1. Introduction

The Dabuzi Cemetery is located on the terrace south of the Jing River (northeast of the Xianyang Plateau), characterized by thick loess deposits and flat, open terrain. Since 2020, the Shaanxi Academy of Archaeology had excavated and cleaned over 400 tombs, unearthing nearly 2,000 artifacts (groups) made of pottery, bronze, jade, iron and other materials, primarily dating to early Western Han Dynasty. Among these, Tomb M68, a vertical shaft tomb with an earthen chamber, standed out as the most well-preserved, yielding the largest quantity, richest variety, and most complete assemblage of artifacts discovered at the Dabuzi site. The tomb contained precious cultural relics, including gilded bronze objects, bronze vessels, jade artifacts, large painted pottery granaries, and sets of painted pottery figurines depicting music and dance performances. A jade seal from the burial chamber identified the tomb occupant as “Yao She.” Two bronze mirrors were found near the head of the deceased, one of which was attached to yellow-green fibrous sheets suspected to be paper (

Figure 1). However, whether this material represented to be paper from the Western Han Dynasty required systematic scientific analysis.

Currently, non-destructive and minimally invasive analytical techniques for paper artifacts were highly advanced, including atomic force microscopy (AFM), confocal Raman microscopy, X-ray photoelectron spectroscopy (XPS), fiber-optic reflectance spectroscopy (FORS), terahertz spectroscopy, micro-computed tomography (micro-CT), and Py-GC/MS. Functionally, these techniques could be categorized into imaging methods—such as optical, infrared, ultraviolet, X-ray, optical microscopy, SEM, and transmission electron microscopy (TEM)—which reveal microscopic structural information, and spectroscopic methods—including chromatography, mass spectrometry, nuclear magnetic resonance (NMR), X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD), X-ray fluorescence (XRF), molecular fluorescence spectroscopy, and Raman spectroscopy—which provide compositional insights [

1,

2,

3,

4,

5,

6].

In this study, we employed stereo microscopy (OM), SEM, FTIR and Py-GC/MS to analyze the yellow-green fibrous sheet wrapped around the bronze mirror from Tomb M68. A combined approach of morphological and compositional analysis was adopted: preliminary characterization of the sample’s physical properties was conducted through microscopic examination, followed by precise determination of its chemical composition using FTIR and Py-GC/MS. This research holded significant importance for advancing our understanding of ancient Chinese paper making technology.

2. Materials and Methods

2.1. Sampling

During the archaeological excavation, surface soil covering the bronze mirror and paper-like residue were carefully removed. A black-brown fibrous woven material was discovered adhered to the reverse side of the paper-like residue. Using tweezers, two samples were gently separated and collected, each of them was stored in individual specimen containers.

Figure 2.

The sampling picture.

Figure 2.

The sampling picture.

2.2. Instrumental Analysis

2.2.1. Morphological Observation

(1) Ultra-Depth Microscopy Observation

Portions of the yellow-green fibrous sheet and individual black-brown fibers

were extracted and examined under a Zeiss Smartzoom 5 ultra-depth microscope

(Germany). Microscopic images were captured at magnifications of 50×, 100×, 200×,

and 300×.

Biological Microscopy Observation

(2) Following the GB/T 4688-2002 standard, small quantities of the two aforementioned samples were placed in stoppered test tubes. A hydrogen peroxide-glacial acetic acid solution (1:1 by volume) was added, and the mixture was incubated in a 60°C water bath for 24 hours. The samples were then filtered through a 300-mesh chemical fiber bag and rinsed. A small amount of the treated sample was placed on a glass slide, stained with 1–2 drops of dye, and evenly dispersed using a dissecting needle. A coverslip was applied, and excess dye was gently absorbed by tilting the slide and using absorbent paper. Observations and imaging were performed under a Leica DM4000B biological microscope (Germany).

(3) SEM Observation

The structural features of the yellow-green fibers were examined using a JEOL JSM-7500F field-emission scanning electron microscope (Japan). Testing conditions included sample coating: ~10 nm of 99.99% gold;accelerating voltage: 5 kV;beam current: 1 × 10⁻¹⁰ A;working distance: 8 mm.

2.2.2. FTIR Spectroscopy Analysis

A Nicolet iN10 FT-IR microscope (equipped with a Nicolet iZ10™ FT-IR auxiliary optical stage) was used for infrared testing. A small amount of powdered sample was placed on a BaF2 window for transmission mode analysis, with the BaF2 window serving as the background. The MCT/A detector was employed under the following parameters: spectral range: 4000–650 cm-1; resolution: 4 cm-1; scans: 32.

2.2.3. Py-GC/MS Analysis

Instrumentation and conditions: Pyrolyzer was Frontier Lab PY-3030D (Japan) ;Gas Chromatograph/Mass Spectrometer was Shimadzu GC/MS-QP2010 Ultra; Column: DB-5MS (Frontier Lab; stationary phase: 5% diphenyl dimethyl polysiloxane), length: 30 m, inner diameter: 0.25 mm, film thickness: 0.25 μm. Pyrolysis conditions: temperature: 550°C, duration: 12 s, injector temperature: 280°C; GC/MS interface temperature: 300°C. Gas chromatography program: initial temperature: 50°C (hold for 5 min), ramp rate: 5°C/min to 300°C (hold for 10 min). MS parameters: carrier gas was high-purity helium, inlet pressure: 100 kPa, split ratio: 1:20. The electronic pressure control system operated in constant current mode, Electron ionization (EI) energy: 70 eV; Mass range (m/z): 30–750; Cycle time: 0.5 s;Spectral libraries: NIST17 and NIST17s.

Method: Approximately 0.1 mg of sample was weighed into a pyrolysis-specific sample cup, which was then loaded into the pyrolyzer’s auto-sampler. The Py-GC/MS system was initiated according to the predefined method.

3. Results and Discussion

3.1. Morphological Observation and Discussion

The microscopic morphology of the black-brown fibers and yellow-green fibrous sheet were shown in

Figure 3 and

Figure 4. As shown in

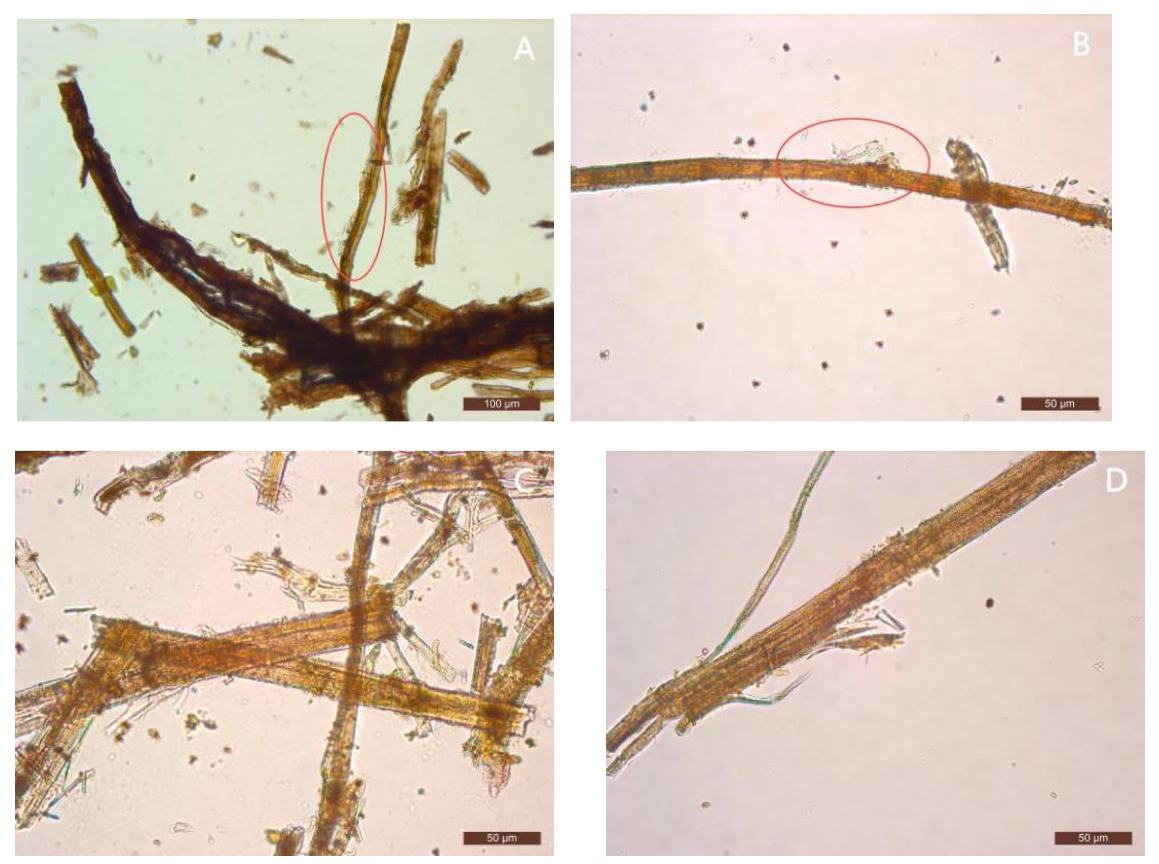

Figure 3A, individual black-brown fibers exhibited a smooth surface and intact edges, indicating excellent conservation state. After chemical treatment, the samples showed appearance of stiff slender filaments. Under biological microscopy, the fibers displayed an elongated morphology with rectangular vessel cells (

Figures 3B, 3C), consistent with the characteristic features of bamboo fibers. Combined with their archaeological context and the historical habit of bamboo mats for wrapping objects, the black-brown residue was identified as a woven bamboo artifact.

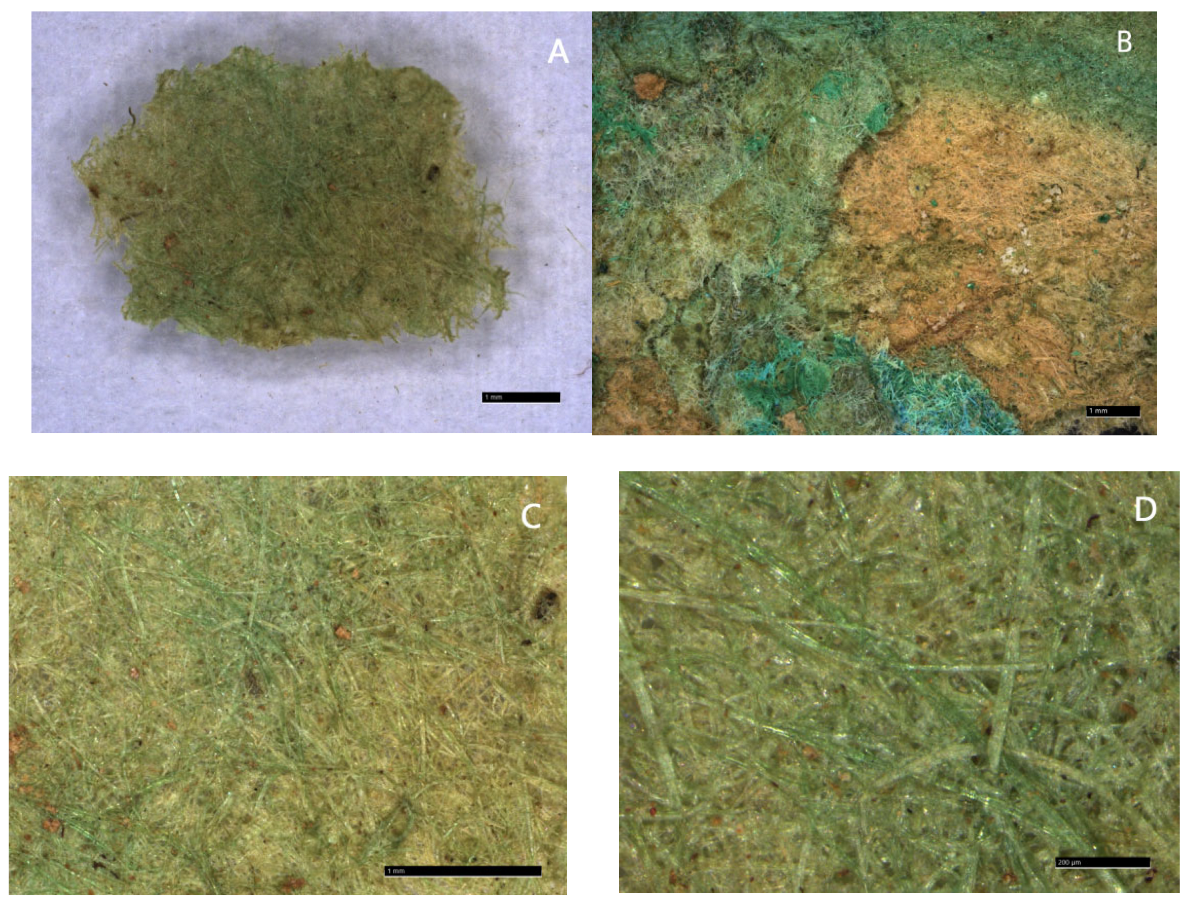

Initial ultra-depth microscopy observations (, A and B represented two samples) revealed that the sheet primarily exhibited a yellow-green hue interspersed with green and blue tones. The blue-green coloration was typical bronze corrosion products, while the yellow represented the natural color of the fibers. The variegated appearance was attributed to the prolonged contact between the hemp fibers and the bronze mirror. The yellow-green fibrous sheet displayed a rough intact surface with multiple fibers randomly interwoven (C, 4D). No laid lines—a hallmark of Eastern Han paper making techniques attributed to Cai Lun—were observed, ruling out the movable-mould paper making method.

After treatment, detailed biological microscopy analysis (

Figure 5) revealed slight fibrillation at the fiber edges (

Figure 5A, 5B), indicating the manual beating during processing. Additionally, transverse nodes and longitudinal striations, distinctive features of ramie or hemp fibers were observed on the cell walls of some fibers in the yellow-green sheet (

Figure 5C, 5D). These findings confirmed the presence of bast fibers in the sample, aligning with the compositional profile of Han Dynasty paper.

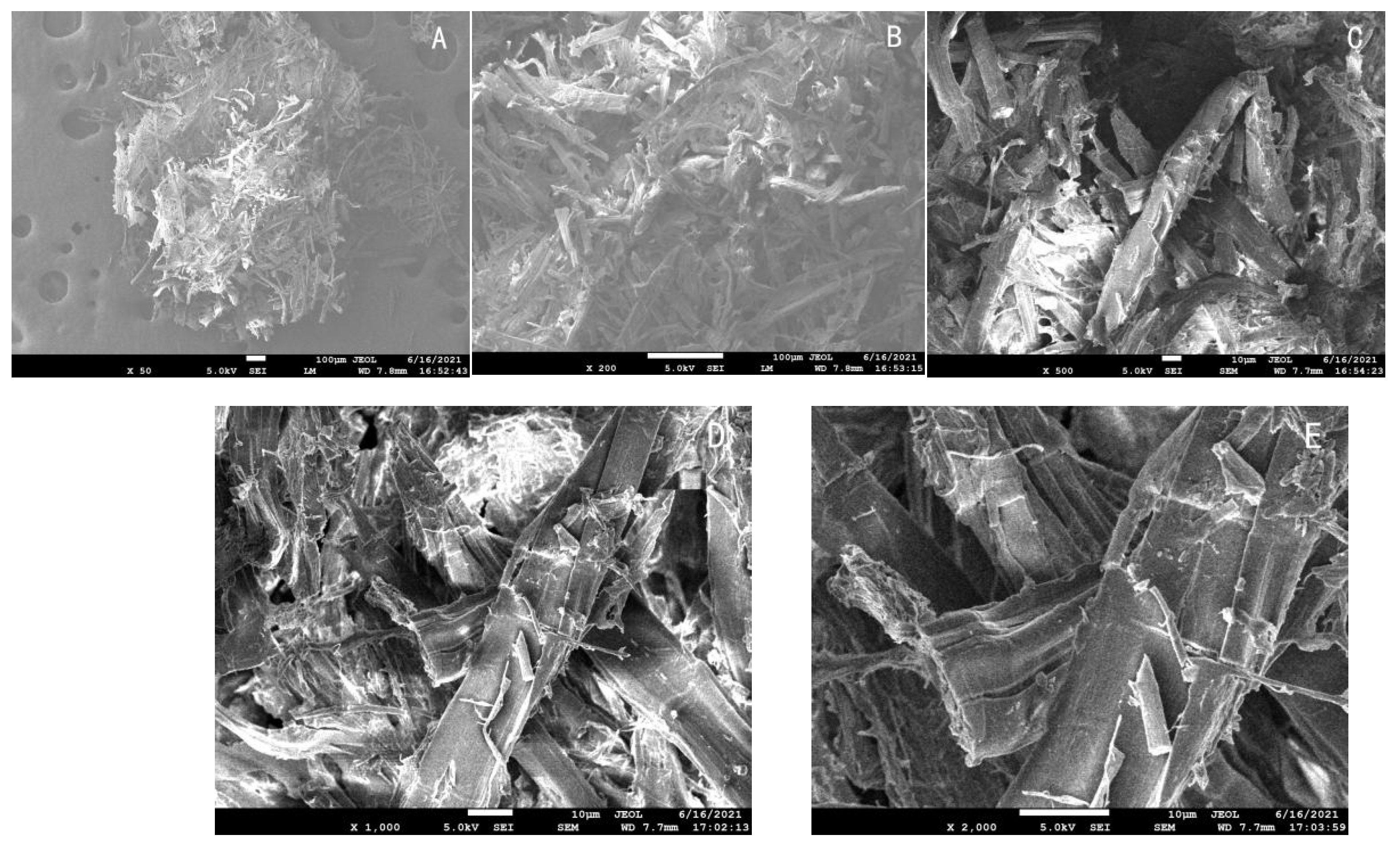

SEM images revealed that the yellow-green fibrous sheet consisted of numerous short fibers exhibiting a disordered and loosely aggregated state (

Figure 6A, 6B, 6C). This morphological arrangement markedly differed from the unidirectional natural structure characteristic of raw hemp fibers. Furthermore, distinct cutting marks were observed on the fibers (

Figure 6D, 6E), providing additional evidence that the fibrous sheet underwent intentional cutting during artificial processing.

Three distinct areas of the yellow-green fibrous sheet were examined and photographed using ultra-depth microscopy, 10 fiber diameters were measured at each location (

Table 1). Cross-sectional morphology was similarly documented at three representative locations, with thickness measured at 10 points per spot (

Table 2). The fibers showed an average diameter of 20.71 μm (range: 17.91-26.49 μm), closely matching published data for hemp paper fibers [

7]. Comparative measurements of hemp (20.87 μm), ramie (27.86 μm), and flax (17.06 μm) [

8] suggested the material was most likely hemp, given its predominant diameter around 20 μm. Notably, the sheet exhibited significant thickness variation (0.17-0.94 mm, average: 0.58 mm), indicating relatively primitive manufacturing techniques.

Based on the aforementioned morphological analysis, it could be concluded that the black-brown residue was bamboo-woven wrapping material, while the yellow-green fibrous flakes exhibited signs of artificial processing and might represent ancient paper that predated the use of movable-mould paper making method. Beyond these morphological characteristics, further compositional analysis were required to verify further findings.

3.2. FTIR Results and Discussion

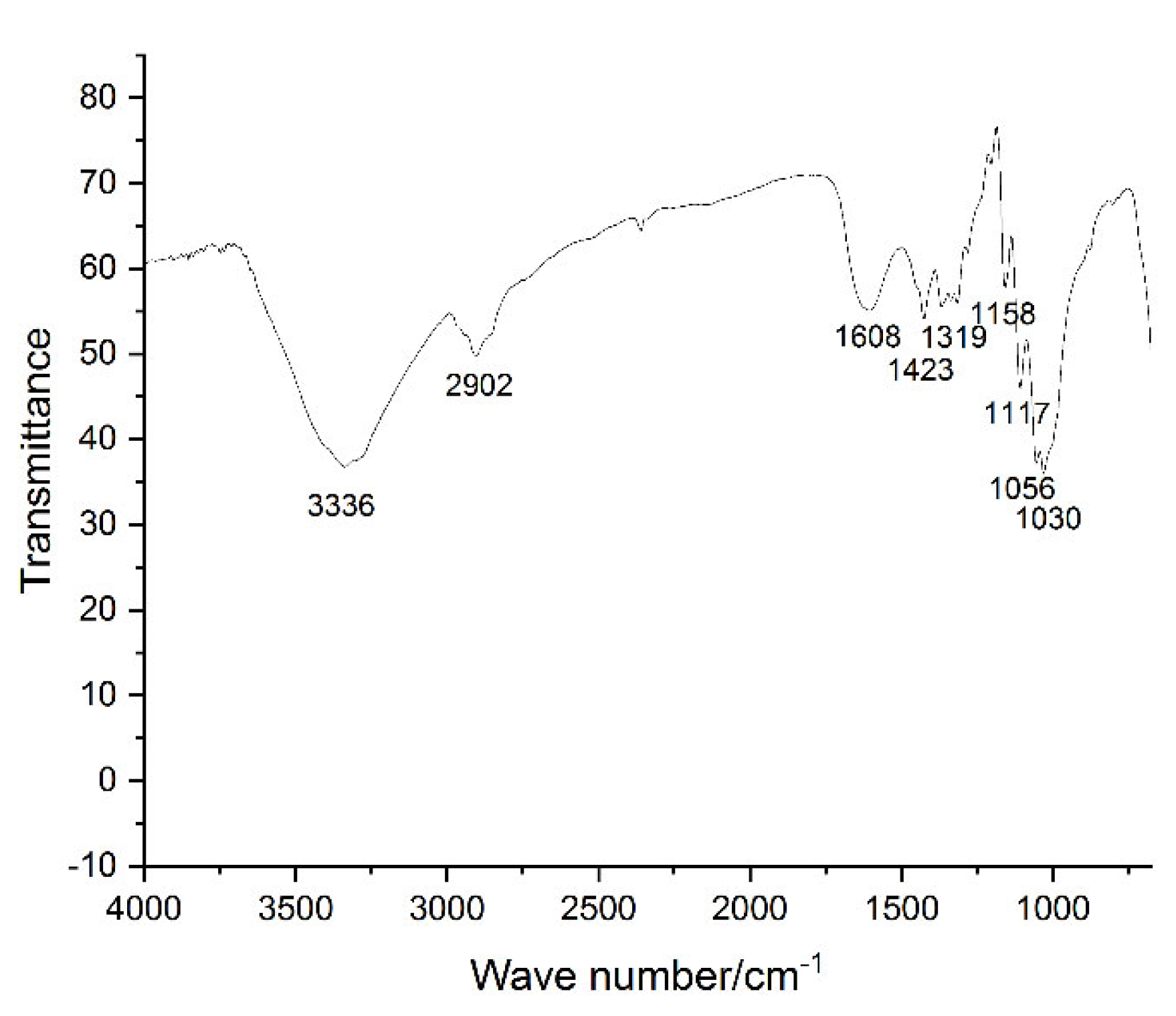

The infrared spectrum of the yellow-green fibrous sheet (

Figure 7) exhibited characteristic absorption bands that were consistent with typical paper spectra [

9]. The observed peaks included: 3336 cm-

1 (O-H stretching vibration of cellulose), 2902 cm

-1 (C-H stretching vibration of cellulose), 1608 cm

-1 (C=O stretching vibration of aromatic rings in lignin), 1423 cm

-1 (symmetric bending vibration of -CH

2 at the C-6 position of cellulose), 1319 cm

-1 (-CH

2 wagging vibration at the C-6 position of cellulose), 1158 cm

-1 (C-O-C glycosidic bridge stretching vibration of β-linkages in cellulose/hemicellulose), 1117 cm

-1 (ring stretching vibration of cellulose), 1056 cm

-1 (C-OH stretching vibration of cellulose), and 1030 cm

-1 (C-O stretching vibration at the C-6 position of cellulose) [

10]. These characteristic absorption peaks clearly demonstrated that the sheet was primarily composed of cellulose, hemicellulose and lignin, which matched the chemical composition of paper materials.

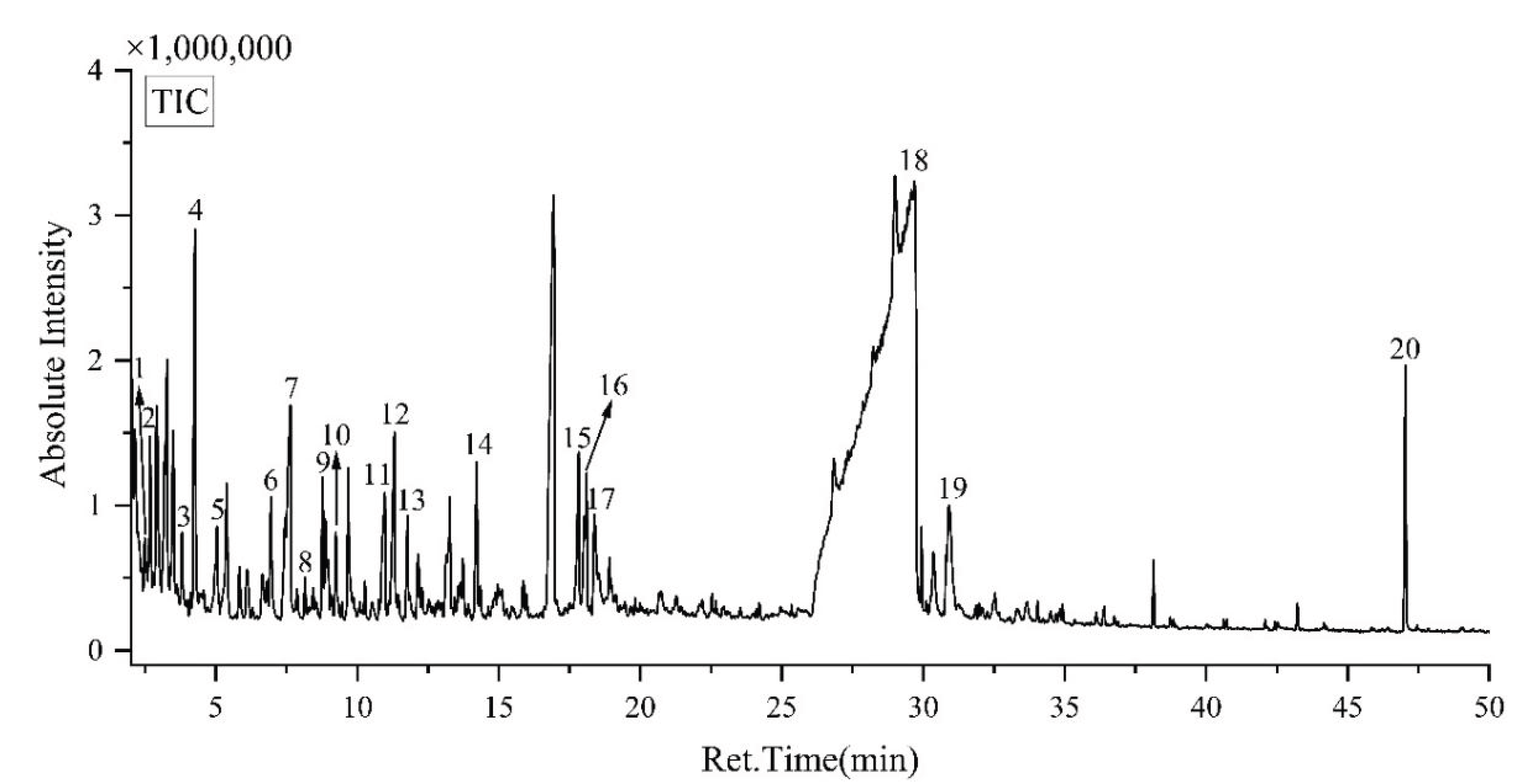

3.3. Pyrolysis-Gas Chromatography/Mass Spectrometry (Py-GC/MS) Results and Discussion

The Py-GC/MS analysis of the yellow-green fibrous sheet (

Figure 8 and

Table 3) revealed pyrolysis products could be categorized into four main groups:

Furans: 2,3-dihydro-3-methylfuran and 2-methylfuran;

Aldehydes and ketones: furfural, 2-butanone, 2(5H)-furanone, 2-methylcyclopentanone, 3-methyl-2,5-furandione, 5-methyl-2-furaldehyde, 2-hydroxy-3-methyl-2-cyclopenten-1-one, 3-methyl-1,2-cyclopentanedione, 4-methyl-5H-furan-2-one, and 5-hydroxymethylfurfural;

Phenolic compounds: maltol and 2-(2H-benzotriazol-2-yl)-4-(1,1,3,3-tetramethylbutyl)phenol;

Sugar derivatives: 1,4:3,6-dihydro-α-D-glucopyranose, 2,3-anhydro-D-galactose, 1,6-anhydro-β-D-glucopyranose, and 1,6-anhydro-β-D-glucofuranose.

Among these compounds, the sugar derivatives which were characteristic pyrolysis products of cellulose showed the highest relative abundance, indicating cellulose as the predominant component in the sample. The aldehydes and ketones were typical degradation products of both hemicellulose and cellulose, while the phenolic compounds mainly originated from lignin. These three components (cellulose, hemicellulose, and lignin) collectively represented the fundamental chemical constituents of paper materials. The Py-GC/MS results thus provided molecular-level confirmation of the sheet’s paper-like composition, corroborating the findings from other analytical techniques.

3.4. Discussion of the Sample

Archaeological evidence demonstrated that plant fiber-based hemp paper was already invented during the early Western Han Dynasty in China, as exemplified by several significant discoveries. The Baqiao paper, unearthed in Baqiao District, Xi’an in 1957, was made solely from hemp bast fibers and appeared as fragmented light yellow sheets upon excavation, exhibiting uneven fiber distribution while maintaining reasonable structural integrity. Another notable finding, the Zhongyan paper discovered in 1978 in Fufeng County, Shaanxi Province, displayed a rough surface with wrinkles and variable fiber thickness (averaging 0.277 mm), showing clear signs of mechanical beating through characteristic fiber fibrillation. In neighboring Gansu Province, important discoveries included the Xuanquanzhi paper, predominantly yellow uneven rough sheets with chaotic fiber arrangements illustrating low-beating-degree pulp, and the Jinguan paper which was thick, uneven sheets with even bast fiber resembling Zhongyan paper in texture.

These early papers consistently shared three distinctive features characteristic of the fixed-mould paper making technique: significant thickness, absence of laid lines, and rough surfaces with disordered fiber orientation. Professor Li Xiaocen’s research revealed that the fixed-mould paper making method utilized raw materials such as hemp, mulberry bark, and paper mulberry bark. These materials underwent cleaning and were then boiled in iron pots with stove ash for alkalization treatment, followed by pulping using wooden mallets or stones. The processed pulp was poured onto a fixed screen placed horizontally on water’s surface, with both screen and paper being sun-dried together before paper separation. This method typically produced thick paper without the characteristic screen marks of bamboo-screen paper making, and exhibited a rough surface texture due to the absence of pressing. Microscopic examination revealed randomly oriented fibers resulting from the top-down pouring process. In the 1970s, Taiwanese paper history scholar Chen Dachuan identified two distinct paper making techniques: the fixed-mould paper making method and the movable-mould paper making method through investigations of traditional paper making in Southeast Asia, Professor Li’s extensive field research and laboratory experiments subsequently established these as two separate paper making systems preserved in mainland China, with historical origins tracing to the Western Han Dynasty for the fixed-mould paper making method and the Eastern Han Dynasty for the movable-mould paper making method.Contemporary practice showed that while most Han Chinese and ethnic minority groups employed the movable-mould paper making method, several minority communities including the Dai and Naxi in Yunnan, Uyghurs in Xinjiang, Tibetans in Sichuan and Tibet, and the Dong in Guizhou provinces continued to preserve the fixed-mould paper making method. The fixed-mould paper making’s production efficiency remained limited by its “one-screen-one-sheet” constraint, requiring complete drying before sheet removal. In contrast, the movable-mould paper making’s multi-step process (including peeling, retting, boiling, pounding, and bleaching) and “one-screen-multiple-sheets” approach significantly enhanced productivity, leading to its widespread adoption as recorded in historical texts. This technically advanced method had maintained continuous production for nearly two millennia up to the present day.

Furthermore, early Western Han Dynasty paper may not have been primarily used for writing purposes. As recorded in the Hanshu·Biography of Empress Zhao of Xiaocheng: “In the box were two packets wrapped in ‘Heti,’ containing a written secret order.” This described how Consort Zhao used “Heti” (thin small paper) to wrap two doses of poison while also inscribing a secret command in her attempt to poison Cao Weineng, a palace maid favored by Emperor Cheng of Han. The commentator Ying Shao noted: “Heti refered to thin, small pieces of paper.”

Based on the experimental results from sections 2.1 to 2.3, the yellowish-green fibrous sheet (M68) discussed in this study exhibited several distinctive characteristics: it owned uneven thickness (averages 0.58 mm) which was twice that of Zhongyan paper (0.277 mm) produced by the fix-mould making method; the surface was rough with chaotic, disordered fiber distribution and showed cutting marks; furthermore, no screen marks were observed. These features were entirely consistent with the characteristics of paper made by the fix-mould making method. Additionally, some fibers displayed distinct transverse nodes and the characteristic longitudinal striations of hemp fibers, with the average diameter suggesting Cannabis sativa (hemp) as the probable material. FTIR and Py-GC/MS analyse confirmed the main components as cellulose, hemicellulose, and lignin. As no writing appeared on its surface, it served solely as wrapping material for a bronze mirror. In conclusion, we preliminarily identified the yellowish-green fibrous sheet unearthed from the Han Dynasty tomb at Dabuzi, Xi’an, Shaanxi Province as hemp paper manufactured during the Western Han Dynasty using the fix-mould making method, specifically for wrapping purposes.

4. Conclusions

(1) Combined observations of ultra-depth microscopy, biological microscopy, and scanning electron microscopy revealed that the yellowish-green sheet unearthed from the Han Dynasty tomb at Dabuzi, Xi’an, Shaanxi Province exhibited a rough surface with randomly distributed fibers, showing evidence of shearing and slight fibrillation which were clear indications of manual beating and cutting processes during production. Its considerable and uneven thickness, along with the absence of screen marks on the surface, were characteristic features consistent with the fix-mould paper making technique.

(2) Microscopic examination identified distinct transverse nodes on some fiber cell walls, along with longitudinal striations characteristic of either ramie or hemp fibers. With an average fiber diameter of 20.71 μm, the material was most probably hemp (Cannabis sativa). Complementary analyses using FTIR and Py-GC/MS confirmed the sheet’s composition, cellulose, hemicellulose, and lignin, as the principal components of paper.

(3) Comprehensive analysis lead to the preliminary conclusion that this yellowish-green fibrous sheet represented hemp paper residue manufactured by the fix-mould making method. Dating based on the tomb’s chronology placed it in the Western Han Dynasty (206 BCE-9 CE). The absence of surface inscriptions suggested its primary function was wrapping material for bronze mirrors. This discovery and its subsequent study hold significant implications for understanding the origins and developmental trajectory of ancient paper making technology.

References

- Cao, X. J. Application of Modern Analysis and Detecting Technology in the Research of Paper Cultural Relics Protection. Paper and Papermaking. 2022, 41(6), 25. [Google Scholar]

- Yao, J. J.; Yan, Y. E.; Zhang, R. H.; Luo, C.; Liu, J.; Bi, N.; Tang, Y. Spectroscopic detection and Analysis for Micro Structure of Aged Traditional Handmade Paper. Spectroscopy and Spectral Analysis. 2021, 41(5), 1559. [Google Scholar]

- Qu, Y. J.; Gu, A.; Zhao, L. H.; Lei, Y. Research on Microscopic Non-destructive In-situ Analysis Methods for Paper-based Cultural Relics. China Cultural Heritage Scientific Research. 2023, (2), 73. [Google Scholar]

- Zhang, J. F.; Xin, M. M.; Wen, X. D.; Zhang Q., W. Non-destructive and micro-destructive analysis technologies for paper cultural relics and review on their applications. Sciences of Conservation and Archaeology. 2024, 36(4), 180–188. [Google Scholar]

- Wang, K. Q.; Zhang, P.; Zhou, Y.; Cha, R. T. Research Progress of Spectroscopy in Scientific Analysis of Paper Cultural Relics. Transactions of China Pulp and Paper. 2023, 28(2), 120–126. [Google Scholar]

- Yan, C. S.; Huang, C.; Han, S. T.; Han, X. L.; Ying, C. N.; Du, Y. D. Review on scientific detection technologies for ancient paper relics. Chinese Optics. 2020, 13(5), 936–964. [Google Scholar]

- Li, X. C.; Wang, H.; He, C. H.

- Unearthed in Xuanquan Site,Gansu. Studies in the History of Natural Sciences. 2012, 31(3), 277.

- Zhao, X. X.; Wang, Y. M.; Zhang, S. Q.; Huang, H. G.; Huang, J. P. Research on Identification of Flax, Ramie and Hemp Fiber. China Fiber Inspection.

- 65-67.

- Yan, H. N.; Zhao, F.; Xing, M. Y.; Wu, Z.Y. Research on Identification of Two Historical Hemp Fibers. Journal of Zhejiang Sci-Tech University (Natural Sciences).

- 2017, 37(2), 185-189.

- Lv, S. X. A Study on the Non-Destructive Method of Identifying Chinese Traditional Handmade Paper With Attenuated Total Reflection Fourier Transform Infrared Spectroscopy. Spectroscopy and Spectral Analysis. 2024, 44(9), 2450–2458. [Google Scholar]

- Zhao, H. S. Technology and Science in Chinese History - From Ancient Times to the Present Day. Beijing: People’s University of China Press, 1997.

- Liu, R. Q.; Hu, Y. X. Preliminary Study of Ancient Paper in China. Cultural Relics. 1976, (5), 74. [Google Scholar]

- Li, X. C. Preliminary Study of Han Dynasty Paper Unearthed in Fufeng, Shaanxi. Cultural Relics. 2012, (7), 93. [Google Scholar]

- Li, X. C. Study on the Unearth Ancient Paper from Xuanquan Site of Han Dynasty in Gasu. Journal of Guangxi Minzu University (Natural Science Edition).

- Li, X. C. The Investigation and Analysis of Ancient Paper of West-Han Dynasty. Journal of Guangxi Minzu University (Natural Science Edition).

- Li, X. C. Fixed-mould paper making method. Encyclopedia of China (Third Edition Online). 2024.

- Li, X. C. Fixed-mould Papermaking Method and Movable-mould Papermaking Method: Two Different Papermaking Method Systems Conserved in Mainland China. Journal of Dialectics of Nature. 2011, 33(5), 76. [Google Scholar]

- Li, X. C.; Wang, S. The Application of Ethnic Investigation in Archaeology. Journal of Guangxi Minzu University (Philosophy and Social Science Edition).

- 2018, 40(2), 10.

- Yang, D. C.; Yang, W.

- Technological Improvements. Journal of Hunan City University. 2003, (2), 79.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).