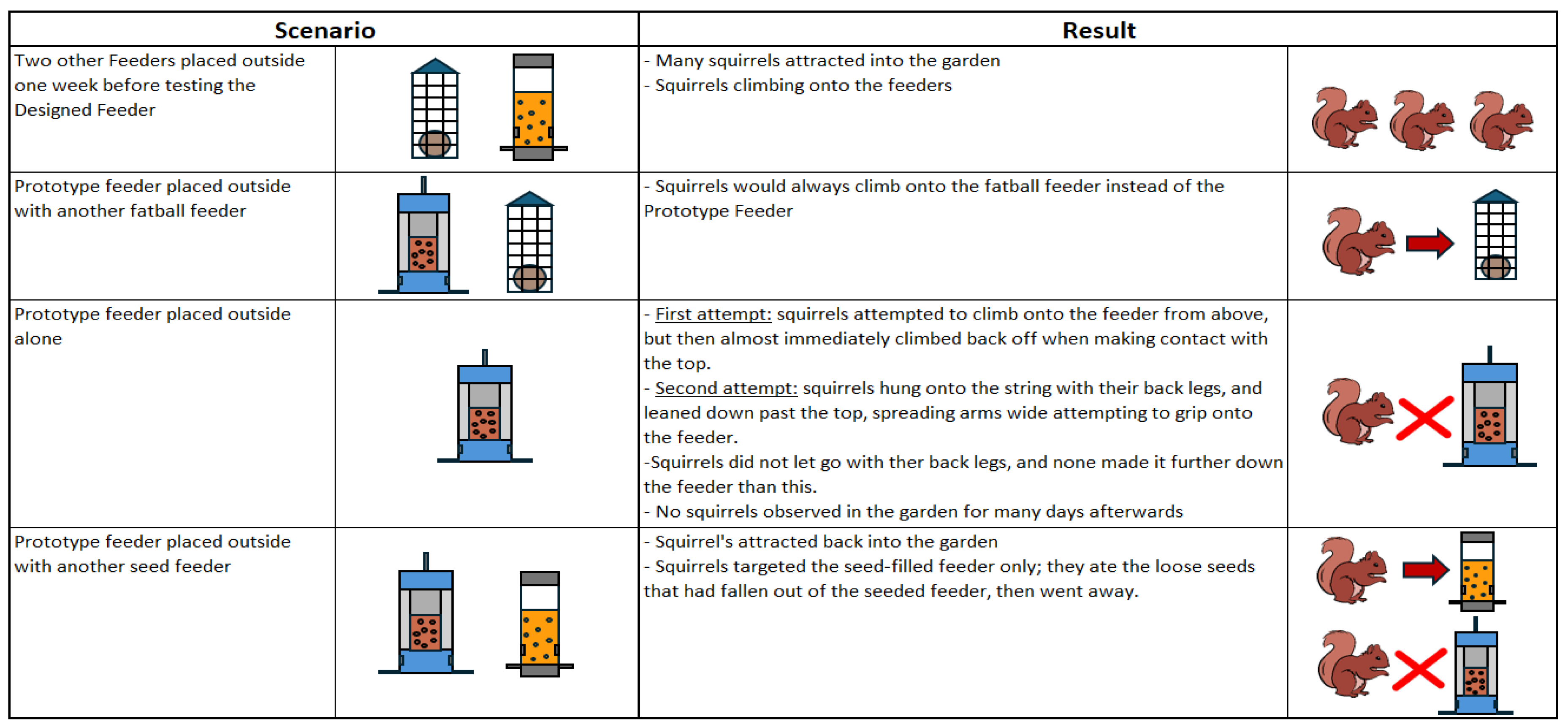

3.7. Testing and Validation of the Bird Feeder

The assembled bird feeder was tested at two different locations to analyse its real-life performance against the desired design goal. One was in the garden in Loughborough while the second location was inside Loughborough University. The testing procedure and the summary of the scenarios observed were summarized in Appendix F and G. The feeder was hung in a garden in Loughborough and observed from a kitchen window for 4 weeks. Within this period, the bird feeder was hung on a tree to observe if that would make it easier for the squirrel to access the bird seeds. A time lapse camera was placed outside to observe the feeder to capture interactions when no one was around to observe the feeder. The two base designs were tested. It was observed that the design with protruding platforms was better because it provided a comfortable perching position for birds while the ladder-like structure design was obscure to the birds, suggesting that the birds can easily see the protruded design, perch in a stable position and remain comfortable as they feed as shown in

Figure 4.

In the same test environment, squirrels attempted to climb onto the bird feeder regardless of the location it was hung. From

Figure 5, a frequent behaviour was an attempt to climb onto the feeder from the top where the bird feeder was attached to the tree or support. It was observed that any contact at the top of the feeder activated the dynamic mass differential mechanism, causing the squirrels to retract from the bird feeder as the spring moves under its weight. This observation suggested that the squirrels felt unstable and unsafe due to the vibrating behaviour caused by dynamic spring mechanism. Therefore, this engineering design solution acts as a deterrence to the squirrel without harming them. Although the squirrel was more confident during subsequent attempts and even hugged the smooth outer cylinder whilst holding on to support, such efforts and maneuvers did not enable it to access the bird seeds. Based on the observations from the testing, the proposed bird feeder proved to be a reliable squirrel-proof device since no squirrel succeeded in feeding from it, but birds perched on the base outer cylinder without activating the closing mechanism of the bird feeder.

Author Contributions

Conceptualization, LP. and CO.; methodology, LP and CO; software, LP; validation, LP., CO. and CN.; formal analysis, LP; investigation, LP.; resources, LP; data curation, LP; writing—original draft preparation, LP.; writing—review and editing, CO and CN.; visualization, LP.; supervision, CO.; project administration, LP. All authors have read and agreed to the published version of the manuscript.