Submitted:

15 May 2025

Posted:

16 May 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Plant Material and Treatments

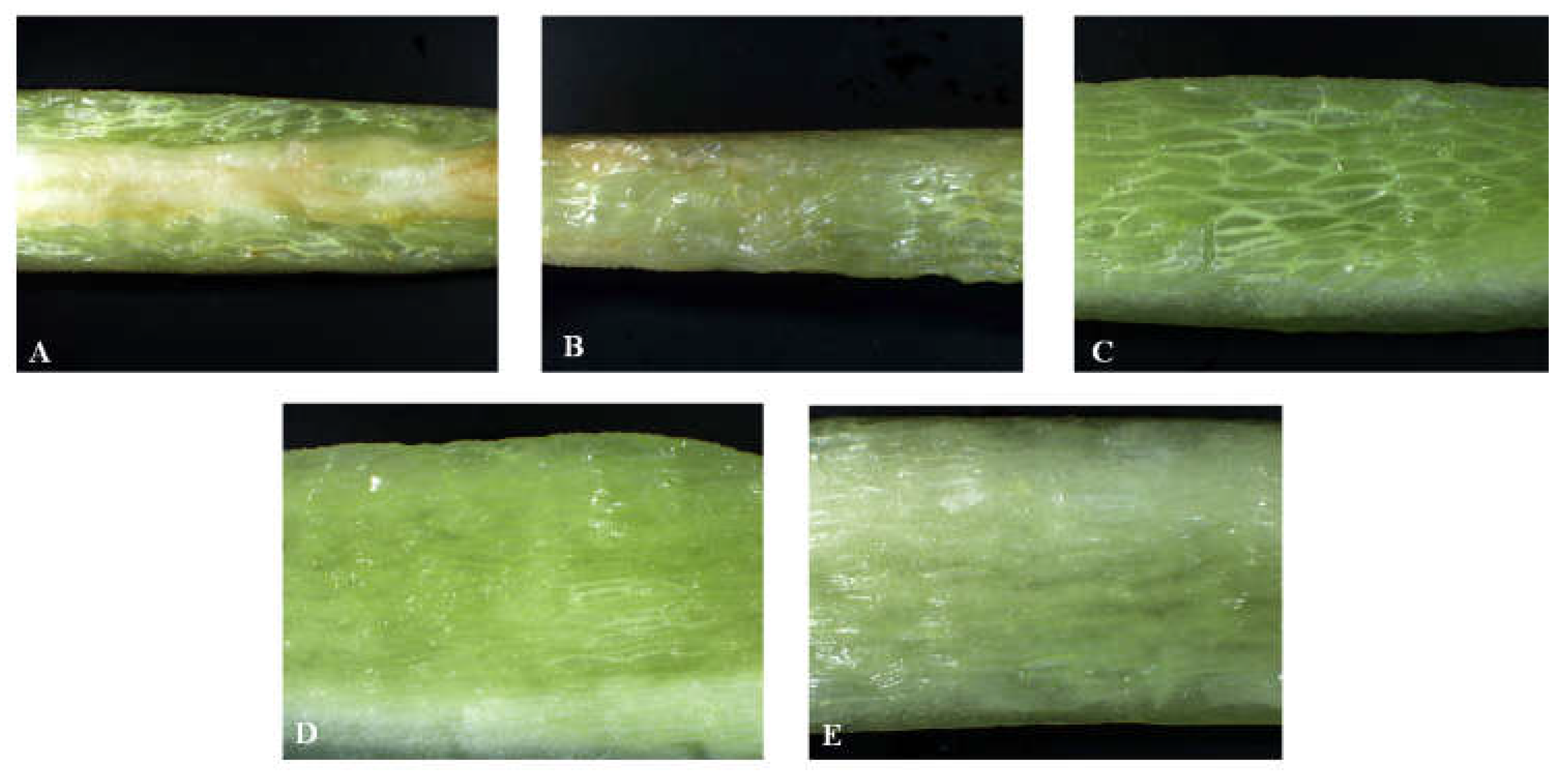

2.2. Quality Assessment

- -

- softening: 1 – none, 3 – light, 5 – medium (clearly perceptible), 7 – strong (soft sticks), 9 – very strong (completely soft sticks);

- -

- browning: 1 – none, 3 – slight, 5 – medium clearly visible, 7 – strong, 9 – very strong (brown);

- -

- rotting: 1 – none, 3 – slight (individual small rot spots), 5 – medium clearly visible (few clearly visible rot spots), 7 – strong, 9 – very strong;

- -

- marketable value: 9 – excellent (appear as freshly cut), 7 – good (light defects, only slightly reduced quality), 5 – sufficient (light and medium defects - lower limit of commercial suitability), 3 – bad (large defects), 1 – very bad.

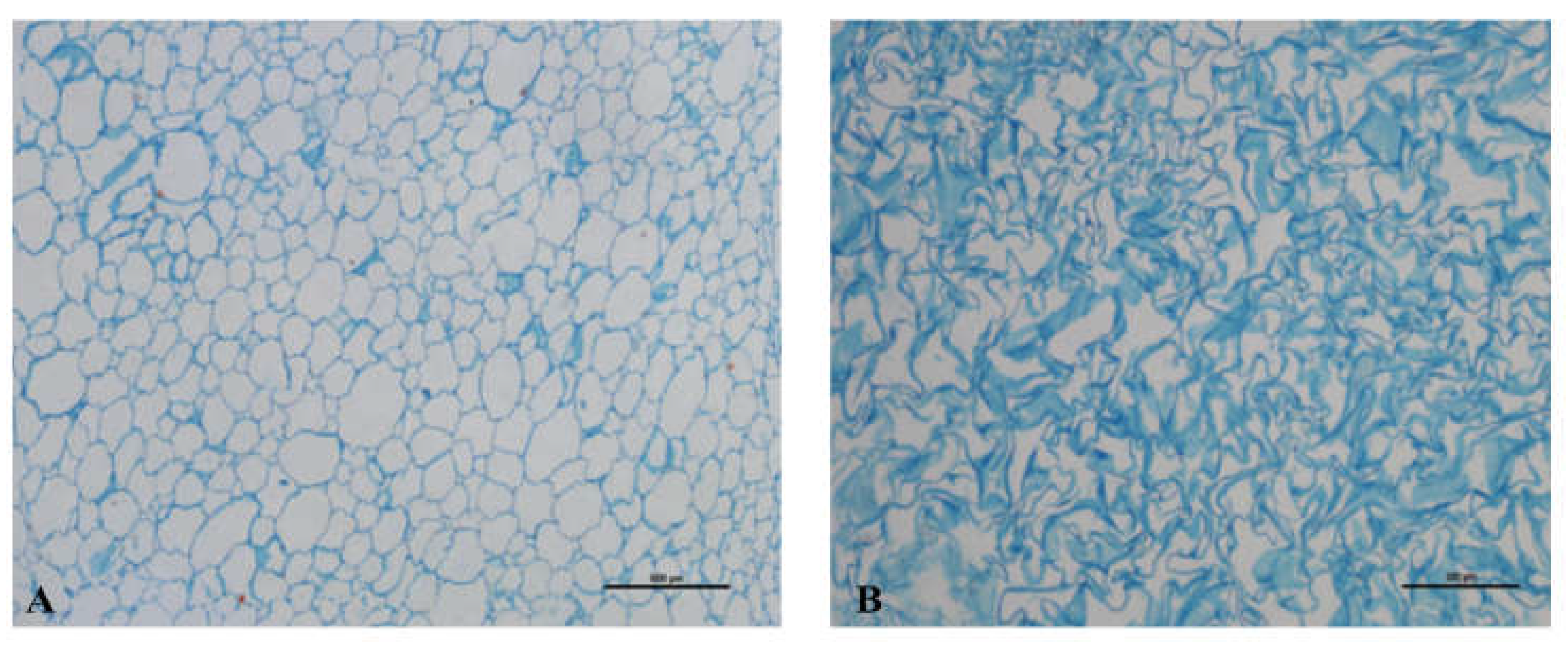

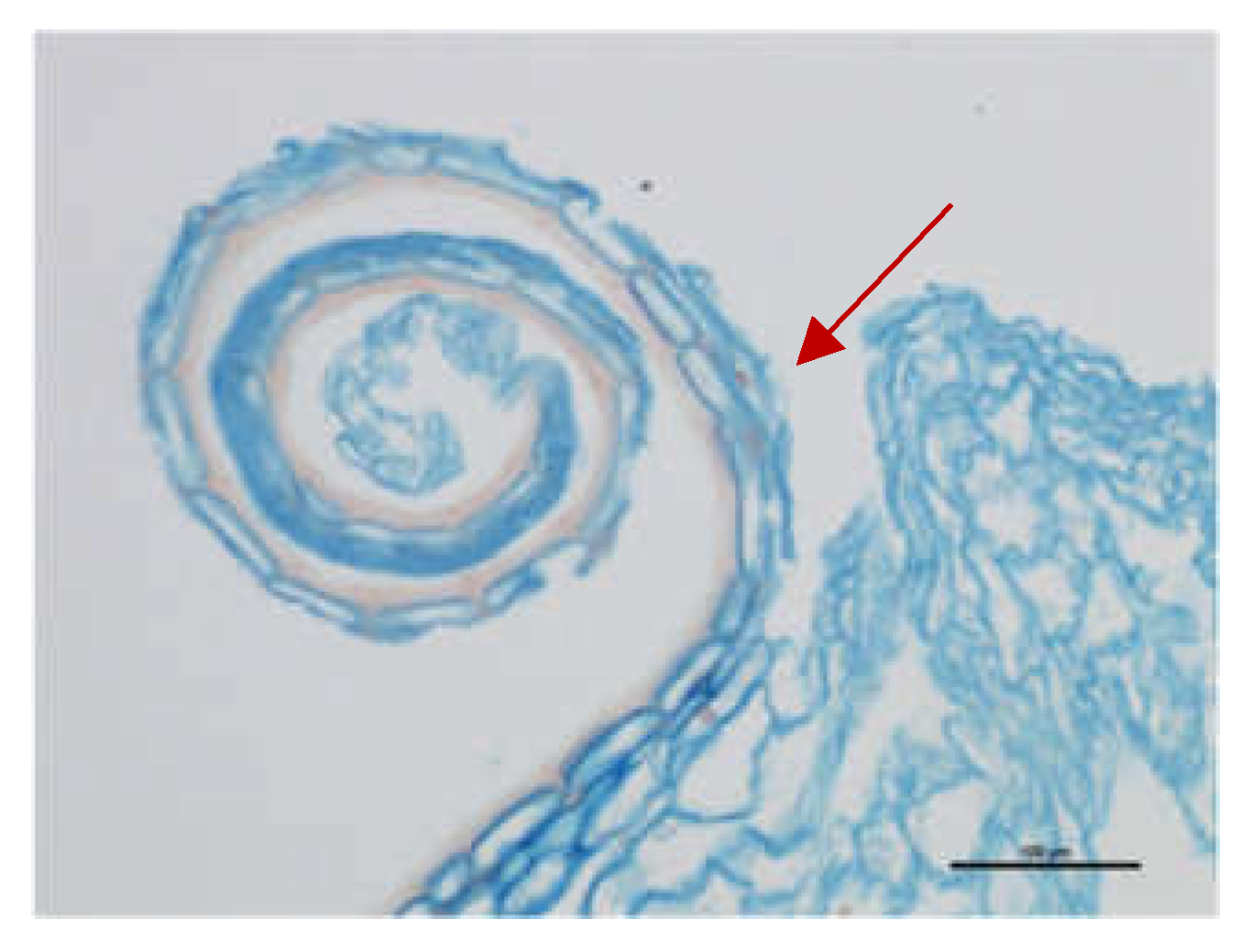

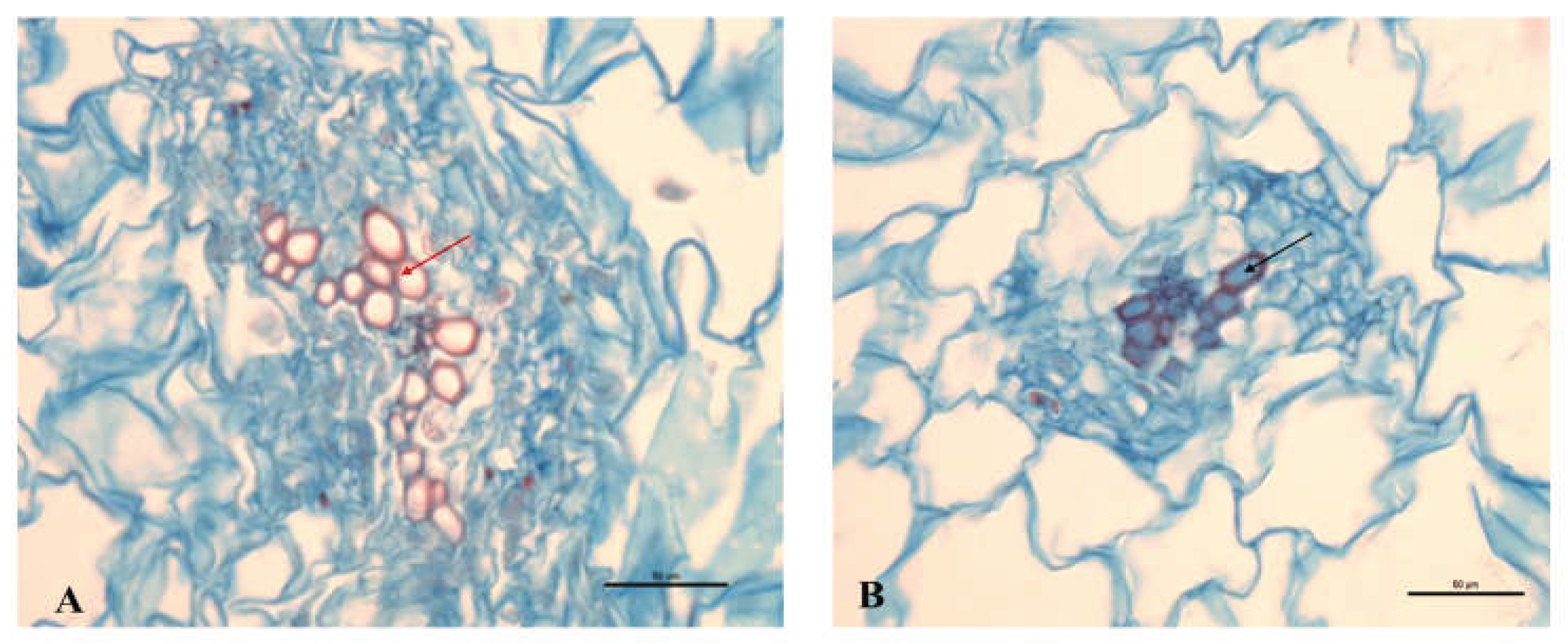

2.3. Microscopic Evaluation

2.4. Data Analysis

3. Results

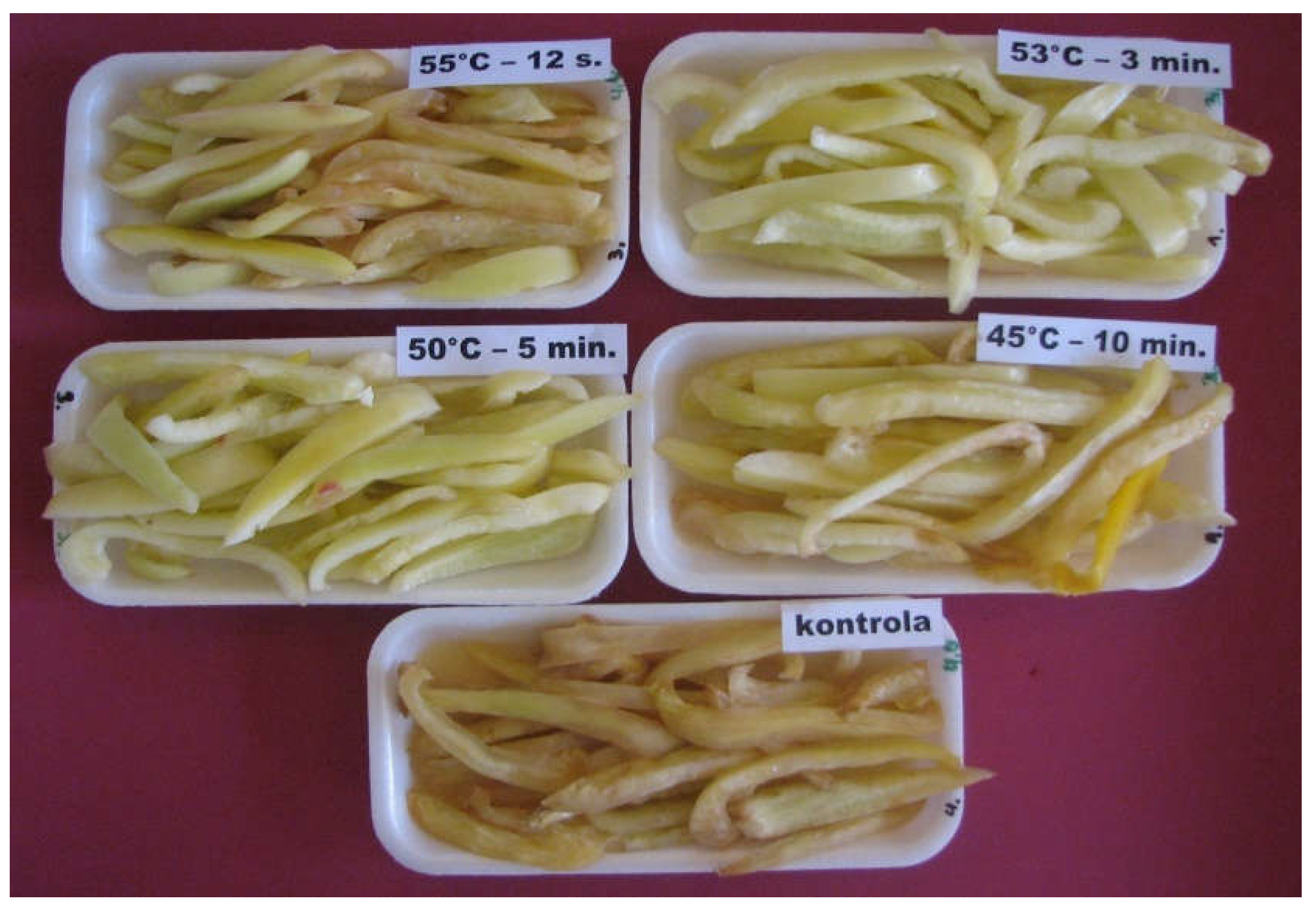

3.1. Changes in Quality Attributes

| Cold storage tempe-rature | Hot water parameters | 1 day at 18-20 °C | 2 days at 18-20 °C | |||||

| softening | surface browning | marketable value | softening | Surface browning | rotting | marketable value | ||

| 3°C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

2.0±1.2a 1.5±0.6a 1.5±0.6a 3.5±2.9a 4.0±1.2a |

2.0±1.2ab 1.0±0.0a 1.0±0.0a 1.8±0.9ab 5.3±1.4d |

5.8±1.4c-f 8.0±0.0f 8.0±0.0f 5.8±0.9c-f 3.5±1.7abc |

6.5±0.6a 3.1±1.6a 3.5±2.9a 6.0±2.3a 8.3±0.3a |

4.5±1.7cde 1.4±0.3a 1.5±0.6ab 2.5±1.7abc 6.0±1.2de |

3.5±2.9a 1.4±0.5a 1.1±0.3a 2.5±1.7a 4.5±4.0a |

2.0±0.0ab 5.5±0.4d 4.9±2.1cd 1.5±0.6ab 1.0±0.0a |

| Mean | 2.5±1.7A | 2.2±1.8A | 6.2±2.0A | 5.5±2.6A | 3.2±2.2A | 2.6±2.5A | 2.9±2.1A | |

| 5 °C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

2.5±1.7a 1.5±0.6a 1.6±0.8a 3.5±2.9a 5.5±0.6a |

2.8±0.9abc 1.0±0.0a 1.0±0.0a 2.5±0.6abc 4.5±1.7cd |

4.8±0.9b-c 8.0±0.0f 7.9±0.0f 4.5±1.7a-d 2.5±0.6ab |

4.0±2.3a 2.6±1.9a 2.8±2.1a 5.5±4.0a 7.5±0.6a |

3.3±0.3abc 1.4±0.5a 1.9±0.9ab 3.3±0.3abc 6.0±1.2de |

3.0±2.3a 1.3±0.3a 1.1±0.3a 3.0±2.3a 4.0±3.5a |

2.0±0.0ab 5.8±0.5d 4.9±2.3bc 1.5±0.6ab 1.5±0.6ab |

| Mean | 2.9±2.1A | 2.4±1.6A | 5.5±2.3A | 4.8±2.9A | 3.2±1.8A | 2.5±2.2A | 3.1±2.1A | |

| 8°C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

3.5±2.9a 2.0±1.2a 2.3±1.5a 4.0±3.5a 5.5±1.7a |

3.5±0.6bcd 1.0±0.0a 1.3±0.3ab 2.0±1.2ab 5.5±1.7d |

3.0±0.0ab 7.4±0.9ef 6.6±1.2def 4.0±2.3d 2.0±0.0a |

6.5±1.7a 4.6±3.3a 5.0±3.5a 6.03.5±a 8.5±0.6a |

5.0±0.0cde 2.9±1.7abc 4.0±1.2bcd 4.5±0.6cde 7.0±0.0e |

3.0±2.3a 1.0±0.0a 2.5±1.7a 3.0±2.3a 4.5±4.0a |

1.8±0.5ab 4.0±2.4bcd 2.5±0.6abc 1.5±0.6ab 1.0±0.0a |

| Mean | 3.5±2.4A | 2.7±1.9A | 4.6±2.4A | 6.1±2.8A | 4.7±1.6B | 2.8±2.5A | 2.2±1.5A | |

3.2. Weight Loss

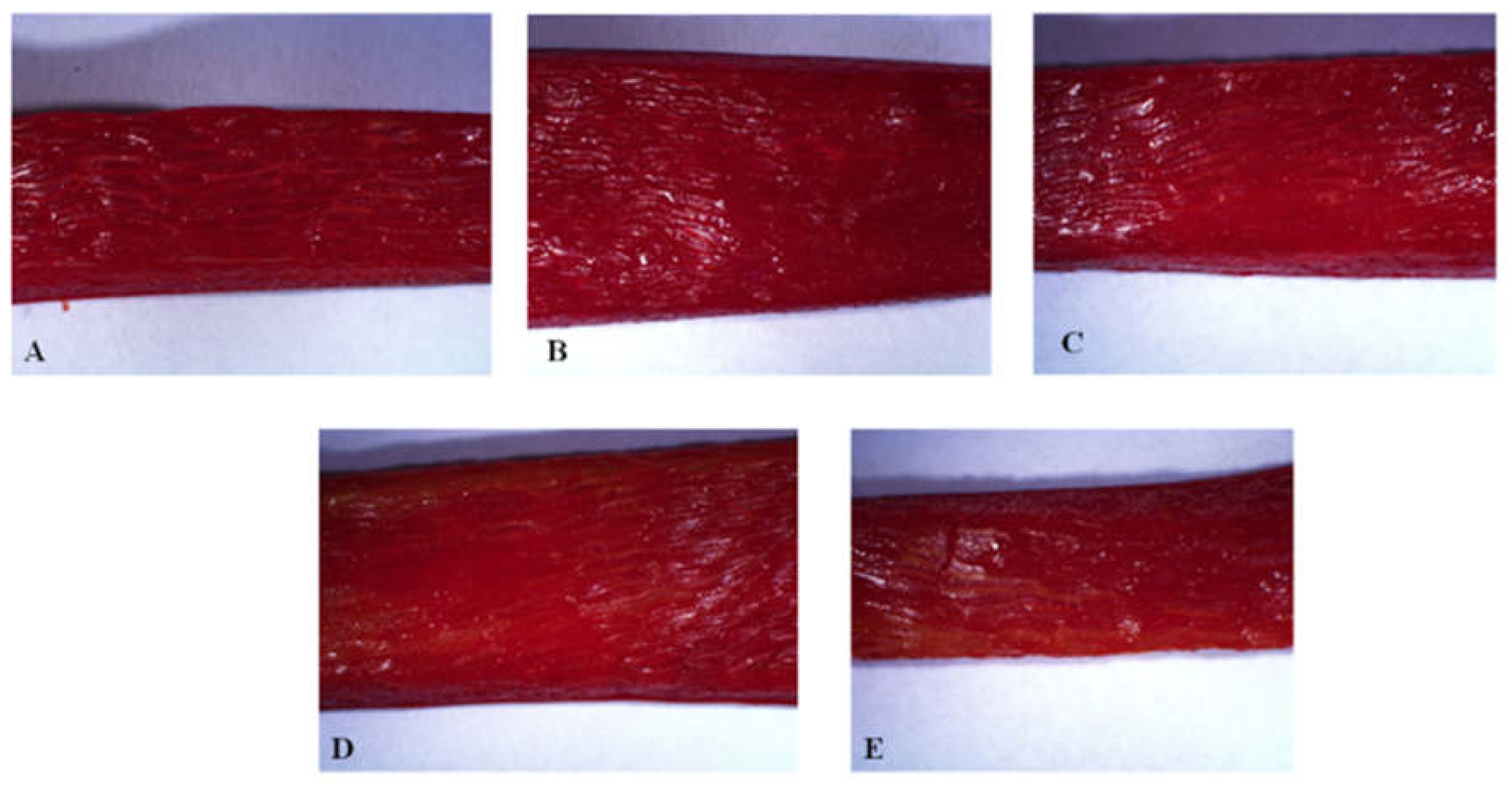

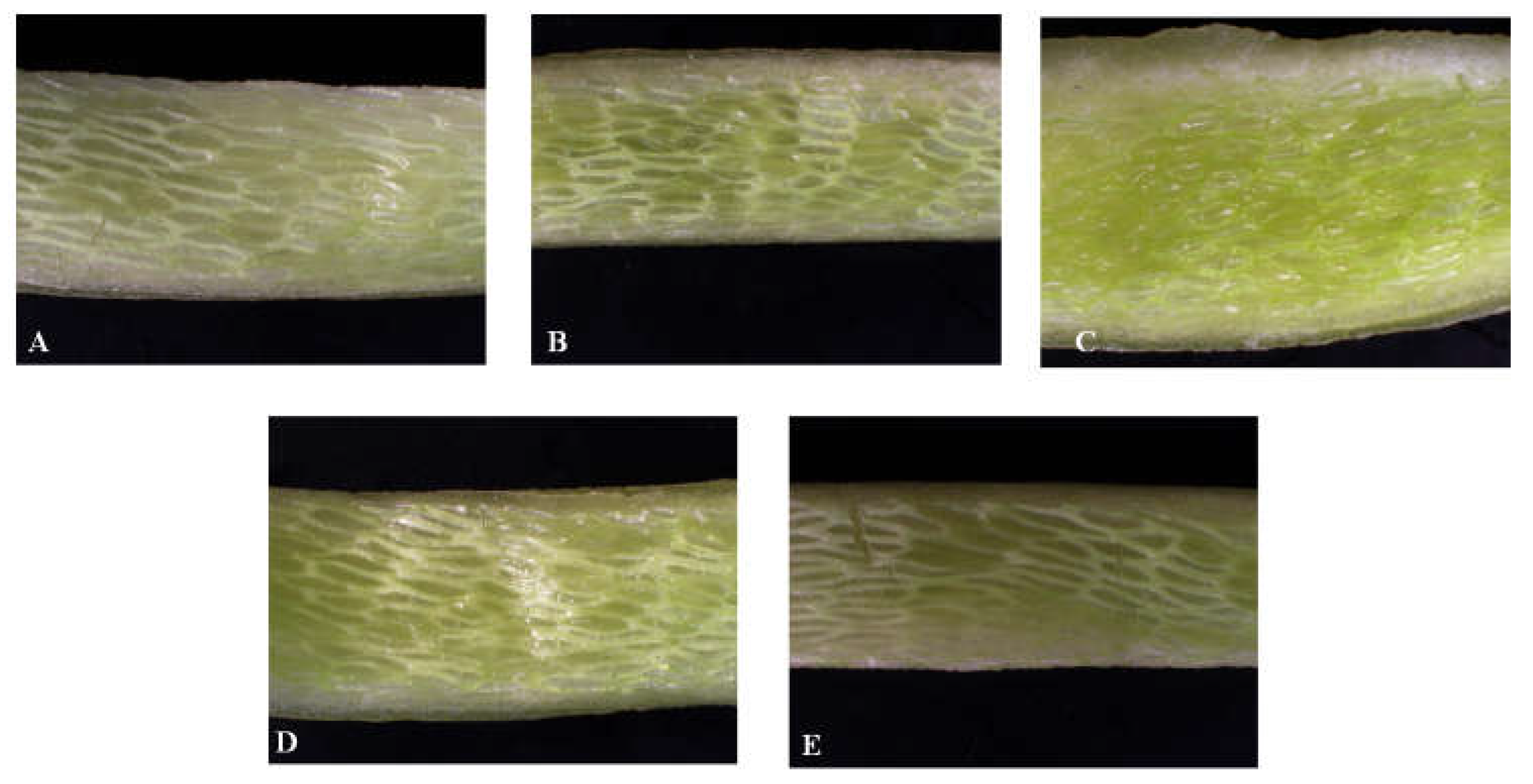

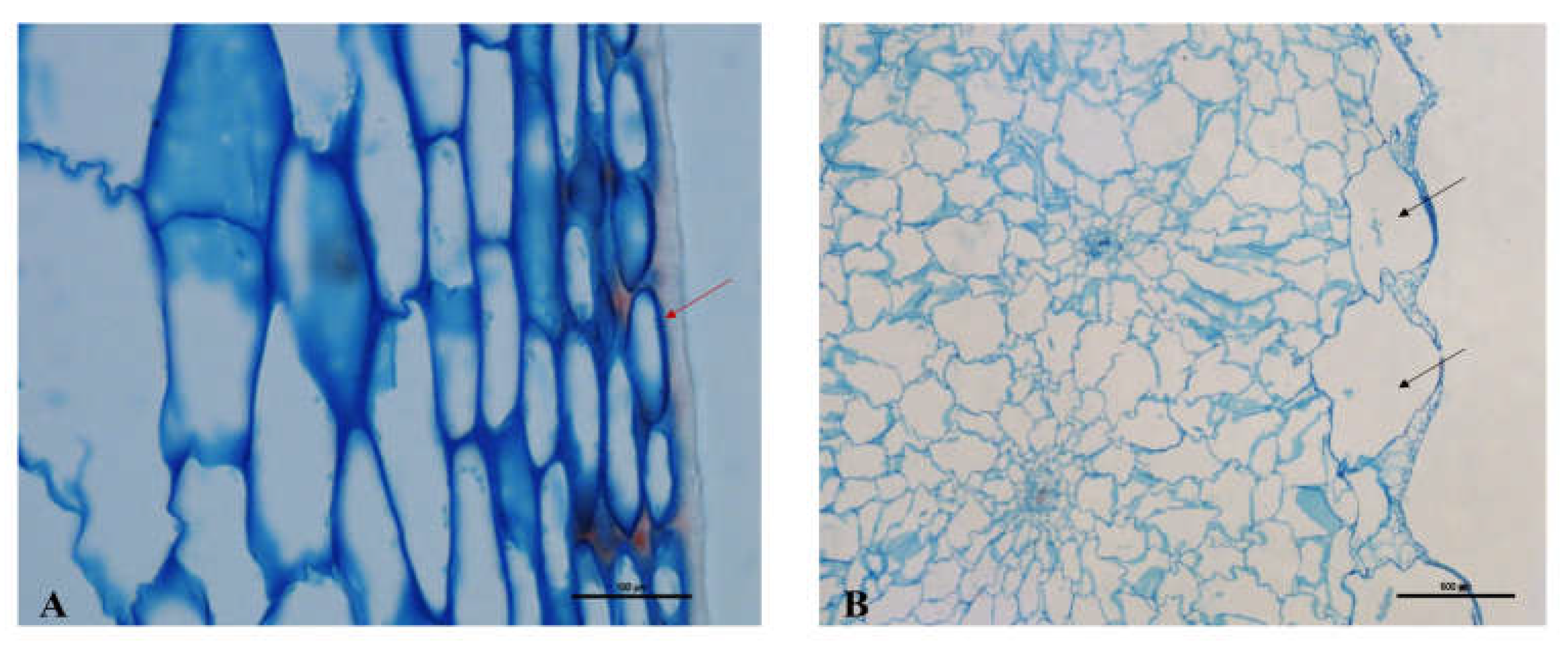

3.3. Microscopic Evaluation

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| HWT | hot water treatment |

| HWRB | hot water rinsing and brushing |

| d | day |

| s | second |

| min. | minute |

| PPO | polyphenol oxidase |

| POD | peroxidase |

| PAL | phenylalanine ammonia lyase |

References

- Iturralde-García, R.D.; Cinco-Moroyoqui, F.J.; Martínez-Cruz, O.; Ruiz-Cruz, S.; Wong-Corral, F.J.; Borboa-Flores, J.; Cornejo-Ramírez, Y.I.; Bernal-Mercado, A.T.; Del-Toro-Sánchez, C.L. Emerging Technologies for Prolonging Fresh-Cut Fruits’ Quality and Safety during Storage. Horticulturae 2022, 8, 731. [Google Scholar] [CrossRef]

- Fallik, E.; Alkalai-Tuvia, S.; Chalupowicz, D. Hot Water Rinsing and Brushing of Fresh Produce as an Alternative to Chemical Treatment after Harvest—The Story behind the Technology. Agronomy 2021, 11, 1653. [Google Scholar] [CrossRef]

- Ndlela S., Mwando N.L., Mohamed S.A. Advances in postharvest disinfestation of fruits and vegetables using hot water treatment technology-updates from Africa. Chapter from book Postharvest Technology – recent advances, new perspectives and applications 2021. [CrossRef]

- Lurie, S. Postharvest heat treatments. Postharvest Biol. Technol. 1998, 14, 257–269. [Google Scholar] [CrossRef]

- Fallik, E.; Grinberg, S.; Alkalai, S.; Yekutieli, O.; Wiseblum, A.; Regev, R.; Beres, H.; Bar-Lev, E. A unique rapid hot water treatment to improve storage quality of sweet pepper. Postharvest Biol. Technol. 1999, 15, 25–32. [Google Scholar] [CrossRef]

- Fallik, E. Prestorage hot water treatments (immersion, rinsing and brushing). Postharvest Biol. Technol. 2004, 32, 125–134. [Google Scholar] [CrossRef]

- Ferguson, I.; Ben-Yehoshua, S.; Mitcham, E.; McDonald, R.; Lurie, S. Postharvest heat treatments: introduction and workshop summary. Postharvest Biol. Technol. 2000, 21, 1–6. [Google Scholar] [CrossRef]

- Saltveit, M.E. 1998. Heat shock and fresh cut lettuce. Perishables Handling Quarterly 95, pp. 5-6.

- He Q., Luo Y. Enzymatic browning and its control in fresh-cut produce. Stewart Postharvest Review 2007, 3 (6), pp. 1-7. [CrossRef]

- Vlachonasios, K.; Kadyrzhanova, D.; Dilley, D. Heat treatment prevents chilling injury of tomato (Lycopersicon esculentum) fruits: heat shock genes and heat shock proteins in the resistance of tomato fruit to low temperatures. Acta Hortic. 2001, 543–548. [Google Scholar] [CrossRef]

- Aghdam, M.S.; Sevillano, L.; Flores, F.B.; Bodbodak, S. Heat shock proteins as biochemical markers for postharvest chilling stress in fruits and vegetables. Sci. Hortic. 2013, 160, 54–64. [Google Scholar] [CrossRef]

- Saltveit, M.E. Wound induced changes in phenolic metabolism and tissue browning are altered by heat shock. Postharvest Biol. Technol. 2000, 21, 61–69. [Google Scholar] [CrossRef]

- Fallik, E., Ilic Z. Control of postharvest decay of fresh produce by heat treatments: The risk and benefits. In Postharvest Pathology of Fresh Horticultural Produce; Palou L., Smilanick J.L. Eds.; CRC press; Boca Raton, FL, USA, 2020, pp. [CrossRef]

- Fallik, E.; Grinberg, S.; Alkalai, S.; Lurie, S. The effectiveness of postharvest hot water dipping on the control of grey and black moulds in sweet red pepper (Capsicum annuum). Plant Pathol. 1996, 45, 644–649. [Google Scholar] [CrossRef]

- Kantakhoo, J.; Imahori, Y. Antioxidative Responses to Pre-Storage Hot Water Treatment of Red Sweet Pepper (Capsicum annuum L.) Fruit during Cold Storage. Foods 2021, 10, 3031. [Google Scholar] [CrossRef] [PubMed]

- Ilic, Z. , Polevaya Y. , Tuvia-Alkalai S., Copel A., Fallik E. A short prestorage hot water rinse and brushing reduces decay development in tomato, while maintaining its quality. Prop. Agric. Res. Ext 2001, 4, pp. 1–6. [Google Scholar]

- Zong, Y.; Liu, J.; Li, B.; Qin, G.; Tian, S. Effects of yeast antagonists in combination with hot water treatment on postharvest diseases of tomato fruit. Biol. Control. 2010, 54, 316–321. [Google Scholar] [CrossRef]

- Grzegorzewska, M.; Badełek, E.; Szczech, M.; Kosson, R.; Wrzodak, A.; Kowalska, B.; Colelli, G.; Szwejda-Grzybowska, J.; Maciorowski, R. The effect of hot water treatment on the storage ability improvement of fresh-cut Chinese cabbage. Sci. Hortic. 2022, 291. [Google Scholar] [CrossRef]

- Loaiza-Velarde, J.G.; Saltveit, M.E. Heat Shocks Applied either before or after Wounding Reduce Browning of Lettuce Leaf Tissue. J. Am. Soc. Hortic. Sci. 2001, 126, 227–234. [Google Scholar] [CrossRef]

- Kang, H.-M.; Saltveit, M.E. Antioxidant Capacity of Lettuce Leaf Tissue Increases after Wounding. J. Agric. Food Chem. 2002, 50, 7536–7541. [Google Scholar] [CrossRef]

- Abreu, M.; Beirão-Da-Costa, S.; Gonçalves, E.M.; Beirão-Da-Costa, M.L.; Moldão-Martins, M. Use of mild heat pre-treatments for quality retention of fresh-cut ‘Rocha’ pear. Postharvest Biol. Technol. 2003, 30, 153–160. [Google Scholar] [CrossRef]

- Koukounaras, A.; Diamantidis, G.; Sfakiotakis, E. The effect of heat treatment on quality retention of fresh-cut peach. Postharvest Biol. Technol. 2008, 48, 30–36. [Google Scholar] [CrossRef]

- Gómez, F.; Fernández, L.; Gergoff, G.; Guiamet, J.J.; Chaves, A.; Bartoli, C.G. Heat shock increases mitochondrial H2O2 production and extends postharvest life of spinach leaves. Postharvest Biol. Technol. 2008, 49, 229–234. [Google Scholar] [CrossRef]

- Sgroppo, S.C.; Pereyra, M.V. Using mild heat treatment to improve the bioactive related compounds on fresh-cut green bell peppers. Int. J. Food Sci. Technol. 2009, 44, 1793–1801. [Google Scholar] [CrossRef]

- Rodoni, L.; Hasperué, J.; Ortiz, C.; Lemoine, M.; Concellón, A.; Vicente, A. Combined use of mild heat treatment and refrigeration to extend the postharvest life of organic pepper sticks, as affected by fruit maturity stage. Postharvest Biol. Technol. 2016, 117, 168–176. [Google Scholar] [CrossRef]

- Tsouvaltzis, P.; Siomos, A.S.; Gerasopoulos, D. Effect of hot water treatment on leaf extension growth, fresh weight loss and color of stored minimally processed leeks. Postharvest Biol. Technol. 2006, 39, 56–60. [Google Scholar] [CrossRef]

- Grzegorzewska, M. The effect of hot water treatment and type of unit packaging on durability of fresh-cut pepper during short storage. Zeszyty Naukowe Instytutu Ogrodnictwa 2014, 22, pp. 19–29 (polish). [Google Scholar]

- Berlyn G.P., Miksche J.M., Sass J.E. Botanical microtechnique and cytochemistry. Iowa State Univ. Press, Ames, Iowa, 1976.

- Sass J.E. Botanical microtechnique. Iowa State College Press, Ames, Iowa 1958.

- Soliva-Fortuny, R.C.; Martı́n-Belloso, O. New advances in extending the shelf-life of fresh-cut fruits: a review. Trends Food Sci. Technol. 2003, 14, 341–353. [Google Scholar] [CrossRef]

- Fonseca S., Silva C.L., Malcata F.X. Microstructural analysis of fresh-cut red bell pepper (Capsicum annum L.) for postharvest quality optimization. Elec. J. Env. Agricult. Food Chem 2005, 4 (5), pp. 1081-1085.

- Li, Z.; Zhang, Y.; Ge, H. The membrane may be an important factor in browning of fresh-cut pear. Food Chem. 2017, 230, 265–270. [Google Scholar] [CrossRef]

- Yuan X.Y., Zhan Z., Lin W., Zhang C., Wang B. The membrane may be a key factor influencing browning: a mini review on browning mechanisms of fresh-cut fruit and vegetables from a multi-omics perspective. Front. Nutr. 2025, 12, 1534594. [CrossRef]

- Sommano S.R., Chanasut U., Kumpoun W. 3-Enzymatic browning and its amelioration in fresh-cut tropical fruits. Fresh-cut fruits and vegetables. Technologies and Mechanisms for Safety Control, 2020, pp. 51-76. [CrossRef]

- Kang, H.-M.; Saltveit, M. Wound-induced increases in phenolic content of fresh-cut lettuce is reduced by a short immersion in aqueous hypertonic solutions. Postharvest Biol. Technol. 2003, 29, 271–277. [Google Scholar] [CrossRef]

- Lurie S. Heat treatments to reduce chilling injury and superficial scald. Environmentally Friendly Technologies for Agricultural Produce Quality. Ben-Yehoshua S.(Eds.), Taylor and Francis Group, CRC Press, Boca Raton, FL, USA, 2005, pp. 43-60. [CrossRef]

- Loaiza-Velarde, J.G.; Mangrich, M.E.; Campos-Vargas, R.; Saltveit, M.E. Heat shock reduces browning of fresh-cut celery petioles. Postharvest Biol. Technol. 2003, 27, 305–311. [Google Scholar] [CrossRef]

- Murata, M.; Tanaka, E.; Minoura, E.; Homma, S. Quality of Cut Lettuce Treated by Heat Shock: Prevention of Enzymatic Browning, Repression of Phenylalanine Ammonia-lyase Activity, and Improvement on Sensory Evaluation during Storage. Biosci. Biotechnol. Biochem. 2004, 68, 501–507. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, L.; Wang, Q. Pre-cut hot water treatment inhibited the browning of fresh-cut eggplant. Acta Hortic. 2021, 187–198. [Google Scholar] [CrossRef]

- Tsouvaltzis, P.; Deltsidis, A.; Brecht, J.K. Hot Water Treatment and Pre-processing Storage Reduce Browning Development in Fresh-cut Potato Slices. HortScience 2011, 46, 1282–1286. [Google Scholar] [CrossRef]

- Dea, S.; Brecht, J.K.; Nunes, M.C.N.; Baldwin, E.A. Occurrence of chilling injury in fresh-cut ‘Kent’ mangoes. Postharvest Biol. Technol. 2010, 57, 61–71. [Google Scholar] [CrossRef]

- Barth, M., Hankinson, T.R., Zhuang, H., Breidt, F. Microbiological spoilage of fruits and vegetables. In: Sperber, W., Doyle M. (eds) Compendium of the Microbiological Spoilage of Foods and Beverages. Food Microbiology and Food Safety. Springer, New York, NY. 2009. [CrossRef]

- Watada, A.E.; Ko, N.P.; Minott, D.A. Factors affecting quality of fresh-cut horticultural products. Postharvest Biol. Technol. 1996, 9, 115–125. [Google Scholar] [CrossRef]

- Lurie, S.; Klein, J.D. Ripening characteristics of tomatoes stored at 12°C and 2°C following a prestorage heat treatment. Sci. Hortic. 1992, 51, 55–64. [Google Scholar] [CrossRef]

| Cold storage tempe-rature | Hot water parameters | 4 days of storage | 6 days of storage | ||

| softening | marketable value | softening | marketable value | ||

| 3 °C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

1.5±0.0 a 1.6±0.2 ab 1.5± 0.0 a 1.5±0.0 a 1.9±0.2 bcd |

8.3±0.63 b 8.1±0.2 b 8.2±0.3 b 8.3± 0.3 b 7.8±0.3 ab |

2.0 ±0.6 a 2.6 ±0.8 a 2.6±0.9 a 2.6±1.2 a 3.0±1.1 a |

7.7±0.5 e 7.2±0.5 de 7.2±0.7 de 7.1±1.0 de 6.5±0.5 cde |

| Mean | 1.6 ±0.2 A | 8.1±0.3 B | 2.6±0.9 A | 7.1±0.7 C | |

| 5 °C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

1.8±0.3 abc 1.9± 0.2 bcd 2.0±0.0 cd 1.9±0.2 bcd 2.0±0.0 cd |

7.7± 0.8 ab 7.6± 0.7 ab 7.5± 0.5 ab 7.6± 0.6 ab 7.5±0.5 ab |

2.8±0.8 a 2.8±0.8 a 2.8±0.8 a 2.8±0.8 a 3.8±1.3 a |

6.5±0.5 cde 6.5±0.5 cde 6.5±0.5 cde 6.5±0.5 cde 5.8±0.8 a-d |

| Mean | 1.9±0.2 B | 7.6±0.6 A | 3.0±1.0 A | 6.4±0.6 B | |

| 8°C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

2.0±0.0 cd 2.0±0.0 cd 2.0±0.0 cd 2.2±0.4 de 2.5±0.5 e |

7.5± 0.5 ab 7.5± 0.5 ab 7.5± 0.5 ab 7.3± 0.9 ab 7.0± 1.1 a |

3.0±0.9 a 4.5±2.7 a 2.7±0.4 a 4.7±2.0 a 4.8±1.3 a |

6.0±0.5 cde 4.5±2.7 ab 6.4±0.4 b-e 4.6±2.0 abc 4.4±1.5 a |

| Mean | 2.1±0.3 C | 7.4±0.7 A | 3.9±1.8 B | 5.3±1.8 A | |

| Cold storage temperature | Hot water parameters | 1 day at 18-20 °C | 2 days at 18-20 °C | |||

| softening | marketable value | softening | rotting | marketable value | ||

| 3 °C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

2.0±1.2 a 2.3±0. 3a 2.5±0.4 ab 2.5±0.6 ab 3.5±0.6 ab |

7.5±1.2 d 7.3±0.3 cd 7.0±0.4 cd 7.0±0.0 cd 5.5±0.6 ab |

3.0 ±2.3 a 3.5±1.7 a 3.4±0.8 a 3.5±1.7 a 5.0±2.3 a |

1.0±0.0 a 1.0±0. 0a 1.3±0.3 ab 1.0±0.0 a 1.3±0.3 ab |

6.0±1.2 b 5.8±1.4 b 5.8±0.3 b 5.8±1.4 b 4.0±1.2 ab |

| Mean | 2.6±0.8 A | 6.9±0.9 A | 3.7±1.8 A | 1.1±0.2 A | 5.5±1.3 A | |

| 5 °C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

2.4±0.5 a 2.8±0.3 ab 2.0±0.6 a 2.5±0.6 ab 3.1±0.3 ab |

6.9±0.3 cd 6.3±0.3 bcd 7.5±0.6 d 7.0±0.6 cd 5.9±1.0 abc |

3.3±1.5 a 4.3±2.0 a 3.5±1.7 a 3.8±2.0 a 5.1±1.2 a |

1.1±0.3 a 1.0±0.0 a 1.0±0.0 a 1.0±0.0 a 2.4±1.6 ab |

5.8±1.3 b 4.5±1.7 ab 5.8±0.9 b 5.5±1.7 ab 2.6±0.5 ab |

| Mean | 2.6±0.6 A | 6.7±0.8 A | 4.0±1.7 A | 1.3±0.8 A | 4.8±1.7 A | |

| 8 °C | 55 °C – 12 s 53 °C – 3 min. 50 °C – 5 min. 45 °C – 10 min. Control – not treated |

2.4±0.5 a 2.5±0.6 ab 2.8±0.5 ab 2.6±0.8 ab 4.0±1.2 b |

7.1±0.3 d 7.0±0.6 cd 6.4±0.8 bcd 6.3±0.3 bcd 4.8±0.3 a |

3.0±1.1 a 4.3±2.0 a 4.3±2.1 a 4.3±2.0 a 6.8±0.9 a |

1.0±0.0 a 1.0±0.0 a 1.0±0.0 a 1.0±0.0 a 3.0±2.3 b |

6.0±0.6 b 4.6±1.9 ab 4.6±2.0 ab 4.5±2.3 ab 2.0±0.0 a |

| Mean | 2.9±0.9 A | 6.3±1.0 A | 4.5±2.0 A | 1.4±1.2 A | 4.4±2.0 A | |

| Cold storage tempe-rature | Hot water parameters | 4 days of storage | 6 days of storage | |||||

| softening | surface browning | marketable value | softening | surface browning | rotting | marketable value | ||

| 3 °C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

1.1±0.1a 1.1±0.1a 1.1±0.1a 1.1±0.1a 1.1±0.1a |

1.0±0.0a 1.0±0.0a 1.0±0.0a 1.0±0.0a 1.8±0.8abc |

8.8±0.3d 8.8±0.3d 8.8±0.3d 8.8±0.3d 7.8±1.3bcd |

1.5±0.3a 1.2±0.1a 1.5±0.0a 3.4±2.3abc 2.6±1.1abc |

1.0±0.0a 1.0±0.0a 1.0±0.0a 1.3±0.3ab 2.5±0.0c |

1.2±0.3a 1.0±0.0a 1.0±0.0a 1.0±0.0a 1.5±0.5a |

7.5±0.3fgh 8.3±0.3h 8.3±0.3h 5.5±2.7def 5.7±0.8d-g |

| Mean | 1.1±0.1A | 1.2±0.5A | 8.6±0.7B | 2.0±1.4A | 1.4±0.6A | 1.1±0.3A | 7.0±1.7B | |

| 5 °C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

1.1±0.1a 1.1±0.1a 1.1±0.1a 1.1±0.1a 1.4±0.2a |

1.3±0.3ab 1.0±0.0a 1.0±0.0a 1.0±0.0a 2.5±1.6c |

8.0±1.1cd 8.5±0.5cd 8.5±0.5cd 8.5±0.5cd 7.0±1.6bc |

1.5±0.0a 2.0±0.9ab 1.5±0.0a 3.8±2.4abc 3.8±1.9abc |

1.8±0.8b 1.0±0.0a 1.0±0.0a 1.3±0.3ab 4.0 ±0.0d |

1.0±0.0a 1.0±0.0a 1.0±0.0a 1.0±0.0a 1.3±0.3a |

7.0±1.1e-h 7.8±0.3gh 8.3±0.3h 5.2±2.9cde 3.8±0.8bcd |

| Mean | 1.1±0.2A | 1.4±0.9A | 8.1±1.1B | 2.5±1.7A | 1.8±1.2A | 1.1±0.2A | 6.4±2.2B | |

| 8 °C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

1.4±0.3a 1.1±0.1a 1.1±a0.1 2.4±1.2b 2.0± 0.0b |

2.3±1.5bc 1.0±0.0a 1.0±0.1a 1.8±0.8abc 4.0±1.2d |

7.1±1.7bc 8.5±0.5cd 8.5±0.5cd 6.3±0.3ab 5.3±1.9a |

3.7±1.3abc 2.4±1.2abc 2.3±0.8ab 5.3±4.0c 4.5±1.6bc |

3.9±0.5d 1.3± 0.3ab 1.4±0.1ab 2.9±0.2c 6.0±1.1e |

1.6±1.0a 1.1±0.2a 1.0±0.0a 1.9±1.1ab 3.0±2.1b |

3.1±0.7abc 6.7±0.4e-h 6.6±0.7e-h 2.5±1.7ab 1.5±0.5a |

| Mean | 1.6±0.7B | 2.0±1.4B | 7.1±1.7A | 3.6±2.5B | 3.1±1.8B | 1.7±1.3B | 4.1±2.4A | |

| Cold storage tempe-rature | Hot water parameters | Cold storage (days) | Shelf life at 18-20 °C after 4 d of cold storage (days) | |||

| 2 | 4 | 6 | 1 | 2 | ||

| 3°C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

0.30±0.05 de 0.30±0.05 de 0.36±0.07 e 0.25±0.06 cd 0.38±0.03 e |

0.32±0.07 def 0.31±0.05 c-f 0.36±0.07 ef 0.27±0.05 b-e 0.39±0.04 f |

0.38±0.09 d 0.31±0.05 bcd 0.37±0.07 cd 0.28±0.05 abc 0.40±0.05 d |

0.70±0.20 e 0.42±0.09 a-d 0.42±0.06 a-d 0.36±0.02 abc 0.50±0.00 cde |

0.91±0.10 fg 0.66±0.14 bcd 0.76±0.05 def 0.54±0.05 abc 0.87±0.03 ef |

| Mean | 0.32±0.07 C | 0.33±0.07 B | 0.35±0.07 B | 0.48±0.15 B | 0.75±0.16 A | |

| 5°C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

0.26±0.06 cd 0.22±0.04 bcd 0.19±0.06 abc 0.12±0.05 a 0.22±0.03 bcd |

0.26±0.06 a-d 0.22±0.04 abc 0.20±0.05 ab 0.20±0.05 ab 0.24±0.04 a-d |

0.28±0.07 abc 0.27±0.03 ab 0.21±0.05 a 0.24±0.04 ab 0.26±0.03 ab |

0.59±0.17 de 0.32±0.06 abc 0.24±0.03 a 0.32±0.06 abc 0.32±0.06 abc |

0.83±0.13 def 0.54±0.06 abc 0.46±0.03 a 0.55±0.08 abc 0.71±0.05 cde |

| Mean | 0.20±0.06 B | 0.22±0.05 A | 0.25±0.05 A | 0.36±0.15 A | 0.62±0.15 A | |

| 8°C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

0.19±0.04 abc 0.18±0.05 abc 0.14±0.06 ab 0.13±0.05 a 0.11±0.04 a |

0.21±0.04 ab 0.21±0.05 ab 0.19±0.06 ab 0.21±0.04 ab 0.17±0.04 a |

0.31±0.06 bcd 0.26±0.06 ab 0.28±0.06 abc 0.28±0.06 abc 0.26±0.04 ab |

0.35±0.04 abc 0.29±0.02 ab 0.22±0.03 a 0.36±0.05 abc 0.47±0.03 bcd |

0.84±0.02 def 0.49±0.03 ab 0.46±0.05 a 0.56±0.02 abc 1.08±0.06 g |

| Mean | 0.15±0.05 A | 0.20±0.05 A | 0.28±0.06 A | 0.34±0.09 A | 0.68±0.25 A | |

| Cold storage tempe-rature | Hot water parameters | Cold storage (days) | Shelf life at 18-20 °C, after 4 d of cold storage (days) | |||

| 2 | 4 | 6 | 1 | 2 | ||

| 3 °C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45°C–10 min. Control – not treated |

0.19±0.02 ab 0.21±0.04 bc 0.29±0.04 de 0.24±0.02bcd 0.19±0.03 ab |

0.23±0.03 abc 0.27±0.03 a-e 0.33±0.05 d-g 0.28±0.05 a-e 0.21±0.04 a |

0.24±0.02 a 0.31±0.04 ab 0.38±0.05 bc 0.32±0.04 ab 0.37±0.05 bc |

0.35±0.04 a 0.36±0.05 ab 0.50±0.04 bcd 0.35±0.04 a 0.54±0.05 cd |

0.94±0.15 a-d 0.70±0.06 ab 0.80±0.15 abc 0.74±0.06 abc 1.89±0.17 gh |

| Mean | 0.23±0.05 B | 0.26±0.06 A | 0.33±0.06 A | 0.42±0.09 A | 1.01±0.55 A | |

| 5 °C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

0.34±0.04 e 0.21±0.03 b 0.22±0.04 bc 0.23±0.03 bcd 0.27±0.04 cd |

0.38±0.04 fg 0.26±0.03 a-d 0.29±0.06 a-e 0.39±0.05 g 0.34±0.07 efg |

0.41±0.05 bc 0.31±0.04 ab 0.66±0.05 bc 0.46±0.04 cd 0.56±0.06 d |

0.57±0.03 de 0.38±0.03 ab 0.39±0.05 ab 0.56±0.02 de 0.60±0.04 de |

1.21±0.02 de 0.60±0.04 a 0.68±0.03 ab 1.06±0.06 cd 1.64±0.08 fg |

| Mean | 0.25±0.06 C | 0.33±0.07 B | 0.42±0.10 B | 0.50±0.11 A | 1.04±0.39 A | |

| 8°C | 55 °C–12 s 53 °C–3 min. 50 °C–5 min. 45 °C–10 min. Control – not treated |

0.21±0.05 b 0.14±0.02 a 0.19±0.02 ab 0.18±0.04 ab 0.18±0.03 ab |

0.31±0.06 c-f 0.22±0.03 ab 0.29±0.03 b-e 0.34±0.04 efg 0.31±0.04 def |

0.56±0.07 d 0.30±0.04 ab 0.38±0.05 bc 0.45±0.07 cd 0.73±0.19 e |

0.69±0.11 e 0.40±0.04 abc 0.50±0.04 bcd 0.59±0.05 de 0.98±0.13 f |

1.51±0.20 ef 0.71±0.05 abc 0.98±0.13 bcd 1.18±0.06 de 2.09±0.36 h |

| Mean | 0.18±0.04 A | 0.29±0.06 A | 0.48±0.20 B | 0.63±0.22 B | 1.30±0.52 A | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).