Submitted:

24 November 2025

Posted:

25 November 2025

You are already at the latest version

Abstract

Keywords:

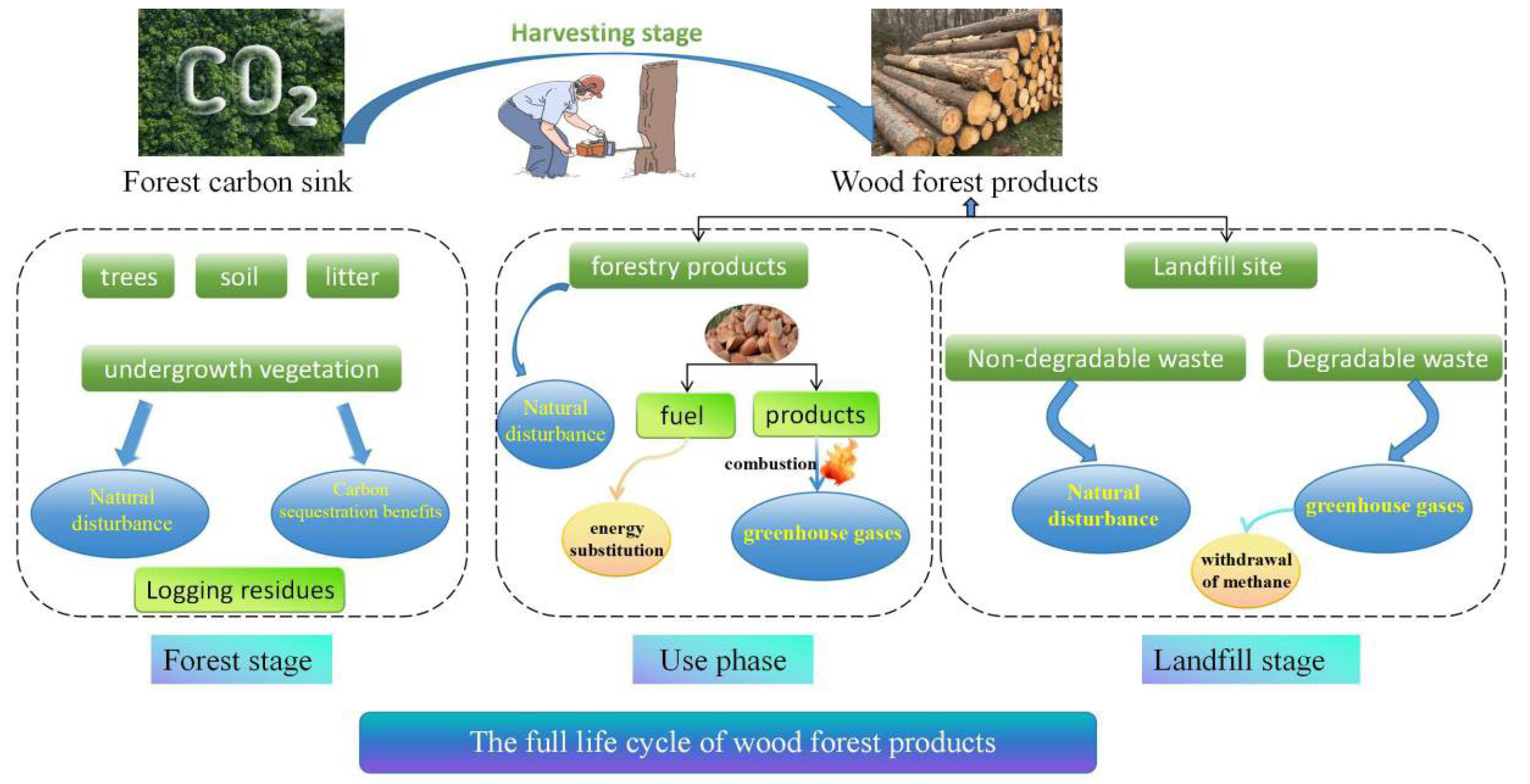

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Carbon Emissions in the Production Stage

2.2.1. Functional Units and System Boundary

2.2.2. Life Cycle Inventory (LCI) Algorithm

2.2.3. Life Cycle Impact Assessment (LCIA) Algorithm

2.3. LCA Index System for Artificial Board Products

2.4. Life-Cycle Modeling Platform and Database

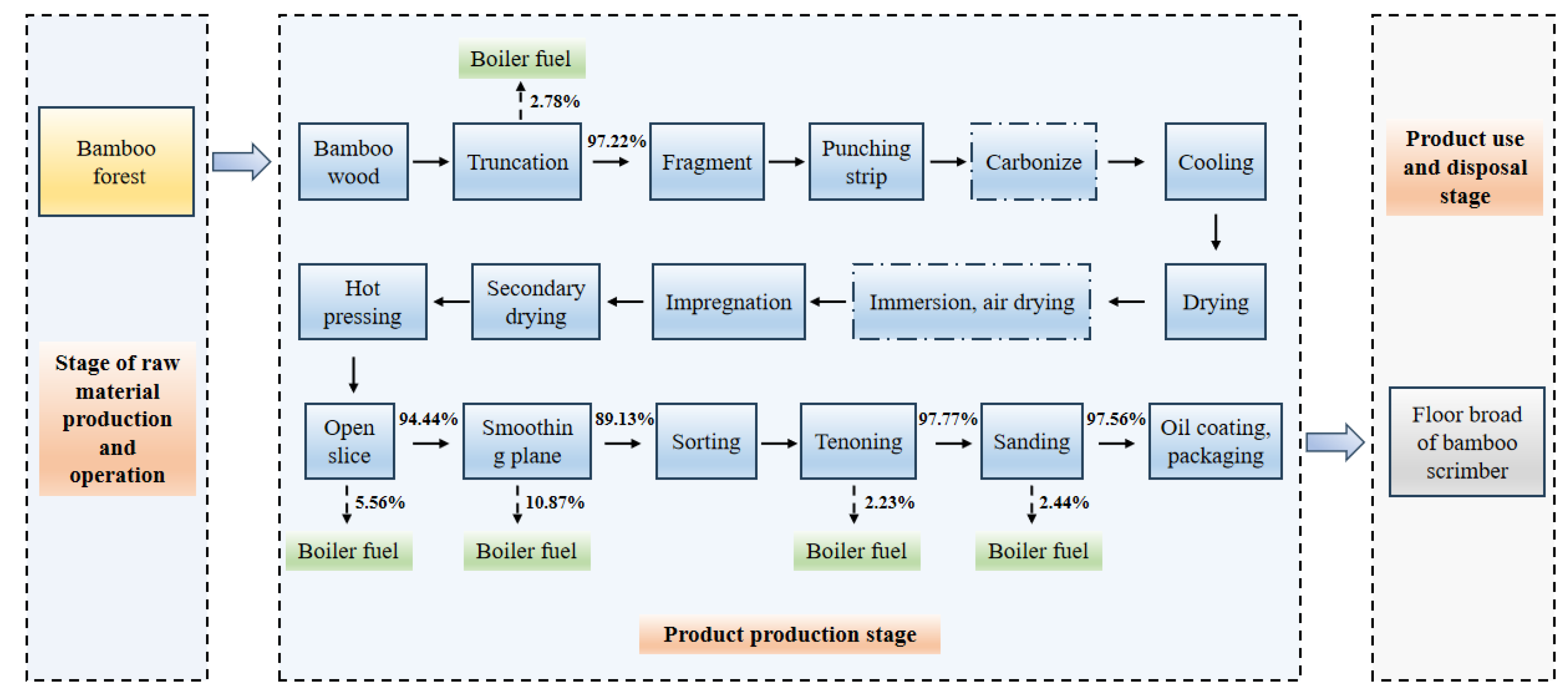

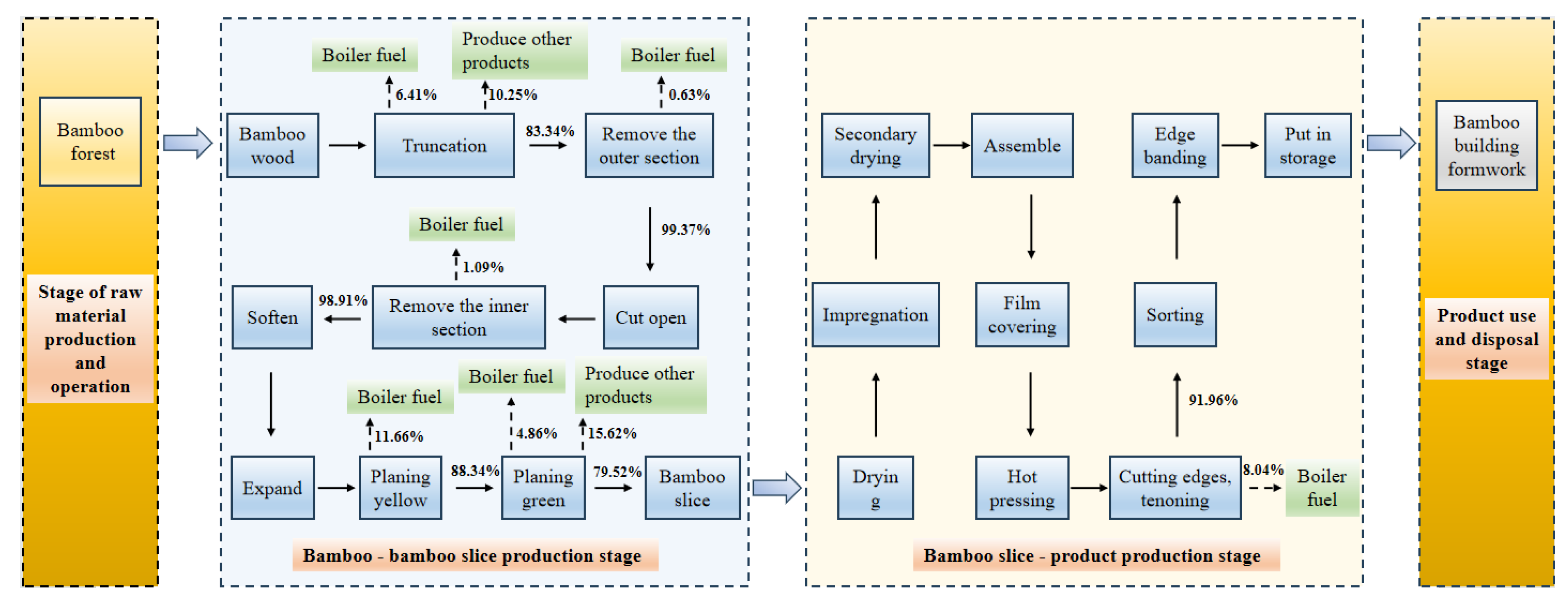

2.4.1. Material Transfer Analysis in the Production Stage of Artificial Board Products

2.4.2. Carbon Storage Measurement in Raw Material Supply

2.4.3. Carbon Storage Calculation for Artificial Board Products

2.5. Integrated Assessment

3. Results and Discussion

3.1. Material Transfer Analysis

3.2. Carbon Emissions in the Production Process of Bamboo Scrimber Flooring

3.2.1. Comparison of Different Heat Treatment Processes for Bamboo Scrimber

3.2.2. The Impact of Adhesives

3.2.3. Comparison of Reconstituted and Laminated Production Methods

3.3. Integrated Evaluation of Carbon Emission Reduction Post-Bamboo Harvest

3.3.1. Extending the System Boundary to the Raw Material End

3.3.2. Extending the System Boundary to the Product Use End

3.4. Integrated Evaluation

3.5. Analysis of Substitution Emission Reduction Effect

3.6. Limitations of the Study

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Green.; Avitabile.; Farrell.. Reporting harvested wood products in national greenhouse gas inventories: Implications for Ireland. Biomass Bioenergy. 2006, 30, 105-114.

- Chen, J.; Ter, M.. Assessing the greenhouse gas effects of harvested wood products manufactured from managed forests in Canada. Forestry. 2018, 91, 193-205.

- 3. Qin, L.; Liu, X., Zhang, Z..Development Status and Trend of Plywood Industry in China. China Forest Products Industry, 2020, 57(11), 1-3,9.

- Gao, F.; Shi, Y..Present Situation and Prospect of Building Formwork Products in China. Construction technology, 2017, 46(2), 98-101.

- Zhou, G.; Jiang, P.. Density, storage and spatial distribution of in Phyllostachys pubescens forest. Scientia Sylvae Sinicae, 2004, 40(6): 20-24.

- Fei, B.; Ma, X.. Connotation of bamboo carbon footprint and its regulating effect on bamboo industrial development.World bamboo and rattan, 2020, 18(2), 12-17.

- Wang, S.; Yang, H.. Study on carbon emission reduction path of China’s wood-based panel industry based on international carbon footprint standards. China population of resources and environment, 2019, 29(4), 27-37.

- Jordan, B.. Scrimber: the leading edge of timber technology. The proceedings of the 2nd Pacific timber engineering conference.1989.

- Yu, Y.; Qin, L.; Yu, W..Manufacturing Technology of Bamboo-Based Fiber Composites Used as Outdoor Flooring. Scientia sylvae sinicae, 2014, 50(1), 133-139.

- Hong, J.; Zhang, F.; Xu, C.. Evaluation of life cycle inventory at macro level: A case study of mechanical coke production in China. The International Journal of Life Cycle Assessment, 2015, 20(6): 751-764.

- Hong, J.; Shaked, S.; Rosenbaum, R.. Analytical uncertainty propagation in life cycle inventory and impact assessment: Application to an automobile front panel. The International Journal of Life Cycle Assessment, 2010, 15(5): 499-510. [CrossRef]

- Liu, X. L.; Wang, H.. Method and basic model for development of Chinese reference life cycle database. Acta scientiae circumstantiae, 2010, 30(10), 2136-2144.

- Author, X. H. Studies on standing tree biomass models and the corresponding parameter estimation. Doctor’s Thesis, Beijing Forestry University, Beijing, China, 1998.

- Yang, H.Q.; Yu, Z.H.. Research trends and future key issues of global harvested wood products carbon science. Journal of Nanjing Forestry University (Natural Sciences Edition), 2021, 45(4):219-228.

- Author, R. S. Study on the Anti-mildew Performance of Rhizoma Corydalis Compound Nano-TiO2 on Bamboo. Inner MongoliaAgricultural University, Huhehaote, China, 2021.

- Wang, G.G.; Van, E.. Accounting Carbon Storage in Decaying Root Systems of Harvested Forests. AMBIO, 2012, 41(3), 284-291.

- Zhang, S.G.; Liu, J.. Biomass and Distribution Patterns of Pinus massoniana Plantation in Northwest Guangxi. Guangxi forestry science, 2010, 39(4), 189-192+219.

- Chen, Z.X.; He, D.B.. Moisture content and model of Pinus Massoniana in Southern China. Central south forest inventory and planning, 2011, 30(2), 56-60, 64.

- Wang, C.; Jiang, Z.H.. Biomass allocation of aboveground components of Phyllostachys edulis and its variation with body size. Chinese Journal of Ecology, 2014, 33(8), 2019-2024.

- Author, Z. J. Study on the Rule of Nitrogen Utilization and its Influence Factors in Phyllostachys edulis Forests.Chinese Academy of Forestry, Beijing, China, 2016.

- Yang, J.J.; Fu, W.S.; Yu, W.J.. Research status of the parameters of internal-mat conditions during hot-pressing. Forestry and Grassland Machinery, 2008, 4(3), 33-37.

- Author, Y. W. Research on the determination of wood carbon content rate and carbon storage database. Northeast Forestry University, Harbin,China,2013.

- Author, Z. Y. Study on the effect of color and physical-mechanical properties for heat-treated bamboo.Chinese Academy of Forestry, Beijing, China, 2010.

- Sathre, R.; O’Connor, J.. Meta-analysis of greenhouse gas displacement factors of wood product substitution. Environmental Science and Policy, 2010, 13(2), 104-114. [CrossRef]

- Churkina, G.; Organschi, A., Reyer, C. P. O.. Buildings as a global carbon sink. Nature Sustainability, 2020, 3(4), 269-276.

- Brunet, N. P. ; Jochheim, H.; Brunet, N.. Effect of cascade use on the carbon balance of the German and European wood sectors. Journal of Cleaner Production, 2018, 170, 137-146.

- Lun, F.; Liu, M.; Zhang, D.. Life Cycle Analysis of Carbon Flow and Carbon Footprint of Harvested Wood Products of Larix principis-rupprechtii in China. Sustainability, 2016, 8(3), 247-258. [CrossRef]

- Zhang, J.Y.; Zhou, L.Y.. Application of blockchain technology in carbon footprint tracing and accounting of textile and apparel products. JOURNAL OF SILK, 2023, 60(2), 14-23.

- Yan, M.F.; Zhang, X.S.. Effect of management practices on forest platation soil carbon. Chinese Journal of Ecology, 2010, 29(11), 2265-2271.

- Halliday, J. C.; Tate, K. R.; Mcmurtrie, R.E.. Mechanisms for changes in soil carbon storage with pasture to Pinus radiata land-use change. Global Change Biology, 2010, 9(9), 1294-1308. [CrossRef]

- Tian, Y. W.; Huang, Z.L.. Advances on effect of forest management on soil carbon sequestration. Journal of Henan Agricultural Sciences, 2012, 41(7), 1-6.

| Environmental Impact Type | Unit of Impact Type Index | Main Inventory Substances |

|---|---|---|

| Global Warming | kg CO2 eq. | CO2, CH4, N2O... |

| Primary Energy Consumption | MJ | Hard coal, lignite, natural gas... |

| Abiotic Resource Depletion | kg Sb eq. | Iron, manganese, copper... |

| Water Resource Consumption | kg | Freshwater, surface water, groundwater... |

| Acidification | kg SO2 eq. | SO2, NOx, NH3... |

| Eutrophication | kg PO43- eq. | NH3, NH4-N, COD... |

| Inhalable Inorganics | kg PM2.5 eq. | CO, PM10, PM2.5... |

| Ozone Layer Depletion | kg CFC-11 eq. | CCl4, C2H3Cl3, CH3Br... |

| Photochemical Ozone Creation | kg NMVOC eq. | C2H6, C2H4… |

| Product Type | Raw Material Carbon Storage(kg CO2e) | Carbon Emissions from Production(kg CO2e) | Production Carbon Storage (kg CO2e) |

Integration Assessment(kg CO2e) |

|---|---|---|---|---|

| Deep carbon bamboo scrimber flooring | -554.01 | 1845.99 | -329.75 | 962.23 |

| Shallow carbon bamboo scrimber flooring | -578.34 | 1570.85 | -314.65 | 677.86 |

| Bamboo plywood templates | -745.43 | 1435.55 | -49.89 | 640.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).