Submitted:

14 February 2025

Posted:

17 February 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Material and Methods

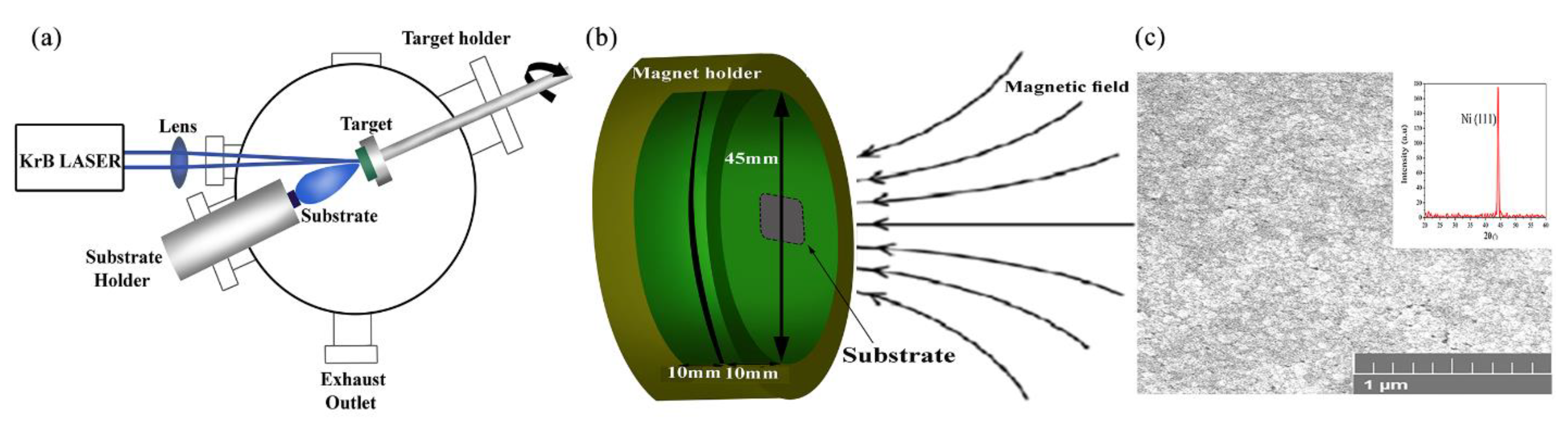

2.1. Graphene Growth

2.2. FeCl3 Intercalation

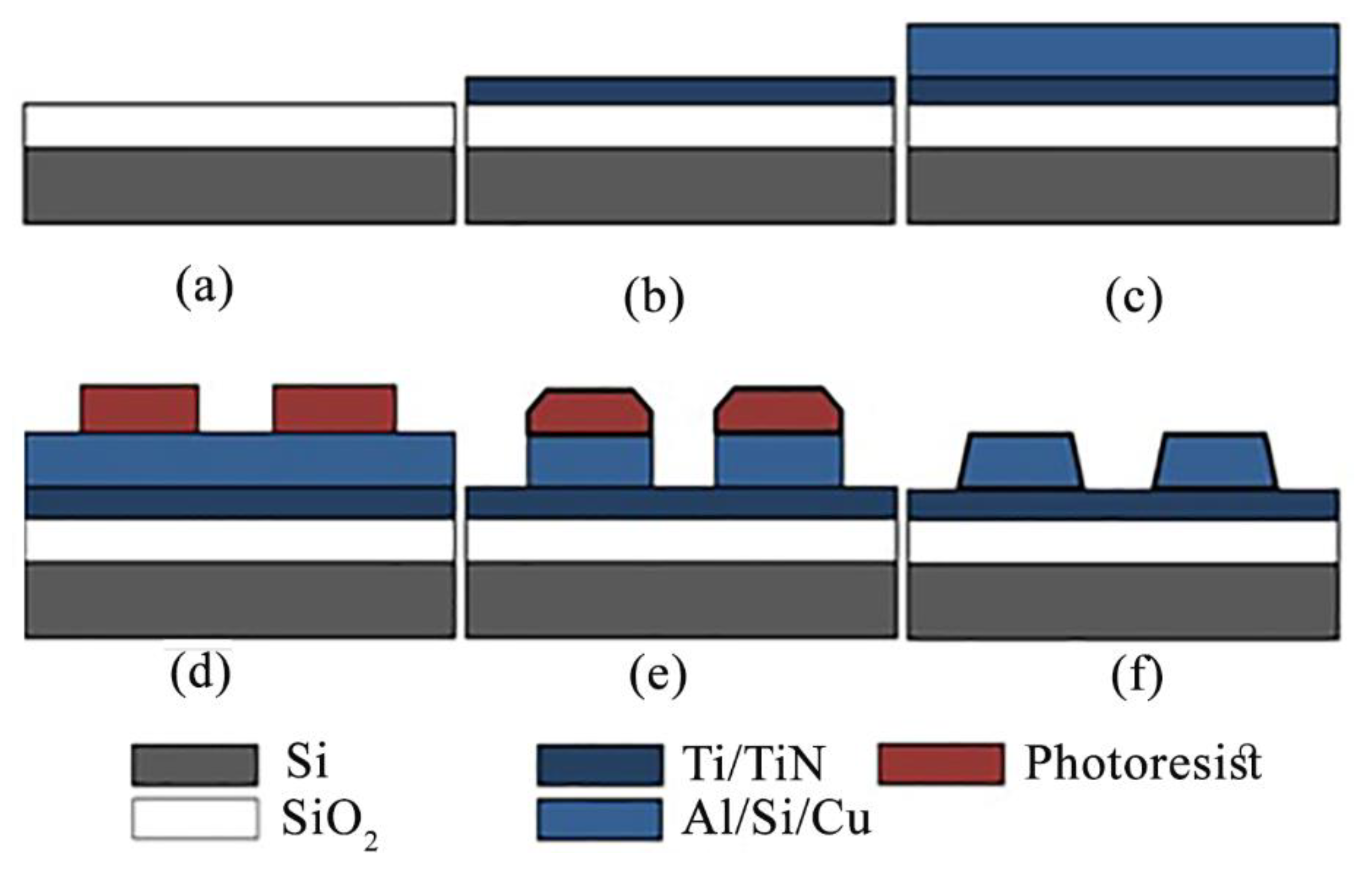

2.3. Metal Contact Fabrication

2.4. Transfer of Grown Graphene to TAM

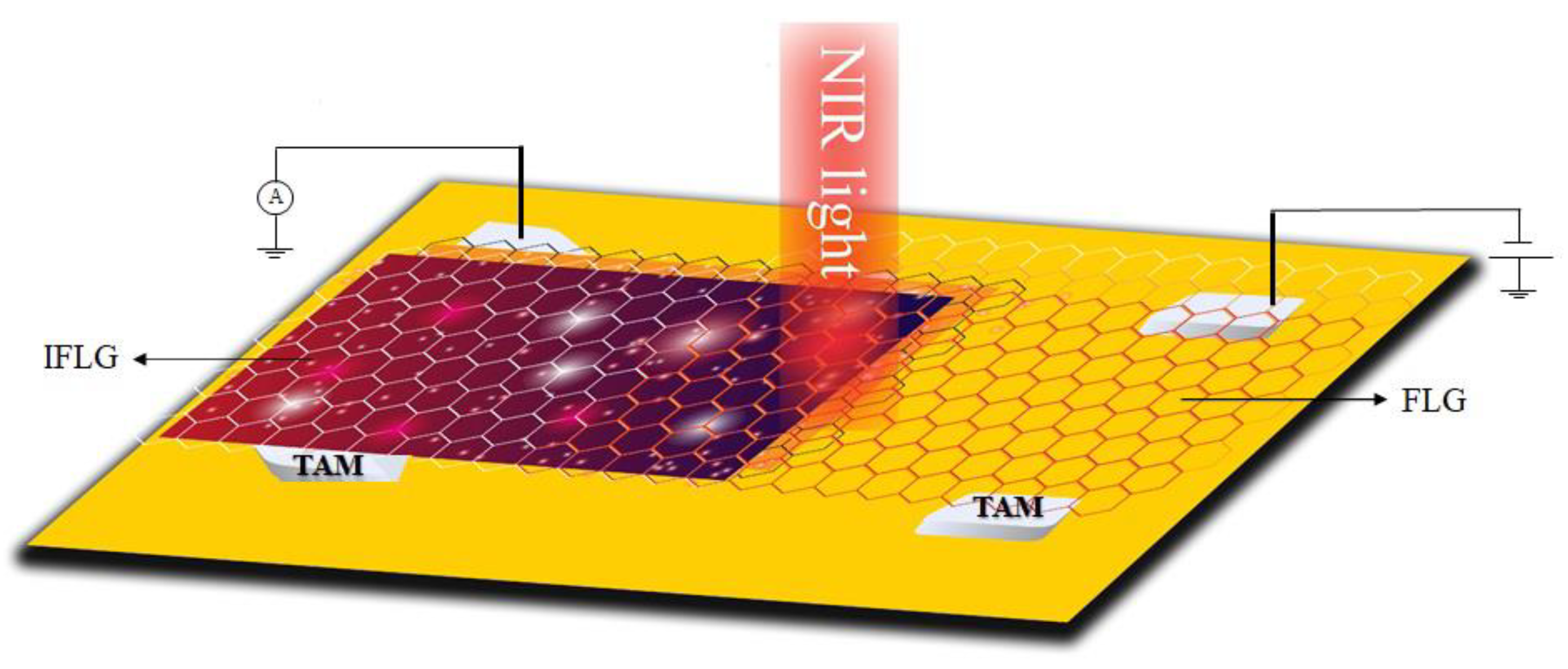

2.5. Characterization and Optoelectronic Test

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Marconi, S.; Giambra, M.A.; Montanaro, A.; Mišeikis, V.; Soresi, S.; Tirelli, S.; Galli, P.; Buchali, F.; Templ, W.; Coletti, C.; et al. Photo thermal effect graphene detector featuring 105 Gbit s−1 NRZ and 120 Gbit s−1 PAM4 direct detection. Nat. Commun. 2021, 12, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Kwon, M.G.; Kim, C.; Chang, K.E.; Yoo, T.J.; Kim, S.-Y.; Hwang, H.J.; Lee, S.; Lee, B.H. Performance enhancement of graphene/Ge near-infrared photodetector by modulating the doping level of graphene. APL Photon- 2022, 7, 026101. [Google Scholar] [CrossRef]

- Polat, E.O.; Mercier, G.; Nikitskiy, I.; Puma, E.; Galan, T.; Gupta, S.; Montagut, M.; Piqueras, J.J.; Bouwens, M.; Durduran, T.; et al. Flexible graphene photodetectors for wearable fitness monitoring. Sci. Adv. 2019, 5, eaaw7846. [Google Scholar] [CrossRef] [PubMed]

- Corsi, C. Infrared: A Key Technology for Security Systems. Adv. Opt. Technol. 2012, 2012, 1–15. [Google Scholar] [CrossRef]

- Esfandiari, M.; Lalbakhsh, A.; Shehni, P.N.; Jarchi, S.; Ghaffari-Miab, M.; Mahtaj, H.N.; Reisenfeld, S.; Alibakhshikenari, M.; Koziel, S.; Szczepanski, S. Recent and emerging applications of Graphene-based metamaterials in electromagnetics. Mater. Des. 2022, 221. [Google Scholar] [CrossRef]

- Hansen, M.P. and D.S. Malchow. Overview of SWIR detectors, cameras, and applications. in SPIE Defense and Security Symposium. 2008. SPIE.

- Rogalski, A. HgCdTe infrared detector material: history, status and outlook. Rep. Prog. Phys. 2005, 68, 2267–2336. [Google Scholar] [CrossRef]

- Dehzangi, A. , et al., Impact of annealing time on copper doping concentration for mid-wave and long-wave mercury cadmium telluride. Journal of Electronic Materials, 54, 2025.

- Kinch, M.A. HgCdTe: Recent Trends in the Ultimate IR Semiconductor. J. Electron. Mater. 2010, 39, 1043–1052. [Google Scholar] [CrossRef]

- Henini, M.; Razeghi, M. Handbook of Infra-red Detection Technologies; Elsevier: Amsterdam, NX, Netherlands, 2002. [Google Scholar]

- Razeghi, M. , et al. Recent advances in InAs/InAs1-xSbx/AlAs1-xSbx gap-engineered type-II superlattice-based photodetectors. in Proc. SPIE 10177, Infrared Technology and Applications XLIII, 1017705 2017. SPIE.

- Arslan, Y.; Oguz, F.; Besikci, C. Extended wavelength SWIR InGaAs focal plane array: Characteristics and limitations. Infrared Phys. Technol. 2015, 70, 134–137. [Google Scholar] [CrossRef]

- Razeghi, M. , et al. High-performance short-wavelength infrared photodetectors based on type-II InAs/InAs1-xSbx/AlAs1-xSbx superlattices. in Proc. SPIE 9819, Infrared Technology and Applications XLII. SPIE.

- Razeghi, M.; Dehzangi, A.; Li, J. Multi-band SWIR-MWIR-LWIR Type-II Superlattice Based Infrared Photodetector. 2, 1000; 54. [Google Scholar] [CrossRef]

- Dehzangi, A.; Wu, D.; McClintock, R.; Li, J.; Jaud, A.; Razeghi, M. Demonstration of Planar Type-II Superlattice-Based Photodetectors Using Silicon Ion-Implantation. Photonics 2020, 7, 68. [Google Scholar] [CrossRef]

- Sai-Halasz, G.A.; Tsu, R.; Esaki, L. A new semiconductor superlattice. Appl. Phys. Lett. 1977, 30, 651–653. [Google Scholar] [CrossRef]

- Dehzangi, A. Multiband strain balanced superlattice material system for third generation infrared detectors. 2024 IEEE Research and Applications of Photonics in Defense Conference (RAPID). LOCATION OF CONFERENCE, United StatesDATE OF CONFERENCE; pp. 01–02.

- Chevallier, R.; Dehzangi, A.; Haddadii, A.; Razeghi, M. Type-II superlattice-based extended short-wavelength infrared focal plane array with an AlAsSb/GaSb superlattice etch-stop layer to allow near-visible light detection. Opt. Lett. 2017, 42, 4299–4302. [Google Scholar] [CrossRef]

- Dehzangi, A.; Haddadi, A.; Chevallier, R.; Zhang, Y.; Razeghi, M. Fabrication of 12 µm pixel-pitch 1280 × 1024 extended short wavelength infrared focal plane array using heterojunction type-II superlattice-based photodetectors. Semicond. Sci. Technol. 2018, 34, 03LT01. [Google Scholar] [CrossRef]

- Xiong, Y.; Chen, T.; Feng, W. Broadband self-powered photodetector based on the large-area continuous WS0.9Se1.1 film. Opt. Mater. 2023, 145. [Google Scholar] [CrossRef]

- Gao, L.; Zhao, Y.; Chang, X.; Zhang, J.; Li, Y.; Wageh, S.; Al-Hartomy, O.A.; Al-Sehemi, A.G.; Zhang, H.; Ågren, H. Emerging applications of MXenes for photodetection: Recent advances and future challenges. Mater. Today 2022, 61, 169–190. [Google Scholar] [CrossRef]

- Veeder, T.; Dehhzangi, A.; Ramanathan, S.; Kats, M.; Yu, N.; Hu, J.; Roberts, C.; Polking, M.; Tibbetts, K.; Majumdar, A.; et al. Accelerating discovery of tunable optical materials (ATOM). Image Sensing Technologies: Materials, Devices, Systems, and Applications XI. LOCATION OF CONFERENCE, United StatesDATE OF CONFERENCE; p. 1303002.

- Larki, F.; Abdi, Y.; Kameli, P.; Salamati, H. An Effort Towards Full Graphene Photodetectors. Photon- Sensors 2022, 12, 31–67. [Google Scholar] [CrossRef]

- Guo, Q.; Yu, R.; Li, C.; Yuan, S.; Deng, B.; de Abajo, F.J.G.; Xia, F. Efficient electrical detection of mid-infrared graphene plasmons at room temperature. Nat. Mater. 2018, 17, 986–992. [Google Scholar] [CrossRef] [PubMed]

- Dehzangi, A.; Mohseni, H. Infrared focal plane arrays based on two-dimensional materials: possibilities and challenges. Infrared Technology and Applications L. LOCATION OF CONFERENCE, United StatesDATE OF CONFERENCE; pp. 75–327.

- Ansari, S.; Bianconi, S.; Kang, C.; Mohseni, H. From Material to Cameras: Low-Dimensional Photodetector Arrays on CMOS. Small Methods 2023, 8, e2300595. [Google Scholar] [CrossRef]

- Bolotin, K.; Sikes, K.; Jiang, Z.; Klima, M.; Fudenberg, G.; Hone, J.; Kim, P.; Stormer, H. Ultrahigh electron mobility in suspended graphene. Solid State Commun. 2008, 146, 351–355. [Google Scholar] [CrossRef]

- Mueller, T.; Xia, F.; Avouris, P. Graphene photodetectors for high-speed optical communications. Nat. Photonics 2010, 4, 297–301. [Google Scholar] [CrossRef]

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T.; Peres, N.M.R.; Geim, A.K. Fine Structure Constant Defines Visual Transparency of Graphene. Science 2008, 320, 1308–1308. [Google Scholar] [CrossRef]

- Cao, X.; Shi, J.-J.; Zhang, M.; Jiang, X.-H.; Zhong, H.-X.; Huang, P.; Ding, Y.-M.; Wu, M. Band Gap Opening of Graphene by Forming Heterojunctions with the 2D Carbonitrides Nitrogenated Holey Graphene, g-C3N4, and g-CN: Electric Field Effect. J. Phys. Chem. C 2016, 120, 11299–11305. [Google Scholar] [CrossRef]

- Mylnikov, D.A.; Kashchenko, M.A.; Kapralov, K.N.; Ghazaryan, D.A.; Vdovin, E.E.; Morozov, S.V.; Novoselov, K.S.; Bandurin, D.A.; Chernov, A.I.; Svintsov, D.A. Infrared photodetection in graphene-based heterostructures: bolometric and thermoelectric effects at the tunneling barrier. npj 2D Mater. Appl. 2024, 8, 1–8. [Google Scholar] [CrossRef]

- Samarakoon, D.K.; Wang, X.-Q. Tunable Band Gap in Hydrogenated Bilayer Graphene. ACS Nano 2010, 4, 4126–4130. [Google Scholar] [CrossRef] [PubMed]

- Lui, C.H.; Li, Z.; Mak, K.F.; Cappelluti, E.; Heinz, T.F. Observation of an electrically tunable band gap in trilayer graphene. Nat. Phys. 2011, 7, 944–947. [Google Scholar] [CrossRef]

- Ullah, S.; Shi, Q.; Zhou, J.; Yang, X.; Ta, H.Q.; Hasan, M.; Ahmad, N.M.; Fu, L.; Bachmatiuk, A.; Rümmeli, M.H. Advances and Trends in Chemically Doped Graphene. Adv. Mater. Interfaces 2020, 7. [Google Scholar] [CrossRef]

- Senevirathna, M.K.I.; Samarakoon, D.K.; Gunasinghe, R.; Wang, X.-Q.; Williams, M.D. Bandgap opening of ferric chloride intercalated graphene by applying small electric field. AIP Adv. 2024, 14. [Google Scholar] [CrossRef]

- Zhao, W. , et al., Intercalation of few-layer graphite flakes with FeCl3: Raman determination of Fermi level, layer by layer decoupling, and stability. Journal of the American Chemical Society, 2011. 133, p. 5941-5946.

- Nathaniel, J.; Wang, X.-Q. Tunable electron and hole doping in FeCl3 intercalated graphene. Appl. Phys. Lett. 2012, 100, 213112. [Google Scholar] [CrossRef]

- Liu, W.; Kang, J.; Banerjee, K. Characterization of FeCl3Intercalation Doped CVD Few-Layer Graphene. IEEE Electron Device Lett. 2016, 37, 1246–1249. [Google Scholar] [CrossRef]

- Larki, F.; Kameli, P.; Nikmanesh, H.; Jafari, M.; Salamati, H. The influence of external magnetic field on the pulsed laser deposition growth of graphene on nickel substrate at room temperature. Diam. Relat. Mater. 2019, 93, 233–240. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, L.; Chen, S. Large area CVD growth of graphene. Synth. Met. 2015, 210, 95–108. [Google Scholar] [CrossRef]

- Dresselhaus, M.; Dresselhaus, G. Intercalation compounds of graphite. Adv. Phys. 1981, 30, 139–326. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Y.; Cai, W.; Borysiak, M.; Han, B.; Chen, D.; Piner, R.D.; Colombo, L.; Ruoff, R.S. Transfer of Large-Area Graphene Films for High-Performance Transparent Conductive Electrodes. Nano Lett. 2009, 9, 4359–4363. [Google Scholar] [CrossRef] [PubMed]

- Malard, L. , et al., Raman spectroscopy in graphene. Physics Reports, 2009. 473(5-6): p. 51-87.

- Kalsoom, U.; Rafique, M.S.; Shahzadi, S.; Fatima, K.; ShaheeN, R. Bi- tri- and few-layer graphene growth by PLD technique using Ni as catalyst. Mater. Sci. 2017, 35, 687–693. [Google Scholar] [CrossRef]

- Wang, K.; Tai, G.; Wong, K.H.; Lau, S.P.; Guo, W. Ni induced few-layer graphene growth at low temperature by pulsed laser deposition. AIP Adv. 2011, 1, 022141. [Google Scholar] [CrossRef]

- Pan, G.; Li, B.; Heath, M.; Horsell, D.; Wears, M.L.; Al Taan, L.; Awan, S. Transfer-free growth of graphene on SiO2 insulator substrate from sputtered carbon and nickel films. Carbon 2013, 65, 349–358. [Google Scholar] [CrossRef]

- Gupta, B.; Kumar, N.; Panda, K.; Kanan, V.; Joshi, S.; Visoly-Fisher, I. Role of oxygen functional groups in reduced graphene oxide for lubrication. Sci. Rep. 2017, 7, srep45030. [Google Scholar] [CrossRef]

- Hui, L.S.; Whiteway, E.; Hilke, M.; Turak, A. Synergistic oxidation of CVD graphene on Cu by oxygen plasma etching. Carbon 2017, 125, 500–508. [Google Scholar] [CrossRef]

- Caswell, N.; Solin, S. Vibrational excitations of pure FeCl3 and graphite intercalated with ferric chloride. Solid State Commun. 1978, 27, 961–967. [Google Scholar] [CrossRef]

- Kumar, I.; Khare, A. Multi- and few-layer graphene on insulating substrate via pulsed laser deposition technique. Appl. Surf. Sci. 2014, 317, 1004–1009. [Google Scholar] [CrossRef]

- Koh, A.T.; Foong, Y.M.; Chua, D.H. Comparison of the mechanism of low defect few-layer graphene fabricated on different metals by pulsed laser deposition. Diam. Relat. Mater. 2012, 25, 98–102. [Google Scholar] [CrossRef]

- Withers, F. , et al., All-graphene photodetectors. ACS nano, 2013. 7(6): p. 5052-5057.

- De Sanctis, A. , et al., Graphene-based light sensing: fabrication, characterisation, physical properties and performance. Materials, 2018. 11(9): p. 1762.

- Zhan, D. , et al., FeCl3-based few-layer graphene intercalation compounds: single linear dispersion electronic band structure and strong charge transfer doping. Advanced Functional Materials, 2010. 20(20): p. 3504-3509.

- Zou, X.; Zhan, D.; Fan, X.; Lee, D.; Nair, S.K.; Sun, L.; Ni, Z.; Luo, Z.; Liu, L.; Yu, T.; et al. Ultrafast carrier dynamics in pristine and FeCl3-intercalated bilayer graphene. Appl. Phys. Lett. 2010, 97, 141910. [Google Scholar] [CrossRef]

- Shabbir, M.W. and M.N. Leuenberger, Plasmonically enhanced tunable spectrally selective NIR and SWIR photodetector based on intercalation doped nanopatterned multilayer graphene. arXiv:2111.05982, 2021.

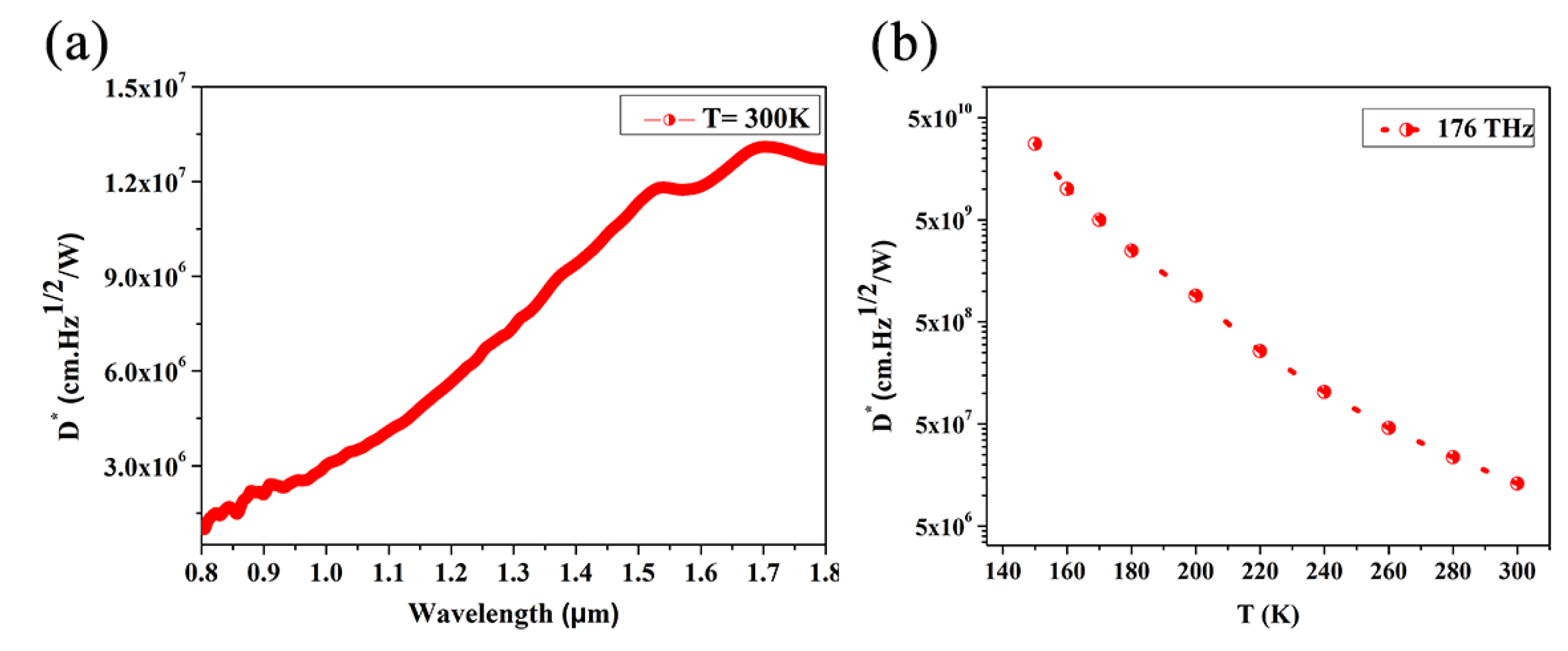

- Jones, R.C. On the Relation between the Speed of Response and the Detectivity of Lead Sulfide Photoconductive Cells. J. Opt. Soc. Am. 1953, 43, 1008–1013. [Google Scholar] [CrossRef]

- Dehzangi, A.; Li, J.; Razeghi, M. Band-structure-engineered high-gain LWIR photodetector based on a type-II superlattice. Light. Sci. Appl. 2021, 10, 1–7. [Google Scholar] [CrossRef] [PubMed]

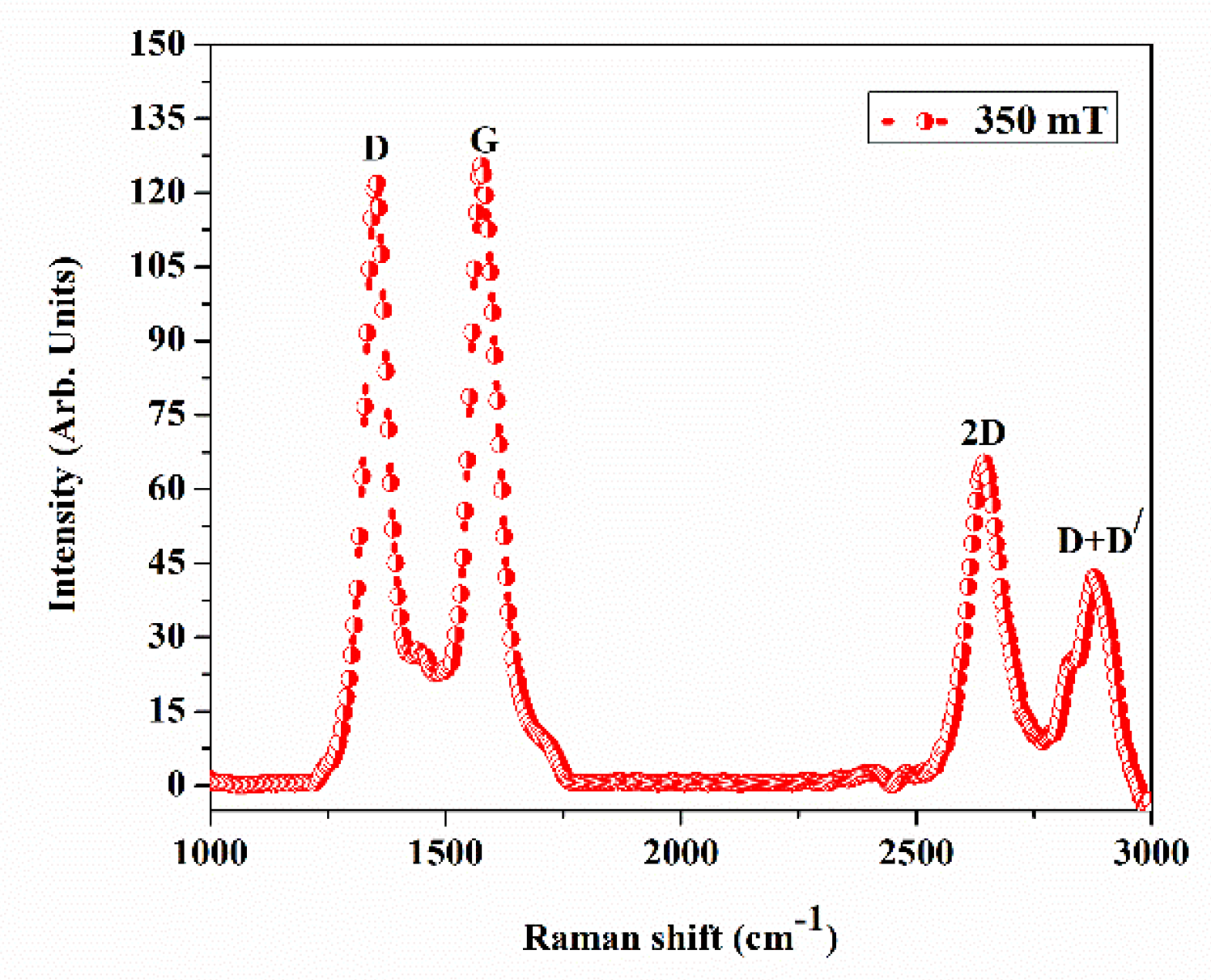

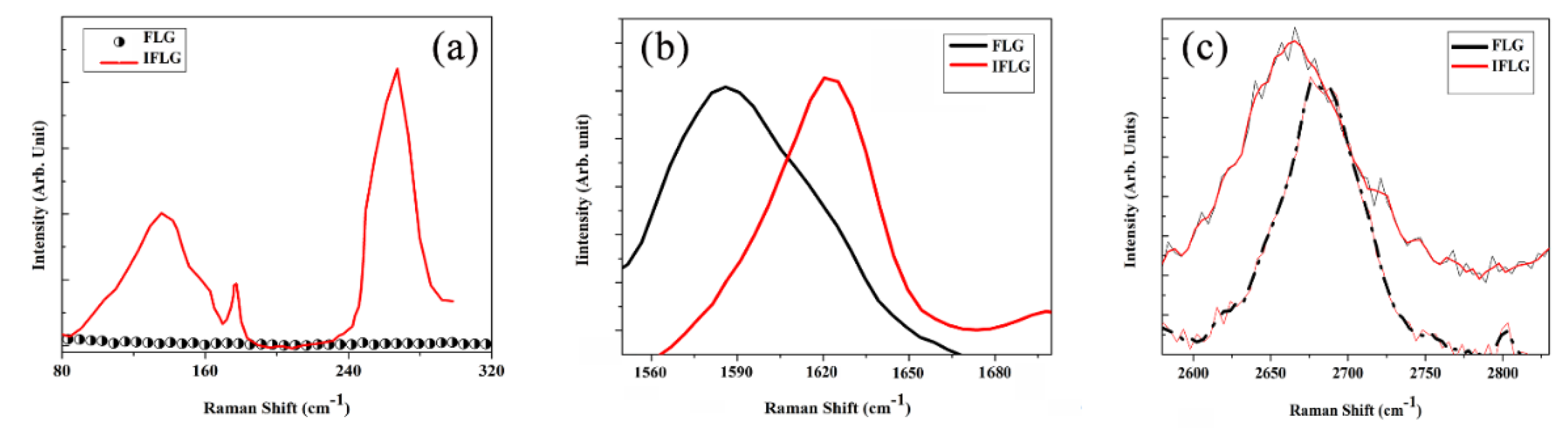

| Intensity | ID(a.u) | IG(a.u) | I2D(a.u) | ID+D’(a.u) | ID/IG | I2D/IG | |

|---|---|---|---|---|---|---|---|

| Growth | |||||||

| 350 mT magnet | 128 (1359) | 120 (1580) | 80(2645) | 44.5(2890) | 1.06 | 0.66 | |

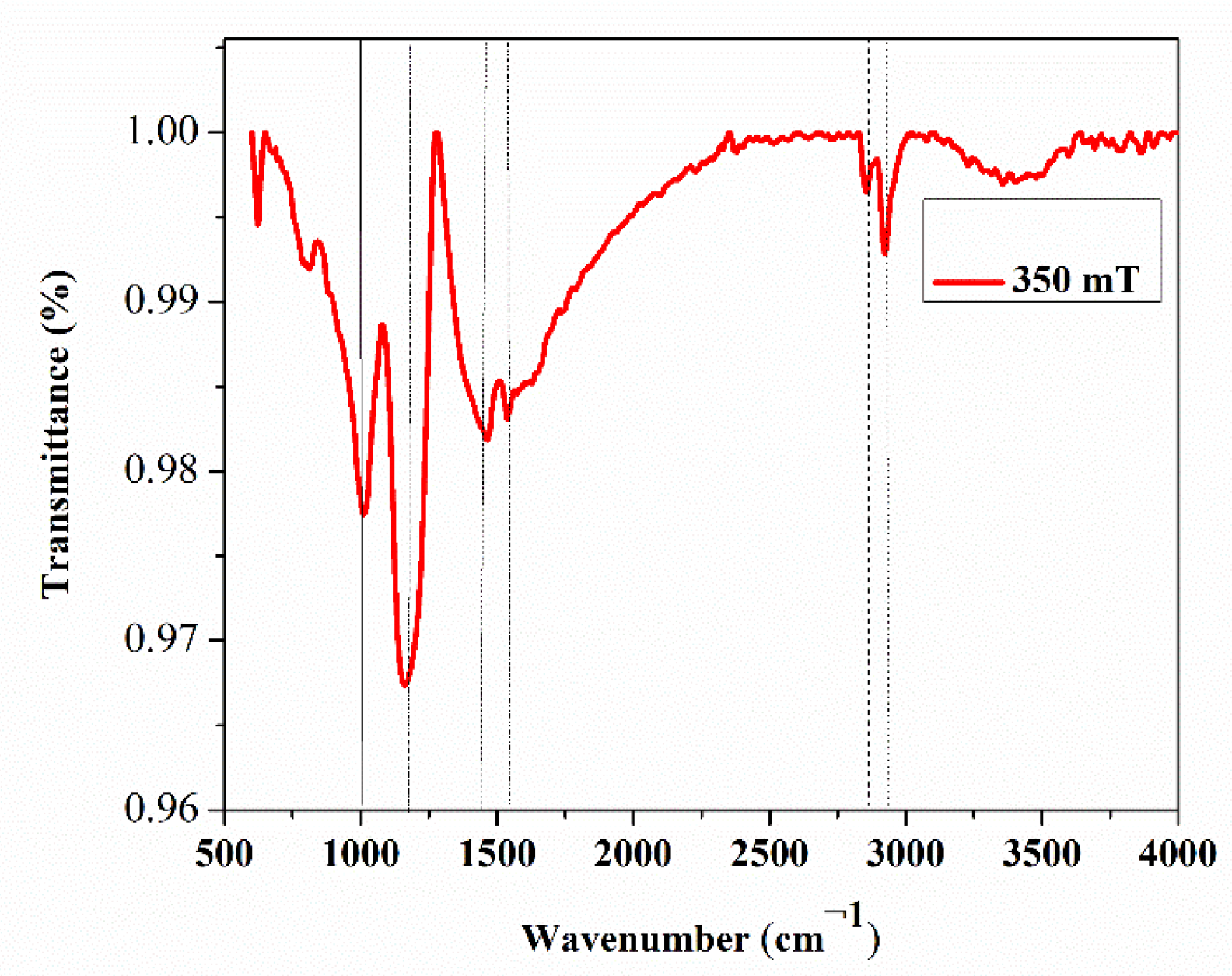

| PP | 1010.65 | 1162.24 | 1464.32 | 1537.04 | 2856.03 | 2924.10 | 3356.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).