1. Introduction

Amid accelerating global digitalization, electronic products have become indispensable to modern life, fueling rapid growth in the electronic manufacturing industry. From smartphones and laptops to smart appliances and wearable devices, rising consumer expectations for quality and performance are driving demand, while also posing increasing challenges in cost control and product quality assurance. Manufacturing electronic products involves complex procedures and numerous precision components, where minor defects can escalate into full product failure. Even with thorough inspections, issues during assembly, environmental interference, or human error may still produce non-conforming items.

Manufacturers must make a series of interrelated decisions: whether to inspect or rework spare parts, semi-finished products, or final goods, and how to manage defect recovery and after-sales returns. These decisions directly affect quality outcomes, production costs, and profitability. To meet these challenges, building a data-driven intelligent decision-making system is increasingly essential. Traditional manual experience-based decision-making falls short in handling high-frequency, high-dimensional production scenarios. In contrast, intelligent systems can integrate production data, quality indicators, and market feedback to support dynamic decision-making through modeling and optimization algorithms.

Cloud computing has emerged as a powerful enabler of enterprise-level intelligent decision systems. Its capabilities in parallel processing, large-scale storage, real-time analytics, and flexible deployment allow manufacturers to overcome computational bottlenecks. Cloud-based systems also integrate seamlessly with core platforms such as MES and ERP, supporting resource coordination and decision automation.

To address these issues, this paper proposes an Intelligent Decision Optimization System for Electronic Product Manufacturing Based on Cloud Computing. The system focuses on optimizing inspection and disassembly strategies at various stages of the production process. The study uses real production data (2011–2014) from a Shenzhen electronics manufacturer, covering inspections, defect rates, costs, and disassembly records. The dataset’s rich structure supports robust modeling and offers practical insights for optimizing quality and cost trade-offs in electronic product manufacturing.

2. Related Work

In the field of electronic product manufacturing, decision optimization plays a vital role in controlling costs and ensuring product quality. Nelson [

1] conducted an in-depth analysis of testing procedures and cost structures, offering a theoretical foundation for optimizing testing strategies to reduce expenses while enhancing quality assurance. Similarly, Korshunov and Petrushevskaya [

2] developed models that correlate production stages with product quality, thereby providing technical tools to improve quality control in digital manufacturing environments.

Meiser and Nowak [

3,

4] investigated testing and certification processes in the context of new product development, using case studies to provide practical guidance. Their work supports enterprises in reducing development risks and improving the market competitiveness of electronic products by implementing effective testing and certification protocols at early stages.

Beyond manufacturing, decision-making models in related domains offer relevant insights. Yoo S.-Keun et al. [

5] developed a cloud computing adoption decision model using AHP and Delphi analysis. They identified key decision factors—such as top management support and competitive pressure—as crucial to adoption outcomes, and highlighted differences in priority between adopters and providers. In a similar context, Wu et al. [

6] examined cloud adoption determinants in Chinese e-government departments. Their structural equation modeling revealed varying drivers across cloud service models and emphasized the influence of cultural factors such as managerial authority.

Collectively, these studies provide robust theoretical and practical frameworks for manufacturing decision-making. However, limitations remain—particularly in comprehensively integrating multiple dynamic factors and adapting to real-time market fluctuations. Building on this foundation, the present study aims to further explore decision optimization in electronic product manufacturing, with a specific focus on the integrated impact of inspection and disassembly strategies for spare parts, semi-finished, and finished products on cost efficiency and quality assurance, thereby offering enterprises more practical and adaptive optimization solutions.

3. Research Hypothesis and Model Establishment

3.1. Research Hypothesis

In this study, several assumptions are made to ensure the accuracy and feasibility of the decision optimization model in electronic product manufacturing. First, the defective rate of spare parts is assumed to follow a binomial distribution, with the sampling process being random and each spare part having an equal probability of being selected [

7]. It is further assumed that all testing procedures are perfectly accurate, meaning there are no errors or missed inspections. If dismantled spare parts have not been previously tested, they will undergo inspection before reuse, and any newly identified defective parts will always be replaced with newly tested components. The enterprise aims to produce 500 qualified finished products for market entry. It is also assumed that dismantling semi-finished products does not damage the individual spare parts, and the production process can be repeated without loss. Additionally, the market is assumed to automatically inspect finished products upon entry. Any unqualified finished products are returned, resulting in exchange-related losses. In this context, the market's defect judgment follows a Beta distribution, while the number of defective products identified during market sampling is expected to follow a binomial distribution [

8]. These assumptions provide the statistical and operational basis for the subsequent decision-making model and cost-benefit analysis.

3.2. Data Processing and Simulation of Production Process

The dataset used in this study originates from a Shenzhen-based electronic manufacturing enterprise and spans four years (2011–2014), covering real-world data from component to final product stages. It includes information on inspections, disassembly activities, defect rates, production costs, volumes, unit prices, and inspection fees. To ensure data quality, missing values (e.g., -99) were removed, and relevant fields were standardized and semantically restructured, resulting in a highly discriminative feature matrix suitable for intelligent decision modeling. In simulation, production parameters—including defect rates, prices, and inspection costs—are organized into a data dictionary. The process models production cycles: purchasing spare parts, deciding inspection points, assembling into semi-finished and finished products, and applying disassembly or discard strategies. Each cycle continues until 500 qualified units are produced, incorporating disassembly and exchange losses into total cost. This framework enables the evaluation of various decision strategies, offering practical insights into optimizing cost-efficiency and quality control in electronic manufacturing.

3.3. Cost Model and Theoretical Analysis

According to the simulated production process, the cost model is established, and the cost is calculated as follows

Among them, is the total inspection cost, is the total purchase cost, is the total assembly cost, is the total exchange loss and is the total disassembly cost.

In order to find the optimal strategy, we traverse all possible production strategies and calculate the total cost under each strategy. The concrete steps are as follows

Define strategy space: production strategies include inspection and disassembly decisions of spare parts, semi-finished products and finished products. Calculate the total cost: for each strategy, the total cost under each strategy is calculated according to the cost model by simulating the process of producing 500 qualified finished products.

Compare total cost: compare the total cost of all strategies and find the strategy with the smallest total cost.

The goal of this paper is to find an optimal strategy and find the optimal decision-making scheme by minimizing the total cost, so the objective function is:

The established model requires that at least 500 qualified finished products must be produced, and the constraint conditions for the number of qualified finished products are:

For the disassembly of finished products and semi-finished products, they must be inspected and found to be unqualified before disassembly. The constraint conditions of semi-finished products and finished products on the inspection and disassembly sequence are as follows:

Where, indicates whether the first semi-finished product is inspected, and the value is 0 or 1, which indicates whether the first semi-finished product is disassembled, and the value is 0 or 1. indicates whether the finished product is inspected, and the value is 0 or 1, indicating whether the finished product is disassembled, and the value is 0 or 1.

The production objective is to obtain 500 qualified finished products. Relevant parameters such as defective rate, unit price, inspection cost, assembly cost, disassembly cost, and exchange loss are predefined. Decisions include whether to inspect eight types of spare parts (uninspected parts go directly to assembly; defective ones are discarded), along with inspection and disassembly choices for semi-finished and finished products. By calculating all possible strategy combinations and sample sizes, the system simulates each strategy to compute its corresponding total cost.

3.4. Design of Enterprise Production Decision Cloud Platform

To support intelligent decision-making and optimization tasks in the electronic product manufacturing process, this study builds a comprehensive system architecture based on cloud computing. The platform encompasses the full lifecycle from data acquisition, preprocessing, analysis, to decision optimization. It features high availability, scalability, and fault tolerance, making it suitable for complex, multi-stage, and concurrent industrial environments. The system design is structured around the following five key technical components:

3.4.1. System Requirement Analysis

At the outset, we conducted an in-depth analysis of the decision-making scenarios in the enterprise's electronic component manufacturing process. The primary system requirements include: (1) support for large-scale historical production data storage and high-speed querying; (2) the ability to simulate complex, multi-stage strategy combinations and compute associated costs; and (3) interactive and visual feedback mechanisms for optimization results. Furthermore, given the real-time nature of production, the system must support high concurrency and rapid strategy response.

3.4.2. High System Reliability

To ensure reliable operation in industrial applications, the platform adopts multi-level redundancy mechanisms and disaster recovery design. All core computing services are deployed using container orchestration technologies (e.g., Kubernetes + Docker), supporting auto-failover and load balancing. Intermediate results during decision processing are stored in object storage services (e.g., OSS) and distributed databases (e.g., HBase) to ensure high data availability. A cloud-based monitoring system (e.g., Prometheus + Grafana) tracks resource usage, system latency, and task statuses in real time, ensuring stable execution of decision workflows.

3.4.3. System Architecture Design

The platform adopts a layered system architecture, structured into five main layers:

Data Layer: Utilizes cloud-based data lake technologies to integrate heterogeneous production data, supporting unified modeling and standardized preprocessing for spare parts, semi-finished, and finished products.

Service Layer: Encapsulates modular services including cost modeling, strategy simulation, and algorithm scheduling. Services are deployed via microservice architecture to facilitate scalability and maintenance.

Computing Layer: Leverages distributed computing frameworks such as Spark and Flink to execute large-scale simulations and machine learning tasks in parallel, significantly enhancing computational efficiency.

Interface Layer: Provides RESTful APIs for integration with enterprise systems like ERP and MES, enabling real-time bidirectional data flow and system interoperability.

Presentation Layer: Offers web-based dashboards (e.g., built with ECharts) for visualizing simulation results, optimal strategies, and sensitivity analyses, enabling interactive decision-making by managers.

3.4.4. System Function Analysis

The core functionality of the platform is divided into four modules:

Strategy Modeling Module: Allows users to define inspection/disassembly strategies at each production stage, set cost functions, and specify optimization objectives.

Simulation & Optimization Module: Executes batch simulations of production flows based on input strategy sets, evaluating economic outcomes under different defect rate conditions.

Algorithm Management Module: Integrates various optimization algorithms (e.g., simulated annealing, genetic algorithms, reinforcement learning), enabling algorithm tuning and parameter management.

Decision Support Module: Generates real-time optimization reports using evaluation metrics such as F1 Score, Precision, and Recall, assisting enterprises in making comprehensive and data-informed decisions.

3.4.5. Cloud Platform Organization Structure

The platform’s organizational structure is designed according to user roles and functional layers, ensuring secure, efficient, and coordinated operations:

Platform Administration Role: Oversees resource allocation, access control, system security policies, and maintenance of containerized environments.

Data Engineering Role: Manages data ingestion, preprocessing, storage, and quality assurance to ensure reliable input for analysis.

Modeling & Analysis Role: Composed of algorithm engineers and domain experts responsible for model construction, strategy evaluation, and large-scale simulation.

Business Decision Role: Targeted at enterprise managers and quality control personnel who interpret results through visual interfaces and participate in strategic decision-making.

Interface Integration Role: Provides API-based integration with ERP, MES, and other business systems to synchronize production plans, order data, and inspection information, thereby establishing a closed-loop intelligent decision framework.

4.Model Solving

4.1. Result Analysis

According to the calculation results of the established model, combined with the contents in

Table 1, it can be known that the strategy with the lowest total cost is that all spare parts 1-8 are inspected, semi-finished products 1-3 are not inspected or disassembled, and finished products are not inspected or disassembled. Under this strategy, enterprises can reduce costs to the maximum extent while meeting the requirements of producing 500 qualified finished products.

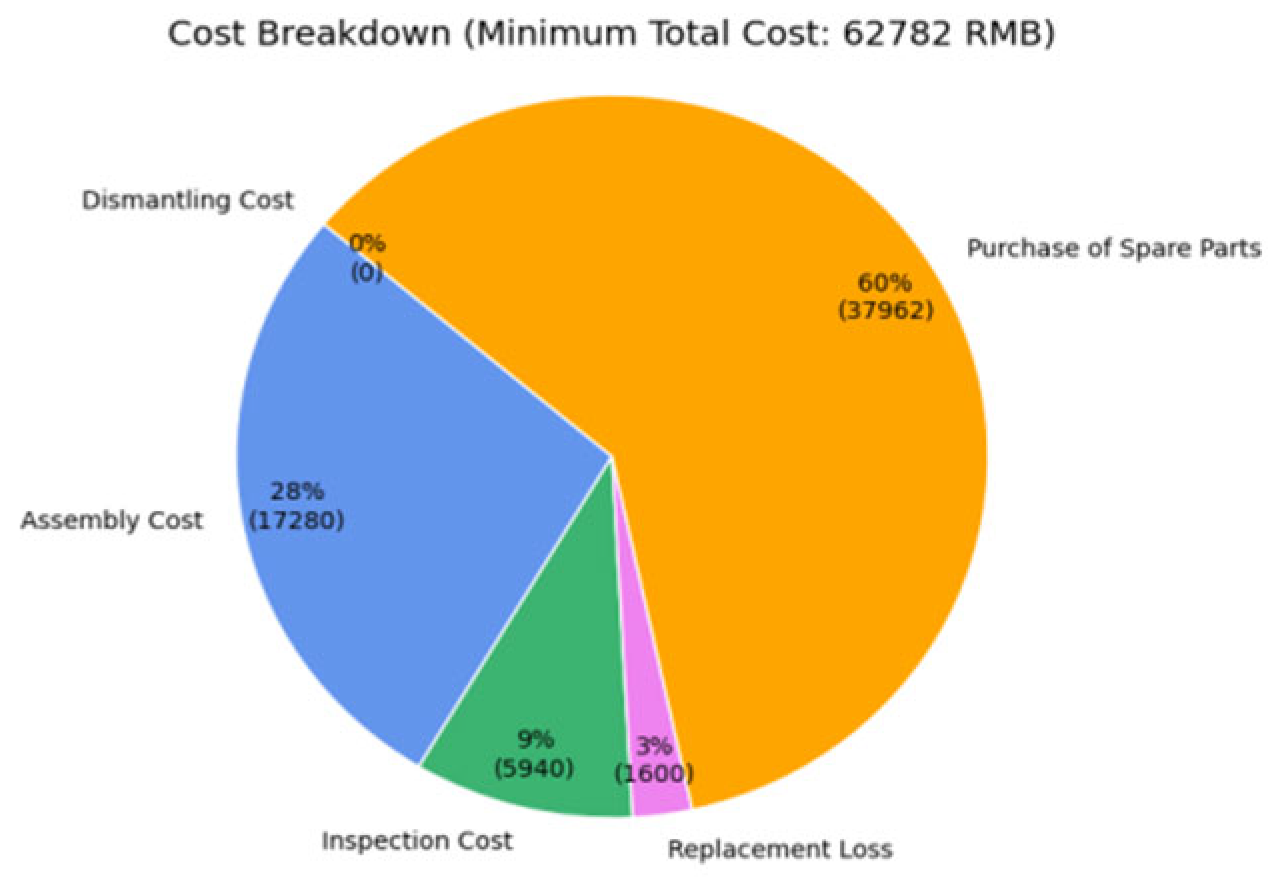

By analyzing the cost composition under the optimal strategy, we can determine the proportion of each part of the cost. In order to complete 500 and 500 finished products, the detailed cost chart is shown in

Figure 1. The lowest total cost is 62,782 yuan, of which the cost of purchasing spare parts is 37,962 yuan, accounting for 60% of the total cost; The assembly cost is 17,280 yuan, accounting for 28% of the total cost; The cost of testing is 5940 yuan, accounting for 9% of the total cost; The dismantling cost is 0, accounting for 0% of the total cost; The exchange loss is 1600 yuan, accounting for 3% of the total cost.

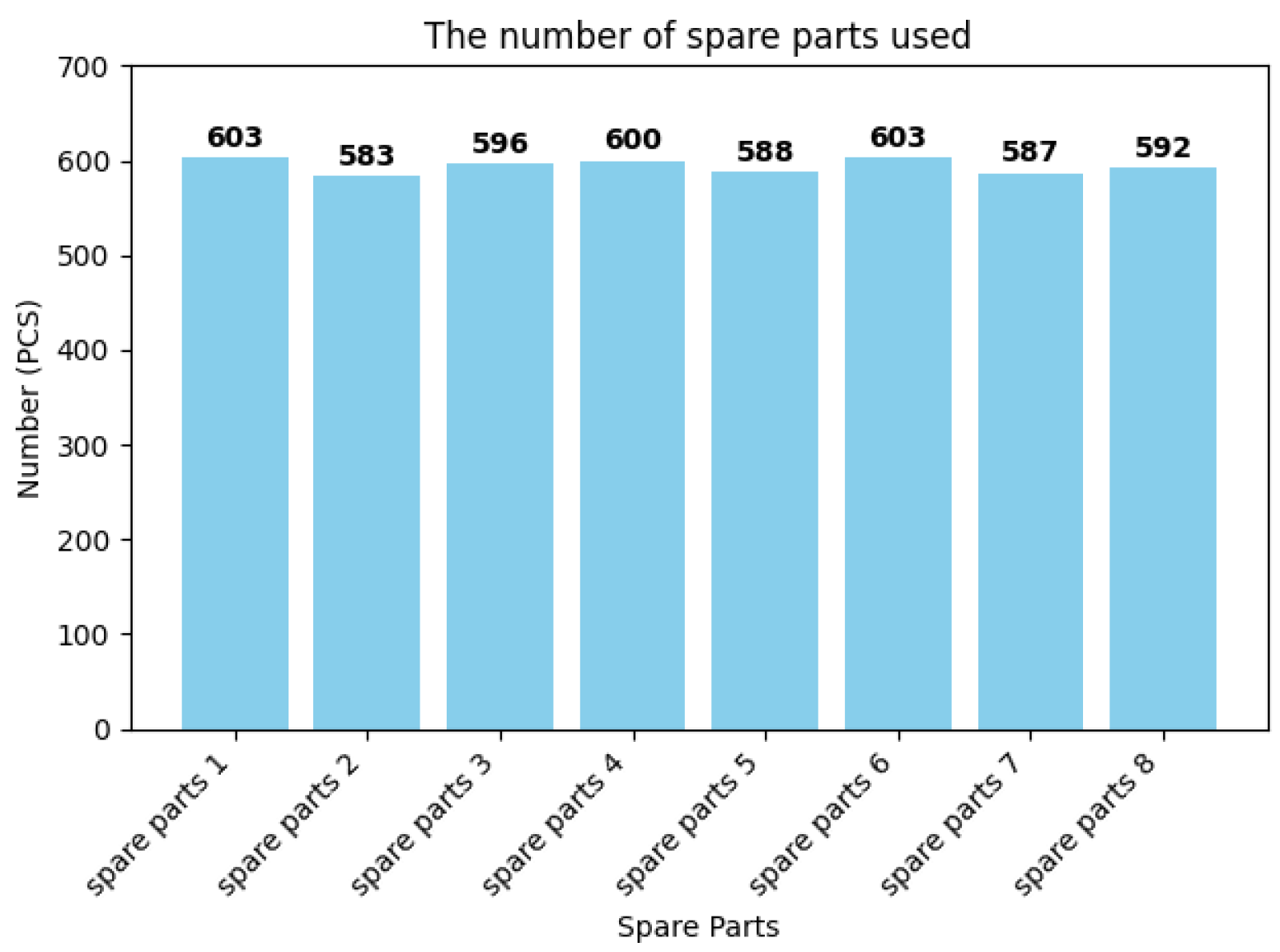

Under the optimal strategy, we simulated the production process to analyze the demand for spare parts required to produce 500 qualified finished products. The simulation revealed the estimated quantities needed for each spare part: spare part 1 (603 units), part 2 (583), part 3 (596), part 4 (600), part 5 (588), part 6 (603), part 7 (587), and part 8 (592). These results, illustrated in Figure 12, demonstrate relatively balanced demand across all components and provide a reliable reference for procurement planning and inventory optimization in electronic product manufacturing.

4.2. Stability Analysis

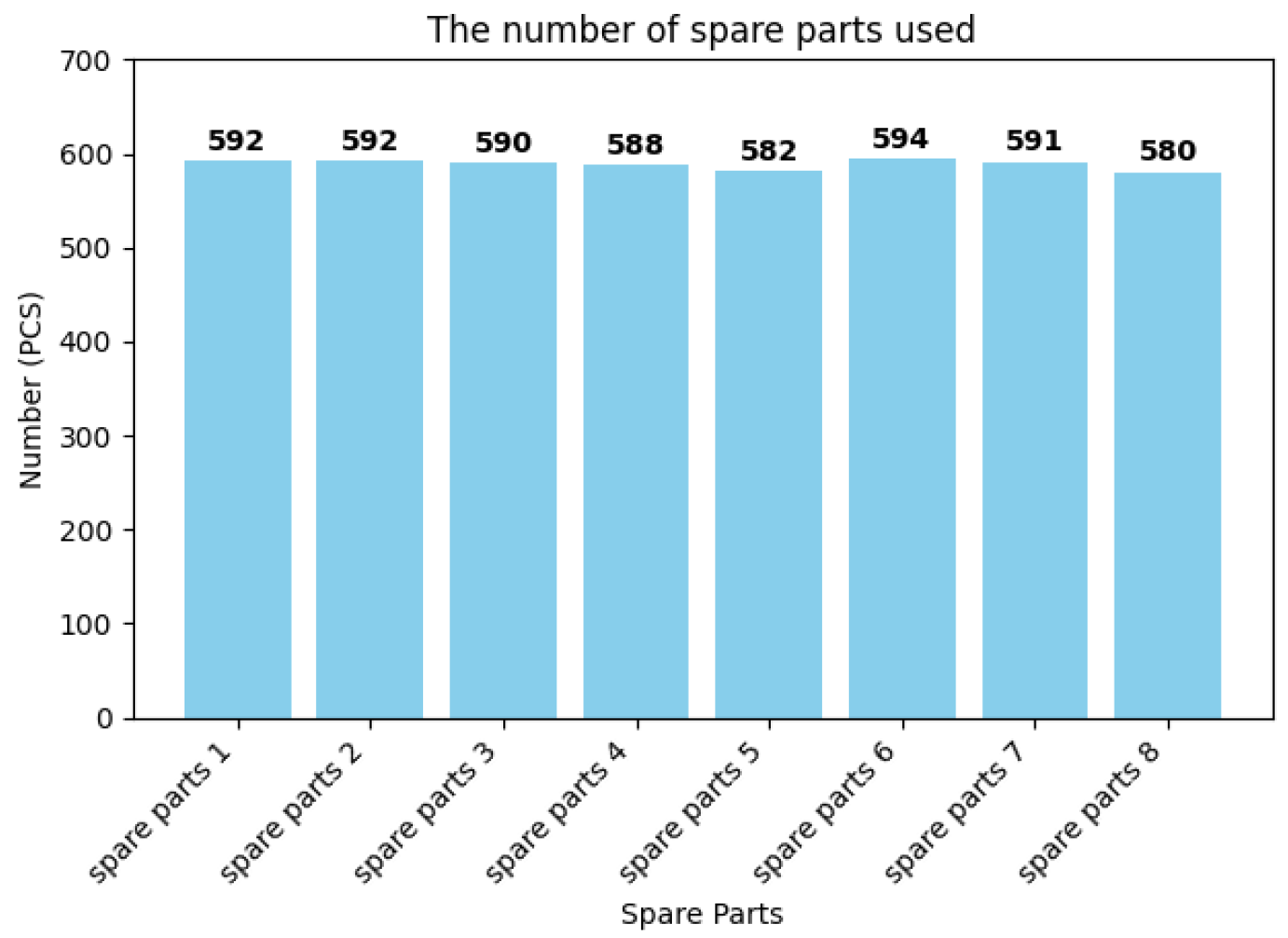

To assess the model’s stability, spare parts demand was analyzed through multiple simulated production cycles. Each cycle involved decisions on part usage and reordering based on defect rates and testing strategies. Assembly quality and costs were evaluated accordingly, incorporating predefined inspection and disassembly strategies. The number of spare parts used across simulations showed limited variation. As illustrated in

Figure 3, the maximum fluctuation for eight spare parts ranged from 5 to 22 units, with fluctuation rates between 0.8% and 3.5%, all below 5%. These results indicate strong model stability in spare parts demand across production scenarios.

To sum up, by simulating the production process many times, it is observed that the fluctuation of spare parts demand is small, demonstrating that the model achieve stable performance across multiple simulations.

5. Conclusions and Enlightenment

This study developed a cloud-based intelligent decision optimization system tailored for electronic product manufacturing enterprises. Based on real production data and simulation-based machine learning algorithms, the system thoroughly analyzes the cost and quality impacts of inspection and disassembly strategies across spare parts, semi-finished products, and finished goods. By building a comprehensive cost model and simulating the production workflow, the system identifies optimal strategy combinations and provides data-driven decision-making support for complex multi-stage manufacturing environments.

The results demonstrate that, under known defect rates, the most cost-effective strategy is to inspect all spare parts while skipping inspection and disassembly for semi-finished and finished products. This strategy successfully meets the production target of 500 qualified finished goods while significantly reducing total costs. In this configuration, the purchase cost of spare parts accounts for the largest portion (approximately 60%) of total expenses, followed by assembly and inspection costs. Furthermore, stability analysis through multiple simulation cycles shows minimal fluctuation in spare part demand, verifying the robustness of the model. This confirms that enterprises can confidently rely on the model to make consistent, risk-averse decisions in real-world production settings.

Built on a cloud computing platform, the system leverages scalable infrastructure, elastic computing resources, and integrated data services to support automated workflows from data acquisition and preprocessing to strategy optimization. With seamless integration into ERP and MES systems via APIs, the platform enables a closed-loop information management framework, enhancing both operational intelligence and decision-making efficiency.

This research not only offers a practical strategy for balancing cost and quality in electronic manufacturing but also demonstrates the value of cloud computing in enterprise-level intelligent decision systems. The combination of strategy simulation and data-driven modeling forms a solid foundation for promoting digital transformation and intelligent production across the manufacturing sector.

Future research can further expand this work in several directions. First, by introducing multi-objective optimization frameworks, decision-making can consider cost, quality, lead time, and other performance indicators simultaneously. Second, incorporating market dynamics, fluctuations in raw material prices, and external disruptions will enhance the system's real-time adaptability. Lastly, by applying advanced algorithms such as reinforcement learning and graph neural networks, future models can evolve through feedback and learning mechanisms, enabling decision-making systems to better reflect the complexity and uncertainty of real-world manufacturing environments.

References

- Nelson E T. Optimizing product testing in the electronics manufacturing industry[D]. Massachusetts Institute of Technology, 2000.

- Korshunov G I, Petrushevskaya A A. Modeling of digital manufacturing of electronics production and product quality assurance[C]//Journal of Physics: Conference Series (JPCS). 2018: 150-159.

- Meiser D, Nowak M. Testing and Certification of New Product Development in the Electronics Industry: Case Studies[M]//Digital Transformation, Perspective Development, and Value Creation. Routledge, 2023: 85-102.

- Shao Zhiqiang. Determination of sample size in sampling survey [J]. statistics and decision, 2012,(22):12-14.

- Yoo, S. K., & Kim, B. Y. (2018). A decision-making model for adopting a cloud computing system. Sustainability, 10(8), 2952.

- Wu, J., Ding, F., Xu, M., Mo, Z., & Jin, A. (2016). Investigating the determinants of decision-making on adoption of public cloud computing in e-government. Journal of Global Information Management (JGIM), 24(3), 71-89.

- Wu Minglu. Method and application of simple random sampling [J]. Educational Science Research, 1993,(01):41-44.

- Su Wen, Bao Dianqing. The application of binomial distribution function of a discrete random variable [J]. Journal of Sichuan University of Technology (Natural Science Edition), 2011,24(5):590-592.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).