Submitted:

29 June 2025

Posted:

30 June 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Background

3. Method

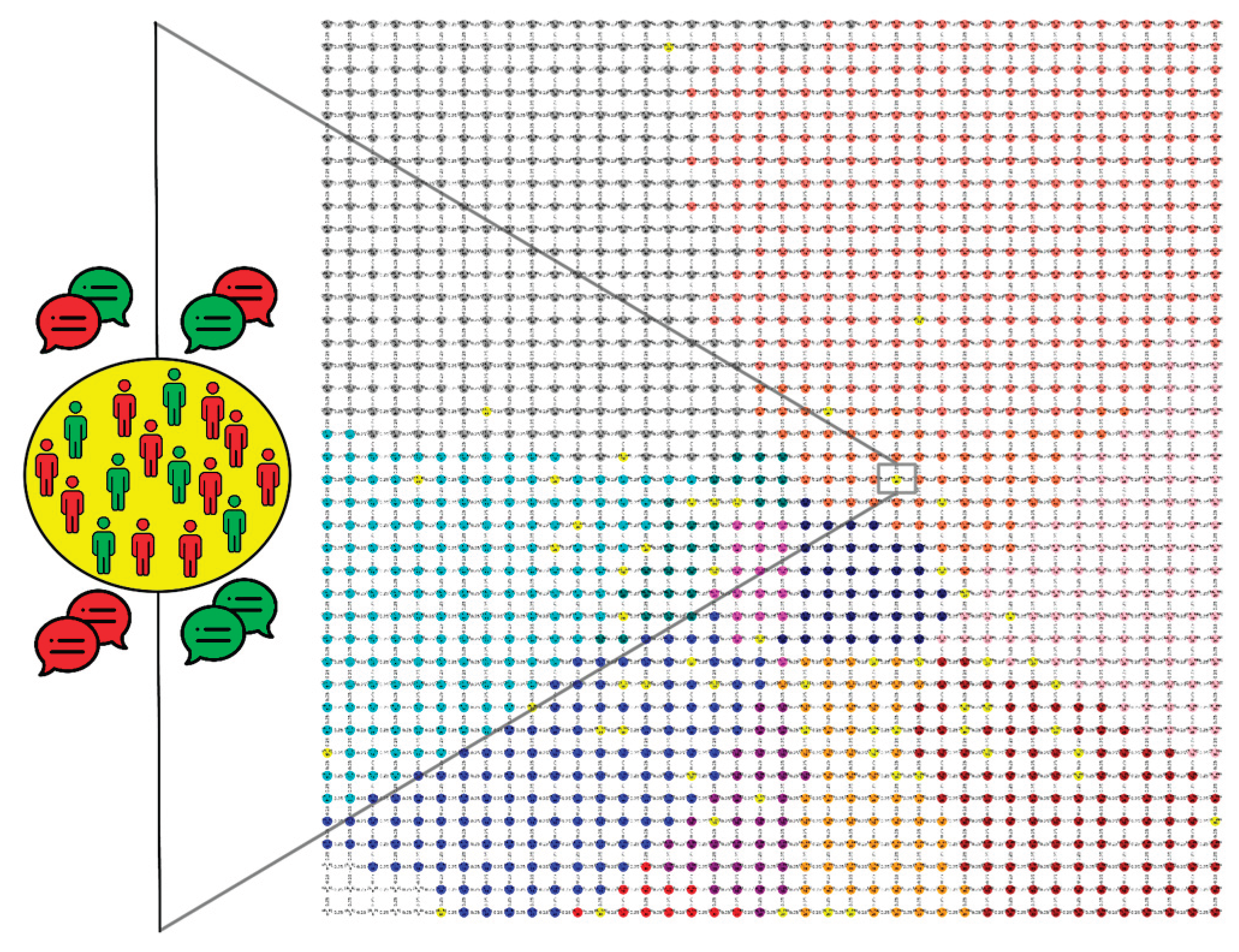

3.1. Dataset Construction

- Prior Research. The first input originates from the dataset used in our previous review [39], which consisted of 25 articles.

- Updated Search. The second source was obtained by extending the original query, to broader the coverage period from February up to the end of 2024. This update resulted in an additional 85 contributions.

- Data Set Refining. The combined pool of 110 articles was then refined to ensure the quality and robustness of the analysis. Specifically, we decided to include only works published in peer-reviewed scientific journals, that are generally subject to stricter review standards, ensuring higher quality. Moreover, due to the greater space typically allowed in journal publications, the models and methodologies are usually described in more detail and with greater clarity. This level of detail is essential for applying the classification framework introduced in the following section. Brief or superficial descriptions, which are more common in conference papers, would not provide sufficient information to support a robust and reliable classification process. This exclusion criterion led to the removal of 49 articles from the initial dataset.

- In Depth Analysis. Each of the remaining articles was examined in depth, to analyse the structure and substance of the simulation models, with particular focus on agent behaviours and modelling choices. During this phase, three additional articles were removed as they addressed operations modelling rather than SC systems. The final dataset comprises 58 peer-reviewed journal articles, each subjected to a systematic classification. The classification framework and methodology are outlined in the following section.

3.2. Classification Parameters

4. Guidelines for the Interpretation of the Classification Method

4.1. Degree of Agent Decision-Making Autonomy

4.2. Nature of Inter-Agent Interactions

4.2.1. Mere Operational Flows vs. Agents Interactions and Responsiveness

4.2.2. Direct Interactions

4.2.3. Indirect Interactions

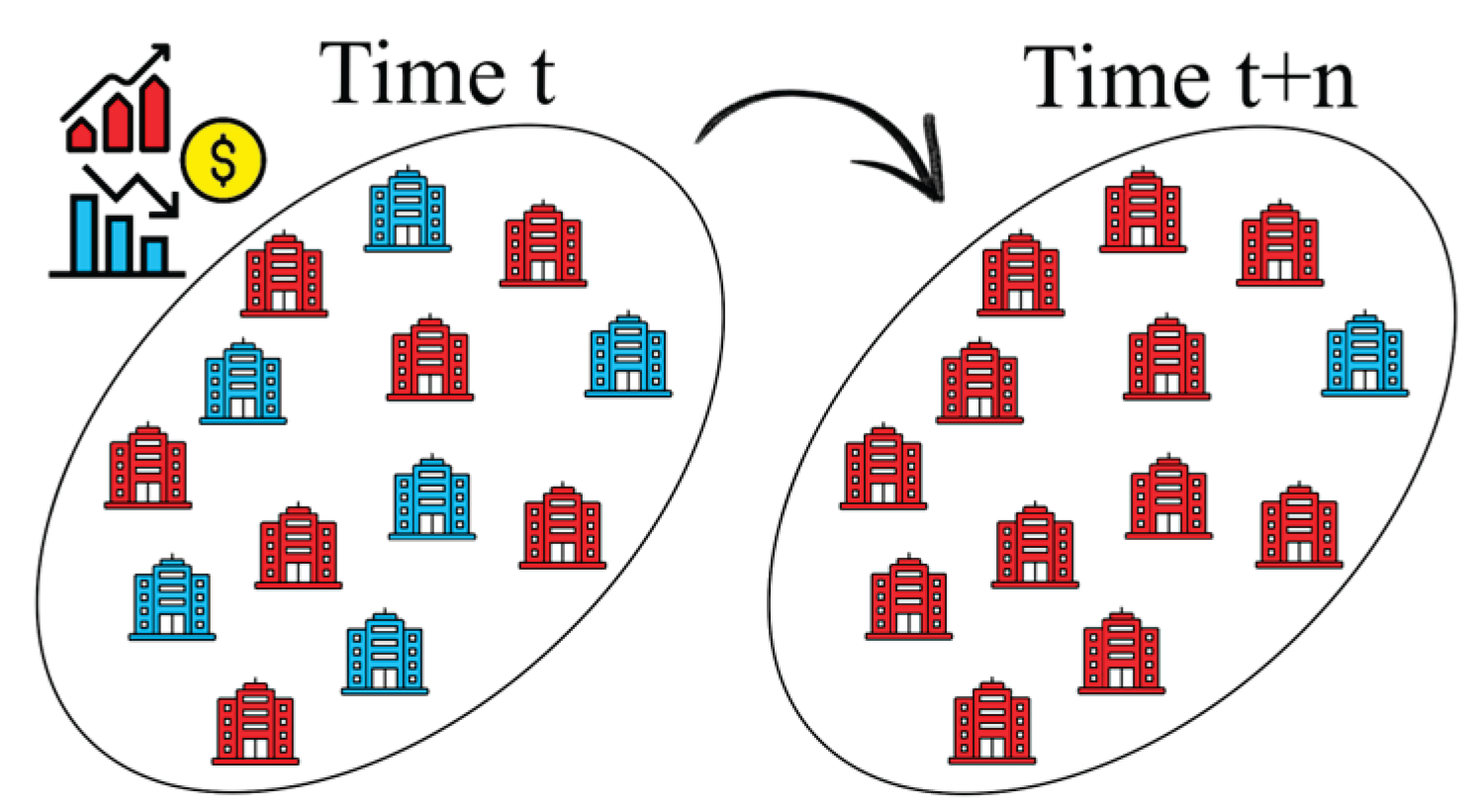

4.3. System Evolution over Time

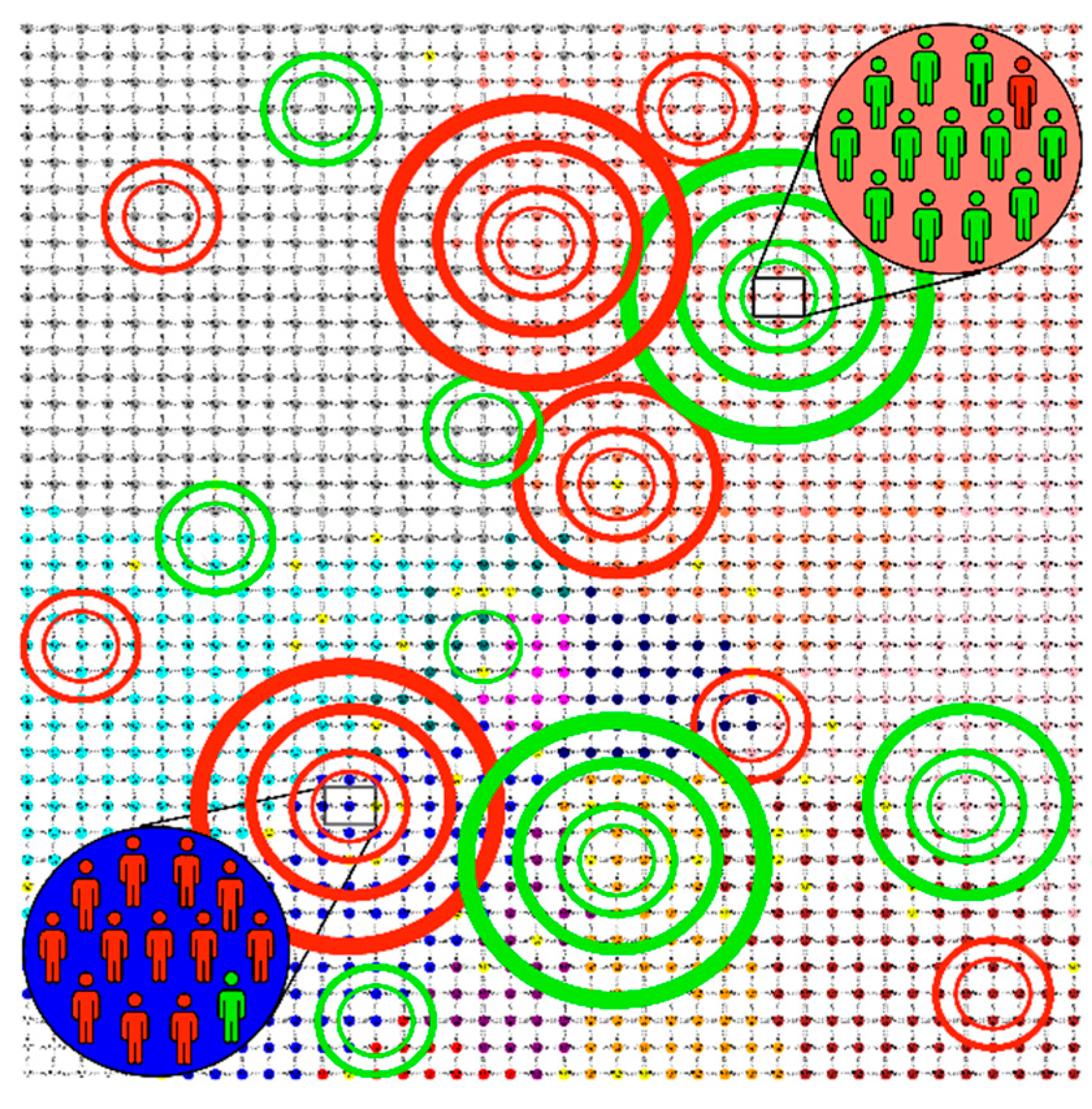

5. Green and Red Flag Model

5.1. The Green Flag – Red Flag Categorization Scheme

5.2. Contextualization of the Classification Scheme

5.2.1. Active Agents - Green Flag Model

5.2.2. Emergent Colony Dynamics – Green Flag Model

5.2.3. A Red Flag Model

6. Results & Discussion

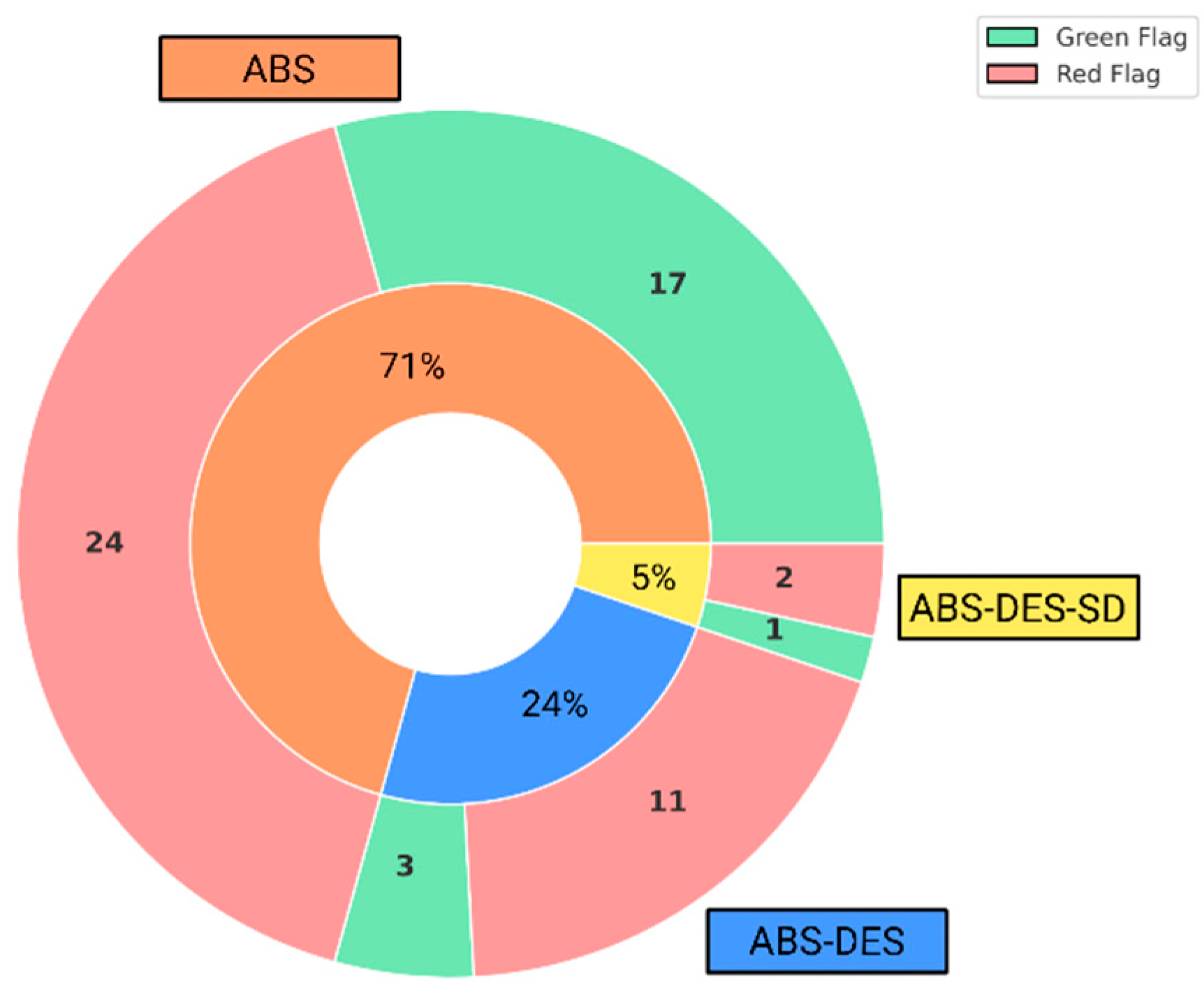

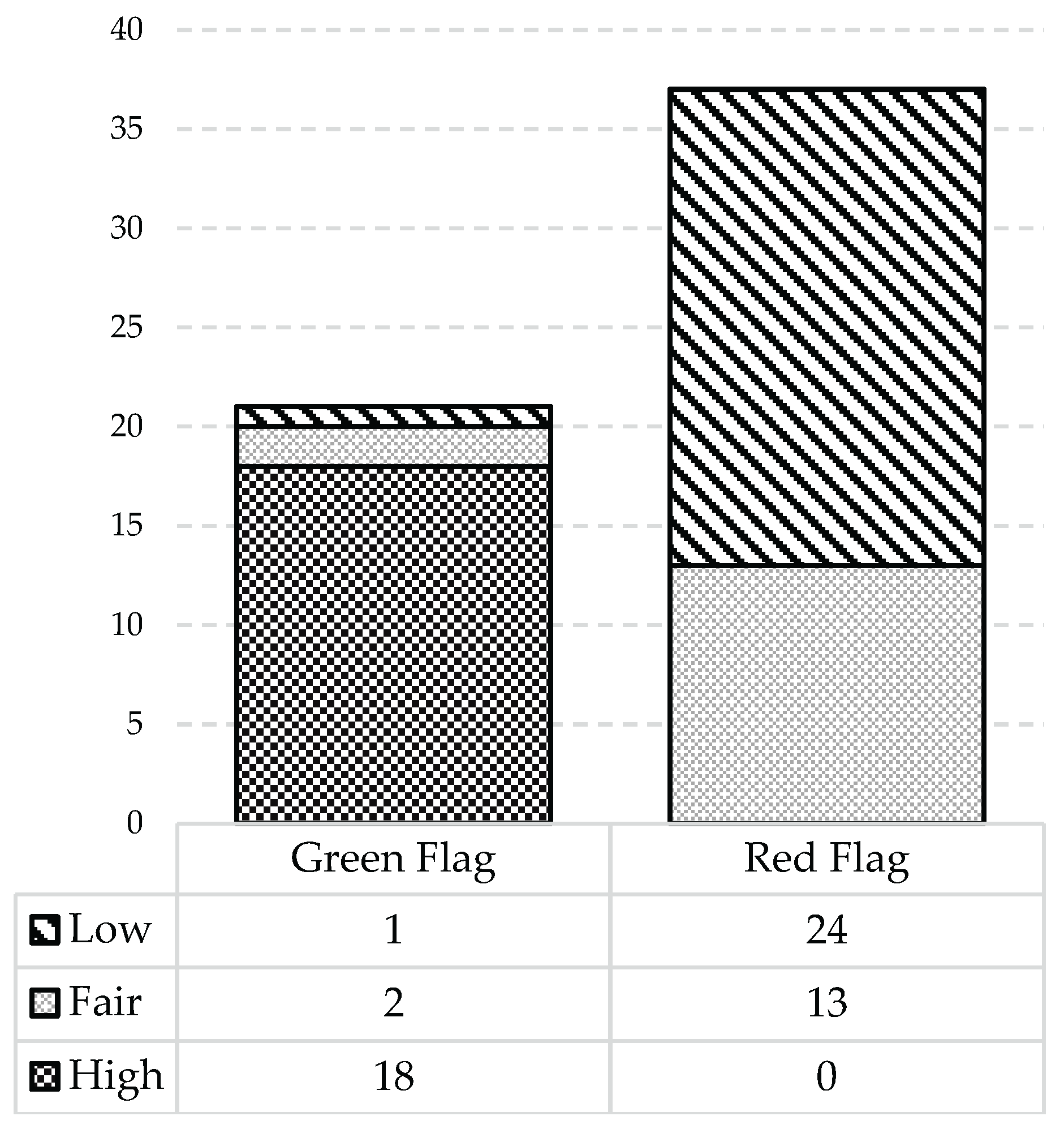

6.1. Green vs Red: Models Divison

6.2. Timeline, Simulation Techniques and Sectors

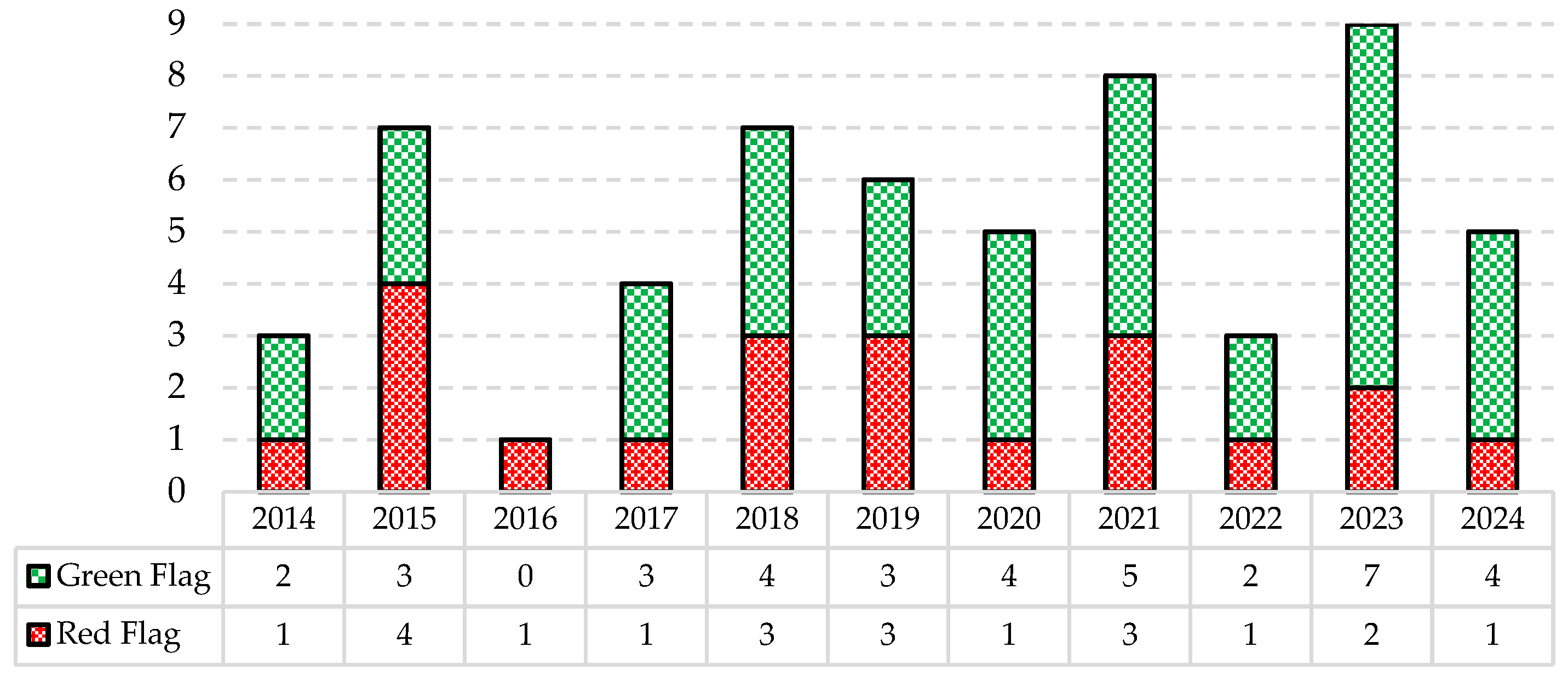

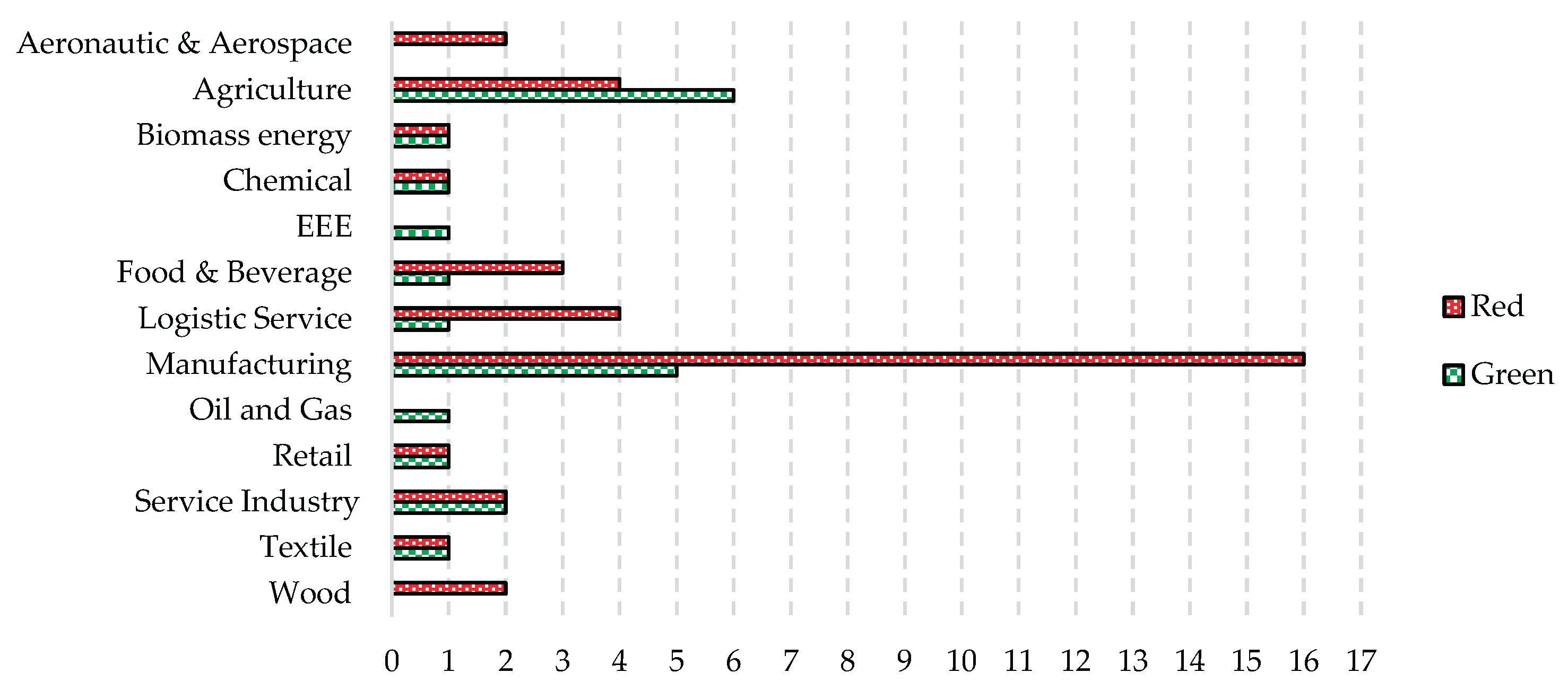

6.3. Inter-Agent Interactions

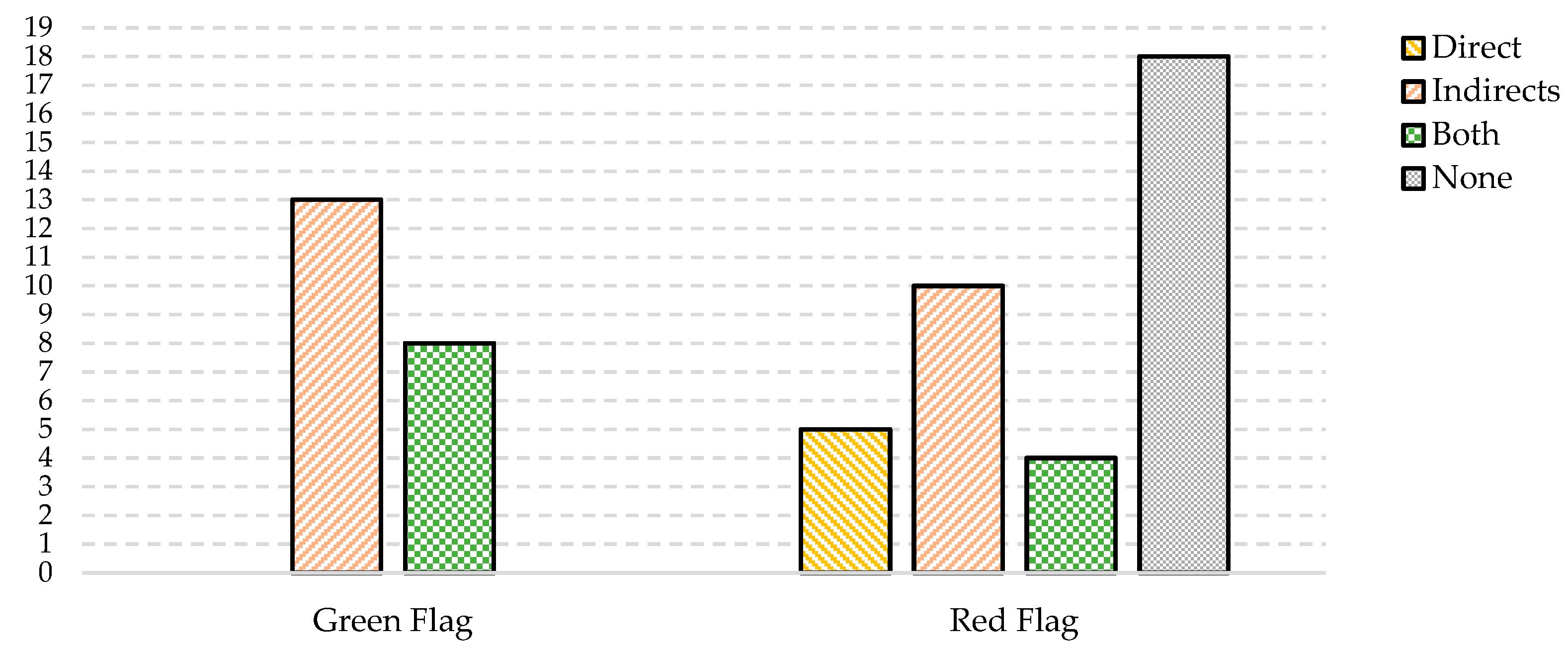

6.4. Declared Motivations for Using ABS

7. Conclusions & Future Developments

7.1. Main Findings

7.2. Possible Implications for Contributors and Developers

7.3. Limitations of the Research

7.4. Future Works

Author Contributions

Funding

Data Availability Statement

Originality Statement

Conflicts of Interest

References

- Moroni, F.; Viola, A.; Gallo, M.; Romagnoli, G.; Zammori, F. Do We Really Need Simulation for a Transition Towards Circular Supply Chain Management? A Possible Answer from Scientific Literature. 2024; 414–428. [Google Scholar] [CrossRef]

- Wang, F.; Wu, D.; Yu, H.; Shen, H.; Zhao, Y. Understanding the role of big data analytics for coordination of electronic retail service supply chain. Journal of Enterprise Information Management 2022, 35, 1392–1408. [Google Scholar] [CrossRef]

- Romagnoli, G.; Moroni, F.; Mercogliano, N.; Zammori, F. Mapping Simulation Trends in Supply Chain Management: A Structured Literature Review. IFIP Adv Inf Commun Technol, 2025.

- Kazancoglu, I.; Ozbiltekin-Pala, M.; Mangla, S.K.; Kazancoglu, Y.; Role of flexibility, F.J. , agility and responsiveness for sustainable supply chain resilience during COVID-19. J Clean Prod 2022, 362, 132431. [Google Scholar] [CrossRef]

- Jaehn, F. Sustainable Operations. Eur J Oper Res 2016, 253, 243–264. [Google Scholar] [CrossRef]

- Choi, T.Y.; Dooley, K.J.; Rungtusanatham, M. Supply networks and complex adaptive systems: control versus emergence. Journal of Operations Management 2001, 19, 351–366. [Google Scholar] [CrossRef]

- Ji, G.; Solari, F.; Lysova, N.; Romagnoli, G.; Montanari, R.; Bottani, E. Insights from 20 Years (2004–2023) of Supply Chain Disruption Research: Trends and Future Directions Based on a Bibliometric Analysis. Sustainability 2024, 16, 7530. [Google Scholar] [CrossRef]

- Solari, F.; Bottani, E.; Romagnoli, G. Sustainable Logistics and Supply Chain Management in the Post-COVID-19 Era: Future Challenges and Challenging Futures. Sustainability 2025, 17, 1772. [Google Scholar] [CrossRef]

- Mercogliano, N.; Zammori, F.; Castellano, D.; Romagnoli, G. Assessing the Effect of Citizens’ Behaviour in Textile Waste Separate Collection: An Agent-based Simulation Model. In Proceedings of the International Conference on Modeling and Applied Simulation, MAS; vol. 2024-September, 2024. [CrossRef]

- Bemthuis, R.H.; Lazarova-Molnar, S. Towards integrating process mining with agent-based modeling and simulation: State of the art and outlook. Expert Syst Appl 2025, 281, 127571. [Google Scholar] [CrossRef]

- Dorigatti, M.; Guarnaschelli, A.; Chiotti, O.; Salomone, H.E. A service-oriented framework for agent-based simulations of collaborative supply chains. Comput Ind 2016, 83, 92–107. [Google Scholar] [CrossRef]

- Jennings, N.R.; Sycara, K.; Wooldridge, M. A Roadmap of Agent Research and Development. Auton Agent Multi Agent Syst 1998, 1, 7–38. [Google Scholar] [CrossRef]

- Labarthe, O.; Espinasse, B.; Ferrarini, A.; Montreuil, B. Toward a methodological framework for agent-based modelling and simulation of supply chains in a mass customization context. Simul Model Pract Theory 2007, 15, 113–136. [Google Scholar] [CrossRef]

- Utomo, D.S.; Onggo, B.S.; Eldridge, S. Applications of agent-based modelling and simulation in the agri-food supply chains. European Journal of Operational Research 2018, 269, 794–805. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J Clean Prod 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Guchhait, R.; Sarkar, B. A decision-making problem for product outsourcing with flexible production under a global supply chain management. Int J Prod Econ 2024, 272, 109230. [Google Scholar] [CrossRef]

- Duan, H.; Zhang, Y.; Huang, Z. Production line location strategy for foreign manufacturer when selling in a market lag behind in manufacturing. Comput Ind Eng 2024, 198, 110678. [Google Scholar] [CrossRef]

- Jaehn, F. Sustainable Operations. Eur J Oper Res 2016, 253, 243–264. [Google Scholar] [CrossRef]

- Choi, T.Y.; Dooley, K.J.; Rungtusanatham, M. Supply networks and complex adaptive systems: Control versus emergence. Journal of Operations Management 2001, 19, 351–366. [Google Scholar] [CrossRef]

- Chan, H.K.; Chan, F.T.S. A review of coordination studies in the context of supply chain dynamics. Int J Prod Res 2010, 48, 2793–2819. [Google Scholar] [CrossRef]

- Bianco, D.; Marenna, E.; Loffredo, F.; Quarto, M.; Di Vito, V.; Federico, L. Monte Carlo Simulations in Aviation Contrail Study: A Review. Applied Sciences 2022, 12, 5885. [Google Scholar] [CrossRef]

- Banks, J.; Carson, J.S.; Nelson, B.L.; Nicol, D.M. Discrete-Event System Simulation. Prentice-Hall, 2010. Available online: https://experts.illinois.edu/en/publications/discrete-event-system-simulation-2 (accessed on 30 May 2025).

- Gallo, M.; Moroni, F.; Popolo, V.; Romagnoli, G. An Association Analysis of Digital Technologies in Circular Economy Scenarios. 2024; 398–413. [Google Scholar] [CrossRef]

- Nilsson, F.; Darley, V. On complex adaptive systems and agent-based modeling for improving decision-making in manufacturing and logistics settings: Experiences from a packaging company. Int. J. Oper. Prod. Manag. 2006, 26, 1351–1373. [Google Scholar] [CrossRef]

- Tako, A.A.; Robinson, S. The application of discrete event simulation and system dynamics in the logistics and supply chain context. Decis Support Syst 2012, 52, 802–815. [Google Scholar] [CrossRef]

- Dominguez, R.; Cannella, S. Insights on multi-agent systems applications for supply chain management. Sustainability 2020, 12, 1935. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, C.O. Multi-agent systems applications in manufacturing systems and supply chain management: A review paper. Int J Prod Res 2008, 46, 233–265. [Google Scholar] [CrossRef]

- Kleijnen, J.P.C. Supply chain simulation tools and techniques: a survey. International Journal of Simulation and Process Modelling 2005, 1, 82–89. [Google Scholar] [CrossRef]

- Macal, C.M. Everything you need to know about agent-based modelling and simulation. Journal of Simulation 2016, 10, 144–156. [Google Scholar] [CrossRef]

- Bodine, E.N.; Panoff, R.M.; Voit, E.O.; Weisstein, A.E. Agent-Based Modeling and Simulation in Mathematics and Biology Education. Bull Math Biol 2020, 82, 101. [Google Scholar] [CrossRef]

- MacAl, C.M.; North, M.J. Tutorial on agent-based modelling and simulation. Journal of Simulation 2010, 4, 151–162. [Google Scholar] [CrossRef]

- Aslam, T.; Ng, A. Agent-based simulation and simulation-based optimisation for supply chain management. In Enterprise Networks and Logistics for Agile Manufacturing; Springer: London, 2010; pp. 227–247. [Google Scholar] [CrossRef]

- Clausen, U.; Brueggenolte, M.; Kirberg, M.; Besenfelder, C.; Poeting, M.; Gueller, M. Agent-Based Simulation in Logistics and Supply Chain Research: Literature Review and Analysis. In Lecture Notes in Logistics; Springer Science and Business Media B.V., 2019; pp. 45–59. [Google Scholar] [CrossRef]

- Xu, L.; Mak, S.; Minaricova, M.; Brintrup, A. On implementing autonomous supply chains: A multi-agent system approach. Comput Ind 2024, 161, 104120. [Google Scholar] [CrossRef]

- Brailsford, S.C.; Eldabi, T.; Kunc, M.; Mustafee, N.; Osorio, A.F. Hybrid simulation modelling in operational research: A state-of-the-art review. Eur J Oper Res 2019, 278, 721–737. [Google Scholar] [CrossRef]

- Fox, M.S.; Barbuceanu, M.; Teigen, R. Agent-oriented supply-chain management. International Journal of Flexible Manufacturing Systems 2000, 12, 165–188. [Google Scholar] [CrossRef]

- Chen, X.; Ong, Y.S.; Tan, P.S.; Zhang, N.S.; Li, Z. Agent-based modeling and simulation for supply chain risk management - A survey of the state-ofthe- Art. 2013 IEEE International Conference on Systems, Man, and Cybernetics, SMC 2013, Jan. 2013; pp. 1294–1299. [Google Scholar] [CrossRef]

- Alonso-Adame, A.; Van Meensel, J.; Marchand, F.; Van Passel, S.; Farahbakhsh, S. Sustainability transitions in agri-food systems through the lens of agent-based modeling: a systematic review. Sustainability Science 2024, 1–18. [Google Scholar] [CrossRef]

- Zammori, F.; Moroni, F.; Viola, A. Supply Chains modelling with Agent Based Simulation: a methodological exploration of agent types and their interactions. 2024. [Google Scholar] [CrossRef]

- Bonabeau, E. Predicting the unpredictable. Harv Bus Rev 2002, 80, 109. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-0036511934&origin=resultslist&sort=cp-f&src=s&sot=b&sdt=b&s=%28TITLE-ABS-KEY%28%22Predicting+the+unpredictable%22%29+AND+AUTH%28%22Bonabeau%22%29%29&sessionSearchId=d39510b3953c9f7ef462499a699cc852 (accessed on 27 May 2025).

- Tong, X.; Chen, J.; Zhu, Q.; Cheng, T.C.E. Technical assistance, inspection regime, and corporate social responsibility performance: A behavioural perspective. Int J Prod Econ 2018, 206, 59–69. [Google Scholar] [CrossRef]

- Buurma, J.; Hennen, W.; Verwaart, T. How social unrest started innovations in a food supply chain. JASSS 2017, 20. [Google Scholar] [CrossRef]

- Mortazavi, A.; Khamseh, A.A.; Azimi, P. Designing of an intelligent self-adaptive model for supply chain ordering management system. Eng Appl Artif Intell 2015, 37, 207–220. [Google Scholar] [CrossRef]

- Ma, K.; Wang, L.; Chen, Y. A collaborative cloud service platform for realizing sustainable make-to-order apparel supply chain. Sustainability (Switzerland) 2018, 10, 11. [Google Scholar] [CrossRef]

- Fikar, C. A decision support system to investigate food losses in e-grocery deliveries. Comput Ind Eng 2018, 117, 282–290. [Google Scholar] [CrossRef]

- Robinson, S.; Dimitriou, S.; Kotiadis, K. Addressing the sample size problem in behavioural operational research: Simulating the newsvendor problem. Journal of the Operational Research Society 2017, 68, 253–268. [Google Scholar] [CrossRef]

- Naghavi, S.; Karbasi, A.; Kakhki, M.D. Agent based modelling of milk and its productions supply chain and bullwhip effect phenomena (Case Study: Kerman). International Journal of Supply and Operations Management 2020, 7, 279–294. [Google Scholar] [CrossRef]

- Labelle, A.; Frayret, J.M. Agent-based model for end-of-life product flow analysis. Resources 2018, 7, 42. [Google Scholar] [CrossRef]

- Elkamel, M.; Rabelo, L.; Sarmiento, A.T. Agent-Based Simulation and Micro Supply Chain of the Food–Energy–Water Nexus for Collaborating Urban Farms and the Incorporation of a Community Microgrid Based on Renewable Energy. Energies (Basel) 2023, 16. [Google Scholar] [CrossRef]

- Namazov, M.; Matsiuk, V.; Bulgakova, I.; Nikolaienko, I.; Vernyhora, R. Agent-based simulation model of multimodal iron ore concentrate transportation. Machinery and Energetics 2023, 14, 46–56. [Google Scholar] [CrossRef]

- Behdani, B.; Lukszo, Z.; Srinivasan, R. Agent-oriented simulation framework for handling disruptions in chemical supply chains. Comput Chem Eng 2019, 122, 306–325. [Google Scholar] [CrossRef]

- Barbosa, C.; Malarranha, C.; Azevedo, A.; Carvalho, A.; Barbosa-Póvoa, A. A hybrid simulation approach applied in sustainability performance assessment in make-to-order supply chains: The case of a commercial aircraft manufacturer. Journal of Simulation 2023, 17, 32–57. [Google Scholar] [CrossRef]

- Cannella, S.; Di Mauro, C.; Dominguez, R.; Ancarani, A.; Schupp, F. An exploratory study of risk aversion in supply chain dynamics via human experiment and agent-based simulation. Int J Prod Res 2019, 57, 985–999. [Google Scholar] [CrossRef]

- Lohmer, J.; Bugert, N.; Lasch, R. Analysis of resilience strategies and ripple effect in blockchain-coordinated supply chains: An agent-based simulation study. Int J Prod Econ 2020, 228, 107882. [Google Scholar] [CrossRef]

- Medini, K.; Rabénasolo, B. Analysis of the performance of supply chains configurations using multi-agent systems. International Journal of Logistics Research and Applications 2014, 17, 441–458. [Google Scholar] [CrossRef]

- Castrellon, J.P.; et al. Assessing the eco-efficiency benefits of empty container repositioning strategies via dry ports. Transp Res D Transp Environ 2023, 120, 103778. [Google Scholar] [CrossRef]

- Barbosa, C.; Azevedo, A. Assessing the impact of performance determinants in complex MTO/ETO supply chains through an extended hybrid modelling approach. Int J Prod Res 2019, 57, 3577–3597. [Google Scholar] [CrossRef]

- Holzfeind, T.; Kanzian, C.; Gronalt, M. Challenging agent-based simulation for forest operations to optimize the European cable yarding and transport supply chain. International Journal of Forest Engineering 2021, 32, 77–90. [Google Scholar] [CrossRef]

- Yu, Y.; Cao, R.Q.; Schniederjans, D. Cloud computing and its impact on service level: a multi-agent simulation model. Int J Prod Res 2017, 55, 4341–4353. [Google Scholar] [CrossRef]

- Lehner, R.; Elbert, R. Cross-actor pallet exchange platform for collaboration in circular supply chains. International Journal of Logistics Management 2023, 34, 772–799. [Google Scholar] [CrossRef]

- Suh, E.S. Cross-docking assessment and optimization using multi-agent co-simulation: a case study. Flex Serv Manuf J 2014, 27, 115–133. [Google Scholar] [CrossRef]

- Riese, J.; Fasel, H.; Pannok, M.; Lier, S. Decentralized production concepts for bio-based polymers - implications for supply chains, costs, and the carbon footprint. Sustain Prod Consum 2024, 46, 460–475. [Google Scholar] [CrossRef]

- Zhu, A.; Han, Y.; Liu, H. Effects of adaptive cooperation among heterogeneous manufacturers on supply chain viability under fluctuating demand in post-COVID-19 era: an agent-based simulation. Int J Prod Res 2024, 62, 1162–1188. [Google Scholar] [CrossRef]

- Vempiliyath, T.; Thakur, M.; Hargaden, V. Development of a hybrid simulation framework for the production planning process in the atlantic salmon supply chain. Agriculture (Switzerland) 2021, 11, 907. [Google Scholar] [CrossRef]

- Kummer, Y.; et al. Facilitating Resilience during an African Swine Fever Outbreak in the Austrian Pork Supply Chain through Hybrid Simulation Modelling. Agriculture (Switzerland) 2022, 12, 352. [Google Scholar] [CrossRef]

- Uhlmann, I.R.; Zanella, R.M.; Frazzon, E.M. Hybrid flow shop rescheduling for contract manufacturing services. Int J Prod Res 2022, 60, 1069–1085. [Google Scholar] [CrossRef]

- Krejci, C.C. Hybrid simulation modeling for humanitarian relief chain coordination. Journal of Humanitarian Logistics and Supply Chain Management 2015, 5, 325–347. [Google Scholar] [CrossRef]

- Xu, X.; Rodgers, M.D.; (Grace) Guo, W. Hybrid simulation models for spare parts supply chain considering 3D printing capabilities. J Manuf Syst 2021, 59, 272–282. [Google Scholar] [CrossRef]

- Tama, I.P.; Hardiningtyas, D.; Sudiarno, A.; Larasati, A.; Nugroho, W.S. identifying the influence of land logistic driver cognitive energy impact on supply chain performance through agent-based simulation. Eastern-European Journal of Enterprise Technologies 2024, 2, 6–13. [Google Scholar] [CrossRef]

- Cramer, F.; Fikar, C. Investigating crowd logistics platform operations for local food distribution. International Journal of Retail and Distribution Management 2024, 52, 836–855. [Google Scholar] [CrossRef]

- Abualkhair, H.; Lodree, E.J.; Davis, L.B. Managing volunteer convergence at disaster relief centers. Int J Prod Econ 2020, 220, 107399. [Google Scholar] [CrossRef]

- Ma, R.; Yang, T. Manufacturer’s channel strategy in live streaming E-commerce supply chain. Managerial and Decision Economics 2024, 45, 2087–2107. [Google Scholar] [CrossRef]

- Bounadi, N.; Boussalia, S.R.; Bellaouar, A. Optimizing Algerian Company’s Delivery Fleet with Agent_Based Model in Anylogic. Transport and Telecommunication 2023, 24, 434–442. [Google Scholar] [CrossRef]

- Shevchenko, A.; Pagell, M.; Lévesque, M.; Johnston, D. Preventing supplier non-conformance: extending the agency theory perspective. International Journal of Operations and Production Management 2020, 40, 315–340. [Google Scholar] [CrossRef]

- Sahay, N.; Ierapetritou, M.; Wassick, J. Synchronous and asynchronous decision making strategies in supply chains. Comput Chem Eng 2014, 71, 116–129. [Google Scholar] [CrossRef]

- Lieder, M.; Asif, F.M.A.; Rashid, A.; Mihelič, A.; Kotnik, S. Towards circular economy implementation in manufacturing systems using a multi-method simulation approach to link design and business strategy. International Journal of Advanced Manufacturing Technology 2017, 93, 1953–1970. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S.; Kiniry, J.R. Two-phase simulation-based location-allocation optimization of biomass storage distribution. Simul Model Pract Theory 2018, 86, 155–168. [Google Scholar] [CrossRef]

- Strmenik, K.; Wall, F.; Mitsch, C.; Mödritscher, G. Volume allocation in multi-sourcing: effects of the quantity–quality trade-off. Cent Eur J Oper Res 2021, 29, 753–771. [Google Scholar] [CrossRef]

- Nguyen, T.T.B. Which Node of Supply Chain Suffers Mostly to Disruption in the Pandemic? Journal of Distribution Science 2021, 19, 59–68. [Google Scholar] [CrossRef]

- Coetsee, L.; Bean, W.L. A multi-method simulation model to investigate the impact of sunflower seed segregation on silos. Simul Model Pract Theory 2024, 132, 102897. [Google Scholar] [CrossRef]

- Dogan, I.; Güner, A.R. A reinforcement learning approach to competitive ordering and pricing problem. Expert Syst 2015, 32, 39–48. [Google Scholar] [CrossRef]

- Ge, H.; Gray, R.; Nolan, J. Agricultural supply chain optimization and complexity: A comparison of analytic vs simulated solutions and policies. Int J Prod Econ 2015, 159, 208–220. [Google Scholar] [CrossRef]

- Zhang, H.P. An agent-based simulation model for supply chain collaborative technological innovation diffusion. International Journal of Simulation Modelling 2015, 14, 313–324. [Google Scholar] [CrossRef]

- Ge, H.; Nolan, J.; Gray, R. Identifying strategies to mitigate handling risks in the canadian grain supply chain. Canadian Journal of Agricultural Economics 2015, 63, 101–128. [Google Scholar] [CrossRef]

- Taghikhah, F.; Voinov, A.; Shukla, N.; Filatova, T.; Anufriev, M. Integrated modeling of extended agro-food supply chains: A systems approach. Eur J Oper Res 2021, 288, 852–868. [Google Scholar] [CrossRef]

- Luévano, A.N.; Barrientos, A.H.; Valverde, N.K. A Hybrid Modelling Framework for E-Commerce Supply Chain Simulation: Complex Adaptive Systems Perspective. Informatica (Slovenia) 2023, 47, 159–172. [Google Scholar] [CrossRef]

- Tang, Y.; Tao, Y.; Li, Y. Collection policy analysis for retired electric vehicle batteries through agent-based simulation. J Clean Prod 2023, 382, 135269. [Google Scholar] [CrossRef]

- van Heeswijk, W.J.A.; Mes, M.R.K.; Schutten, J.M.J.; Zijm, W.H.M. Evaluating Urban Logistics Schemes Using Agent-based Simulation. Transportation Science 2020, 54, 651–675. [Google Scholar] [CrossRef]

- Sha, M.; Srinivasan, R. Fleet sizing in chemical supply chains using agent-based simulation. Comput Chem Eng 2016, 84, 180–198. [Google Scholar] [CrossRef]

- Upton, E.; Nuttall, W.J. Fuel panics: Insights from spatial agent-based simulation. IEEE Transactions on Intelligent Transportation Systems 2014, 15, 1499–1509. [Google Scholar] [CrossRef]

- Mittal, A.; Krejci, C.C. A hybrid simulation modeling framework for regional food hubs. Journal of Simulation 2019, 13, 28–43. [Google Scholar] [CrossRef]

- Castillo, V.E.; Mollenkopf, D.A.; Bell, J.E.; Esper, T.L. Designing technology for on-demand delivery: The effect of customer tipping on crowdsourced driver behavior and last mile performance. Journal of Operations Management 2022, 68, 424–453. [Google Scholar] [CrossRef]

- Zhao, K.; Zuo, Z.; Blackhurst, J.V. Modelling supply chain adaptation for disruptions: An empirically grounded complex adaptive systems approach. Journal of Operations Management 2019, 65, 190–212. [Google Scholar] [CrossRef]

- Tong, X.; Lai, K.H.; Zhu, Q.; Zhao, S.; Chen, J.; Cheng, T.C.E. Multinational enterprise buyers’ choices for extending corporate social responsibility practices to suppliers in emerging countries: A multi-method study. Journal of Operations Management 2018, 63, 25–43. [Google Scholar] [CrossRef]

- Huang, J.; Song, J. Optimal inventory control with sequential online auction in agriculture supply chain: an agent-based simulation optimisation approach. Int J Prod Res 2018, 56, 2322–2338. [Google Scholar] [CrossRef]

- Scholz, J.; Breitwieser, F.; Mandl, P. Simulating the forest fuel market as a socio-ecological system with spatial agent-based methods: A case study in Carinthia, Austria. Nat Resour Model 2021, 34, e12291. [Google Scholar] [CrossRef]

- Inoue, Y.; Takenaka, T.; Kurumatani, K. Sustainability of service intermediary platform ecosystems: Analysis and simulation of Japanese hotel booking platform-based markets. Sustainability (Switzerland) 2019, 11, 4563. [Google Scholar] [CrossRef]

- Backs, S.; Jahnke, H.; Lüpke, L.; Stücken, M.; Stummer, C. Traditional versus fast fashion supply chains in the apparel industry: an agent-based simulation approach. Ann Oper Res 2021, 305, 487–512. [Google Scholar] [CrossRef]

| PARAMETER | DESCRIPTION |

|---|---|

| Context and Objectives | The application domain and the specific goals for which the ABM was developed (e.g., decision support, policy testing, behavioural exploration). |

| Justification for ABS | The rationale provided by the authors for adopting an agent-based approach, including reference to complexity, decentralisation, or adaptiveness. |

| Simulation Objects | The entities modelled as agents in the simulation (e.g., firms, consumers, logistics nodes), including their role and level of autonomy. |

| System Evolution over Time | Evidence of system-level evolution over time, driven by agent behaviour and interaction; includes structural shifts, convergence, or emergent patterns. |

| Type of Interactions | The presence and nature of interactions among agents: whether agents influence each other explicitly (directly) or through shared environmental variables (indirectly). |

| CONDITION | DESCRIPTION | GREEN FLAG ELIGIBILITY |

|---|---|---|

| (i) Interaction | Presence of direct or indirect interactions among agents. | Mandatory |

| (ii) Two or more Active Agents | At least two agents show autonomy, adaptivity, or goal-oriented logic. | Sufficient if (i) is met |

| (iii) System Evolution | System dynamics change over time due to agent behaviours. | Alternative to (ii), if (i) is met |

| Ref. | Ind. Sector |

Context and Objectives | Justification for ABS | Simulation Objects | System Evolution | Interactions Type |

|---|---|---|---|---|---|---|

| [41] | Manufacturing |

Corporate social responsibility issues within buyer-supplier relationship. The study examines how technical assistance (TA) programs initiated by buyers influence the CSR performance of suppliers within a regulatory environment characterized by periodic inspections. It introduces a dynamic, multi-period model of buyer –supplier regulator interactions, accounting for risk preferences, bounded rationality, and uncertainty. The core objective is to evaluate how these behavioural and institutional mechanisms drive CSR improvements or deterioration over time, offering insights for both corporate strategy and regulatory policy design. |

The authors use a multi-agent simulation to model how buyers and suppliers adapt to inspections, penalties, and technical assistance. ABS is justified by the need to capture heterogeneous risk preferences, bounded rationality, and temporal learning within a SC. The framework supports sequential, contingent decision-making (e.g., delivering TA, upgrading CSR practices, reacting to regulatory thresholds), across multiple periods, which would be analytically intractable. |

1) Buyer agents. Each buyer is linked to a single supplier and decides whether to offer technical assistance (TA) based on the supplier’s perceived CSR level and its own risk preference. These decisions are dynamically updated in response to regulatory inspections or past TA outcomes. 2) Supplier agents. Based on their current CSR level, risk preference, and absorptive capacity, suppliers choose whether to upgrade or downgrade their CSR practices in response to buyer incentives and the perceived probability of inspection. 3) Regulator agent. An exogenous actor that conducts random inspections, penalizes underperforming suppliers, and periodically adjusts CSR thresholds. It indirectly influences buyer and supplier behavior through deterrence effects. |

The system operates through repeated three-phase cycles: (1) Decision phase. Buyers and suppliers make CSR-related choices based on risk–cost trade-offs. (2) Inspection phase. The regulator performs inspections and applies penalties when CSR thresholds are not met. (3) Update phase. CSR levels and buyer perceptions are revised based on observed outcomes. Across multiple iterations, adaptive behaviors emerge; for example, opportunistic CSR downgrades by suppliers following inspections, or increased TA investments by risk-averse buyers under heightened regulatory pressure. |

Buyer–Supplier. Interact through the provision of technical assistance (TA) and updates to supplier reputation, influenced by CSR performance and the supplier’s absorptive capacity. Supplier–Regulator. Suppliers are subject to inspections, with penalties applied when CSR thresholds are not met. Buyer–Regulator. Buyers are indirectly affected through the performance of their suppliers, primarily via reputational risks. Although interactions are indirect and state-dependent, they shape agent behavior over time through feedback loops driven by the gap between perceived and actual CSR levels. |

| [42] | Agriculture |

Food Supply Chains; Animal Welfare in Pork Production This study explores how public debates, particularly around animal welfare in Dutch pork production, influence the adoption of sociotechnical innovations in food supply chains. Combining dramaturgical analysis with agent-based simulation, it examines how stakeholder interactions and media-driven events shape societal norms and drive structural change. The aims are twofold: (1) to validate hypothesized behavioural dynamics from content and discourse analysis, and (2) to explore how shifts in public opinion and SC practices might have unfolded under alternative behavioural or external event scenarios. |

The authors justify ABS as the appropriate tool to capture the heterogeneous, adaptive behaviours of consumers, producers, retailers, and NGOs engaged in public discourse on food ethics. ABS effectively models opinion dynamics and emergent change, reflecting how bottom-up interactions and external shocks (e.g., media events) can drive long-term transformations in production practices. It enables micro-level reasoning, evolving feedback, and patterns of opinion convergence or divergence critical to understanding policy-relevant transitions. |

Four main agent classes, segmented into subtypes are adopted. Consumers (8 types). Defined by their orientation (e.g., price or welfare-sensitive) and responsiveness to media events. They form opinions through interactions with NGOs, peers, and retailers. Producers (5 types). Represent farmers with varying balances of economic and ethical concerns, influenced by peer interactions, the producers’ organization, and retail demand. Retailers (4 types). Ranging from passive to proactive, capable of adjusting supply chain standards in response to market signals and NGO pressure. NGOs (3 types). Include one activist NGO (with fixed welfare stance), one moderate NGO (with flexible position), and a producers’ organization (risk-averse but adaptable). All agents’ behaviours are governed by bounded-confidence opinion dynamics equations with asymmetric thresholds. |

The simulation runs in weekly time steps over a ten-year period. Agents exchange opinions shaped by their social networks and sporadic media events, which may increase receptiveness to opposing views. As certain stakeholder clusters align (e.g., moderate NGO and a proactive retailer), critical tipping points can emerge, triggering system-wide shifts toward animal-friendly production practices. In their absence, the system may instead exhibit opinion polarisation or stagnation. By testing hundreds of parameter configurations, the simulation highlights the fragile conditions under which meaningful systemic change can unfold. |

Consumers ↔ NGOs. Exchange narratives and cues, with media events enhancing consumer responsiveness. Consumers ↔ Consumers. Peer interactions drive gradual opinion shifts or reinforcement. Consumers ↔ Retailers. Feedback loops influence retailer behaviour and responsiveness. Retailers ↔ Producers. Retailers demand more ethical practices, prompting producer adaptation. Producers ↔ Producers’ Organisation. Norm adoption shaped through internal alignment and peer influence. NGOs ↔ Retailers/Producers. Exert pressure, propose compromises, or lead advocacy efforts. All interactions follow structured yet probabilistic opinion convergence, with asymmetric susceptibility reflecting real-world biases and power imbalances. |

| Ref. | Ind. Sector |

Context and Objectives | Justification for ABS | Simulation Objects | System Evolution | Interactions Type |

|---|---|---|---|---|---|---|

| [43] | Wood |

Wood SC The study examines how energy price fluctuations impact the bullwhip effect in the wood extraction supply chain. It introduces a simulation-based optimization framework that integrates ABM with reinforcement learning, to model and optimize order management policies across a four-echelon supply chain under non-stationary demand conditions. |

The authors used AnyLogic for modelling, justifying their choice by highlighting its agent-based paradigm, where system components are represented as autonomous, self-organizing agents capable of decision-making and communication. T These agents operate based on defined rules, making ABS well-suited for capturing the non-linear dynamics of complex systems. |

Four agent types are used. Retailer agent. Manages customer demand while accounting for inventory levels, as well as order-related setup, maintenance, and transportation costs. Distributor agent. Processes weekly orders from the retailer, either fulfilling them immediately or recording them as backorders until the next inventory replenishment. Manufacturer agent. Receives weekly orders from the distributor and manages both raw material and finished goods inventories. It seeks to fulfill orders while avoiding backorder penalties, making it the most complex agent in the simulation. Supplier agent. Supplies raw materials and components. It processes weekly orders based on current inventory levels, fulfilling requests when possible or incurring penalties for unfulfilled orders. |

The model simulates the flow of goods by tracking inventory levels and order dynamics, while optimizing transport routes to balance supply and demand across the supply chain. System evolution is absent, as the objective is to obtain near-optimal replenishment policy under non-stationary-demand and using the Q-Learning algorithm. |

Interactions are purely procedural. Agents adjust inventories and order quantities in response to upstream and downstream signals, without explicit coordination mechanisms. There is no negotiation, messaging, or direct agent-to-agent influence beyond standard material and information flows typical of supply chains. Coordination emerges solely from isolated reinforcement learning processes, shaped by shared environmental constraints such as holding costs, delivery delays, and backorder penalties. Agent behavior is thus reactive and system-driven, rather than socially or strategically interactive |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).