1. Introduction

The degradation mechanisms affecting railway wheels and rails are multifaceted and interdependent, with rolling contact fatigue (RCF) identified as the principal cause of damage occurring at the wheel-rail interface. Rolling contact fatigue arises from cyclic stresses generated during the continuous rolling contact between the wheel tread and railhead, leading to the initiation and propagation of cracks both at the surface and subsurface levels. This fatigue phenomenon is critical because it directly contributes to the progressive deterioration of both wheel and rail materials, ultimately impacting the operational safety, reliability, and maintenance schedules within railway systems. Track failures or rail vehicle derailments represent approximately 50% of overall accidents in railway transport. The complexity of RCF damage is amplified by the dynamic interaction between wheels and rails, which are subjected to variable loading conditions dictated by train speed, axle load, track geometry, and operational frequency. These factors induce fluctuating contact stresses that promote microstructural alterations and damage accumulation. As a consequence, the contact surfaces experience progressive wear, crack initiation, and crack growth, which can culminate in severe surface defects such as spalling, shelling, and pitting, compromising the structural integrity of the components. The susceptibility of railway wheels to damage under RCF is governed by a broad spectrum of parameters. Mechanical loads—both in terms of magnitude and frequency—play a pivotal role in determining the rate of damage accumulation. Environmental and climatic influences, including temperature fluctuations, humidity levels, and the presence of contaminants such as moisture and particulate matter, further exacerbate wear and fatigue processes by altering surface conditions and promoting corrosion or lubrication breakdown. The fundamental process driving surface damage in railway wheels involves the progressive accumulation of defects within the metal’s crystal lattice. These defects typically manifest as dislocations, microcracks, voids, and inclusions that propagate and coalesce under repeated mechanical loading conditions inherent in wheel-rail contact [ref]. The spatial distribution and uniformity of these defects are equally critical; a non-uniform defect distribution can create localized stress concentrations, which serve as preferential sites for crack nucleation and accelerated crack growth. Such localized damage compromises the overall structural integrity of the wheel and raises the risk of catastrophic failure [

1,

2,

3,

4,

5,

6,

7].

These external factors interact synergistically with material properties to dictate damage evolution. The metallurgical characteristics of wheel materials are of paramount importance in defining their resistance to damage under operational stresses. The chemical composition, incorporating alloying elements that influence hardness, toughness, and fatigue strength, sets the foundational properties of the steel. Microstructural features, including grain size, phase distribution, and the presence of inclusions or precipitates, critically affect the initiation and propagation of fatigue cracks. Furthermore, heat treatment regimens applied during wheel manufacturing impart specific mechanical properties by modifying microstructure, such as enhancing hardness and residual stress profiles, thereby influencing fatigue life. Collectively, these metallurgical factors determine the wheel’s intrinsic capacity to withstand cyclic loading without premature failure [

8,

9,

10,

11].

Empirical and theoretical studies extensively documented in the literature emphasize that damage to the wheel running surface is not the result of a singular event but rather the cumulative effect of microstructural degradation over extended periods of service. This gradual damage evolution is influenced by the synergistic effect of mechanical contact stresses, frictional interactions, and thermal cycling at the wheel-rail interface. Also the steadily growing technical requirements are very crucial—e.g., with the increase in train speed and service frequency, the thermal load on railway freight wagon wheels has been steadily increasing, making wheel tread thermal fatigue damage a critical issue in heavy-haul railway transportation. Thermal effects, induced by frictional heating during rolling contact, can cause microstructural transformations and residual stress development, further complicating the damage mechanisms. The wheel-rail interface represents a highly complex tribological system where mechanical, thermal, and chemical phenomena converge. The interplay of these factors underlines the necessity for comprehensive investigation into the microstructural and mechanical responses of wheel materials under realistic service conditions. Understanding these responses is vital for optimizing material selection, improving wheel design, and developing maintenance protocols aimed at mitigating the detrimental effects of rolling contact fatigue [

12,

13,

14,

15,

16,

17,

18].

Currently, carbon steel remains the predominant material utilized in the manufacture of railway wheels, owing to its advantageous balance of mechanical properties, widespread availability, and cost-effectiveness. The selection of carbon steel as the standard material is supported by its ability to provide sufficient strength, toughness, and wear resistance required for the demanding conditions of railway service. The manufacturing processes and quality control standards for railway wheelsets are rigorously defined by the international standard titled “Railway—Wheel sets and bogies—Wheels—Product requirements,” specifically the PN-EN 13262:2021-2 standard. This standard, formally adopted as a European Norm in February 2021, establishes comprehensive specifications and technical requirements designed to ensure the safety, reliability, and functional performance of newly manufactured railway wheels and wheelsets. The PN-EN 13262:2021-2 standard delineates five distinct steel grades authorized for the production of monoblock railway wheels: ER6, ER7, ER8, ERS8, and ER9 [ref]. These steel grades differ in chemical composition, mechanical properties, and intended application environments, but all are engineered to meet the stringent demands of railway operations. Among these grades, ER7 steel is notably prevalent within the industry and serves as a common focus for academic and industrial research due to its well-balanced mechanical properties and extensive adoption across various railway networks [ref]. Characteristics of ER7 include a medium carbon content, controlled alloying elements, and an optimized heat treatment process that collectively contribute to a desirable combination of hardness, strength, and fatigue resistance [

19,

20,

21].

In practical railway operation, wheels are subjected to multifaceted and dynamic loading conditions, including variable axle loads, speed fluctuations, and environmental influences. These complex service conditions often give rise to multiple damage phenomena that compromise wheel integrity and safety. Common forms of damage observed in service include surface wear, rolling contact fatigue (RCF) cracks, spalling, shelling, and other fatigue-related defects.

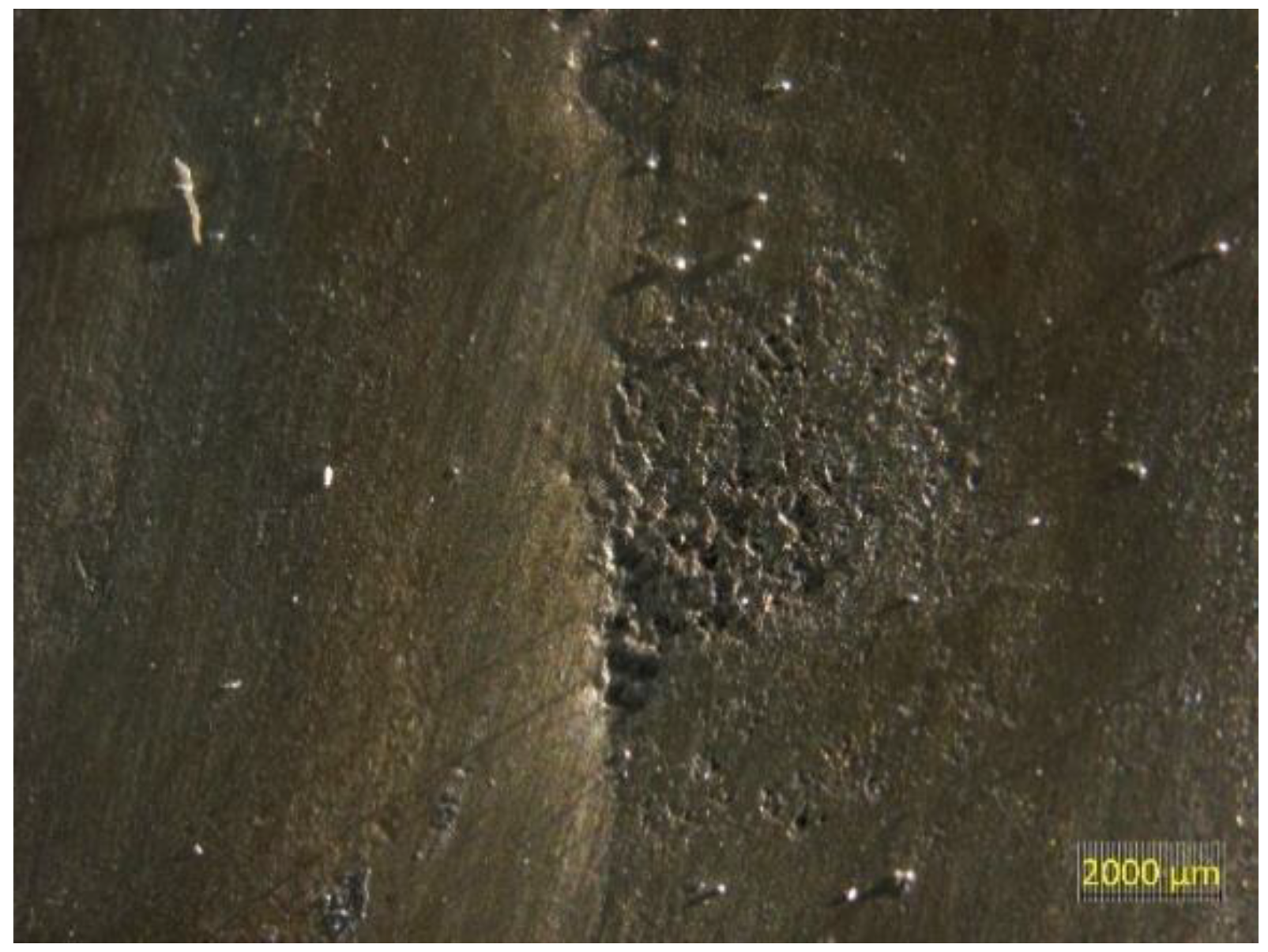

Figure 1 and

Figure 2 illustrate typical damage manifestations encountered on wheel running surfaces, highlighting the severity and diversity of wear and fatigue mechanisms.

Recent advances in materials science and engineering have focused on elucidating the microstructural changes that occur during the service life of railway wheels and on developing innovative materials and surface treatments to enhance fatigue resistance. These efforts include the design of alloy compositions tailored to resist crack initiation, heat treatments to refine microstructures, and surface engineering techniques such as laser cladding and plasma transferred arc (PTA) treatments to produce wear-resistant coatings. Through such approaches, it is possible to improve the durability and performance of railway wheels and rails, thereby reducing maintenance costs and enhancing safety. The collective body of research highlights the critical importance of a detailed understanding of the microstructural evolution and mechanical behaviour of wheel materials under cyclic loading conditions. This knowledge base supports the development of engineering solutions that effectively mitigate rolling contact fatigue, ensuring the long-term operational reliability of railway infrastructure [

22,

23,

24].

The continuous exposure to these harsh operational stresses necessitates ongoing research efforts targeted at improving the durability and longevity of railway wheels to ensure reliable and safe train operations. One promising avenue for extending the service life and performance of railway wheels lies in advanced surface engineering techniques that modify the chemical and microstructural properties of critical surface regions. Among these techniques, laser surface treatment has attracted significant attention due to its precision and ability to selectively modify localized areas without adversely affecting the bulk substrate material. Laser surface treatment methods, such as laser cladding, laser hardening, and laser alloying, enable the controlled alteration of surface chemistry and microstructure in key zones such as the wheel tread and flange, where contact stresses and wear rates are highest [

23].

The application of laser surface treatments can lead to substantial improvements in mechanical properties, including enhanced surface hardness, superior wear resistance, and increased fatigue life. These improvements arise from the formation of refined microstructures, such as fine martensitic phases, carbides, or intermetallic compounds, and from controlled residual stress profiles induced by the rapid heating and cooling cycles characteristic of laser processing. By creating tailored surface zones with superior metallurgical characteristics, laser treatments can effectively delay the initiation and propagation of surface cracks and reduce material loss due to wear. The strategic integration of laser surface treatments with conventional wheel manufacturing and maintenance processes represents a significant technological advancement in railway wheel production. Such integration offers the potential to extend wheel service intervals, reduce maintenance-related downtime, and lower operational costs, all while enhancing the safety and reliability of rail transportation systems. Moreover, the flexibility of laser surface modification techniques allows for on-site repair and refurbishment of wheels, further contributing to sustainable asset management and lifecycle optimization. Despite these promising developments, further experimental and analytical investigations are warranted to optimize laser treatment parameters, understand long-term performance under realistic service conditions, and evaluate the economic feasibility of large-scale implementation. Research efforts aimed at characterizing the microstructural changes, mechanical behaviour, and wear mechanisms of laser-treated wheels will provide critical insights necessary for the widespread adoption of these advanced surface engineering solutions in the railway industry. Carbon steel remains the backbone material for railway wheels, with standards such as PN-EN 13262:2021-2 ensuring consistent quality and performance. The emergence of laser surface treatment technologies offers a sophisticated approach to mitigate wear and fatigue damage, promising enhanced durability and operational efficiency. Continued research and development in this field will enable the railway sector to leverage these advancements, ultimately contributing to safer, more reliable, and cost-effective rail transport systems [

25,

26].

In contemporary materials engineering, alloying through the addition of various powders and metal wires has emerged as an effective strategy for enhancing the surface properties of structural components. This approach leverages the incorporation of carefully selected alloying elements into the base metal matrix to induce the formation of intermetallic phases, which are known to impart significant improvements in mechanical properties such as hardness, strength, and resistance to fatigue and wear. The fundamental premise underlying this methodology is that these alloying elements, when introduced via powders or wires during surface modification processes, interact metallurgically with the substrate material to form coherent or semi-coherent precipitates. These precipitates contribute to the strengthening of the surface layer by impeding dislocation motion and enhancing the overall microstructural stability under service conditions. The primary objective of the present research is to systematically investigate the microstructural evolution and resultant mechanical property enhancements induced by laser cladding combined with the addition of metal wire alloys. Laser cladding is an advanced surface engineering technique that facilitates the precise and controlled deposition of alloying materials—either in the form of powders or wire—onto a substrate to form a metallurgically bonded coating with tailored microstructural features. This process allows for the localized modification of surface chemistry and structure without compromising the integrity of the underlying bulk material, thereby offering a significant advantage over conventional surface treatments. In this study, the focus centers on characterizing the nature, distribution, and morphology of the phases formed within the laser-cladded layers. Particular attention is given to identifying the intermetallic compounds and precipitate phases that emerge as a consequence of alloying additions and laser processing parameters. These analyses provide insights into the nucleation and growth mechanisms of the precipitates and their spatial distribution within the matrix, which are critical factors influencing the mechanical behaviour of the treated surface. In parallel with microstructural characterization, the research evaluates the mechanical property enhancements afforded by the alloying additions. Hardness measurements, tensile testing, and fatigue resistance assessments are conducted to quantify the improvements in surface hardness, strength, and durability. These mechanical tests are designed to simulate service conditions and assess the performance of the cladded layers under operationally relevant stresses and cyclic loading scenarios. The correlation between microstructural features and mechanical performance is rigorously analysed to elucidate the mechanisms by which laser cladding with metal wire additions enhances surface properties. Laser cladding offers several technical advantages, including precise control over heat input, minimal dilution of the base material, and the ability to produce coatings with fine and uniform microstructures. By optimizing laser parameters such as power, scanning speed, and wire feed rate, as well as selecting appropriate alloy compositions, coatings with superior wear resistance, hardness, and fatigue life can be engineered. These attributes are particularly important for high-demand applications such as railway wheels, where surface durability directly impacts operational safety, maintenance intervals, and cost-effectiveness. The findings of this research contribute to the broader understanding of surface engineering through laser cladding and underscore the potential of metal wire alloy additions as a versatile tool for tailoring surface properties. This knowledge facilitates the development of advanced coatings that meet the stringent requirements of demanding industrial applications, ultimately leading to enhanced component lifespan and improved reliability. The insights gained from this study also pave the way for future innovations in surface treatment technologies aimed at addressing the challenges posed by wear and fatigue in critical mechanical components such as railway wheels [

27].

2. Experimental procedure

In accordance with the research methodology and the need for comparative analysis, it is essential to conduct tests on the materials currently employed in the manufacture of railway wheels. Consequently, the initial set of samples have selected for testing consisted of steel obtained from a railway wheel fabricated from ER7 grade steel. The detailed chemical composition of this steel is provided in

Table 1 for reference. A careful examination of the data presented in

Table 1 reveals that the carbon content in the ER7 steel does not exceed 0.60%, thereby classifying it as a medium-carbon steel. This carbon concentration is critical as it directly influences the mechanical properties of the steel, including hardness, tensile strength, and toughness, which are pivotal for the wheel’s performance under operational stresses. Medium-carbon steels, such as ER7, represent a balanced compromise between strength and ductility, making them suitable for demanding applications like railway wheels where resistance to rolling contact fatigue and wear is essential. The characterization of this baseline material serves as a fundamental reference point for evaluating the effects of subsequent surface modification treatments, such as laser cladding with alloying additions. By understanding the intrinsic properties and composition of the ER7 steel, the study can more accurately assess the extent of microstructural and mechanical enhancements achieved through advanced processing techniques.

For the conducted investigations, the following testing conditions are systematically applied to evaluate the material behaviour and performance under various operational scenarios:

Load levels of 450 MPa, 650 MPa, and 850 MPa

Rotational velocities of 100 min−1, 200 min−1, and 300 min−1

Hardness values of 60 HRC, 70 HRC, and 80 HRC.

These parameters are selected to simulate a broad range of service conditions representative of those experienced by railway wheels in actual operation. The experimental design is structured to include 11 distinct measurement points, with data collected for each combination of the above parameters to ensure statistically significant and comprehensive analysis. Based on the experimental results, a mathematical model was developed to describe the relationship between the tested variables and the observed responses. This model takes the form of a second-degree polynomial equation, which captures the nonlinear interactions between load, velocity, and hardness. The general form of the polynomial equation is expressed as follows:

where:

z—represents the dependent variable (e.g., wear rate, fatigue life, or another relevant response),

x1, x2, x3—correspond to the independent variables (load, velocity, and hardness, respectively)

k0, k1, k2…- are the regression coefficients determined through the fitting of the experimental data.

This polynomial model enables the prediction of material performance under varying conditions and facilitates the identification of optimal parameter combinations to enhance the durability and reliability of railway wheels. To validate the accuracy and reliability of the derived polynomial equation in representing the experimental data, the Fisher’s F-test was employed. This statistical test was used to assess the significance of the regression model by comparing the variance explained by the model against the unexplained variance (residual error). A favorable outcome of the Fisher test confirms that the equation provides a statistically significant fit to the experimental results, thereby supporting its applicability for predicting material behavior under the tested conditions.

3. Results and Discussion

The Plasma Transferred Arc (PTA) method was employed for surface alloying, utilizing metal wires in combination with metallic powders to produce wear-resistant layers on the substrate material. The microstructural characteristics of the treated surface layers are illustrated in

Figure 4 and

Figure 5. A distinct difference is observed between the surfaces alloyed using the NiBSiWC/36C composite treatment and those treated solely by the PTA process. The surface treated by the PTA method alone exhibits a more uniform and regular morphology, characterized by the absence of visible surface defects or damage. In contrast, the NiBSiWC and 36C alloyed surfaces display noticeable imperfections, including bubble formations and irregularities on the remelted layer. These surface discontinuities may be attributed to the complex interactions during the alloying process, such as gas entrapment, rapid solidification, or differences in thermal expansion between the base material and the alloying constituents. The observed differences highlight the influence of alloying composition and processing parameters on the quality and integrity of the surface layers produced by PTA. Understanding these microstructural variations is critical for optimizing the PTA alloying process to enhance the wear resistance and overall performance of treated components.

Structural investigations at both the macro- and microstructural levels enable a comprehensive analysis of the surface layers, including the characterization of the shape and depth of the remelted zones. The alloyed layers produced through the surface modification process are illustrated in

Figure 3 and

Figure 4. From these observations, it is evident that the type of alloying material employed has a significant impact on the remelting depth as well as the surface roughness of the treated area. Variations in chemical composition, melting point, and thermal conductivity of the different alloying materials influence the heat transfer dynamics during the remelting process, thereby affecting the extent of the molten pool and the resulting surface morphology. Consequently, the choice of alloying materials plays a critical role in controlling the microstructural features and surface quality of the remelted layers, which are key factors in determining the wear resistance and mechanical performance of the treated components. These findings underscore the importance of carefully selecting alloying materials and optimizing processing parameters to achieve desired surface characteristics.

Figure 3.

Surface layer of the 61 PTA treated material.

Figure 3.

Surface layer of the 61 PTA treated material.

Figure 4.

Surface layer of the 36C treated material.

Figure 4.

Surface layer of the 36C treated material.

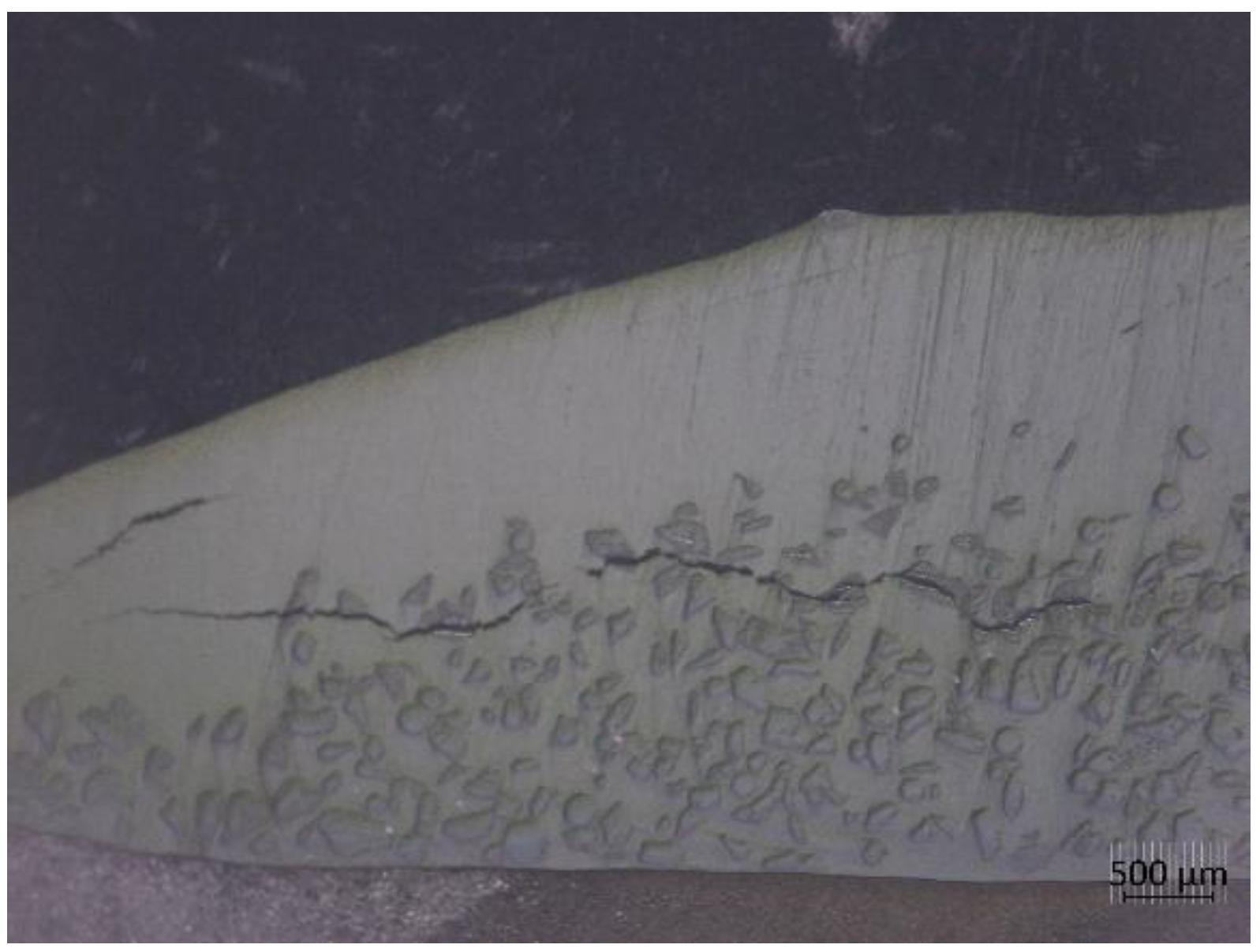

A distinctive zone-like structure was observed in the cross-section of the treated surfaces, characterized by the presence of a remelting zone comprising the molten fed wire material, an intermediate transition zone, and the underlying substrate material. In certain cases, a heat-affected zone (HAZ) was also identified, particularly in samples treated with the 15 E alloy, where a noticeable grain growth was observed due to thermal exposure during processing. The measured thicknesses of the surface layers varied depending on the alloying material used, with the following values recorded: 15 E—approximately 2500 µm, 61 PTA—1500 µm, 36 C—4000 µm, and 505 PTA—3000 µm. It is important to emphasize that only the 15 E and 36 C materials produced surface layers with relatively uniform thickness and consistent quality, exhibiting an absence of cracks, porosity, or unevenness, as documented in

Figure 5 and

Figure 6. These findings highlight that both the choice of alloying material and the processing parameters critically influence not only the microstructural characteristics but also the integrity and homogeneity of the remelted layers. The uniformity and defect-free nature of the layers obtained with 15 E and 36 C alloys suggest their greater suitability for applications requiring enhanced wear resistance and structural reliability.

Figure 5.

Cross-section of the ssurface layer after feeding of the 36 C material.

Figure 5.

Cross-section of the ssurface layer after feeding of the 36 C material.

Figure 6.

Cross-section of the ssurface layer after feeding of the 61 PTA material.

Figure 6.

Cross-section of the ssurface layer after feeding of the 61 PTA material.

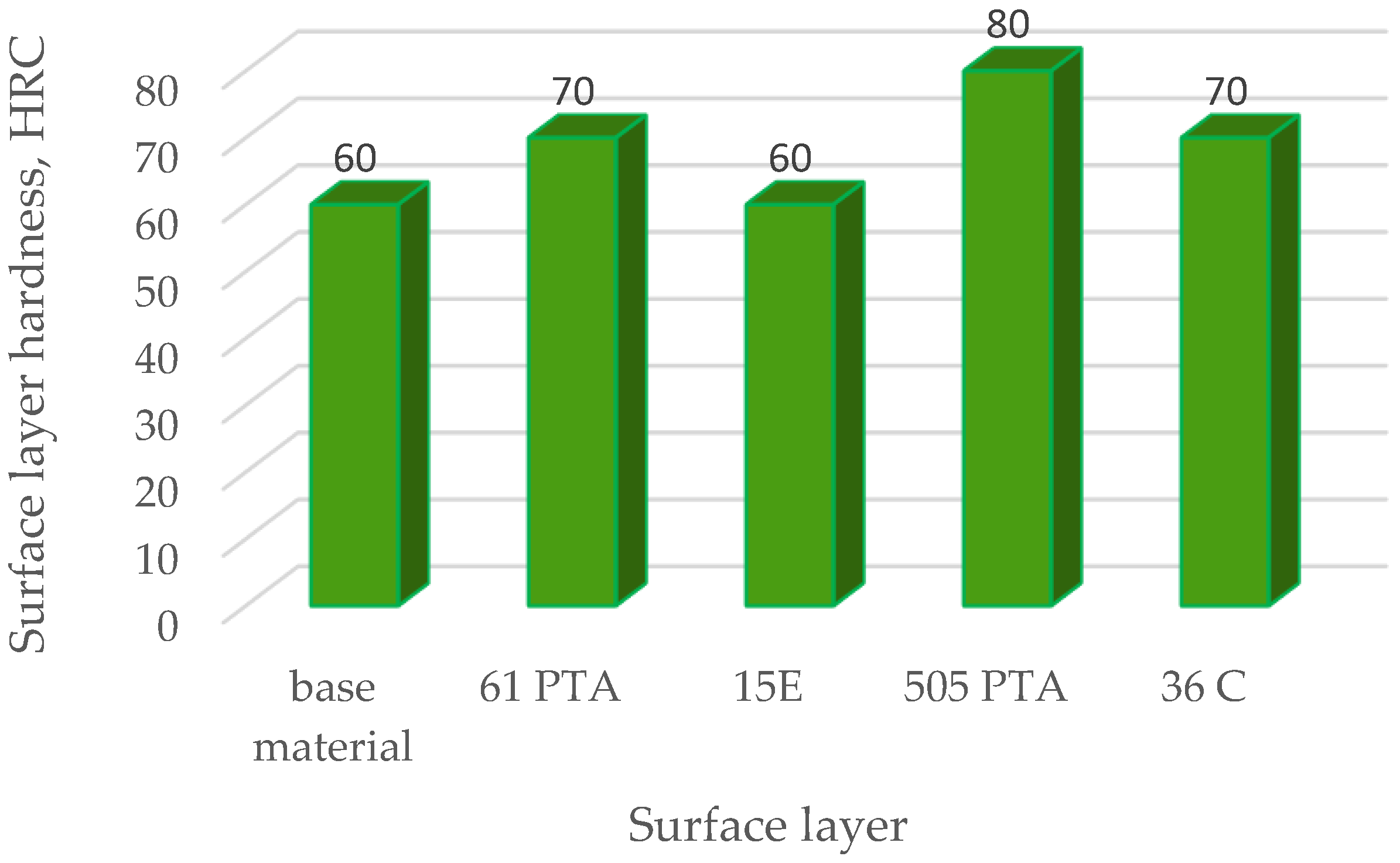

Figure 7 presents the measured hardness values of the surface layers obtained through the alloying process.

Figure 7.

Surface hardness of the treated steel surface layer, HRC.

Figure 7.

Surface hardness of the treated steel surface layer, HRC.

It is evident from the data that the hardness of the remelted zones is significantly higher than that of the base (parental) material, which exhibits a hardness of approximately 60 HRC. Among the tested materials, the highest hardness value was recorded for the 505 PTA treated layer. However, it is important to note that such elevated hardness levels, as observed in the 505 PTA layer, are generally not recommended for the repair of railway wheels. This is primarily because the hardness of the wheel surface should not exceed that of the corresponding rails. Excessive hardness in the wheel can lead to accelerated wear of the rail, resulting in increased maintenance costs and potential operational inefficiencies. Therefore, while higher hardness may improve wear resistance of the wheel, it must be carefully balanced against the wear behaviour of the rail to optimize overall system performance and cost- effectiveness.

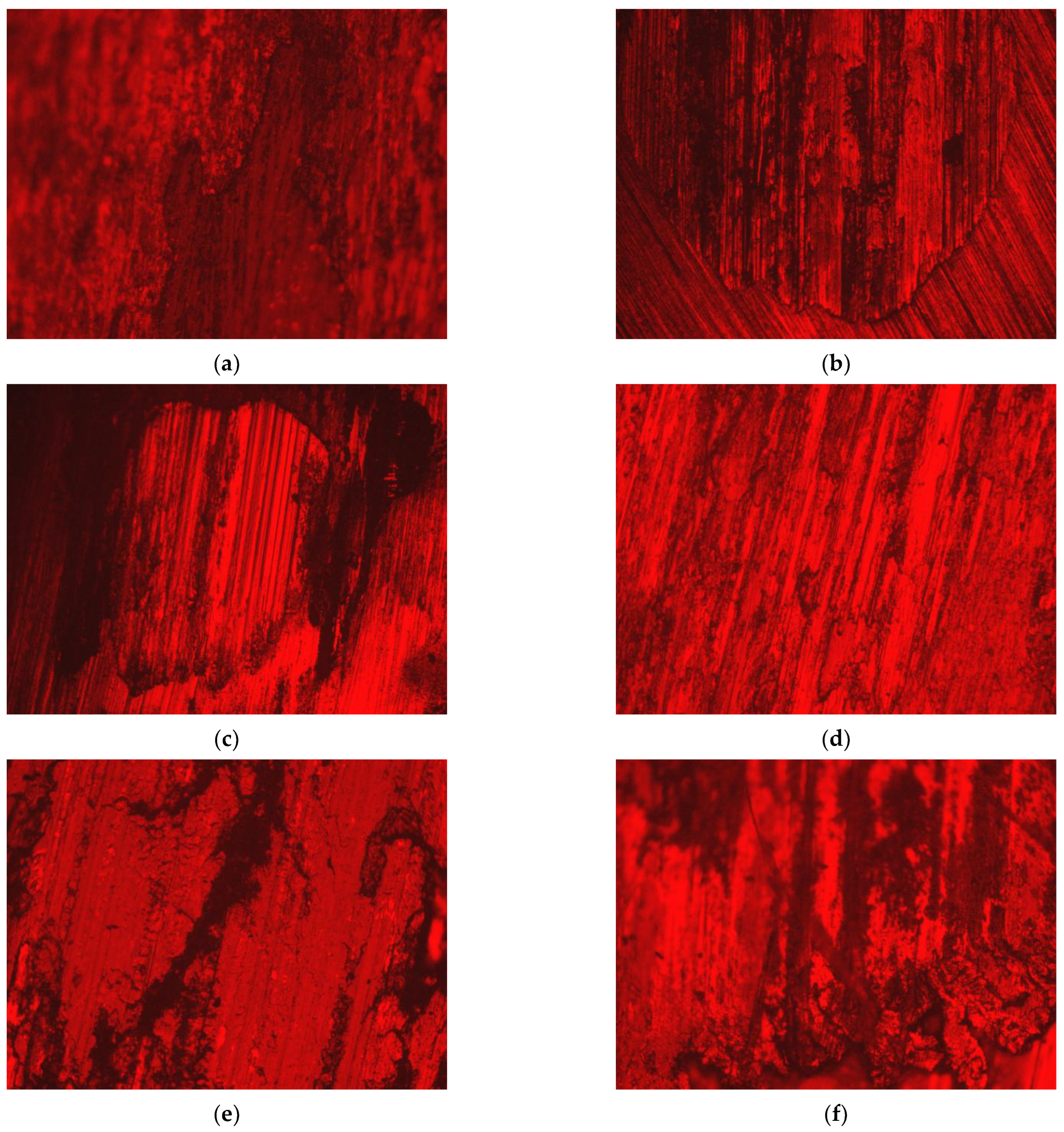

Figure 8 presents micrographs of the abrasion surfaces resulting from the resistance-to-abrasive-wear tests conducted on the samples.

These micrographs provide detailed visual evidence of the damage mechanisms induced by the applied forces during testing. By analyzing the images, the extent and nature of surface degradation can be assessed under varying test conditions, including differences in applied load, test duration, and the pressure exerted on the sample surface. The micrographs reveal distinct patterns of wear damage across the different samples. Observations include the characterization of abrasion morphology, such as the presence of parallel grooves and scratches formed as a result of the abrasive action, as well as cases where the entire surface layer was substantially worn away. Furthermore, the images enable evaluation of the retention and distribution of hard carbide particles embedded within the overlay material, which play a critical role in enhancing wear resistance. These insights are essential for understanding the comparative performance of different coatings and the effectiveness of alloying treatments in improving the durability of the surface layers under abrasive conditions.

4. Conclusions

In summary, the investigation demonstrated that the carbon steel substrate subjected to alloying via Plasma Transferred Arc (PTA) cladding with DURMAT 505 PTA, BD-3.61 PTA, and NiBSiWC wires successfully produced high-quality surface layers. These layers were characterized by a generally defect-free microstructure, exhibiting an absence of cracks and other common surface imperfections. Moreover, the treated layers showed a significant enhancement in hardness relative to the untreated base material, which is a critical factor in improving wear resistance and extending the service life of components

(i) Among the materials tested, the 61 PTA alloy was found to be unsuitable for practical application in the context of railway wheel refurbishment or enhancement. This unsuitability is primarily due to the high risk of defects observed in the alloyed layers, such as porosity and cracking, which compromise structural integrity. Additionally, the processing of 61 PTA proved to be technically challenging, further limiting its feasibility for industrial application.

(ii) The native, untreated carbon steel exhibited the greatest variability in friction coefficients across the range of testing conditions. This variability suggests that the wear rate of the untreated material is highly sensitive to operational parameters such as load, speed, and contact conditions. Notably, under low-speed but high-load conditions, the untreated steel demonstrated a comparatively lower wear rate than the coated materials. Conversely, at elevated rotational speeds, the untreated material experienced dramatically increased wear, with rates approaching nearly eight times that of the alloyed coatings. This finding underscores the critical advantage of applying surface treatments to enhance performance under demanding high-speed operating conditions.

(iii) Although the 61 PTA and 505 PTA alloys may not be optimal for improving the mechanical properties of railway wheels themselves, these materials possess potential utility within the broader railway industry for the refurbishment and regeneration of other critical components. Specifically, their application could be highly beneficial for the restoration of friction plates on axle boxes and various hydraulic system elements. This application is particularly relevant for older locomotives originating from the 1960s and 1970s, especially those from Eastern Bloc countries, where the availability of replacement parts is steadily diminishing. In this context, PTA-applied coatings offer a viable solution for regenerating components such as pump impellers and slide bearing elements within drive systems, thereby extending the operational lifespan of aging rolling stock.

Author Contributions

Conceptualization, methodology, resources, project administration, writing—review and editing, supervision: K.L., J.K., P.W., H.A., methodology, formal analysis, validation, writing—review and editing, K.L., J.K., P.W., H.A., formal analysis, data curation, writing—review and editing, A.W.F, M.P.R., methodology, data curation, software, writing—original draft preparation, visualization, K.L., J.K., P.W., H.A., A.W.F, M.P.R. All authors have read and agreed to the published version of the manuscript.”.

Funding

This research received no external funding.

Data Availability Statement

We encourage all authors of articles published in MDPI journals to share their research data. In this section, please provide details regarding where data supporting reported results can be found, including links to publicly archived datasets analyzed or generated during the study. Where no new data were created, or where data is unavailable due to privacy or ethical restrictions, a statement is still required. Suggested Data Availability Statements are available in section “MDPI Research Data Policies” at

https://www.mdpi.com/ethics.

Acknowledgments

In this section, you can acknowledge any support given which is not covered by the author contribution or funding sections. This may include administrative and technical support, or donations in kind (e.g., materials used for experiments). Where GenAI has been used for purposes such as generating text, data, or graphics, or for study design, data collection, analysis, or interpretation of data, please add “During the preparation of this manuscript/study, the author(s) used [tool name, version information] for the purposes of [description of use]. The authors have reviewed and edited the output and take full responsibility for the content of this publication.”.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Vaičiūnas, G.; Bureika, G.; Steišūnas, S. Measurement Repeatability of Rail Wheel Loads Caused by Rolling Surface Damages. Appl. Sci. 2023, 13, 4474. [Google Scholar] [CrossRef]

- Ekberg, A.; Kabo, E. Fatigue of railway wheels and rails under rolling contact. Wear 2005, 258, 1288–1300. [Google Scholar] [CrossRef]

-

Modern Tribology Handbook; Bhushan, B., Ed.; CRC Press: Boca Raton, USA, 2001; Volume II, pp. 1271–1326. [Google Scholar]

- Mazzù, A.; Solazzi, L.; Lancini, M.; Petrogalli, C.; Ghidini, A.; Faccoli, M. An experimental procedure for surface damage assessment in railway wheel and rail steels. Wear 2015, 342-343, 22–32. [Google Scholar] [CrossRef]

- Askerov, H.; Vakulenko, I. O.; Grischenko, N. Insights into factors of damage of surface rolling of railway wheels during operation. Sci. J. Sil. Univ. Technol., Series Transp. 2019, 105(105), 27–33. [Google Scholar] [CrossRef]

- Melo, R.; Finotti, R.; Guedes, A.; Gonçalves, V.; Meixedo, A.; Ribeiro, D.; Barbosa, F.; Cury, A. Out-of-Roundness Wheel Damage Identification in Railway Vehicles Using AutoEncoder Models. Appl. Sci. 2025, 15, 2662. [Google Scholar] [CrossRef]

- Knott, J.F. Fundamentals of fracture mechanics; Butterworths, UK: London, 1973. [Google Scholar]

- Koymatcik, H.; Tozlu, T.; Cug, H.; Sun, Y.; Ahlatci, H. Hardening of the head portions of the pearlitic rails by accelerated cooling. JESTECH 2013, 16(2), 53–58. [Google Scholar]

- Mykola, S.; Gerber, U.; Gruen, D.; Nabochenko, O.; Kovalchuk, V. Modelling and vehicle based measurements of ballast settlements under the common crossing. European Transport \ Trasporti Europei 2019, 71(5). [Google Scholar]

- Vasauskas, V.; Bazaras, Ž.; Čapas, V. Strength anisotropy of railway wheels under contact load. Mechanics 2005, 1(51), 31–38. [Google Scholar]

- Li, D.; Wang, H.; Shen, X.; Lin, S.; Feng, H.; Peng, Y.; Jiang, F.; Zhou, X. Quantitative Distribution Characterization and Correlation Study of Composition, Structure and Hardness of Rim Region in Railway Wheel. Materials 2022, 15, 4762. [Google Scholar] [CrossRef]

- Walther, F.; Eifler, D. Fatigue behaviour of railway wheels at different temperatures. Mater. Test. 2004, 46, 158–162. [Google Scholar] [CrossRef]

- Gubenko, S.; Proidak, Y. Investigation of wear mechanism of tread during operation of railway wheels. Transport problems 2012, 7, 111–125. [Google Scholar]

- Maglio, M.; Vernersson, T.; Nielsen, J. C. O.; Ekberg, A.; Kabo, E. Influence of railway wheel tread damage on wheel–rail impact loads and the durability of wheelsets. Railw. Eng. Sci. 2024, 32, pp 20–35. [Google Scholar] [CrossRef]

- Asplund, M. Test run with wheel tread damage over a wheel damage detector, Technical report; in Swedish; Trafikverket: Luleå, Sweden, 2018; p. pp. 18. [Google Scholar]

- Nielsen, JCO; Pieringer, A; Thompson, D; Torstensson, P. Wheel–rail impact loads, noise and vibration: a review of excitation mechanisms, prediction methods and mitigation measures. In Proceedings of the 13th international workshop on railway noise Notes on numerical fluid mechanics and multidisciplinary design Noise and vibration mitigation for rail transportation systems; Ghent, Belgium, Degrande, G, et al., Eds.; Springer 2021, 16-23 September 2019; pp. pp 3–40. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, Y. Experimental Study on Damage of the Rail/wheel Sliding Contact Surface in Heavy-haul. J. Phys. Conf. Ser. 2022, 2381, 012085. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, J.; Zuo, J. Development of a Non-Uniform Heat Source Model for Accurate Prediction of Wheel Tread Temperature on Long Downhill Ramps. Lubricants 2025, 13(6), 235. [Google Scholar] [CrossRef]

- Lisowski, F.; Lisowski, E. Optimization of ER8 and 42CrMo4 Steel Rail Wheel for Road–Rail Vehicles. Appl. Sci. 2020, 10, 4717. [Google Scholar] [CrossRef]

- Ren, J.; Qie, Y.; Xie, H.; Yin, F.; Cui, X. Fatigue analysis of 75 kg/m12 heavy-haul railway frog based on finite element simulation. Eng. Fail. Anal. 2020, 117, 1–16. [Google Scholar] [CrossRef]

- Lisowski, E.; Lisowski, F. Numerical Analysis of Stresses in ER8 Steel Railway Wheel under Service Conditions. Appl. Sci. 2021, 11, 4021. [Google Scholar] [CrossRef]

- Kennedy, E.; Byrne, G.; Collins, D. N. Review of the use of high power diode lasers in surface hardening. J. Mater. Process. Technol. 2004, 155(1), 1855–1860. [Google Scholar] [CrossRef]

- Appiah, A.N.S.; Bialas, O.; Czupryński, A.; Adamiak, M. Powder Plasma Transferred Arc Welding of Ni-Si-B+60 wt%WC and Ni-Cr-Si-B+45 wt%WC for Surface Cladding of Structural Steel. Materials 2022, 15, 4956. [Google Scholar] [CrossRef] [PubMed]

- Gwozdzik, M.; Kulesza, S.; Bramowicz, M.; Bałaga, Z. Surface Morphology Analysis of Martensitic Stainless Steel after Different Treatments. Acta Phys. Pol., A 2019, 135(2), 157–161. [Google Scholar] [CrossRef]

-

PN-EN 13262: 2021-2; Railway applications—Wheelsets and bogies—Wheels—Product requirements.

-

PN-EN 13262:2020; Railway monoblock wheels.

- Fasihi, P.; Kendall, O.; Abrahams, R.; Mutton, P.; Qiu, C.; Schläfer, T.; Yan, W. Tribological Properties of Laser Cladded Alloys for Repair of Rail Components. Materials 2022, 15, 7466. [Google Scholar] [CrossRef] [PubMed]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).