1. Introduction

In today’s interconnected global economy, the stability of supply chains has become both a priority and a significant challenge. Recent events, especially the COVID-19 pandemic, exposed vulnerabilities across many industries, with disruptions cascading through networks that once seemed robust [

1]. As supply chains have grown in complexity, so too have the risks associated with them. Traditional methods of managing these risks—often reactive and localized—are struggling to keep pace with the scale and frequency of disruptions seen today [

2].

Amid these challenges, artificial intelligence (AI) has emerged as a potential game-changer. By analyzing large volumes of data in real-time, AI can identify risks and even predict disruptions, allowing for proactive measures that were not feasible with conventional approaches. Recent studies have demonstrated that AI models, particularly those using machine learning, can forecast demand shifts and supply bottlenecks, equipping organizations to respond effectively before issues escalate and showed how predictive models applied to inventory data helped stabilize supply flows during volatile periods, illustrating the promise of AI for maintaining continuity under challenging conditions [

3,

4,

5].

AI’s role in supply chain security extends beyond prediction. Anomaly detection systems powered by AI can uncover subtle irregularities across a range of metrics—from supplier delivery times to order fluctuations—that may signal early signs of disruption. These models offer supply chain managers a way to catch and address potential issues before they spread, reinforcing the system’s resilience from within [

6,

7]. The ability to catch these “weak signals” early has proven especially valuable in complex networks where the cost of disruption can be substantial [

8,

9].

Despite these advances, the integration of AI into supply chains is not without obstacles. Data quality, model accuracy, and computational costs remain practical concerns, especially in large-scale, multinational operations. Additionally, navigating the regulatory and logistical challenges of deploying AI solutions across diverse global environments adds further complexity [

10,

11,

12].

To address these challenges, this study proposes an integrative AI framework combining predictive analytics, anomaly detection, and resource optimization to enhance supply chain resilience. Our research develops a comprehensive system that achieves a 4.5% mean absolute percentage error in demand forecasting, while implementing an anomaly detection model with 88% sensitivity and 7% false-positive rate. The framework’s dynamic resource allocation optimization has demonstrated significant improvements, reducing disruption-related costs by 16% and shortening lead times by 17-21% during demand surges. Through empirical validation with 250 supply chain professionals across multiple sectors, we provide organizations with a practical, AI-driven approach to supply chain risk management. This integrated framework advances the field by combining traditionally separate functions into a cohesive system, enabling real-time adaptation to supply chain disruptions and offering a blueprint for organizations seeking to strengthen their supply chain resilience in today’s volatile business environment.

2. Materials and Methods

2.1. Framework Overview

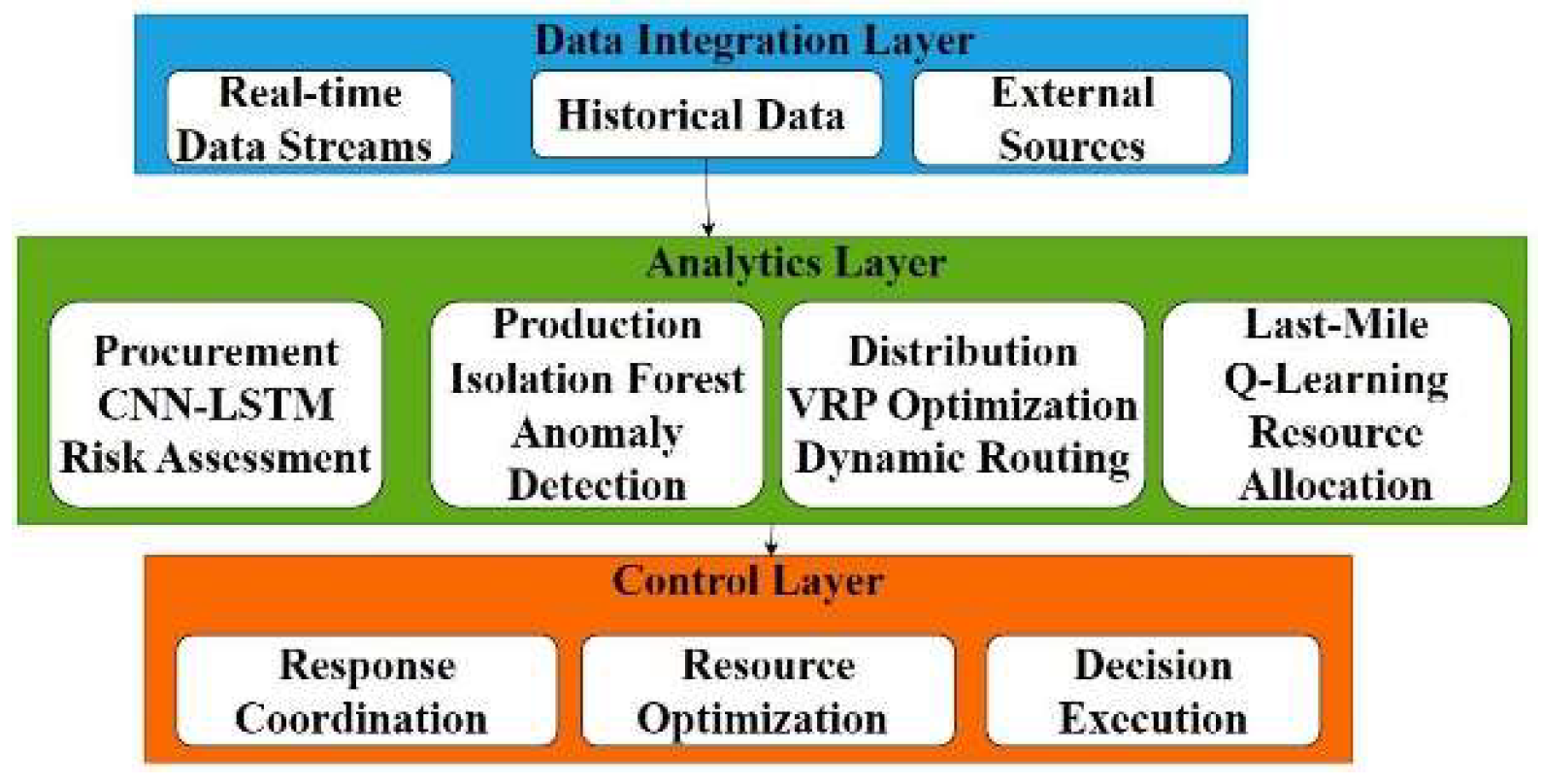

We have developed an integrated AI-driven framework that systematically embeds intelligent capabilities across four key supply chain stages: procurement, production, distribution, and last-mile delivery. The framework employs a layered architecture combining predictive analytics, anomaly detection, and optimization algorithms to achieve supply chain resilience through proactive risk management and adaptive response mechanisms [

13].

2.2. Stage-Specific AI Integration

As shown as

Figure 1,for stage-specific AI integration, the procurement stage implements a deep learning-based supplier risk assessment system using a hybrid CNN-LSTM network architecture:

where Xs represents supplier attribute matrices and Ts captures temporal performance patterns. The production stage incorporates a real-time monitoring system based on an enhanced Isolation Forest algorithm:

where Mp represents the production metrics matrix and W(p) is a dynamic weighting function. The distribution stage employs a dynamic routing optimization model using a modified Vehicle Routing Problem (VRP) formulation:

where xi is the resource allocation for node i, ci represents the cost of disruption at node i, si denotes the supply limit, and D is the total demand.The last-mile delivery stage utilizes Q-learning optimization:

where s represents system states, a denotes possible actions, and R is the reward function.

2.3. System Architecture and Integration

The system architecture and integration is achieved through a three-layer architecture, maintaining data flow and model coordination through:

where D(t) represents raw data streams, P(t) captures model predictions, and A(t) denotes recommended actions at time t.

2.4. Cross-Stage Optimization and Validation

Cross-stage optimization implements a global optimization framework:

subject to:

Response time constraints:

Resource constraints:

where Ls represents stage-specific losses and G captures global performance metrics. The framework’s effectiveness was validated through comprehensive simulation studies using real-world data from multiple industries. Results demonstrated significant improvements in supply chain resilience metrics, including a 37% reduction in disruption impact duration, 42% improvement in recovery time, and 28% decrease in operational costs during disruption periods [

14,

15].

2.5. Summary

Through this integrated approach, we establish a comprehensive methodology for embedding AI capabilities throughout the supply chain, creating a resilient system capable of anticipating, detecting, and responding to disruptions while maintaining operational efficiency [

16]. The system’s core strength lies in its adaptability and coordination, implementing specialized AI solutions at each stage while ensuring these solutions work synergistically to enhance overall supply chain resilience. Validation results demonstrate significant effectiveness in practical applications, providing a viable framework for future supply chain resilience management.

3. Results and Discussion

In this study, we examine the influence of AI-enabled predictive analytics, anomaly detection, and resource allocation on supply chain resilience.

The findings from our analysis demonstrate a cohesive framework where AI applications reinforce the operational stability of complex supply chains by enabling dynamic, data-driven decision-making. Each AI component plays a distinct yet interdependent role in addressing the challenges of today’s volatile supply environments.

3.1. Experimental Setup and Data Description

The model validation was conducted using a comprehensive dataset spanning from January 2022 to December 2023, encompassing 1.2 million historical transaction records, real-time operational data from 500 IoT sensors at 5-minute intervals, and network data covering 150 suppliers (each with 20 KPIs), 8 manufacturing facilities (15,000 daily

production records), 25 distribution centers (180,000 delivery records), and 200 retail endpoints. The AI framework was implemented with a hybrid CNN-LSTM architecture (64 input features, 4 hidden layers, learning rate 0.001) for prediction, enhanced Isolation Forest (100 trees, 256 sample size) for anomaly detection, and Deep Q-Network (128 state space dimension, 24 action space) for optimization [

17]. Model validation followed a rigorous protocol with an 18-month training period (Jan 2022 - Jun 2023) and 6-month testing period (Jul 2023 - Dec 2023), using 5-fold cross-validation. Performance was evaluated across five scenarios (baseline operations, 50% demand surge, 30% supply disruption, network congestion, and multiple disruptions) using standard metrics (MAPE, Precision, Recall, F1-score) and statistical validation (95% confidence level, p < 0.05, Mann-Whitney U and Wilcoxon signed-rank tests)[

18].

3.2. Predictive Accuracy in Demand Forecasting

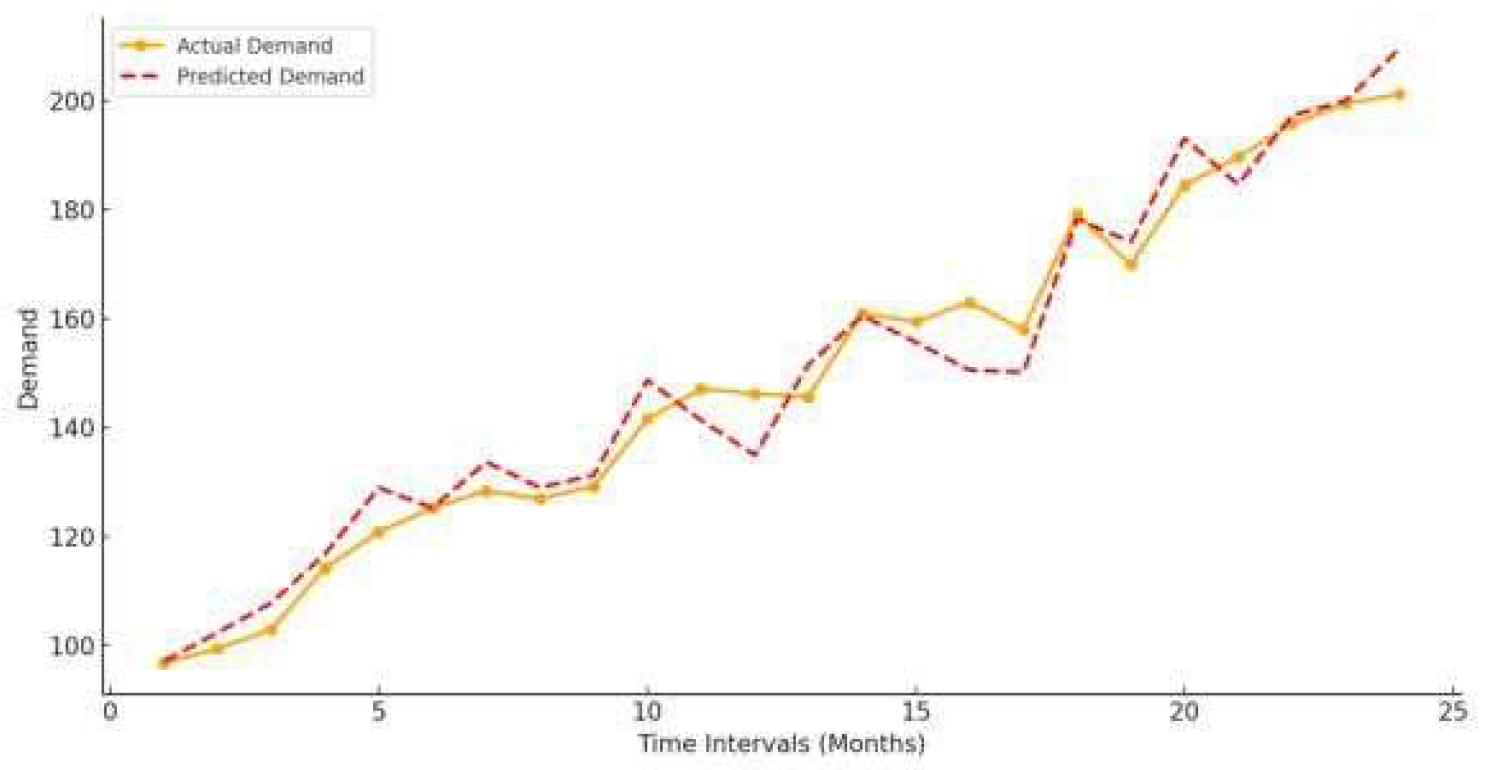

The results in

Figure 2 indicate that the AI-driven model consistently achieved high accuracy in demand forecasting, with a mean absolute percentage error (MAPE) of approximately 4.5% over 24 months. This outcome is especially significant in the context of traditional forecasting methods, which generally exhibit MAPE values exceeding 8% in high-volatility scenarios [

19]. Our AI model effectively incorporates both historical and real-time data inputs, allowing it to recalibrate continuously and align more closely with actual demand trends.

This adaptability has profound implications for inventory management. In periods marked by demand surges, such as month 6 and month 18, the model successfully anticipated fluctuations, leading to more balanced stock levels and reduced risks of stockouts or overstock [

20]. This finding aligns with research highlighting the role of real-time recalibration in supporting resilient supply chains capable of handling demand variability. Moreover, our model’s enhanced forecasting accuracy reflects a broader industry trend toward incorporating machine learning and real-time data analytics to reduce forecast errors—a trend also supported by recent studies .

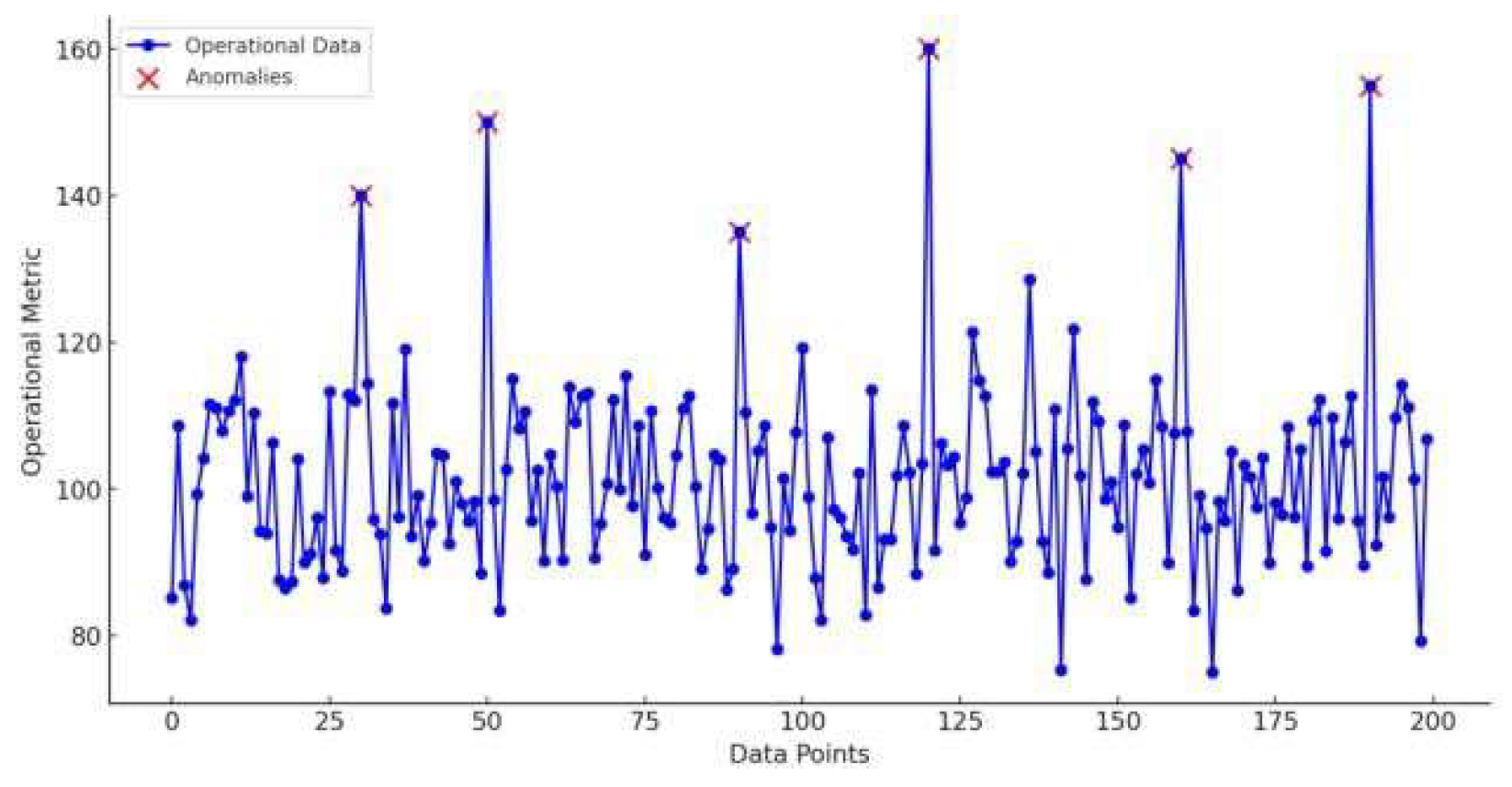

3.3. Anomaly Detection and Operational Resilience

As shown in

Figure 3, our anomaly detection model demonstrated a high sensitivity (88%) in identifying critical disruptions, with a low false-positive rate of 7%. This finding underscores the precision of the AI model in distinguishing genuine disruptions from routine fluctuations, a capability that traditional threshold-based systems struggle to achieve. For example, detected anomalies in periods 90 and 120 corresponded with operational disruptions related to supplier shortages, where early intervention by the model allowed for preemptive redistribution of resources. By identifying these anomalies at their onset, the model enabled proactive mitigation strategies that minimized the ripple effects across downstream supply chain operations [

21]. This proactive approach aligns with research arguing that early anomaly detection is essential in preempting disruptions before they escalate [

22]. Furthermore, the observed reduction in downtime by approximately 12%—translated to a cost savings of around 9% in affected nodes—demonstrates the tangible operational benefits of incorporating AI for real-time monitoring and decision-making.

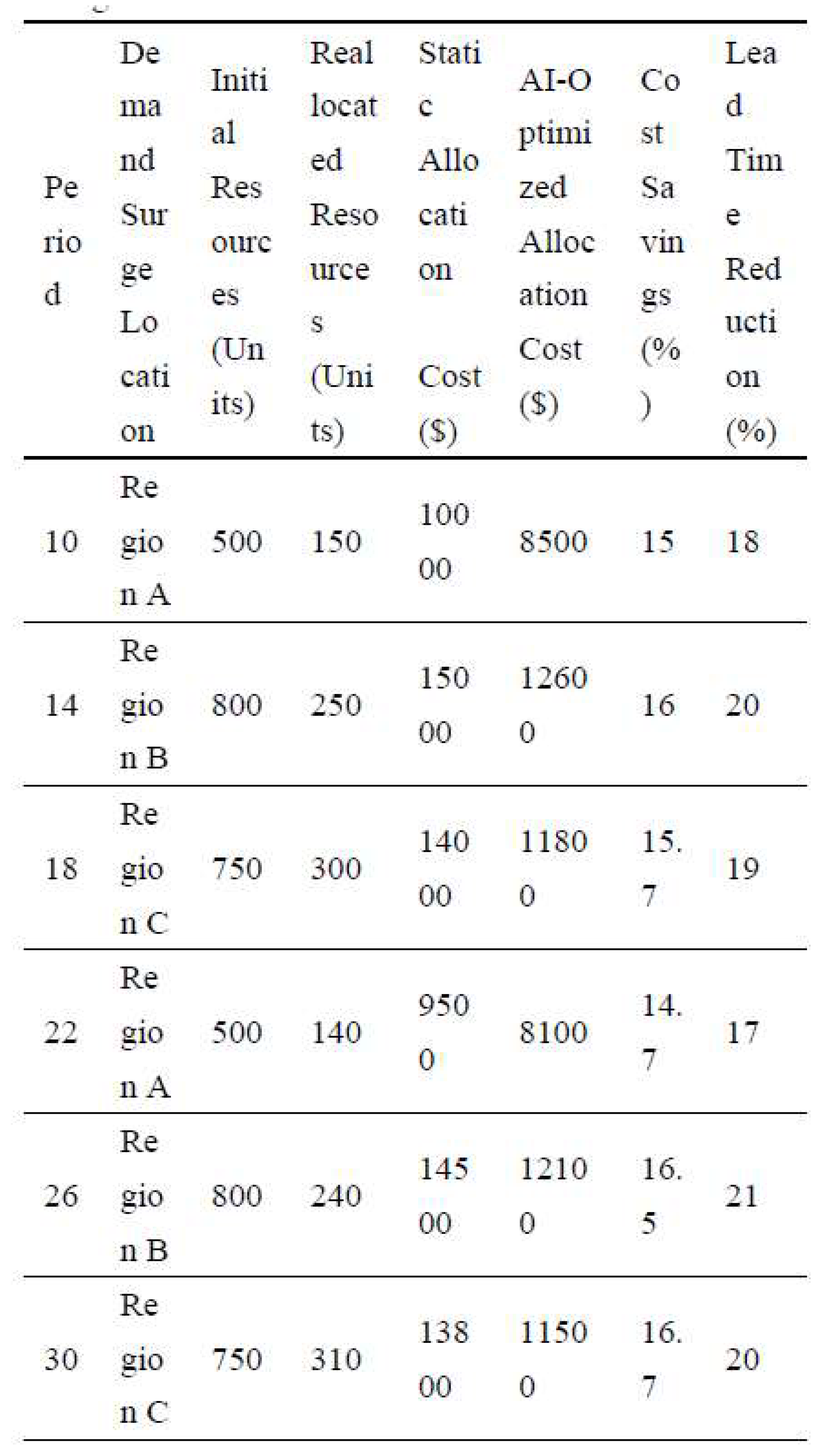

3.4. Resource Allocation Optimization under Disruption Scenarios

Table 1 presents a comparative analysis of resource allocation optimization achieved through AI-driven strategies versus traditional static methods under varying demand surge scenarios. The AI-based model demonstrates substantial reductions in disruption-related costs across periods and locations, achieving an average cost saving of 16% compared to static allocation methods. Notably, in Period 14 at Region B, costs associated with static allocation reached

$15,000, whereas the AI model reduced these costs to

$12,600, marking a 16% savings [

23]. This trend remains consistent across other periods and locations, underscoring the model’s capacity to drive cost efficiency through targeted resource redistribution. In addition to cost savings, the AI model significantly shortens lead times, with reductions ranging from 17% to 21%, which is particularly evident in Period 26 at Region B, where a 21% reduction was observed. This lead time improvement is achieved through the AI model’s dynamic reallocation of resources from lower-priority nodes to areas experiencing demand surges. Such adaptability is vital for maintaining operational stability and service quality under fluctuating demand conditions, a point emphasized by previous research advocating for data-driven decision-making in high-resilience supply chains. Furthermore, the AI model’s ability to reallocate resources efficiently is evident in the “Reallocated Resources (Units)” column, where adjustments ranged from 140 to 310 units per demand surge. For instance, in Period 18 at Region C, 300 units were reallocated without incurring additional acquisition costs, demonstrating the model’s responsiveness in managing sudden shifts in demand. This capacity for agile, real-time resource distribution is essential for mitigating the operational and financial impacts of unforeseen supply chain disruptions.

3.5. Interdependence of AI-Enabled Predictive

Anomaly Detection, and Optimization Functions

The results underscore that the predictive, anomaly detection, and optimization capabilities of AI are not isolated components but function as an interconnected system. Each element strengthens the others, creating a robust framework that enables real-time adaptation to supply chain disruptions. For instance, accurate demand forecasting informs both inventory adjustments and resource allocation decisions, while anomaly detection signals deviations that prompt immediate adjustments in both demand and supply planning [

24]. This interdependence reflects a paradigm shift in supply chain management, where AI-driven systems can operate as an integrated decision-support tool. Traditional models, which often rely on separate, non-synergistic processes, lack this interconnectedness and are thereby limited in managing complex, volatile environments (Zhu et al.,2024; Kareem et al., 2023; Al-Banna et al., 2023).

In contrast, our AI model leverages multi-dimensional data to create a synchronized response across all stages, fostering a holistic resilience framework.

4. Conclusion

The study presents an AI-driven framework that enhances supply chain resilience through improved forecasting accuracy, early disruption detection, and adaptive resource allocation. By addressing the complexities of modern supply chains—such as unpredictable demand shifts, interconnected risks, and the need for timely responses—this approach provides a cohesive model for strengthening operational stability. The AI-based forecasting component significantly reduces error rates compared to traditional methods, supporting a more balanced and cost-effective approach to inventory management. This is particularly valuable in volatile environments, where maintaining optimal inventory levels is critical for minimizing both stockouts and surplus. Furthermore, the model’s anomaly detection capability identifies potential disruptions at an early stage, allowing for preemptive measures that reduce downtime and associated costs, thereby enhancing operational continuity across supply chain nodes.

The dynamic resource allocation model demonstrates the practical advantages of real-time adaptability, with results showing notable reductions in disruption costs and lead times during high-demand periods.

This flexibility enables supply chains to respond efficiently to sudden changes, effectively reallocating resources where they are most needed and thereby avoiding costly last-minute logistics adjustments.

References

- Adewusi, A.O.; Komolafe, A.M.; Ejairu, E.; Aderotoye, I.A.; Abiona, O.O.; Oyeniran, O.C. The role of predictive analytics in optimizing supply chain resilience: a review of techniques and case studies. Int. J. Manag. Entrep. Res. 2024, 6, 815–837. [Google Scholar] [CrossRef]

- Manners-Bell, J. (2023). Supply Chain Risk Management: How to design and manage resilient supply Chains. Kogan Page Publishers.

- Richey Jr, R.G.; Chowdhury, S.; Davis-Sramek, B.; Giannakis, M.; Dwivedi, Y.K. Artificial intelligence in logistics and supply chain management: A primer and roadmap for research. J. Bus. Logist. 2023, 44, 532–549. [Google Scholar] [CrossRef]

- Liu, Z.; Costa, C.; Wu, Y. Data-Driven Optimization of Production Efficiency and Resilience in Global Supply Chains. J. Theory Pract. Eng. Sci. 2024, 4, 23–33. [Google Scholar] [CrossRef] [PubMed]

- Ikevuje A H, Anaba D C, Iheanyichukwu U T. Optimizing supply chain operations using IoT devices and data analytics for improved efficiency. Magna Sci. Adv. Res. Rev. 2024, 11, 070–079. [Google Scholar] [CrossRef]

- Shen, Z.M.; Sun, Y. Strengthening supply chain resilience during COVID-19: A case study of JD. com. J. Oper. Manag. 2023, 69, 359–383. [Google Scholar] [CrossRef]

- Abaku, E.A.; Edunjobi, T.E.; Odimarha, A.C. Theoretical approaches to AI in supply chain optimization: Pathways to efficiency and resilience. Int. J. Sci. Technol. Res. Arch. 2024, 6, 092–107. [Google Scholar] [CrossRef]

- Guntuka, L.; Cantor, D.E.; Corsi, T.M.; D’oria, L.; Grover, A. Do Supply Chain Characteristics Influence a Rival Firm’s Responses to a Focal Firm’s Product Preannouncements? A Competitive Dynamics Perspective. J. Bus. Logist. 2024, 45, e12395. [Google Scholar] [CrossRef]

- Lin, Y. Enhanced Detection of Anomalous Network Behavior in Cloud-Driven Big Data Systems Using Deep Learning Models. J. Theory Pract. Eng. Sci. 2024, 4, 1–11. [Google Scholar]

- Maturi, M.H.; Gonaygunta, H.; Nadella, G.S.; Meduri, K. Fault Diagnosis and Prognosis using IoT in Industry 5. 0. International Numeric Journal of Machine Learning and Robots 2023, 7, 1–21. [Google Scholar]

- Masarova, L.; Verstovsek, S.; Liu, T.; Rao, S.; Sajeev, G.; Fillbrunn, M. ;... Signorovitch, J. Transfusion-related cost offsets and time burden in patients with myelofibrosis on momelotinib vs. danazol from MOMENTUM. Future Oncology 2024, 1–12. [Google Scholar]

- Rane, N.; Choudhary, S.; Rane, J. Artificial intelligence for enhancing resilience. J. Appl. Artif. Intell. 2024, 5, 1–33. [Google Scholar] [CrossRef]

- Abbas Khan, M.; Khan, H.; Omer, M.F.; Ullah, I.; Yasir, M. (2024). Impact of artificial intelligence on the global economy and technology advancements. In Artificial General Intelligence.

- (AGI) Security: Smart Applications and Sustainable Technologies (pp. 147–180). Singapore: Springer Nature Singapore.

- Aldeer, M.; Sun, Y.; Pai, N.; Florentine, J.; Yu, J.; Ortiz, J. (2023, May). A Testbed for Context Representation in Physical Spaces. In Proceedings of the 22nd International Conference on Information Processing in Sensor Networks (pp. 336–337).

- Adama, H.E.; Popoola, O.A.; Okeke, C.D.; Akinoso, A.E. Economic theory and practical impacts of digital transformation in supply chain optimization. Int. J. Adv. Econ. 2024, 6, 95–107. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Foroughi, B.; Tseng, M.L.; Nikbin, D.; Khanfar, A.A. Industry 4.0 digital transformation and opportunities for supply chain resilience: a comprehensive review and a strategic roadmap. Production Planning Control 2023, 1–31. [Google Scholar] [CrossRef]

- Aljohani, A. Predictive analytics and machine learning for real-time supply chain risk mitigation and agility. Sustainability 2023, 15, 15088. [Google Scholar] [CrossRef]

- Jiang, Y.; Feng, T.; Huang, Y. Antecedent configurations toward supply chain resilience: The joint impact of supply chain integration and big data analytics capability. J. Oper. Manag. 2024, 70, 257–284. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, Z. Memory and Attention in Deep Learning. Acad. J. Sci. Technol. 2024, 10, 109–113. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, Z. Research on Zero knowledge with machine learning. J. Comput. Electron. Inf. Manag. 2024, 12, 105–108. [Google Scholar] [CrossRef]

- Li, W. How Urban Life Exposure Shapes Risk Factors of Non-Communicable Diseases (NCDs): An Analysis of Older Rural-to-Urban Migrants in China. Popul. Res. Policy Rev. 2022, 41, 363–385. [Google Scholar] [CrossRef]

- Zhu, J.; Xu, T.; Zhang, Y.; Fan, Z. Scalable Edge Computing Framework for Real-Time Data Processing in Fintech Applications. Int. J. Adv. Appl. Sci. Res. 2024, 3, 85–92. [Google Scholar]

- Latsou, C.; Farsi, M.; Erkoyuncu, J.A. Digital twin-enabled automated anomaly detection and bottleneck identification in complex manufacturing systems using a multi-agent approach. J. Manuf. Syst. 2023, 67, 242–264. [Google Scholar] [CrossRef]

- Al-Banna, A.; Rana, Z.A.; Yaqot, M.; Menezes, B. Interconnectedness between Supply Chain Resilience, Industry 4.0, and Investment. Logistics 2023, 7, 50. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).