1. Introduction

Smart materials offer tremendous potential in the field of civil engineering [

1]. Their unique properties, such as Smart materials, actuators, shape memory alloys, piezoelectric materials, sensing capabilities, energy efficiency, Make them well-suited for a wide range of civil engineering applications. Smart materials have the ability to improve the performance and sustainability of civil engineering structures, from structural health monitoring to energy harvesting and adaptive structural systems [

2]. While there are still research gaps that need to be addressed, on-going research in this area is expected to improve the understanding and adoption of smart materials in civil engineering applications. Standardization, durability, cost-effectiveness, compatibility with existing materials, and large-scale implementation are some of the key research areas that need to be studied further to ensure the widespread adoption of smart materials. The potential benefits of smart materials in civil engineering applications cannot be ignored. With continued research and development, smart materials have the potential to transform the field of civil engineering, making structures more efficient, sustainable, and resilient to environmental challenges [

2]. It is clear that smart materials will play an increasingly important role in the future of civil engineering, and the research efforts in this area will undoubtedly lead to exciting innovations in the years to come.

Integrating smart materials in civil engineering can revolutionize the design, construction, and maintenance of structures and infrastructure systems [

3]. Smart materials are a class of materials that can sense and respond to changes in their environment, making them highly desirable for use in civil engineering applications. These materials possess unique properties such as the ability to change shape, conductivity, or stiffness in response to external stimuli such as temperature, pressure, or electric fields. Smart materials offer several benefits for civil engineering applications, including improved durability, enhanced sensing capabilities, and increased energy efficiency [

4]. For instance, the use of smart materials can improve the performance of civil engineering structures by reducing the risk of structural failure, enhancing energy efficiency, and improving safety. This paper comprehensively reviews the latest developments and applications of smart materials in civil engineering. The review covers the types of smart materials, their properties, and the various applications of smart materials in the construction and maintenance of civil engineering structures. Additionally, the paper discusses the challenges associated with the implementation of smart materials in civil engineering and the future research directions in this field.

Several studies have demonstrated the potential of smart materials in civil engineering applications. For instance, in a study conducted by Wang et al. (2019), shape memory alloy (SMA) wires were used to improve the seismic performance of concrete columns [

5]. The results showed that the SMA wires significantly improved the concrete columns’ ductility and energy dissipation capacity, thereby reducing the risk of collapse during seismic events. Another study [

6] demonstrated the use of piezoelectric materials for energy harvesting in civil engineering structures. The piezoelectric materials were integrated into a pedestrian walkway, and the energy generated from the footsteps of pedestrians was used to power streetlights and other applications. These studies highlight the significant potential of smart materials in civil engineering applications, and the need for further research in this field to fully realize their potential.

2. Findings

2.1. Smart Materials

Smart materials also known as responsive or intelligent materials refer to materials that have the ability to change their physical properties, such as shape, stiffness, or color, in response to external stimuli such as temperature, light, pressure, or magnetic fields [

7]. These materials are designed to have an active or adaptive response to their environment, allowing them to perform specific functions or tasks without the need for external control or intervention.

Smart materials have been widely used in various fields, including civil engineering, due to their unique properties and potential applications. In civil engineering, smart materials are used to enhance the durability, safety, and performance of structures and infrastructure and to enable innovative designs and novel applications [

8].

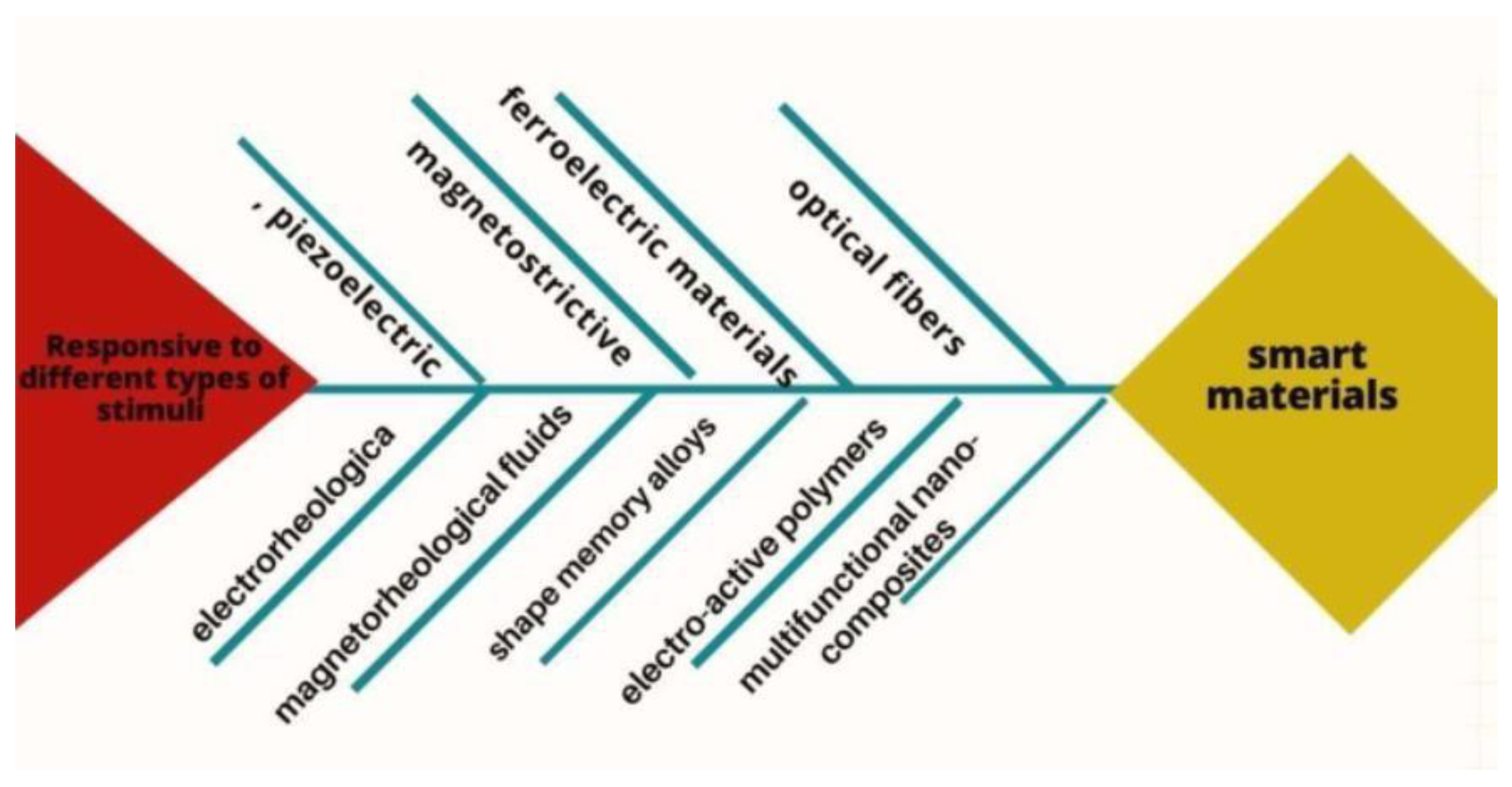

Figure 1.

Illustration of different types of smart materials [

1].

Figure 1.

Illustration of different types of smart materials [

1].

The

Table 1 provides an overview of various smart materials, outlining their unique properties and diverse applications. Shape memory alloys (SMA) exhibit remarkable traits such as the ability to revert to their original shape after deformation, high strength, and resistance to fatigue, making them suitable for applications like bridges, seismic-resistant structures, and pipe connectors [

9]. On the other hand, Piezoelectric materials can generate electricity under mechanical stress and deform under an electric field, finding applications in energy harvesting, vibration control, and structural health monitoring. Electrostrictive and magnetostrictive materials possess the ability to deform under electric and magnetic fields, respectively, enabling applications like actuators, vibration control, and sensing [

10]. Electrochromic materials can alter color and transparency in response to an electric field, making them ideal for smart windows and enhancing energy efficiency. Lastly, shape memory polymers (SMP) with their lightweight, flexible nature and shape recovery capabilities find use in smart concrete, self-healing materials, and adaptive structures, showcasing the diverse applications of these innovative smart materials [

11].

2.2. Actuators

Actuators are devices or components that convert electrical, hydraulic, or pneumatic signals into mechanical motion or force [

18]. They control or manipulate objects or systems’ movement, position, or orientation in various applications, including robotics, automation, aerospace, and civil engineering [

19]. In the context of smart materials, actuators play a crucial role in enabling the responsive or adaptive behavior of the materials. Actuators can be integrated into smart materials to create a feedback loop that allows the material to sense changes in its environment and respond accordingly [

20]. This makes smart materials with actuators highly versatile and adaptable, with potential applications in fields such as civil engineering, where they can be used to monitor and control the behaviour of structures and infrastructure.

The

Table 2 provides an overview of various smart materials, outlining their unique properties and diverse applications. Shape memory alloys (SMA) exhibit remarkable traits such as the ability to revert to their original shape after deformation, high strength, and resistance to fatigue, making them suitable for applications like bridges, seismic-resistant structures, and pipe connectors. On the other hand, Piezoelectric materials can generate electricity under mechanical stress and deform under an electric field, finding applications in energy harvesting, vibration control, and structural health monitoring [

13]. Electrostrictive and magnetostrictive materials possess the ability to deform under electric and magnetic fields, respectively, enabling applications like actuators, vibration control, and sensing. Electrochromic materials can alter color and transparency in response to an electric field, making them ideal for smart windows and enhancing energy efficiency [

21]. Lastly, shape memory polymers (SMP) with their lightweight, flexible nature and shape recovery capabilities find use in smart concrete, self- healing materials, and adaptive structures, showcasing the diverse applications of these innovative smart materials.

2.3. Shape Memory Alloys

Shaper memory alloys (SMAs) are a class of metallic materials that exhibit a unique shape-memory effect, wherein they can recover their original shape after being deformed by an external force or temperature change. SMAs are typically composed of a combination of nickel, titanium, and copper, and are characterized by their ability to undergo a reversible martensitic transformation under certain conditions [

27]. Due to their exceptional mechanical properties and functional characteristics, SMAs are widely used in various fields, including aerospace, automotive, biomedical, and civil engineering. In civil engineering, SMAs can be used for applications such as earthquake-resistant structures, bridge bearings, and dampers, where their high damping capacity and energy absorption can help mitigate structural damage and improve the safety and durability of infrastructure [

28]. SMAs are a promising class of smart materials that offer unique capabilities and properties that can be leveraged for a variety of applications in different fields, including civil engineering.

The provided

Table 3 highlights different alloy types, their compositions, transformation temperatures, and applications. Nitinol, composed of Nickel and Titanium, transforms within a temperature range of 70-130°C, finding applications in medical implants, eyeglasses, dental braces, and robotics [

29]. Copper-based alloys, consisting of Copper, Zinc, Aluminium, and Nickel, undergo transformation between -200 to 100°C, and are utilized in actuators, micro electro mechanical systems (MEMS), and the automotive industry. Iron-based alloys, made of Iron, Nickel, and Manganese, transform in the 20-200°C range and are applied in actuators, sensors, and biomedical devices. Nickel-based alloys, comprising Nickel and Titanium or Copper, have a transformation temperature of 100-300°C, and are used in actuators, dampers, and the aerospace industry [

30]. Gold-based alloys, incorporating Gold and Zinc or Copper, transform between 50-150°C, finding applications in biomedical devices, drug delivery, and microfluidics. These alloys demonstrate diverse applications across various industries based on their unique compositions and transformation properties.

2.3.1. Piezoelectric Materials

Piezoelectric materials are types of smart material that exhibit an electric charge when subjected to mechanical stress or deformation, and conversely, experience mechanical deformation when subjected to an electric field. This phenomenon, known as the piezoelectric effect, is due to the asymmetric crystal structure of the material, which allows for the separation of positive and negative charges in the material [

35]. Piezoelectric materials have found widespread use in various applications, including actuators, sensors, energy harvesting, and even medical devices. In civil engineering, piezoelectric materials have been utilized in structural health monitoring systems, where they can be used to detect and measure the strain and deformation of structural components, such as bridges and buildings. They can also be used for vibration damping and control and energy harvesting from ambient vibrations [

36]. Overall, piezoelectric materials offer a unique set of capabilities that can be leveraged in a variety of applications, making them an important class of smart materials in civil engineering and beyond.

2.3.2. Sensing Capabilities

Sensing capabilities refer to the ability of a material to detect and respond to external stimuli, such as changes in temperature, pressure, or moisture [

37]. In the context of civil engineering, sensing capabilities can be used to monitor the structural health of buildings and infrastructure and to detect and predict environmental hazards such as earthquakes and landslides. The sensing capabilities in civil engineering can be achieved through the use of smart materials such as piezoelectric materials, fibre optic sensors, and shape memory alloys. These materials can be embedded within the structure or placed on the surface to detect changes in strain, temperature, or other environmental conditions. The data collected by these sensors can then be analyzed to assess the structure’s performance and condition and inform maintenance and repair decisions.

2.3.3. Energy Efficiency

Energy efficiency is the measure of how efficiently energy is being used to perform a certain task or function. It is typically expressed as a percentage, with the higher percentage indicating a more efficient use of energy. Energy efficiency is an important consideration in designing and operating buildings, appliances, and transportation systems, as it can reduce energy consumption and lower operating costs [

38].

3. Discussion

3.1. Comparative Study of Smart Materials

Creating a comprehensive comparative table of smart materials used in transportation requires detailed information about various smart materials, their properties, and their applications in transportation. The

Table 4 shows smart materials commonly used in transportation.

This table provides a starting point for comparing smart materials used in transportation. However, specific properties, applications, and additional smart materials can be added based on detailed research and specific needs.

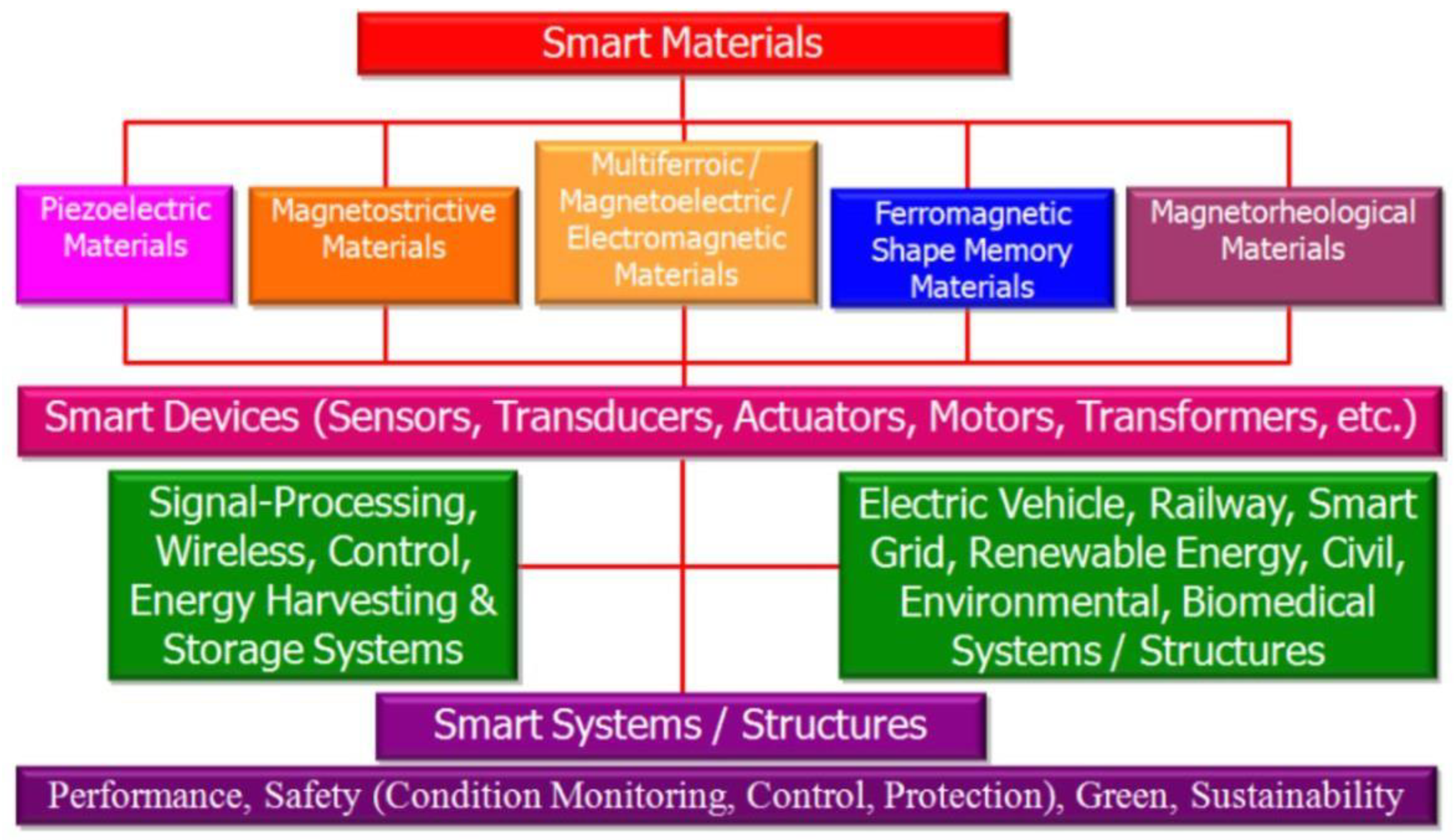

Figure 2.

Smart Materials classification done as per uses [

39].

Figure 2.

Smart Materials classification done as per uses [

39].

3.2. Applications of Smart Materials in Civil Engineering

Smart materials, also known as intelligent or responsive materials, have gained significant attention in various fields, including civil engineering, due to their unique properties and potential to enhance the performance and functionality of structures. Here are several applications of smart materials in civil engineering:

3.2.1. Structural Health Monitoring (SHM)

Smart materials like piezoelectric sensors and fiber optic sensors can be integrated into structures to monitor their health in real-time. These sensors can detect changes in strain, stress, temperature, and other parameters, allowing for early structural damage or deterioration detection.

3.2.2. Self-Healing Concrete

Incorporating capsules filled with healing agents or using microorganisms that can repair cracks and damages in concrete can extend structures’ service life and durability. This self-healing ability can reduce maintenance costs and increase the sustainability of buildings and infrastructure.

3.2.3. Shape Memory Alloys (SMAs) for Seismic Mitigation

SMAs, such as Nitinol, can be used in structural elements to provide seismic resistance. These alloys have the ability to deform under stress and return to their original shape when the stress is removed, dissipating seismic energy and reducing structural damage during earthquakes.

3.2.4. Adaptive Damping Systems

Smart materials like magnetorheological (MR) and electrorheological (ER) fluids can be used in adaptive damping systems to control and adjust the structural response of buildings and bridges in real-time. This technology enhances the structures’ ability to withstand dynamic loads and vibrations.

3.2.5. Piezoelectric Materials for Energy Harvesting

Piezoelectric materials can be embedded in structural elements to convert mechanical vibrations or strains into electrical energy. This harvested energy can be used to power sensors, lighting, or other low-power electronic devices within the structure.

3.2.6. Smart Glass for Energy Efficiency

Electrochromic and thermochromic smart glass can dynamically control the amount of light and heat entering a building, improving energy efficiency by reducing the need for heating, cooling, and artificial lighting.

3.2.7. Smart Insulation Systems

Phase-change materials (PCMs) can be integrated into building insulation to regulate indoor temperatures by absorbing and releasing thermal energy. This helps in reducing energy consumption for heating and cooling.

3.2.8. Smart Pavements

Incorporating piezoelectric materials in road pavements can generate electricity from traffic-induced vibrations and pressure. This harvested energy can be used for various applications, including street lighting and road monitoring.

3.2.9. Smart Coatings for Corrosion Protection

Self-healing or corrosion-resistant coatings containing smart materials can protect structures from corrosion and degradation, extending their lifespan and minimizing maintenance needs.

3.2.10. Magnetic Levitation (Maglev) for Transportation

Maglev technology, which uses superconducting magnets, is a type of smart material that can be applied in transportation infrastructure like high-speed trains, providing efficient and frictionless transportation.

Civil engineers can use these smart materials to enhance the performance, durability, sustainability, and safety of structures and infrastructure. Ongoing research and advancements in smart materials are likely to expand their applications in civil engineering.

Shape memory alloys (SMAs) are used in seismic-resistant structures as energy-dissipating devices due to their unique properties such as high damping capacity and large deformation capability. Piezoelectric materials are used as sensors for structural health monitoring in bridges, buildings, and other civil structures. They can detect structural damage such as cracks and deformations by measuring the changes in the electric charge generated when the material is subjected to stress [

40]. Magnetostrictive materials are used in smart dampers for seismic protection of structures [

41]. The dampers can provide both passive and active control of the structure’s response to seismic waves by changing the magnetic field applied to the material [

42]. Shape memory polymers (SMPs) are used in self-healing materials for repairing cracks and other damage in concrete and asphalt pavements. The SMPs can be embedded in the material and activated by external stimuli such as heat to fill the cracks and restore the material’s integrity. Electrochromic materials are used in smart windows for energy-efficient buildings. The windows can switch between transparent and opaque states depending on the ambient light and temperature conditions, reducing the need for artificial lighting and heating/cooling systems [

43].

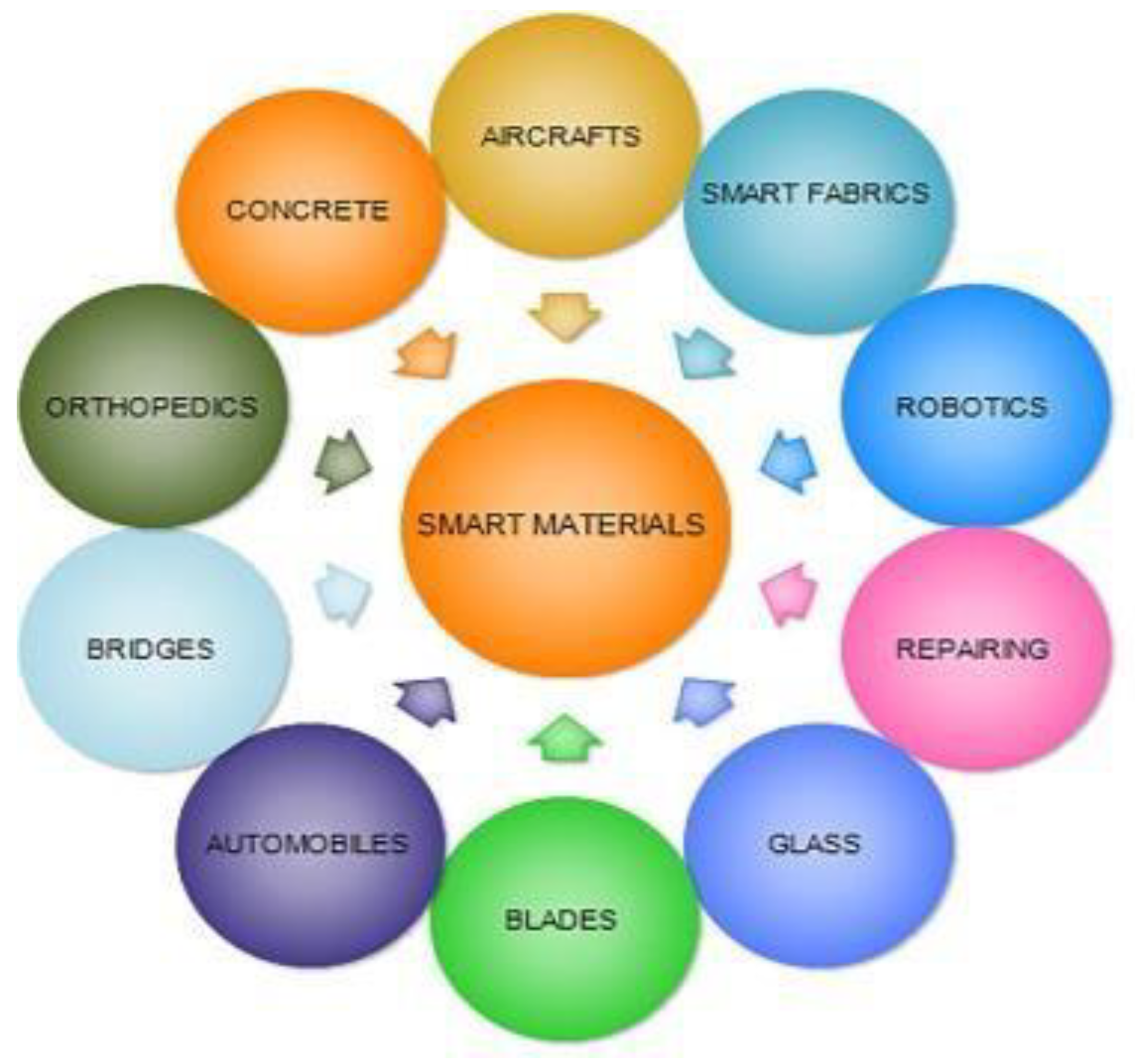

Smart materials, characterized by their responsive and adaptive properties, have found extensive applications across diverse fields. In structural engineering, shape memory alloys (SMA) are employed in seismic-resistant structures and bridges, providing enhanced safety and resilience. Piezoelectric materials play a pivotal role in energy harvesting and vibration control systems, contributing to sustainable energy solutions and structural stability. The automotive industry utilizes copper-based alloys for actuators and micro electro mechanical systems (MEMS), enhancing operational efficiency and precision. In healthcare, nitinol, a type of SMA, is extensively used in medical implants and dental braces, revolutionizing patient care and treatment approaches. These materials have also made significant strides in the field of electronics, such as smart sensors utilizing shape memory polymers (SMP) for damage detection and adaptive structures. With their versatility and innovative applications, smart materials continue to drive advancements and shape the future across various sectors. As shown in the

Figure 3 we can see wide ranges of applications of the smart materials in various fields.

Smart materials have the potential to revolutionize the field of civil engineering by improving the performance and sustainability of structures. The unique properties of smart materials, such as shape memory, piezoelectricity, electrostriction, magnetostriction, and self-healing, make them well-suited for a wide range of civil engineering applications, from structural health monitoring to energy harvesting and adaptive structural systems [

44]. There is need for widespread life cycle assessment normes needed for development of the roads using the waste materials [

45]. However, several research gaps still need to be addressed before the widespread adoption of smart materials in civil engineering applications. Standardization, durability, cost-effectiveness, compatibility with existing materials, and large -scale implementation are some of the key research areas that need to be studied further. Standardization is critical to ensure the reliability and consistency of smart materials in civil engineering applications. Developing standardized testing protocols will help ensure the performance of smart materials is consistent and reliable across different applications.

3.3. Novel Qualities of Smart Materials

Smart materials possess novel and unique qualities that distinguish them from traditional materials. These qualities enable them to respond to stimuli or environmental changes in a controlled and often reversible manner. Here are some of the key novel qualities of smart materials:

3.3.1. Sensitivity and Responsiveness

Smart materials are highly sensitive to various stimuli such as temperature, light, pressure, electric or magnetic fields, pH, or moisture. They can respond promptly and adapt their properties in real-time based on the changes in these stimuli.

3.3.2. Adaptive and Dynamic Behavior

These materials have the ability to adapt and change their properties or behavior in response to external conditions. This adaptability allows for dynamic adjustments, making them suitable for a wide range of applications.

3.3.3. Multifunctionality

Smart materials often possess multiple functionalities, meaning they can exhibit different responses or behaviors based on the type and magnitude of the applied stimuli. For instance, a smart material may respond to both temperature and electrical fields.

3.3.4. Memory and Hysteresis

Some smart materials have memory characteristics, meaning they can “remember” a previous state and return to it once the external stimulus is removed. Hysteresis is often observed, where the material’s response may depend on its prior state and the rate of change of the stimulus.

3.3.5. Self-Healing and Self-Repair

Certain smart materials have the ability to repair minor damages or defects autonomously. They can heal and restore their structure or functionality without external intervention, contributing to increased durability and longevity.

3.3.6. Phase Transitions and Phase Change

Smart materials can undergo reversible phase transitions or changes in their physical or chemical structure in response to stimuli such as temperature changes. This phase change often leads to significant alterations in properties.

3.3.7. Energy Conversion and Harvesting

Smart materials have the capability to convert one form of energy into another. For example, piezoelectric materials can convert mechanical stress into electrical energy, while thermoelectric materials can convert heat gradients into electrical energy.

3.3.8. Nonlinear and Non-Homogeneous Behavior

The response of smart materials may not follow linear or homogeneous behavior. Their properties can change nonlinearly and vary spatially, providing tailored responses to specific conditions or stimuli.

3.3.9. Fast Response Times

Smart materials can often respond rapidly to changes in stimuli, sometimes in milliseconds or even microseconds. This fast response is crucial for applications that require quick adjustments or sensing.

3.3.10. Low Energy Consumption

Smart materials are designed to operate with low energy consumption, making them energy-efficient and suitable for sustainable and portable applications.

3.3.11. Tunability and Controllability

These materials can be engineered to have tunable properties, allowing precise control over their behavior by adjusting the external conditions or stimuli.

Harnessing these novel qualities, smart materials find applications across various fields, including aerospace, healthcare, robotics, energy, construction, and consumer electronics. Ongoing research and development continue to expand the range of novel qualities and potential applications of smart materials.

Durability is also a critical factor that needs to be studied further. The long-term performance and reliability of smart materials in harsh environmental conditions need to be evaluated to ensure their effectiveness over time. Understanding the effects of exposure to UV radiation, moisture, and temperature on the performance of smart materials will be critical for their long-term viability. Cost-effectiveness is another key research area that needs to be addressed. While smart materials offer improved performance and sustainability, their high cost is a barrier to their widespread adoption in civil engineering applications. Developing cost-effective methods for manufacturing and integrating smart materials into structures will be critical for their large-scale adoption.

Compatibility with existing materials is another important factor to consider. The use of smart materials may result in compatibility issues with existing materials used in civil engineering structures, which could lead to reduced performance or failure of the structure. Evaluating the compatibility of smart materials with existing materials is critical for ensuring the effectiveness of smart materials in civil engineering applications. Finally, the scalability of smart materials needs to be studied to ensure their effectiveness in large-scale applications. Understanding how smart materials perform at a large scale will be critical for their widespread adoption in civil engineering applications. While research gaps still need to be addressed, smart materials have tremendous potential in civil engineering applications. On-going research in this area is expected to improve the performance and cost-effectiveness of smart materials, making them a viable option for improving the sustainability and performance of civil engineering structures.

3.4. Challenges of Smart Materials

Standardization: The lack of standardization in the testing and evaluation of smart materials is a major challenge for their adoption in civil engineering applications. There is a need to develop standardized testing protocols to ensure consistency and reliability in the performance of smart materials.

Durability: Smart materials’ long-term durability and reliability in harsh environmental conditions need to be evaluated. The effects of exposure to UV radiation, moisture, and temperature on the performance of smart materials need to be studied to ensure their long-term reliability.

Cost-effectiveness: The cost-effectiveness of smart materials is another challenge that needs to be addressed. While smart materials offer improved performance and sustainability, their high cost is a barrier to their widespread adoption in civil engineering applications. There is a need to develop cost- effective methods of manufacturing and integrating smart materials into structures.

Compatibility with existing materials: The compatibility of smart materials with existing materials used in civil engineering structures needs to be studied. The use of smart materials may result in compatibility issues with existing materials, which could lead to reduced performance or failure of the structure.

Large-scale implementation: The feasibility of large-scale implementation of smart materials in civil engineering structures needs to be evaluated. The scalability of smart materials needs to be studied to ensure their effectiveness in large-scale applications.

Addressing these research gaps will improve the understanding and adoption of smart materials in civil engineering applications.

4. Conclusions

In conclusion, smart materials represent a remarkable advancement in material science, showcasing a spectrum of novel qualities that set them apart from conventional materials. These materials possess exceptional sensitivity and responsiveness to a wide array of stimuli, allowing for adaptive and dynamic behavior. The multifunctionality exhibited by smart materials further enhances their versatility, enabling diverse applications in various industries. Smart materials’ memory and hysteresis properties contribute to their ability to retain and revert to specific states, offering opportunities for self-healing and repair and enhancing durability. Their capacity for phase transitions and phase changes, combined with energy conversion and harvesting capabilities, holds promise for sustainable and energy-efficient solutions.

Moreover, the nonlinear and non-homogeneous behavior of smart materials and their rapid response times and low energy consumption opens new horizons for innovative applications. The tunability and controllability of these materials offer engineers and scientists the ability to tailor their properties to specific requirements, making them highly attractive for evolving technological needs. Incorporating smart materials in various domains such as civil engineering, healthcare, aerospace, and more, augments the potential for groundbreaking solutions that improve efficiency, sustainability, and overall quality of life. As ongoing research and development continue to unveil additional novel qualities and expand applications, the future of smart materials is poised to revolutionize industries and drive transformative technological advancements.

References

- Jain N, Nandu Ovhal S, Patil V and Nani Kartik K 2023 Smart materials—A state-of-the-art-review. Materials Today: Proceedings 82 381–9. [CrossRef]

- Zheng Q, Hou Y, Yang H, Tan P, Shi H, Xu Z, Ye Z, Chen N, Qu X, Han X, Zou Y, Cui X, Yao H, Chen Y, Yao W, Zhang J, Chen Y, Liang J, Gu X, Wang D, Wei Y, Xue J, Jing B, Zeng Z, Wang L, Li Z and Wang Z L 2022 Towards a sustainable monitoring: A self-powered smart transportation infrastructure skin Nano Energy 98 107245. [CrossRef]

- Utsev T, Tiza T M, Mogbo O, Kumar Singh S, Chakravarti A, Shaik N and Pal Singh S 2022 Application of nanomaterials in civil engineering Materials Today: Proceedings 62 5140–6. [CrossRef]

- Matin Nazar A, Narazaki Y, Rayegani A and Rahimi Sardo F 2022 Recent progress of triboelectric nanogenerators as self-powered sensors in transportation engineering Measurement 203 112010. [CrossRef]

- Wang D, Wang Z, Yu T and Li H 2018 Seismic performance of CFRP-retrofitted large-scale rectangular RC columns under lateral loading in different directions Composite Structures 192 475–88. [CrossRef]

- Covaci C and Gontean A 2020 Piezoelectric Energy Harvesting Solutions: A Review Sensors 20 3512. [CrossRef]

- Amano K, Lou E C W and Edwards R 2018 Integration of point cloud data and hyperspectral imaging as a data gathering methodology for refurbishment projects using building information modelling (BIM). Journal of Facilities Management 17 57–75. [CrossRef]

- Soliman A, Hafeez G, Erkmen E, Ganesan R, Ouf M, Hammad A, Eicker U and Moselhi O 2022 Innovative construction material technologies for sustainable and resilient civil infrastructure Materials Today: Proceedings 60 365–72. [CrossRef]

- Yan L, Li Y, Chang W-S and Huang H 2023 Seismic control of cross laminated timber (CLT) structure with shape memory alloy-based semi-active tuned mass damper (SMA-STMD) Structures 57 105093. [CrossRef]

- Zhen-Bang K 2007 Some problems in electrostrictive and magnetostrictive materials Acta Mechanica Solida Sinica 20 219–27. [CrossRef]

- Wang X, He Y, Liu Y and Leng J 2022 Advances in shape memory polymers: Remote actuation, multi- stimuli control, 4D printing and prospective applications Materials Science and Engineering: R: Reports 151 100702. [CrossRef]

- Muntasir Billah A, Rahman J and Zhang Q 2022 Shape memory alloys (SMAs) for resilient bridges: A state-of-the-art review Structures 37 514–27. [CrossRef]

- Zhu Y, Chen H, Wang L, Ye L, Zhou H, Peng Q, Zhu H and Huang Y 2023 Piezoelectric materials for pollutants degradation: State-of-the-art accomplishments and prospects Chinese Chemical Letters 108884. [CrossRef]

- Zhao L, Zheng H, Ma Z, Wu W, Chen M, Tao H, Ma J, Zhao C and Wu B 2023 Insights into the correlation between strain and electrostrictive coefficient of potassium sodium niobate based ceramics from relaxor structure Ceramics International 49 4614–21. [CrossRef]

- Chen G, Jin Z and Chen J 2023 A review: Magneto-optical sensor based on magnetostrictive materials and magneto-optical material Sensors and Actuators Reports 5 100152. [CrossRef]

- Wang Z and Liu R 2023 PEDOT:PSS-based electrochromic materials for flexible and stretchable devices. Materials Today Electronics 4 100036. [CrossRef]

- Hornat C C, Nijemeisland M, Senardi M, Yang Y, Pattyn C, van der Zwaag S and Urban M W 2020 Quantitative predictions of maximum strain storage in shape memory polymers (SMP) Polymer 186 122006. [CrossRef]

- Wang Y, Liu X-J and Zhao H 2022 Speeding up soft pneumatic actuators through pressure and flow dynamics modeling and optimization Extreme Mechanics Letters 57 101914. [CrossRef]

- Mukherjee A, Deepmala, Srivastava P and Sandhu J K 2023 Application of smart materials in civil engineering: A review Materials Today: Proceedings 81 350–9. [CrossRef]

- Zheng Q, Xu C, Jiang Z, Zhu M, Chen C and Fu F 2021 Smart Actuators Based on External Stimulus Response Frontiers in Chemistry 9. [CrossRef]

- Singh P K, Pareta A S, Bhushan A, Panda S K and Shyam Kumar M B 2023 The effect of temperature on giant magnetostrictive thin films in high pre-stress environment for sensor application Materials Today: Proceedings 84 61–7. [CrossRef]

- Salman W, Zhang X, Li H, Wu X, Li N, Azam A and Zhang Z 2022 A novel energy regenerative shock absorber for in-wheel motors in electric vehicles Mechanical Systems and Signal Processing 181 109488. [CrossRef]

- Schmidt L, Groenkjaer M, Pedersen H C and Andersen T O 2017 Position Control of an Over-Actuated Direct Hydraulic Cylinder Drive Control Engineering Practice 64 1–14. [CrossRef]

- Gaheen O A, Benini E, Khalifa M A and Aziz M A 2022 Pneumatic cylinder speed and force control using controlled pulsating flow Engineering Science and Technology, an International Journal 35 101213. [CrossRef]

- Bai D, Deng S, Li Y and Li H 2023 A novel inchworm piezoelectric actuator with rhombic amplification mechanism Sensors and Actuators A: Physical 360 114515. [CrossRef]

- Rahmanian S, Alibakhshi A, Mouharrar H, Benitez J M and Montáns F J 2023 Low-voltage dielectric elastomer actuators by electro-mechanical resonance syntonization International Journal of Mechanical Sciences 108758. [CrossRef]

- Chowdhury P 2018 Frontiers of Theoretical Research on Shape Memory Alloys: A General Overview. Shap. Mem. Superelasticity 4 26–40. [CrossRef]

- Han B, Wang Y, Dong S, Zhang L, Ding S, Yu X and Ou J 2015 Smart concretes and structures: A review Journal of Intelligent Material Systems and Structures 26 1303–45. [CrossRef]

- Chan W-S, Gulati K and Peters O A 2023 Advancing Nitinol: From heat treatment to surface functionalization for nickel–titanium (NiTi) instruments in endodontics Bioactive Materials 22 91–111. [CrossRef]

- Ponmozhi J, Frias C, Marques T and Frazão O 2012 Smart sensors/actuators for biomedical applications: Review Measurement 45 1675–88. [CrossRef]

- Farber E, Zhu J-N, Popovich A and Popovich V 2020 A review of NiTi shape memory alloy as a smart material produced by additive manufacturing Materials Today: Proceedings 30 761–7. [CrossRef]

- Dasgupta R 2014 A look into Cu-based shape memory alloys: Present scenario and future prospects. Journal of Materials Research 29 1681–98. [CrossRef]

- Gu D, Ma C, Dai D, Yang J, Lin K, Zhang H and Zhang H 2021 Additively manufacturing-enabled hierarchical NiTi-based shape memory alloys with high strength and toughness Virtual and Physical Prototyping 16 S19–38. [CrossRef]

- Mohd Jani J, Leary M, Subic A and Gibson M A 2014 A review of shape memory alloy research, applications and opportunities Materials & Design (1980-2015) 56 1078–113. [CrossRef]

- Li J, Liu X, Zhao G, Liu Z, Cai Y, Wang S, Shen C, Hu B and Wang X 2023 Piezoelectric materials and techniques for environmental pollution remediation Science of The Total Environment 869 161767. [CrossRef]

- Li V and Kanda T 1998 Structural Applications of Engineered Cementitious Composites Journal of Materials in Civil Engineering—J MATER CIVIL ENG 10. [CrossRef]

- Mu S, Li S, Zhao H, Wang Z, Xiao X, Xiao X, Lin Z, Song Z, Tang H, Xu Q, Wang D, Lee W W, Wu C and Ding W 2023 A platypus-inspired electro-mechanosensory finger for remote control and tactile sensing Nano Energy 116 108790. [CrossRef]

- Anon Energy Efficiency Indicators for Public Electricity Production from Fossil Fuels—Analysis IEA.

- Anon 2019 Smart materials and integral sensors enabling intelligent transportation Globalspec.com.

- Lynch J and Loh K 2006 A Summary Review of Wireless Sensors and Sensor Networks for Structural Health Monitoring The Shock and Vibration Digest 38 91–128. [CrossRef]

- Toohey K S, Sottos N R, Lewis J A, Moore J S and White S R 2007 Self-healing materials with microvascular networks Nature Mater 6 581–5. [CrossRef]

- Spencer B F and Nagarajaiah S 2003 State of the Art of Structural Control Journal of Structural Engineering 129 845–56. [CrossRef]

- Azens A and Granqvist C 2003 Electrochromic smart windows: energy efficiency and device aspects J Solid State Electrochem 7 64–8. [CrossRef]

- Sharma S N, Prajapati R, Jaiswal A and Dehalwar K 2024 A Comparative Study of the Applications and Prospects of Self-healing Concrete/Biocrete and Self-Sensing Concrete IOP Conference Series.

- Earth and Environmental Science vol 1326 (IOP Publishing) p 012090.

- Sharma S N, Lodhi A S, Dehalwar K and Jaiswal A 2024 Life Cycle Assessment (LCA) of Recycled & Secondary Materials in the Construction of Roads IOP Conf. Ser.: Earth Environ. Sci. 1326 012102. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).