Submitted:

17 March 2025

Posted:

18 March 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

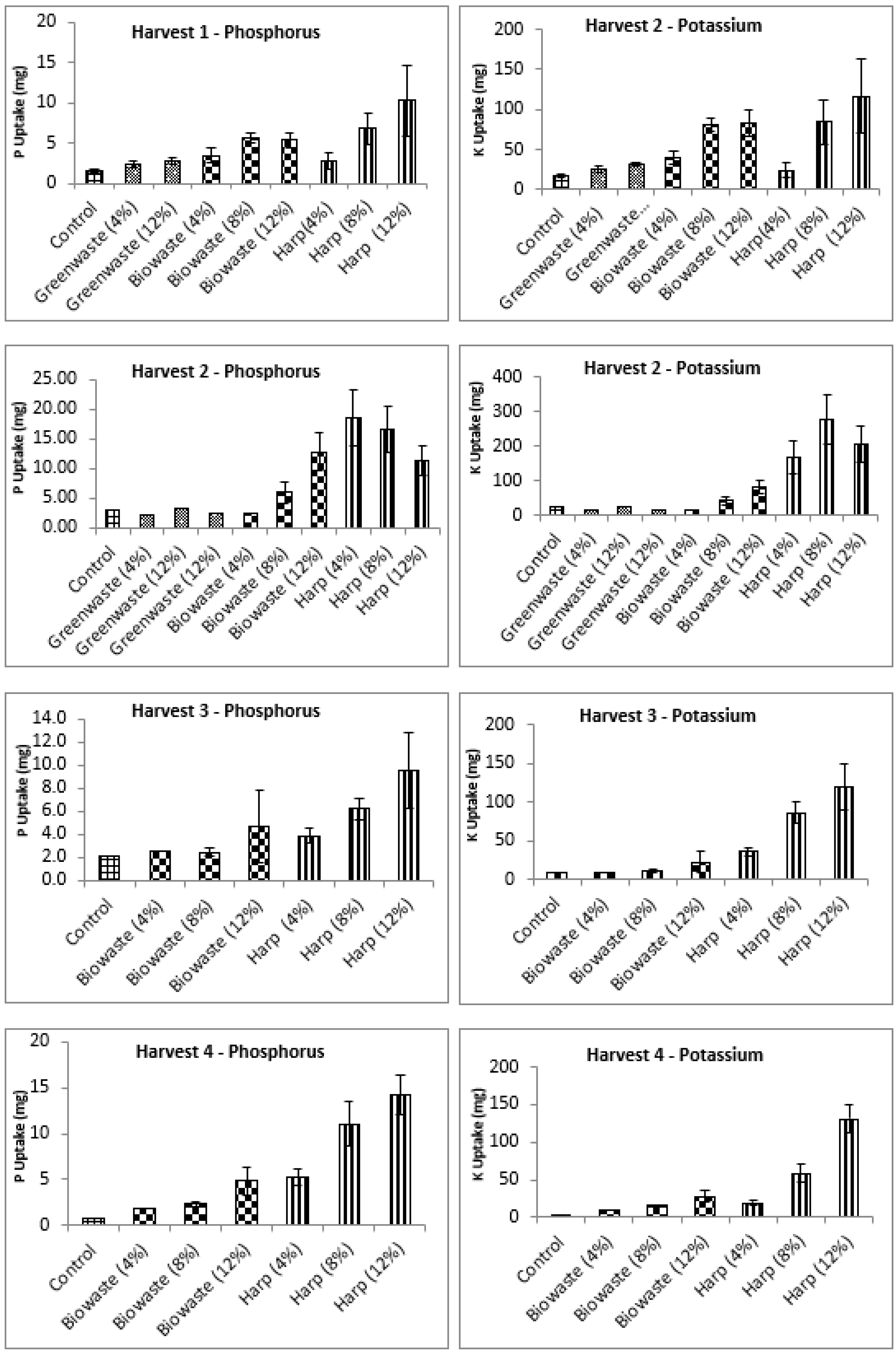

3. Results and Discussion

3.1. Effect of Addition of Enzymes Versus Thermal Drying

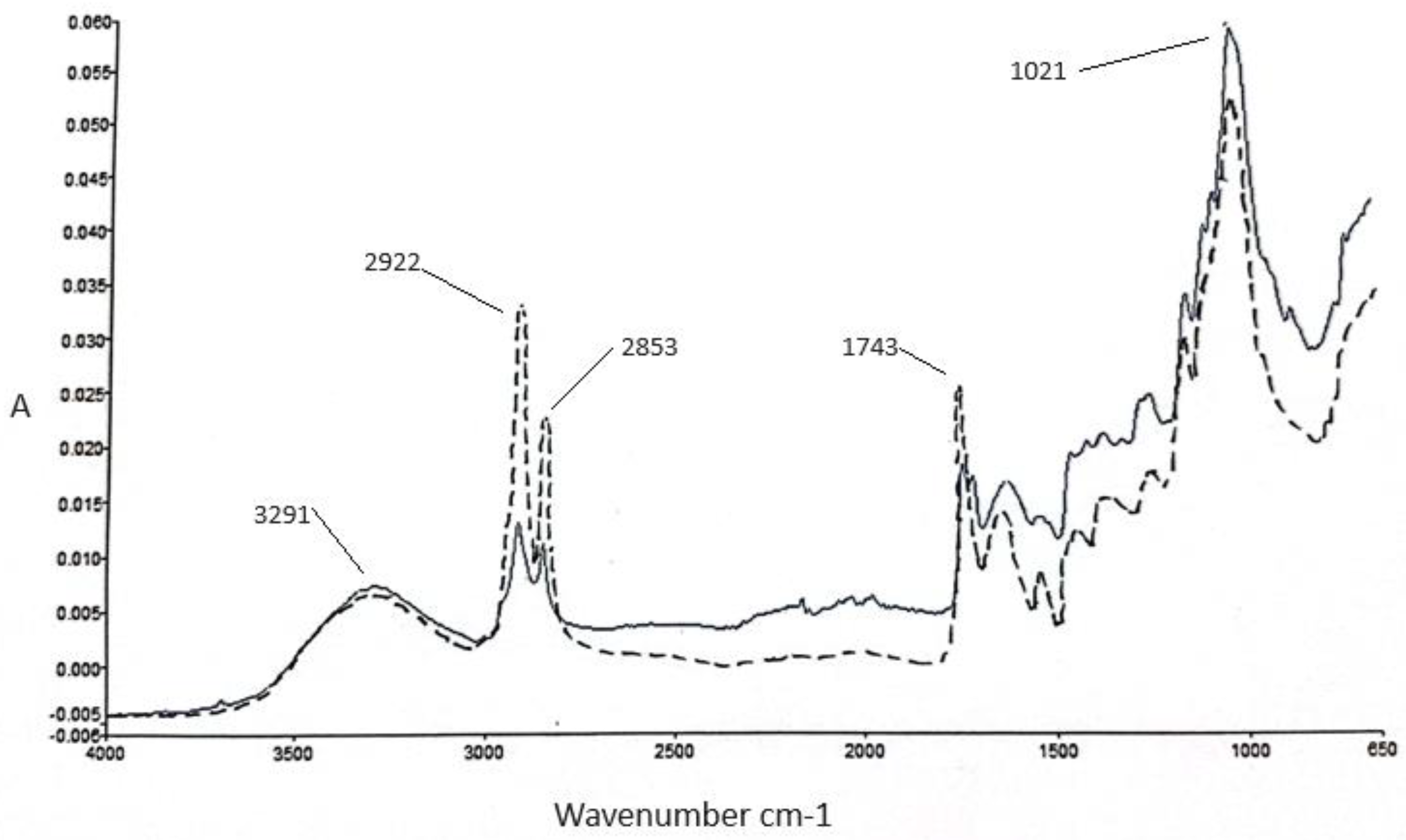

| Wave Number cm-1 | Significance Level |

|---|---|

| 3200 | p=0.086 NS OH (phenols, carboxylic groups) |

| 2930 | p=<0.001 C-H stretching of alkyl structures |

| 2830 | p=<0.001 C-H stretching of alkyl structures |

| C=O stretching of carboxyl, acids and ketones | |

| 1720 | p=<0.001 ketones |

| 1620 | NS Aromatic C=C. COO-, C=O |

| 1460 | p=<0.0001 C-H stretching of aiphatic structures |

| 1148 | p=<0.001 C-O stretching of polysaccharides |

| 1017 | p=<0.002 Increase silica, carbohydrates |

| 2920/1620 | p=<0.001 |

| 1720/1017 | p=0.001 |

| pH | EC | Ext.N | Ext.P | Ext.K | |

|---|---|---|---|---|---|

| μS/cm | mg/L | mg/L | mg/L | ||

| Untreated | 5.0 | 7793 | 35.8 | 973 | 5566 |

| treated | 5.3 | 8250 | 44.2 | 1360 | 7541 |

| Sig. | x | NS | NS | NS | NS |

| Ammonium (NH4+) | Nitrate (NO3-) | ||||

|---|---|---|---|---|---|

| Material | Dry Sample (mg/Kg) | Fresh Sample (mg/L) | Dry Sample (mg/Kg) | Fresh Sample (mg/L) | |

| Harp product | 427.4 | 210 | 103.8 | 51 | |

| Greenwaste | 79 | 20 | 122.5 | 31 | |

| BioWaste | 227.5 | 128.5 | 211.5 | 119.5 | |

| Application Rate (Volume/ml) | Weight of Addition (g) | Dry Weight of Addition (g) | TKN (Addition) (g) | NH4 (Addition) (g) | NO3 (Addition) (g) | P (Addition) (g) | K (Addition) (g) | Organic Matter (g) | Organic Carbon (g) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Harp product (4%) | 80 | 45.6 | 39.31 | 1.217 | 0.0168 | 0.0041 | 0.0481 | 0.4720 | 35.179944 | 20.439744 |

| Harp product (8%) | 160 | 91.2 | 78.61 | 2.435 | 0.0336 | 0.0082 | 0.0962 | 0.9440 | 70.359888 | 40.879488 |

| Harp product (12%) | 320 | 136.8 | 117.92 | 3.652 | 0.0504 | 0.0122 | 0.1443 | 1.4160 | 105.539832 | 61.319232 |

| Greenwaste (4%) | 80 | 46.16 | 20.22 | 0.472 | 0.0016 | 0.0025 | 0.0060 | 0.1707 | 9.1992264 | 5.3577912 |

| Greenwaste (8%) | 160 | 92.32 | 40.44 | 0.944 | 0.0032 | 0.0050 | 0.0120 | 0.3414 | 18.3984528 | 10.7155824 |

| Greenwaste (12%) | 320 | 138.48 | 60.65 | 1.416 | 0.0048 | 0.0074 | 0.0180 | 0.5120 | 27.5976792 | 16.0733736 |

| Biowaste (4%) | 80 | 49.6 | 45.19 | 0.616 | 0.0103 | 0.0096 | 0.0034 | 0.1117 | 10.392688 | 6.0548704 |

| BioWaste (8%) | 160 | 99.2 | 90.37 | 1.232 | 0.0206 | 0.0191 | 0.0067 | 0.2233 | 20.785376 | 12.1097408 |

| Biowaste (12%) | 320 | 148.8 | 135.56 | 1.848 | 0.0308 | 0.0287 | 0.0101 | 0.3550 | 31.178064 | 18.1646112 |

4. Conclusions

Supplementary Materials

Acknowledgments

References

- Alejandra Cerda, Adriana Artola, Xavier Font, Raquel Barrena, Teresa Gea, Antoni Sánchez.

- A Composting of food wastes: Status and challenges.

- Bioresource Technology 248 (2018) 57–67. [CrossRef]

- Alexander, R- Composting, Food Waste, Markets.

- Electric Kitchen “Composter” Confusion, Biocycle September 25, 2023.

- Axis Environmental Services. Limerick 2016, Report No.4580-16-01 www.axisenv.ie.

- Azis, F.A.; Choo, M.; Suhaimi, H.; Abas, P.E. The Effect of Initial Carbon to Nitrogen Ratio on Kitchen Waste Composting Maturity. Sustainability 2023, 15, 6191. https:/doi.org/10.3390/su15076191.

- Cao, Y. et al., Mitigation of ammonia, nitrous oxide, and methane emissions during solid waste.

- composting with different additives: A meta-analysis, J. Clean. Prod., vol. 235, pp. 626–635, Oct.

- 2019. [CrossRef]

- Chrysargyris, A., Panayiotou, C., Tzortzakis, N., 2016. Nitrogen and phosphorus levels affected plant growth, essential oil composition and antioxidant status of lavender plant (Lavandula angustifolia Mill.). Ind. Crops Prod. 83, 577–586. [CrossRef]

- Dong-Qing Zhang, Pin-Jing He *, Tai-Feng Jin, Li-Ming Shao.

- Bio-drying of municipal solid waste with high water content by aeration.

- procedures regulation and inoculation.

- Bioresource Technology 99 (2008) 8796–8802. [CrossRef]

- EEA Report No 3/2011, Using a life-cycle perspective, this report analyses the greenhouse gas emissions (GHG) from municipal solid waste management in the EU.

- Hwang HY, Kim SH, Shim J, Park SJ. Composting Process and Gas Emissions during Food Waste Composting under the Effect of Different Additives. Sustainability. 2020; 12(18):7811. [CrossRef]

- IS EN 13037-2002 Determination of PH.

- IS EN 13038-2002 Determination of Electrical Conductivity.

- IS EN 13650:2001 Extraction of aqua regia soluble elements.

- IS EN 13654-2:2002 – Soil improvers and growing media – determination of N – part 2 Dumas method.

- IS EN 13651-2002 Soil Improvers and Growing Media -Extraction of Calcium Chloride/DTPA (CAT), Soluble nutrients. 2002.

- IS EN 13038:2011 Soil improvers and growing media –Determination of Electrical Conductivity.

- IS EN 13039:2011Soil improvers and growing media - Determination of organic matter content and ash.

- Jiao Ma, Lei Zhang, Lan Mu, Kongyun Zhu, Aimin Li.

- Thermally assisted bio-drying of food waste: Synergistic enhancement and energetic evaluation. Waste Management 80 (2018) 327–338. [CrossRef]

- JRC-IPTS (Joint Research Centre Institute for Prospective Technological Studies), 2008. End-of waste Criteria. Draft report. European Commission Joint Research Centre, Seville, Spain.

- Naturemill composters http://www.peoplepoweredmachines.com/naturemill/naturemill_plus.htm.

- Lucas Lourenço Castiglioni Guidoni , Roger Vasques Marques ,Rodrigo Bilhalva Moncks, Fabiana Torma Botelho, Matheus Francisco da Paz,Luciara Bilhalva Corr^ea , _Erico Kunde Corr^ea.,.

- Home composting using different ratios of bulking agent to food waste.

- Journal of Environmental Management 207 (2018) 141-150. [CrossRef]

- Prasad, M. and Foster, P., 2008. Development of an Industry-led Standard Quality Standard for Source separated Biodegradable Materials Derived Compost. Environmental Protection Agency, Johnstown Castle, Ireland.

- Prasad, M., Lee, A. and Gaffney, M.T., 2012. A Detailed Chemical and Nutrient Characterization of Compost and Digestate Fiber. rx3, Department of Environment, Dún Laoghaire, Ireland.

- REGULATION (EU) 2019/1009, Laying down rules on the making available on the market of EU fertilising product, Publishing European Commission Web portal. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32019R1009&from=EN.

- SUMMARY STATE FERTILIZER LAWS 2003, Fertilizer Institute Product Quality &Technology Committee Publishing document. site. https://documen.site/download/2003-summary-state-fertilizer-laws_pdf.

| Arsenic (As) | Copper (Cu) | Chromium (Cr) | Lead (Pb) | Mercury (Hg) | Nickel (Ni) | Zinc (Zn) | |

|---|---|---|---|---|---|---|---|

| NN | mg/kg | mg/kg | mg/kg | mg/kg | mg/kg | mg/kg | mg/kg |

| Mean | 1 | 9.06 | 2.14 | 2.48 | 0.11 | 2.22 | 74.38 |

| SD | 0.5 | 6.53 | 0.91 | 2.66 | 0.03 | 1.09 | 76.94 |

| n=12 | n=14 | n=10 | n=13 | n=9 | n=13 | n=14 | |

| EU Fertilizer/Soil Improver https://eur-lex.europa.eu/eli/reg/2019/1009/oj ( |

na | 300 | na | 120 | 1 | 50 | 800 |

| N | P2O5 | K2O | Ca | Mg | S | NPK Index (5.1% EU Fert. Regs [15]) | Total Organic Carbon | |

| % | % | % | % | % | % | % | ||

| Mean | 2.81 | 0.85 | 1.57 | 1.18 | 0.15 | 1.09 | 5.23% | 45.7 |

| SD | 0.25 | 0.04 | 0.17 | 0.26 | 0.06 | 0.23 | 2.8 | |

| n=70 | n=70 | n=70 | n=70 | n=70 | n=70 | n=70 |

| Material | Bulk Density (g/L) | Moisture % | Organic Matter % | Organic Carbon % | pH | EC (μS/cm) | C:N ratio |

|---|---|---|---|---|---|---|---|

| Harp product | 570 | 13.8 | 89.5 | 52 | 5.5 | 5410 | 16 |

| Greenwaste | 577 | 56.2 | 45.5 | 26.5 | 8.7 | 970 | 11 |

| Biowaste Compost | 600 | 8.9 | 23 | 13.4 | 7.8 | 2120 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).