1. Introduction

Industry 4.0 marks a major turning point for factories around the world, moving well beyond earlier ideas of automation. At its core, this new phase connects Cyber-Physical Systems (CPS), the Industrial Internet of Things (IIoT), vast pools of data, and Artificial Intelligence (AI), producing smart plants that respond instantly and tune themselves to changing conditions. Through standardized communication protocols, machines now trade information on their own, raising efficiency, dependability, and flexibility in ways once thought impossible [

1,

2]. Taken together, these building blocks enable data-led, self-governing production lines that spot defects and recalibrate without needing a human hand. Industry 5.0 builds on that technical base but puts people back at centre stage, balancing speed with resilience, inclusivity, and care for the planet. Championed by the European Commission and echoed by scholars worldwide, this next chapter ties digital progress to human welfare and ecological limits [

3,

4]. Its goal is a give-and-take partnership between smart machines and skilled workers, resulting in workplaces that are both highly productive and genuinely humane [

5].

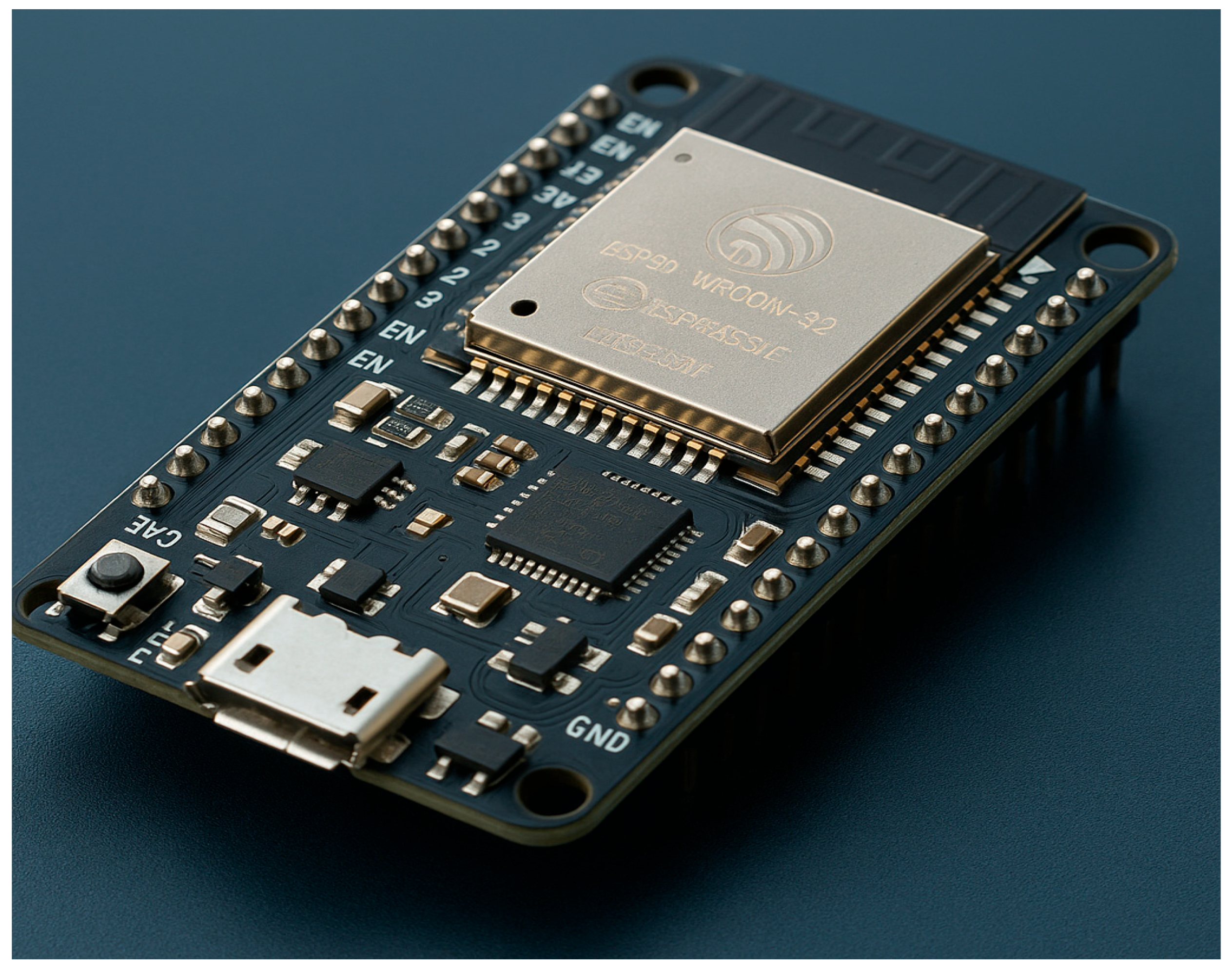

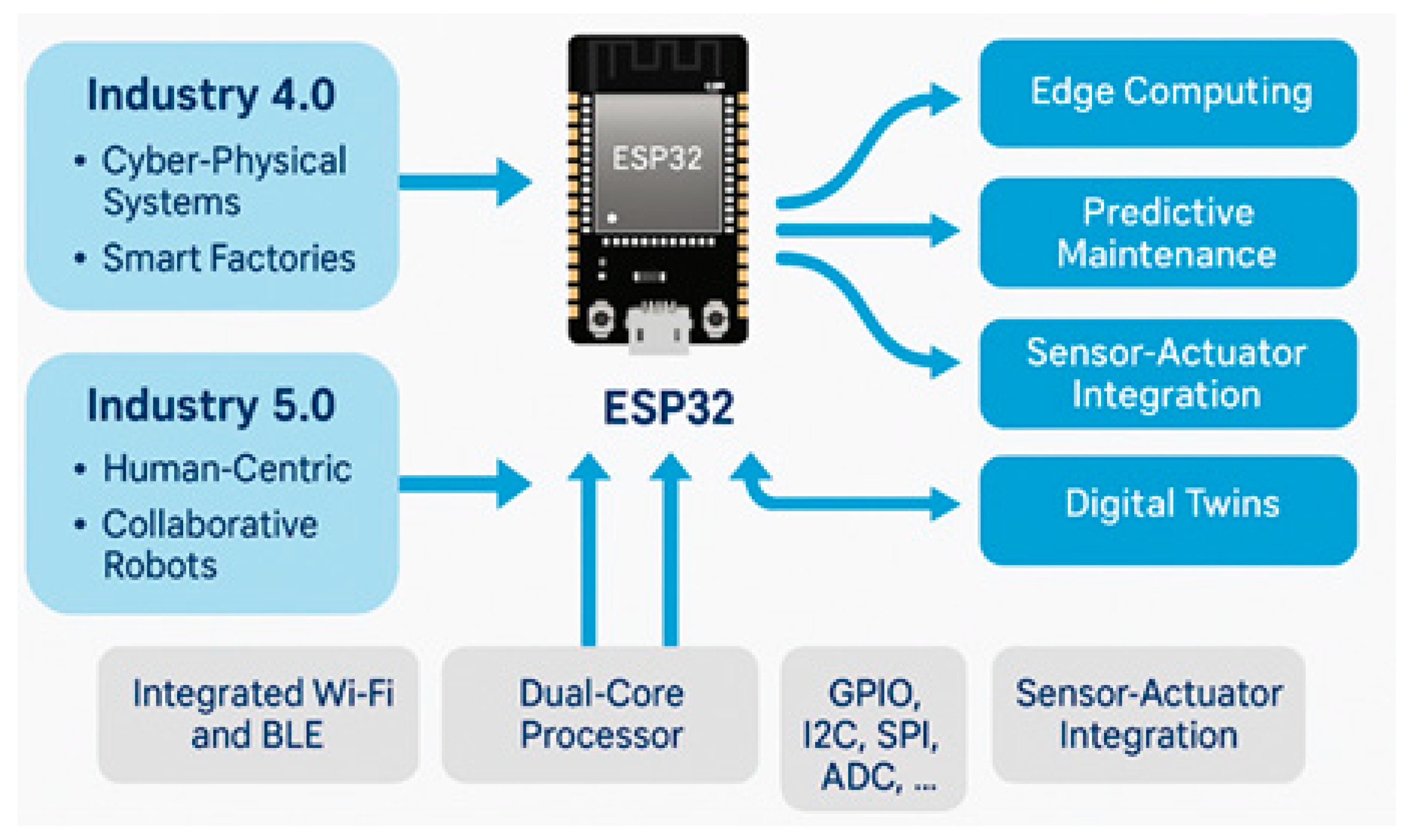

At the heart of both smart-manufacturing ideas sit tiny embedded gadgets-low-energy microcontrollers and edge computing boards-that work like nerve endings in an industrial body (

Figure 1). Because they run, sense, and react without much power or memory, they handle local tasks efficiently. The ESP32 chip from Espressif Systems shines among them, thanks to its twin CPU cores, built-in Wi-Fi and Bluetooth, and flexible coding tools [

6]. People choose the ESP32 not only for specs-a dual-core Xtensa LX6/LX7 running up to 240 MHz, Wi-Fi, BLE, and wide GPIO, I2C, SPI, ADC, and DAC options-but also for its knack of connecting real machines with smart, data-led choices. With it, factories get real-time edge analysis, tight sensor-to-actuator feedback, and sturdy wireless links for jobs like predictive upkeep or building digital twins [

7,

8]

The ESP32 stands out next to older boards like the Arduino Uno, which has no wireless built in and little processing muscle, or even the STM32, usually forced to wear extra shields for Wi-Fi or Bluetooth. Its mix of power, easy scaling, and tight on-chip integration makes it appealing for quick prototypes and real production lines alike, spanning smart grids, farms, hospitals, and energy setups [

2,

8]. Yet research papers still box the ESP32 into small, hobby-like topics or narrow industry silos, leaving its wider role in joining machines, networks, and people-a key idea behind Industry 5.0-mostly unspoken [

6,

7]. That trend shows a clear need for work that pulls together what the chip can do, where it might stumble, and the big changes it could drive.

This narrative review steps into that space by looking at the ESP32s chip design, protocol stacks, software tools, and real deployments in factories, farms, and clinics. By blending fresh studies, open-source projects, and field stories, it argues that the ESP32 might be a key brick in making smart manufacturing friendlier to people, a central goal of Industry 5.0 and whatever comes next [

1,

3].

2. Overview of ESP32 Microcontroller: A Story of Industrial Intelligence at the Edge

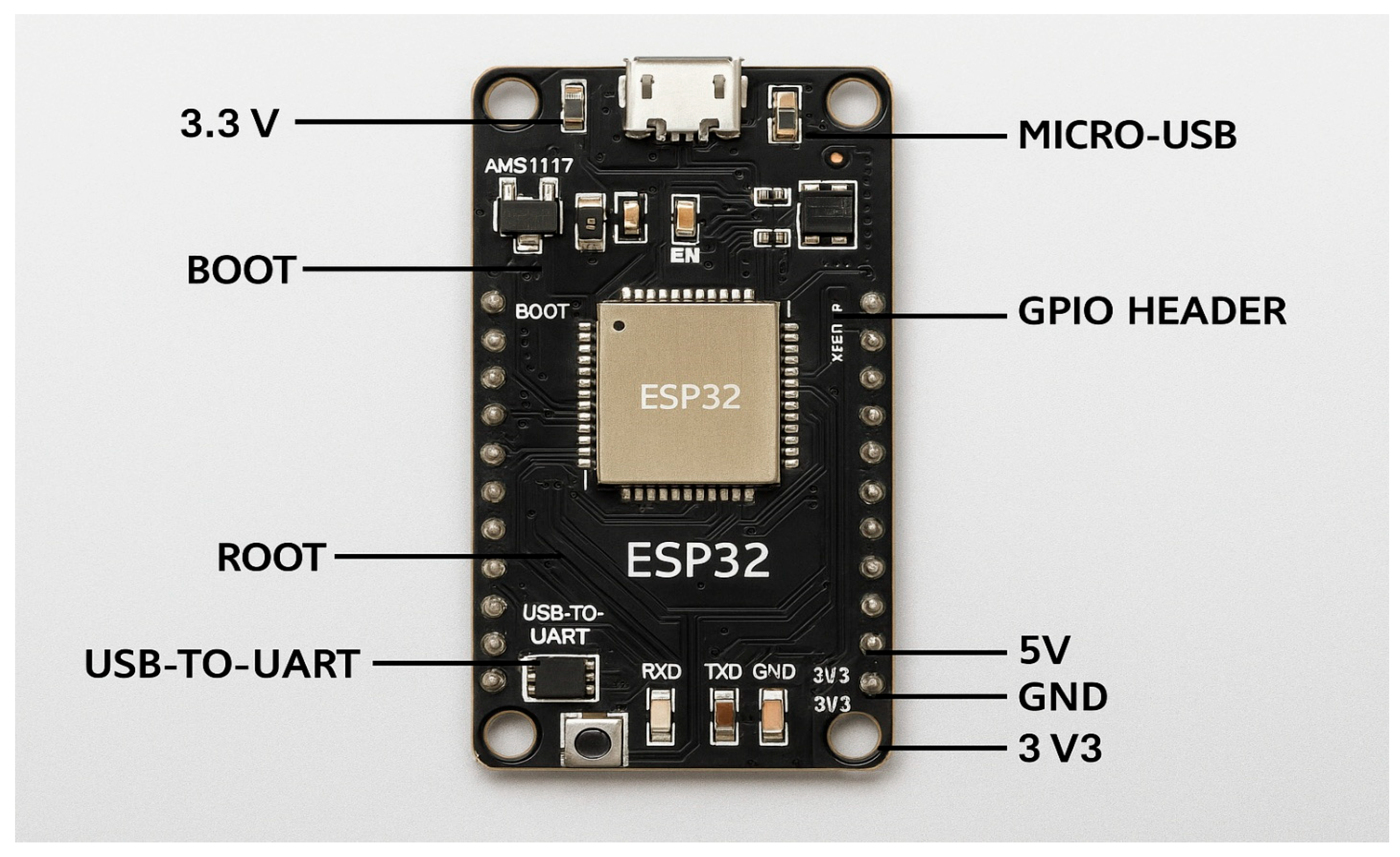

The ESP32 microcontroller is a compact, versatile system-on-chip that integrates multiple functionalities, making it ideal for managing connected factory floors. Its combination of Wi-Fi and Bluetooth capabilities, dual-core processing, and low power consumption allows for efficient edge processing and communication across various devices (

Figure 2). This chip can facilitate real-time monitoring and control, enhancing operational efficiency in industrial settings.

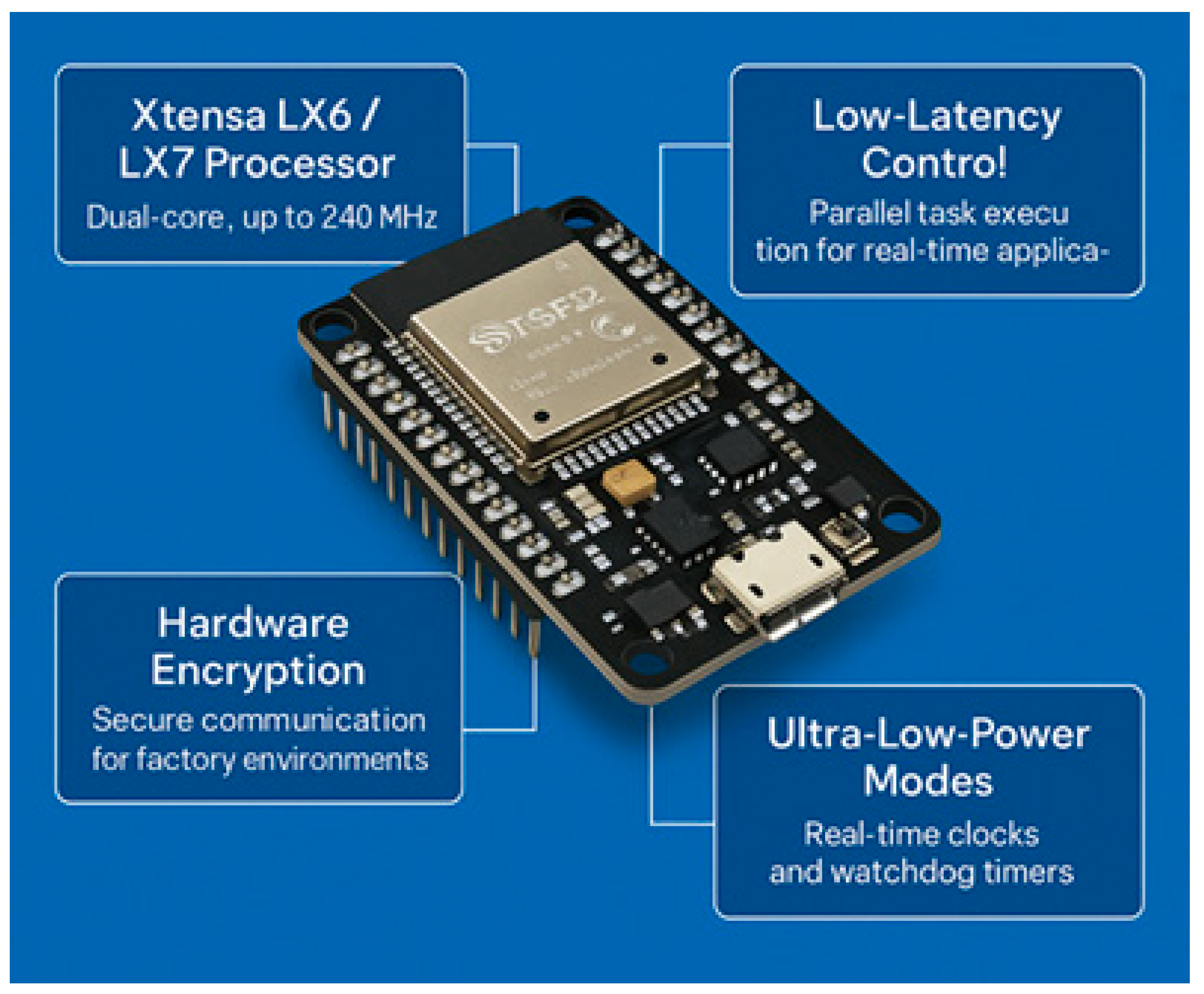

2.1. Architecture and Performance: The Dual-Core Backbone of Smart Industry

Inside the ESP32 sits a dual-core Xtensa LX6 or LX7 CPU running up to 240 MHz. The ability to handle tasks in parallel-sensor reading on one core, encrypted Wi-Fi on the other-keeps latency low and throughput high (

Figure 3). For factories that rely on split-second control and fast data streams, this design is a clear advantage. The chip also packs hardware encryption, real-time clocks, sleep modes for power savings, and watchdog timers to survive rough shop-floor environments. A recent case study shows the ESP32 slashing response times in predictive maintenance, outperforming older single-core designs [

9].

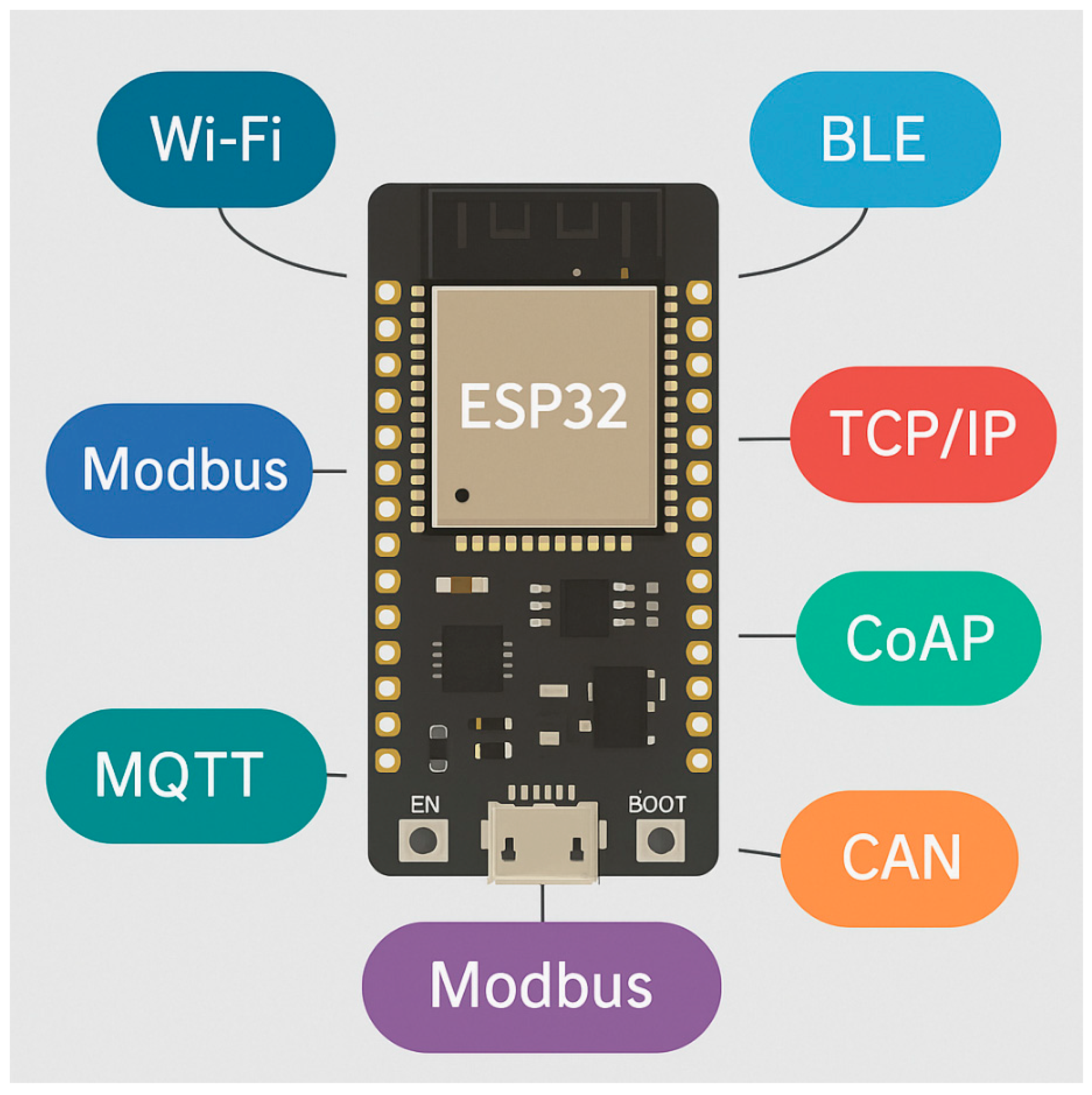

2.2. Supported Protocols: Speaking the Language of the Industrial Internet

The ESP32 is a connectivity powerhouse. It handles a wide array of protocols-Wi-Fi, BLE, MQTT, Modbus, CoAP, TCP/IP, CAN-which makes it ideal for fresh installations and for bridging older machines (

Figure 4). By serving both as a data generator and as a local broker, the chip can slot into almost any IIoT architecture. For example, in a study by Lousado and Antunes, ESP32 devices were used in a telemedicine project that securely relayed real-time patient statistics via LoRaWAN and MQTT, underscoring its versatility in medical and industrial telemetry alike [

10].

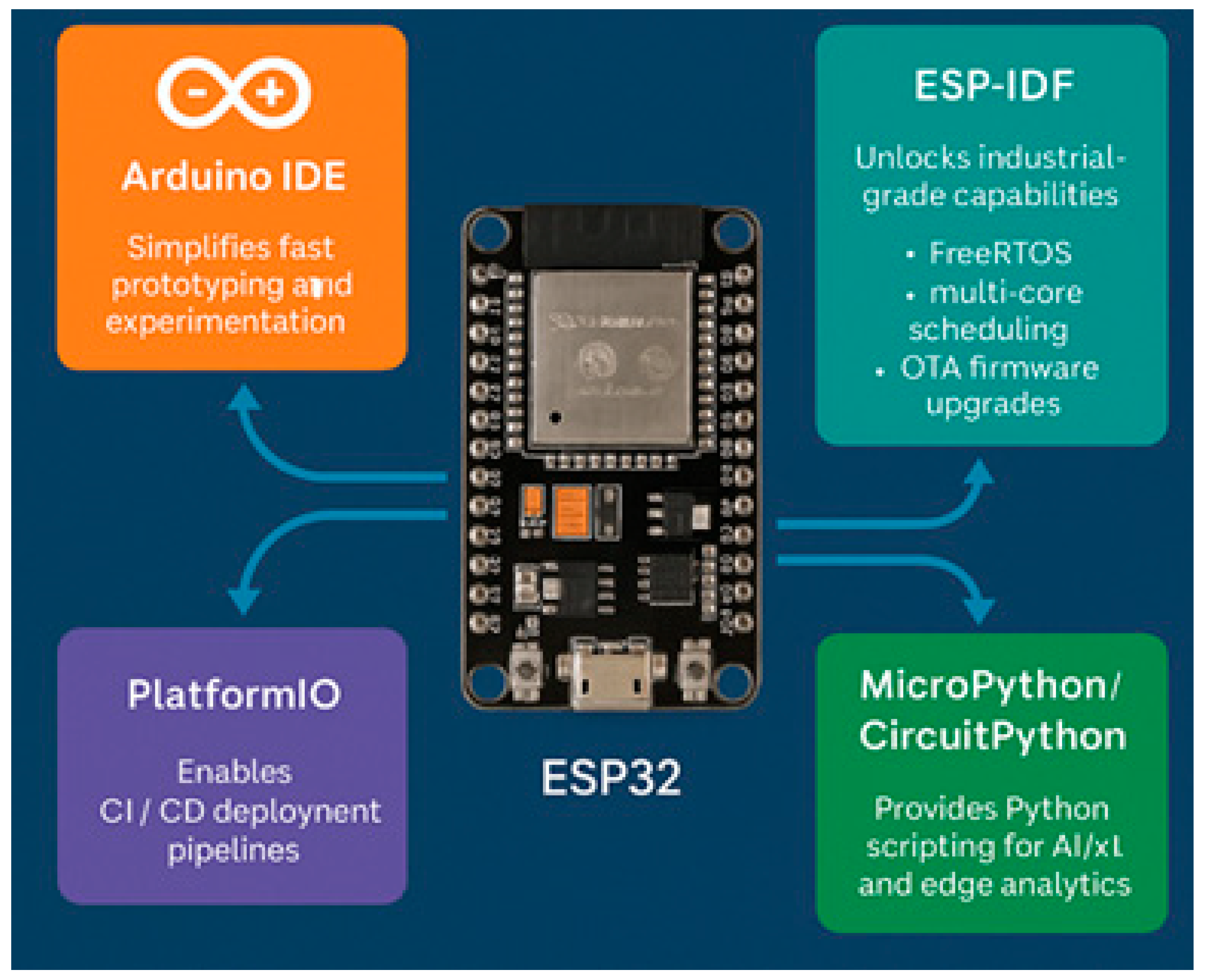

2.3. Programming Environments: From Hackerspaces to Industrial Pipelines

The ESP32 microcontroller has gained significant popularity due to its versatile developer ecosystem, accommodating both beginners and experts. With support for various programming environments like Arduino IDE and ESP-IDF, users can easily engage with the platform, making it suitable for a wide range of projects (

Figure 5). This adaptability is reflected in the diverse applications and formats available for the ESP32, from simple IoT devices to complex smart home systems [

11].

Arduino IDE keeps rapid prototyping painless and quick.

ESP-IDF opens doors to production features such as FreeRTOS, multicore task management, and over-the-air firmware updates.

PlatformIO, paired with GitHub Actions, supports CI/CD workflows, a setup seen in cloud-linked smart-grid systems [

12].

MicroPython and CircuitPython let users run Python for light AI, ML inference, or on-the-spot analytics without wrestling with C/C++ [

13].

Such flexibility allows the ESP32 to slip comfortably into both prototype workbenches and mature commercial-IoT installations.

2.4. Comparative Advantages: Standing out Among Peers

The chip sits in the middle ground between budget boards like the Arduino Uno and high-end models such as the STM32 family. Its strengths include:

32-bit dual-core processor (compared with the 8-bit ATmega328P in the Arduino Uno)

Onboard Wi-Fi and Bluetooth (rather than extra shields with Arduino or STM32 boards)

Lower idle current plus built-in cryptographic co-processors.

In contrast to many STM32 designs that need elaborate pin routing and extra radios, the ESP32 bundles everything together. This integrated design suits remote factory controllers where every cent spent and every milliamp saved counts [

14].

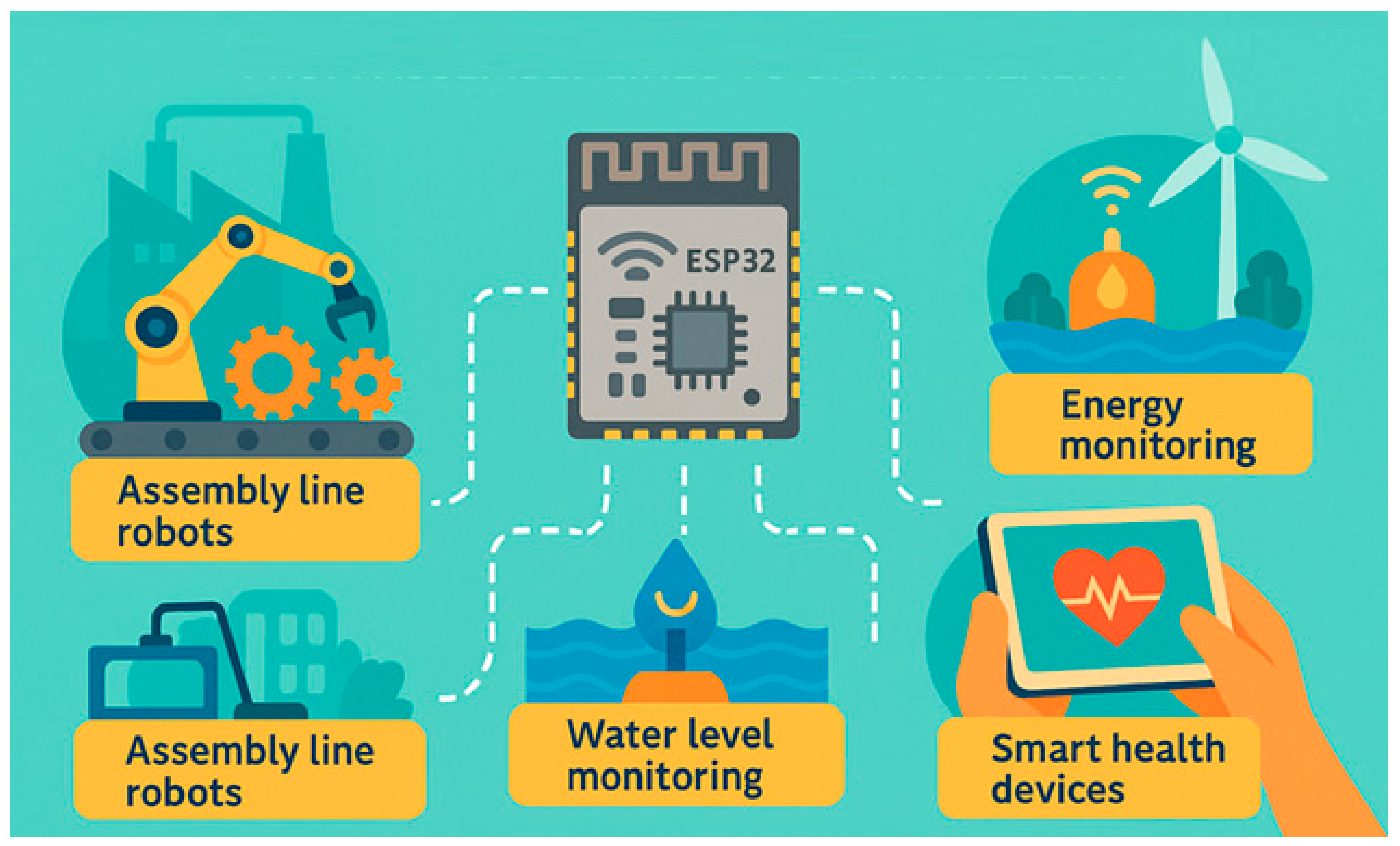

2.5. Real-World Industrial Applications: From Assembly Lines to Smart Health

ESP32 is no longer just for prototyping. Its capabilities are increasingly used in production-ready systems including (

Figure 6),

Smart-grid load balancing: linked to SCT sensors, the chip tracks current in real time and sends quick load-shift orders to central nodes [

15].

Predictive maintenance: on rotating machines, it logs vibration and temperature data, spotting wear trends that warn users before failure [

9].

Telemedicine: strapped to the skin, the module gathers pulse, SpO2, and temperature readings, relaying them to doctors over secure MQTT links [

16].

Smart cities: in air-quality nets, the device samples CO₂, PM2.5, and VOCs, then streams the results to city dashboards for fast regulation [

17].

3. Discussion on the ESP32 Programming Ecosystem

The ESP32 platform earns much of its flexibility from the range of programming environments it supports, letting developers choose the level of control and scale they need. The Arduino IDE, Espressif IoT Development Framework (ESP-IDF), and PlatformIO are the most popular options; each shine in a different area, whether low-latency code, robust debugging, or smooth industrial deployment.

3.1. ESP-IDF vs Arduino IDE: Performance and Latency

Although the Arduino IDE remains a go-to tool for hobbyists and quick prototypes, its high-level layers mask hardware details and introduce extra overhead. In contrast, ESP-IDF exposes the ESP32s dual-core scheduler, precise memory pools, and interrupt registers, granting engineers the low-level leverage time-sensitive industrial tasks demand.

Benchmarks published by Ismayilov (2020) reveal that ESP-IDF projects incur markedly lower execution latencies and tighter memory footprints when reacting to fast sensor readings or steady MQTT bursts than their Arduino counterparts [

18].

3.2. PlatformIO and CI/CD Integration for Industrial DevOps:

PlatformIO offers a unified workspace that serves both ESP-IDF and Arduino cores, yet adds unit tests, library pinning, and task runners that tidy every build. Such features nest comfortably within industrial DevOps pipelines and link to CI/CD services like GitHub Actions, GitLab CI, or Jenkins.

Pisco (2023) illustrates using the PlatformIO command-line interface in Docker pods to spin builds, run tests, and push artifacts for ESP32. His pipeline supports continuous integration and over-the-air rollout of firmware, a must for large, remote production fleets [

19].

In addition, PlatformIO supports test simulations through QEMU-based emulation, letting developers check firmware logic without a physical board, which boosts teamwork and cuts reliance on hardware in early stages [

18].

3.3. Comparative Advantages:

When compared to the Arduino Uno, which has no built-in wireless link and runs on an 8-bit core, the ESP32 supplies 32-bit processing, multitasking, and hardware-accelerated cryptography.

STM32 devices usually demand add-on modules for networking and present a tougher learning path, yet they may exceed the ESP32 in analog precision. Overall, the ESP32 strikes a balance between user-friendliness and industrial robustness[

20].

3.3.1. Energy Efficiency:

Benchmarking Power efficiency matters greatly in edge and factory settings, especially for gear that must run for weeks on a single charge. Thanks to low-power sleep modes and onboard radio, the ESP32 suits battery-driven industrial IoT (IIoT) and edge-AI tasks. The sections that follow compare its energy draw with STM32, Arduino Uno, and Raspberry Pi across three typical use cases [

21].

3.3.2. Idle Power Consumption:

When placed in idle or deep-sleep mode, the ESP32 settles at roughly 5 to 10 A, rendering it highly efficient when sensor readings are taken sporadically. By contrast, the classic Arduino Uno, which lacks advanced low-power states, idles at about 50 to 60 A under the same conditions. The STM32L4 series performs similarly, frequently dipping to around 0.6 A in its ultra-low-power sleep setting [

21].

In high-performance scenarios, however, the Raspberry Pi 4B pales in idle economy, pulling over 600 to 1000 mW even when underclocked [

22].

Summary Table: Typical Power Consumption Ranges

Table 1.

Comparison of power power consumption of different microcontroller.

Table 1.

Comparison of power power consumption of different microcontroller.

| Device |

Idle Mode |

Wi-Fi Transmission |

AI Inference (TinyML) |

| ESP32 |

5–10 µA |

528–792 mW |

250–300 mW |

| STM32 |

0.6–10 µA |

100–400 mW (ext. module) |

200–350 mW |

| Arduino Uno |

50–60 µA |

700–1000 mW (w/ shield) |

N/A |

| Raspberry Pi 4B |

600–1000 mW |

1500–2500 mW |

3–5 W |

3.3.3. Wi-Fi Transmission

Wi-Fi transmission ranks among the most power-hungry tasks encountered on edge nodes. While sending data continuously, the ESP32 draws around 160 to 240 mA at 3.3 V, a figure that varies with the chosen bit rate and packet duty cycle; this translates to about 528 to 792 mW in practical usage [

23]. Although respectable, that total remains markedly lower than the Raspberry Pi 4, which can consume 1.5 to 2.5 W during equivalent Wi-Fi sessions because its full Linux operating system and assorted peripherals continue running [

24].

Typical low-power wide-area network (LPWAN) modes such as LoRa or Zigbee, an STM32 device equipped with a Wi-Fi chip-say the STM32WL or STM32WB-delivers a current of roughly 15 to 30 mA; true Wi-Fi functionality still requires a separate module. The standard Arduino Uno, when outfitted with common Wi-Fi shields like the ESP8266, pushes the total draw even higher.

3.3.4. AI Inference and TinyML Tasks

Amid rising edge AI use, researchers are scrutinising how much power is consumed during on-device inference. The ESP32-S3 is particularly promising because its built-in AI co-processor and vector math units cut cycle counts dramatically. Zeeshan (2024) reports that TinyML models run via TensorFlow Lite Micro draw roughly 250 to 300 mW when detecting keywords or monitoring for anomalies [

25].

By comparison:

An STM32 executing NanoEdge AI Studio code on Cortex-M4 or M7 cores hits a similar or slightly lower figure, though it usually lacks onboard radio.

A Raspberry Pi 4B is far quicker but pulls 3 to 5 W for even elementary models, which rules it out for battery-operated or remote projects [

26].

The findings thus confirm that the ESP32 microcontroller can reliably support low-power edge applications in which constant Wi-Fi connectivity and lightweight machine-learning workloads run side by side without quickly exhausting battery life. Meanwhile, the newer ESP32-S3 boosts energy efficiency further by adding vector acceleration and fine-tuned instruction sets, positioning it as an excellent choice for embedded artificial-intelligence projects.

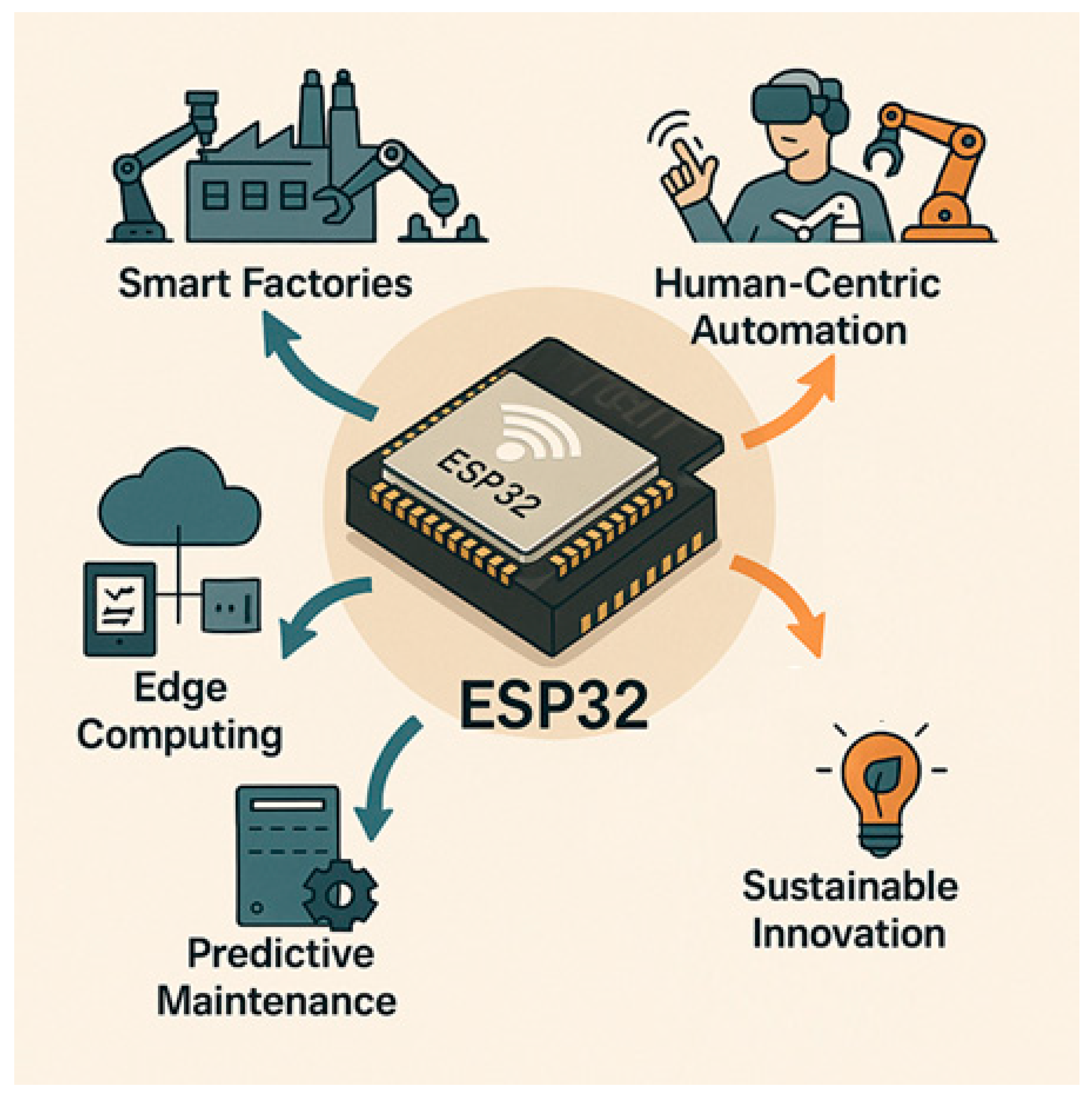

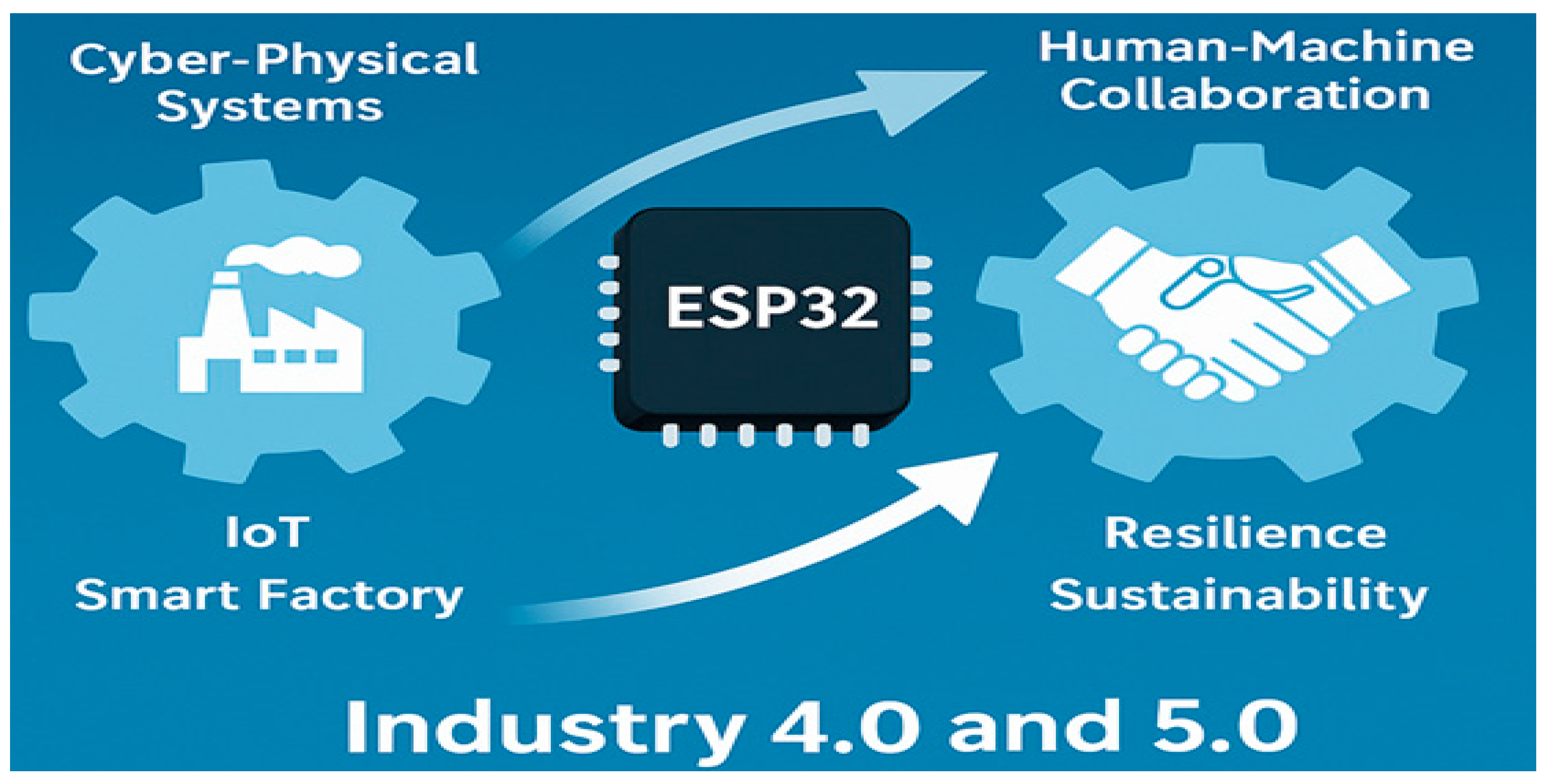

4. ESP32: Enabling Industry 4.0 and 5.0

The ESP32 microcontroller has quickly become a key building block in todays factory floors, connecting edge computing, automation, and people in ways that drive both Industry 4.0 and the newer Industry 5.0 vision (

Figure 7).

4.1. From Smart Sensors to Digital Twins: ESP32 in Industry 4.0

At the core of Industry 4.0 sits the cyber-physical system-an ever-talking network of machines that sense data, think about it, and respond in real time. Thanks to its dual cores, built-in Wi-Fi and Bluetooth, and plentiful GPIO pins, the ESP32 acts as a budget-friendly edge node that gathers readings, runs tiny AI models, and pushes results to the cloud or a local screen. This capability is vital for predictive upkeep in places like solar farms, where ESP32 loggers monitor output and send early alerts about looming failures [

27].

Supervisory control and data acquisition (SCADA) is also getting more modular. The ESP32 steps in here by speaking Modbus, MQTT, or LoRaWAN, bridging older machines and modern apps. Folgado et al. (2024) note that this low-cost gateway lets factories run edge analytics without the expense of a full PLC setup [

28].

Beyond classical supervisory control and data acquisition (SCADA) systems, the ESP32 microcontroller now anchors digital-twin networks by bridging the physical world with its virtual counterpart. In solar installations, for instance, the chip publishes live sensor data to a cloud model, allowing operators to track wear, predict faults, and schedule power output more intelligently [

29].

4.2. ESP32s Role in the Human-Centric Era of Industry 5.0

As Industry 4.0s machine-dominant paradigm shifts toward the cooperative spirit of Industry 5.0, the same ESP32 chip evolves into a backbone for human-machine interfaces (HMIs) and green automation. Wearables such as ESP32-linked smart gloves or simple gesture boards let workers command machines with natural motions, cutting training times and easing physical strain.

The platform also widens access to clean technology in resource-constrained areas. Because the ESP32 is cheap and low-power, it fits in microgrid dashboards, off-grid health checks, and locally managed water and power nodes. By placing edge smarts directly in those communities, researchers affirm the chips role in bridging the digital divide, as Boucif (2025) show when using ESP32 boards for solar watchdogs and fault alerts in remote villages [

30].

At the same time, Sverko and colleagues (2022) highlight the ESP32 in freelance manufacturing and on-the-spot process tuning, where it swaps pricey PLCs for agile, firmware-updatable boards that respond instantly to local AI signals [

31].

4.3. Future-Proofing: ESP32 in Next-Gen Industrial Networks

Looking ahead, the ESP32 lineup, especially newer chips like the ESP32-S3 with built-in AI hardware and extra PSRAM, can run on-device AI models that handle tougher tasks. Such processing power will prove vital in Industry 5.0-plus worlds where cyber-physical systems, human feedback in real time, and digital twins act as co-pilots for workers [

32].

In short, the chip has shifted from a simple microcontroller to a broad platform that fuels tomorrow’s factories by merging automation, AI, strong connectivity, and designs that put people first (

Figure 8).

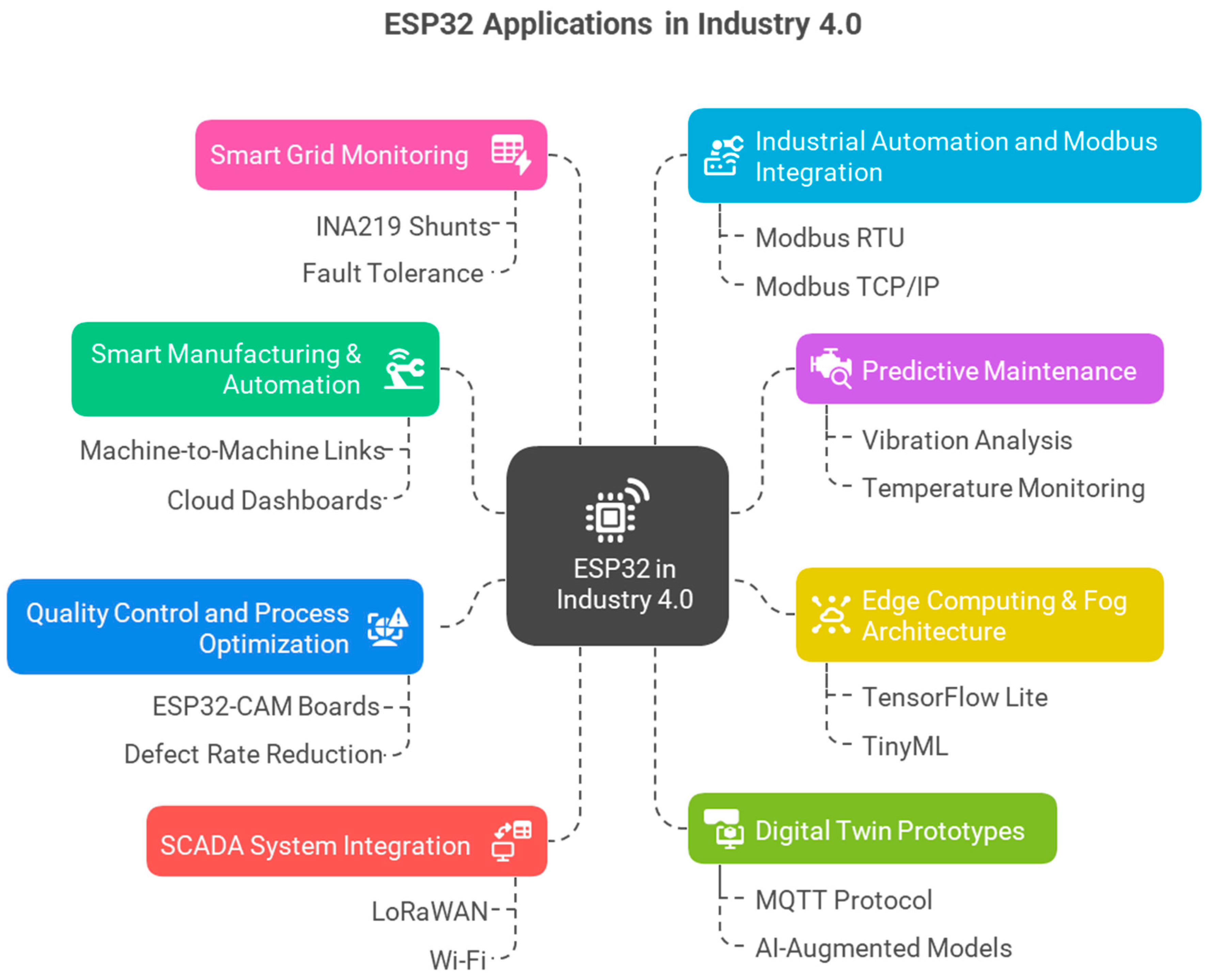

4.4. ESP32 in Industry 4.0 Applications

ESP32, a compact yet powerful microcontroller with integrated Wi-Fi and Bluetooth capabilities, plays a pivotal role in enabling smart, connected, and decentralized industrial systems under the Industry 4.0 paradigm. Its flexibility, low cost, and compatibility with a wide range of sensors and protocols make it ideal for edge intelligence, real-time monitoring, and automation.

The

Figure 9 highlights key Industry 4.0 application areas where ESP32 is widely deployed

4.4.1. Smart Manufacturing & Automation

Within smart manufacturing, the ESP32 often sits at the heart of machine-to-machine (M2M) links (

Figure 10). Its modest power draw, dual-core CPU, and fast Wi-Fi stack let it talk with MQTT brokers and PLCs in real time. By doing so, it permits each machine to watch itself and adjust locally while still sending clear, steady data to cloud dashboards or on-site screens.

Singh and colleagues built an ESP32-based CNC-monitoring unit that logs spindle speed, tool heat, and similar dials then sends the numbers to a cloud screen where engineers scan for odd readings [

33]. Wider still, makers have hooked the same chip to welding rigs so they trim power waste and tighten bead quality through on-the-fly machine-to-machine rules [

34].

Such use underlines the ESP32s place at the hub of real-time cyber-physical orchestras and shows how it fuels fast, edge-first smart-factory setups [

35]. It has also powered ultra-low-power overseer boards for mixed-model plants, proving its versatility outside heavy industrial boxes [

23].

4.4.2. Predictive Maintenance

In predictive upkeep, the ESP32 sits on machines and gathers vibration, current, and temperature tracks, feeding them into edge-friendly AI stacks such as TinyML. From those streams it fuses data and runs simple thresholds, flagging trouble early on for motors, pumps, gearboxes, and other key parts. De La Fuente and colleagues (2025) integrated a hierarchical inference network directly on ESP32 boards in heavy-mining equipment, achieving noticeable drops in both breakdowns and power use during predictive maintenance [

36]. In parallel, Halenar and co-authors (2024) crafted a similar edge-monitoring unit that analyzed multivariate time-series signals onboard the ESP32, eliminating reliance on distant cloud servers for inference [

37].

Manonmani and Sumesh (2025), meanwhile, presented a sturdy ESP32-based system that slots effortlessly into power plants, proving that the low-cost module scales well and can withstand cyber threats [

38]. Njor et al. (2024) also compiled a wide-ranging review that details how TinyML stacks on the ESP32 are transforming PdM practices in manufacturing, energy, and beyond [

22].

4.4.3. Edge Computing & Fog Architecture

Given the edge-first ethos of Industry 4.0, the ESP32 now serves as an indispensable fog node, running local AI inferences with TensorFlow Lite and TinyML. Its dual-core layout lets sensor polling and model execution happen in parallel, yielding troubleshooting decisions in milliseconds. Raj (2024) introduced a fog computing node built on the ESP32, using it to monitor shop-floor conditions in real time; their setup cut latency by 40% when measured against traditional cloud links [

39]. Building on this hardware, Bongomin and colleagues (2024) showed that distributed ESP32 fog units could control indoor elements such as air quality and lighting while feeding a shared digital twin model [

7].

Meanwhile, Oliveira et al. (2024) proposed a broader vision, coining the term Internet of Intelligent Things to describe the synergy of edge AI, embedded firmware, and IoT, with the ESP32 at its core [

40]. Taken together, these contributions paint a clear picture: the humble ESP32 now sits at the heart of many edge-processing architectures meant to deliver smart, decentralized control in future factories.

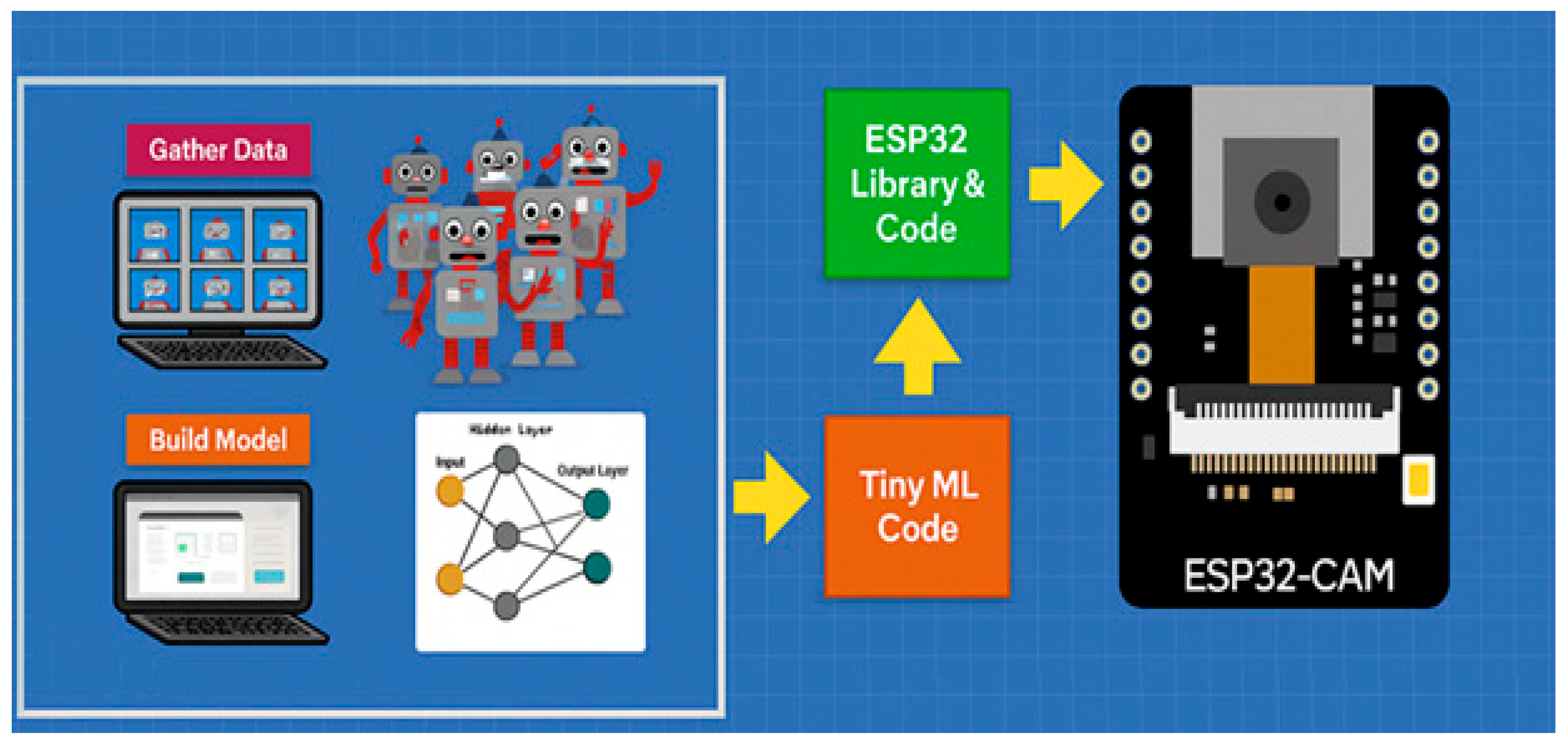

4.4.4. Quality Control and Process Optimization

ESP32-CAM boards, which bundle a small camera with basic image processing, are finding their way into quality-control roles on the line. Because they work locally, these nodes spot surface flaws, misalignments, or stray particles in real time and do so without the budget hit of full industrial vision suites. Scarton et al. (2025) report that their ESP32-based inspection cells, guided by rule-based logic, dropped defect rates by more than 25% on small-batch runs [

41]. Tasmi (2025) pushes the case further, using the same cameras in solar-cell fabs to perform edge object detection (

Figure 11), an example that underlines how easily this technology scales across different embedded-machine-vision tasks. Data collection and model training are the first steps in the process. TinyML code is then created and deployed to the ESP32-CAM using compatible libraries, allowing for on-device AI-based object recognition [

42].

Rosca and colleagues (Rosca et al., 2025) assembled a defectmonitoring platform for foundry operations, using an ESP32 board to merge sensor readings and images so that forecast control and clearer insight could be achieved [

33].

4.4.5. ESP32 in SCADA System Integration

Adding the ESP32 to Supervisory Control and Data Acquisition networks offers a cost-effective route for refreshing ageing hardware. Saban et al. (2023) showed this in practice, using the chip to manage irrigation pumps over LoRaWAN and Wi-Fi, which allowed live scheduling while also cutting energy use [

43]. Their setup linked older field instruments with modern web dashboards and lessened reliance on expensive programmable logic controllers. The case fits the wider trend described by Sverko et al. (2022), who examined how light-duty devices such as the ESP32 are shaping modular and decentralised SCADA architectures in factorie [

31]. Folgado et al. (2024) also surveyed current automation movements and pointed out that the ESP32 works well with standard protocols like Modbus and MQTT, thus easing its incorporation into existing SCADA schemes [

28].

4.4.6. ESP32 in Digital Twin Prototypes

Handoko (2023) recently showcased a digital twin prototype for photovoltaic arrays that relied on the ESP32; it continuously sent cloud-ready readings-voltage, temperature, energy output-to guide maintenance and boost performance [

44]. The work fits a growing body of research, including Folgado et al. (2024), who stress how the ESP32s native MQTT protocol links physical components and their virtual counterparts [

28]. Likewise, Ledmaoui and partners (2025) established a plug-and-play twin for solar networks, collecting inverter data over Modbus with ESP32 boards and feeding it into AI-augmented models [

27]. Sverko et al. (2022) added that the ESP32s open hardware and built-in MQTT stack make it an economical choice for mapping decentralized factories inside a digital twin environment [

31].

4.4.7. Smart Grid Monitoring with ESP32

A parallel study by Permana et al. (2024) used the same microcontroller with INA219 shunts to track key electrical metrics-voltage, current, power factor-in real time. The edge solution issued instant alerts when voltages drifted out of range, supporting rapid local actions that are especially valuable in remote, off-grid microgrids [

45].

Boucif and colleagues (2025) broadened the field by linking Modbus energy meters to an ESP32 unit and an AI back end, reporting that real-time load profiles noticeably sharpened fault tolerance and strengthened grid resilience [

30]. Similarly, Ledmaoui and partners (2025) employed the same microcontroller in solar-smart-grid oversight, fusing energy data with predictive models to detect faults and boost overall efficiency [

27].

4.4.8. Industrial Automation and Modbus Integration

Within factories, engineers now lean on the ESP32 to bridge both Modbus RTU and TCP/IP traffic. Harianto et al. (2021) deployed the chip in a textile mill to log machine states in a distributed fashion and to govern the line in real time. Priced under

$10, the module outperformed legacy industrial gateways without sacrificing features [

46]. Folgado et al. (2024) confirmed the approach, noting the ESP32s cost-effectiveness for Modbus-driven automation in mid-sized plants that seek cheaper, yet reliable, PLC replacements [

28]. Boucif et al. (2025) stressed that smooth protocol interoperability, paired with the ESP32, enabled low-latency Modbus links for field data capture in their solar-monitoring projects [

30].

The ESP32 microcontroller is essential to Industry 4.0 because it makes wireless networking, edge computing, and real-time data collecting possible in smart production systems (

Figure 12). It is perfect for IoT-based predictive maintenance, monitoring, and automation applications due to its affordability and adaptability.

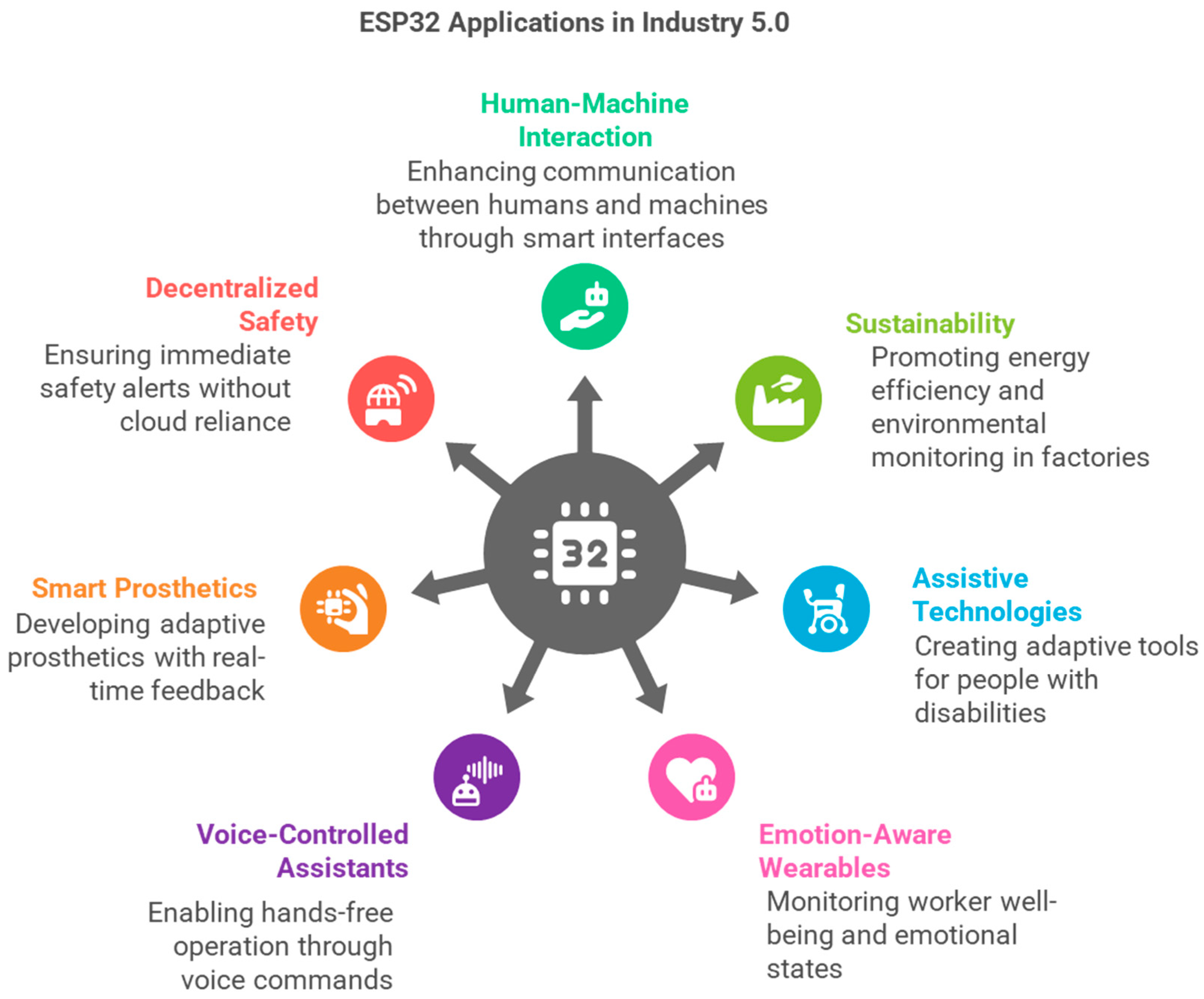

4.5. ESP32 in Industry 5.0 Applications

ESP32 is essential to Industry 5.0 because it makes intelligent, affordable edge computing solutions possible that facilitate automation, real-time data processing, and human-machine cooperation. It is perfect for smart sensors, robotics, and Internet of Things systems that improve customisation and flexibility in next-generation industrial settings because of its integrated Wi-Fi, Bluetooth, and powerful computing capacity. The image demonstrates how ESP32 works with sensors and cloud computing platforms to enable human-centered automation and smart manufacturing processes (

Figure 12).

4.5.1. Human-Machine Interaction (HMI)

In the context of Industry 5.0, ESP32 microcontrollers support user-friendly, people-first human-machine interfaces. These devices drive smart gloves, wearable tactile sensors, and gesture-recognition modules that allow instinctive, low-latency exchanges between operator and machine (

Figure 13).

The researchers created a lightweight glove built around an ESP32 for virtual and augmented reality. The arrangement tracked hand motion and delivered haptic cues via GPIO lines controlled by the chip, resulting in immersive feedback [

47].

Separately, Yang and colleagues (Yang et al., 2024) showed that ESP32-based tactile panels boost two-way dialogue between workers and industrial equipment, thereby enhancing speed and safety in shared production spaces [

48]. Nguyen and co-authors (Nguyen et al., 2024) likewise examined the same chip inside wearable suites for Industry 5.0, spotlighting roles in cooperative robotics and real-time operator support. Their architecture monitored user health and adjusted machine commands through a robust wireless IoT link, forming an adaptive, responsive work partnership [

49].

4.5.2. Sustainability and Energy Monitoring

The ESP32 microcontroller lends itself to sustainability projects in smart manufacturing and green factory design owing to its low power consumption and ability to connect multiple sensors. These features allow developers to build real-time energy dashboards, environmental monitoring nodes, and smart meters without overwhelming the factorys power budget.

Rahmani et al., (2023) show that in energy-efficient additive manufacturing, ESP32-based controllers cut idle power losses and simultaneously support haptic links to digital twin models, guiding operators toward better settings and shorter cycles [

50]. Fraga-Lamas et al. (2022) describe a mist-and-edge computing framework that pairs ESP32 IoT nodes with thermal cameras to map energy hotspots across the shop floor. By moving analysis to the edge, their system not only curtails energy costs but also alerts workers to areas of unsafe heat stress [

6].

Khalid et al. (2024) showcase an open-source SCADA platform for solar arrays driven by the ESP32, where standard HTTP and TCP/IP commands merge real-time production data with automatic tilt and cooling controls, boosting yield and reliability [

51].

4.5.3. Custom Assistive Technologies

In assistive and inclusive technology, the ESP32 lowers costs while offering easy code tweaks and built-in wireless links, so developers can deliver tailored devices without lengthy certification stalls. It has already powered prototypes in prosthetics, smart wheelchairs, exoskeletons, and tele-rehabilitation platforms, giving users tools that adapt to their specific mobility and communication needs. Katuk and colleagues (2024) showcased a smart-microcontroller system that pairs ESP32 chips with Amazon cloud services and ESP32-CAM cameras, giving users with disabilities on-the-spot, vision-driven help at home and on factory floors [

5]. Turning to offshore work, Barbosa and co-authors (2022) built a rugged, water-resistant ESP32 wearable that gathers biosignals while submerged and beams those readings to surface crews, thus allowing real-time health checks in punishing sea and dive conditions [

52]. Rojas et al. (2022) extended this theme by proposing ESP32-based human-machine interfaces for older workers and staff with limited cognition, designing screens that shift layout and content according to how hard a person is focused-an early instance of the inclusive ethos that underpins Industry 5.0 [

53].

4.5.4. Emotion-Aware Wearables and Worker Well-Being

At Industry 5.0's heart lies a simple yet profound idea: people matter more than productivity speed. To match this aim, engineers now outfit helmets and wristbands with ESP32 units that track stress, hydration, and fatigue in real time. Davila-Gonzalez and Martin (2024) describe a human digital twin system in which tiny ESP32 nodes log metrics like heart-rate variability and skin moisture, flaging burnout before it escalates and giving crews the chance to step back, hydrate, or rest before accidents can occur [

54].

Nguyen and colleagues (2023) designed a compact safety unit built on the ESP32 that interprets physiological data to infer worker emotions and, crucially, relays instant warnings to supervisors, thereby closing the empathy loop the factory had long lacked between algorithms and people [

49].

4.5.5. Voice-Controlled Factory Assistants and Conversational Agents

The same chip features in hands-free factory assistants that let operatives speak commands instead of fumbling with buttons. Ayhem et al (2024) paired the ESP32 with a conversational AI, allowing both patients and shop-floor staff to dialogue naturally with machines, a clear shift from screens to voice-first control [

55].

4.5.6. Smart Prosthetics and Bio-Feedback Interfaces

ESP32 also anchors next-generation prostheses that adapt in real time to users. Balaji (2023) presented skin-mounted sensors, powered by the chip, that track gestures and even relay emotional cues, giving people with disabilities an intuitive grip on robotic limbs through tiny embedded motors [

56].

4.5.7. Decentralized Safety Alert Systems

Its fast, short-range radio, the ESP32 has formed peer-to-peer safety nets that do not rely on cloud servers (

Figure 14). Suman et al. (2024) outfitted workers in extreme heat with wristbands that watch hydration and heart rate, wirelessly firing alerts the instant limits are crossed, thus ensuring immediate local response [

57].

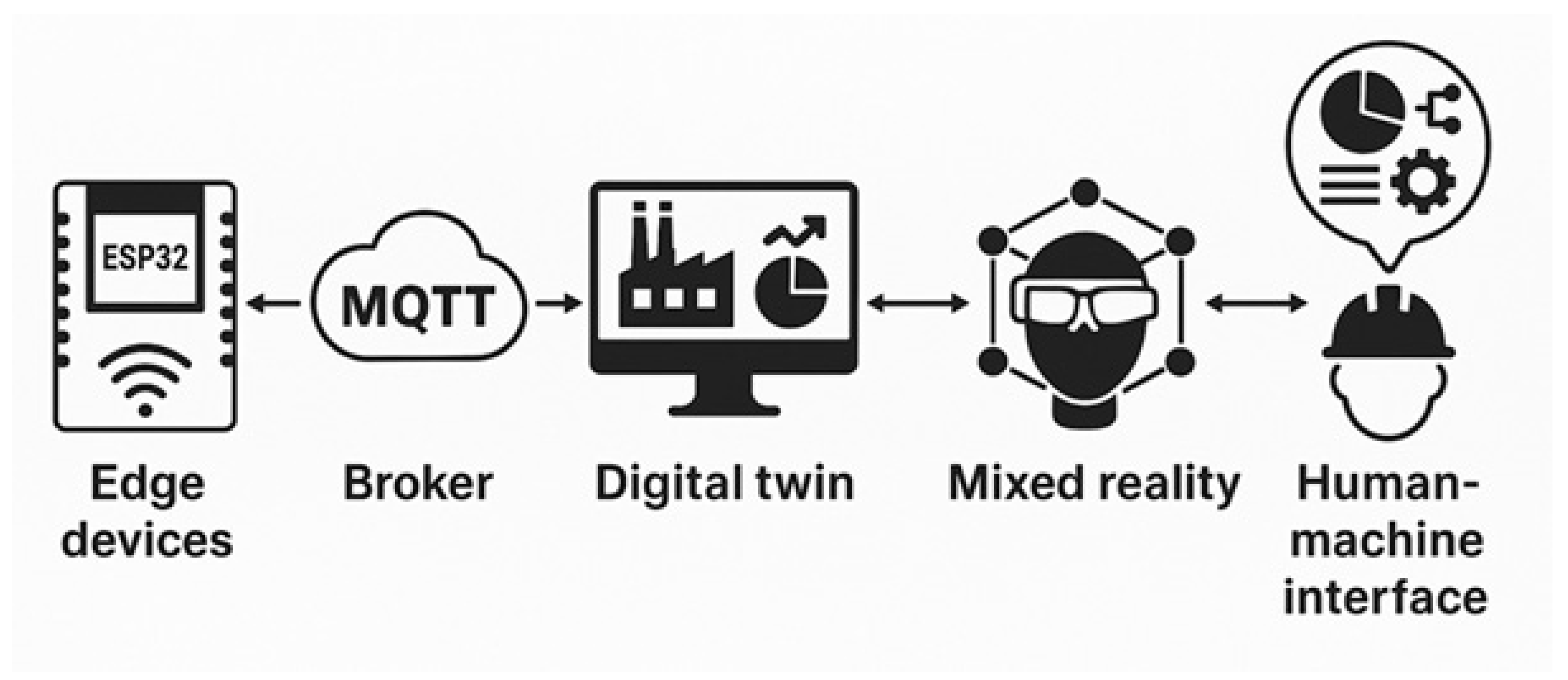

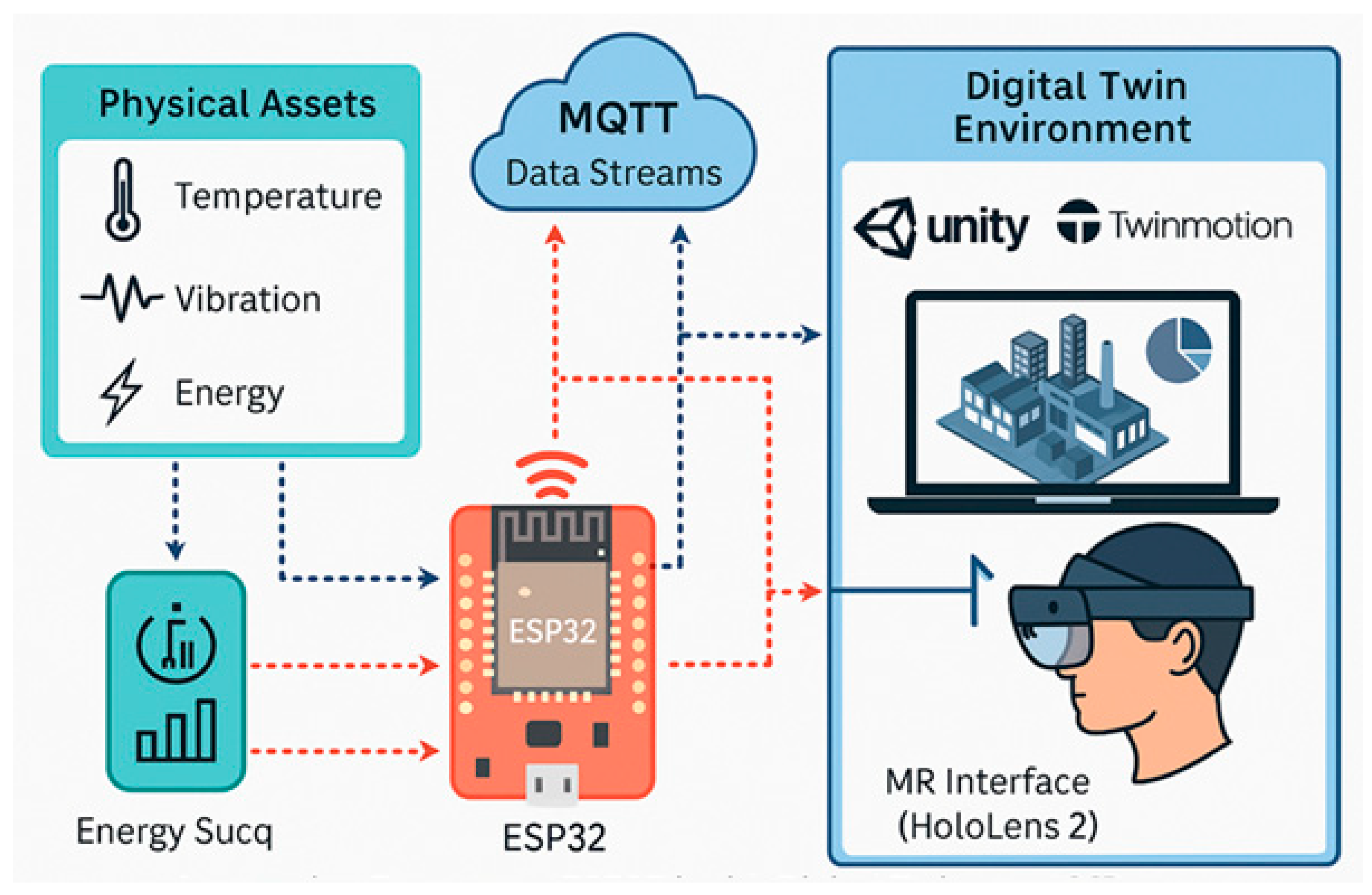

5. Integration Ecosystem: ESP32 with Digital Twins and MR

The ESP32 microcontroller therefore sits at the heart of many live digital-twin projects, quietly doubling as a two-way data pipe between real factory machines and the 3D models that mirror them. Using lean messaging tools such as MQTT, any ESP32 board can plug in a string of sensor readings-temperatures, vibration peaks, power dips-and ship that stream straight into graphics packages like Unity or Twinmotion. The moment those numbers arrive, the software swaps static widgets for glowing real-time graphs, turning code into a moving dashboard that speaks about health, efficiency, and future surprises (

Figure 15).

Tu (2024) argues that hooking Unity to MQTT feeds from edge boards makes building an industrial metaverse both quick and wallet-friendly. Once the link is alive, operators gain more than pretty pictures; they can run shifting simulations, walk through digital playbooks, and rehearse procedures in mixed-reality spaces-all tricks that sharpen predictive control and staff training [

58].

The picture deepens when mixed-reality headsets, say HoloLens 2 or Meta Quest 3, join the party. As shown by Fernández-Caramés and Fraga-Lamas (2024), ESP32 sensors keep sending field data to Unity, which then streams live holograms to the goggles. From there, team members can point, swipe, or just speak to check machine health, sound alarms, or kick off diagnostics, all within an interactive 3D factory that feels as immediate as the floor itself [

59].

MQTT, serving as the system's nerve center, not only delivers data with minimal delay but also allows commands to flow in both directions. Sensor readings, alerts when limits are crossed, and key performance metrics zip straight to Unity dashboards, which then change appearance and send warnings. Operators can therefore see forecast charts and failure alerts projected over real machines in mixed reality, making maintenance more proactive.

Campos (2024) added a method that links ESP32-based hardware to these digital displays. By treating MQTT messages and Unity scenes as shared middleware, their set-up pairs changes in the physical room with real-time updates in the digital twin, a big move toward interactive Industry 5.0 [

60]. When all components are joined-ESP32 gadgets, MQTT pipes, Unity or Twinmotion graphics, and MR headsets-they form an agile cyber-physical-human loop. That loop does more than watch data; it invites users to touch, talk, learn, and let machines step in on their behalf, exactly what Industry 5.0 promises.

6. Security, Challenges, and Limitations

The ESP32 chip is often picked for industrial Internet of Things projects because it is cheap and carries Wi-Fi and Bluetooth inside. Yet putting the board into real Industry 4.0 or 5.0 factories brings its own headaches. Administrators must deal with hacking risks, clumsy firmware upgrades, limits in the physical device itself, harsh surroundings, and the awkward job of making new gear speak the same language as aging machines.

6.1. Cybersecurity Challenges

6.1.1. Security Challenges and Vulnerabilities of ESP32 in Industry 5.0 Edge Applications

The ESP32 chip indeed includes useful security tools, like Transport Layer Security (TLS), AES hardware encryption, and a secure-boot feature, yet its small memory and limited CPU cycles hinder the roll-out of more exhaustive defenses. As Sabbatini (2024) points out, many factories skip advanced cryptographic routines because they seem too complex or burden the system [

61]. Rönty (2025) showed that crane-control nodes communicating over MQTT fell prey to sniffing and unauthorized commands when credentials were mishandled and encryption was optional [

62]. In a similar vein, Jepson (2024) found that long-range ESP32 sensors used in smart farming became easy targets for relay attacks once mutual TLS was absent, revealing a persistent gap between what the hardware can do and what developers actually deploy [

63].

Although the ESP32 chip has built-in tools for light-weight symmetric encryption, many real-world projects skip the basics of secure over-the-air (OTA) updates and certificate handling. Rönty (2023) illustrated that lax Wi-Fi settings can let intruders harvest stored passwords [

62]. Jepson (2024) pointed out that without a solid provisioning plan, edge devices turn into door knobs for attackers [

63]. Sabbatini (2024) and co-authors therefore urge updated key exchange methods and robust firmware pipelines, especially when sensors and gateways act as a network of nodes [

61]. Podder et al. (2025) further argue that in a layered Industry 5.0 framework, ignoring edge security-where the ESP32 usually sits-opens holes that reach up to fog and cloud services [

64].

6.1.2. Secure OTA Firmware Updates

In industrial IoT settings, OTA updates let operators fix bugs, roll out fresh cryptographic keys, and add useful features to ESP32-based machines. The chip handles OTA out of the box, yet sloppy coding-passing unsigned images over HTTP, using easy passwords, or skirting certificate checks-can let attackers swap genuine bins for rogue ones or intercept plain traffic. As Peng (2022) reminds us, even an AES-encrypted stream loses all value if the receiver cannot prove the sender is trusted, and that gap leaves devices open to payload take-over [

65].

To mitigate these vulnerabilities, Podder et al. (2025) introduced the S-RFUP (Secure Remote Firmware Update Protocol), which harnesses asymmetric encryption paired with a secure boot chain to deliver real-time, resilient over-the-air (OTA) protection for ESP32 devices [

64]. Wang et al. (2024) likewise showed that layering public-key crypto on standard checksum checks improves both the integrity of the code and users trust in its delivery [

66]. In broader surveys, El Jaouhari and Bouvet (2022) noted that, although the ESP32 platform supports strong OTA security tools, actual deployments-especially those at fog or edge levels-often skip key protective steps [

67].

While the ESP32 packs impressive functionality into a single chip, its baseline 520 KB of SRAM (upgradable to 2-8 MB of external PSRAM in later models) can bottleneck memory-hungry applications like on-the-fly object detection, multi-sensor data fusion, or full deep-learning inference. The chip handles lightweight TinyML workloads reasonably well, yet tasks that exceed simple threshold checks frequently trigger out-of-memory errors or starved scheduling.

Recent smart-farming trials showed that latency and throughput on an ESP32 plummeted when the device juggled encrypted MQTT messages and ADC soil readings, forcing developers to isolate some duties through task offloading [

68].

6.1.3. Environmental Limitations

Factories and heavy plants usually expose electronics to extreme heat, strong electromagnetic noise, moisture, and unstable power. By itself, an ESP32 chip lacks the rugged ratings needed for such settings; only when it sits inside an IP-rated case does it gain extra protection. Without proper shielding, engineers see watchdog resets, lost EEPROM data, and momentary voltage spikes that damage components.

Jepson (2024) documented failures in ESP32-based electronic logging devices when installed in freight trucks lacking thermal pads and voltage filters. In response, todays industrial engineers routinely recommend purpose-built metal enclosures, heavy-duty capacitors, and inline regulators for any critical ESP32 project [

63].

6.1.4. Compatibility with Legacy Systems

Older factory networks run on proprietary Fieldbus, RS-485 links, or non-IP SCADA protocols, making ESP32 adoption challenging. Although the microcontroller handles Modbus RTU, Modbus TCP, and even CAN, each of those standards demands external transceivers and middleware that glue modern code to vintage hardware. Absent these protocol wrappers or OPC-UA bridges, getting legacy programmable logic controllers to talk with an ESP32 system quickly turns into a costly headache.

Podder et al. (2025) note that secure firmware management across mixed industrial topologies needs modular gateways that translate, buffer, and log traffic between new Wi-Fi nodes and existing assets, a solution most plants still avoid [

64].

6.2. Standardization and Compliance

6.2.1. ISO/IEC 30141 Compliance and IoT Architecture Integration

ISO/IEC 30141:2018 lays out a common reference framework for the Internet of Things, promoting interoperability, scalability, and security among diverse industrial devices. Although the ESP32 chip lacks formal ISO/IEC 30141 certification, developers frequently deploy it in compliant environments because it supports well-established protocols-MQTT, CoAP, TLS/SSL, Modbus-and thus fits smoothly into fog and edge layers.

As Sabbatini (2024) notes, the ESP32 can join security-focused IoT grids when users adopt NIST SP 800-53 and ISO/IEC 27001 measures, including over-the-air (OTA) signature checks, TLS 1.2 sessions, and role-based access via lightweight message brokers [

61]. Its modular firmware, properly tuned, permits seamless insertion into ISO/IEC 30141-based networks, particularly in private industrial IoT or SCADA settings that demand deterministic, low-latency communication.

6.2.2. Challenges in Meeting Industrial Certifications

Even though the ESP32 has found a home in many production environments, several hurdles still block its path to full factory certification, especially in projects where functional safety and tight timing rules matter:

IEC 61131 (Programmable Controllers Standard): The chip comes without certified real-time firmware or deterministic timing that PLCs must show. It also lacks built-in support for ladder logic (LD), structured text (ST), or function block diagrams (FBD); though projects like OpenPLC try to fill that hole, hardware and timing guarantees are still shaky.

ISO 13849 (Safety of Machinery - Functional Safety): The rule asks for fault-tolerant hardware and verified safety layers. As Michael et al (2021) notes, off-the-shelf ESP32 boards have no redundancy, no safety-rated watchdogs, and cannot reach any SIL (Safety Integrity Level) on their own. That leaves them off limits in jobs where a silent fault might hurt people, unless engineers install extra verified safety relays or controllers [

69].

7. Ethical and Societal Implications of ESP32 in Industry 5.0

7.1. Ethical Concerns: AI Bias at the Edge

ESP32 chips are now stepping up as local brains on the factory floor, running compact AI tasks with lean frameworks such as TensorFlow Lite Micro. As this practice spreads, fears about bias and the murky transparency of edge decisions grow. Unlike cloud servers, which command heavy compute power and face clear regulatory eyes, on-board models usually train on small or skewed samples and offer little in the way of explainability or audit trails.

Imbalances in those training sets can leak into services such as facial ID, gesture steering, or fault spotting when the chips are set loose in messy, unstandardized industrial spaces. Kostadimas and colleagues (2025) urge builders of ESP32 edge-AI gear to weave bias guards into the design-using simple tweaks like extra synthetic frames, richer sensor mixes, and hard-coded fairness rules-so that the output treats every worker and machine fairly [

70].

The problem sharpens in high-stakes settings such as smart helmets or mobility aids; a wrong or slanted call from a wrist-mounted chip might endanger a person or degrade critical care [

71].

As these devices shift from tools to teammates in Industry 5.0, AL-Refaey and co-authors (2024) call for governance that lines up ethics with the limits of on-chip reasoning and the "black-box" aura surrounding embedded learning [

72].

7.2. Bridging the Digital Divide with ESP32

The ESP32 microcontroller is proving to be a low-cost gateway into twenty-first-century technology. Typically priced below ten dollars and supported by an open-source software community, it allows rural schools, tight-budget neighborhoods, and emerging economies to experiment with Industry 5.0 ideas without heavy capital outlay. On-the-ground projects now deploy ESP32 sensors for affordable air quality checks, simple energy management, and basic e-health dashboards in often-neglected regions [

12,

73,

74].

Rane (2024) notes a parallel trend in classrooms; ESP32 starter kits are nudging costly programmable logic controller simulators off the bench, widening access to STEM lessons and IIoT skill-building [

75]. Senoo et al. (2024) illustrate the chip in precision farming, linking it to low-cost AI for real-time soil monitoring and irrigation advice that can offset droughts and erratic weather-thus proving that inclusive tech diffusion is possible at scale [

76].

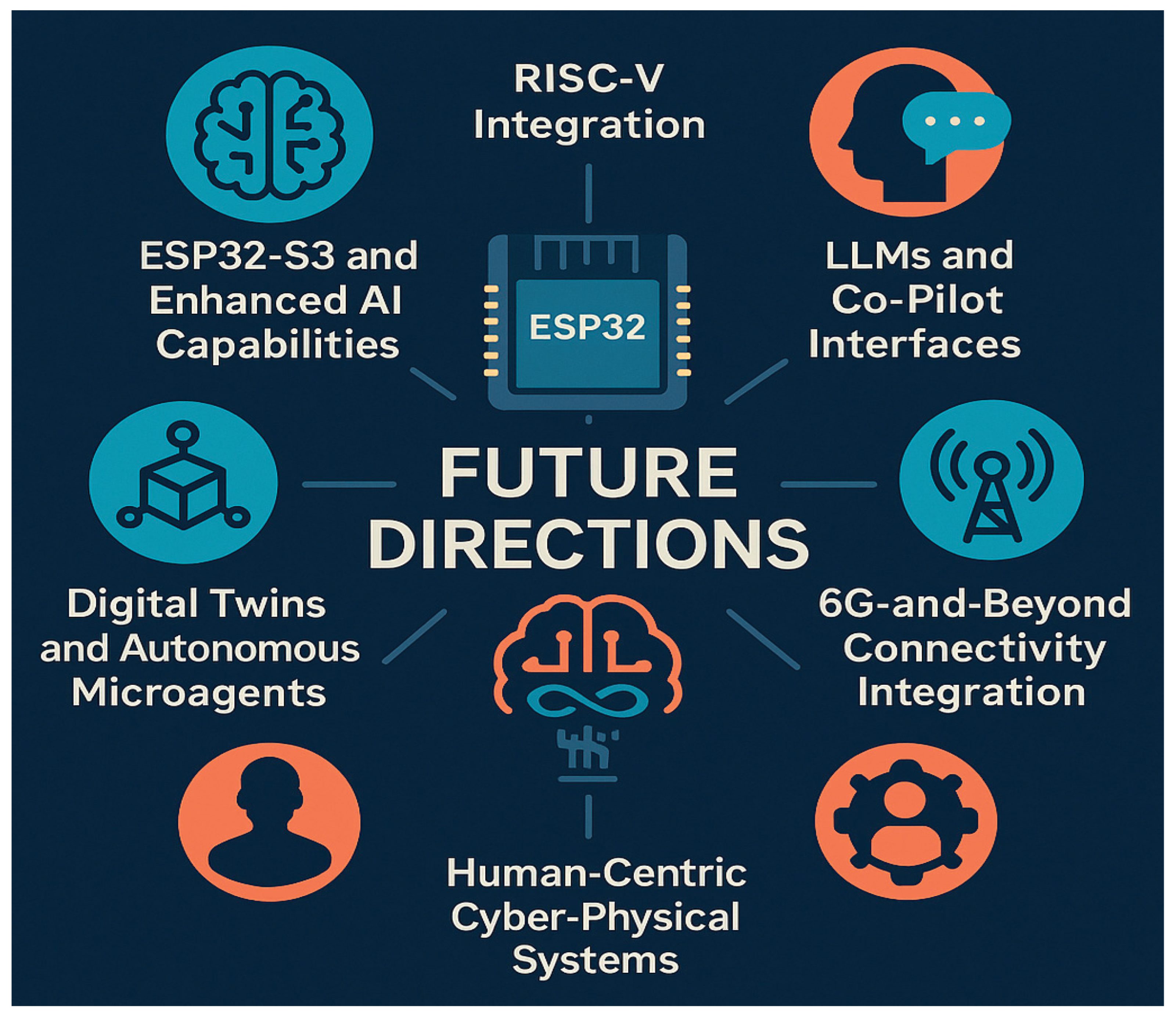

8. Future Directions

The future trajectory of the ESP32 community is intricately linked to advancements in embedded AI, open hardware frameworks, resilient wireless links, and enhanced cyber-physical-human collaboration, all of which are foundational to the industry 5.0 paradigm (

Figure 16). This evolution emphasizes a human-centric approach, leveraging intelligent systems to foster sustainable and efficient industrial practices.

8.1. ESP32-S3 and Enhanced AI Capabilities

The ESP32-S3 represents a notable step forward in Espressifs product family. With dedicated vector instructions and on-chip AI hardware, the chip runs TinyML models, recognizes gestures, initiates voice wake-ups, and carries out local anomaly detection. These frameworks support the development of cognitive cobots and other intelligent systems that enhance productivity and sustainability [

77]. These features make it a vital building block for intelligent edge devices that must act in real time. Support for TensorFlow Lite Micro allows developers to load quantized neural networks straight onto the chip, reducing reliance on cloud services [

78].

8.2. RISC-V Integration

Espressifs shift toward RISC-V cores in future products like the ESP32-C6 mirrors the growing open-source hardware movement. The RISC-V architecture enables deeper customization, optional hardware security features, and an instruction set well suited to edge inference [

79]. As a result, designers gain fresh headroom for instruction-level parallelism and tighter control over real-time latencies [

80].

8.3. LLMs and Co-Pilot Interfaces

A promising frontier pairs ESP32 boards with large language models (LLMs) such as GPT-4, letting the microcontroller serve as a bridge between sensors and actuators and a remote brain. It can pack telemetry into structured prompts and relay them to an LLM dashboard or chatbot, which in turn acts as a virtual co-pilot. Such systems diagnose faults, walk users through tasks, or even simulate entire workflows based on data the ESP32 has gathered [

81]. LLMs can process vast amounts of sensor data, providing insights and summaries that enhance decision-making in IoT environments. Case studies demonstrate LLMs' effectiveness in applications such as DDoS attack detection and macroprogramming, showcasing their ability to write scripts and manage incidents autonomously [

82]. The Alchemist system illustrates how LLMs can empower end-users to develop robot applications through natural language inputs, reducing the need for extensive programming knowledge [

83].

8.4. Digital Twins and Autonomous Microagents

The ESP32 can continuously publish time-series data over MQTT or HTTP, making it a solid choice for live digital twins [

84]. Paired with small microservices, each board turns into a local agent that senses change, applies simple rules, and updates its virtual twin in the cloud. This architecture supports decentralized decision-making in smart factories, energy grids, and precision farms [

85,

86].

8.5. 6G-and-Beyond Connectivity Integration

The integration of 6G-and-beyond connectivity is expected to revolutionize data transmission and processing, especially through edge-fog computing architectures that will significantly enhance the functionality of devices like the ESP32. Key enabling technologies include massive cell-free MIMO, which improves signal quality and supports a dense network of connected devices [

87] and terahertz band communication, offering wider bandwidths and ultra-fast data rates essential for real-time applications [

88]. Additionally, artificial intelligence is central to optimizing network management, enabling self-healing networks, and enhancing user experiences [

89]. In the context of edge-fog computing, 6G facilitates ultra-low-latency control loops necessary for robotics and autonomous systems, while AIoT integration enables predictive analytics and intelligent decision-making [

89,

90]. Despite these advancements, challenges such as security, ethical implications, and the demand for resilient infrastructure continue to be critical areas of research [

90,

91].

8.6. Human-Centric Cyber-Physical Systems

The integration of the ESP32 into human-centric cyber-physical systems (HCPS) supports the vision of Industry 5.0 by fostering collaboration between humans and intelligent systems, particularly in applications such as wearable exoskeletons and haptic gloves that enhance physical capabilities and enable tactile interaction with digital environments [

92]. Its ability to process real-time data allows for context-aware responses and the monitoring of cognitive load, thereby optimizing task assignments to improve operator performance and well-being [

93]. Additionally, the ESP32 enables proactive safety measures through the analysis of physiological and environmental data and supports intuitive human-machine interfaces when integrated with XR headsets and smart health monitors [

94,

95]. Despite these advancements, ensuring safety, trust, and adherence to ethical principles remains a challenge, underscoring the importance of aligning technological development with human-centered values to achieve the goals of Industry 5.0.

9. Conclusion

Even though Industry 4.0 made factories lean on machines, Industry 5.0 now puts people and the planet back in the mix and asks plants to be smart, green, and sturdy all at once. Within this new outlook, the compact ESP32 microcontroller stands out as a quiet hero, tying together edge computing, quick on-the-spot choices, and constant wireless chatter so that every machine can pull its own weight while talking to the cloud when needed.

With its dual-core brains, built-in Wi-Fi, low power draw, and wide-range protocols, the chip slides easily into many roles-from keeping an eye on failing gear to spinning up complete digital twins. It runs tiny AI models on the factory floor, sparks near-instant feedback between sensors and actuators, and links old gear to fresh networks, moving beyond hobby projects and proving itself a trusted platform, even for systems that factories cannot afford to lose.

The ESP32 has become a key tool for making industrial smart tech available to a wider audience. Because it costs little and runs on open-source tools-Arduino IDE, ESP-IDF, PlatformIO-it reaches schools, small firms, and regions with few resources. This openness nurtures hands-on skills, bottom-up ideas, and wider involvement in the Fourth and Fifth Industrial Revolutions. As a result, low-income neighborhoods and stretched sectors can join smart farming, health tracking, weather monitoring, and microgrid projects, slowly closing the worlds digital gap.

Seen through the lens of Industry 5.0, which puts workers first and steers AI toward ethics and ecology, the ESP32 shines even brighter. It drives friendly machine interfaces, mood-sensing wearables, voice-guided robots, and other aids that tailor factory life and boost ergonomic and mental safety. When two ESP32s or a cloud model feeds a digital twin, or when fog and edge nodes link XR headsets, the chip shows how human, machine, and data can learn and adapt together in tomorrow's factories.While these advantages are notable, hurdles persist. The ESP32 falls short of stringent industrial benchmarks such as IEC 61131 or ISO 13849, restricting its deployment in safety-critical settings unless paired with externally certified subsystems. Limited RAM and CPU cycles can bottleneck demanding AI models or high-rate data streams. Its true value lies, however, in modularity-it connects easily to cloud back ends, off-board AI chips, and mature toolchains that together complete a distributed system.

Upcoming parts like the ESP32-S3 with on-chip AI acceleration, as well as future RISC-V variants, promise even wider reach at the edge. As industry shifts toward human-centered design, greener practices, and more decentralized smarts, the ESP32 will remain a vital, ethical, and inclusive building block for tomorrow’s innovations.

References

- Rojas, E.; Carrascal, D.; Lopez-Pajares, D.; Alvarez-Horcajo, J.; Carral, J. A.; Arco, J. M.; Martinez-Yelmo, I. A Survey on AI-Empowered Softwarized Industrial IoT Networks. Electronics 2024, 13 (10), 1979. [CrossRef]

- Fraga-Lamas, P.; Lopes, S. I.; Fernández-Caramés, T. M. Green IoT and Edge AI as Key Technological Enablers for a Sustainable Digital Transition towards a Smart Circular Economy: An Industry 5.0 Use Case. Sensors 2021, 21 (17), 5745. [CrossRef]

- Sharma, M.; Tomar, A.; Hazra, A. Edge Computing for Industry 5.0: Fundamental, Applications, and Research Challenges. IEEE Internet Things J. 2024, 11 (11), 19070–19093. [CrossRef]

- Pal, S. Artificial Intelligence-Based IoT-Edge Environment for Industry 5.0; 2024; pp 111–148. [CrossRef]

- Katuk, N.; Vergallo, R.; Sugiharto, T. The Future of Human-Computer Integration; CRC Press, 2024. [CrossRef]

- Fraga-Lamas, P.; Barros, D.; Lopes, S. I.; Fernández-Caramés, T. M. Mist and Edge Computing Cyber-Physical Human-Centered Systems for Industry 5.0: A Cost-Effective IoT Thermal Imaging Safety System. Sensors 2022, 22 (21), 8500. [CrossRef]

- Bongomin, O.; Mwape, M. C.; Mpofu, N. S.; Bahunde, B. K.; Kidega, R.; Mpungu, I. L.; Tumusiime, G.; Owino, C. A.; Goussongtogue, Y. M.; Yemane, A.; Kyokunzire, P.; Malanda, C.; Tigalana, D.; Gumisiriza, O.; Ngulube, G. Digital Twin Technology Advancing Industry 4.0 and Industry 5.0 Across Sectors, 2025. [CrossRef]

- Barros, D.; Fraga-Lamas, P.; Fernández-Caramés, T. M.; Lopes, S. I. A Cost-Effective Thermal Imaging Safety Sensor for Industry 5.0 and Collaborative Robotics; 2023; pp 3–15. [CrossRef]

- Krejčí, J.; Babiuch, M.; Suder, J.; Krys, V.; Bobovský, Z. Internet of Robotic Things: Current Technologies, Challenges, Applications, and Future Research Topics. Sensors 2025, 25 (3), 765. [CrossRef]

- Lousado, J. P.; Antunes, S. Monitoring and Support for Elderly People Using LoRa Communication Technologies: IoT Concepts and Applications. Future Internet 2020, 12 (11), 206. [CrossRef]

- Ahmed, D.; Ali, S. Z.; Khan, F. B.; Faruki, M. H. Design And Implementation Of An ESP32-Based Smart Home Automation System With Environmental Monitoring And Automated Controls. IOSR J. Electron. Commun. Eng. 2024, 19 (6), 23–28. [CrossRef]

- Abdulmalek, S.; Nasir, A.; Jabbar, W. A.; Almuhaya, M. A. M.; Bairagi, A. K.; Khan, M. A.-M.; Kee, S.-H. IoT-Based Healthcare-Monitoring System towards Improving Quality of Life: A Review. Healthcare 2022, 10 (10), 1993. [CrossRef]

- Islam, M. M.; Raju, S. M. T. U.; Nooruddin, S.; Karray, F.; Muhammad, G. Internet of Health Things: An Introduction. In Blockchain and Digital Twin for Smart Healthcare; Elsevier, 2025; pp 19–44. [CrossRef]

- Ianculescu, M.; Constantin, V.-Ștefan; Gușatu, A.-M.; Petrache, M.-C.; Mihăescu, A.-G.; Bica, O.; Alexandru, A. Enhancing Connected Health Ecosystems Through IoT-Enabled Monitoring Technologies: A Case Study of the Monit4Healthy System. Sensors 2025, 25 (7), 2292. [CrossRef]

- Sabo, A.; Suleiman, H. O.; Dahiru, Y.; Jatau, N. D.; Yusuf, A.; Chikodi, A. T. Development and Implementation of an ESP32 IOT-Based Smart Grid for Enhanced Energy Efficiency and Management. Eur. J. Theor. Appl. Sci. 2024, 2 (3), 565–576. [CrossRef]

- Atta, R. M. Cost-Effective Vital Signs Monitoring System for COVID-19 Patients in Smart Hospital. Health Technol. 2022, 12 (1), 239–253. [CrossRef]

- González-Baldovinos, D. L.; Sánchez-Fernández, L. P.; Cano-Rosas, J. L.; López-Chau, A.; Guevara-López, P. Innovations and Technological Advances in Healthcare Remote Monitoring Systems for the Elderly and Vulnerable People: A Scoping Review. Appl. Sci. 2025, 15 (6), 3200. [CrossRef]

- Ismayilov, M. T. VIRTUAL IOT LAB FOR EMBEDDED SOFTWARE DEVELOPMENT FOR ESP32 AND RASPBERRY PI BASED DEVICES. PhD Thesis, TALLINN UNIVERSITY OF TECHNOLOGY, 2020. https://digikogu.taltech.ee/et/Download/95967cfa-0338-424c-906e-3a91a66d96a7/VirtuaalneIoTlaborsardtarkvaraarendamiseksESP.pdf.

- Pisco, X.; Dias, J. Adopting Containers in Microcontrollers for the IoT; 2023. https://repositorio-aberto.up.pt/bitstream/10216/152017/2/636811.pdf.

- Ojo, M. O.; Giordano, S.; Procissi, G.; Seitanidis, I. N. A Review of Low-End, Middle-End, and High-End Iot Devices. IEEE Access 2018, 6, 70528–70554. [CrossRef]

- Fanariotis, A.; Orphanoudakis, T.; Kotrotsios, K.; Fotopoulos, V.; Keramidas, G.; Karkazis, P. Power Efficient Machine Learning Models Deployment on Edge IoT Devices. Sensors 2023, 23 (3), 1595. [CrossRef]

- Njor, E.; Hasanpour, M. A.; Madsen, J.; Fafoutis, X. A Holistic Review of the TinyML Stack for Predictive Maintenance. IEEE Access 2024, 1–1. [CrossRef]

- He, W. Design of Supervisory Controllers and Ultra-Low Power Data Loggers for Hybrid Power Systems. PhD Thesis, Memorial University of Newfoundland, 2024. https://research.library.mun.ca/16657/1/thesis.pdf.

- Lamaakal, I.; Essahraui, S.; Maleh, Y.; Makkaoui, K. E.; Ouahbi, I.; Bouami, M. F.; El-Latif, A. A. A.; Almousa, M.; Peng, J.; Niyato, D. A Comprehensive Survey on Tiny Machine Learning for Human Behavior Analysis. IEEE Internet Things J. 2025, 1–1. [CrossRef]

- Zeeshan, M. Efficient Deep Learning Models for Edge IOT Devices - A Review, 2024. [CrossRef]

- Shuvo, M. M. H.; Islam, S. K.; Cheng, J.; Morshed, B. I. Efficient Acceleration of Deep Learning Inference on Resource-Constrained Edge Devices: A Review. Proc. IEEE 2023, 111 (1), 42–91. [CrossRef]

- Ledmaoui, Y.; Maghraoui, A. E.; Aroussi, M. E.; Saadane, R. Review of Recent Advances in Predictive Maintenance and Cybersecurity for Solar Plants. Sensors 2025, 25 (1), 206. [CrossRef]

- Folgado, F.; Calderón, D.; González, I.; Calderón, A. Review of Industry 4.0 from the Perspective of Automation and Supervision Systems: Definitions, Architectures and Recent Trends. Electronics 2024, 13 (4), 782. [CrossRef]

- Codreanu, A. AI, IoT and Edge Continuum Impact and Relation on 5G/6G: Enabling Technologies and Challenges, 4.0.; Austrian Institute of Technology, 2025.

- Boucif, O. H.; Lahouaou, A. M.; Boubiche, D. E.; Toral-Cruz, H. Artificial Intelligence of Things for Solar Energy Monitoring and Control. Appl. Sci. 2025, 15 (11), 6019. [CrossRef]

- Sverko, M.; Grbac, T. G.; Mikuc, M. SCADA Systems With Focus on Continuous Manufacturing and Steel Industry: A Survey on Architectures, Standards, Challenges and Industry 5.0. IEEE Access 2022, 10, 109395–109430. [CrossRef]

- Manikandan, P. T. N. Advanced Manufacturing Systems and Industry 4.0. In Industry 4.0 for Manufacturing Systems; 2025.

- Rosca, C.-M.; Rădulescu, G.; Stancu, A. Artificial Intelligence of Things Infrastructure for Quality Control in Cast Manufacturing Environments Shedding Light on Industry Changes. Appl. Sci. 2025, 15 (4), 2068. [CrossRef]

- Fufon, K.; Notesiri, U.; Lekchaum, K.; Chomsuwan, K.; Tanitteerapan, T.; Puengsungewan, S. Smart Electric Resistance Welding Based on Artificial Intelligence (AI) Based on Real-Time Adaptive Statistical Features Completed with Bibliometric Analysis. ASEAN J. Sci. Eng. 2025, 5 (1), 173–198. [CrossRef]

- Radia, M. A. Next-Generation Monitoring; 2025; pp 351–398. [CrossRef]

- Fuente, R. de la; Radrigan, L.; Morales, A. S. Enhancing Predictive Maintenance in Mining Mobile Machinery Through a Hierarchical Inference Network. IEEE Access 2025, 13, 59480–59504. [CrossRef]

- Halenar, I.; Halenarova, L.; Tanuska, P.; Vazan, P. Machine Condition Monitoring System Based on Edge Computing Technology. Sensors 2024, 25 (1), 180. [CrossRef]

- Manonmani, A.; Sumesh, A.; E, K.; S, M. K. M. Review on IoT-Enhanced Predictive Maintenance and Safety for Energy Generating Facilities. In 2025 International Conference on Electronics and Renewable Systems (ICEARS); IEEE, 2025; pp 481–486. [CrossRef]

- Raj, A. Fog Computing in Smart City IoT Architectures for Latency Reduction. Comput. Eng. Technol. Innov. 2024, 1 (4), 248–257.

- Oliveira, F.; Costa, D. G.; Assis, F.; Silva, I. Internet of Intelligent Things: A Convergence of Embedded Systems, Edge Computing and Machine Learning. Internet Things 2024, 26, 101153. [CrossRef]

- Scarton, G.; Formentini, M.; Romano, P. Automating Quality Control through an Expert System. Electron. Mark. 2025, 35 (1), 14. [CrossRef]

- Tasmi, T. F. IOT ENABLED OBJECT DETECTION ON EDGE DEVICES. PhD Thesis, SAVONIA UNIVERSITY OF APPLIED SCIENCES, 2025. https://www.theseus.fi/bitstream/handle/10024/891288/Tasmi_Tahsina%20Ferdous.pdf?sequence=2&isAllowed=y.

- Saban, M.; Bekkour, M.; Amdaouch, I.; El Gueri, J.; Ait Ahmed, B.; Chaari, M. Z.; Ruiz-Alzola, J.; Rosado-Muñoz, A.; Aghzout, O. A Smart Agricultural System Based on PLC and a Cloud Computing Web Application Using LoRa and LoRaWan. Sensors 2023, 23 (5), 2725. [CrossRef]

- Handoko, C. R.; Sutrisno, I.; Sidi, P.; Ardiansyah. Enhancing Aquaculture Efficiency through IoT-Based Monitoring of Solar PV Systems. Formosa J. Comput. Inf. Sci. 2025, 4 (1), 93–100. [CrossRef]

- Permana Muqorrobin, Z.; Nawawi, A.; Aris Ardani, A.; Putra Setia, S.; Rahmadian, R. Off-Grid Solar System Monitoring Based on ESP-32 and INA219 In Pesanggrahan Gordomulyo. Vokasi Unesa Bull. Eng. Technol. Appl. Sci. 2024, 26–37. [CrossRef]

- Harianto, D.; Bintang, H. S.; Ardiyanto, A.; Widyawan, V. L. D. Development and Evaluation of an ESP32-Based Temperature and Humidity Control Unit for Textile Storage. Int. J. Eng. Contin. 2024, 4 (1), 1–19. [CrossRef]

- XIAN, L. Z. DEVELOPMENT OF A WEARABLE GLOVE FOR VIRTUAL REALITY APPLICATION. Thesis, Universiti Tunku Abdul Rahman, 2023. http://eprints.utar.edu.my/5820/1/MH_1802784_Final_LOW_ZE_XIAN.pdf.

- Yang, J.; Liu, Y.; Morgan, P. L. Human–Machine Interaction towards Industry 5.0: Human-Centric Smart Manufacturing. Digit. Eng. 2024, 2, 100013. [CrossRef]

- Nguyen, T.; Nguyen, D. H.; Nguyen, Q.-T.; Tran, K. D.; Tran, K. P. Human-Centered Edge AI and Wearable Technology for Workplace Health and Safety in Industry 5.0; 2024; pp 171–183. [CrossRef]

- Rahmani, R.; Karimi, J.; Resende, P. R.; Abrantes, J. C. C.; Lopes, S. I. Overview of Selective Laser Melting for Industry 5.0: Toward Customizable, Sustainable, and Human-Centric Technologies. Machines 2023, 11 (5), 522. [CrossRef]

- Khalid, W.; Jamil, M.; Khan, A. A.; Awais, Q. Open-Source Internet of Things-Based Supervisory Control and Data Acquisition System for Photovoltaic Monitoring and Control Using HTTP and TCP/IP Protocols. Energies 2024, 17 (16), 4083. [CrossRef]

- Barbosa, W. S.; Gonçalves, F. M.; Henriques, F. R.; Gurgel, J. L.; Gouvea, F. C.; Gioia, M. M. Industry 4.0: Construction of a Waterproof Wearable Biosignal Device to Assist in Submerged Offshore Work. In 2022 8th International Conference on Control, Decision and Information Technologies (CoDIT); IEEE, 2022; pp 159–164. [CrossRef]

- Rojas, M.; Ponce, P.; Molina, A. Development of a Sensing Platform Based on Hands-Free Interfaces for Controlling Electronic Devices. Front. Hum. Neurosci. 2022, 16, 867377. [CrossRef]

- Davila-Gonzalez, S.; Martin, S. Human Digital Twin in Industry 5.0: A Holistic Approach to Worker Safety and Well-Being through Advanced AI and Emotional Analytics. Sensors 2024, 24 (2), 655. [CrossRef]

- Ayhem, D. M.; Bekhoucha, M.; Guessoum, S. H. E.; Zouai, M. Integrating Conversational AI into a Physical Autonomy for Medical Applications, University of Mohamed Khider - Biskra, 2024. https://documentation.univ-biskra.dz/bibsenv/opac_css/index.php?lvl=notice_display&id=8608 (accessed 2025-01-01).

- Balaji, A. N. DESIGN OF WEARABLE APPLICATIONS AND PLATFORMS FOR NEXT GENERATION PERSONALIZED SENSING. PhD Thesis, NATIONAL UNIVERSITY OF SINGAPORE, 2023. https://www.proquest.com/openview/708bee0aee04a14c298aade9dc7dcd9c/1?pq-origsite=gscholar&cbl=2026366&diss=y.

- Suman, P.; Suman, A.; Padhay, S.; Kumar, N.; H, S. M.; Singh, A.; Sharma, A. Wearable Devices—A New Dimension in Healthcare. In Healthcare Industry Assessment: Analyzing Risks, Security, and Reliability; Manoj, D., Pardeep, G. D. K., Singh, Eds.; Springer Nature Switzerland, 2024; pp 279–300. [CrossRef]

- Tu, X.; Autiosalo, J.; Jadid, A.; Tammi, K.; Klinker, G. A Mixed Reality Interface for a Digital Twin Based Crane. Appl. Sci. 2021, 11 (20). [CrossRef]

- Fernández-Caramés, T. M.; Fraga-Lamas, P. Forging the Industrial Metaverse for Industry 5.0: Where Extended Reality, IIoT, Opportunistic Edge Computing, and Digital Twins Meet. IEEE Access 2024, 12, 95778–95819. [CrossRef]

- CAMPOS, N. MAKING THE VIRTUAL A REALITY: A FRAMEWORK TO CONNECT PHYSICAL DEVICES TO VIRTUAL WORLDS. PhD Thesis, Universidade Europeia, 2024. https://comum.rcaap.pt/entities/publication/e5961fd2-04fd-47c0-b830-2d4f94b2e183.

- Sabbatini, M. Hardening IoT Devices: An Analysis of the ESP32 Microcontroller. PhD Thesis, University of Zurich, 2024. https://files.ifi.uzh.ch/CSG/staff/gruebl/extern/theses/ba-sabbatini.pdf.

- Rönty, T. Embedded Communication System for Crane Data Access. PhD Thesis, Aalto University, 2025. https://aaltodoc.aalto.fi/items/1388062e-a416-4f51-b61f-c64a35a36dd4.

- Jepson, J. CYBERSECURITY VULNERABILITIES IN ELECTRONIC LOGGING DEVICES AND DEVELOPMENT OF A SOFTWARE DEFINED TRUCK TESTBED. Thesis, Colorado State University, 2024. https://www.proquest.com/openview/62273e2af9381bdd3d5000a4e4be417e/1?pq-origsite=gscholar&cbl=18750&diss=y.

- Podder, R.; Rios, T.; Ray, I.; Raman, P.; Righi, S. S-RFUP: Secure Remote Firmware Update Protocol. In Information Systems Security; Patil, V. T., Krishnan, R., Shyamasundar, R. K., Eds.; Lecture Notes in Computer Science; Springer Nature Switzerland: Cham, 2025; Vol. 15416, pp 42–62. [CrossRef]

- Peng, C.; Song, Y.; Yang, L. Detection of Weak Ship Radiation Characteristic Signal Based on Wavelet and Chaos Array. In 2022 IEEE 6th Information Technology and Mechatronics Engineering Conference (ITOEC); IEEE: Chongqing, China, 2022; pp 139–150. [CrossRef]

- Wang, Y.; Wan, C.; Zhang, H. A 6bit Ultra-Wideband Passive Phase Shifter in 0.13μm BiCMOS Technology. In 2022 7th International Conference on Integrated Circuits and Microsystems (ICICM); IEEE, 2022; pp 574–577. [CrossRef]

- El Jaouhari, S.; Bouvet, E. Secure Firmware Over-The-Air Updates for IoT: Survey, Challenges, and Discussions. Internet Things 2022, 18, 100508. [CrossRef]

- Piridi, S.; Asundi, S. Rise of the AI Bureaucrats, 2025. [CrossRef]

- Michael, O.; Tung Lun, L.; Eng Keong, K. Methodology to Improve Safety Critical SoC Based Platform: A Case Study. In 2021 IEEE International Reliability Physics Symposium (IRPS); IEEE: Monterey, CA, USA, 2021; pp 1–4. [CrossRef]

- Kostadimas, D.; Kasapakis, V.; Kotis, K. A Systematic Review on the Combination of VR, IoT and AI Technologies, and Their Integration in Applications. Future Internet 2025, 17 (4), 163. [CrossRef]

- Pineda-Alpizar, A. F.; Mourraille-Rojas, J.; Cruz-Alvarenga, A. Challenges and Strategies in AI-Enhanced Occupational Therapy for Large-Scale Dementia Rehabilitation: In Advances in Medical Technologies and Clinical Practice; Liu, H., Tripathy, R. K., Bhattacharya, P., Eds.; IGI Global, 2024; pp 123–144. [CrossRef]

- AL-Refaey, M. R.; Tyagi, A. K.; AL-Ghamdi, A. S. A.-M.; Kukreja, S. Topics in Artificial Intelligence Applied to Industry 4.0; John Wiley & Sons, 2024.

- Bogdanffy, L.; Lorinț, C. R.; Nicola, A. Development of a Low-Cost Traffic and Air Quality Monitoring Internet of Things (IoT) System for Sustainable Urban and Environmental Management. Sustainability 2025, 17 (11), 5003. [CrossRef]

- El-Khozondar, H. J.; Mtair, S. Y.; Qoffa, K. O.; Qasem, O. I.; Munyarawi, A. H.; Nassar, Y. F.; Bayoumi, E. H. E.; Halim, A. A. E. B. A. E. A Smart Energy Monitoring System Using ESP32 Microcontroller. E-Prime - Adv. Electr. Eng. Electron. Energy 2024, 9, 100666. [CrossRef]

- Rane, N. L. Artificial Intelligence and Industry in Society 5.0; Deep Science Publishing, 2024.

- Senoo, E. E. K.; Anggraini, L.; Kumi, J. A.; Karolina, L. B.; Akansah, E.; Sulyman, H. A.; Mendonça, I.; Aritsugi, M. IoT Solutions with Artificial Intelligence Technologies for Precision Agriculture: Definitions, Applications, Challenges, and Opportunities. Electronics 2024, 13 (10), 1894. [CrossRef]

- Zulkifli, A.; Wasesa, M. Industry 5.0 Research in the Sustainable Information Systems Sector: A Scoping Review Analysis. Int. J. Adv. Data Inf. Syst. 2024, 5 (2). [CrossRef]

- G, D. R.; Boopathy, P. A Survey on AI Integration into Industry 5.0. Gazi Univ. J. Sci. 2025, 38 (1), 99–113. [CrossRef]

- Kumar M, A.; Kumar, V.; John, D.; Shanker, S. Implementation and Analysis of Custom Instructions on RISC-V for Edge-AI Applications. In 14th International Symposium on Highly Efficient Accelerators and Reconfigurable Technologies (HEART’24)); ACM: Porto Portugal, 2024; pp 126–129. [CrossRef]

- Zuckerman, J.; Mantovani, P.; Giri, D.; Carloni, L. P. Enabling Heterogeneous, Multicore SoC Research with RISC-V and ESP. arXiv 2022. [CrossRef]

- Xu, J.; Wang, Q.; Cao, Y.; Zeng, B.; Liu, S. A General-Purpose Device for Interaction with LLMs. arXiv 2024. [CrossRef]

- Zong, M.; Hekmati, A.; Guastalla, M.; Li, Y.; Krishnamachari, B. Integrating Large Language Models with Internet of Things: Applications. Discov. Internet Things 2025, 5 (1), 2. [CrossRef]

- Karli, U. B.; Chen, J.-T.; Antony, V. N.; Huang, C.-M. Alchemist: LLM-Aided End-User Development of Robot Applications. In Proceedings of the 2024 ACM/IEEE International Conference on Human-Robot Interaction; ACM: Boulder CO USA, 2024; pp 361–370. [CrossRef]

- Cho, Y.; Noh, S. D. Design and Implementation of Digital Twin Factory Synchronized in Real-Time Using MQTT. Machines 2024, 12 (11), 759. [CrossRef]

- Redeker, M.; Weskamp, J. N.; Rössl, B.; Pethig, F. A Digital Twin Platform for Industrie 4.0. In Data Spaces; Curry, E., Scerri, S., Tuikka, T., Eds.; Springer International Publishing: Cham, 2022; pp 173–200. [CrossRef]

- Human, C.; Basson, A. H.; Kruger, K. Digital Twin Data Pipeline Using MQTT in SLADTA. In Service Oriented, Holonic and Multi-Agent Manufacturing Systems for Industry of the Future; Borangiu, T., Trentesaux, D., Leitão, P., Cardin, O., Lamouri, S., Eds.; Studies in Computational Intelligence; Springer International Publishing: Cham, 2021; Vol. 952, pp 111–122. [CrossRef]

- Mishra, A. K.; Ponnusamy, V. Key Technologies and Architectures for 6G and Beyond Wireless Communication System. In AI and Blockchain Technology in 6G Wireless Network; Dutta Borah, M., Singh, P., Deka, G. C., Eds.; Blockchain Technologies; Springer Nature Singapore: Singapore, 2022; pp 25–44. [CrossRef]

- Akyildiz, I. F.; Kak, A.; Nie, S. 6G and Beyond: The Future of Wireless Communications Systems. IEEE Access 2020, 8, 133995–134030. [CrossRef]

- Akinwunmi, D.; Uche, O.; Shokunbi, O.; Akinwumi, H.; Awodele, O.; Ajaegbu, C. Navigating the Horizon Towards 6G Wireless Communication Networks. In 2024 IEEE SmartBlock4Africa; IEEE: Accra, Ghana, 2024; pp 1–9. [CrossRef]

- Gupta, M.; Gayathri, V.; Bhutani, M. Next-Generation Wireless Standards: 6G and Beyond. In Wireless Communication Networks and Applications; Bhutani, Dr. M., Gupta, Dr. M., Gupta, Dr. K., Pathak, Dr. N., Eds.; Iterative International Publishers, Selfypage Developers Pvt Ltd, 2024; pp 98–111. [CrossRef]

- Molefe, M.; Sibiya, K.; Nleya, B. A Futuristic Optical and Wireless Convergence Network Towards 6G and Beyond. In 2024 International Conference on Electrical, Computer and Energy Technologies (ICECET; IEEE: Sydney, Australia, 2024; pp 1–6. [CrossRef]

- Saadati, Z.; Barenji, R. V. Toward Industry 5.0: Cognitive Cyber-Physical System. In Industry 4.0; Azizi, A., Barenji, R. V., Eds.; Emerging Trends in Mechatronics; Springer Nature Singapore: Singapore, 2023; pp 257–268. [CrossRef]

- Simeone, A.; Grant, R.; Ye, W.; Caggiano, A. A Human-Cyber-Physical System for Operator 5.0 Smart Risk Assessment. Int. J. Adv. Manuf. Technol. 2023, 129 (5–6), 2763–2782. [CrossRef]

- Rane, N. L.; Kaya, Ö.; Rane, J. Artificial Intelligence, Machine Learning, and Deep Learning Technologies as Catalysts for Industry 4.0, 5.0, and Society 5.0. In Artificial Intelligence, Machine Learning, and Deep Learning for Sustainable Industry 5.0; Deep Science Publishing, 2024. [CrossRef]

- Lou, S.; Hu, Z.; Zhang, Y.; Feng, Y.; Zhou, M.; Lv, C. Human-Cyber-Physical System for Industry 5.0: A Review From a Human-Centric Perspective. IEEE Trans. Autom. Sci. Eng. 2025, 22, 494–511. [CrossRef]

Figure 1.

ESP32-WROOM-32 development board, highlighting its compact layout, robust microcontroller chip, and micro-USB interface.

Figure 1.

ESP32-WROOM-32 development board, highlighting its compact layout, robust microcontroller chip, and micro-USB interface.

Figure 2.

ESP32 development board, highlighting key components.

Figure 2.

ESP32 development board, highlighting key components.

Figure 3.

Architecture and performance features of the ESP32, showcasing it as the dual-core backbone of smart industry.

Figure 3.

Architecture and performance features of the ESP32, showcasing it as the dual-core backbone of smart industry.

Figure 4.

Communication protocols supported by the ESP32 microcontroller.

Figure 4.

Communication protocols supported by the ESP32 microcontroller.

Figure 5.

Primary programming environments of ESP32.

Figure 5.

Primary programming environments of ESP32.

Figure 6.

ESP32 as a central enabler of Industry 4.0 and 5.0 applications, supporting smart factories, predictive maintenance, edge computing, and human-centric automation all while promoting sustainable innovation.

Figure 6.

ESP32 as a central enabler of Industry 4.0 and 5.0 applications, supporting smart factories, predictive maintenance, edge computing, and human-centric automation all while promoting sustainable innovation.

Figure 7.

ESP32 microcontroller empowers both Industry 4.0 and Industry 5.0 transitions.

Figure 7.

ESP32 microcontroller empowers both Industry 4.0 and Industry 5.0 transitions.

Figure 8.

ESP32 bridges Industry 4.0 and 5.0 by different enabling technologies, it powers both smart factories and human-centric collaborative systems.

Figure 8.

ESP32 bridges Industry 4.0 and 5.0 by different enabling technologies, it powers both smart factories and human-centric collaborative systems.

Figure 9.

Key application domains of ESP32 in Industry 4.0 environments.

Figure 9.

Key application domains of ESP32 in Industry 4.0 environments.

Figure 10.

Machine to machine link via ESP32 in industry 4.0.

Figure 10.

Machine to machine link via ESP32 in industry 4.0.

Figure 11.

Object detection by ESP32 by TinyML.

Figure 11.

Object detection by ESP32 by TinyML.

Figure 12.

Role of ESP32 a central hub for Industry 4.0 and 5.0 innovations.

Figure 12.

Role of ESP32 a central hub for Industry 4.0 and 5.0 innovations.

Figure 13.

Human-Machine Interaction chain.

Figure 13.

Human-Machine Interaction chain.

Figure 14.

Real world industrial application, from assembly lines to smart health, demonstrating its versatility across Industry 4.0 and smart infrastructure domains.

Figure 14.

Real world industrial application, from assembly lines to smart health, demonstrating its versatility across Industry 4.0 and smart infrastructure domains.

Figure 15.

The integration ecosystem of ESP32 in a digital twin and mixed reality (MR) environment.

Figure 15.

The integration ecosystem of ESP32 in a digital twin and mixed reality (MR) environment.

Figure 16.

ESP32's future course in Industry 5.0. It illustrates the ways in which these developments come together to form intelligent, cooperative, and sustainable industrial ecosystems.

Figure 16.

ESP32's future course in Industry 5.0. It illustrates the ways in which these developments come together to form intelligent, cooperative, and sustainable industrial ecosystems.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).