Introduction

In recent years, environmental management and the promotion of sustainable development have become priority issues for both governments and the productive sector. Industrial and population growth in the department of Sucre represents significant progress in terms of economic development and job creation; however, it has also brought increased pressure on natural resources and the environment. While some companies have adopted technologies and practices aimed at mitigating the environmental impacts of their operations, significant gaps remain in the implementation of effective waste management solutions, particularly with regard to industrial wastewater. In this context, there has been an increase in collective awareness about the need to separate, treat, and, in some cases, reuse industrial waste. However, these practices are not yet fully integrated into most industries or households, highlighting the need to strengthen both technical knowledge and environmental education.

Wastewater generation is an inevitable consequence of various productive and domestic activities. This wastewater contains a variety of pollutants at different concentrations, which pose a potential risk to ecosystems if not properly managed. Among the industries with the highest wastewater generation in Sincelejo are the vehicle and motorcycle washing industry, which has experienced notable growth in recent years, and the ready-mix concrete industry, which has also experienced significant expansion in the department.

Both sectors generate wastewater with high levels of contamination daily. In the case of vehicle washing, the waste includes detergents, fuels, grease, oils, and heavy metals. In the concrete industry, the water used to wash mixers and other equipment contains cementitious residues, chemical additives, nitric acid, and other aggressive compounds. Despite this reality, many of these companies lack adequate wastewater treatment systems, which leads to direct discharge into the drainage system or surface water bodies, generating a significant risk of environmental pollution.

Faced with this problem, this research proposes the design and implementation of a physical treatment system for industrial wastewater based on the use of permeable concrete, with the goal of enabling its reuse and reducing its environmental impact. Permeable concrete, also known as porous concrete, is a special material that allows water to pass through its structure thanks to a specific granulometry and the absence or low proportion of fines, which generates an interconnected network of voids. This type of concrete, originated in the United Kingdom after World War II as a solution to material shortages, has traditionally been used in low-traffic pavements, pedestrian paths, and parks. However, its application as an industrial wastewater treatment system represents an innovation that this research seeks to explore.

To validate this proposal, designs adapted to the materials available in the region were developed, as well as laboratory tests to evaluate the system's effectiveness in removing contaminants. The study focused on the system's application in local companies in the concrete and vehicle washing sectors, demonstrating promising results in terms of efficiency, sustainability, and economic viability.

Materials

CEMENT: The cementitious material used was structural cement, which has distinct chemical characteristics compared to conventional cement, favoring the development of mechanical strength at early ages.

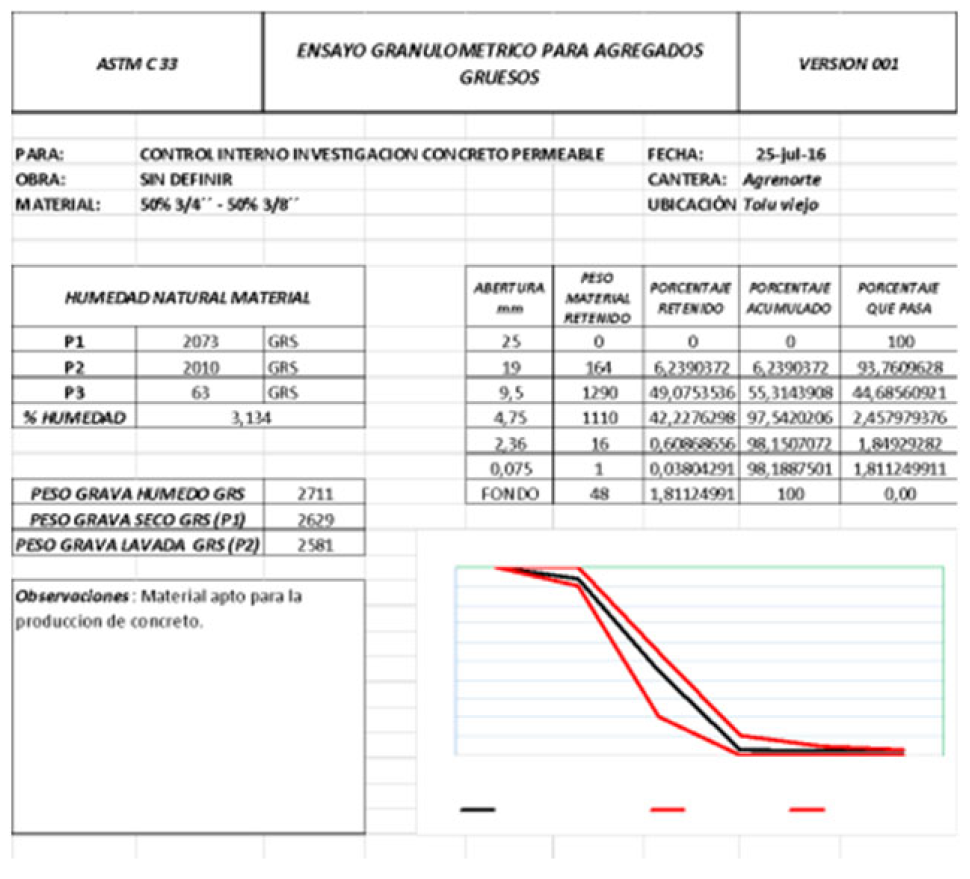

GRAVEL: Crushed limestone is commonly used as the main material in the production of permeable concrete due to its physical and chemical properties. For its application in this study, the gravel was subjected to various characterization tests, the results of which allowed us to establish the necessary parameters for an adequate mix design. Among the tests performed, granulometry and determination of specific gravities were essential to guarantee the quality and functionality of the concrete.

Figure 1.

Granulometric analysis of gravel. Source: Own.

Figure 1.

Granulometric analysis of gravel. Source: Own.

SAND: The sand used in this study comes from the Sinú River in Lorica, Córdoba, and is considered a high-quality material due to its origin in igneous rocks, as well as its high degree of purity and durability. This material was incorporated in relatively low proportions into the mix to maintain an adequate level of permeability in the pervious concrete samples.

ADDITIVES: The incorporation of admixtures in the production of this concrete was essential. First, a significant reduction in water content was required to increase the material's strength. Furthermore, prolonging the setting time was vital to ensure adequate bonding between the different aggregates in the mix. A mid-range water-reducing admixture and a retarding admixture were used.

Design Method

Porous concrete does not yet have a design methodology standardized by international standards, as is the case with conventional concrete, whose design is based on American Concrete Institute (ACI) regulations. However, in recent years, various research projects and authors have proposed methodologies based on the relationship between the voids present in coarse aggregate and its interaction with the cement paste, also considering the water-cement ratio to achieve adequate interconnection between the aggregate and the paste.

A notable example is the study entitled "Laboratory Study of Mixture Proportioning for Pervious Concrete Pavements," which develops a proportioning methodology based on the derivation of an equation that analyzes the behavior of 18 mixtures with different water-cement ratios (between 0.29 and 0.41) and their effect on void content. This approach allows for the design of optimized pervious concrete mixtures to achieve an adequate balance between permeability and strength.

To apply this methodology, it is essential to have initial data derived from the physical and chemical characterization of the materials used, which facilitates the calculation of factors necessary to determine the precise quantities of materials per cubic meter of mix.

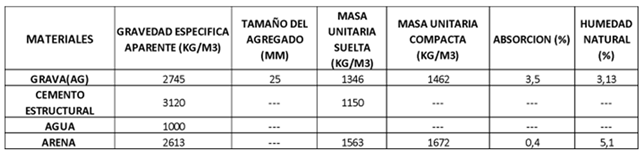

Table 1.

input data for calculations.

Table 1.

input data for calculations.

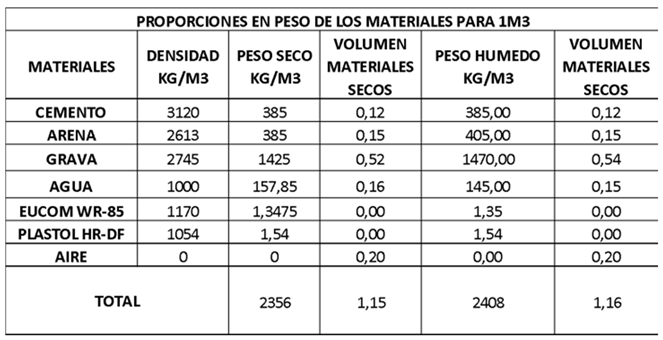

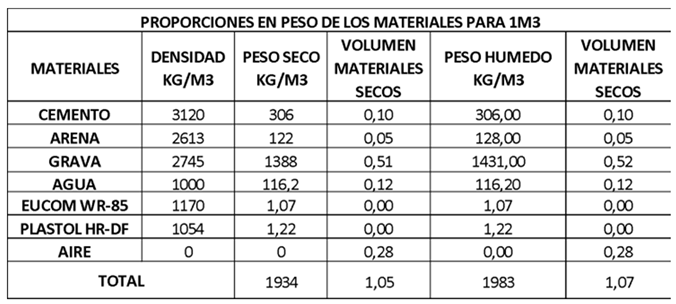

Mix Ratio

After performing the analytical calculation for the mix design, the weights in kilograms per cubic meter were determined to obtain a homogeneous pervious concrete mix. When preparing the first sample, both in 4" × 8" cylindrical specimens and in 6" × 6" × 21" joists, it was observed that the mix was excessively dense, presenting a very low void ratio. For this reason, it was necessary to readjust the design to take into account the temperature conditions and the specific quantities of each type of material, given that these materials did not come from the same sources as those used in previous investigations.

Table 2.

Quantities for design.

Table 2.

Quantities for design.

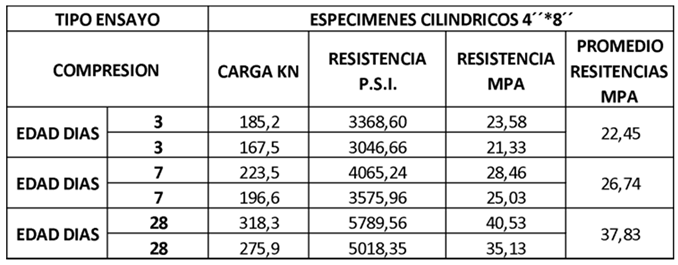

Table 3.

compressive strengths.

Table 3.

compressive strengths.

Table 4.

Corrected quantities.

Table 4.

Corrected quantities.

Table 5.

New resistances obtained.

Table 5.

New resistances obtained.

The difference in strengths obtained between

Table 3 and

Table 5 is notable, due to the increased void ratio of the mix to achieve adequate permeability.

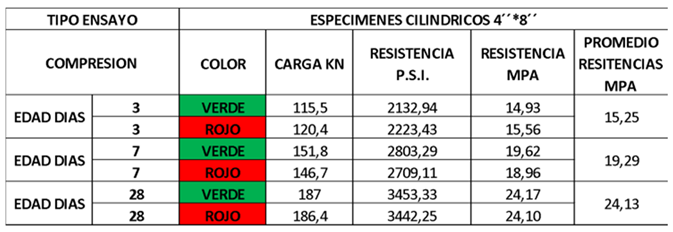

Concrete Implementation

During this research, permeable concrete structures were implemented, facilitating efficient operation in industrial wastewater treatment. First, the vehicle wash plant was involved, where a pavement was designed and built that allowed for the initial separation of sand and grease from the wastewater. Thanks to the concrete's porosity, the liquid was able to travel through the entire structure, retaining solids and oils, which were then directed to a WWTP tank system to complete the filtration process. In this way, the treated water could be recirculated and reused in new vehicle wash cycles.

Figure 2.

Laundry room in permeable concrete. Source: Own.

Figure 2.

Laundry room in permeable concrete. Source: Own.

The concrete industry required a different type of structure. To achieve this, a wastewater treatment plant was designed with permeable concrete panels that facilitated the passage of water, while other elements, such as cotton and organic charcoal, contributed to the retention of suspended solids. This waste was safely collected and stored in sacks, where the moisture evaporated, allowing the production of a reusable cementitious material.

Figure 3.

PTAR tanks. Source: Own.

Figure 3.

PTAR tanks. Source: Own.

Results

Based on the results obtained in this research, the following conclusions can be drawn: The production of pervious concrete using the void ratio methodology, using materials available in our region, is entirely viable. This concrete is of high quality and allows for the incorporation of mineral pigments to obtain different colors without affecting its strength. The implementation of an industrial wastewater treatment system is feasible and effective, as it ensures that chemical agents do not significantly contaminate surface or groundwater bodies. Furthermore, this system facilitates the reuse of water in various industrial activities, contributing to considerable savings and reducing the exploitation of underground sources. The application of this technology is adaptable to any industry, regardless of the working method employed, due to the flexibility it offers to adjust to the variations present in different production processes. Pervious concrete is a versatile material that can be molded and adapted to the specific needs of each location, allowing for the consistent and widespread application of this research. These systems require simple maintenance and are highly durable over time, which prevents premature material wear and represents significant economic savings.

References

- Cárdenas Gutiérrez, E.; Albiter Rodríguez, Á.; Jaimes Jaramillo, J. (2017). Pavimentos permeables: Una aproximación convergente en la construcción de vialidades urbanas y en la preservación del recurso agua. Redalyc. https://www.redalyc.org/articulo.oa?id=10450491009.

- Castro, J. (2004). Diseño de mezcla y construcción de pavimentos de hormigón poroso en Chile (Tesis de Magíster). Pontificia Universidad Católica de Chile.

- Castro, J.; de Solminihac, H.; Videla, C.; Fernández, B. Estudio de dosificaciones en laboratorio para pavimentos porosos de hormigón. Revista Ingeniería de Construcción 2009, 24. [Google Scholar] [CrossRef]

- Dos Santos Gentil, F.; Rojas Manzano, M.A. (2020). Métodos de dosificación de concreto permeable: Revisión de estado del arte. IX Congreso Internacional y 23ª Reunión Técnica.

- Hernández Ávila, J.; Gutiérrez Ribon, G.; Jove Wilches, F. A methodology for the design of hydraulic concrete mixtures for the porous pavement project, using construction materials from northern Colombia. Webology 2022, 19, 326, http://www.webology.org. [Google Scholar]

- Hiriart, E. (2016). Pavimentos permeables. Instituto Mexicano del Cemento y del Concreto. http://imcyc.com/50/ponencia/IngHiriart.ppt.

- Jato, D.; Andrés, V.; Rodríguez, J.; Castro, D. (2019). Pavimentos urbanos permeables. Revista de Obras Públicas.

- Redondo Polanco, L.; Zúñiga Páez, L.F. (2016). Principales variables para el diseño y la construcción de pavimentos permeables para su control en origen de la escorrentía urbana. SlideShare. https://es.slideshare.net/luisfernandozuigapae/monografiaprincipales-variables-para-el-diseo-de-pavimentos-permeables-udc.

- Rodríguez Hernández, J.; Rodríguez Bayón, J.; Castro Fresno, D.; Calzada Pérez, M.A.; Canteras Jordana, J. C.; Ballester Muñoz, F.; Marañón Maison, E.; Muñoz Vega, M.; Lasa, P. (2006). Construcción de pavimentos permeables para el control en origen de la escorrentía urbana: Ejemplo práctico del aparcamiento del Palacio de Deportes de La Guía.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).