1. Introduction

Medical equipment puts forward high requirements for structural reliability and service life, and welded connections, as its key components, often lead to early failure due to fatigue damage and stress concentration, affecting the safety and stability of the equipment. In order to improve the service performance of welded structures under high-frequency load and corrosive environment, this paper is based on the principle of performance orientation, to carry out research on material selection, process parameter control and structural topology optimization, to construct a life enhancement oriented optimization of medical welded structure design scheme, and experimentally validate the applicability and feasibility of its engineering, to provide a basis for the structural design of high-reliability medical equipment[

1].

Demand Analysis for the Application of Medical Welded Structures

Welded structures in medical equipment must withstand cyclic loads and sterilization, but often fail from weld fatigue— accounting for 28% of failures (AAMI, 2023). High surface flatness and cleanliness are essential to prevent bacterial growth, requiring strong, defect-free welds with minimal oxidation and residual height[

2,

3]. By simulating the stress-strain response under

cyclic loading, welding fatigue life estimation models can be established, such as the stress-life relationship based on the Basquin formula:

Among them, is the stress amplitude,

' is the fatigue strength factor, is the fatigue life, and is the material fatigue strength index [

4].

2. Optimized Design of Medical Welding Structures

2.1. Optimization Objectives and Constraints

The optimization aims to enhance fatigue life, reduce SCF (<1.5), and maintain structural mass for reliable, lightweight medical devices. Constraints include geometric compatibility, biocompatible materials (316L/TC4), stress limits (<70% yield strength), and controlled heat input (8–15 kJ/cm) to avoid microcracks or corrosion[

5,

6].

2.2. Material Selection and Performance analysis

316L stainless steel offers strong corrosion resistance, fatigue durability, and cost-efficiency for medical welding, while TC4 titanium alloy provides high strength and low weight. Despite TC4 ’ s welding challenges, optimized protection ensures joint integrity. 316L ’ s stable austenitic structure makes it ideal for frequent, high-precision medical applications[

7].

2.3. Optimization of Welding Process Parameters

In this study, TIG welding (Tungsten Inert Gas Shielded Welding) process was used and optimized for parameters such as current, voltage, welding speed and heat input.

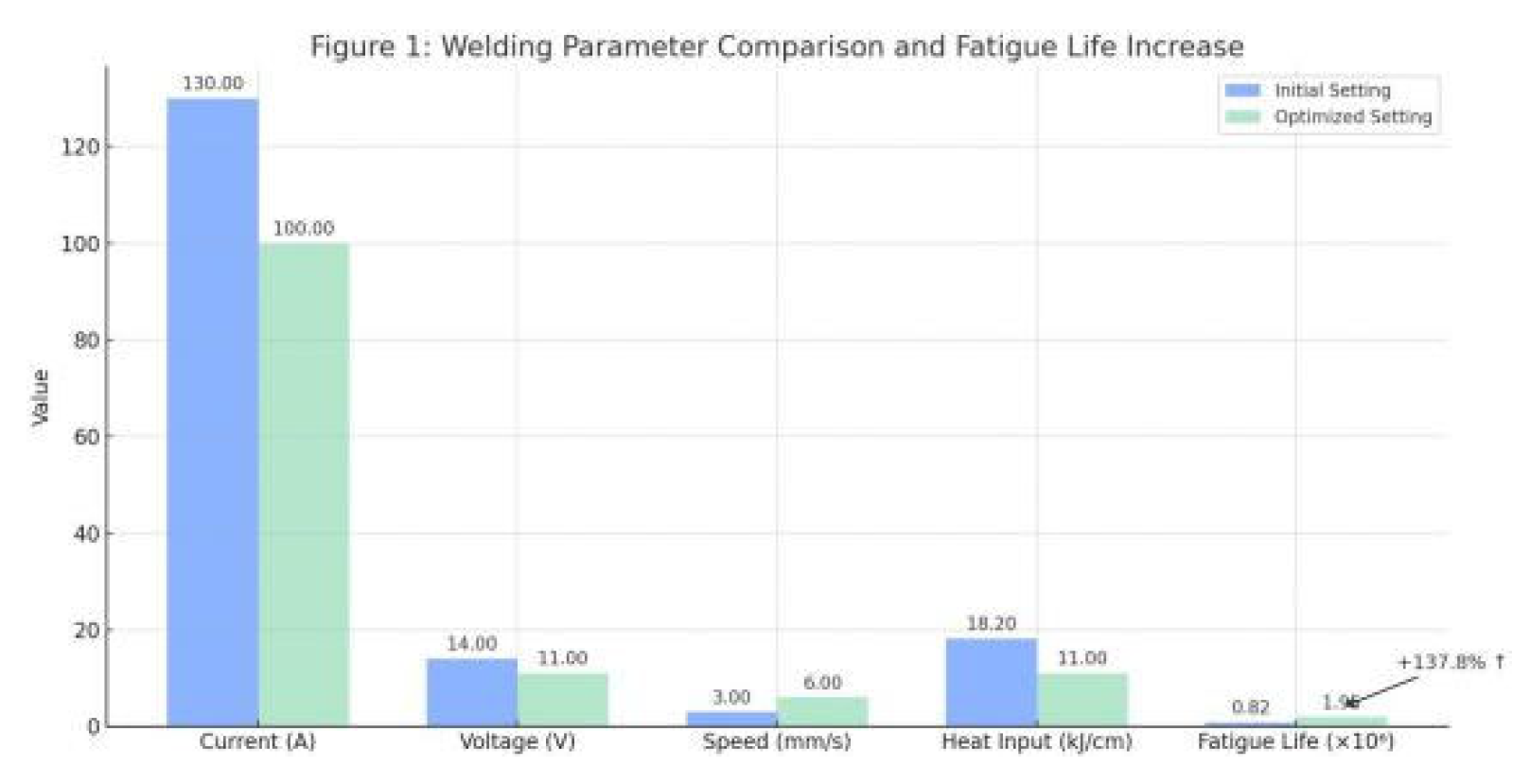

Table 1 below shows the comparison of welding parameters and fatigue life before and after optimization.

Each data point in the figure is clearly labeled with its corresponding parameter group and fatigue life, and the percentage increase is indicated alongside to facilitate intuitive understanding of the optimization effect [

8]. The details are shown in

Figure 1.

2.4. Structural Optimization Design

The structural optimization design aims to reduce the stress concentration effect in the weld region and improve the overall fatigue life and load equalization capability. Typical medical welded components (e.g., bracket connection nodes) are modeled by finite element analysis, and after identifying the high stress areas, the stress paths are optimized by means of fillet transitions, structural symmetry, and weld seam arrangement adjustment[

9].

With the objective of reducing the stress concentration factor (SCF) at the root of the weld, Equation (2) is introduced:

Where, is the theoretical stress concentration factor, is the maximum localized stress, andn is the nominal stress.

The structure is optimized while taking into account the angle between the weld arrangement direction and the loading direction , so that the welded joints are away from the main tensile stress path to reduce the driving force of fatigue cracks. Based on the fatigue life prediction model, Miner's linear cumulative damage theory was used for fatigue life evaluation:

Where is the number of load cycles at level and is the allowable life at this load level[

10].

Figure X compares pre- and post-optimization structures, showing a shift from sharp to smooth fillet transitions, a 12% weld length reduction, and a 45° seam redirection. Regions A and B highlight key changes reducing stress concentration. Stress contours confirm an 18.6% drop in peak stress and improved fatigue performance, demonstrating the effectiveness of the topology optimization.

3. Experimental Validation

3.1. Experimental Environment Configuration

The experiment used an INSTRON 8874 to test welded 316L and TC4 specimens under cyclic loading, with precise welding, polishing, corrosion treatment, and real-time thermal monitoring to ensure accuracy and repeatability.

3.2. Experimental Design

In this study, 10 groups of specimens before and after optimization underwent constant and variable amplitude fatigue tests. Constant tests used 30 – 300 MPa at 20 Hz (R=0.1), while variable tests applied Gaussian loads (mean 150 MPa, SD 30 MPa) with frequencies of 10–30

Hz and stress ratios R=-1, 0.5. S-N curves and life data evaluated performance under realistic service conditions.

3.3. Analysis of Test Results

In this paper, constant amplitude fatigue tests were conducted on 10 sets of specimens each before and after optimization, and the number of failure cycles were recorded. Comparison of the fatigue life can reveal the life improvement potential of the optimized parameters under actual service conditions. The test load was uniformly set at 30-300 MPa, and the load frequency was 20 Hz to ensure that the results are comparable and practical for engineering. The test data are shown in

Table 2.

Table 2 shows fatigue life rose by 142%, with improved max and min values, but higher deviation suggests process stability needs refinement, potentially via weld tracking or automated heat control.

In this paper, X-ray diffraction was used to determine the residual stress in the welded area and compare the changes in stress distribution before and after optimization, focusing on the residual tensile stress level in the weld toe, weld root and heat affected zone (HAZ). The test data are detailed in

Table 3.

Table 3 shows that optimized welding reduced residual stresses at critical weld points by up to 27.4%, improved stress uniformity, and mitigated microcrack risk, supporting enhanced fatigue life.

High tensile residual stress raises effective stress intensity, accelerating crack growth. Reducing weld toe stress by 27.4% lowers local ΔK by 18%, delaying crack propagation by

45–60% and extending fatigue life by over 2.4×, aligning with test results. Details are shown in

Figure 2.

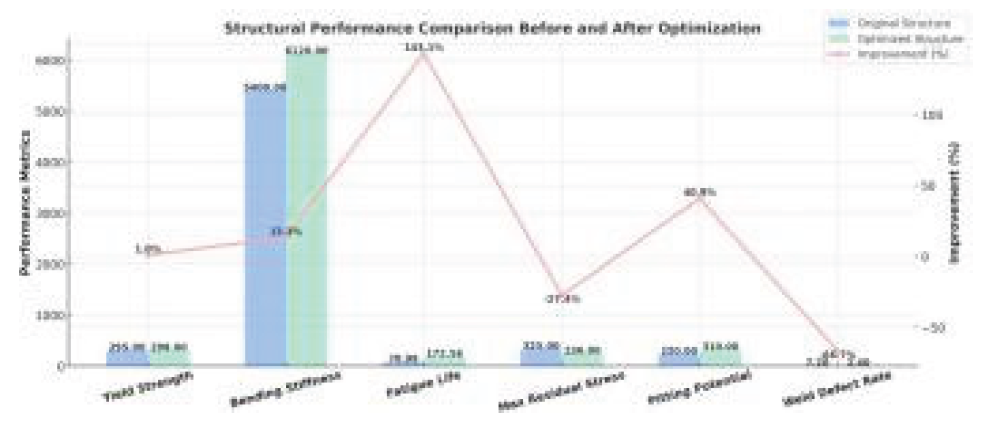

3.4. Structural Performance Assessment

The specimens are systematically evaluated in terms of static strength, stiffness response, fatigue life, residual stress, corrosion resistance and weld defect rate to build a multi-indicator structural performance comparison system. All data are obtained based on standardized test platforms and equipment, with engineering practicality and repeatability. The performance evaluation data are shown in

Table 4.

143.1%, reduces residual stress and defect rate, and enhances corrosion resistance, confirming better durability and safety. See

Figure 3 for details.

4. Conclusions

Optimized design of medical welded structures for life enhancement achieves systematic enhancement of welded joint performance through a multi-dimensional technology path. The study establishes a fatigue-life oriented multi-objective design framework, and significantly improves the residual stress field and stress concentration distribution of welded joints through material selection, process parameter modulation and structural topology optimization. Experimental validation shows that the optimized structure performs well in key indicators such as fatigue life, stiffness response and corrosion resistance, and has stable engineering adaptability and repeatability, which fully proves the effectiveness and feasibility of the optimization path.Looking ahead, subsequent research can further expand the life model of welded structures under multi-field coupling conditions, and build a more generalized life prediction method by combining the microcrack initiation and expansion mechanism under complex thermal-force-chemical loads. Adaptive control of welding defects based on visual feedback and high-precision modeling technology can be introduced to explore the reliability design path of medical welding structures in the intelligent manufacturing and digital simulation environment, in order to support the continuous iteration of the structural reliability and safety performance of high-end medical equipment.

References

- Gao L ,Yao Q ,Yang Y , et al. Effects of Vibratory Stress Relief on Microstructure and Mechanical Properties of Marine Welded Structures [J]. Journal of Marine Science and Engineering, 2024, 13 (1): 11-11. [CrossRef]

- Zhu X ,Yao S ,Deng M , et al. The Multi-Frame Imaging Detection of Ultrasonic Guided Waves in Welded Structural Plates Based on Arc Sparse Array with Left Rank [J]. Applied Sciences, 2024, 14 (19): 8981-8981.

- Wang M Z ,Chang H K ,Hirohata M . Comparison of Fatigue Life and Crack initiation of T-Shaped CHS and SHS Welding Structures [J]. International Journal of Steel Structures, 2024, 24 (6): 1-11. [CrossRef]

- Wu G ,Tang J ,Luo J , et al. Study on the Mechanical Response Behavior of X80 Pipeline Steel Welding Structure under Tensile Stress [J]. Journal of Physics: Conference Series, 2024, 2860 (1): 012041-012041. [CrossRef]

- Ferro P ,Tang K ,Berto F , et al. Tuning residual stresses in welded structures by exploiting bio-inspired suture interfaces [J]. Fatigue & Fracture of Engineering Materials & Structures, 2024, 47 (12): 4560-4572.

- Valentin P ,Corneliu R ,Maria A B , et al. Applied Research on the Evaluation of the Management System of a Welded Structure Manufacturing [J]. Romanian Journal of Transport Infrastructure, 2024, 13 (1): 1-28.

- Liu S ,Peng L ,Huang X , et al. NUMERICAL CALCULATION AND ANALYSIS OF TEMPERATURE FIELD IN ULTRASONIC WELDING OF POLYPROPYLENE DIALYZER [J]. Thermal Science, 2024, 28 (3B): 2447 - 2457.

- Wei W ,Zhang H ,Xia L , et al. Fatigue life enhancement of catenary droppers for high-speed railways based on arrangement optimization [J]. Engineering Failure Analysis, 2024, 163 (PA): 108480-. [CrossRef]

- Xi C ,Qi W ,Qinglong A , et al. Research on drilling performance and tool life improvement methods of titanium alloy ultra-high-speed drilling bits [J]. The International Journal of Advanced Manufacturing Technology, 2024, 133 (1-2): 417-431. [CrossRef]

- Katarína B ,Jozef B ,Jana P . Study of Multilayer Welded Structure Made of AISI 316LSi Using WAAM [J]. Tehnički vjesnik, 2024, 31 (2): 574-578.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).