1. Introduction

Today, Building Information Modeling (BIM) technologies are extensively employed throughout all stages of the engineering structures' life cycle. Information modeling is also increasingly being applied to bridge design - Bridge Information Modeling (BrIM) - which enables engineers and stakeholders to enhance project self-assessment and the preparation of design documentation.

However, the utilization of information models (IMs) during the post-design stages of the life cycle for bridge structures remains limited [

1]. On one hand, Bridge Management Systems (BMS), which essentially contain information models of bridges, are widely implemented during the operational stage (OS) all over the world. Nevertheless, these models exhibit significant differences from those employed in the design stage (DS), as they prioritize operational history data over graphical (geometric) information. This discrepancy highlights a critical issue regarding the interaction between two distinctly different approaches to information modeling across consecutive stages. Consequently, a pertinent question arises: Can the design-stage information model (DS IM) be beneficial not only during design but also in subsequent stages?

This paper summarizes the practical experience gained by the author and his team in the tasks aimed at the continuation of the "life" of design-stage information models of the bridges. Based on real cases, the author identified two principal scenarios in which the DS IMs can be effectively utilized in the subsequent stages of the life cycle:

1. The application of a DS IM for the automated generation of the draft operational-stage information model (OS IM) through the unidirectional automated processes of data export and import.

2. The utilization of a DS IM in bridge condition assessment tasks, namely the identification of geometric discrepancies by comparing the actual point cloud with the geometric data derived from the DS IM [

2].

The study presents two case studies based on bridge projects completed during the years 2023-2024. The first case involves a medium city street overpass in which both scenarios were executed. The second case pertains to a small pedestrian bridge in a historical city center, where only the second scenario was evaluated.

2. Case Study #1. City Street Overpass

2.1. Object Description

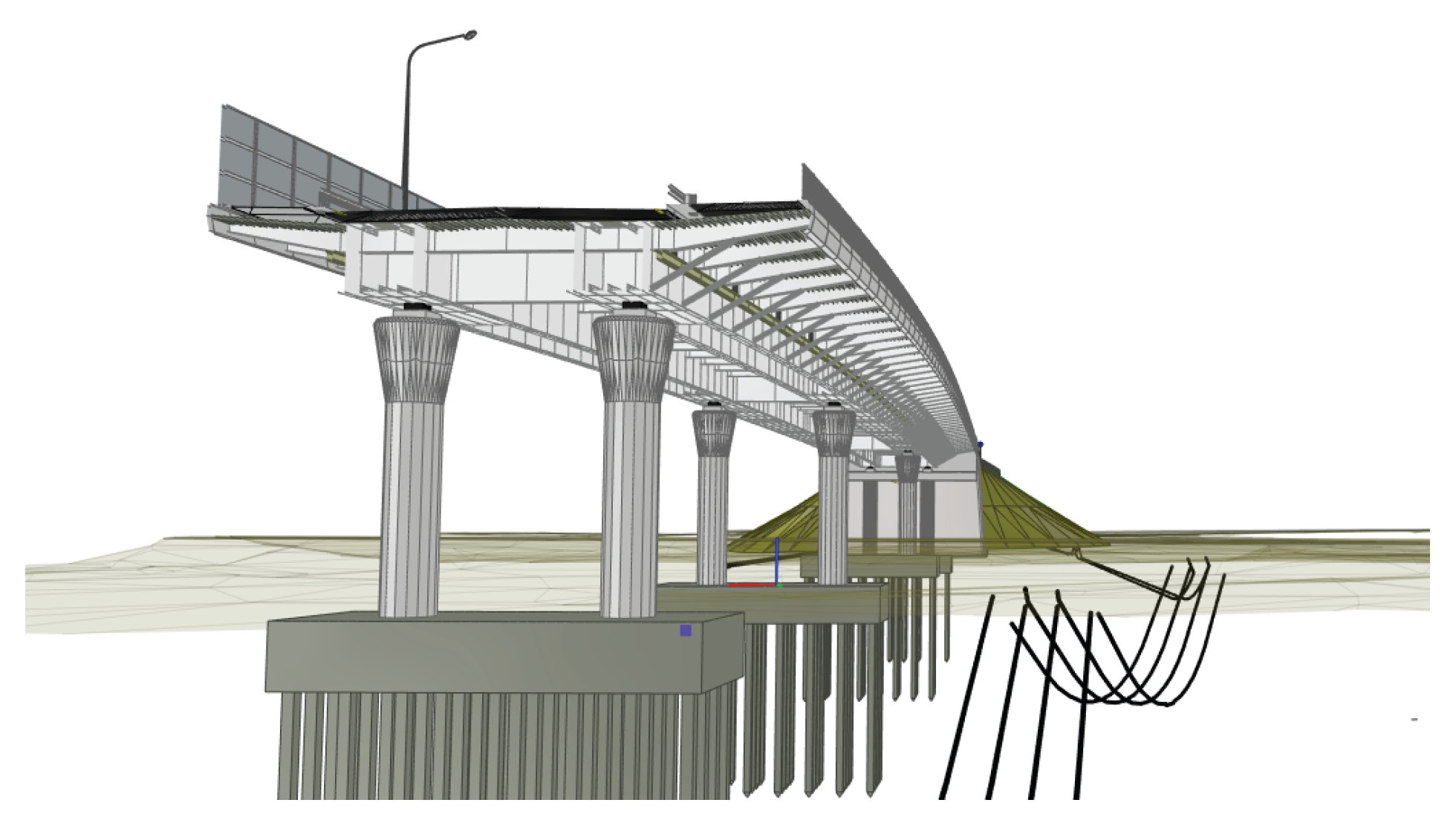

The overpass on a curved street was constructed in a large city in central Russia during the years 2023-2024. This structure is designed to traverse a high-speed railway and local railways (

Figure 1). The overpass superstructure consists of two composite steel-concrete continuous box beams combined by an in-situ slab. The overall length of the overpass is 246 meters, with a maximum span of 54 meters. The overpass accommodates two street traffic lanes, wide sidewalks and a bicycle path.

2.2. Details of the Information Modeling

During the design stage, a complex information model of the transport infrastructure facility was developed with a level of detail of at least LOD 300 In addition to the overpass model, the complex information model includes a model of the street on the approaches, models of approach structures (retaining walls, pedestrian tunnel), as well as models of some utility systems (city street lighting, high-voltage underground electric power lines, gas pipeline) [3-5]. The overall view is shown in

Figure 2.

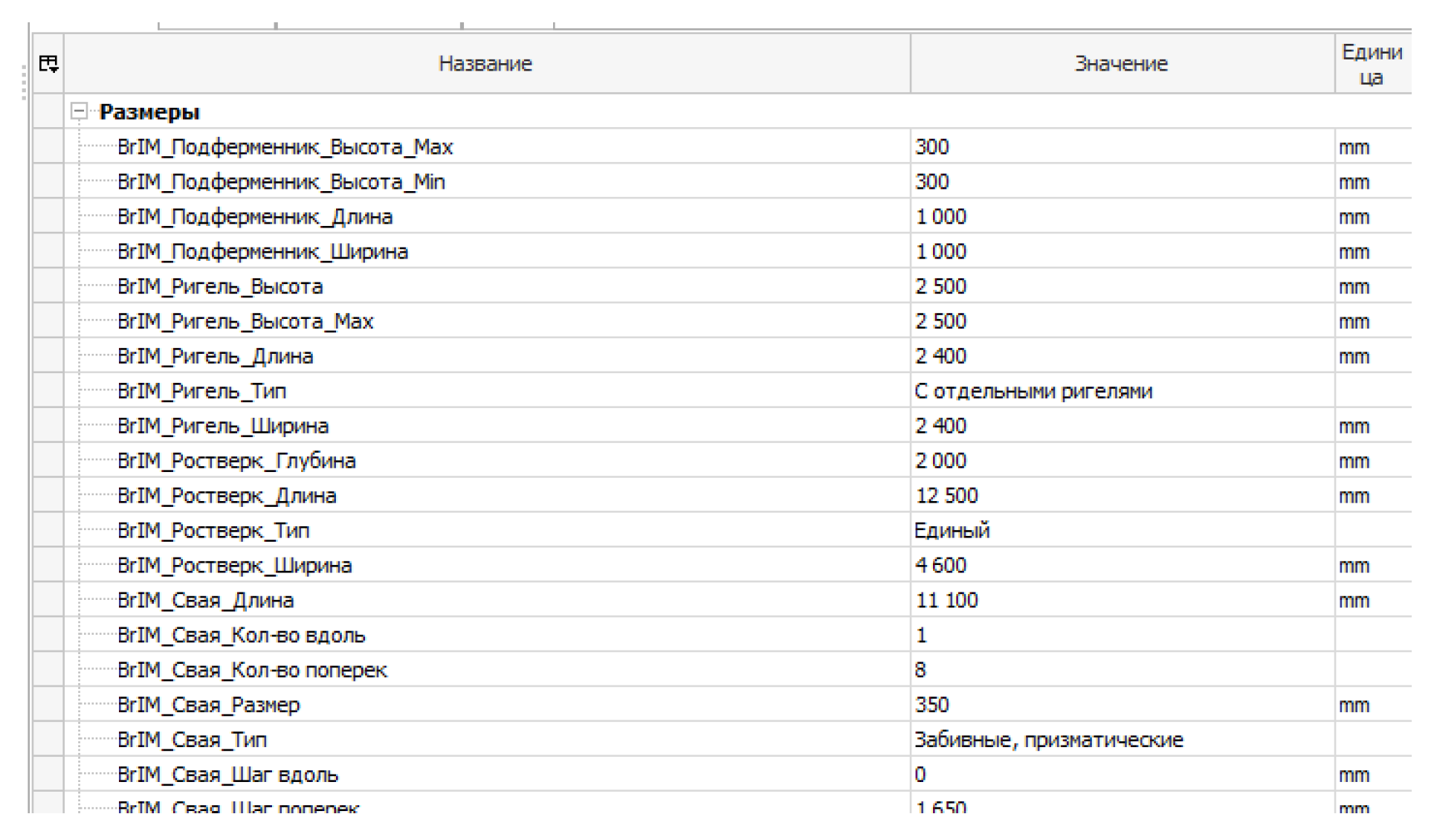

2.3. BrIM as Draft for BMS Database

As part of the technical experiment, during the development of a DS IM, a large number of attributes associated with the data fields in the OS IM of the most common bridge management systems (BMS) in the country were added (

Figure 3).

It is posited that these characteristics will enable a prompt and effective transmission of project information from the DS IM to the BMS, limited to the necessary scope. Regrettably, the testing of the automated generation of the preliminary operational-stage information model for the BMS has yet to be undertaken due to certain technical and system limitations.

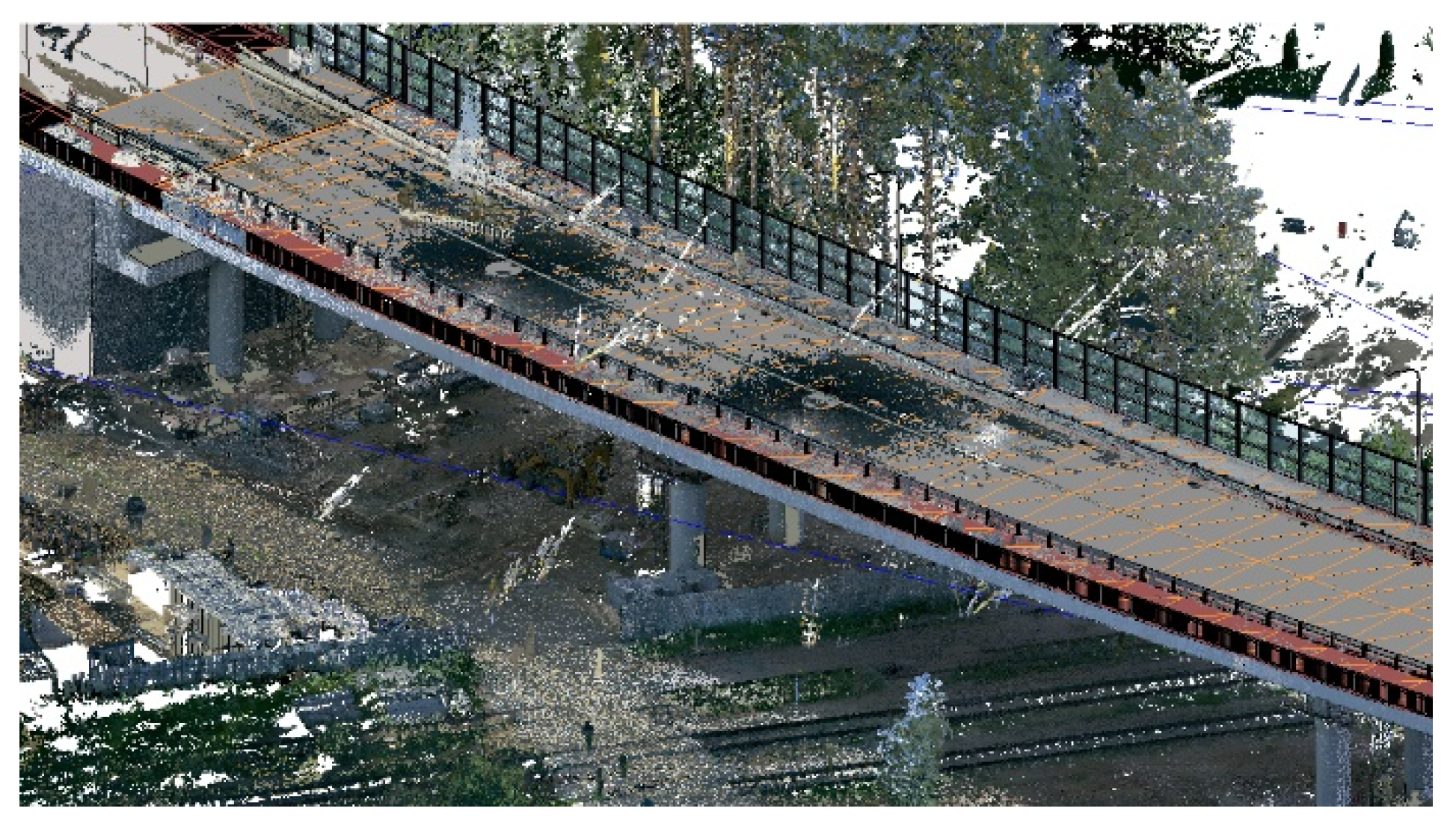

2.4. “BrIM + TLS” Expertise Method

During the pre-operation inspection of the overpass, a comprehensive terrestrial laser scanning (TLS) of all piers, retaining walls, and the bottom part of the span structure was carried out (

Figure 4).

During the pre-operation inspection of the overpass, a comprehensive terrestrial laser scanning (TLS) of all piers, retaining walls, and the bottom part of the span structure was carried out. The purpose of the scanning was to obtain information about the actual positioning, shape, and dimensions of the structural elements. For qualitative and quantitative analysis of the processed point cloud, graphical information derived from the DS IM served as a comparative element. The comparison of the point cloud with the DS IM was executed in a semi-automatic mode utilizing specialized software.

The utilization of this method facilitated the identification and quantitative evaluation of the discrepancies between the constructed structures and their designated values.

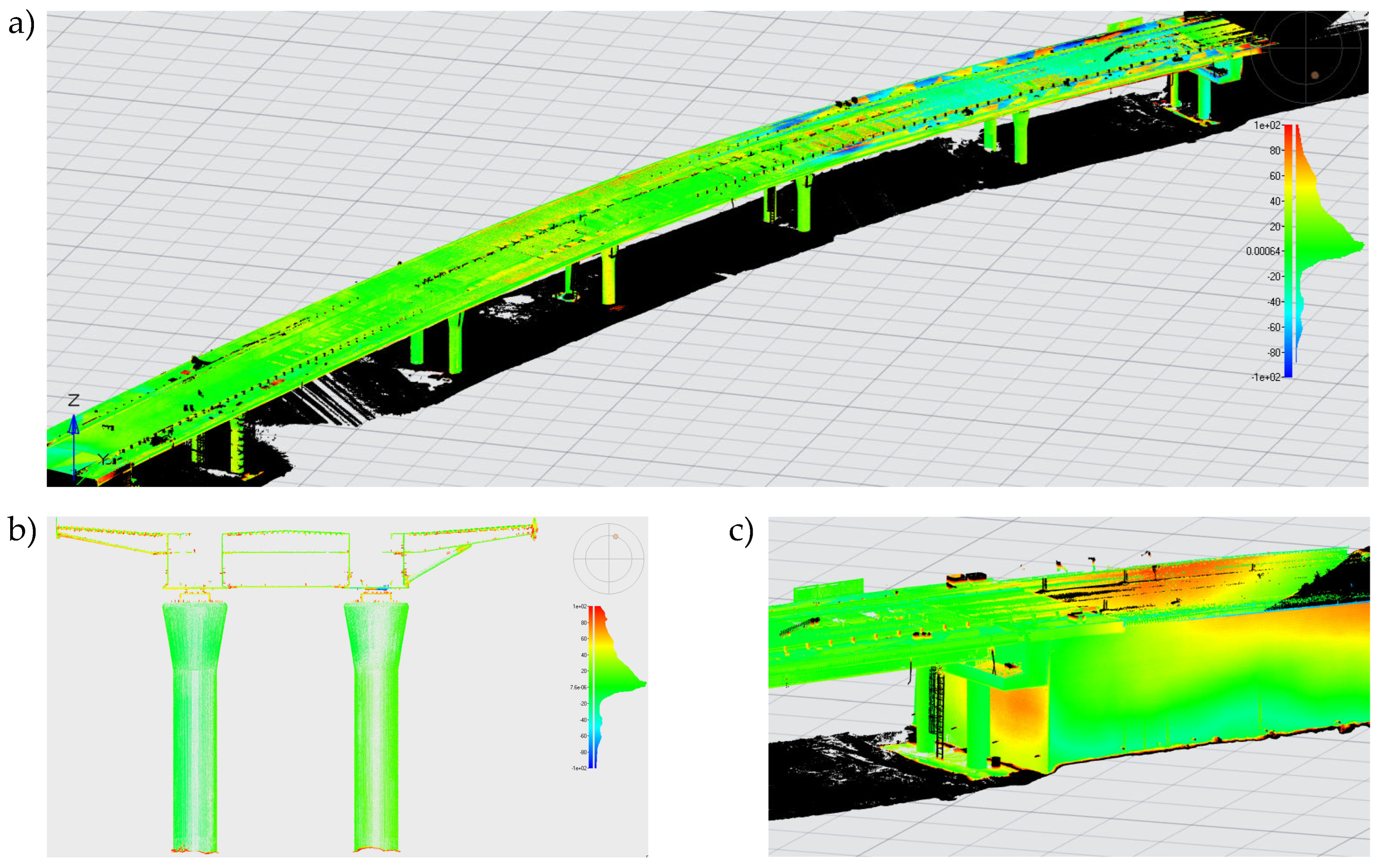

The overall view of the composed model is shown in

Figure 5a. Green areas are related to the areas with low deviations and red or blue – with high. The following figures show details: cross section of the overpass (

Figure 5b) and a part of the overpass approach in retaining walls with some geometrical deviations obtained during construction (

Figure 5c).

This method appears to be especially effective when applied to structural elements characterized by complex geometries, such as curves in both plan and profile.

3. Case Study #2. Pedestrian Bridge

3.1. Object Description

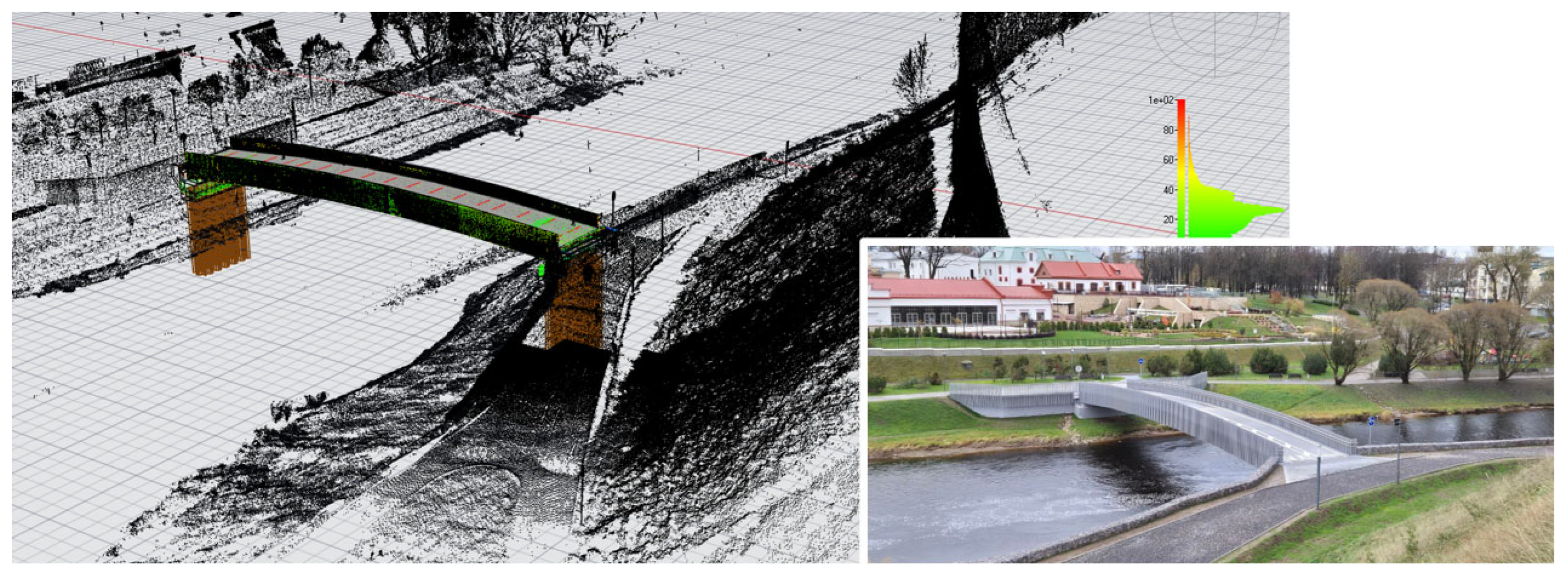

The small pedestrian bridge with an arched outline of the superstructure was built in 2024 in the historic center of a city in western Russia, under the walls of a medieval fortress (

Figure 6). The total length of the bridge measures 40 meters. The span structure consists of 3 steel I-beams combined by a steel orthotropic plate. The bridge's railing is designed to resemble a historical wooden fence of old villages.

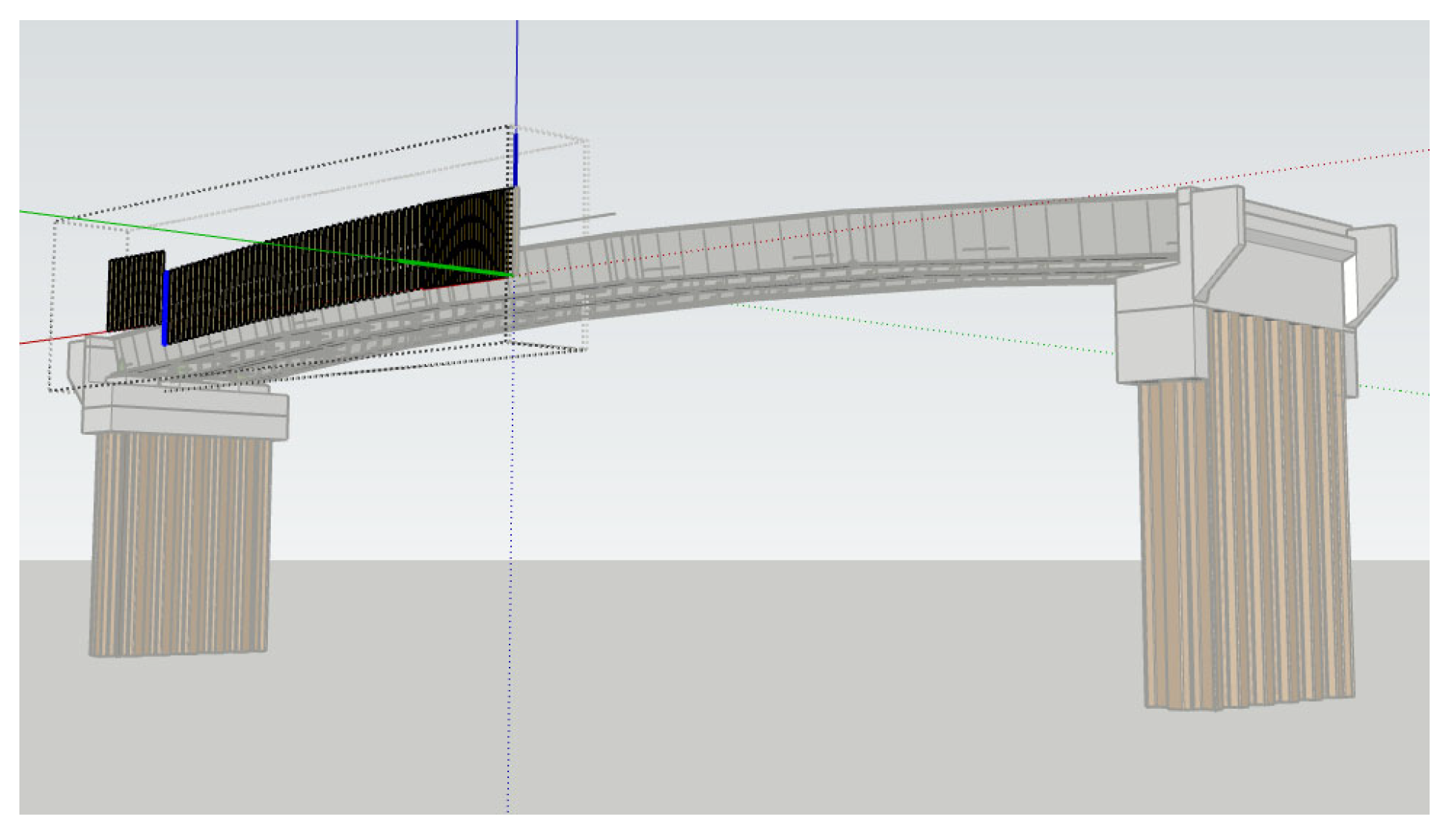

3.2. Details of the Information Modeling

During the design of the bridge, an information model was not established, and all design data were conveyed through traditional drawings and tables. Consequently, to evaluate the proposed method, the author specifically assembled a digital geometric model of the bridge devoid of any attribute data (

Figure 7).

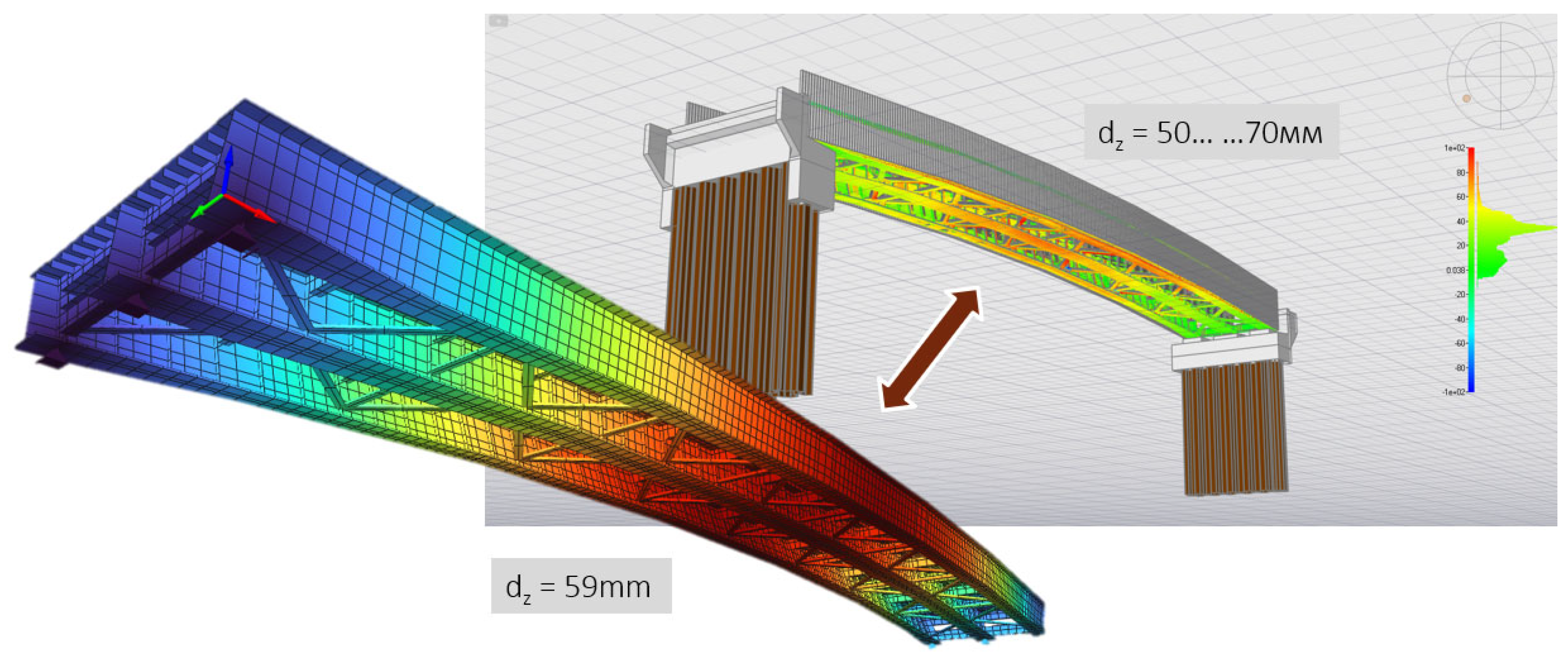

During the pre-operation inspection of the bridge, terrestrial laser scanning method was also used, which allowed for obtaining data for comparison of the actual positioning and dimensions of the structural elements with the design ones (

Figure 8). When interpreting the results graphically, the sagging of the main beams relative to the design geometry with pre-camber was clearly noted (

Figure 9). The deviations were compared with the results of finite element analysis. As the results were quite close, it could be noted that this is another promising area of application of this technology.

4. Conclusions

Based on the results of the study, it can be confidently noted that design-stage information models could stay applicable at consequent stages of the bridge's life cycle. The most significant appears to be the use of geometry data of the information models in conjunction with the point clouds obtained from terrestrial laser scanning in tasks related to the identification of geometric discrepancies of structural elements during or after the completion of bridge construction (first scenario). The possibility of automated generation of the draft operational-stage information model also seems quite promising. However, it is essential to recognize that realizing these opportunities necessitates harmonizing data storage formats and exchange protocols across all mentioned life cycle stages. It is suggested that the second scenario may be actualized over an extended timeframe.

References

- Kozak NV, Yaroshutin DA, Utenkov OV. Information Models of Bridges in the Context of the Interaction with the Owners and Experts: Analysis of Current Problems on the Side of Contractors. Proc. BIMAC. 2024: 204-211. [CrossRef]

- Yaroshutin D, Syrkov A, Kozak N, Shestovitsky D. Use of terrestrial 3D laser scanning technology for examination of transportation structures Proc. IABSE Congress in New Delhi. 2023: 1120-1127. [CrossRef]

- Kozak NV, Zobova MA, Gumaniuk IA. Case Study of Bridge Information Modeling. Proc. BIMAC. 2024: 196-203. [CrossRef]

- Kozak N, Yaroshutin D, Utenkov O, Daliaev N. Information modelling of curved city steel- concrete overpass over high-speed railway. Preprint. 2025. [CrossRef]

- Kozak N, Yaroshutin D, Utenkov O, Daliaev N. Design, construction and testing of curved overpass using BrIM technologies. Preprint. 2025. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).