Submitted:

11 August 2025

Posted:

12 August 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Basic Theory of Aeroacoustic Characteristics of the Ducted Fan

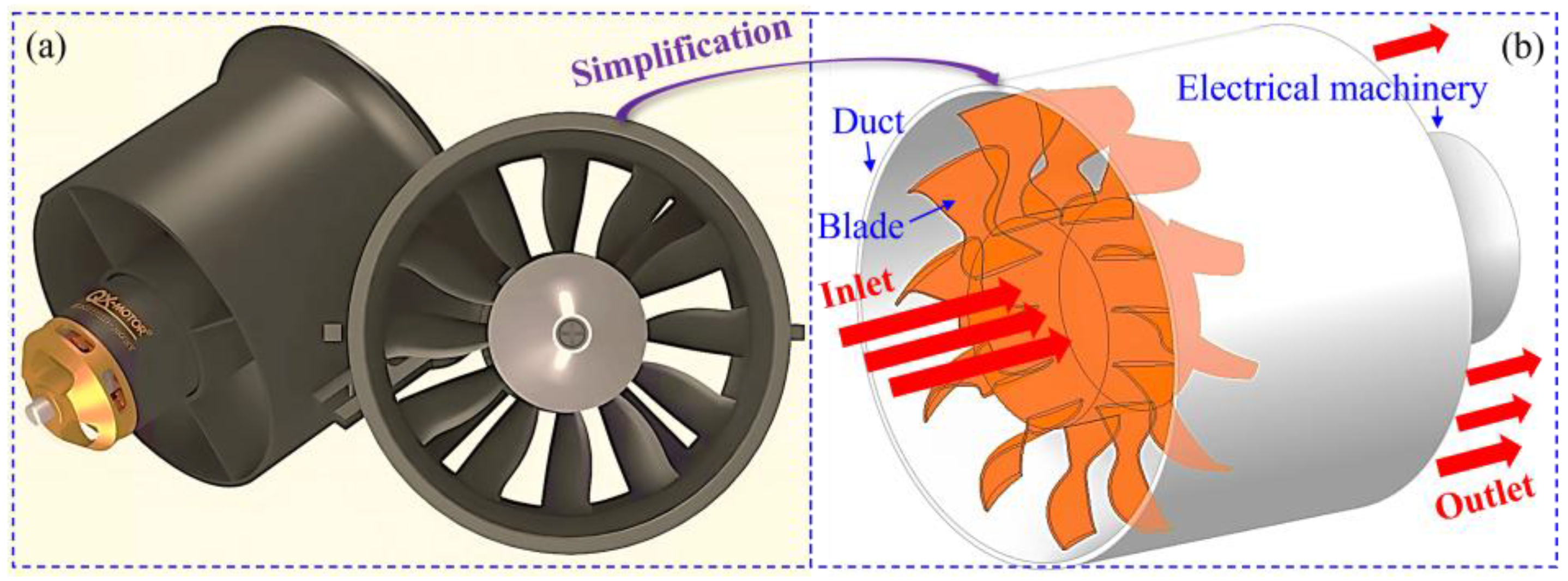

2.1. Working Principle and Governing Equation

2.2. Noise Generation Mechanism of the Integral Ducted Fan

2.3. Evaluation Parameters of Ducted Fan Noise Level

3. Numerical Simulation of Aerodynamic Noise of Ducted Fan

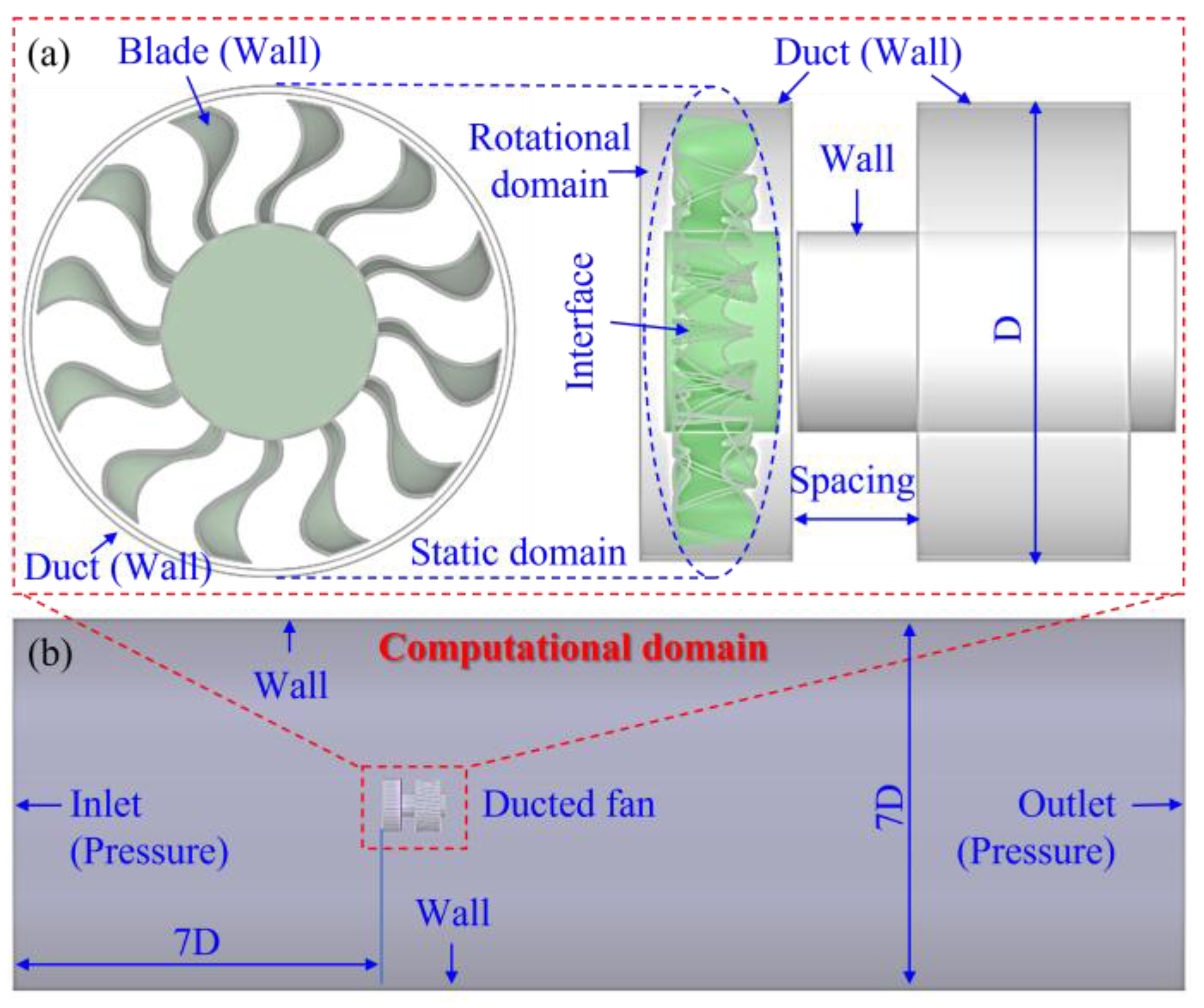

3.1. Segmented Ducted Fan and Boundary Condition Setting

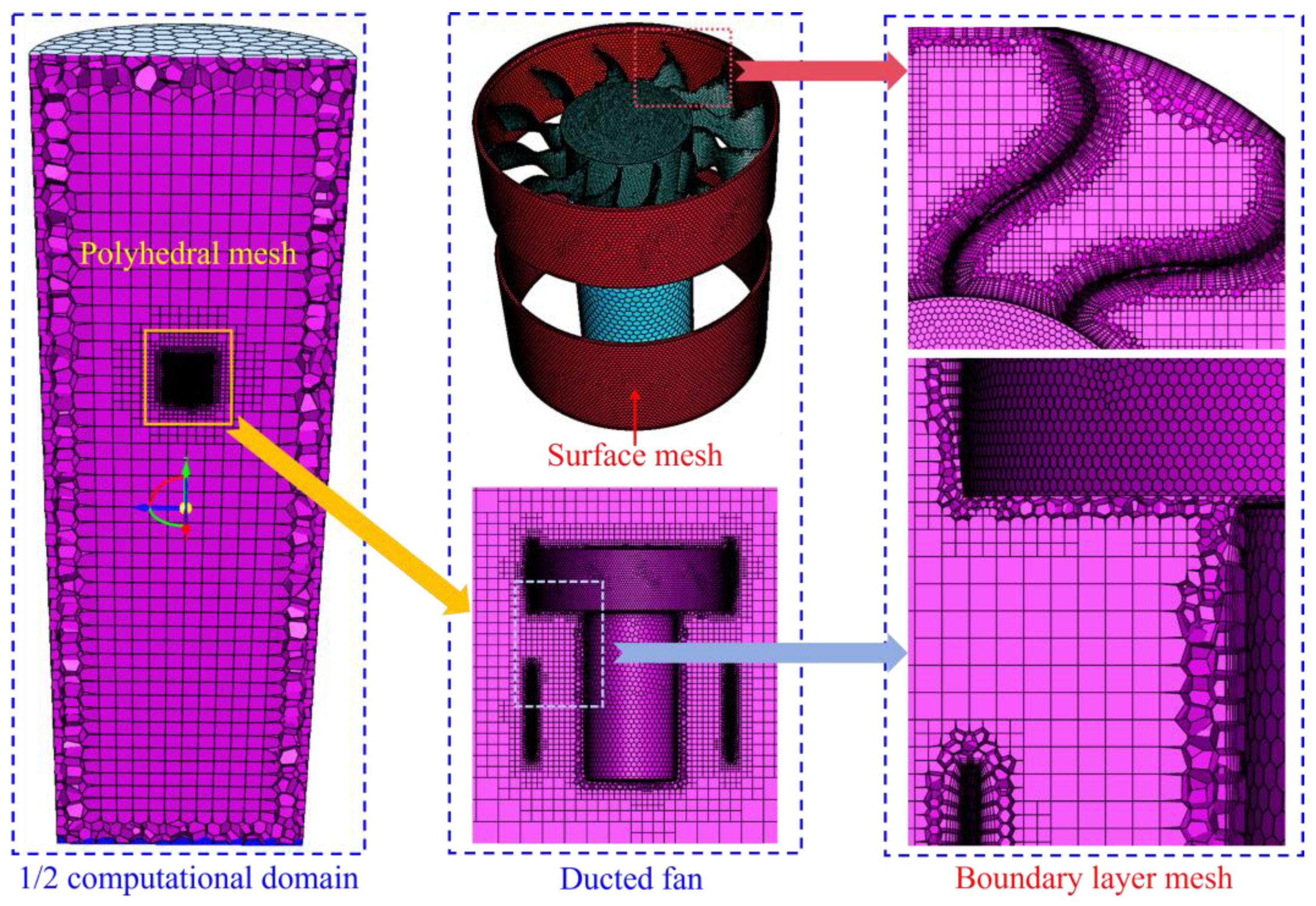

3.2. Grid Generation Strategy and Simulation Settings of the Computing Domain

3.3. Reliability Verification of the CFD Finite Element Model

4. Results and Discussion

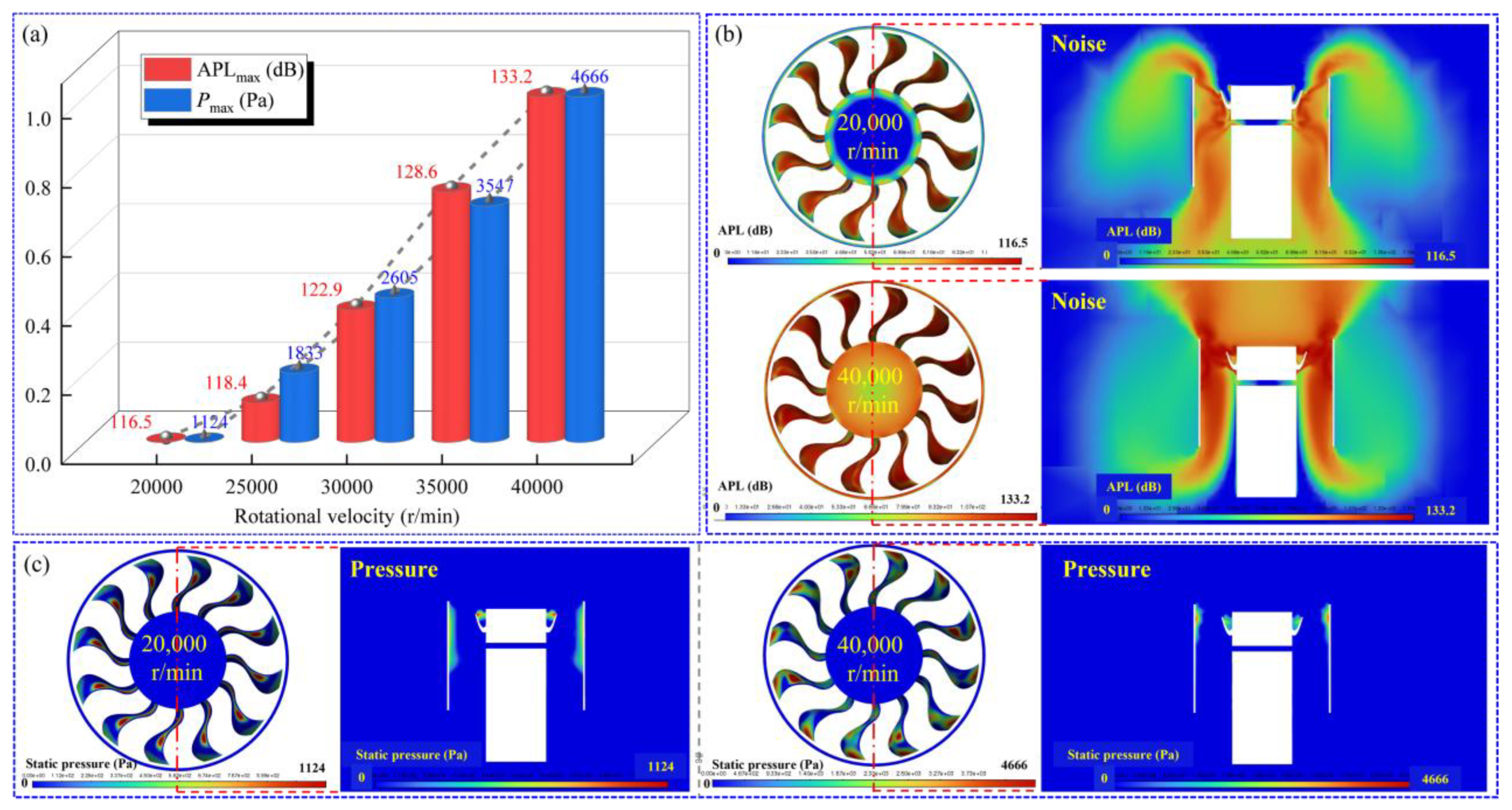

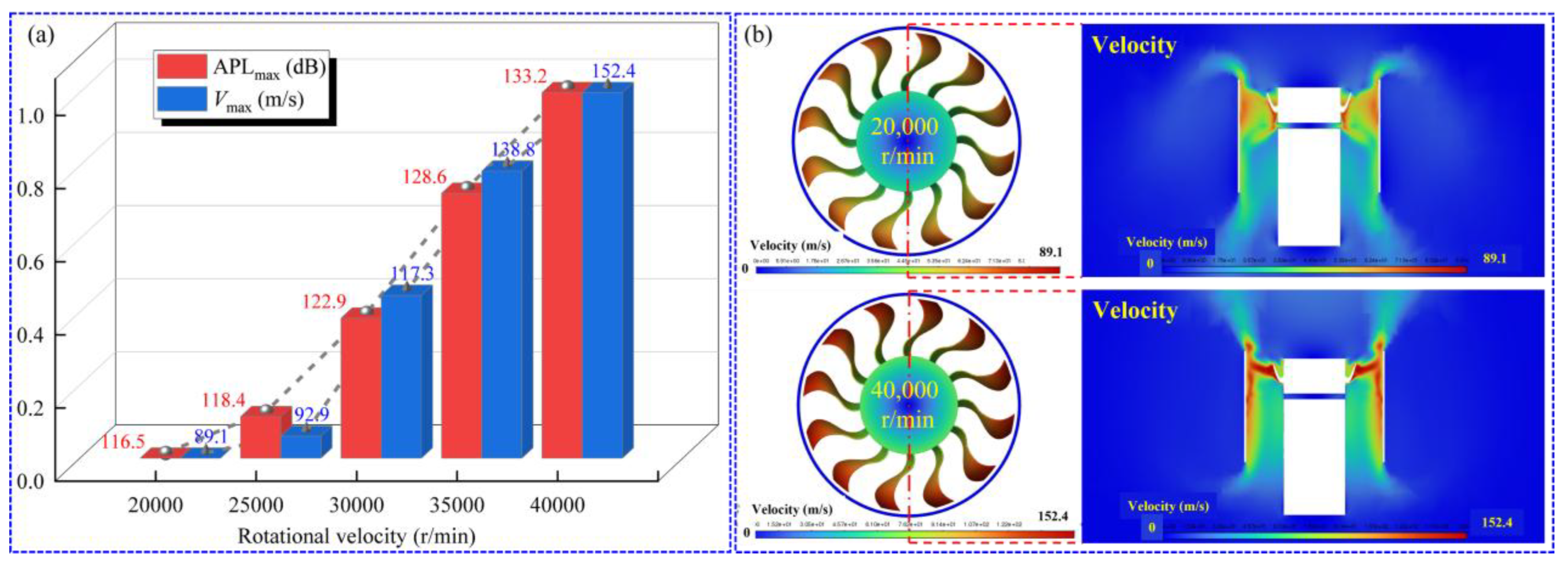

4.1. Influence of Fan Speed on the Aeroacoustic Performance of an Integral Ducted Fan

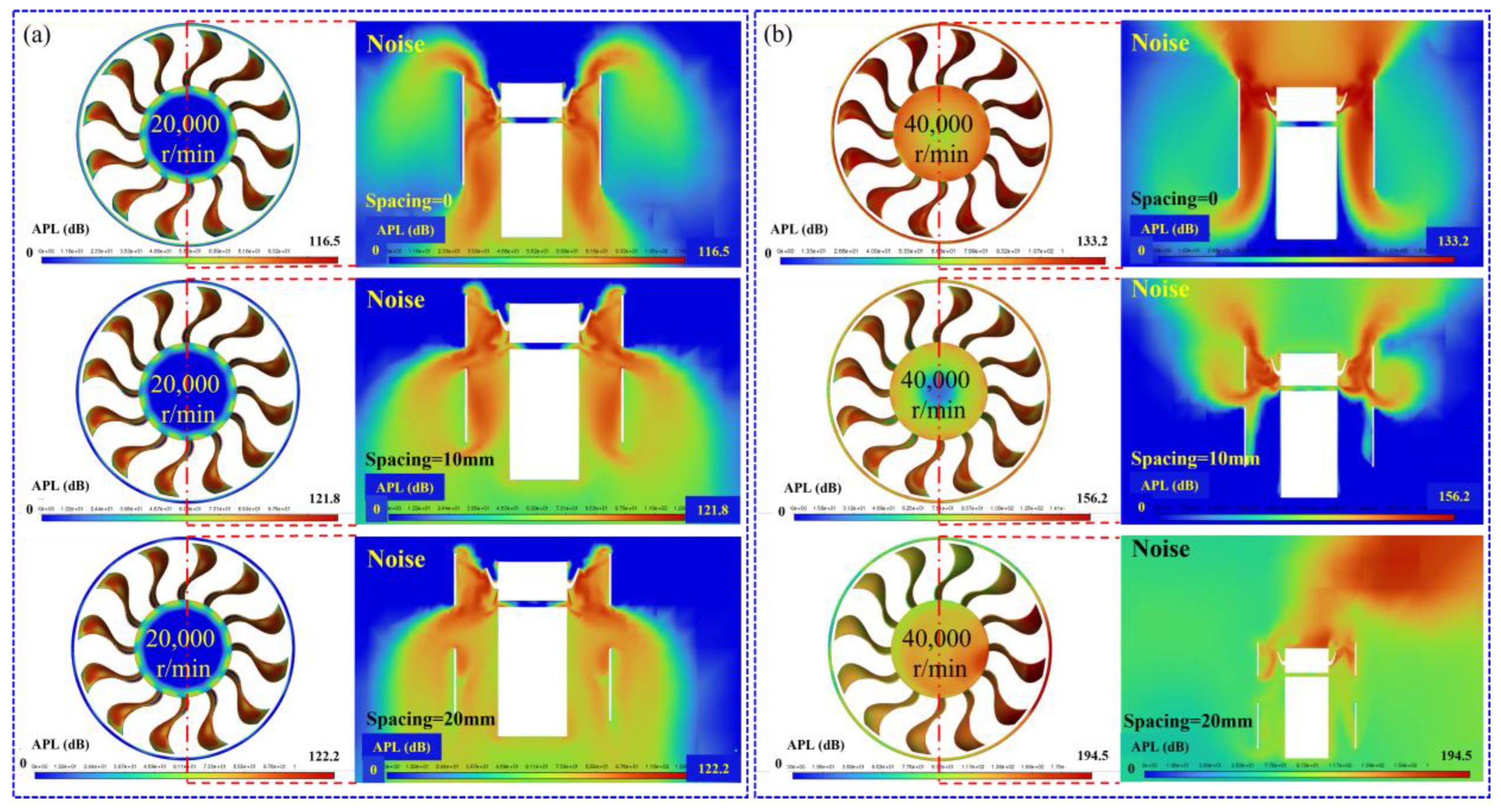

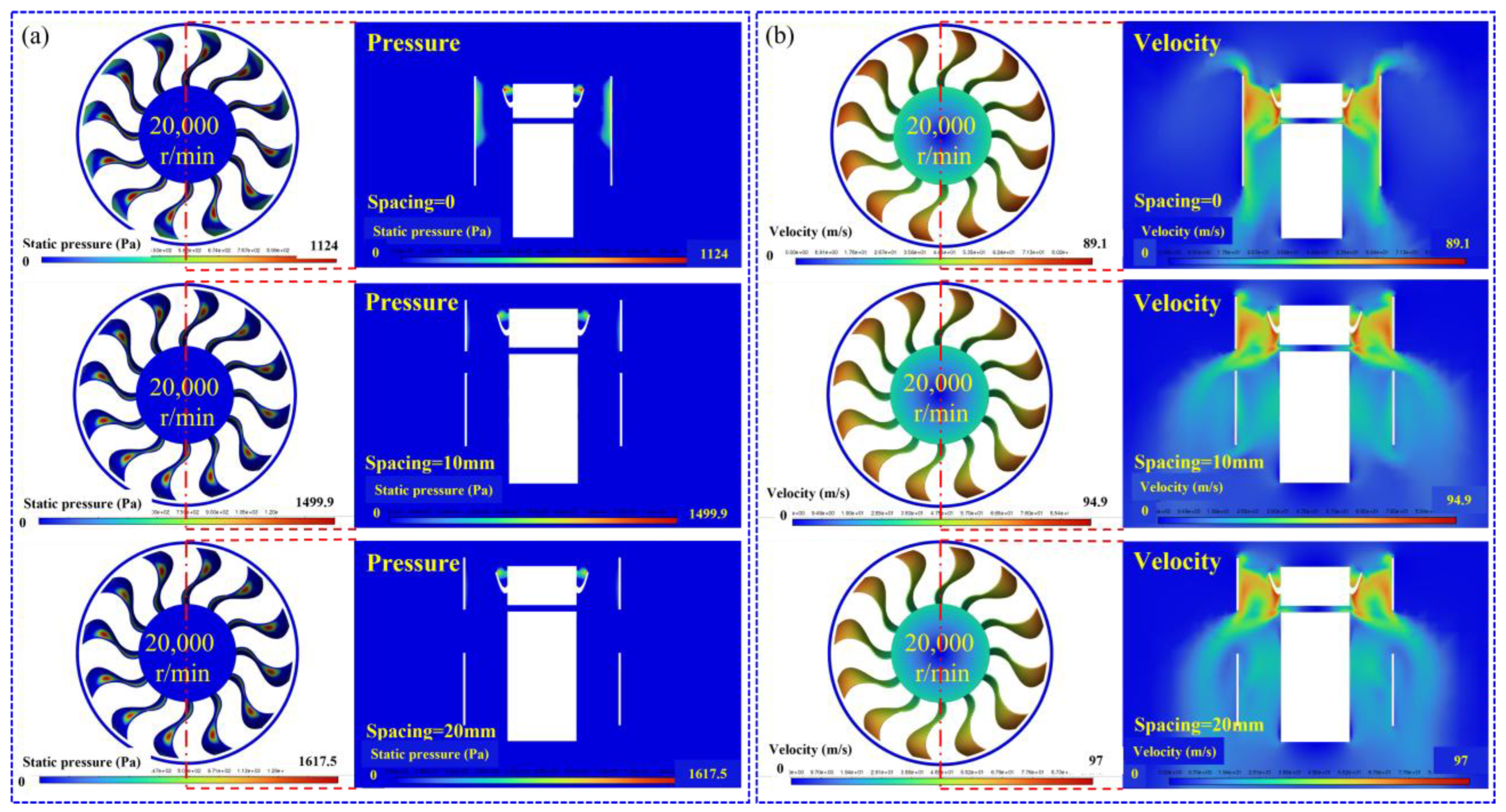

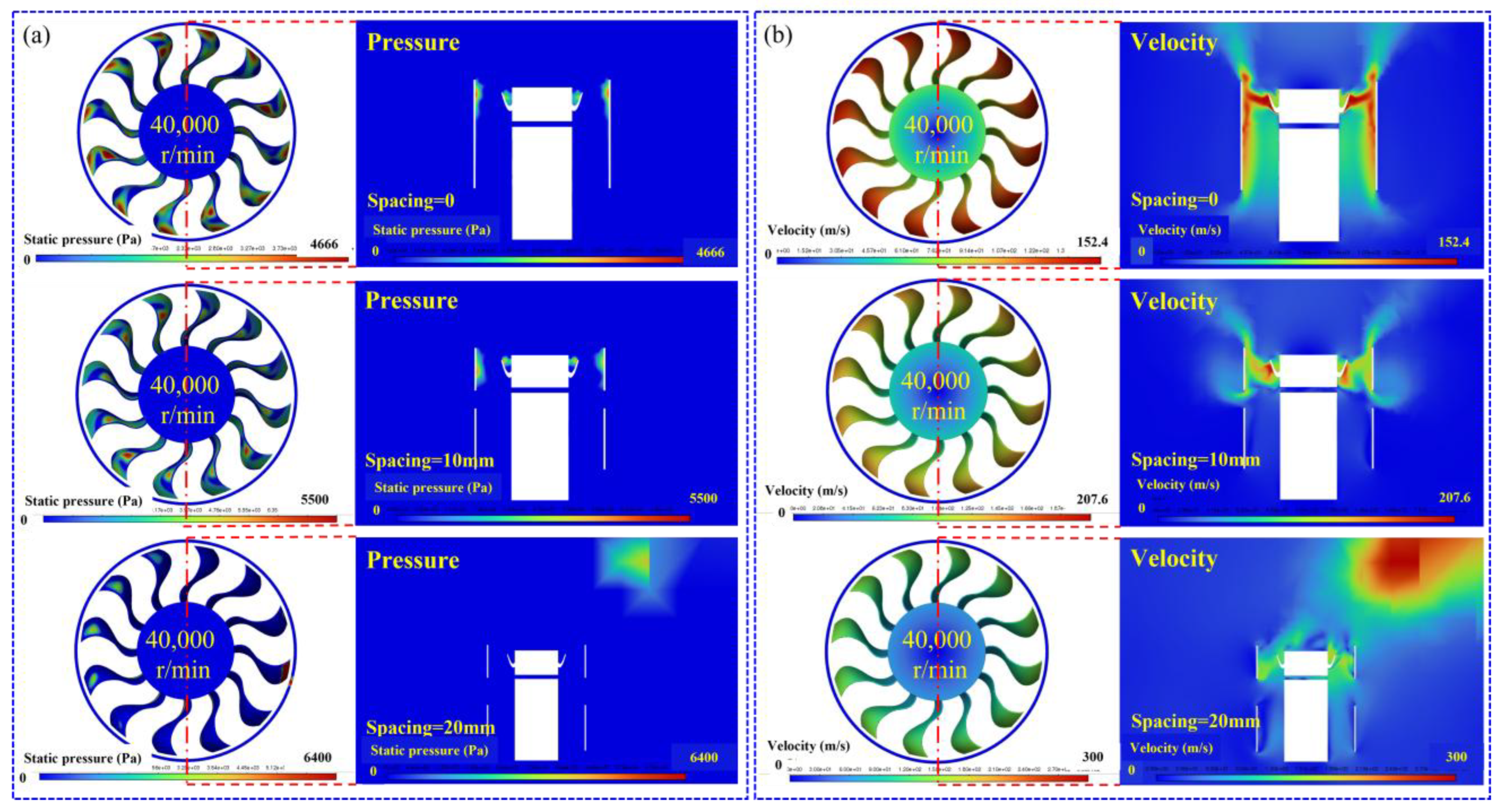

4.2. Effect of Spacing on the Aeroacoustic Performance of a Segmented Ducted Fan

4.2.1. Analysis of the Physical Mechanism of the Flow Field-Sound Field Correlation

4.2.2. Three-Stage Chain Generation Mechanism of Segmented Ducted Fan Noise

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Luo, Y.W.; Ai, T.F.; He, Y.H.; Xu, B.; Qian, Y.P.; Zhang, Y.J. Numerical analysis of wind effects on aerodynamic characteristics of a ducted fan. Chin. J. Aeronaut. 2024, 37, 263-280. [CrossRef]

- Sun, Y.H.; Kang, G.W. Simulation and analysis of aerodynamic noise of the ducted fan based on FW-H model. Green Energy Aviation 2023, 1, 75-81. https://kns.cnki.net/kcms2/article/abstract?v=hx6LgM6qJjuwn0mLsiiQvj1fwzIsO2kL-o-KjiAf3j658R9KIhw-PB8VMSmRqy15rTMWc4fiIaZUBSor3xxiSMsvQXnJdAWIu0Gdf_VZBvNIK-s2c4Gr1gCfBaoToNrFQpenK5wxH3Oju1FRkXVCbXgquZeI-pKoQ0LWQaeU7rTaWLfo7I_QNA==&uniplatform=NZKPT&language=CHS.

- Luo, Y.W.; Ai, T.F.; He, Y.H.; Xu, B.; Qian, Y.P.; Zhang, Y.J. Numerical investigation on unsteady characteristics of ducted fans in ground effect. Chin. J. Aeronaut. 2023, 36, 79-95. [CrossRef]

- Luo, Y.W.; He, Y.H.; Ai, T.F.; Xu, B.; Qian, Y.P.; Zhang, Y.J. Numerical study on dynamic performance of a ducted fan moving in proximity to ground and ceiling. Phys. Fluids 2024, 36, 115151. [CrossRef]

- Luo, Y.W.; He, Y.H.; Xu, B.; Ai, T.F.; Qian, Y.P.; Zhang, Y.J. Numerical simulation and analysis of a ducted-fan drone hovering in confined environments. Adv. Aerodynam. 2024, 6, 18. [CrossRef]

- Li, Z.Y.; Wu, J.H.; Pei, B.R.; Chen, L.; Zou, Z.P.; Lin, H.Y. Numerical investigation on aerodynamic characteristics of equivalent distributed ducted propellers. Chin. J. Aeronaut. 2025, 38, 103487. [CrossRef]

- Wang, J.J.; Chen, R.L.; Lu, J.X. Experimental and numerical studies on the effect of airflow separation suppression on aerodynamic performance of a ducted coaxial propeller in hovering. Aerospace 2023, 10, 11. [CrossRef]

- Wei, W.; Wei, S.Y.; Ke, Z.F.; Guo, M.; Shu, Y.J.; Meng, Q.K.; Jia, L.L.; Zhang, M.F.; Han, S.R. Optimizing the aerodynamic performance of a duct-rotor system for drones: A comprehensive study on the coupled parameters. Drones 2025, 9, 45. [CrossRef]

- Liu, Q.; Liu, H.R.; Wang, Y.G.; Shang, X.; Wang, S.W. Acoustic mechanisms and tonal noise control of contra-rotating ducted fan by rotating speed regulation. Appl. Acoust. 2024, 219, 109917. [CrossRef]

- Wu, W.Q.; Zhang, Y.B.; Xu, L.; Zhao, L.X.; Chen, T.G. Design and evaluation of an acoustic metamaterial for ducted fan noise control. Appl. Acoust. 2025, 233, 110612. [CrossRef]

- Sun, Z.H.; Tian, J.; Zhang, T.; Du, Z.H.; Ouyang, H. Cooling fan aerodynamic noise reduction with short inlet duct and its applicability. Int. J. Refrig. 2023, 148, 117-130. [CrossRef]

- Wang, R.C.; Ma, Z.K.; Huang, X. Experimental investigation of ducted fan noise control by turbulence grids insertion between propellers and struts. Phys. Fluids 2024, 36, 085109. [CrossRef]

- Lu, H.B.; Xiao, Y.H.; Huang, Y.T.; Liu, Z.G.; Yuan, Y. Zhou, P.L.; Yang, G.H. Simulation research on aerodynamic noise characteristics of a compressor under different working conditions. J. Acoust. Soc. Am. 2024, 155, 2517-2537. [CrossRef]

- Lendvai, B.; Benedek, T. Experimental and numerical investigation of the blade tip-related aeroacoustic sound source mechanisms of a ducted low-speed axial flow fan. Appl. Acoust. 2023, 215, 109705. [CrossRef]

- Hickey, J.; Zhao, W.G.; Persoons, T. Experimental and numerical investigation of winglet designs for optimized performance of small axial fans. Appl. Acoust. 2025, 231, 110448. [CrossRef]

- Lewis, D.; Moreau, S.; Jacob, M.C.; Sanjosé, M. Large Eddy Simulation of the ACAT1 fan stage for broadband noise prediction. J. Sound Vibr. 2023, 565, 117888. [CrossRef]

- Kusuda, S.; Yamasaki, N.; Inoue, C.; Namba, M. Aircraft engine fan tone noise due to back-pressure distortion caused by a downstream pylon under high-speed conditions. J. Sound Vibr. 2024, 572, 118163. [CrossRef]

- Hirono, F.C.; Torija, A.J.; Grimshaw, S.D.; Cousins, D.; Farman, J.; Taylor, J.V. Aerodynamic and aeroacoustic design of electric ducted fans. Aerosp. Sci. Technol. 2024, 153, 109411. [CrossRef]

- Yokoyama, H.; Nagao, N.; Tokai, K.; Nishikawara, M. Control of flow and acoustic fields around an axial fan utilizing plasma actuators. J. Fluids Eng.-Trans. ASME 2025, 147, 011201. [CrossRef]

- Ghosh, D.; Vourakis, M.; Andersson, N.; Etemad, S. Computational aeroacoustics of low-pressure axial fans installed in parallel. J. Fluids Eng.-Trans. ASME 2025, 147, 021204. [CrossRef]

- Dietrich, P.; Schneider, M. Aeroacoustic simulations of an axial fan with modelled turbulent inflow conditions. Int. J. Turbomach. Propuls. Power 2023, 8, 13. [CrossRef]

- Li, N.; Zhang, Y.F.; Winkler, J.; Reimann, C.A.; Voytovych, D.; Joly, M.; Lore, K.G.; Mendoza, J.M.; Grace, S. Machine learning aided low-order predictions of fan stage broadband interaction noise. AIAA J. 2024, 62, 2174-2185. [CrossRef]

- Pouryoussefi, S.G.; Abdolali, G.; Bakhsheshizanjani, M.; Khoshnejad, A.; Doostmahmoudi,A. J. Experimental investigation of aerodynamic characteristics of an embedded wing-electric ducted fan boundary layer ingestion setup. Braz. Soc. Mech. Sci. Eng. 2023, 45, 301. [CrossRef]

- Suzuki, T. Spiral flow instability between a rotor and a stator in high-speed turbomachinery and its relation to fan noise. J. Fluid Mech. 2023, 966, A1. [CrossRef]

- Blázquez-Navarro, R.; Corral, R. Validation of broadband noise prediction methodology based on linearized Navier-Stokes analyses. J. Turbomach.-Trans. ASME 2023, 145, 091002. [CrossRef]

- Hu, R.; Cao, C.K.; Zhao, G.Q.; Zhao, Q.J. Investigations of the layout parameter influence on the aerodynamic characteristics of ducted fan. Flight Dynamics 2023, 41, 7-12. [CrossRef]

- Zhang, S.G.; Wang, P.C.; Chen, H.B.; Hong, L.; Zhang, L. Numerical simulation and analysis of the aerodynamic characteristics of a marine three-blade ducted propeller. Ship Science and Technology 2024, 46, 1-8. https://kns.cnki.net/kcms2/article/abstract?v=iLvembebNjxxE5WTkcj-lH-7D8wbqTkCL-M9VuMnuvkMOh1ODtY0I69jWiULnulvznmuZA2lciRN_5cqNEsT_UQbn3vF5QYueA-yQH9FxLqPh7V3uGKLlbuVYWiy7qKflLuCOLkjL37k5y4mfnvN4PY6WJxuP6Gw1YBJKRy4cqoV296gFcd2JQ==&uniplatform=NZKPT&language=CHS.

- Chen, K.A.; Zeng, X.Y.; Li, H.Y. Acoustic measurement; Science Press: Beijing, China, 2005; pp. 13-14.

- Fukano, T.; Kodama, Y.; Senoo, Y. Noise generated by low pressure axial flow fans, I: Modeling of the turbulent noise. J. Sound Vibr. 1977, 50, 63-74. [CrossRef]

- Fukano, T.; Kodama, Y.; Takamatsu, Y. Noise generated by low pressure axial flow fans, II: Effects of number of blades, chord length and camber of blade. J. Sound Vibr. 1977, 50, 75-88. [CrossRef]

- Fukano, T.; Kodama, Y.; Takamatsu, Y. Noise generated by low pressure axial flow fans, III: Effects of rotational frequency, blade thickness and outer blade profile. J. Sound Vibr. 1978, 56, 261-277. [CrossRef]

| Parameters | Values | Unit |

|---|---|---|

| Number of blades | 12 | 1 |

| Blade chord length | 19 | mm |

| Blade twist angle | 15 | ° |

| Inner diameter of duct | 71 | mm |

| Thickness of duct wall | 1 | mm |

| Duct length | 58 | mm |

| Motor diameter | 32 | mm |

| Component | Mesh size (mm) | Orthogonality | Skewness | Draw ratio | Boundary layers | First layer height (mm) | y+ |

|---|---|---|---|---|---|---|---|

| Blade | 0.5-0.7 | 0.85 | 0.15 | 3.2 | 15 | 0.02 | 0.8 |

| Duct | 1.0-1.2 | 0.78 | 0.25 | 4.5 | 15 | 0.02 | 0.8 |

| Electrical machinery | 1.0-1.2 | 0.72 | 0.28 | 5.0 | 15 | 0.02 | 0.8 |

| Numerical method | Values |

|---|---|

| Solver type | Pressure-based |

| Velocity formulation | Absolute |

| Time | Steady |

| Models | SST k-ω, Broadband noise sources |

| Cell zone conditions | Fluid-air-constant |

| Rotational velocity (r/min) | 20,000-40,000 |

| Import setting | Pressure |

| Pressure-inlet (Pa) | 0 |

| Ducted fan | Cells | APLmax (dB) |

|---|---|---|

| Integral (Spacing = 0 mm) | 1,492,353 | 118.3 |

| 1,349,407 | 117.9 | |

| 1,220,678 | 117.3 | |

| 1,044,801 | 116.5 | |

| Spacing = 10 mm | 1,435,971 | 123.1 |

| 1,343,231 | 122.8 | |

| 1,272,171 | 122.5 | |

| 1,243,540 | 121.8 | |

| Spacing = 20 mm | 1,514,198 | 123.2 |

| 1,366,122 | 122.9 | |

| 1,325,645 | 122.7 | |

| 1,211,937 | 122.2 |

| Rotational velocity (r/min) | Spacing=0, APLmax (dB) | Spacing=10mm, APLmax (dB) | Spacing=20mm, APLmax (dB) |

|---|---|---|---|

| 20,000 | 116.5 | 121.8 | 122.2 |

| 40,000 | 133.2 | 156.2 | 194.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).