Submitted:

12 March 2025

Posted:

13 March 2025

You are already at the latest version

Abstract

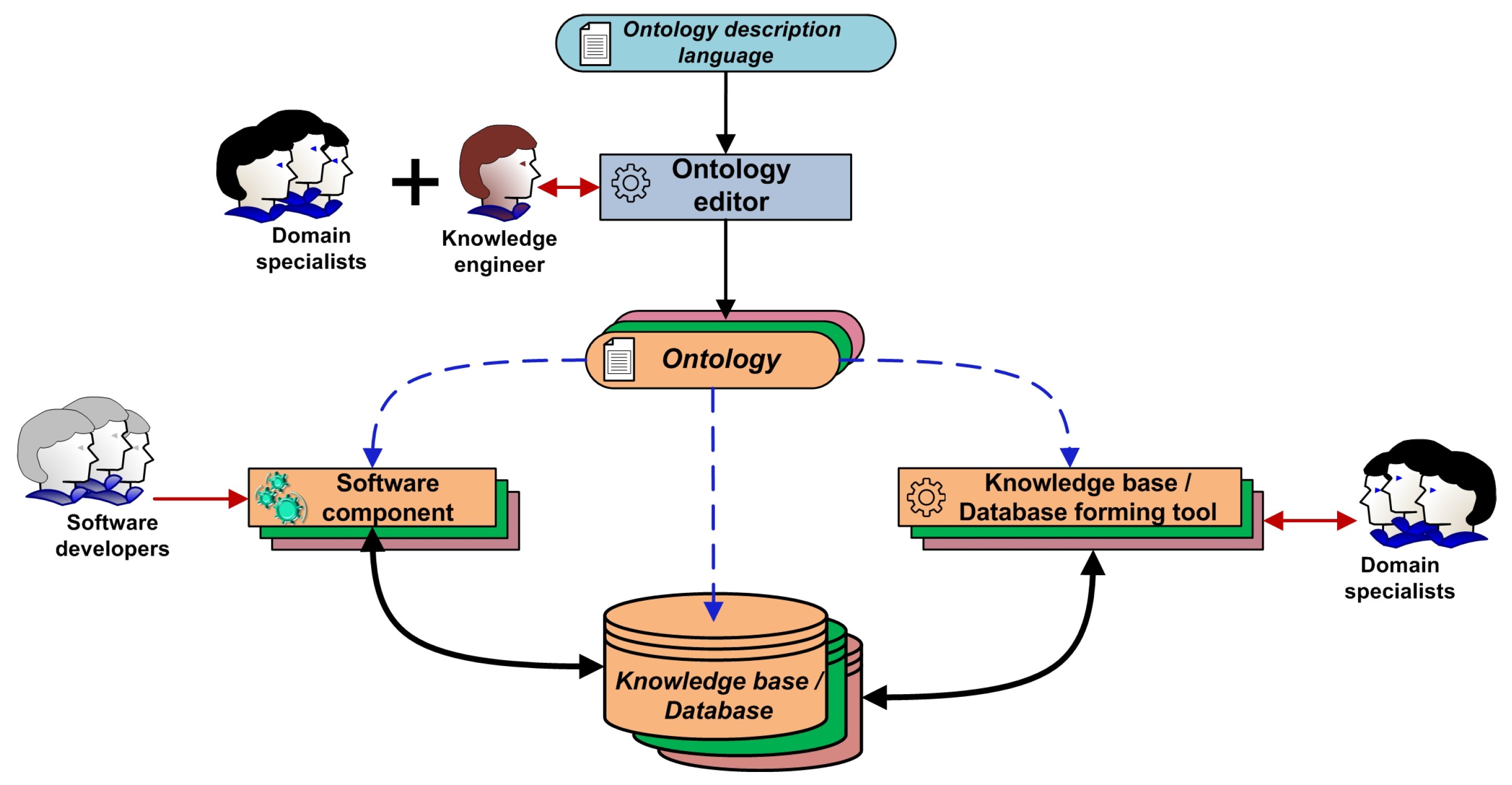

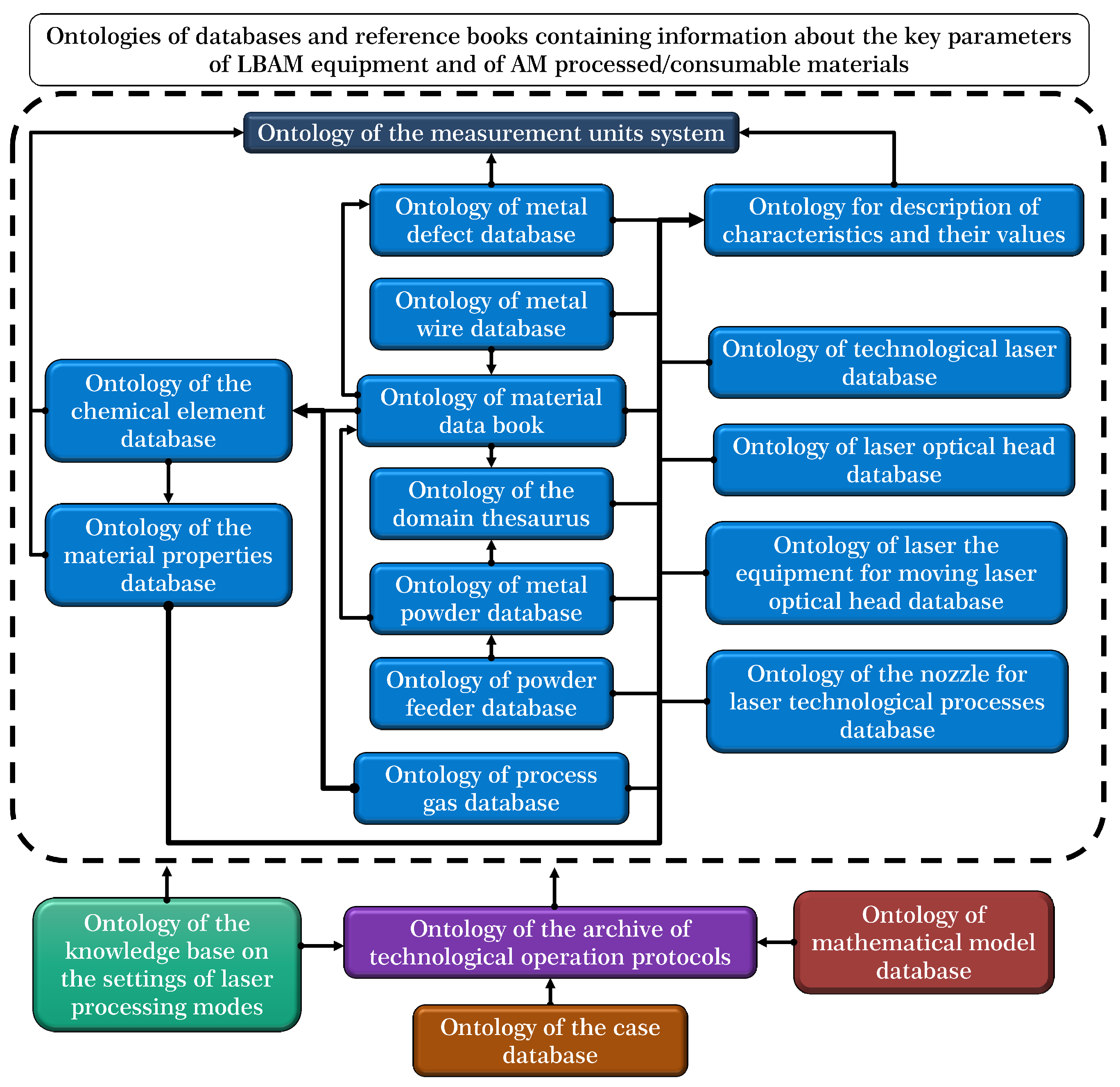

Obstacles that hinder the mass adoption of additive manufacturing (AM) processes for fabrication and processing of metal parts are discussed. The necessity of integrating an intelligent decision support system (DSS) into the professional activities of AM process engineers is proved. Advantages of applying a two-level ontological approach to the creation of semantic information for developing an ontology-based DSS are pointed out. Its key feature is that ontological models are clearly separated from data & knowledge bases formed on their basis. An ensemble of ontological models is presented, which is the basis for the intelligent DSS being developed. The ensemble includes ontologies for equipment and materials reference databases, a library of laser processing technological operation protocols, knowledge base of settings used for laser processing and for mathematical model database. The ensemble of ontological models is implemented at IACPaaS cloud platform. Ontologies, databases and knowledge base, as well as DSS, are part of the laser-based AM knowledge portal, which was created and is being developed on the platform. Knowledge and experience obtained by various technologists and accumulated in the portal will allow us to lessen a number of trial experiments for finding suitable settings and to reduce requirements to skills of users.

Keywords:

1. Introduction

2. Materials and Methods

3. Results

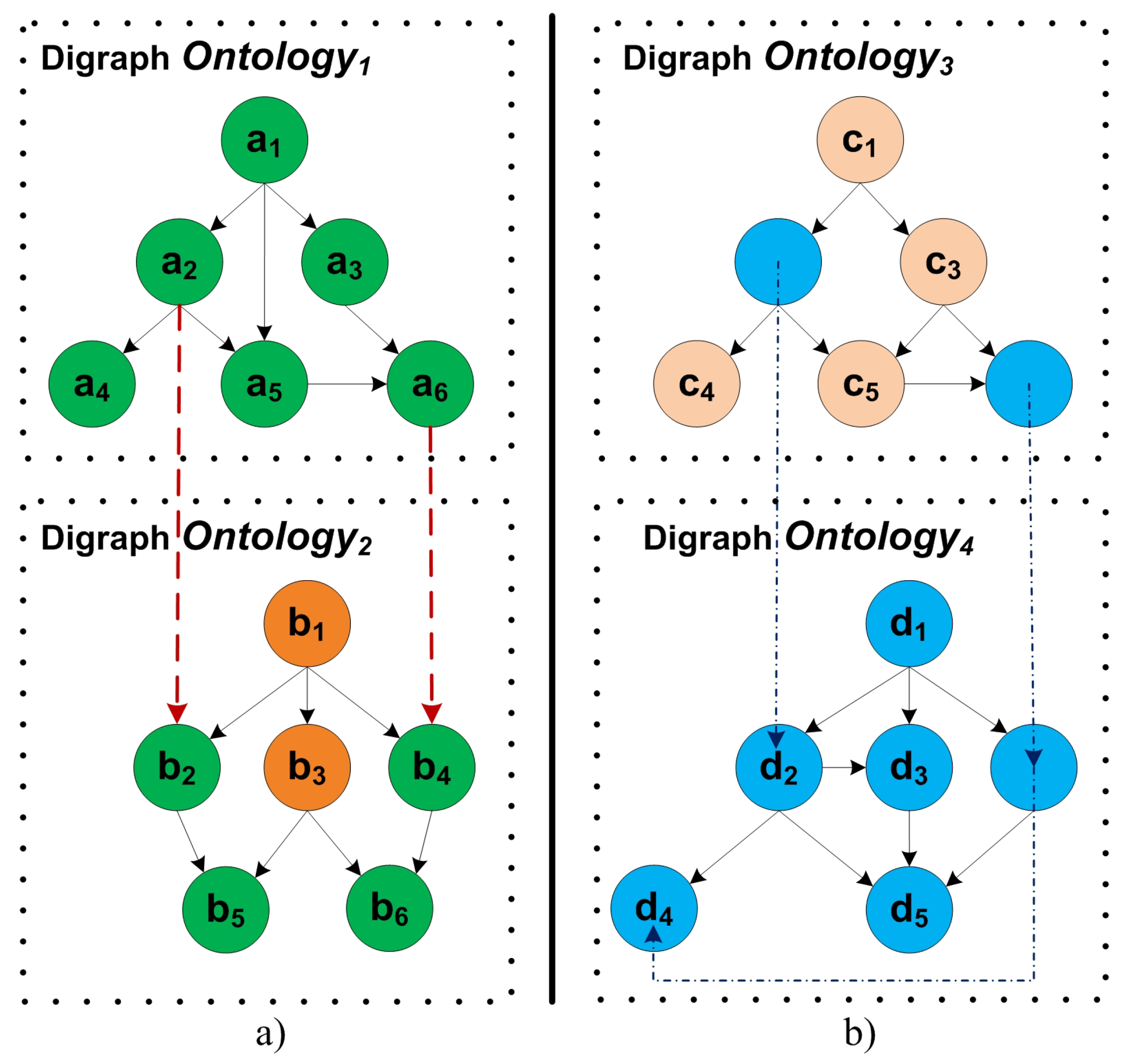

- Structural coherence. The directed connections between the concepts of ontologies (arcs between vertices of corresponding ontology digraphs) determine the multiple use in some digraph of the ontology of subgraphs of digraphs of other ontologies. Such subgraphs can represent either a single terminal vertex or a digraph as a whole. In Figure 3a, connections of this type are represented by dotted arcs → and →. Vertices , , , belong to the digraph of the , but they become attainable and thus logically included in the digraph.

- Terminological coherence. Such directed connections are set for labels of ontology concepts and determine the fact that labels are “borrowed” by some vertices of the digraph (which in this case do not have their own labels) from other vertices whose labels are their own. In Figure 3b, connections of this type are represented by dash-and-dot arrows coming out of vertices that do not have their own labels and entering vertices with their own labels – and , respectively.

- These are one-to-many relationships: the label of one vertex can be borrowed by many vertices other than it.

- A vertex with its own label and vertices with borrowed labels from it can belong to different digraphs or to the same digraph. At the same time, there may be or may not be a path in the digraph between a vertex with its own label and a vertex that borrows this label.

- The borrowing of a label can be both direct and indirect. In the first case, for a pair of vertices, one of them necessarily has its own label, and the other borrows it. This case is represented by a vertex with its own label and a vertex that is a direct descendant of vertex . In the second case, the vertex whose label is being borrowed may also have not its own label, but borrow the label of another vertex. This situation is iterative, and the condition for completion is the occurrence of the first case. The second case is represented by a two-step iteration, which ends in a situation where one of the vertices in the pair becomes a vertex labeled . The natural limitation here is that the sequence of such connections should not form a cycle.

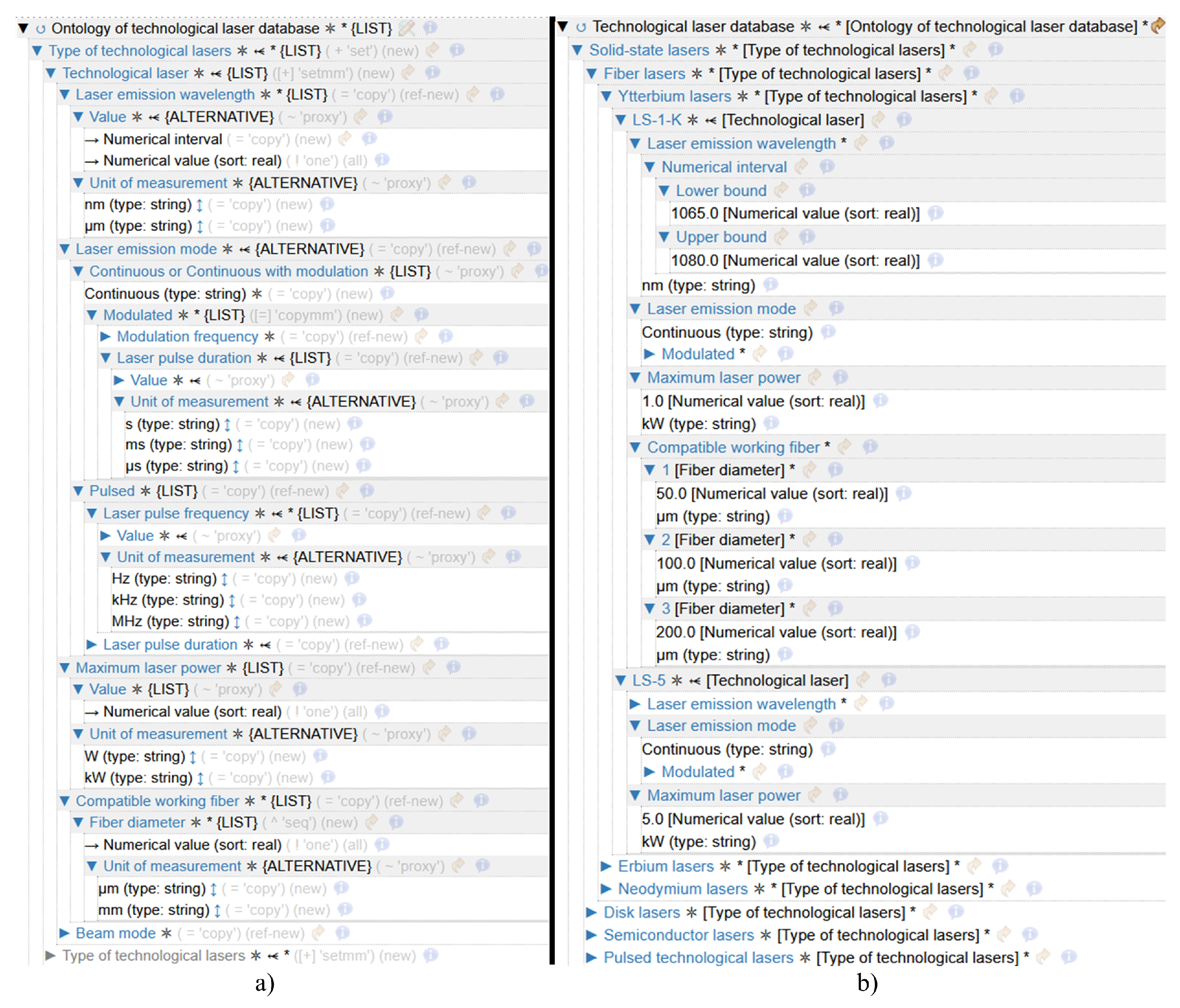

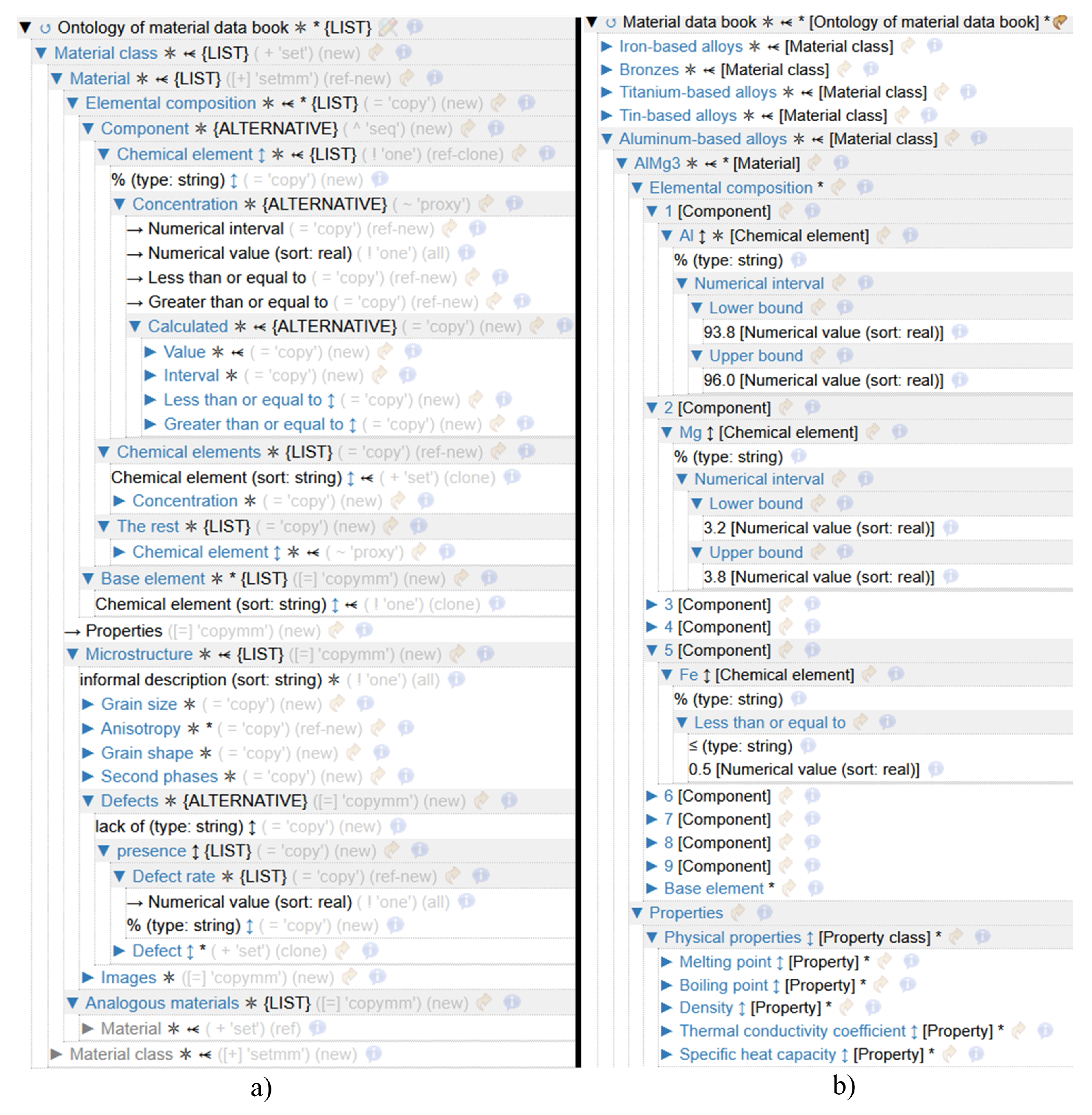

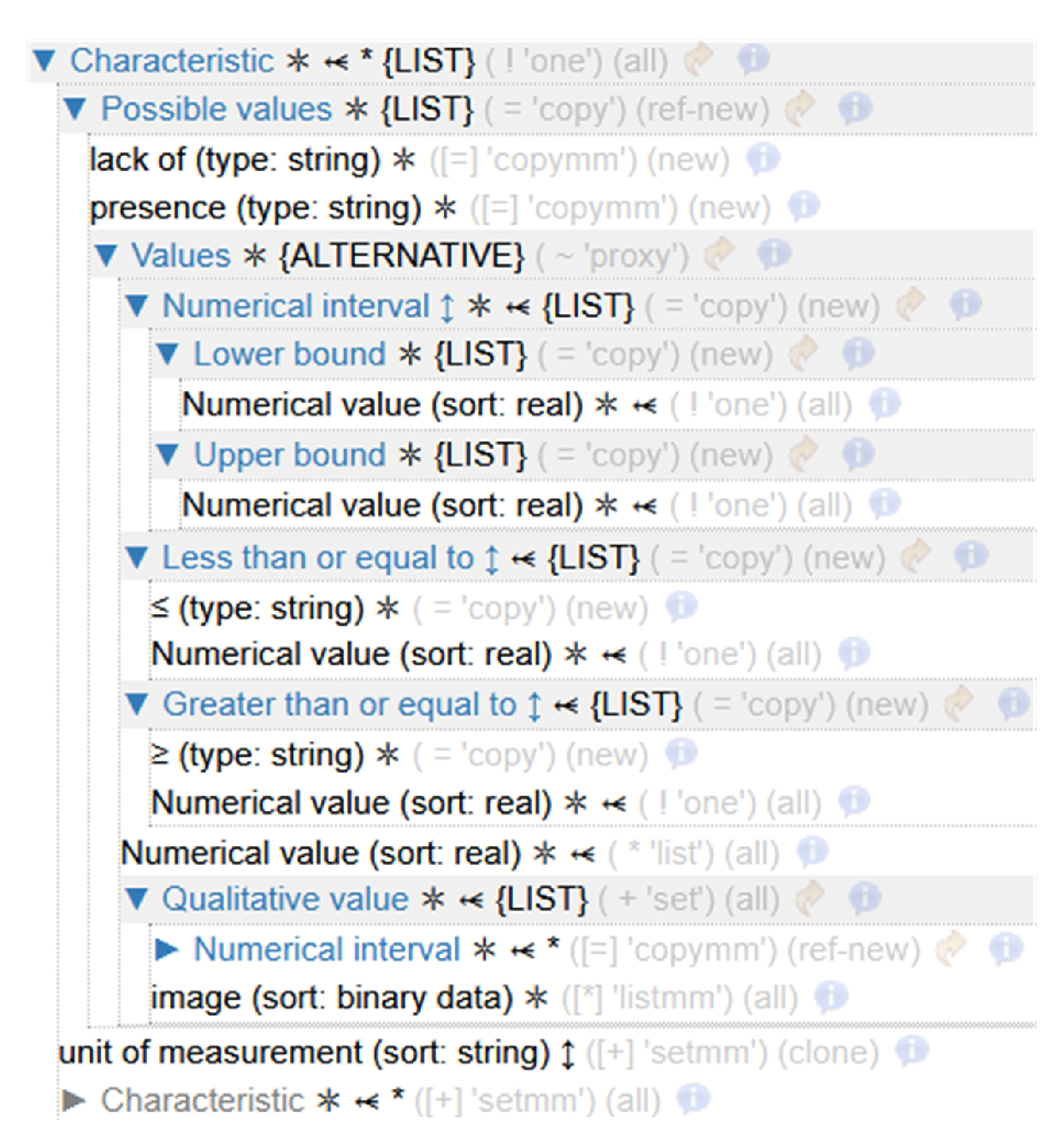

3.1. Ontologies of Reference Databases on Equipment and Materials

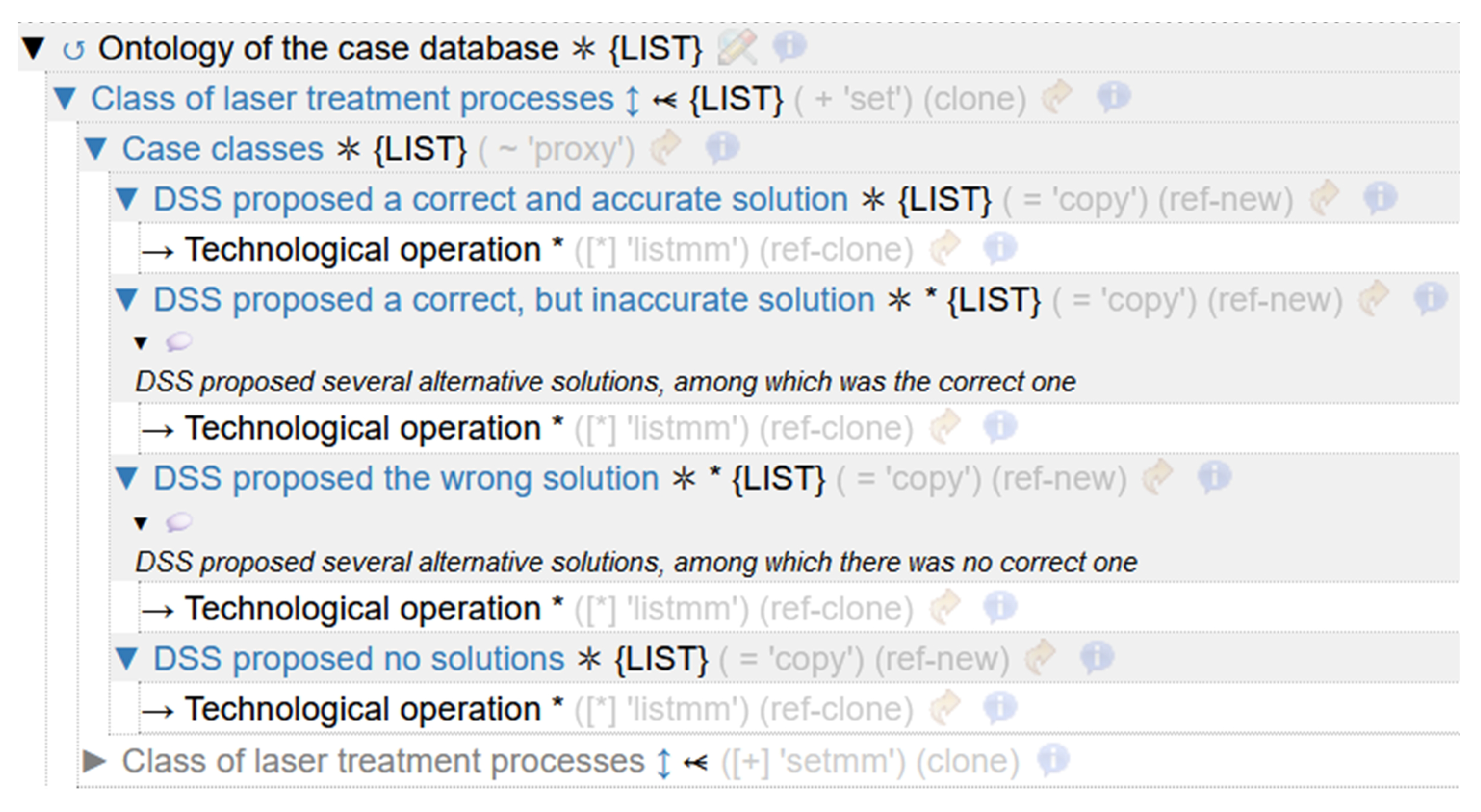

3.2. The Ontology of the Case Database

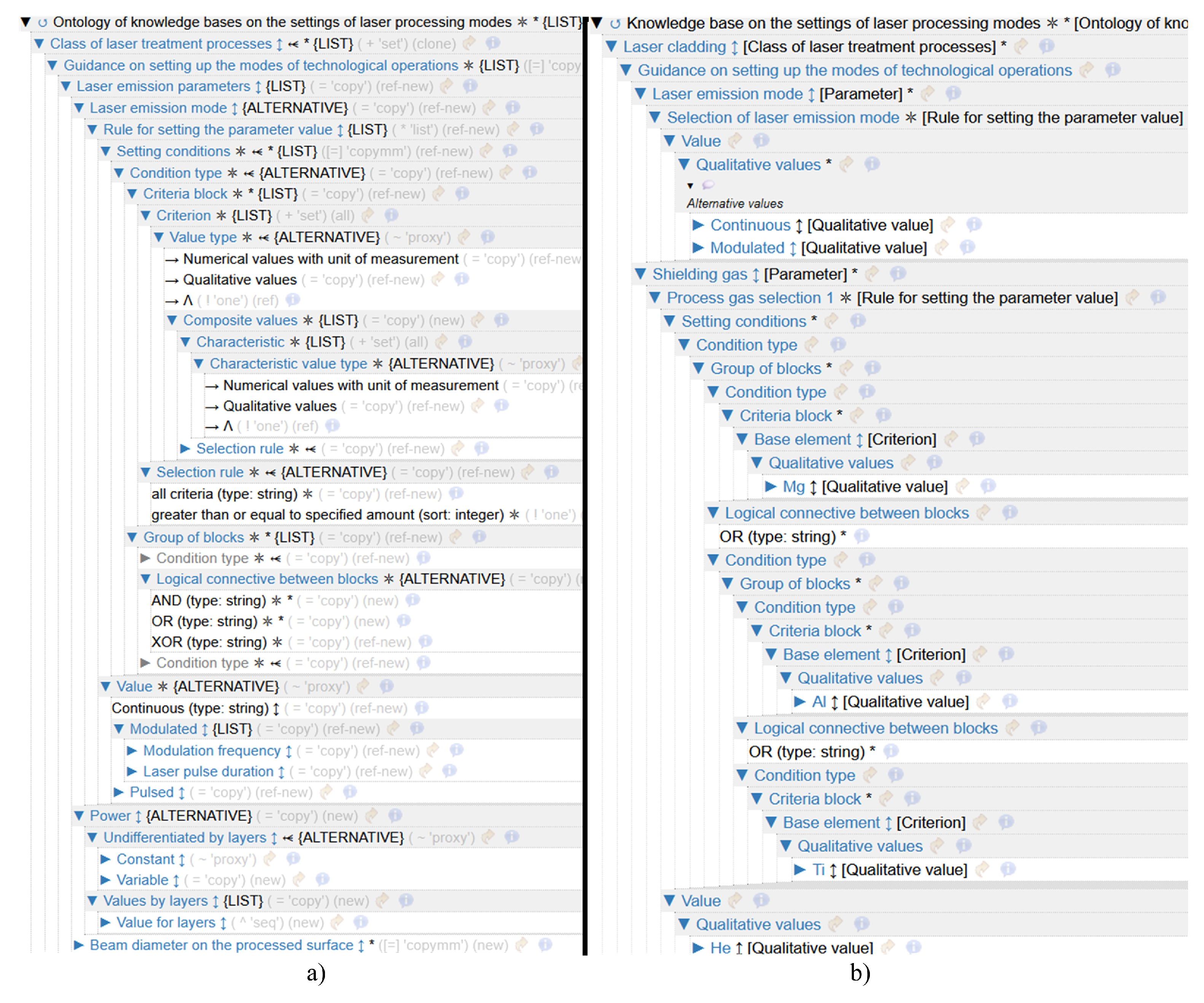

3.3. Ontology of the Knowledge Base

3.4. Implementation of the OM Ensemble

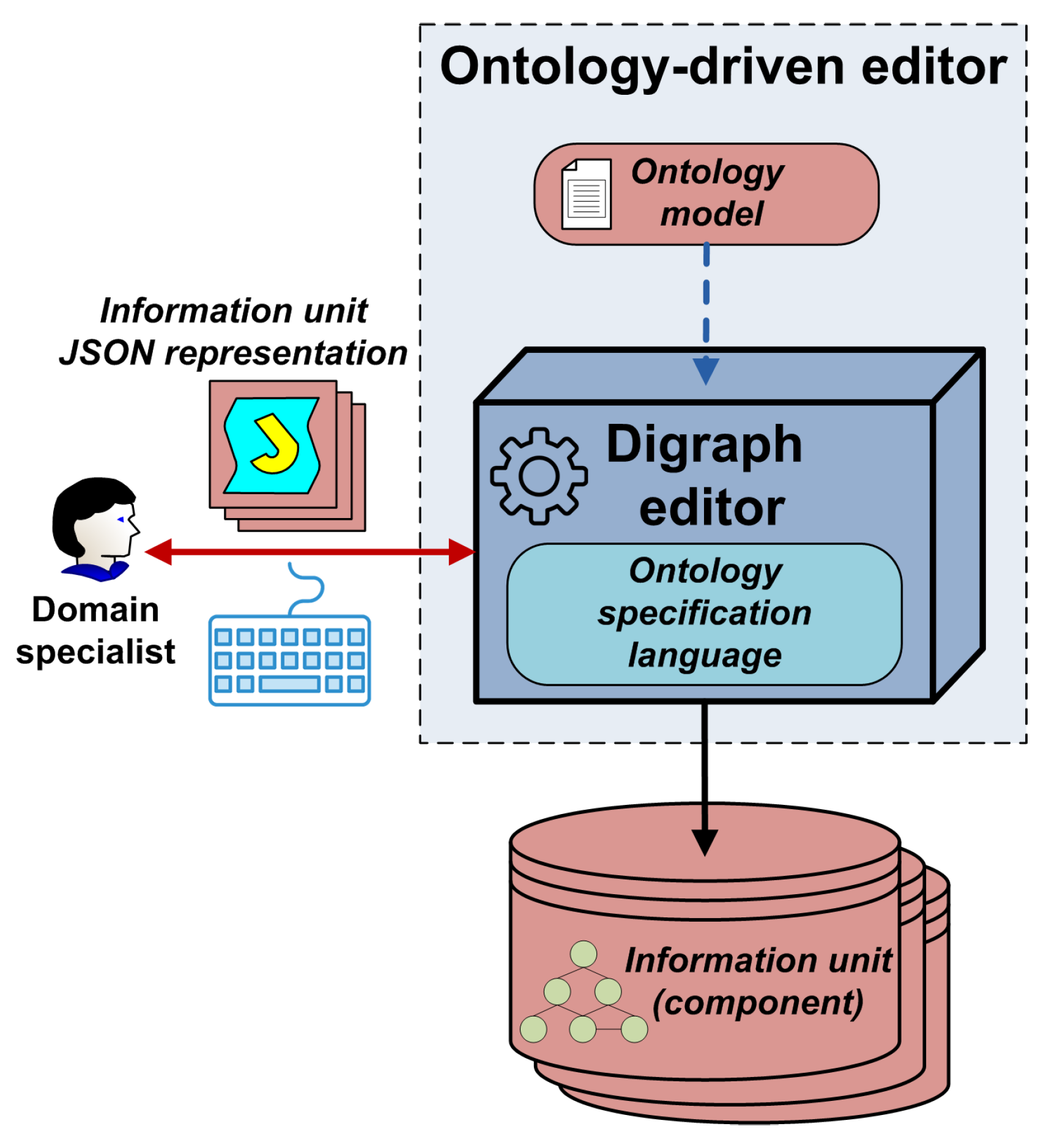

- the editing process is controlled by the ontology model, and the user interface is generated basing on the ontology model;

- when the ontology model is modified, the user interface and the editing process are adapted automatically (if necessary, all corresponding data or knowledge bases are also adjusted to match the modified ontology automatically).

4. Discussion and Future Work

- the possibilities of creating databases and knowledge bases in a conceptual representation and terminology understandable to domain specialists;

- scalability and operational extensibility of the DSS without the involvement of software developers. The emergence of new types of materials (alloys), laser and other technological equipment, the expansion of the range of processed parts, the expansion/modification of knowledge bases should not (in most cases) lead to changes in the developed ontology-oriented algorithms (being developed for interpreting subject databases) that perform reasoning based on concepts and relations specified in ontologies.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Inayathullah, S.; Buddala, R. Review of machine learning applications in additive manufacturing. Results in Engineering 2025, 25, 103676. [Google Scholar] [CrossRef]

- Sibisi, T.H.; Shongwe, M.B.; Tshabalala, L.C.; Mathoho, I. LAM additive manufacturing: a fundamental review on mechanical properties, common defects, dominant processing variables, and its applications. The International Journal of Advanced Manufacturing Technology 2023, 128, 2847–2861. [Google Scholar] [CrossRef]

- Svetlizky, D.; Zheng, B.; Vyatskikh, A.; Das, M.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Laser-based directed energy deposition (DED-LB) of advanced materials. Materials Science and Engineering: A 2022, 840, 142967. [Google Scholar] [CrossRef]

- Zoting, S.; Shivarkar, A. Additive Manufacturing Market Size, Share, and Trends 2025 to 2034. https://www.precedenceresearch.com/additive-manufacturing-market, 2025. (accessed on 18 Feb 2025).

- Wolff, S. Directed Energy Deposition. In Springer Handbook of Additive Manufacturing; Springer: Cham, 2023; pp. 459–474. [Google Scholar] [CrossRef]

- Piscopo, G.; Iuliano, L. Current research and industrial application of laser powder directed energy deposition. The International Journal of Advanced Manufacturing Technology 2022, 119, 6893–6917. [Google Scholar]

- Piscopo, G.; Atzeni, E.; Saboori, A.; Salmi, A. An Overview of the Process Mechanisms in the Laser Powder Directed Energy Deposition. Applied Sciences 2023, 13. [Google Scholar] [CrossRef]

- Blaha, R.; Hajnys, J.; Mesicek, J.; Mechali, A.; Krisak, D.; Pagac, M. Review of Directed Energy Deposition (DED) in Component Repair. In Proceedings of the From Smart City to Smart Factory for Sustainable Future: Conceptual Framework, Scenarios, and Multidiscipline Perspectives, Cham; 2024; pp. 197–205. [Google Scholar] [CrossRef]

- Klahn, C.; Butler, D.; Pei, E. Economics of Additive Manufacturing. In Springer Handbook of Additive Manufacturing; Springer: Cham, 2023; pp. 31–42. [Google Scholar] [CrossRef]

- Soori, M.; Jough, F.K.G.; Dastres, R.; Arezoo, B. Additive Manufacturing Modification by Artificial Intelligence, Machine Learning, and Deep Learning: A Review. Additive Manufacturing Frontiers 2025, 200198. [Google Scholar] [CrossRef]

- Ethiraj, N.; Sivabalan, T.; Sofia, J.; Harika, D.; Nikolova, M.P. A comprehensive review on application of machine intelligence in additive manufacturing. Turkish Journal of Engineering 2025, 9, 37–46. [Google Scholar] [CrossRef]

- Fan, H.l.; Liu, Y.b.; Wang, Z.w.; Han, R.h.; Zheng, M.j.; Qi, H.b. Analysis of powder flow from the nozzle to the substrate in multiangle laser cladding. Journal of Laser Applications 2024, 36, 042080. [Google Scholar] [CrossRef]

- Joshi, S.; Martukanitz, R.P.; Nassar, A.R.; Michaleris, P. Additive manufacturing with metals: Design, processes, materials, quality assurance, and applications; Springer: Cham, 2023. [Google Scholar] [CrossRef]

- Singh, C.; Sharma, N.; Kumar, N. Analysis Of Software Maintenance Cost Affecting Factors And Estimation Models. International Journal of Scientific & Technology Research 2019, 8, 276–281. [Google Scholar]

- Islam, M.; Farooqui, N.; Haleem, M.; Zaidi, S. An Efficient Framework For Software Maintenance Cost Estimation Using Genetic Hybrid Algorithm: OOPs Prospective. International Journal of Computing and Digital Systems 2023, 14, 933–943. [Google Scholar] [CrossRef]

- Gribova, V.V.; Shalfeeva, E.A. Ensuring of viability of systems based on knowledge. Information Technology 2019, 25, 738–746, (In Russ.). [Google Scholar] [CrossRef]

- Xiao, J.; Anwer, N.; Huang, H.; Bonnard, R.; Eynard, B.; Huang, C.; Pei, E. Information exchange and knowledge discovery for additive manufacturing digital thread: a comprehensive literature review. International Journal of Computer Integrated Manufacturing 2024, 1–26. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, P.; Yan, H.; Chen, G.; Sun, T.; Lu, Q.; Chen, Y.; Shi, H. A review of machine learning in additive manufacturing: design and process. The International Journal of Advanced Manufacturing Technology 2024, 135, 1051–1087. [Google Scholar] [CrossRef]

- Beniwal, R.; Abhijeet, K.; Kumar, K.; Sagar, M. Ontology Driven Software Development for Better Understanding and Maintenance of Software System. In Proceedings of the Second International Conference on Sustainable Technologies for Computational Intelligence; Luhach, A.K., Poonia, R.C., Gao, X.Z., Singh Jat, D., Eds.; Singapore, 2022; pp. 73–81. [Google Scholar]

- Listl, F.G.; Fischer, J.; Sohr, A.; Grimm, S.; Weyrich, M. Ontological Architecture for Knowledge Graphs in Manufacturing and Simulation. In Proceedings of the 2022 IEEE 27th International Conference on Emerging Technologies and Factory Automation (ETFA). IEEE, 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Meyers, B.; Vangheluwe, H.; Lietaert, P.; Vanderhulst, G.; Van Noten, J.; Schaffers, M.; Maes, D.; Gadeyne, K. Towards a knowledge graph framework for ad hoc analysis in manufacturing. Journal of Intelligent Manufacturing 2024, 35, 3731–3752. [Google Scholar] [CrossRef]

- Gribova, V.V.; Kleshchev, A.S.; Moskalenko, F.M.; Timchenko, V.A. A two-level model of information units with complex structure that correspond to the questioning metaphor. Automatic Documentation and Mathematical Linguistics 2015, 49, 172–181. [Google Scholar]

- Gribova, V.V.; Kleshchev, A.S.; Moskalenko, F.M.; Timchenko, V.A. A model for generation of directed graphs of information by the directed graph of metainformation for a two-level model of information units with a complex structure. Automatic Documentation and Mathematical Linguistics 2015, 49, 221–231. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Bambach, M. Modelling and simulation of metal additive manufacturing processes with particle methods: A review. Virtual and Physical Prototyping 2023, 18, e2274494. [Google Scholar] [CrossRef]

- Gribova, V.; Kulchin, Y.; Nikitin, A.; Timchenko, V. The Concept of Support for Laser-Based Additive Manufacturing on the Basis of Artificial Intelligence Methods. Lecture Notes in Computer Science 2020, 12412, 403–415. [Google Scholar]

- Gribova, V.; Kulchin, Y.; Nikitin, A.; Velichko, A.; Basakin, A.; Timchenko, V. The Concept of Intelligent Support for Laser Additive Manufacturing Process Engineer. In Proceedings of the Studies in Systems, Decision and Control; Springer, 2023; Vol. 457, pp. 355–368. [Google Scholar] [CrossRef]

- Gribova, V.V.; Moskalenko, P.M.; Timchenko, V.A.; Shalfeeva, E.A. The IACPaaS Platform for Developing Systems Based on Ontologies: A Decade of Use. Scientific and Technical Information Processing 2023, 50, 406–413. [Google Scholar]

- Xiao, J.; Anwer, N.; Huang, H.; Bonnard, R.; Eynard, B.; Huang, C.; Pei, E. Information exchange and knowledge discovery for additive manufacturing digital thread: a comprehensive literature review. International Journal of Computer Integrated Manufacturing 2024, 1–26. [Google Scholar] [CrossRef]

- Gouttebroze, S.; Friis, J.; Hovig, E.W.; Boivie, K. Toward semantic standard and process ontology for Additive manufacturing. IOP Conference Series: Materials Science and Engineering 2023, 1281, 012014. [Google Scholar] [CrossRef]

- Huang, M.; Fan, B.; Chen, L.; Pan, Y.; Qin, Y. Selection of Additive Manufacturing Machines via Ontology-Supported Multi-Attribute Three-Way Decisions. Applied Sciences 2023, 13. [Google Scholar] [CrossRef]

- Phillips, P.J.; Hahn, C.A.; Fontana, P.C.; Yates, A.N.; Greene, K.; Broniatowski, D.A.; Przybocki, M.A. Four principles of explainable artificial intelligence, 2021. (accessed on 06 Feb 2025). [CrossRef]

| 1 | The markup of the digraph arcs is not shown in the figure, in order not to complicate it with insignificant details in this case. |

| 2 | This figure, as well as Figure 5-10, show the user interface of the IACPaaS cloud platform tool (https://iacpaas.dvo.ru/) Digraph editor, which is used to create both ontologies and databases/knowledge bases in the platform’s storage. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).