1. Introduction

The development of reliable metal-ceramic joints for vacuum, electronic, and power engineering applications represents a critical challenge in materials science [

1]. These joints, which combine the high strength, corrosion resistance, and wear resistance of ceramics with the ductility and toughness of metals [

2], serve as essential components in hermetic enclosures, insulators, and thermally stressed electronics. The established industrial standard, the multi-step molybdenum-manganese (Mo-Mn) process, requires preliminary ceramic metallization [

3,

4]. Its labor-intensive nature, however, has driven the search for alternatives, among which active metal brazing is considered the most promising. This single-step process employs brazing alloys doped with active elements (Ti, Zr) that promote ceramic wetting via redox reactions at the interface [

5,

6].

Brazing alloys based on the Ag-Cu-Ti and Ag-Cu-Zr systems are the most widely used for this purpose. Foundational research in this area [

7] demonstrated that both Ti and Zr, when added to the Ag-Cu eutectic, actively react with oxide and nitride ceramics to form interfacial reaction layers, with titanium-containing alloys generally exhibiting better wettability. For the Ag-Cu-Ti system, the primary reaction products with Al

2O

3 have been identified as titanium intermetallics and oxides, such as Ti

3Cu

3O, Ti2O, and Ti

2Cu [

8,

9]. In zirconium-containing alloys, studies [

10,

11] show that a ZrO

2 layer forms at the ceramic interface, while intermetallic phases like Cu

4AgZr precipitate within the filler metal bulk. Subsequent work [

12,

13,

14,

15,

16] has focused on modifying Ag-Cu-Zr alloy compositions (e.g., with Sn, Al, Ti additions) to enhance joint microstructure and strength, and on investigating the kinetics of zirconium segregation to the ceramic surface [

17,

18].

Despite this substantial body of knowledge, systematic studies focusing specifically on rapidly quenched ribbon brazing alloys from the Ag-Cu-Ti and Ag-Cu-Zr systems are scarce. Meanwhile, the benefits of rapid solidification—such as forming metastable structures with high homogeneity and fine phase dispersion-have been proven for other systems like nickel-based brazes, where they suppress brittle intermetallic formation and improve joint strength [

19,

20]. The melt-spinning technique can produce such refined microstructures, which may enhance filler metal properties like wettability and, ultimately, joint performance. Notably, the thermal shock resistance of joints made with rapidly quenched brazing alloys remains poorly characterized. Defined as the ability to maintain hermeticity and mechanical strength under cyclic thermal loading, thermal shock resistance is a critical parameter for many applications [

21,

22,

23,

24]. While data exist for joints made via traditional metallization routes [

4], information for active-brazed joints, particularly those using rapidly quenched filler metals, is fragmentary.

Therefore, the aim of this work is to produce and conduct a comprehensive investigation of rapidly quenched ribbon brazing alloys with the following compositions (wt.%): Ag-26.5Cu-1.5Ti, Ag-25Cu-5Ti, Ag-26.5Cu-1.5Zr, and Ag-25Cu-5Zr. The specific objectives were to: synthesize homogeneous master ingots; produce rapidly quenched ribbons and characterize their structure and phase composition using X-ray diffraction (XRD) and electron microscopy; determine the solidus and liquidus temperatures of both ingots and ribbons via differential scanning calorimetry (DSC); perform a comparative analysis of material microhardness; and evaluate the wetting behavior of the rapidly quenched ribbons on 99% Al2O3 (alumina) ceramic substrate.

The results of this study establish a foundation for subsequent research, which will primarily focus on evaluating how the composition and microstructure of these developed rapidly quenched brazing alloys influence the thermal shock resistance and mechanical strength of brazed joints under thermal cycling conditions.

2. Materials and Methods

The compositions of the brazing alloys substrate materials considered in the work are presented in

Table 1.

Master ingots (

Table 1) were produced by induction melting in a «Crystall-702» unit. The charge materials consisted of copper, titanium, zirconium, and 999.9-purity silver. Rapidly quenched brazing alloy ribbons, approximately 50-100 µm thick, were subsequently fabricated from these ingots using the flat jet casting technique on the same «Crystall-702» facility. The estimated cooling rate during this process was 10⁵–10⁶ K/s.

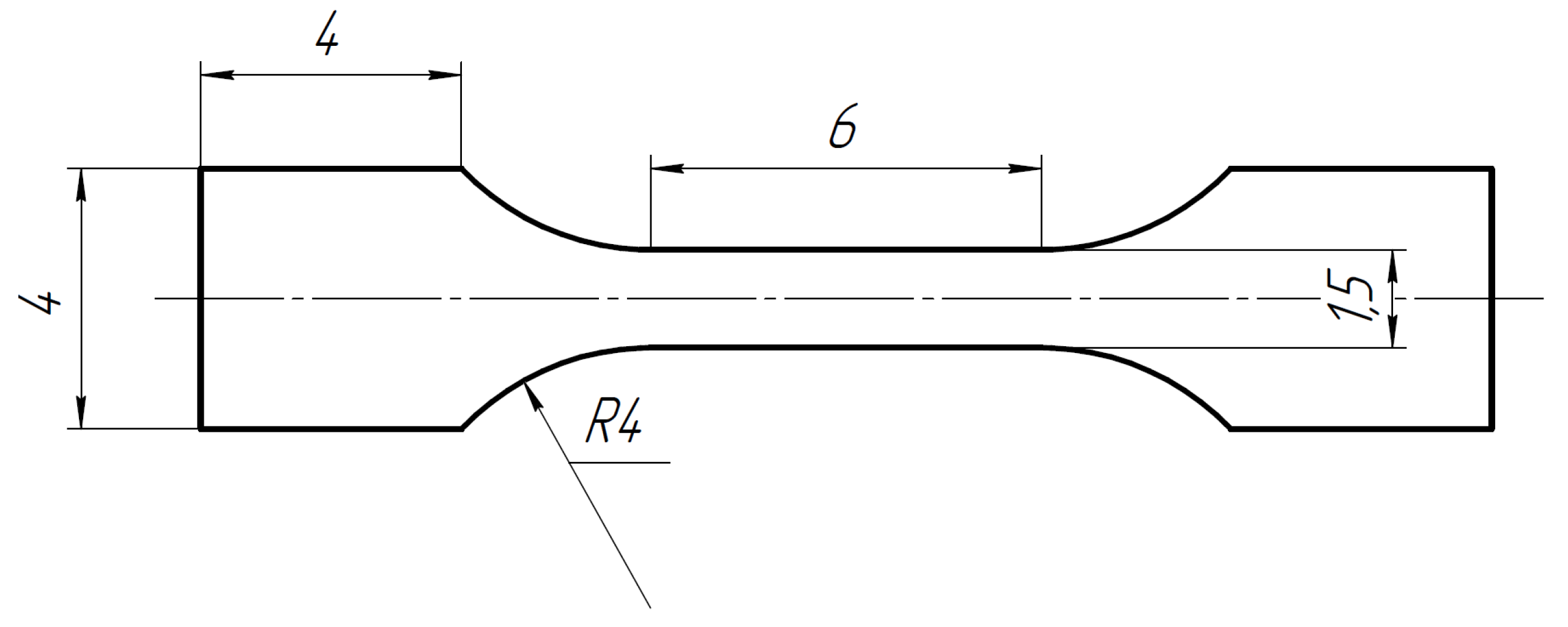

The mechanical properties of the ingots were characterized by tensile strength and microhardness measurements. Tensile specimens of the required geometry (

Figure 1) were cut from homogenized ingots using wire electrical discharge machining (EDM). Uniaxial tensile tests were performed on a UTS-111.2-50 universal testing machine (Test Systems, Ivanovo) at a crosshead speed of 1 mm/min, using self-aligning grips to minimize bending moments.

The Vickers microhardness of the ingots was measured in both the as-cast and homogenized states (

Table 1) using a FM-810 microhardness tester.

To analyze the microstructure and composition of the brazed joints, cross-sectional specimens were prepared by mounting in polymer resin, followed by grinding and polishing on a semi-automated LaboPol-5 machine (Struers) using water-based diamond suspensions and appropriate polishing cloths. The prepared cross-sections were examined using a Carl Zeiss EVO 50 scanning electron microscope (SEM). Microstructural analysis was performed in backscattered electron (BSE) mode with a 4Q-BSD detector. Local composition was determined by energy-dispersive X-ray spectroscopy (EDX) using an INCA X–Act detector at a beam accelerating voltage of 5 kV. The bulk phase composition of the ingots was analyzed via X-ray diffraction (XRD) on a DX-27mini diffractometer.

The thermal characteristics of the produced ribbons were determined using a NETZSCH STA 409 thermal analyzer. Samples were subjected to two consecutive heating cycles to 1100 °C.

Wetting studies were performed on substrates of 99% Al2O3 ceramic (

Table 1). Following GOST 23904-79, brazing alloy samples with a volume of ~64 mm3 (approximately 0.2 g) were prepared by cutting and spot-welding segments of the ribbon. These preforms were placed on the substrates and heated in the vacuum chamber of an EP–IRIS electric furnace designed for wetting experiments. Tests were conducted under a vacuum better than 1×10-3 Pa, with a heating rate of 5 °C/min to a peak temperature of 1000 ℃. The spreading process was monitored in situ, and images of the molten alloy on the Al2O3 ceramic were captured with a digital camera. Final wetting angles were measured from these images using KOMPAS–3D software.

The manuscript was proofread and formatted with the assistance of DeepSeek artificial intelligence.

3. Results and Discussion

3.1. Subsection Characteristics of the Obtained Ingots

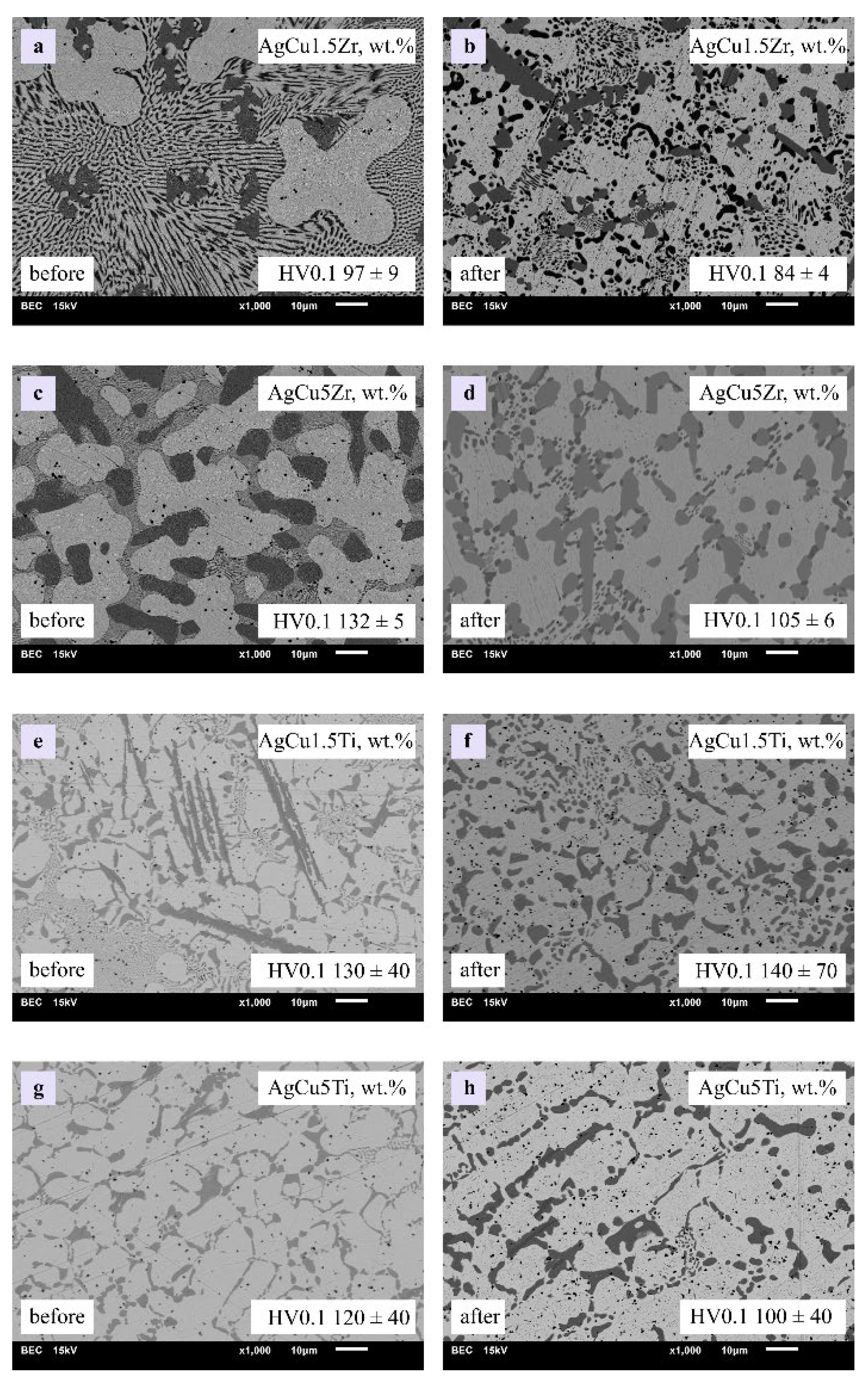

The microstructure of ingot cross-sections before and after annealing is shown in

Figure 2, with corresponding microhardness values provided in the images. The increase in hardness observed for the AgCu1.5Ti ingot after annealing is attributed to a finer and denser distribution of intermetallic compounds.

In the as-cast state after solidification in an induction furnace, the investigated Ag-Cu-based alloys exhibit a pronounced dendritic structure. This structure consists of light dendrites of a silver-based solid solution and interdendritic regions of a (Ag+Cu) eutectic. The key distinction between the alloys lies in the morphology of the formed intermetallic compounds. In zirconium-doped alloys, these intermetallics are finely dispersed as isolated particles. In contrast, in titanium-doped alloys, they precipitate as a continuous, brittle network along the dendritic boundaries.

Upon annealing, significant microstructural evolution occurs toward a more equilibrium state. This process involves homogenization, which reduces chemical segregation from the dendritic solidification, and spheroidization of the eutectic constituent. In Zr-containing alloys, the dispersed intermetallic particles coarsen but maintain their overall dispersed distribution. Conversely, in Ti-containing alloys, the most critical transformation is the fragmentation and spheroidization of the continuous intermetallic network. This breakdown of the brittle skeleton is crucial, as it enhances ductility and toughness by eliminating easy paths for crack propagation. Thus, annealing transforms the non-equilibrium as-cast structure into a more homogeneous one. This involves the coarsening of dispersed phases in Zr-alloys and the beneficial disruption of the brittle network in Ti-alloys, leading to an anticipated improvement in mechanical properties.

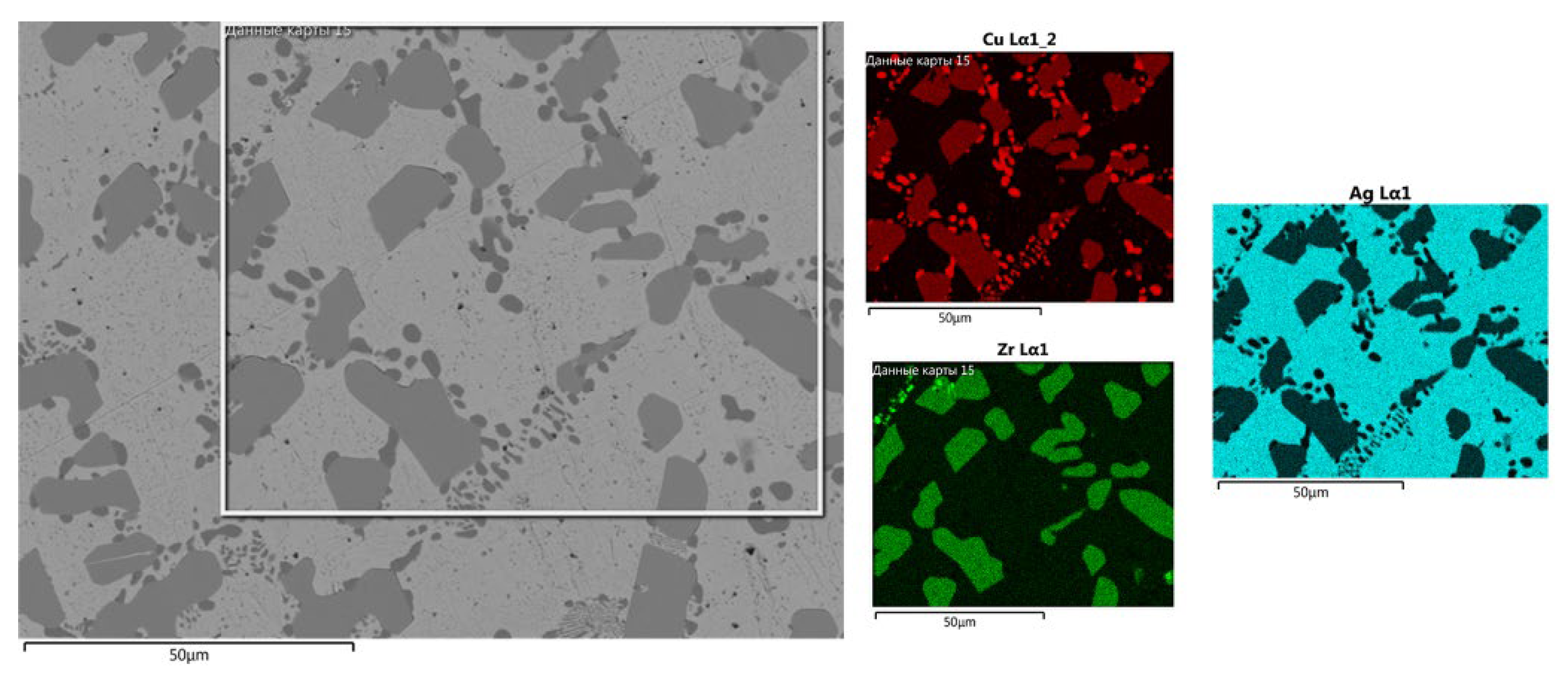

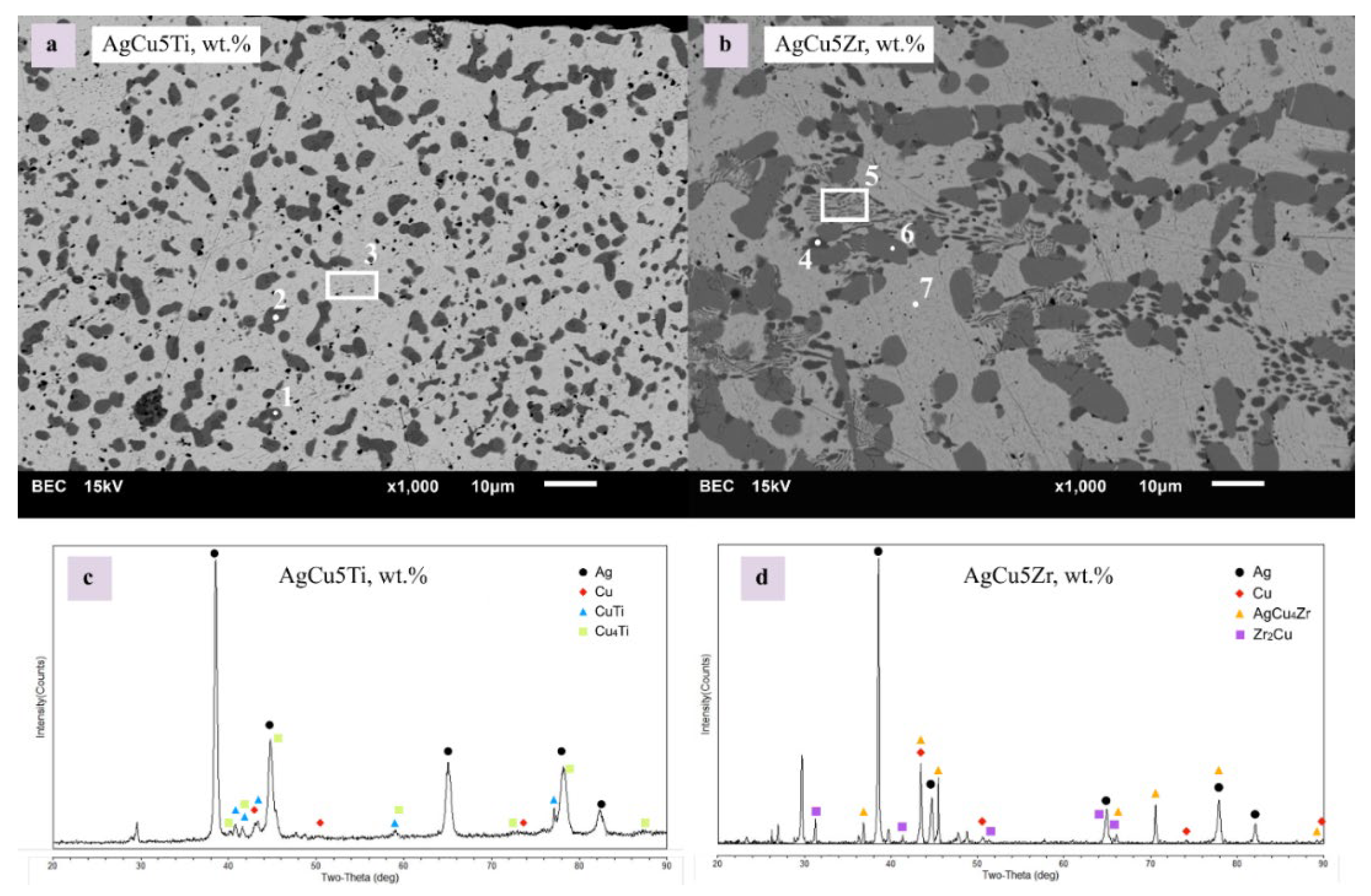

The phase composition of the obtained ingots was studied using EDX and confirmed by XRD analysis. The investigation focused on ingots with the highest percentage of the active element. The analysis confirmed the multiphase nature of the ingot structure. Micrographs of the brazing alloy structures containing 5% of the active element are presented in

Figure 3.

The structure of the ingots can be seen to consist of several discrete phases. In the case of the zirconium-containing ingot (

Figure 3), a silver matrix is evident, within which large structures composed of zirconium and copper are located, with copper accumulations present at their boundaries.

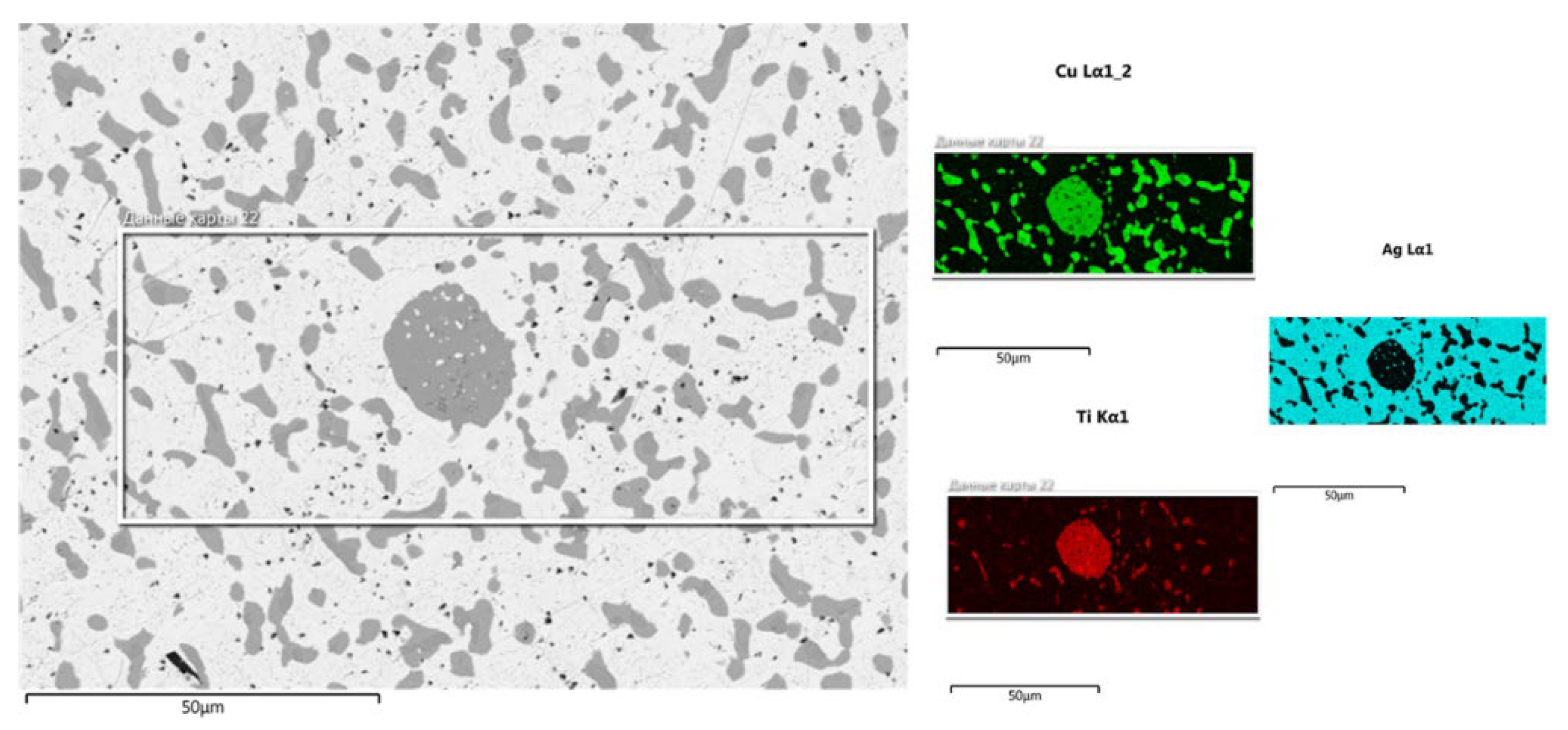

The structure of the AgCu5Ti ingot (

Figure 4) is also represented by a silver matrix, in which copper phases and copper-titanium intermetallic phases are uniformly distributed. These phases will be examined in more detail in the following section.

The phase composition was examined in greater detail using EDX (

Table 2) and XRD (

Figure 5c,d) analyses.

EDX analysis of the AgCu5Ti ingot (

Figure 5a), results of which are presented in

Table 2, indicates the presence of a silver-based solid solution (Region 3) and Ti-Cu intermetallic compounds (Regions 1 and 2). According to the X-ray diffraction (XRD) analysis (

Figure 5c), these phases are the intermetallics CuTi and Cu4Ti.

The AgCu5Zr ingot exhibits a more complex structure, shown in

Figure 5b. It consists of a silver-based solid solution (Region 7), a copper-based solid solution (Region 4), a distinct eutectic mixture (Region 5), and zirconium-rich intermetallic compounds (Region 6) of the types AgCu

4Zr and Zr

2Cu, as indicated by the XRD spectrum (

Figure 5d). Although the phase diagram suggests the possible presence of an AgZr compound in the ingot composition, this was not confirmed by the XRD analysis.

The mechanical properties of the ingots were also investigated via tensile testing. A total of five specimens of each type were prepared for testing. The test results are presented in

Figure 6.

The figure reveals markedly different behavior between the titanium-doped and zirconium-doped alloys with increasing alloying element content. As the zirconium content increases from 1.5 wt.% to 5 wt.%, a significant deterioration in plasticity is observed. The yield strength decreases from 299 MPa to 220 MPa, the ultimate tensile strength from 331 MPa to 258 MPa, and the plasticity (elongation) drops by more than a factor of three. This sharp decline in plastic properties is likely due to the substantial influence of brittle intermetallic compounds on the overall alloy characteristics.

Conversely, increasing the titanium content from 1.5 wt.% to 5 wt.% results in a marginal improvement in plastic properties. This may be attributed to a more homogeneous and equilibrium microstructure formed under these conditions.

3.2. Characteristics of the Ribbons

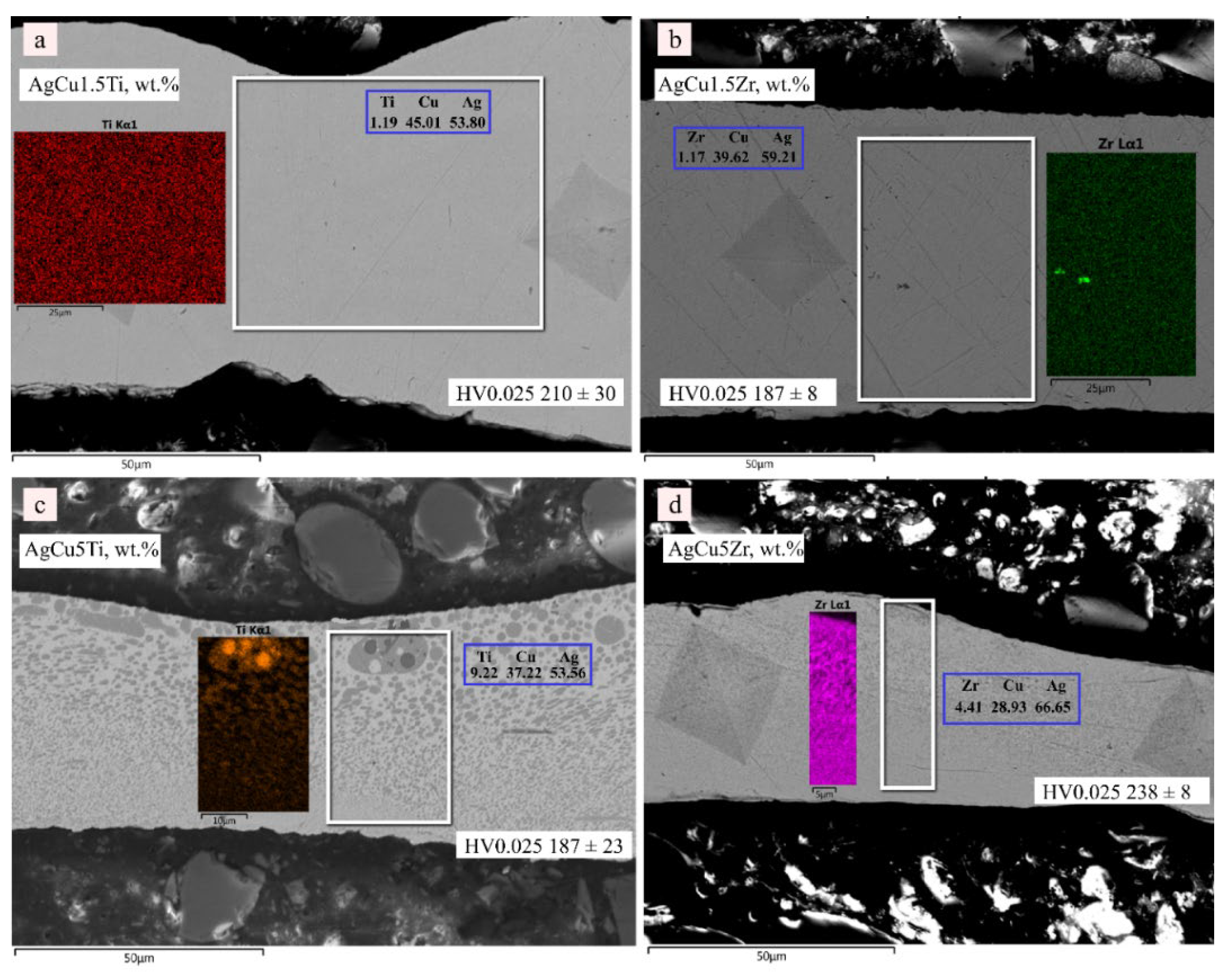

The composition of the obtained rapidly quenched ribbons was also examined using EDX analysis, the results of which are presented in

Figure 7.

Figure 7 shows that the ribbons containing 1.5 wt.% of the active element (Figure 7a,b) possess a more homogeneous structure, with their elemental composition close to the nominal target. In alloys with a higher active element content, the intermetallic phases on the side that was in contact with the copper disk during fabrication tend to be finer. It is also evident that the AgCu5Ti brazing alloy may locally contain a higher titanium concentration than intended, whereas the zirconium content in AgCu5Zr remains within the specified range.

The melting range of the produced brazing alloys was investigated using differential scanning calorimetry. The measurement results are presented in

Table 3.

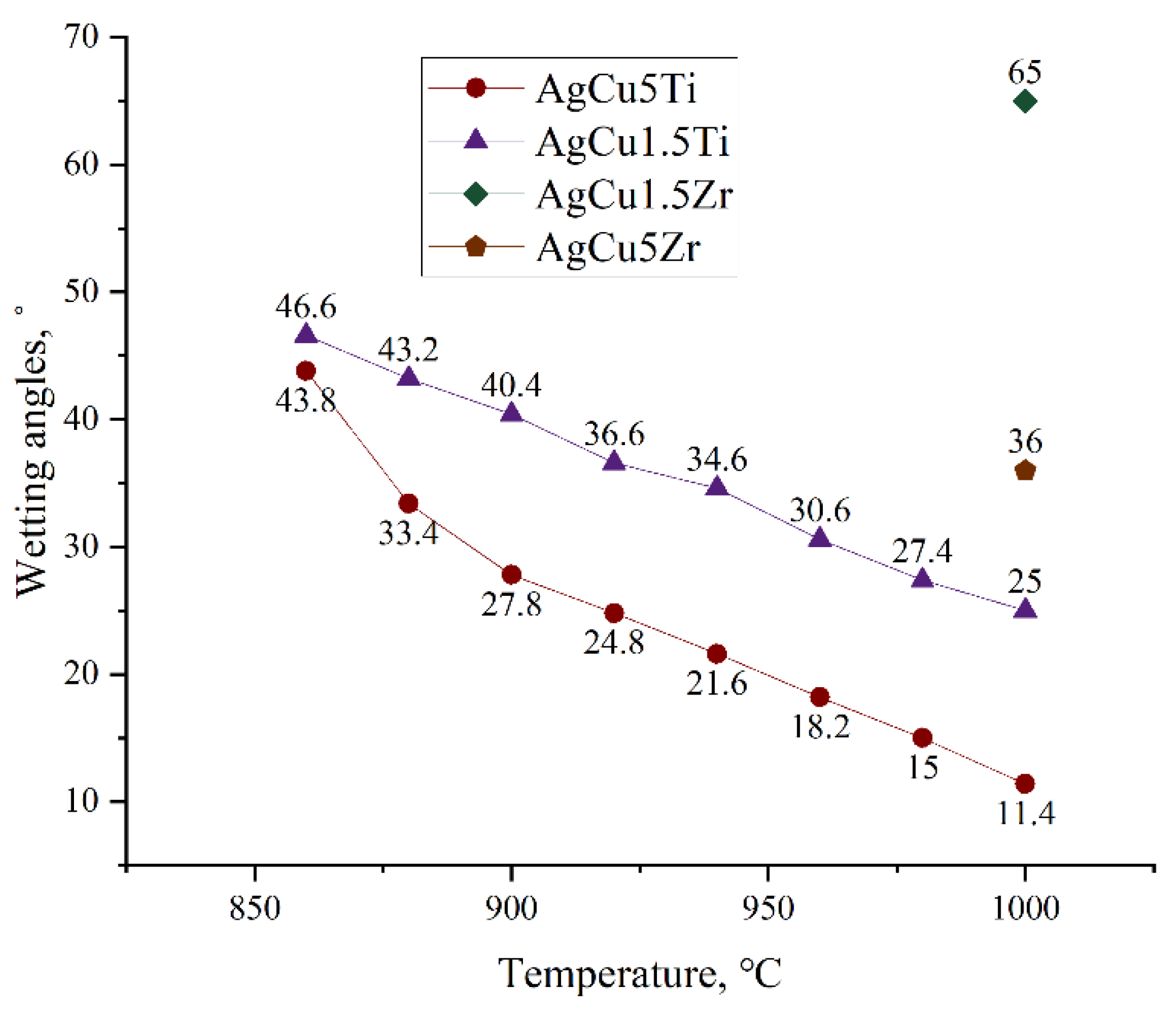

The obtained values are in good agreement with literature data and phase diagrams. These data were used to determine appropriate heating parameters for the wetting experiments. The wetting angles of the investigated brazing alloys are presented graphically in

Figure 8.

The data in

Figure 8 indicate that the AgCu5Ti alloy exhibits the best wettability on the ceramic substrate, achieving a wetting angle of 11.4° at 1000 °C. The AgCu1.5Ti alloy shows slightly less active interaction, resulting in a wetting angle of 25°. Although the melting of the AgCu5Zr alloy is expected to begin at 860 °C, droplet formation was observed only at 1000 °C. This delay is attributed to an oxide film on the alloy surface, which impedes the droplet formation process. Nevertheless, some interaction with the substrate was observed, suggesting potential applicability in specialized high-temperature brazing scenarios. The AgCu1.5Zr brazing alloy demonstrated significantly worse spreading characteristics, which makes it a less suitable candidate for creating metal-ceramic joints.

4. Conclusions

This work focused on the synthesis and comprehensive characterization of rapidly quenched ribbon brazing alloys based on the Ag-Cu-Ti (Ag-26.5Cu-1.5Ti, Ag-25Cu-5Ti) and Ag-Cu-Zr (Ag-26.5Cu-1.5Zr, Ag-25Cu-5Zr) systems. The study encompassed the analysis of their microstructure, phase composition, thermal properties, mechanical characteristics, and wetting behavior on ceramic substrate to assess their potential for high-temperature metal-ceramic joining. The main findings are as follows:

1) Rapid quenching from the melt successfully produced metastable ribbon structures with refined phase distribution. Post-solidification annealing of the master ingots induced significant microstructural evolution, promoting homogeneity and transforming continuous brittle intermetallic networks in Ti-containing alloys into dispersed particles, which is beneficial for ductility.

2) The phase composition of the alloys was confirmed by XRD and EDX analyses. The Ag-Cu-Ti system is characterized by the formation of Cu4Ti and CuTi intermetallics, while the Ag-Cu-Zr system features AgCu4Zr and Zr2Cu phases. The increase in the active element (Ti, Zr) content from 1.5 wt.% to 5 wt.% leads to a higher volume fraction of these intermetallic compounds.

3) The mechanical properties of the ingots are strongly influenced by the type and amount of the active element. Increasing the Zr content to 5 wt.% drastically reduces plasticity (by more than three times) and strength due to the embrittling effect of intermetallics. In contrast, a similar increase in Ti content results in a more balanced microstructure and marginally improves plastic properties

4) Wettability studies on 99% Al₂O₃ ceramic revealed that Ti-containing rapidly quenched alloys exhibit excellent bonding potential. The AgCu5Ti ribbon achieved a superior wetting angle of 11.4° at 1000 ℃, followed by AgCu1.5Ti at 25°. The AgCu5Zr alloy showed delayed wetting onset due to surface oxides but demonstrated some substrate interaction at high temperatures. Among the alloys considered, AgCu1.5Zr exhibits the poorest wetting properties.

5) The determined solidus and liquidus temperatures for the developed alloys, consistent with equilibrium phase diagrams, provide a critical basis for optimizing brazing thermal cycles in subsequent joint fabrication research.

In summary, the rapidly quenched ribbons AgCu1.5Ti, AgCu5Ti, and AgCu5Zr demonstrate promising characteristics for creating heat-resistant joints. The results establish a foundation for the next research phase: fabricating and testing brazed joints to evaluate their mechanical strength and thermal shock resistance under cyclic loading conditions.

Author Contributions

Conceptualization, I.A. and S.T.; methodology, I.A. and S.T; software, A.A. and V.K.; formal analysis, V.M. and A.B.; investigation, I.K., N.P. and P.M.; resources, I.F.; writing—original draft preparation, S.T.; writing—review and editing, I.A. and S.T.; visualization, S.T.; supervision, O.S.; project administration, O.S.; funding acquisition, I.A. All authors have read and agreed to the published version of the manuscript.

Funding

The research was carried out at the expense of a grant from the Russian Science Foundation № 25-19-00778, https://rscf.ru/project/25-19-00778/.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Vianco, P.T. A Review of Interface Microstructures in Electronic Packaging Applications: Brazing and Welding Technologies. JOM 2022, 74, 3557–3577. https://doi.org/10.1007/s11837-022-05308-x. [CrossRef]

- Elssner, G.; Petzow, G. Metal/Ceramic Joining. ISIJ Int. 1990, 30, 1011–1032, https://doi.org/10.2355/isijinternational.30.1011. [CrossRef]

- Sekulić, D.P., Ed. Advances in Brazing: Science, Technology and Applications; Elsevier: Amsterdam, The Netherlands, 2013.

- Mishra, P.; Athavale, S.N.; Pappachan, A.L.; Grover, A.K.; Suri, A.K.; Sengupta, P.; Kale, G.B.; Bhanumurthy, K.; De, P.K. Brazing of Hot Isostatically Pressed-Al2O3 to Stainless Steel (AISI 304L) by Mo-Mn Route Using 72Ag-28Cu Braze. Metall. Mater. Trans. A 2005, 36, 1487–1494, https://doi.org/10.1007/s11661-005-0240-y. [CrossRef]

- Mishra, S.; Sharma, A.; Jung, D.-H.; Jung, J.P. Recent Advances in Active Metal Brazing of Ceramics and Process. Met. Mater. Int. 2020, 26, 1087–1098. https://doi.org/10.1007/s12540-019-00536-4. [CrossRef]

- Naidich, Y.V.; Zhuravlev, V.S.; Gab, I.I.; Kostyuk, B.D.; Krasovskyy, V.P.; Adamovskyy, A.A.; Taranets, N.Yu. Liquid Metal Wettability and Advanced Ceramic Brazing. J. Eur. Ceram. Soc. 2008, 28, 717–728, https://doi.org/10.1016/j.jeurceramsoc.2007.07.021. [CrossRef]

- Loehman, R.E.; Tomsia, A.P. Reactions of Ti and Zr with AlN and Al2O3. Acta Metall. Mater. 1992, 40 (Suppl.), S75–S83. https://doi.org/10.1016/0956-7151(92)90266-H. [CrossRef]

- Hongqi, H.; Zhihao, J.; Xiaotian, W. The Influence of Brazing Conditions on Joint Strength in Al2O3/Al2O3 Bonding. J. Mater. Sci. 1994, 29, 5041–5046, https://doi.org/10.1007/BF01151094. [CrossRef]

- Mandal, S.; Ray, A.K.; Ray, A.K. Correlation between the Mechanical Properties and the Microstructural Behaviour of Al2O3-(Ag-Cu-Ti) Brazed Joints. Mater. Sci. Eng. A 2004, 383, 235–244. https://doi.org/10.1016/j.msea.2004.06.002. [CrossRef]

- Kim, J.H.; Yoo, Y.C. Bonding of Alumina to Metals with Ag-Cu-Zr Brazing Alloy. J. Mater. Sci. Lett. 1997, 16, 1212–1215. https://doi.org/10.1023/A:1018581615209. [CrossRef]

- Stephens, J.J.; Hosking, F.M.; Walker, C.A.; Dudley, E.C.; Yost, F.G. The Evolution of a Ternary Ag-Cu-Zr Active Braze Filler Metal for Kovar®/Alumina Braze Joints. In Proceedings of the 3rd International Brazing and Soldering Conference, San Antonio, TX, USA, 24–26 April 2006; pp. 207–213.

- Yoo, Y.C.; Kim, J.H.; Park, K. Microstructure and Bond Strength of Ni–Cr Steel/Al2O3 Joints Brazed with Ag–Cu–Zr Alloys Containing Sn or Al. Mater. Sci. Technol. 1999, 15, 1331–1334. https://doi.org/10.1179/026708399101505293. [CrossRef]

- Yoo, Y.C.; Kim, J.H.; Park, K. Microstructural Characterization of Al2O3/AISI 8650 Steel Joint Brazed with Ag–Cu–Sn–Zr Alloy. Mater. Lett. 2000, 42, 362–366. https://doi.org/10.1016/S0167-577X(99)00212-8. [CrossRef]

- Jasim, K.M.; Hashim, F.A.; Yousif, R.H.; Rawlings, R.D.; Boccaccini, A.R. Actively Brazed Alumina to Alumina Joints Using CuTi, CuZr and Eutectic AgCuTi Filler Alloys. Ceram. Int. 2010, 36, 2287–2295, https://doi.org/10.1016/j.ceramint.2010.07.029. [CrossRef]

- Ramsheh, H.H.; Sani, M.F.; Kokabi, A.H. Microstructure and Mechanical Properties of MoSi2–MoSi2 Joints Brazed by Ag–Cu–Zr Interlayer. Mater. Des. 2013, 49, 197–202, https://doi.org/10.1016/j.matdes.2013.01.027. [CrossRef]

- Rajendran, S.H.; Hwang, S.J.; Jung, J.P. Active Brazing of Alumina and Copper with Multicomponent Ag-Cu-Sn-Zr-Ti Filler. Metals 2021, 11, 509. https://doi.org/10.3390/met11030509. [CrossRef]

- Simhan, D.R.; Mukhopadhyay, P.; Ghosh, A. On Segregation of Zr and Wettability of Active Ag-Cu-Zr Alloy on Cubic Boron Nitride Surface. Mater. Lett. 2017, 207, 183–186, https://doi.org/10.1016/j.matlet.2017.07.080. [CrossRef]

- Simhan, D.R.; Ghosh, A. Vacuum Brazing of Cubic Boron Nitride to Medium Carbon Steel with Zr Added Passive and Ti Activated Eutectic Ag-Cu Alloys. Ceram. Int. 2018, 44, 4891–4899, https://doi.org/10.1016/j.ceramint.2017.12.079. [CrossRef]

- Ivannikov, A.; Tukhbatov, V.; Ustyuzhaninov, A.; Bogachev, I. Rapid-Quenched Nickel-Based Solder for High-Temperature Brazing of Various Constructive Elements. Tsvetnye Metally 2014, 12, 27–31.

- Logvenchev, I.S.; Ivannikov, A.A.; Volkov, A.A.; Arofikin, N.V.; Sevryukov, O.N.; Fedotov, V.T.; Suchkov, A.N.; Fedotov, I.V.; Skrytnyi, V.I. The Brazing of Nickel Alloys for Nuclear Reactor with the Using of the Rapidly-Quenched Filler Metals. Inorg. Mater. Appl. Res. 2014, 5, 263–267, https://doi.org/10.1134/S2075113314030101. [CrossRef]

- Wang, J.L.; Yang, Z.W.; Wang, Y.; Wang, D.P.; Li, H.J. Microstructural Stability and Mechanical Properties of Al2O3/Kovar 4 J34 Joint Vacuum Brazed Using Ag-5Cu-1Al-1.25Ti (wt%) Filler Metal. J. Manuf. Process. 2021, 72, 553–564, https://doi.org/10.1016/j.jmapro.2021.10.057. [CrossRef]

- Zhu, Q.; Li, S.; Hu, K.; Liang, X.; Cai, Y.; Liu, Z.; Zhang, Y. Enhanced Mechanical Properties and Thermal Cycling Stability of Al2O3-4J42 Joints Brazed Using Ag–Cu–Ti/Cu/Ag–Cu Composite Filler. Ceram. Int. 2021, 47, 30247–30255, https://doi.org/10.1016/j.ceramint.2021.07.204. [CrossRef]

- Terekhova, S.M.; Ivannikov, A.A.; Abramov, A.V.; Kirillova, V.O.; Sevryukov, O.N. Thermal Stability of Metal-Ceramic Kovar®/94% Alumina Joints. Ceram. Int. 2025, https://doi.org/10.1016/j.ceramint.2025.10.165. [CrossRef]

- Qi, J.; Du, D.; Zhang, D.; Xue, S.; Zhang, J.; Yi, J.; You, H.; Chang, B. Study on the Layered Structure of Ceramic-Side Bonding Area and the Mechanical Property of Al2O3–Kovar Brazed Joint with Ag-Cu-Ti Filler. J. Manuf. Mater. Process. 2025, 9, 355. https://doi.org/10.3390/jmmp9110355. [CrossRef]

- Irmagambetova, S.M.; Ermakov, S.A.; Glushenkov, A.E.; Torgunaev, D.A.; Egorov, A.A. Vliyanie razmerov i formy ploskikh obraztsov na opredelyaemye kratkovremennye mekhanicheskie svoistva materialov [The Effect of the Size and Shape of Flat Samples on the Determined Short-Term Mechanical Properties of Materials]. Vopr. At. Nauki Tekh. 2025, *2*, 18–24.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).