1. Introduction

The increasing number of motorcycle accidents worldwide has underscored the need for advanced safety measures in the form of smart technologies. The Smart Helmet Project, utilizing the LPC2418 microcontroller, seeks to address these challenges by integrating multiple sensors and real-time monitoring systems to enhance rider safety. This paper presents the development of a smart helmet equipped with various sensors, such as a gyroscope, accelerometer, GPS, and alcohol detection modules, aimed at improving accident prevention, providing emergency alerts, and promoting safer riding behavior.

The LPC2418, a high-performance ARM-based microcontroller, serves as the core processing unit for the helmet's sensor network. It processes data from the sensors in real-time, enabling immediate responses such as triggering emergency notifications, location tracking, and other safety measures. The helmet is designed to detect accidents through the gyroscope and accelerometer, identify impaired riding through gas sensors, and send automated emergency messages to pre-configured contacts, ensuring a swift response in case of a fall or accident.

By incorporating such a combination of technologies, this project aims to demonstrate the potential of smart helmets in improving rider safety. The integration of sensors and microcontroller-based processing highlights the feasibility of wearable, intelligent systems that can monitor a rider’s condition, provide situational awareness, and assist in reducing the response time during critical situations, ultimately leading to a safer riding experience.

2. Related Work & Identified Gaps

2.1. “Internet of Things-Based Smart Helmet with Accident Identification and Logistics Monitoring for Delivery Riders (2023)”

The paper presents an IoT-based smart helmet system aimed at improving the safety of delivery riders [

2]. The system integrates accelerometer and vibration sensors for accident detection, an MQ3 alcohol sensor to monitor rider sobriety, and a GPS module for real-time location tracking. Data from these sensors is sent to a cloud-based system via the ESP32-C3 microcontroller, which allows for real-time monitoring and notifications through a mobile app. The system achieved significant results, with 90% accuracy in crash detection, 89.09% in alcohol detection, and minimal GPS tracking error. The system was praised for its low latency and its ability to provide quick notifications, thus enhancing safety. However, it also relied on Wi-Fi connectivity, which may limit the system’s reliability in areas with poor or no network coverage.

While the work of Alcantara et al. (2023) provides a solid foundation, there are some key limitations that need to be addressed. First, the ESP32-C3 microcontroller, while suitable for basic sensor integration, may lack the necessary processing power to handle more complex data or advanced sensor systems. Second, the system's reliance on Wi-Fi connectivity could cause issues in areas with poor or inconsistent network coverage, limiting the effectiveness of the real-time alerts. monitoring. Lastly, the lack of scalability for larger fleet management and integration with existing logistics systems limits its broader applicability.

The proposed project aims to address the identified gaps by utilizing the LPC2148 microcontroller, which offers better processing power and a broader range of peripheral support for handling more complex sensors and real-time data processing. Unlike the ESP32-C3, the LPC2148 can support more advanced sensor integration and data fusion algorithms, which will improve the accuracy of accident detection and offer better rider health monitoring. To tackle the issue of connectivity, the system will integrate GSM or LTE modules, ensuring reliable communication even in areas with weak network signals. The project also plans to develop a scalable architecture that can be applied to larger fleet management systems, enhancing the safety and operational efficiency of delivery fleets.

2.2. “IoT Based Smart Helmet System for Accident Prevention”

This paper developed a smart helmet system aimed at enhancing rider safety through IoT integration. The system incorporates an MQ-3 alcohol sensor to detect inebriation, an IR sensor to verify helmet usage, and a vibration sensor to identify accidents. In the event of an accident, the system utilizes a GPS module to determine the rider's location and a GSM module to send SMS alerts to predefined contacts. Additionally, the system prevents the bike from starting if the rider is not wearing a helmet or is under the influence of alcohol, thereby promoting safer riding practices.

While the proposed system introduces essential safety features, it has several limitations that could impact its overall effectiveness. The use of the Arduino Uno microcontroller restricts processing capabilities and limits multitasking, which may affect real-time performance. Additionally, the reliance on basic sensors could compromise the accuracy and reliability of accident detection and helmet usage monitoring. The system also lacks real-time monitoring and cloud-based data storage, which are crucial for comprehensive incident tracking and analysis. Moreover, the current helmet fit detection mechanism, which uses an IR sensor, is prone to false triggers and can be bypassed. Lastly, the system does not address power consumption, raising concerns about long-term usability and battery life.

To overcome these challenges, the proposed project includes several key enhancements. A more advanced microcontroller will replace the Arduino Uno to improve processing power and multitasking capabilities. Additional and more sophisticated sensors will be integrated to enhance the accuracy of accident detection and helmet monitoring. Real-time monitoring and cloud-based data storage will be implemented to allow continuous tracking and data analysis. The helmet fit detection mechanism will be made more robust to reduce the likelihood of false detection. Finally, power consumption will be optimized to improve energy efficiency and ensure the system is viable for extended use.

3. Methodology

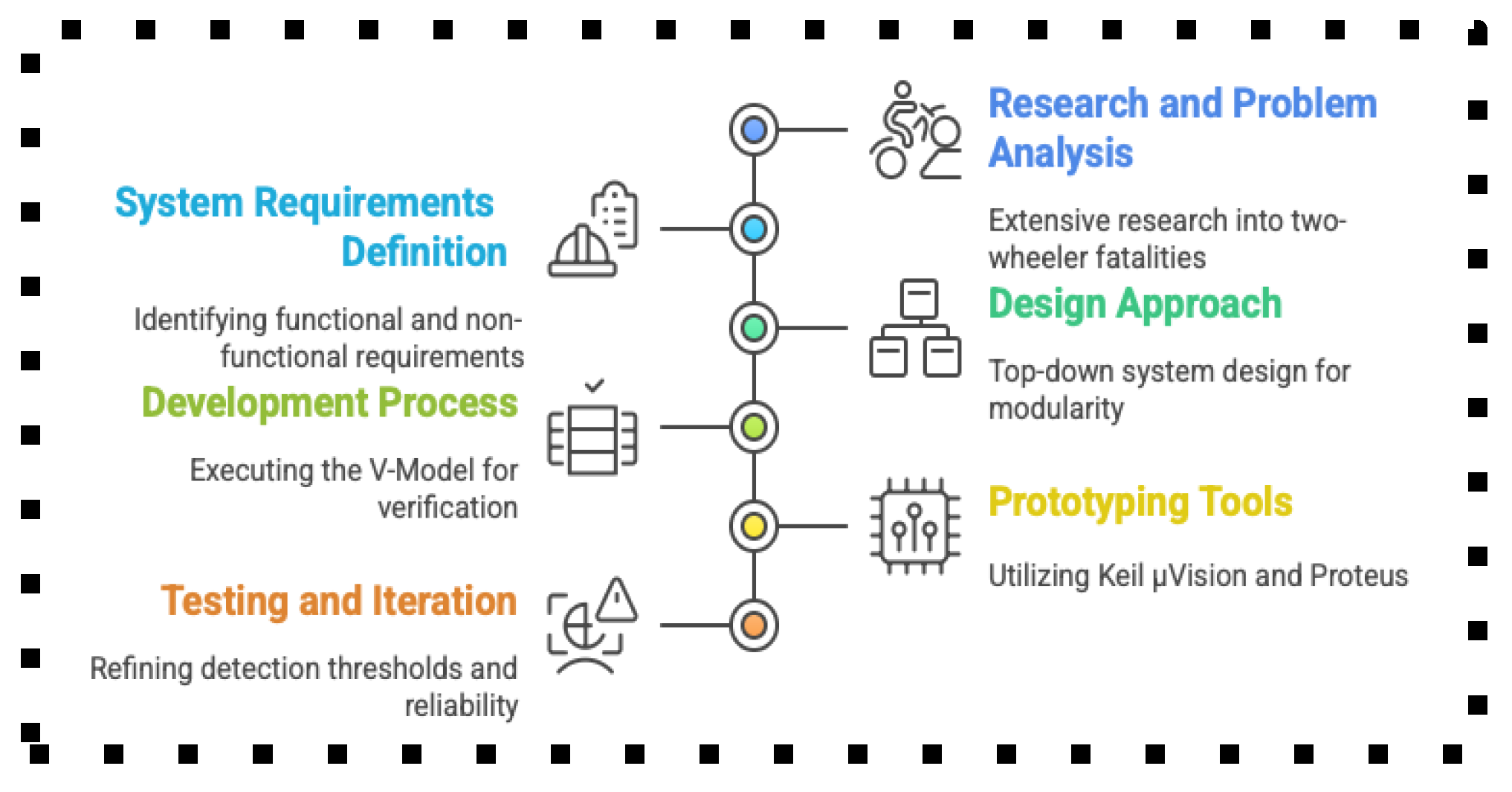

3.1. Research and Problem Analysis

The project commenced with in-depth research into the primary causes of two-wheeler road fatalities, emphasizing accident detection delays, drunk driving incidents, and the absence of location-based emergency alerts. A thorough review of existing smart helmet solutions was conducted to evaluate their features and limitations, which helped identify unmet user safety needs and technology gaps. This analysis guided the definition of system requirements. Additionally, insights from prior research [

1,

2,

3] provided a solid foundation for understanding real-world challenges and helped shape the design of a more effective and responsive smart helmet system.

3.2. System Requirements Definition

Based on the research, several functional and non-functional requirements were identified to ensure rider safety and system efficiency. These included fall or accident detection using motion sensors, alcohol level monitoring, real-time location tracking, and automated emergency alerts via SMS and optional voice calls. Additional features such as voice feedback to the rider and a power-efficient design with battery backup were also emphasized. These requirements played a crucial role in guiding the selection of appropriate hardware components and communication protocols, aligning with strategies observed in similar implementations [

2,

3,

5].

3.3. Design Approach

A top-down system design approach was adopted, enabling early identification of modular subsystems such as sensing, processing, communication, and power management. This approach facilitated efficient task distribution between hardware and firmware components while ensuring scalability for future enhancements like Bluetooth app synchronization [

3,

7]. The design process progressed through iterative stages, beginning with low-fidelity prototypes, advancing to breadboard circuit testing, and culminating in custom PCB prototyping for functional validation [

4,

6,8].

3.4. Development Process

The project was executed using the V-Model development methodology, which emphasizes verification at every stage of development. The phases included:

Requirement Specification

System Architecture Design

Module Development (Hardware + Software)

Integration

Validation and Testing

Each sensor and module was initially tested in isolation before integration into the complete system [

1,

5,8].

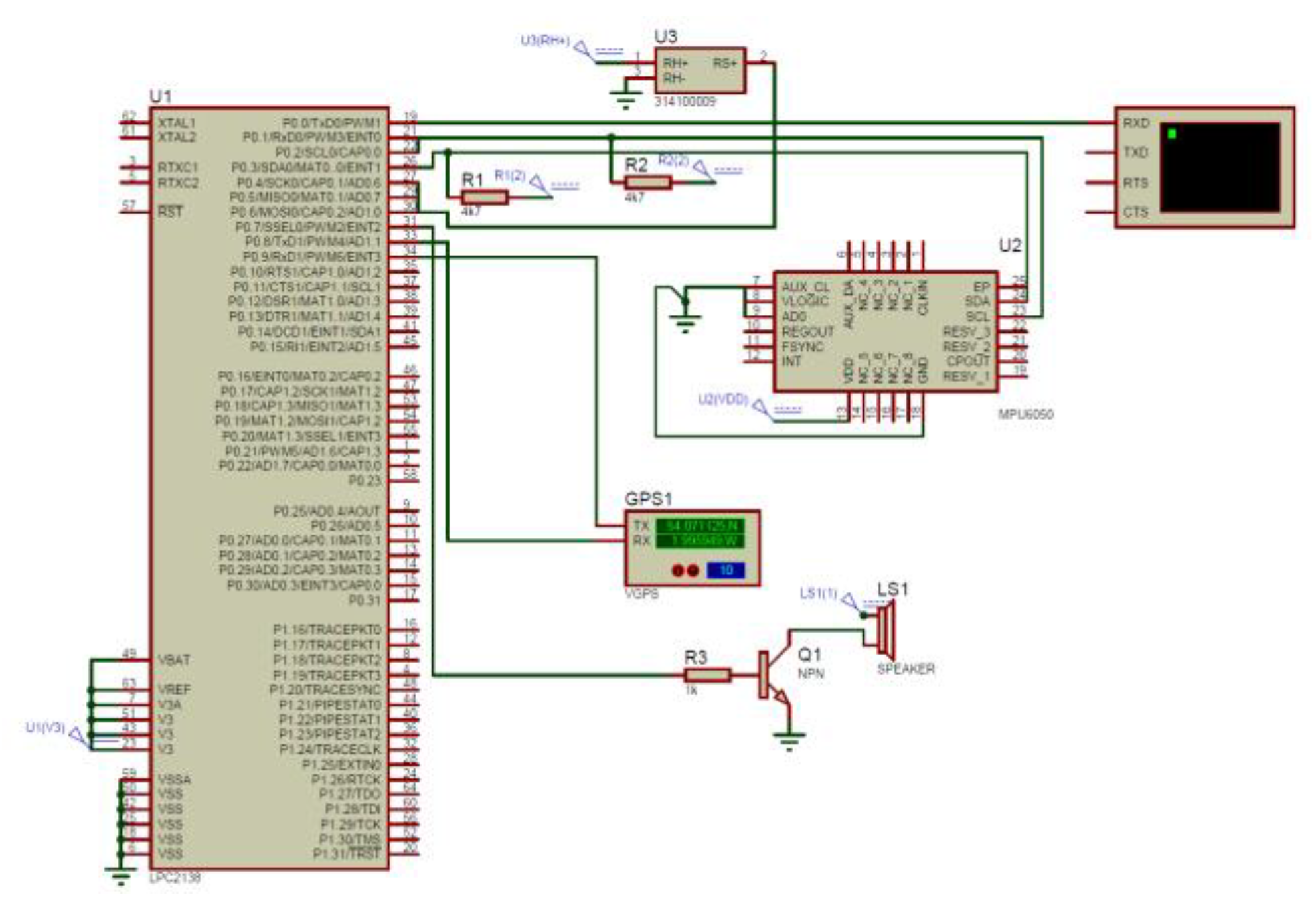

3.5. Prototyping Tools

The prototyping phase utilized a range of tools to streamline development and testing. Keil µVision was employed for embedded C firmware development, while circuit design and simulation were carried out using Proteus and Fritzing. Flash Magic facilitated code uploading to the LPC2148 microcontroller. Before advancing to PCB fabrication, physical breadboarding was used to verify and refine the hardware setup [

4,

5]

3.6. Testing and Iteration

Functional testing was conducted in both simulated and real-world environments, with iterative testing cycles used to fine-tune detection thresholds and enhance communication reliability. Key evaluations included drop tests to validate fall detection, alcohol vapor simulations for calibrating the MQ-3 sensor, and testing GPS and GSM connectivity during motion [

2,

3,

4,

5,

6]. Each iteration led to targeted improvements in sensor noise filtering algorithms, power management strategies, and the timing of emergency alerts, ensuring a more robust and responsive system [

1,

4,9]

Figure 1.

Development Process.

Figure 1.

Development Process.

4. Mathematical Modelling and Equations

4.1. Accelerometer Model (MPU6050)

The MPU6050 accelerometer measures linear acceleration along three orthogonal axes. The raw digital readings must be converted to physical units (g) using the sensitivity scale factor SS, typically 16384 LSB/g for the ±2g configuration:

Where: ai is the linear acceleration along axis ii (in g), Ai is the raw accelerometer output, S is the accelerometer sensitivity.

4.2. Gyroscope Model (MPU6050)

The gyroscope measures angular velocity, which is used to track orientation changes. The conversion from raw sensor output to angular velocity (°/s) is:

Where: ωi is the angular velocity around axis ii, Gi is the raw gyroscope output, Sg is the sensitivity (e.g., 131 LSB/(°/s) for ±250°/s range).

4.3. Sensor Fusion Using Complementary Filter

For real-time orientation estimation, accelerometer and gyroscope data are combined using a complementary filter:

Where: θ is the estimated orientation angle, ω is the angular velocity from the gyroscope, Δt is the sampling time interval, θacc is the angle from accelerometer data, α is the filter coefficient (usually between 0.90 and 0.98).

4.4. Gas Detection Sensor Model

Gas sensors such as the MQ-series work on the principle of resistance variation in the presence of gases. The sensor resistance RsRs is computed as:

Where: Rs is the sensor resistance, Vc is the circuit voltage, VRL is the voltage across the load resistor RL.

4.5. Gas Concentration Estimation

The concentration of the gas is derived from the ratio of sensor resistance in gas (R

s) to the resistance in clean air (R

0):

Where

A and

B are constants obtained through calibration based on the sensor's datasheet.

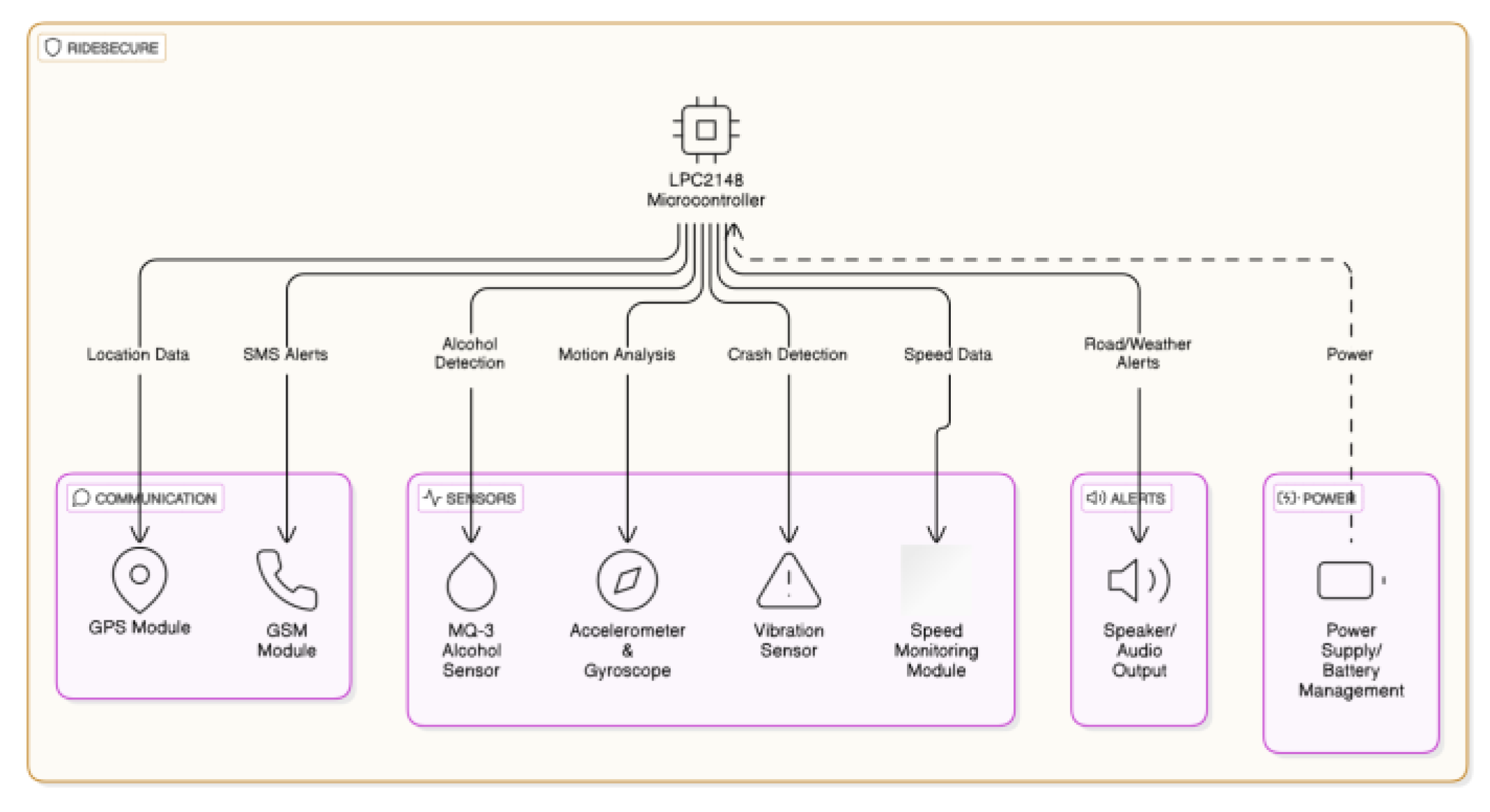

5. System Design and Architecture

5.1. Block Diagram/System Overview

The architecture of the RideSecure smart helmet is centered around the LPC2148 microcontroller, responsible for processing inputs from various sensors and managing real-time safety responses. The system includes both digital and analog sensors, and modules for communication and user interfacing.

Functional Modules:

| Sensor |

Type |

Function |

| MPU6050 |

Accelerometer + Gyroscope |

Motion tracking, accident detection, and fall analysis |

| MQ-3 Alcohol sensor |

Alcohol Sensor |

Breath alcohol monitoring |

| Vibration sensor |

Impact Detection Sensor (Digital) |

Detects sudden impacts that may indicate an accident |

These sensors are commonly used in smart helmet applications to detect intoxicated driving and real-time accidents, forming the core of safety alert systems [

1,

2,

3].

- 2.

Communication Module:

| Module |

Type |

Function |

| GSM Module (SIM800L) |

Cellular (GSM/GPRS) |

Sends emergency SMS alerts including data on accidents and alcohol detection |

| GPS Module (NEO-6M) |

Satellite Positioning |

Provides real-time geolocation to aid in tracking and emergency response |

These modules are frequently used in

IoT-based smart helmet systems for reliable communication and geolocation[

3,

4,

5]

- 3.

Output Module:

| Module |

Type |

Function |

| Audio Output (Helmet Speakers) |

Audio Playback |

Delivers voice-based alerts to the rider (e.g., accident warning, alcohol detection) |

| LED/Buzzer Alerts (Testing Only) |

Visual & Audio Signal |

Provides immediate local alert through blinking or beeping for feedback/testing |

The output modules are critical for providing feedback and ensuring rider safety through immediate alerts and notifications [

3,

5].

- 4.

Power Management:

| Module |

Type |

Function |

| Battery Pack with Voltage Regulator |

Power Supply |

Provides necessary voltage levels (5V and 3.3V) to operate the microcontroller and sensors |

| Power on Reset Circuit |

Power Control |

Ensures proper initialization of the system by resetting the components upon power-on |

These power management modules are essential for maintaining stable operation of the system, ensuring that all components receive the appropriate voltage and are properly initialized during startup [

3,

4,

5].

Sensor data is pre-processed by the LPC2148, which then triggers specific events such as emergency SMS, alert tones.

5.2. LPC2148 Microcontroller (Core of the System)

The LPC2148 is a 16/32-bit ARM7TDMI-S based microcontroller with rich peripheral support, chosen for its balance of performance, low power consumption, and peripheral flexibility.

Technical Specifications:

| Component |

Specification |

| Core Clock Frequency |

Up to 60 Mhz |

| Flash Memory |

512KB |

| SRAM |

32KB |

| I/O Pins |

Over 45 pins |

| On-Chip ADC |

10-bit |

| Timers |

Speed estimation |

| UART Interfaces |

GPS and GSM module |

| I2C/SPI |

I2C for MPU6050 |

The microcontroller polls or interrupts each sensor at different rates based on priority—MPU6050 and vibration sensor are polled frequently, while MQ-3 and GPS are sampled at slower intervals.

5.3. Sensors and Modules

The RideSecure smart helmet integrates a range of sensors and communication modules to continuously monitor the rider’s condition and surroundings, enabling proactive safety responses. Central to motion detection is the MPU6050, a 6-axis MEMS sensor (accelerometer + gyroscope) interfaced via I²C at 100–400 kHz. It captures 16-bit acceleration and angular velocity data, filtered through Kalman or moving average algorithms to detect falls, sharp turns, or crashes. For alcohol detection, the MQ-3 sensor outputs an analog voltage based on ethanol concentration, read by the LPC2148’s 10-bit ADC. When this voltage exceeds a calibrated threshold, an intoxication alert is triggered. Impact detection is supported by a digital vibration sensor (e.g., SW-420), connected via GPIO with interrupt handling for immediate response.

For location and speed tracking, the NEO-6M GPS module communicates via UART (9600 baud), providing real-time NMEA data such as latitude, longitude, and speed—used in emergency alerts and overspeed detection. The SIM800L GSM module, also interfaced via UART, uses AT commands to send SMS alerts with GPS data and make automated calls to emergency contacts. A queuing system prevents blocking during transmission, requiring a 2G SIM with active signal. Voice feedback is provided through PWM DAC output or a DFPlayer Mini, delivering pre-recorded messages like “Weather Alert,” “Speed Limit Exceeded,” or “Emergency triggered.” Together, these components form a modular, responsive system capable of real-time monitoring, alerts, and rider communication, laying the groundwork for a reliable smart helmet solution.

5.4. Communication Protocols

The proposed system employs multiple communication protocols and peripheral interfaces to efficiently integrate various sensors and modules. I2C (Inter-Integrated Circuit) serves as the master-slave protocol between the LPC2148 microcontroller (master) and MPU6050 accelerometer/gyroscope (slave), requiring only two lines (SCL and SDA) which effectively conserves GPIO pins. UART (Universal Asynchronous Receiver/Transmitter) communication is implemented through two channels: UART0 interfaces with the GSM module at configurable baud rates ranging from 9600 to 115200, while UART1 receives NMEA data from the GPS module typically operating at 9600 baud. For analog signal processing, the system utilizes the 10-bit ADC (Analog-to-Digital Converter) to read measurements from the MQ-3 alcohol sensor, providing sufficient resolution to detect voltage variations between 0-3.3V with high accuracy. GPIO pins with interrupt capabilities are employed to connect the vibration sensor and optional switches (such as a reset button), enabling low-latency response to sudden events and ensuring timely system reaction to critical conditions.

5.5. Power Supply and Battery Management

The system incorporates a comprehensive power management approach, utilizing a 7.4V Li-ion battery pack as the primary power source. Step-down voltage regulators, specifically AMS1117 or LM2596 models, provide appropriate voltage levels throughout the device: 5V for the GPS and GSM modules, and 3.3V for the LPC2148 microcontroller and associated sensors. To ensure safe operation and extend battery life, a dedicated battery protection circuit is integrated to prevent potentially damaging deep discharge conditions. The power efficiency of the system can be further enhanced through optional sleep modes implemented in firmware, allowing the device to conserve energy during periods of inactivity by reducing power consumption of non-essential components when the system is idle.

Figure 2.

System Architecture.

Figure 2.

System Architecture.

Figure 3.

Proteus Interfacing Diagram.

Figure 3.

Proteus Interfacing Diagram.

6. Results and Discussion

6.1. Testing Results

The RideSecure helmet underwent both simulated testing in Proteus and real-world validation using a prototype helmet embedded with sensors and communication modules.

Summary of Key Test Metrics:

| Feature |

Metric |

Result |

| Alcohol Detection |

Detection time |

2–3 seconds after exposure to alcohol vapors |

| Speed Limit Enforcement |

Accuracy in speed-based beep triggering |

97–99% accuracy (based on GPS speed) |

| Accident Detection |

Response to impact and tilt |

Detected falls > 1.5 feet within 1 second |

| Emergency SMS/Call |

Time to initiate emergency alert |

3–5 seconds from trigger |

| Power Consumption |

Average draw on 9V battery |

~250–300mA |

| System Reliability |

Sensor recovery from failure |

100% via watchdog and reinitialization logic |

6.2. Comparative Analysis

| Feature |

Traditional Helmets |

Existing Smart Helmets |

RideSecure (Proposed) |

| Alcohol Detection |

Not Present |

Present, (Few models) |

Present, Real-time + Emergency SMS |

| Speed Monitoring |

Not Present |

Not Present |

Present, With audible alerts |

| Accident Detection |

Not Present |

Present |

Present, With response window + SOS |

| Real-time Location Tracking |

Not Present |

Not Present |

Present, GPS-enabled |

| Speaker Alerts (Weather) |

Not Present |

Not Present |

Present, In-helmet speaker |

| Emergency Call |

Not Present |

Not Present |

Present, Automatic after crash |

RideSecure delivers a multi-functional, low-latency, and autonomous safety system that goes beyond current commercial solutions by integrating both proactive (alerts, speed enforcement) and reactive (accident SOS, alcohol detection) capabilities.

7. Conclusions

RideSecure offers an integrated and proactive solution to enhance rider safety by combining accident detection, alcohol sensing, and emergency alert capabilities within a smart helmet framework. Leveraging the LPC2148 microcontroller, along with components such as the MPU6050, RFID, and GSM modules, the system effectively monitors rider behavior and environmental conditions in real-time. By moving beyond passive safety features, RideSecure introduces intelligent preventive mechanisms that can reduce the risk of accidents and improve emergency response time. The successful simulation and validation of the system using Keil and Proteus environments affirm its functional viability. With its modular IoT-based design, RideSecure holds the potential for future scalability and real-world deployment, marking a significant step toward safer two-wheeler travel.

Author Contributions

Formal analysis, Sumedh Uppinkudru, Vishal Bhat and Sreenivaas V S; Methodology, Sumedh Uppinkudru, Vishal Bhat and Sreenivaas V S; Project administration, Ramesh K B; Software, Sumedh Uppinkudru and Sreenivaas V S; Supervision, Ramesh K B; Validation, Vishal Bhat; Writing – review & editing, Sumedh Uppinkudru, Vishal Bhat and Sreenivaas V S. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

We would like to express our sincere gratitude to our project guide and lecturer, Ramesh K B from R. V. College of Engineering for his invaluable guidance, support, and encouragement throughout the development of this project. Special thanks to our peers and well-wishers whose constructive feedback helped us refine our work. Finally, we are grateful to our families for their constant motivation and support during the course of this project.

References

- Jadhav, A. Vaidya, Y. Thakur, Y. Mhatre, and S. Patil, “Alcohol and accident detection with sharing of mobile notification along location using smart helmet system,” Research & Reviews: A Journal of Embedded System & Applications, vol. 12, no. 2, pp. 7–20, 2024.

- T. Vanaja, S. Kothai, R. Ashmitha, A. K. Mishra, and J. Nodirjon, “Smart helmet for drunk & drive detection and alert system,” E3S Web of Conferences, vol. 399, p. 04057, Jul. 2023.

- A. D. T. Alcantara, J. D. T. Liwanag, K. J. F. Avila, and A. A. D. Macapagal, “Internet of things-based smart helmet with accident identification and logistics monitoring for delivery riders,” Engineering Proceedings, vol. 58, no. 1, p. 129, 2023.

- P. Dhanush, S. J. Patil, R. U. Girish, G. Chethan, and S. K. Chethan, “Smart headgear for unsafe operational environment,” in Emerging Research in Computing, Information, Communication and Applications, vol. 4, N. R. Shetty, L. M. Patnaik, and N. H. Prasad, Eds. Singapore: Springer, 2023, pp. 443–451.

- P. S. Babu, K. M. Reddy, S. V. Lalitha, P. N. Timmaiah, and V. Srikanth, “Smart helmet with alcohol sensing and bike authentication for riders,” J. Energy Eng. Thermodyn., vol. 2, no. 3, pp. 1–7, Apr. 2023. [CrossRef]

- Kartik and P. Manimaran, “IoT based smart helmet for hazard detection in mining industry,” arXiv preprint, arXiv:2304.10156, Apr. 2023.

- G. Agorku, A. Owusu, K. Agyekum, and J. Darkwa, “Real-time helmet violation detection using YOLOv5 and ensemble learning,” arXiv preprint, arXiv:2304.09246, Apr. 2023.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).