2. Structure and Design of a Large AFPM Generator

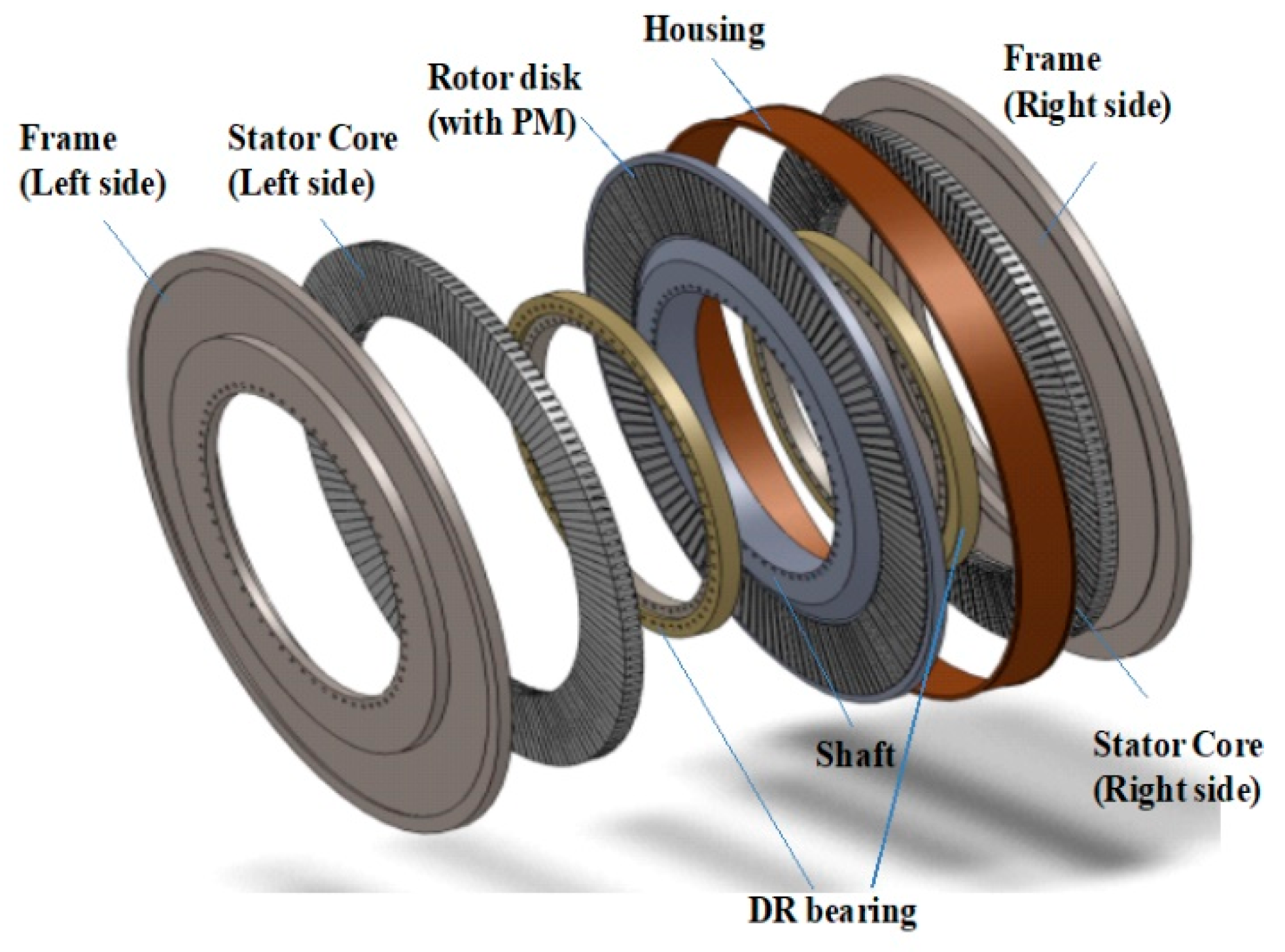

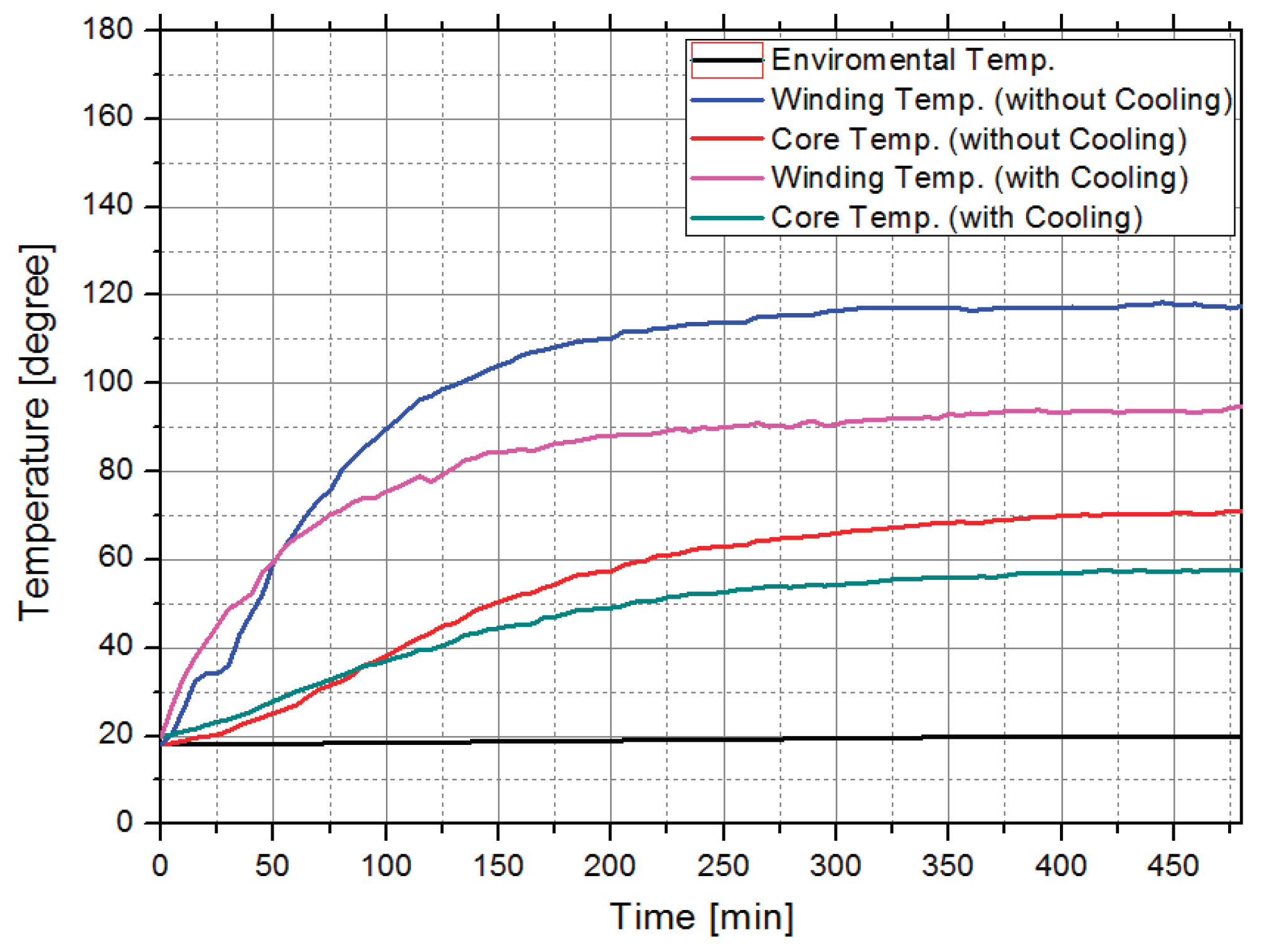

The AFPM generator features an air-gap surface that is orthogonal to the rotational axis, and the magnetic flux within the air gap is oriented parallel to the shaft. In one configuration, permanent magnets are embedded into holes formed in a disk-shaped rotor. This structure can be implemented either as an internal-rotor type, where two stators are positioned on both sides of the rotor disk, or as an external-rotor type, where the stator is placed in the center and two disk-type rotors rotate on both sides of it. The AFPM topology also offers advantages in achieving efficient cooling structures. In addition, due to its significantly shorter axial length approximately one quarter that of a conventional induction machine of equal output the axial length is further reduced when directly driven without a gearbox.

Structurally, the AFPM generator can be manufactured in a modular fashion by leveraging its large diameter and short axial length. This enables multiple modules to be connected axially to meet higher power requirements, providing excellent scalability for large-capacity systems.

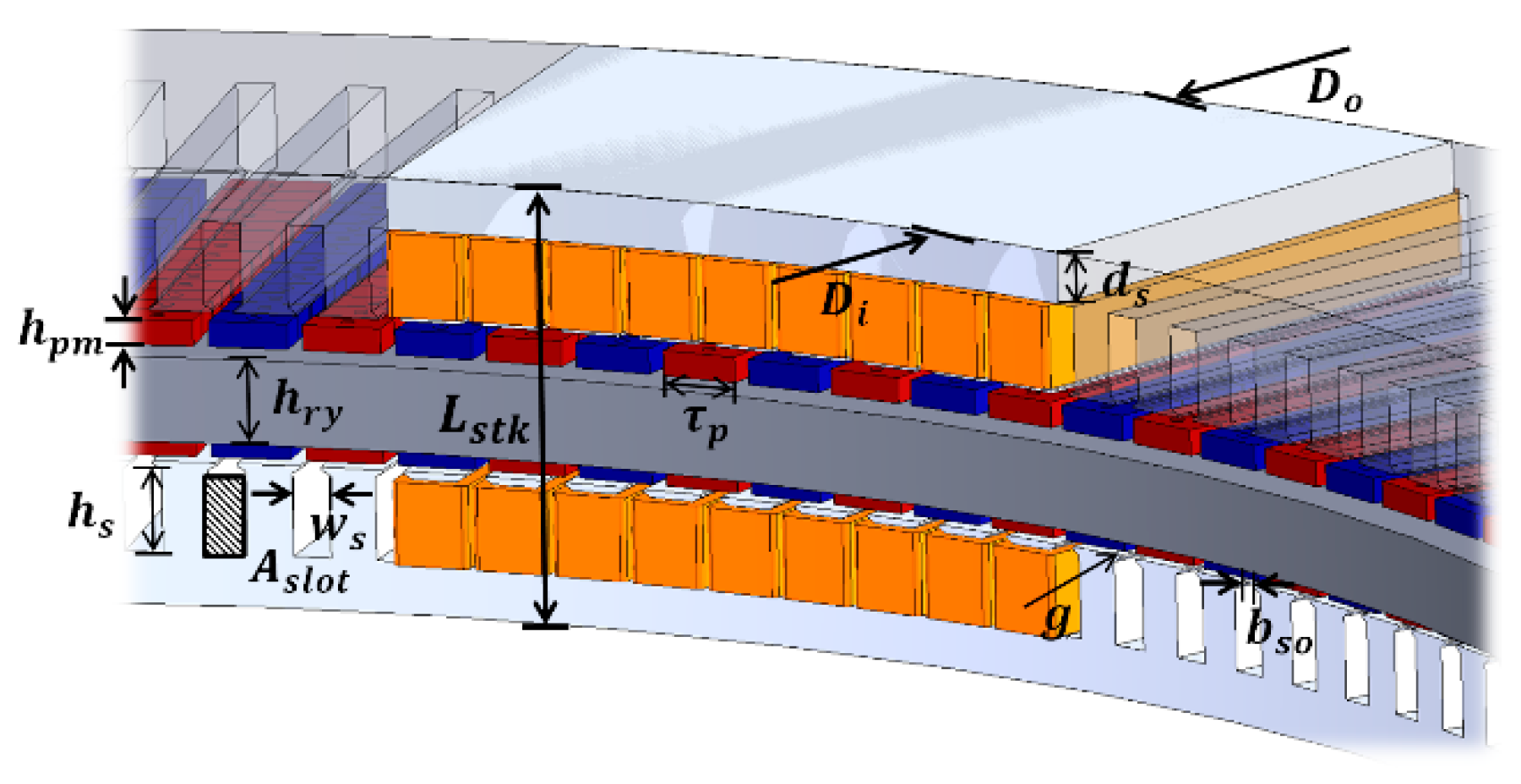

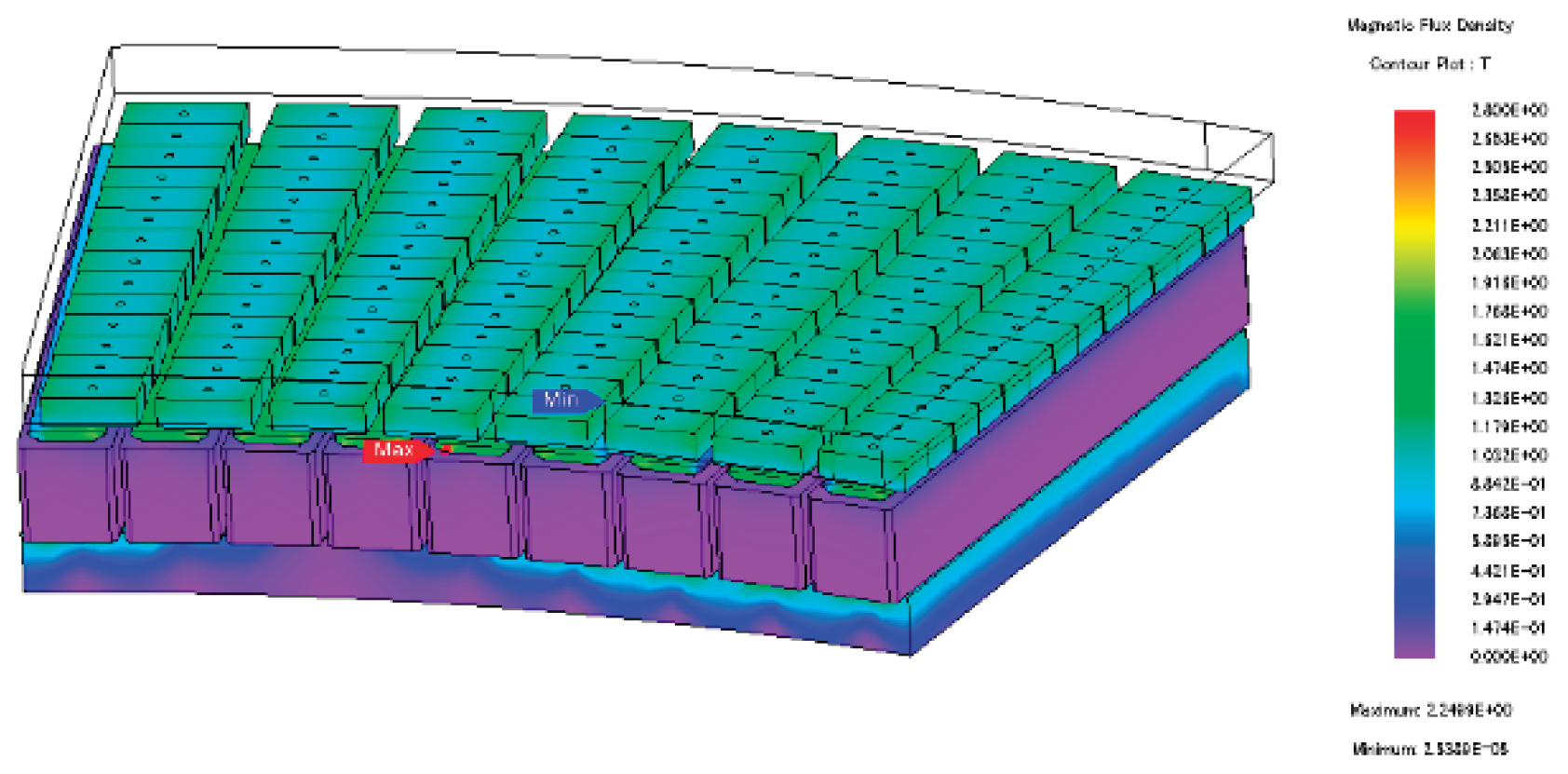

The structure of the AFPM generator applied in this study is shown in

Figure 1. The generator employs an internal-rotor type configuration in which the external wind turbine blades are directly connected to the generator shaft. A segmented core structure is adopted, in which the stator teeth and yoke are fabricated together without separation, and the assembly is supported by an outer frame. The stator teeth consist of laminated salient-pole slot cores, while the rotor, positioned between the stators on both sides, is equipped with surface-mounted permanent magnets. As a result, the proposed generator is a double-sided internal-rotor AFPM machine with surface-mounted permanent magnets.

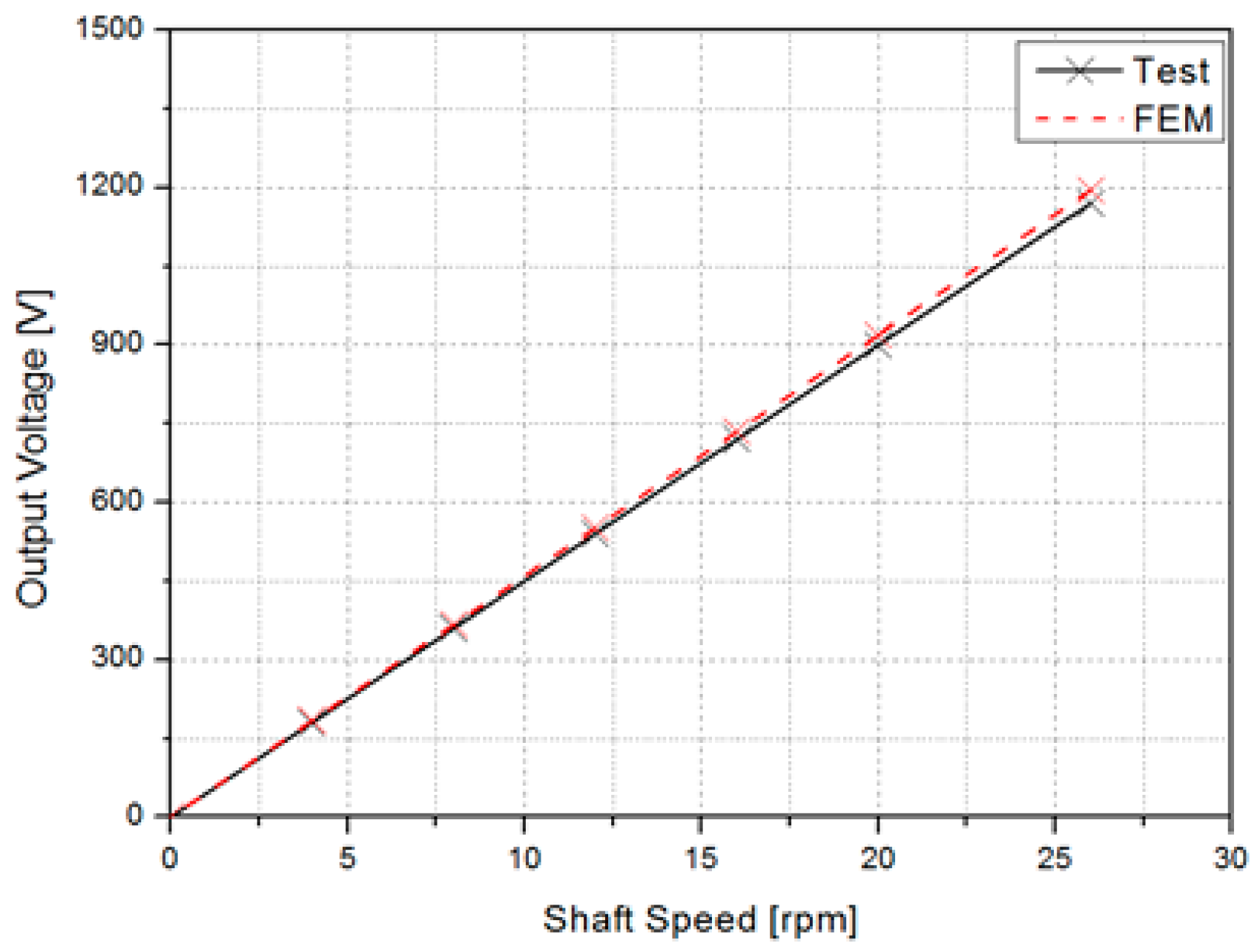

The major design parameters for each component of the large-capacity AFPM generator are expressed mathematically, and the generator specifications required for the direct-drive wind turbine system considered in this study are summarized in

Table 1. Based on the blade specifications, the generator is designed to deliver a rated power of 2.5 MW at a rated shaft speed of 16 rpm and an output voltage of 690 V. A water-cooling system utilizing the stator core is applied as the cooling method, and the initial design target for the generator efficiency is set to exceed 94% at rated speed.

The overall AFPM generator design procedure is presented as a design flowchart in

Figure 3. First, the fundamental design is performed by considering the required specifications such as generator capacity, shaft speed, and output voltage. In this stage, the major dimensions and material properties of the active components are determined using basic sizing equations. After modeling for analysis, the electromagnetic characteristics of the generator are evaluated. During the analysis stage, both electromagnetic and mechanical analyses are conducted in parallel, followed by mechanical component design and iterative refinement.

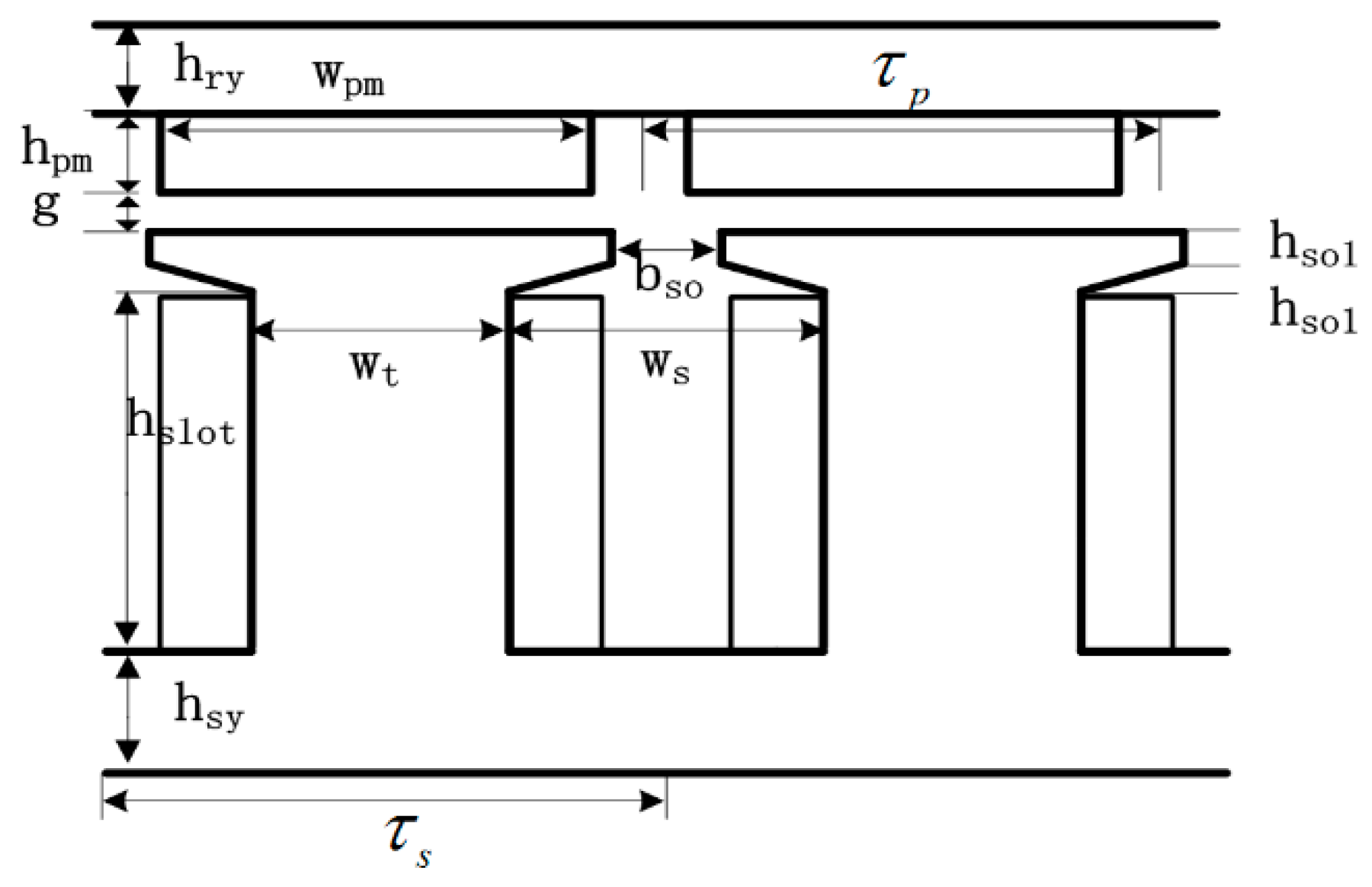

Figure 2 shows the major design variables of the large-capacity AFPM generator. The basic dimensions related to the generator volume include the outer diameter, inner diameter, and axial length. For stator-related variables, the slot area is denoted as

, slot width as

, slot height as

, slot opening as

, and stator yoke thickness as

. Rotor-related variables include the magnet pole pitch, permanent magnet thickness and rotor yoke thickness. The air-gap length between the stator and rotor is represented by

.

Figure 2.

Design variables of Large-Scale AFPMG.

Figure 2.

Design variables of Large-Scale AFPMG.

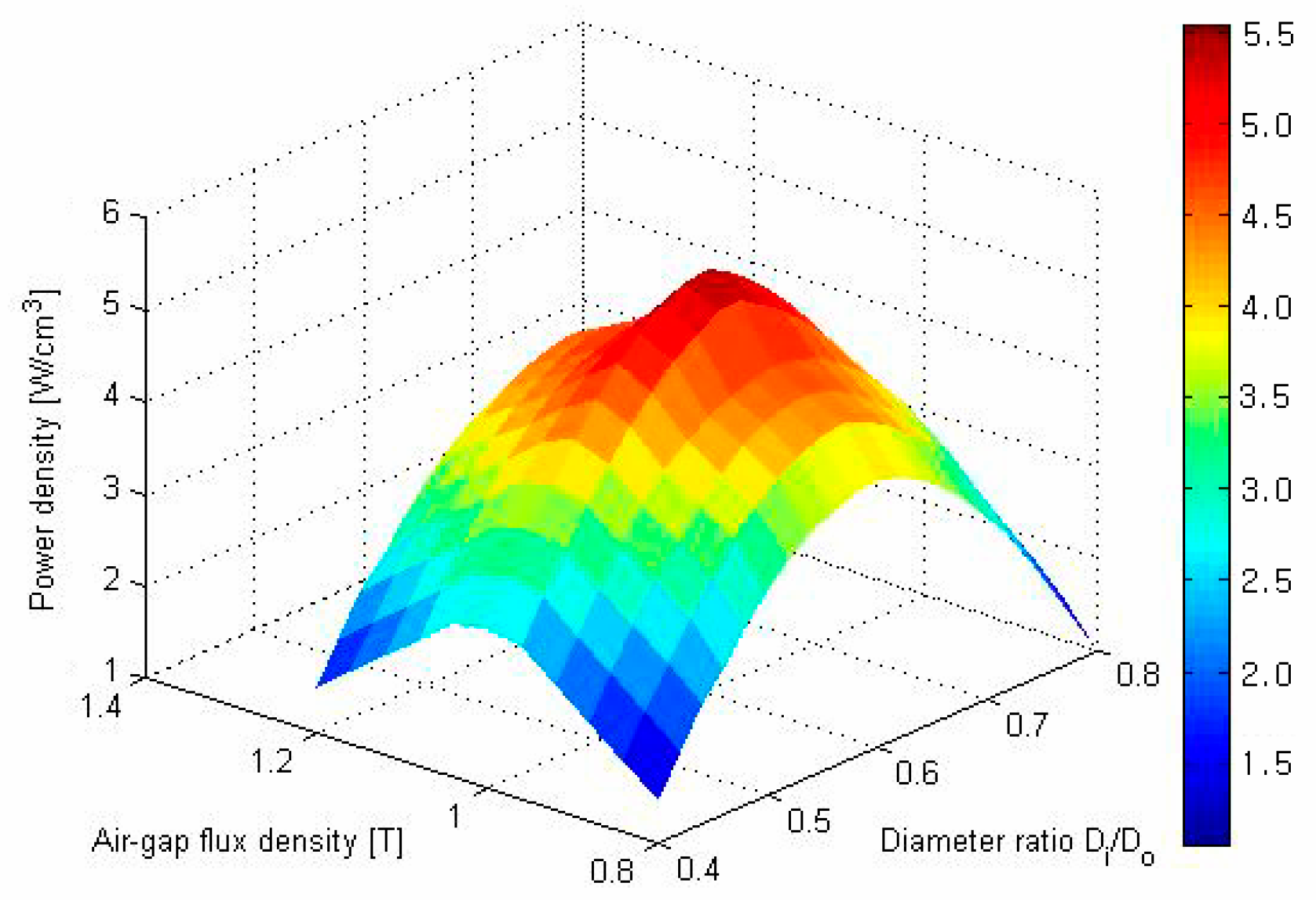

Figure 3.

Power density according to magnetic flux density and diameter ratio.

Figure 3.

Power density according to magnetic flux density and diameter ratio.

In the preliminary design stage of an AFPM generator, the major dimensions related to power output can be determined using sizing equations [

3]. These equations are derived by applying the mean radius of an AFPM machine to the conventional sizing equations used for radial-flux permanent magnet machines.

Based on the characteristic equations of the AFPM generator, the torque produced per pole of the permanent magnet,

, and the torque constant,

, can be expressed as follows.

where

is the magnet pole-arc ratio,

is the stator constant,

is the number of series turns,

is the winding factor,

is the stator current, and

is the air-gap flux density. The corresponding back electromotive force (EMF) can be expressed as follows.

By substituting these expressions into the generator output equation,

, the resulting form can be written as follows.

where

is the coefficient related to the ratio of the outer to inner diameter of the generator. Using this coefficient, the expression can be rewritten as Equation (4).

Due to the inherent characteristics of AFPM machines, maximizing output within a constrained outer diameter requires reducing the inner diameter to increase the effective cross-sectional area. This also leads to a shorter axial length, enabling one of the key advantages of AFPM generators—their compact structure. However, reducing the inner diameter to shorten the axial length while maintaining the same outer diameter can result in output inefficiencies. Therefore, an appropriate ratio between the inner and outer diameters, , must be selected during the AFPM design process.

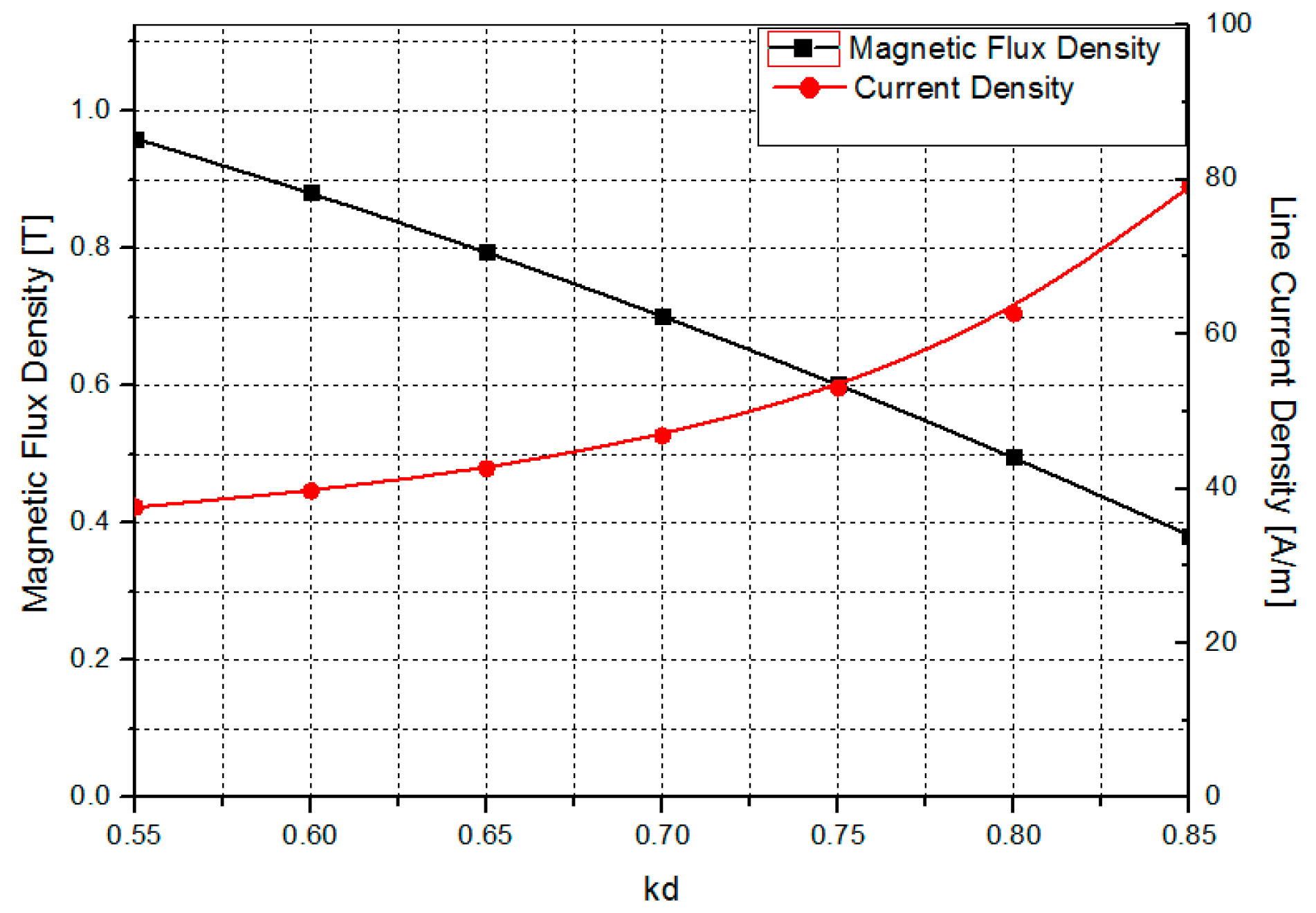

Since the inner and outer diameters of the stator and rotor are among the most critical factors determining generator performance, the output density was compared as a function of the diameter ratio and air-gap flux density, as shown in

Figure 3. Considering the maximum output of the generator, torque calculated based on the output equation yields an optimal diameter ratio of approximately

. However, in practical manufacturing, applying a ratio below 0.6 becomes difficult. As the inner diameter decreases, interference between the stator winding end-turns and the shaft must be taken into account. Additionally, in large-capacity machines, the axial forces increase significantly, causing mechanical components to enlarge, which negatively affects both size and cost.

Therefore, when designing the generator, the axial forces generated between the permanent magnets and stator at different diameter ratios must be considered to determine approximate dimensions for the stator yoke, frame, and rotor disk yoke. In this study, various performance characteristics corresponding to the diameter ratio were analyzed and incorporated into the final design.

The load distribution according to

was examined for generators of the same power rating, and an appropriate value was selected based on this analysis.

Figure 4 illustrates the relationship between the air-gap flux density and the line current density as a function of

.

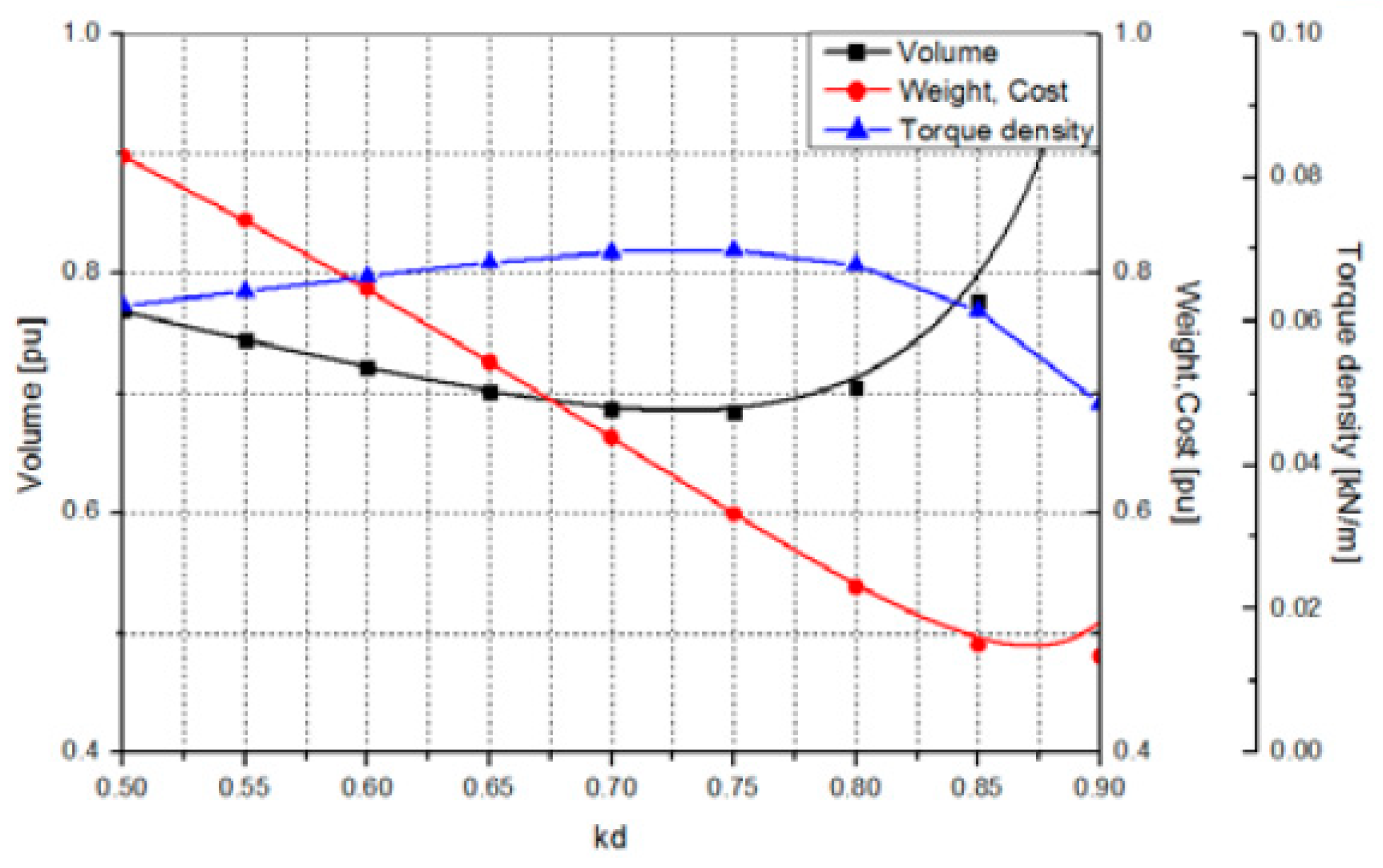

Based on these results, the overall generator volume, weight, and torque density were calculated and are presented in

Figure 5. Considering these various characteristics as a function of

, along with verification through detailed analysis, the diameter ratio for the AFPM generator proposed in this study was determined to be

.

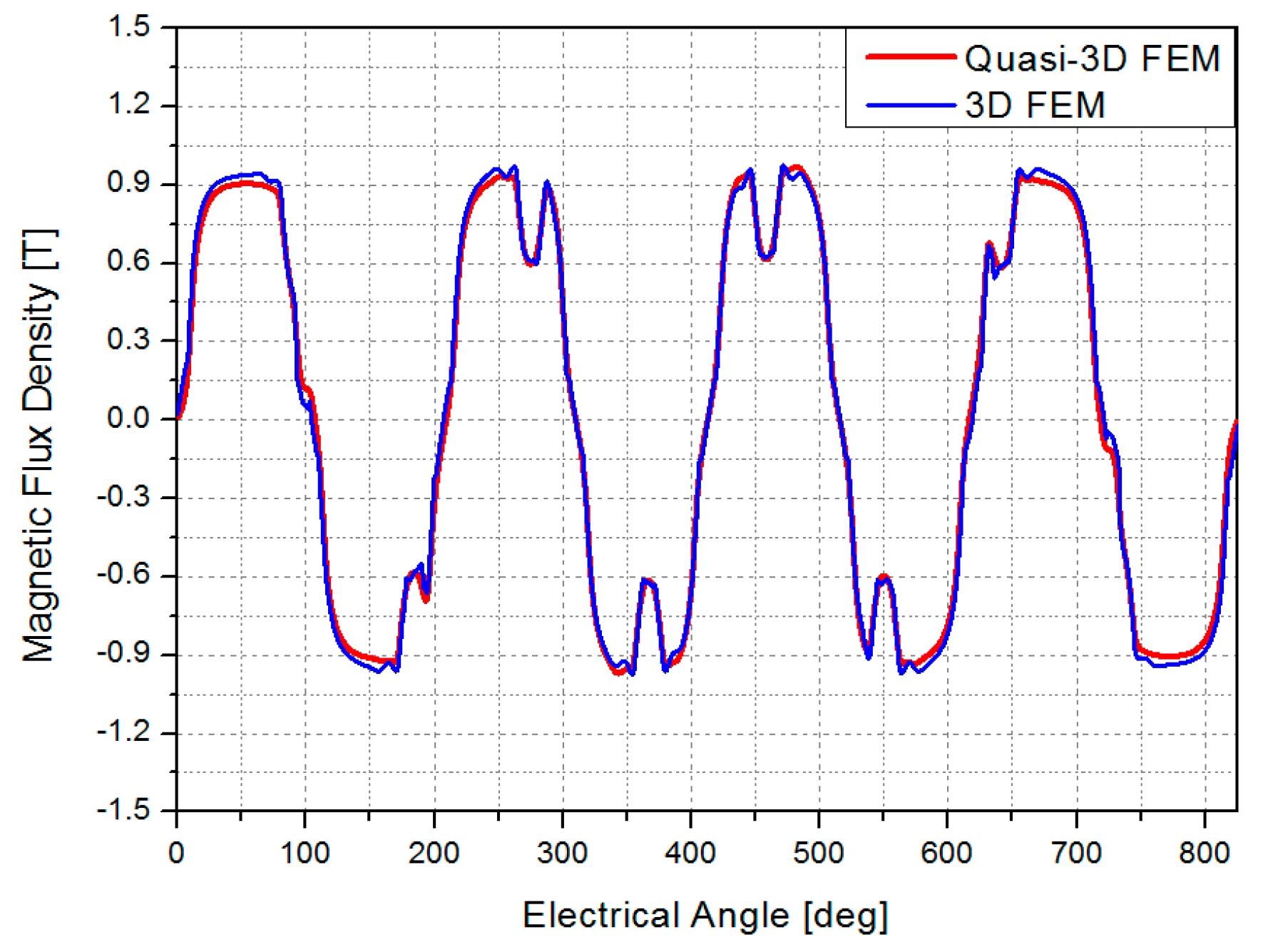

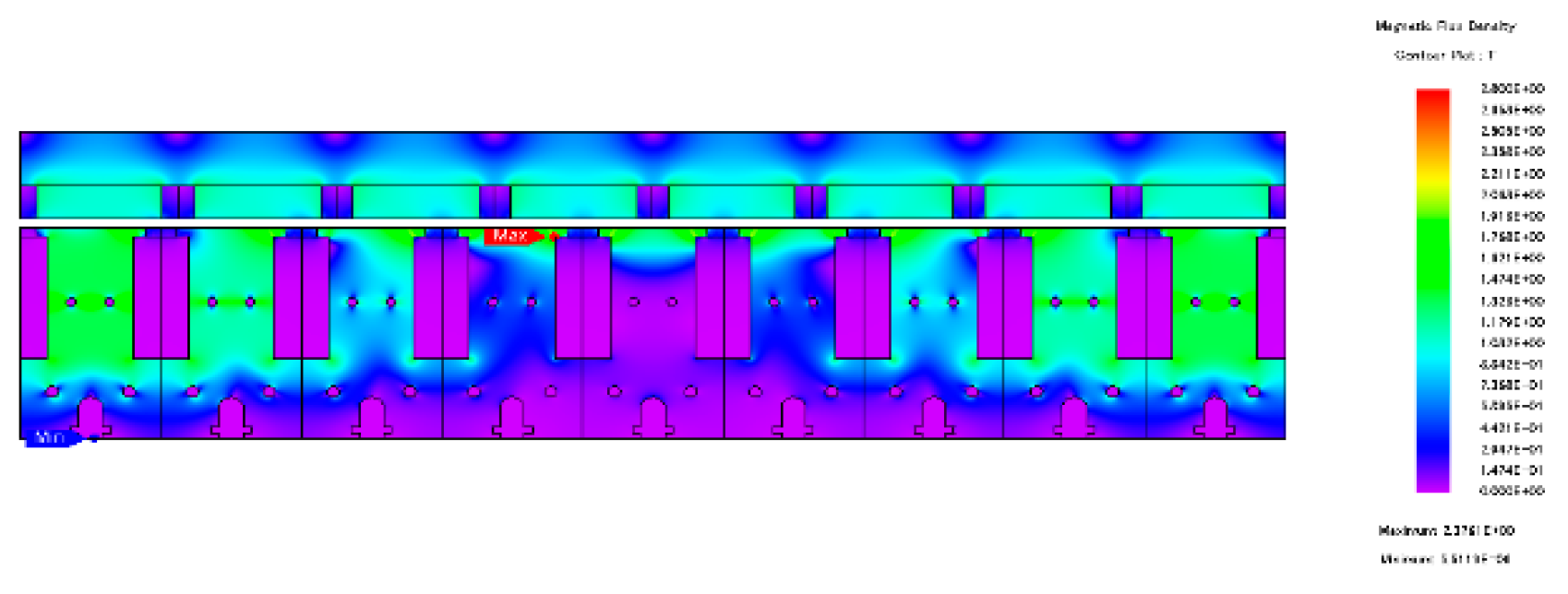

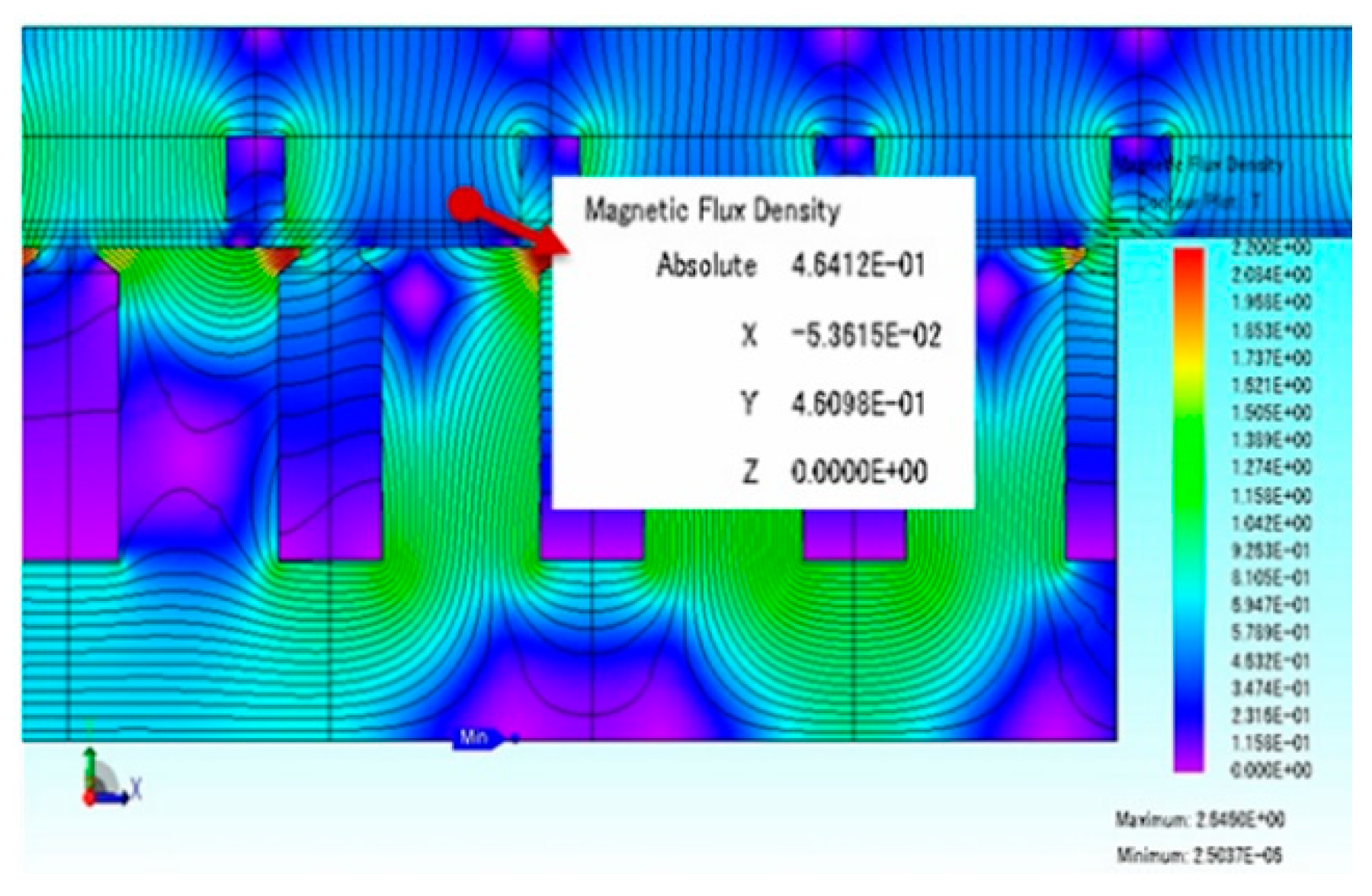

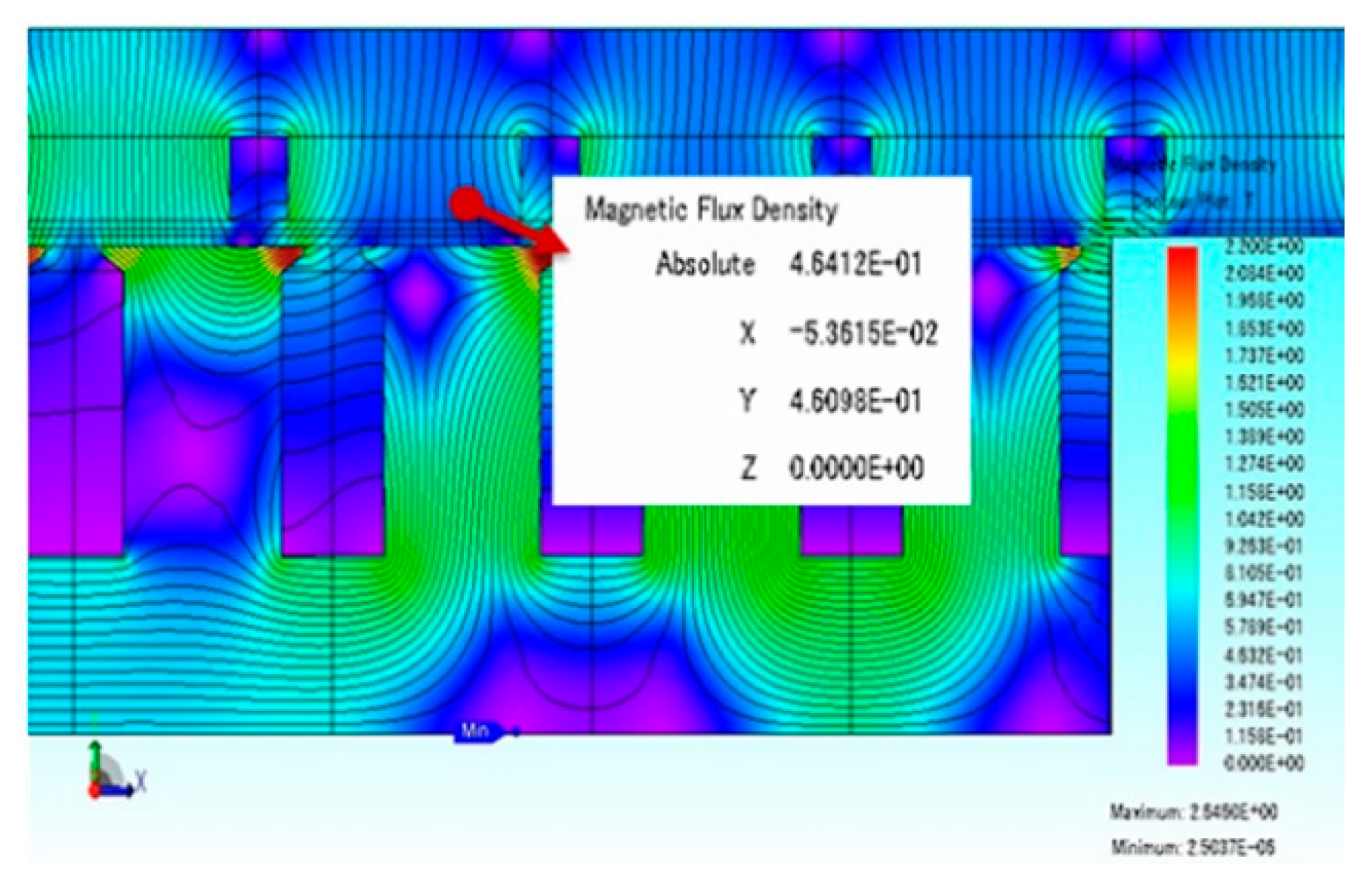

In this study, a quasi–3D analysis model is introduced, in which the AFPM machine is divided into five radial slices to approximate the behavior of a full 3D finite element model. Although a simplified 2D linear model can be derived by using the average values of the inner and outer radii, the analysis results obtained from such a model deviate significantly from those of a full 3D analysis. This discrepancy occurs because the flux density is not uniform due to leakage reactance components near the inner and outer radii of the generator, leading to differences from the actual machine characteristics.

To address this issue, correction factors based on the inner and outer radii are applied in the quasi–3D model, enabling more accurate prediction of machine performance. The validity of the proposed quasi–3D model is verified by comparing its analysis results with those obtained from the full 3D finite element model.

Figure 5 shows the basic concept of the quasi–3D model. In this approach, the 3D model of the machine is divided into multiple segments along the radial direction, from radius

to

. Each segmented region is then converted into an equivalent 2D model, and the overall characteristics are obtained by superimposing the analysis results of all segments.

Figure 6 presents the major variables used in the quasi–3D analysis model.

In this method, the circumferential length at each radial position is aligned with the direction of rotor motion, and the major stator and rotor dimensions are modeled as functions of the radius, . Each radial segment is then converted into a 2D model by accounting for the lamination length, . The number of slices, , used in the quasi–3D approach varies depending on the analysis objective. For example, if the magnet width, stator slot width, and slot pitch remain constant along the radial direction, the generator characteristics can be analyzed using a single slice. In such cases, the key parameters related to machine performance can be obtained using basic magnetic equivalent circuit methods.

Although the structural characteristics of AFPM machines typically require full 3D finite element analysis, the characteristics can still be approximately predicted using a single-slice 2D model based on the mean radius. However, when the slot opening ratio or other radial geometric variations differ among regions, the accuracy of a single-slice model decreases significantly. To address this limitation, a multi-slice approach with slices is employed, allowing each segment to be analyzed independently and combined to obtain an overall, more accurate representation of the machine behavior.