1. Introduction

In the midst of the fourth Industrial Revolution, where transformative technologies such as Artificial Intelligence (AI), advanced robotics and Internet of Things (IoT) are reshaping production and business overall, the lines between humans and machines are becoming less distinct. And what is more, Industry 5.0 brings humans and technology even closer [

1,

2]. In general, AI involves the use of computers to perform tasks that are typically run by humans, such as learning, understanding, recognizing, reasoning, and adapting [

3]. The economic contribution of AI technologies will reach around 13

$ trillion by 2030 [

4], while the supply chain management market is expected to surpass 62.2

$ billion by the same year [

5].

Supply chains hold a lot of concern and focus from many enterprises, governments, consumers, and gain broader media coverage [

6]. In today’s major competitive environment, a cloud supply chain based on Industry 4.0 technologies and digital platforms transforms in the "supply chain-as-a-service" paradigm [

7]. The benefits of employing AI in Supply Chain Management (SCM) are resilience improvement [

8,

9,

10] and risk management [

11,

12,

13], end-to-end visibility and transparency [

2,

14,

15], information and process resilience [

16], real-time tracking of goods in every part of the supply chain [

17], sustainability [

18], food safety and public health [

19].

Past academic work concerning AI in SCM emphasized the need to lessen the current hype [

20], brought to the surface the lack of know-how in organizations [

21] and the lack of understanding from ordinary decision-makers [

22], proposed an AI taxonomy relevant to SCM [

4], described the most frequent AI techniques and SCM subfields [

23,

24], utilized a bibliometric review to trace the evolution of AI research in SCM [

2], critically reviewed the drivers, practices, benefits, barriers and consequences of AI adoption [

25,

26,

27], proposed an AI integration framework [

28], and reviewed the effect of AI in operational efficiency, strategic innovation and sustainability [

29]. Moreover, the following studies offered a practical framework of AI applications in SCM [

30], reviewed the role of AI in supply chain analytics[

31,

32], examined the organizational and behavioral factors that promote AI adoption in supply chain [

33], introduced a research framework for AI in supply chain resilience [

34], and explored the relationship between AI applications and supply chain concentration [

35]. Finally, these studies investigated the potential of AI in supply chain visibility [

36], evaluated the benefits and challenges of AI in agricultural supply chain [

37], examined the relationship between AI and supply chain finance [

38,

39], and proposed specific officer roles in overseeing AI utilization in SCM [

40].

The scope of this research covers a thorough analysis of AI applications in SCM, with a focus on the key processes of the chain. Chapter two and three cover relevant information on supply chain and AI, respectively. Also, chapter three describes specific AI applications in SCM, and more specifically in the areas of customer relationship management, inventory management, transportation networks, procurement, demand forecasting, resilience, and risk management. Finally, chapter four highlights future trends, challenges, and threats of AI presence in SCM and finally, in chapter five, conclusions are presented.

2. Supply Chain

A supply chain can be understood as a network that creates value through interconnected elements. It involves various business sectors working closely together including production, services, funds, and information. The main objective is to ensure that products are available to consumers [

41]. It is vital for contemporary businesses to build integrated supply chains with infrastructure and networking features [

42]. The SCM research landscape has evolved significantly over time. Initially, the focus was on freight transportation. However, subsequent studies have brought to light other critical areas such as risk [

43], performance [

44] and integration [

45]. In addition, there is an increasing focus on the flow of information within the network of organizational relationships [

46], both internally and externally, alongside the management of supply networks. Given these research challenges, the main objective of SCM is to enhance four key flows: goods, information, cash flows and overall processes [

47]. A major obstacle to managing the supply chain as an integrated system is the lack of appropriate information technology. Despite the emergence of the industry 4.0 technologies, the significant costs associated with their installation and operation at each stage of the chain have not yet been fully explored [

48]. Moreover, there are specific barriers and drivers that allow for a sustainable SCM [

49]. Namely, there are social, economic, and environmental concerns on one hand, and technological, competitive, and operational benefits on the other hand.

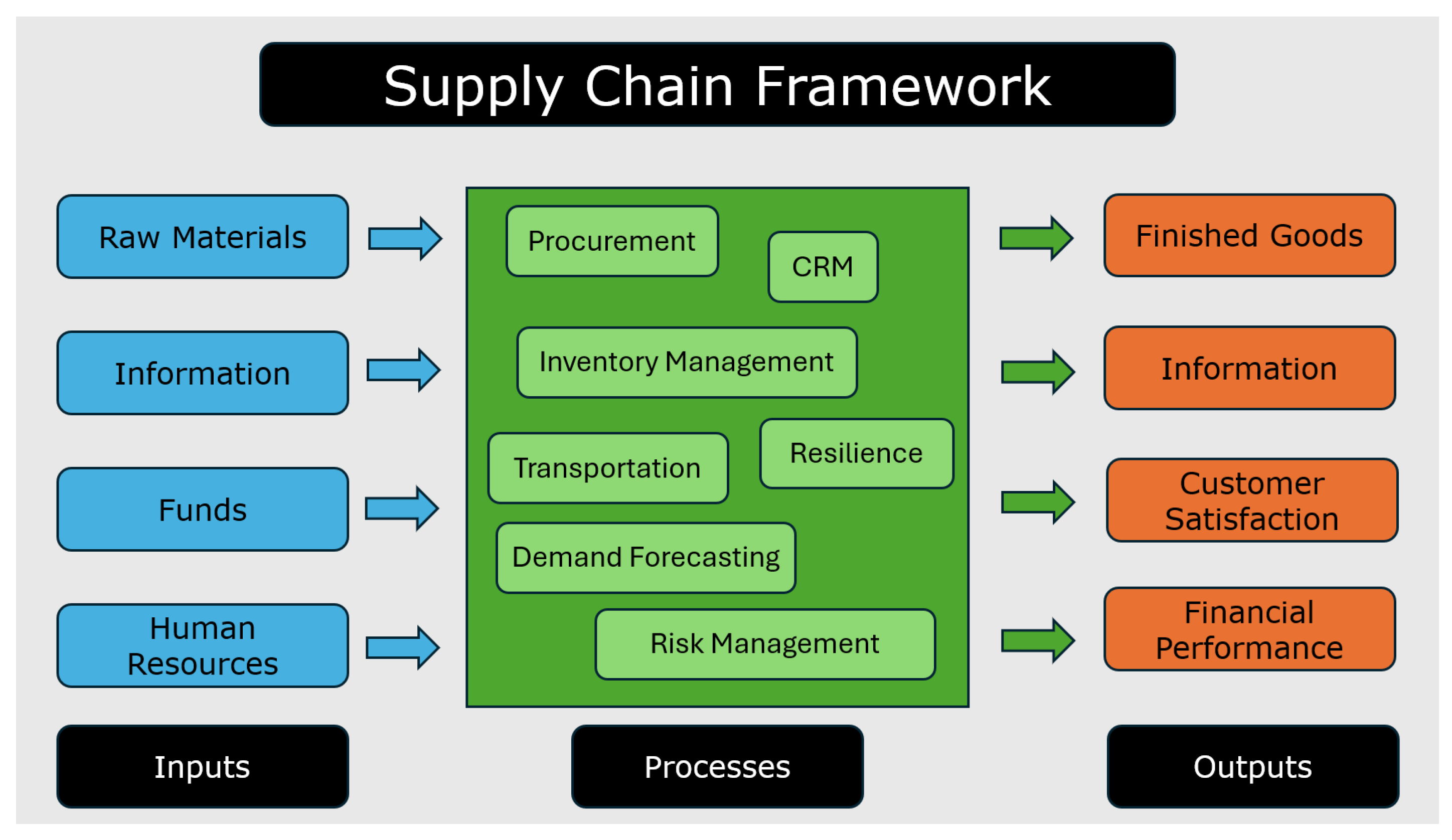

Key components that are typically included in a SCM framework (

Figure 1) are Customer Relationship Management (CRM), inventory management, transportation networks, procurement, demand forecasting, resilience, and risk management. These principal activities play a critical role in both the internal and external aspects of a business, which can be understood as a complex system involving inputs, internal processes, and outputs. There are quite a few challenges and opportunities from implementing AI technologies in the above processes, that both pave the way for a cautious but fruitful transition [

20].

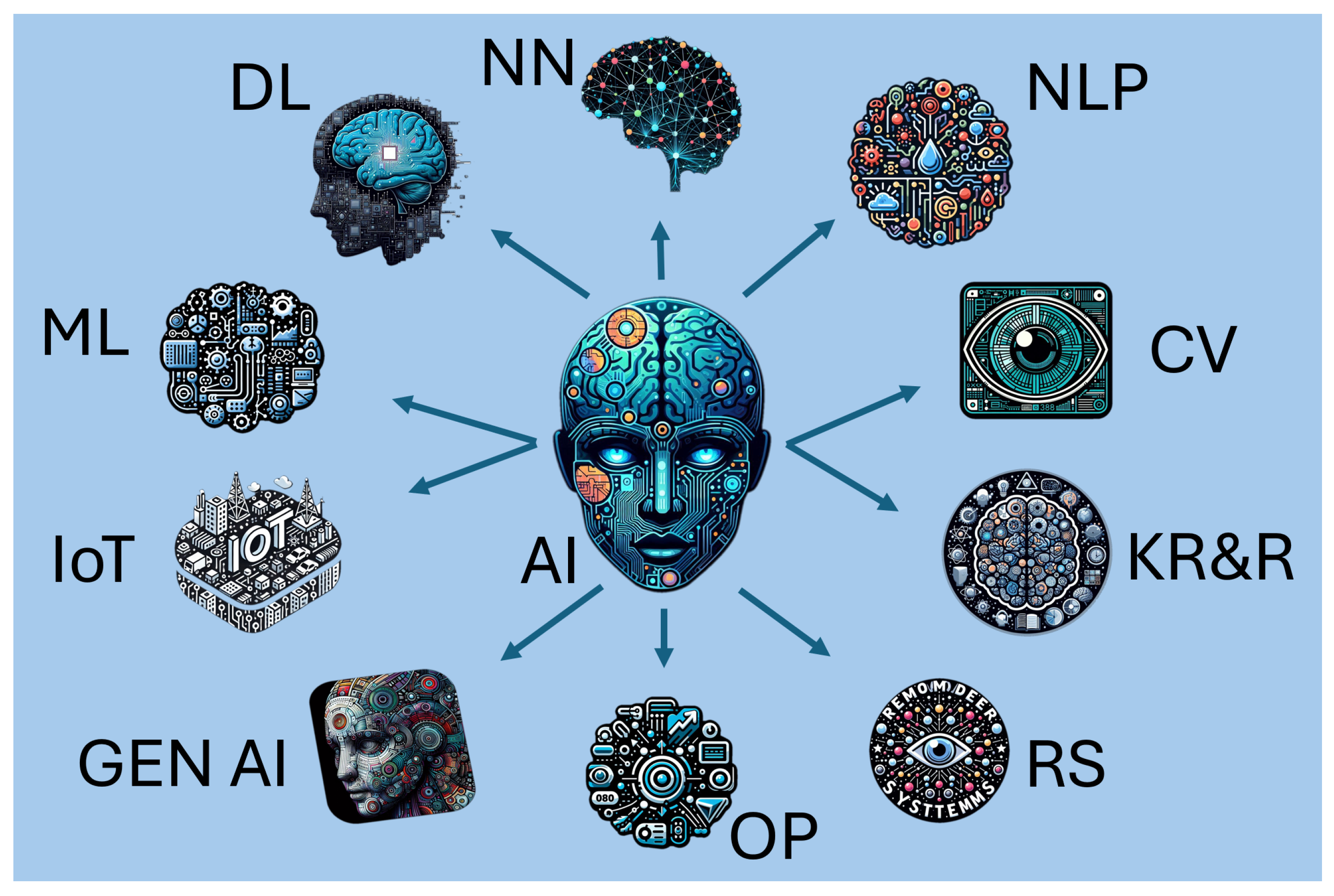

3. Artificial Intelligence

AI is defined as intelligence that machines can display and emulate all human cognitive functions, such as problem-solving and decision-making to the benefit of organizational optimization and automation. The presence of AI is evident in the fields of agricultural management, education, healthcare, fashion, e-commerce, gaming, and military [

1]. The roots of AI go back to the 1950s, and its key techniques include Machine Learning (ML), Deep Learning (DL), Neural Networks (NN), Natural Language Processing (NLP), Computer Vision (CV), Knowledge Representation and Reasoning (KR&R), Recommender Systems (RS), and Optimization (OP) [

3,

50]. A branch of AI is Generative AI (GEN AI), which can produce a variety of different forms of content, namely, text, graphics, audio, video or other data forms and leverages machine learning models [

51]. A prime example of Generative AI is ChatGPT, which offers an adequate number of benefits, but also various threats and challenges to SCM [

52,

53]. IoT has the leading role of generating data for AI to analyze. Integrating IoT and AI within the SCM context provides notable advancements in supply chain transparency, agility, and overall functionality [

54]. Artificial Intelligence of Things, which refers to utilizing IoT to execute smart tasks with the aid of AI integration, is one of these upcoming developments that can convert a complex supply chain into a unified process [

55].

Figure 2 depicts various AI manifestations as they have been AI-generated by the Microsoft Designer program.

Nowadays, it is more than evident that AI leads the way in revolutionizing every aspect of SCM and is employed to make educated predictions on demand and transportation routes, suggest innovative solutions, and optimize operations costs [

56]. Moreover, the need to make ends meet in a highly competitive environment sets AI as the main force to succeed. Even when faced with a global pandemic crisis, such as COVID-19, AI is a crucial factor that helps management achieve its goals [

57]. Furthermore, although there is a hesitation in managers to utilize AI [

57], neurosymbolic AI is explicitly suitable to give explanations for every decision based on AI models [

58].

Managers’ perceptions and intentions in utilizing AI in decision-making are still in a contemplating phase, even though the COVID-19 crisis strengthen business operations through AI [

57]. AI-driven SCM optimization delivers a range of benefits that markedly enhance inventory management, improve demand projection, optimize logistics, increase efficiency, productivity, and upgrade decision-making policies [

59]. The adoption of AI in supply chain decision-making is also triggered by the Environmental, Social, Governance framework. Respectively, these triggers are product waste reduction and greenhouse gas emissions reduction, product security and quality, and agile and lean practices [

60].

3.1. Customer Relationship Management

Customer Relationship Management comes to further address and nurture customer needs, boosting the role of classic SCM. An agent-based model that tracks customer experiences in a social network can build upon word-of-mouth reputation to accelerate revenues generation [

22]. Chatbots and virtual assistants powered by AI can address customer concerns, manage order fulfillment, support tickets, improve response time and ensure live shipment tracking [

14,

59].

3.2. Inventory Management

One of the biggest challenges in SCM is inventory management and its relevant cost, as demand patterns change to facilitate diverse needs [

61]. AI-powered systems can optimize inventory, when taking into consideration factors such as demand, storage costs, lead time and even supply chain constraints [

14]. Integrating AI in inventory management offers numerous advantages, namely reduced stock-outs, minimized overstocking, strategic clearance sales and improved profit margins [

17]. AI techniques provide new, innovative ways to inventory control and planning challenges by capturing inventory patterns naked to the human eye [

22]. Machine Learning techniques, like reinforcement learning and anomaly detection, are capitalizing on data insights to fine-tune inventory levels. The analysis of historical stock quantities, abrupt changes in trends, and handling of large volumes of data produces informative reports on estimated inventory status [

62,

63]. Robotic systems assisted by AI and drones can rationalize warehouse operations and automate functions, such as picking, packing [

64] and inventory counting [

65], leading to accuracy improvement and enhanced use of human resources [

14]. In all available picking scenarios, there have been numerous proposed solutions based on simulation and mathematical models. An intelligent agent-based method could handle the added complexity driven by the growing adoption of new and premium services [

22]. Large Language Models have played a crucial role in automating inventory management and order fulfillment by enabling advanced data analysis and decision-making capabilities, in areas such as historical logistics data (delivery logs, transportation trends, climatic conditions, and consumer demand predictions) [

66].

3.3. Transportation Networks

The supply chain network is the backbone of SCM, as it brings together suppliers, manufacturers, distributors and customers [

67]. AI can streamline delivery routes, vehicle loads, and logistics timelines to cut back fuel consumption and save work hours [

14]. The use of network theory and graph algorithms allows for a better understanding of the key features of such a network by identifying bottlenecks and facilitating the flow of goods and information [

62]. Identifying optimal areas for logistics, storage facilities, and retail operations requires intricate planning since costs and performance depend on these decisions. AI is a valuable assistant in facility location planning by taking into consideration multiple factors, for example, customer demographics, land costs, transportation infrastructure and regulatory environment [

68]. Dynamic route scheduling constitutes a major challenge for SCM, notably the last-mile delivery task. Although there are many heuristic techniques to handle everyday transportation issues, AI really shines in solving this vehicle routing problem, in the forms of genetic algorithms, ant colony optimization algorithms [

22] and reinforcement learning [

63]. On top of that, Generative AI can be employed to create backup plans to neutralize disturbances such as traffic jams and severe weather [

69].

3.4. Procurement

Procurement and resource planning departments have to make everyday decisions concerning volume, capital, and risk related to obtaining items necessary for all operational purposes. Intelligent agent-based systems take up the role of a human decision-maker or provide aid to the purchasing manager with the sequence of strategic and operational procurement choices [

22]. Intelligence process automation can refine routine operation, in cases of data entry, order management and invoice processing, while data collected from appliances and machinery is used to predict equipment failure and program predictive maintenance [

59]. Generative AI analyzes a lot of parameters, like financial viability, product excellence, dependability, operational effectiveness, and green practices to put together an optimal portfolio of potent suppliers [

69].

3.5. Demand Forecasting

The integration of AI into demand projection presents many benefits, such as improved production planning, strategic inventory allocation, risk mitigation and new product development [

17]. Machine Learning techniques, like support vector machines, Neural Networks and decision trees are utilizing data-informed insights to produce more precise forecasts and give companies tools to develop dynamic inventory policies to satisfy ever-changing demand [

62]. In another research [

63], AI techniques used for demand forecasting are the auto-regressive integrated moving average, long short-term memory networks, gradient boosting machines, support vector machines and Deep Neural Networks.

Supply chain demand prediction and administration is a primary focus for SCM, where Artificial Neural Networks, data mining, and fuzzy models are employed to foresee consumer consumption [

23]. Demand forecasting is solely based on historical data for existing products and services. In cases where there is a new product or an innovative service, the absence of any chronological records remains deterring for any estimated demand. Precisely for these instances, AI is a viable alternative for sales projection and planning [

22]. AI-based analysis of social media, like sentiment analysis [

70], can help in gaining deeper insights into customer behaviors and preferences, allowing predictive models to identify potential markets and profit margins [

71].

The application of AI in demand forecasting for irregular demands [

61] was investigated and the most effective approaches were identified. Neural Networks that were employed improved demand forecast accuracy, especially in cases of intermittent demands, lowering overall financial burdens, such as higher stock levels. Large Language Models have shown noteworthy progress in enhancing demand prediction accuracy by processing and analyzing large volumes of data, in both text and numeric form [

66].

3.6. Resilience and Risk

Supply chain resilience is improved with the help of AI in turmoil times. Moreover, firm performance is related to AI and supply chain resilience [

72]. Especially, AI improves transparency by employing continuous monitoring, handling last-mile delivery and tailored-made demands and lessens the negative impacts of global crises, like COVID-19 [

8,

9]. A quality measure of resilience is also important, not just a quantity one. While it is crucial to understand the disruption and recovery actions a firm must take to roll back to normal proceedings, it is even more intuitive to boost the quality of the network health, by investing in prevention policies [

73]. There is empirical evidence that the level of visibility maintained and shared with all supply chain partners defines the impact of disruption events. Thus, AI fosters resilience in the supply chain [

74].

Artificial Neural Networks are used to recognize and lessen risks in everyday operations in supply chains. These risk cases are disruptions in supply, variations in demands and shifts in market conditions [

75]. Once again, analysis of historical data, patterns and trends can recognize and create risk management policies that alleviate disruptions’ affect and fortify resilience [

62]. The integration of Deep Reinforcement Learning and predictive analysis further enhance decision-making processes in real time and anticipate disruptions [

76]. The most used AI technique in supply chain resilience is Bayesian Networks, as a thorough approach to evaluate risk, analyze uncertainty, and decide amidst structural dynamics [

77]. There is concrete evidence demonstrating that the data processing functionalities of AI impact supply chain performance by enhancing supply chain resilience overall [

78]. The numerous successive crises and supply chain instabilities attest to the need for further utilization of AI to bolster resilience.

Additionally, resilience necessitates a forward-thinking approach to risk management, namely identification of potential threats, assessment of likelihood and impact, and implementation of prevention and/or mitigation policies [

79]. Risks in SCM can be categorized to supply and demand risk, process and control risk, environmental and information risk [

12], and is quantified as the multiplication of its likelihood and effects. Predictive risk management is based on AI methods and instruments, like ensemble learning and Neural Networks to anticipate risks and take actions to mitigate them [

63]. Specific AI techniques, including fuzzy logic programming, Machine Learning, Big Data, and agent-based systems could be used to promote resilience in supply chain management [

80]. A proactive approach to risk reduction in SCM can be achieved with Generative AI. The continual analysis of specific supplier performance indicators, data obtained from markets and IoT devices, and AI algorithms can identify potential emerging threats and facilitate documented decision-making [

69]. Deep Convolutional Neural Networks (DCNNs) demonstrate remarkable efficiency stemming from calculating intricate and nonlinear correlations among variables. The utilization of DCNNs bolsters predictability and robustness in the global supply chain [

81]. Large Language Models have demonstrated their worth as essential assets for improving risk assessment and mitigation by analyzing various data sources and delivering actionable intelligence [

66].

Table 1 summarizes SCM key activities with their corresponding AI applications.

4. Future Trends, Challenges, Threats

The future of AI is promising across all domains of human endeavor and innovation [

1], garnering significant academic attention [

31,

82]. Significant disruptions, such as COVID-19, have commenced a discussion on reversing outsourcing in supply chains and further developing local and in-house manufacturing, utilizing the Manufacturing-as-a-Service model (MaaS) [

4]. A shift towards human-centered AI in SCM is expected to manifest in the form of training and specializing human workforce, while boosting AI familiarity among the general population [

56]. There is a clear trend in utilizing AI applications to tackle both traditional and fresh problems [

24].

Nowadays, AI faces many challenges, namely data privacy [

66] and algorithmic bias [

83], cybersecurity [

66] and ethics [

84], absence of transparency and documentation, lack of specialized professionals [

31], and implementation challenges [

1,

63]. Also, there is a lack of evidence to measure its Return on Investment (ROI) in supply management enterprises, thus making it difficult to appraise its value [

56]. Managers’ attitudes toward adopting AI for decision-making remain in a deliberative stage, despite the COVID-19 crisis highlighting AI’s potential to enhance business operations [

57]. Additional challenges for AI in SCM are strong dependence on computer software, difficult implementation, and inapplicable in cross-function and cross-border supply chain decision frameworks [

22]. On top of that, companies must advance and elevate their degree of digital maturity in their organizational culture context before trying to implement AI solutions in their SCM [

85]. Over and above technical challenges, there are organizational hurdles to overcome, namely redefining processes, roles, and responsibilities [

83].

The main threats of AI presence in human societies are disruption of current job landscape, use for nefarious purposes, weaponization, and increase in inequalities [

1].

Industry 4.0 buzz is not consistent with companies’ readiness to adopt its technologies, since they lack the expertise, specifically tied to their existent business domain [

21]. Managers should be cautious and not hold lofty expectations [

86] to the implications of AI concerning performance, since organizational features are critical as well [

20]. Besides AI in SCM, Big Data, IoT, advanced Natural Language Processing, Blockchain [

87], Robotics, Autonomous Vehicles and Drones are all crucial fields to explore scientifically for refining even more the management in the supply chain [

50,

88].

5. Conclusions

This paper highlights the transformative role of AI in revolutionizing SCM within the evolving contexts of Industry 4.0 and the emerging paradigms of Industry 5.0. By leveraging AI technologies, such as Machine Learning, Natural Language Processing, and Generative AI, SCM processes can unlock unprecedented levels of efficiency, resilience, and adaptability. Moreover, this study provides a thorough analysis of AI applications across key supply chain processes, including customer relationship management, inventory management, transportation networks, procurement, demand forecasting, resilience, and risk management. Notable advancements from existing literature are presented including enhanced demand prediction accuracy, optimization of logistics operations, improved supplier and customer relationships, and reduced operational risks, all contributing to a more agile and responsive supply chain ecosystem. Moreover, AI’s critical role in fostering supply chain visibility and resilience has been underscored, particularly in mitigating challenges posed by global crises, disruptions, and uncertainties. However, despite these promising developments, several barriers impede the full-scale adoption of AI in SCM. These include technological implementation obstacles, disparities in organizational digital maturity, and concerns around ethics, transparency, and cybersecurity. Addressing these challenges is essential to unlocking AI’s full potential for creating dynamic and sustainable supply chains. This comprehensive review outlines guidelines for future research to address these gaps by focusing on optimizing AI integration strategies, fostering digital readiness across industries, and addressing ethical and security-related concerns to ensure equitable and responsible AI deployment. To conclude, embracing a human-centric approach to AI paired with innovations in AI-driven tools will be vital in shaping sustainable, resilient, and adaptable supply chains.

Author Contributions

Conceptualization, A.D. and A.K.; methodology, A.D.; validation, A.D. and N.K.; formal analysis, A.D.; investigation, A.D.; resources, A.D. and N.K.; writing—original draft preparation, A.D.; writing—review and editing, N.K.; visualization, A.D.; supervision, I.K. and A.K. ; project administration, I.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| Artificial Intelligence |

AI |

| Internet of Things |

IoT |

| Supply Chain Management |

SCM |

| Customer Relationship Management |

CRM |

| Machine Learning |

ML |

| Deep Learning |

DL |

| Neural Networks |

NN |

| Natural Language Processing |

NLP) |

| Computer Vision |

CV |

| Knowledge Representation and Reasoning |

KR&R |

| Recommender Systems |

RS |

| Optimization |

OP |

| Generative AI |

GEN AI |

| Deep Convolutional Neural Networks |

DCNNs |

| Manufacturing-as-a-Service |

MaaS |

| Return on Investment |

ROI |

References

- Rashid, A.B.; Kausik, A.K. AI revolutionizing industries worldwide: A comprehensive overview of its diverse applications. Hybrid Advances 2024, p. 100277.

- Sharma, R.; Shishodia, A.; Gunasekaran, A.; Min, H.; Munim, Z.H. The role of artificial intelligence in supply chain management: mapping the territory. International Journal of Production Research 2022, 60, 7527–7550.

- Khaleel, M.; Jebrel, A.; Shwehdy, D.M. Artificial Intelligence in Computer Science: Int. J. Electr. Eng. and Sustain. 2024, pp. 01–21. [CrossRef]

- Pournader, M.; Ghaderi, H.; Hassanzadegan, A.; Fahimnia, B. Artificial intelligence applications in supply chain management. International Journal of Production Economics 2021, 241, 108250.

- Sharma, P.; Gunasekaran, A.; Subramanian, G. Enhancing Supply Chain: Exploring and Exploiting AI Capabilities. Journal of Computer Information Systems 2024, pp. 1–15.

- MacCarthy, B.L.; Ahmed, W.A.; Demirel, G. Mapping the supply chain: Why, what and how? International Journal of Production Economics 2022, 250, 108688.

- Ivanov, D.; Dolgui, A.; Sokolov, B. Cloud supply chain: Integrating Industry 4.0 and digital platforms in the “Supply Chain-as-a-Service”. Transportation Research Part E: Logistics and Transportation Review 2022, 160, 102676.

- Modgil, S.; Singh, R.K.; Hannibal, C. Artificial intelligence for supply chain resilience: learning from Covid-19. The International Journal of Logistics Management 2022, 33, 1246–1268.

- Modgil, S.; Gupta, S.; Stekelorum, R.; Laguir, I. AI technologies and their impact on supply chain resilience during COVID-19. International Journal of Physical Distribution & Logistics Management 2022, 52, 130–149.

- Dey, P.K.; Chowdhury, S.; Abadie, A.; Vann Yaroson, E.; Sarkar, S. Artificial intelligence-driven supply chain resilience in Vietnamese manufacturing small-and medium-sized enterprises. International Journal of Production Research 2024, 62, 5417–5456.

- Baryannis, G.; Validi, S.; Dani, S.; Antoniou, G. Supply chain risk management and artificial intelligence: state of the art and future research directions. International journal of production research 2019, 57, 2179–2202.

- Ganesh, A.D.; Kalpana, P. Future of artificial intelligence and its influence on supply chain risk management–A systematic review. Computers & Industrial Engineering 2022, 169, 108206.

- Nimmagadda, V.S.P. AI-Powered Predictive Analytics for Retail Supply Chain Risk Management: Advanced Techniques, Applications, and Real-World Case Studies. Distributed Learning and Broad Applications in Scientific Research 2020, 6, 152–194.

- Khadem, M.; Khadem, A.; Khadem, S. Application of artificial intelligence in supply chain revolutionizing efficiency and optimization. International journal of industrial engineering and operational research 2023, 5, 29–38.

- Pal, S. Integrating AI in sustainable supply chain management: A new paradigm for enhanced transparency and sustainability. International Journal for Research in Applied Science and Engineering Technology 2023, 11, 2979–2984.

- Charles, V.; Emrouznejad, A.; Gherman, T. A critical analysis of the integration of blockchain and artificial intelligence for supply chain. Annals of Operations Research 2023, 327, 7–47.

- Gayam, S.R. AI for Supply Chain Visibility in E-Commerce: Techniques for Real-Time Tracking, Inventory Management, and Demand Forecasting. Distributed Learning and Broad Applications in Scientific Research 2019, 5, 218–251.

- Sanders, N.R.; Boone, T.; Ganeshan, R.; Wood, J.D. Sustainable supply chains in the age of AI and digitization: research challenges and opportunities. Journal of Business logistics 2019, 40, 229–240.

- Kollia, I.; Stevenson, J.; Kollias, S. Ai-enabled efficient and safe food supply chain. Electronics 2021, 10, 1223.

- Culot, G.; Podrecca, M.; Nassimbeni, G. Artificial intelligence in supply chain management: A systematic literature review of empirical studies and research directions. Computers in Industry 2024, 162, 104132.

- Sony, M.; Naik, S. Key ingredients for evaluating Industry 4.0 readiness for organizations: a literature review. Benchmarking: An International Journal 2020, 27, 2213–2232.

- Min, H. Artificial intelligence in supply chain management: theory and applications. International Journal of Logistics: Research and Applications 2010, 13, 13–39.

- Toorajipour, R.; Sohrabpour, V.; Nazarpour, A.; Oghazi, P.; Fischl, M. Artificial intelligence in supply chain management: A systematic literature review. Journal of Business Research 2021, 122, 502–517.

- Riahi, Y.; Saikouk, T.; Gunasekaran, A.; Badraoui, I. Artificial intelligence applications in supply chain: A descriptive bibliometric analysis and future research directions. Expert Systems with Applications 2021, 173, 114702.

- Shahzadi, G.; Jia, F.; Chen, L.; John, A. AI adoption in supply chain management: a systematic literature review. Journal of Manufacturing Technology Management 2024, 35, 1125–1150.

- Cannas, V.G.; Ciano, M.P.; Saltalamacchia, M.; Secchi, R. Artificial intelligence in supply chain and operations management: a multiple case study research. International Journal of Production Research 2024, 62, 3333–3360.

- Hangl, J.; Behrens, V.J.; Krause, S. Barriers, drivers, and social considerations for AI adoption in supply chain management: a tertiary study. Logistics 2022, 6, 63.

- Hendriksen, C. Artificial intelligence for supply chain management: Disruptive innovation or innovative disruption? Journal of Supply Chain Management 2023, 59, 65–76.

- Eyo-Udo, N. Leveraging artificial intelligence for enhanced supply chain optimization. Open Access Research Journal of Multidisciplinary Studies 2024, 7, 001–015.

- Jackson, I.; Ivanov, D.; Dolgui, A.; Namdar, J. Generative artificial intelligence in supply chain and operations management: a capability-based framework for analysis and implementation. International Journal of Production Research 2024, pp. 1–26.

- Sodiya, E.O.; Jacks, B.S.; Ugwuanyi, E.D.; Adeyinka, M.A.; Umoga, U.J.; Daraojimba, A.I.; Lottu, O.A. Reviewing the role of AI and machine learning in supply chain analytics. GSC Advanced Research and Reviews 2024, 18, 312–320.

- Dubey, R.; Bryde, D.J.; Blome, C.; Roubaud, D.; Giannakis, M. Facilitating artificial intelligence powered supply chain analytics through alliance management during the pandemic crises in the B2B context. Industrial Marketing Management 2021, 96, 135–146.

- Cadden, T.; Dennehy, D.; Mantymaki, M.; Treacy, R. Understanding the influential and mediating role of cultural enablers of AI integration to supply chain. International Journal of Production Research 2022, 60, 4592–4620.

- Naz, F.; Kumar, A.; Majumdar, A.; Agrawal, R. Is artificial intelligence an enabler of supply chain resiliency post COVID-19? An exploratory state-of-the-art review for future research. Operations Management Research 2022, 15, 378–398.

- Han, M.; Yang, T.; Zhong, J.; Zhong, Y. AI applications and supply chain concentration. Applied Economics Letters 2024, 31, 2099–2103.

- Kalusivalingam, A.K.; Sharma, A.; Patel, N.; Singh, V. Enhancing Supply Chain Visibility through AI: Implementing Neural Networks and Reinforcement Learning Algorithms. International Journal of AI and ML 2020, 1.

- Elufioye, O.A.; Ike, C.U.; Odeyemi, O.; Usman, F.O.; Mhlongo, N.Z. Ai-Driven predictive analytics in agricultural supply chains: a review: assessing the benefits and challenges of ai in forecasting demand and optimizing supply in agriculture. Computer Science & IT Research Journal 2024, 5, 473–497.

- Olan, F.; Arakpogun, E.O.; Jayawickrama, U.; Suklan, J.; Liu, S. Sustainable supply chain finance and supply networks: The role of artificial intelligence. IEEE Transactions on Engineering Management 2022.

- Olan, F.; Liu, S.; Suklan, J.; Jayawickrama, U.; Arakpogun, E.O. The role of Artificial Intelligence networks in sustainable supply chain finance for food and drink industry. International Journal of Production Research 2022, 60, 4418–4433.

- Ejjami, R.; Boussalham, K. Resilient supply chains in Industry 5.0: Leveraging AI for predictive maintenance and risk mitigation. IJFMR-Int J Multidiscip Res [Internet] 2024, 6.

- Monjur, M.E.I.; Akon, T.; et al. Supply chain management and logistics: How important interconnection is for business success. Open Journal of Business and Management 2023, 11, 2505–2524.

- Shcherbakov, V.; Silkina, G. Supply chain management open innovation: Virtual integration in the network logistics system. Journal of Open Innovation: Technology, Market, and Complexity 2021, 7, 54.

- Gurtu, A.; Johny, J. Supply chain risk management: Literature review. Risks 2021, 9, 16.

- Sánchez-Flores, R.B.; Ojeda-Benítez, S.; Cruz-Sotelo, S.E.; Navarro-González, C.R. Supply chain performance improvement: A Sustainable perspective. Techniques, tools and methodologies applied to global supply chain ecosystems 2020, pp. 333–358.

- Khanuja, A.; Jain, R.K. Supply chain integration: a review of enablers, dimensions and performance. Benchmarking: An international journal 2019, 27, 264–301.

- Vanpoucke, E.; Boyer, K.K.; Vereecke, A. Supply chain information flow strategies: an empirical taxonomy. International Journal of Operations & Production Management 2009, 29, 1213–1241.

- Power, D. Supply chain management integration and implementation: a literature review. Supply chain management: an International journal 2005, 10, 252–263.

- Daios, A.; Kostavelis, I. Industry 4.0 Technologies in Distribution Centers: A Survey. In Proceedings of the Olympus International Conference on Supply Chains. Springer, 2024, pp. 3–11.

- Samper, M.G.; Florez, D.G.; Borre, J.R.; Ramirez, J. Industry 4.0 for sustainable supply chain management: Drivers and barriers. Procedia Computer Science 2022, 203, 644–650.

- Nzeako, G.; Akinsanya, M.O.; Popoola, O.A.; Chukwurah, E.G.; Okeke, C.D. The role of AI-Driven predictive analytics in optimizing IT industry supply chains. International Journal of Management & Entrepreneurship Research 2024, 6, 1489–1497.

- Anantrasirichai, N.; Bull, D. Artificial intelligence in the creative industries: a review. Artificial intelligence review 2022, 55, 589–656.

- Wamba, S.F.; Queiroz, M.M.; Jabbour, C.J.C.; Shi, C.V. Are both generative AI and ChatGPT game changers for 21st-Century operations and supply chain excellence? International Journal of Production Economics 2023, 265, 109015.

- Fosso Wamba, S.; Guthrie, C.; Queiroz, M.M.; Minner, S. ChatGPT and generative artificial intelligence: an exploratory study of key benefits and challenges in operations and supply chain management. International Journal of Production Research 2024, 62, 5676–5696.

- Parida, P.R.; Ratnala, A.K.; Kondaveeti, D. Integrating IoT with AI-Driven Real-Time Analytics for Enhanced Supply Chain Management in Manufacturing. Journal of Artificial Intelligence Research and Applications 2024, 4, 40–84.

- Nozari, H.; Szmelter-Jarosz, A.; Ghahremani-Nahr, J. Analysis of the challenges of artificial intelligence of things (AIoT) for the smart supply chain (case study: FMCG industries). Sensors 2022, 22, 2931.

- Mohsen, B.M. Impact of artificial intelligence on supply chain management performance. Journal of Service Science and Management 2023, 16, 44–58.

- Chen, Y.; Biswas, M.I.; Talukder, M.S. The role of artificial intelligence in effective business operations during COVID-19. International Journal of Emerging Markets 2022, 18, 6368–6387.

- Kosasih, E.E.; Papadakis, E.; Baryannis, G.; Brintrup, A. A review of explainable artificial intelligence in supply chain management using neurosymbolic approaches. International Journal of Production Research 2024, 62, 1510–1540.

- Adenekan, O.A.; Solomon, N.O.; Simpa, P.; Obasi, S.C. Enhancing manufacturing productivity: A review of AI-Driven supply chain management optimization and ERP systems integration. International Journal of Management & Entrepreneurship Research 2024, 6, 1607–1624.

- Hao, X.; Demir, E. Artificial intelligence in supply chain decision-making: an environmental, social, and governance triggering and technological inhibiting protocol. Journal of Modelling in Management 2024, 19, 605–629.

- Amirkolaii, K.N.; Baboli, A.; Shahzad, M.; Tonadre, R. Demand forecasting for irregular demands in business aircraft spare parts supply chains by using artificial intelligence (AI). IFAC-PapersOnLine 2017, 50, 15221–15226.

- Abaku, E.A.; Edunjobi, T.E.; Odimarha, A.C. Theoretical approaches to AI in supply chain optimization: Pathways to efficiency and resilience. International Journal of Science and Technology Research Archive 2024, 6, 092–107.

- Kasaraneni, R.K. AI-Enhanced Supply Chain Collaboration Platforms for Retail: Improving Coordination and Reducing Costs. Journal of Bioinformatics and Artificial Intelligence 2021, 1, 410–450.

- Daios, A.; Kladovasilakis, N.; Kostavelis, I. Mixed Palletizing for Smart Warehouse Environments: Sustainability Review of Existing Methods. Sustainability 2024, 16, 1278.

- Daios, A.; Xanthopoulos, A.; Folinas, D.; Kostavelis, I. Towards automating stocktaking in warehouses: Challenges, trends, and reliable approaches. Procedia Computer Science 2024, 232, 1437–1445.

- Krishnamoorthy, G.; Kurkute, M.V.; Sreerama, J. Integrating LLMs into ai-driven supply chains: Best practices for training, development, and deployment in the retail and manufacturing industries. Journal of Artificial Intelligence Research and Applications 2024, 4, 592–627.

- Surana, A.; Kumara*, S.; Greaves, M.; Raghavan, U.N. Supply-chain networks: a complex adaptive systems perspective. International Journal of Production Research 2005, 43, 4235–4265.

- Kondapaka, K.K. Advanced AI Models for Retail Supply Chain Network Design and Optimization: Techniques, Applications, and Real-World Case Studies. Distributed Learning and Broad Applications in Scientific Research 2019, 5, 598–636.

- Yandrapalli, V. Revolutionizing supply chains using power of generative ai. International Journal of Research Publication and Reviews 2023, 4, 1556–1562.

- Skoularikis, K.; Savvas, I.K.; Garani, G.; Kakarontzas, G. A Scalable Framework for Customer Sentiment Analysis in the Telecommunication Industry. In Proceedings of the 2021 29th Telecommunications Forum (TELFOR). IEEE, 2021, pp. 1–4.

- Khatua, A.; Khatua, A.; Chi, X.; Cambria, E. Artificial intelligence, social media and supply chain management: The way forward. Electronics 2021, 10, 2348.

- Mukherjee, S.; Baral, M.M.; Nagariya, R.; Chittipaka, V.; Pal, S.K. Artificial intelligence-based supply chain resilience for improving firm performance in emerging markets. Journal of Global Operations and Strategic Sourcing 2024, 17, 516–540.

- Ivanov, D. Two views of supply chain resilience. International Journal of Production Research 2024, 62, 4031–4045.

- Singh, R.K.; Modgil, S.; Shore, A. Building artificial intelligence enabled resilient supply chain: a multi-method approach. Journal of Enterprise Information Management 2024, 37, 414–436.

- Nezamoddini, N.; Gholami, A.; Aqlan, F. A risk-based optimization framework for integrated supply chains using genetic algorithm and artificial neural networks. International Journal of Production Economics 2020, 225, 107569.

- Kalusivalingam, A.K.; Sharma, A.; Patel, N.; Singh, V. Enhancing Supply Chain Resilience through AI: Leveraging Deep Reinforcement Learning and Predictive Analytics. International Journal of AI and ML 2022, 3.

- Kassa, A.; Kitaw, D.; Stache, U.; Beshah, B.; Degefu, G. Artificial intelligence techniques for enhancing supply chain resilience: A systematic literature review, holistic framework, and future research. Computers & Industrial Engineering 2023, 186, 109714.

- Belhadi, A.; Mani, V.; Kamble, S.S.; Khan, S.A.R.; Verma, S. Artificial intelligence-driven innovation for enhancing supply chain resilience and performance under the effect of supply chain dynamism: an empirical investigation. Annals of Operations Research 2024, 333, 627–652.

- Chukwu, N.; Yufenyuy, S.; Ejiofor, E.; Ekweli, D.; Ogunleye, O.; Clement, T.; Obunadike, C.; Adeniji, S.; Elom, E.; Obunadike10, C. Resilient Chain: AI-Enhanced Supply Chain Security and Efficiency Integration. Int. J. Sci. Manag. Res 2024, 7, 46–65.

- Belhadi, A.; Kamble, S.; Fosso Wamba, S.; Queiroz, M.M. Building supply-chain resilience: an artificial intelligence-based technique and decision-making framework. International Journal of Production Research 2022, 60, 4487–4507.

- Mittal, U.; Panchal, D. AI-based evaluation system for supply chain vulnerabilities and resilience amidst external shocks: An empirical approach. Reports in Mechanical Engineering 2023, 4, 276–289.

- Helo, P.; Hao, Y. Artificial intelligence in operations management and supply chain management: An exploratory case study. Production Planning & Control 2022, 33, 1573–1590.

- Nimmagadda, V.S.P. Artificial Intelligence for Supply Chain Visibility and Transparency in Retail: Advanced Techniques, Models, and Real-World Case Studies. Journal of Machine Learning in Pharmaceutical Research 2023, 3, 87–120.

- krishna Vaddy, R. Future of AI/ML in digital commerce and supply chain. International Transactions in Artificial Intelligence 2023, 7, 1–19.

- Zamani, E.D.; Smyth, C.; Gupta, S.; Dennehy, D. Artificial intelligence and big data analytics for supply chain resilience: a systematic literature review. Annals of Operations Research 2023, 327, 605–632.

- Sodhi, M.S.; Seyedghorban, Z.; Tahernejad, H.; Samson, D. Why emerging supply chain technologies initially disappoint: Blockchain, IoT, and AI. Production and Operations Management 2022, 31, 2517–2537.

- Tsolakis, N.; Schumacher, R.; Dora, M.; Kumar, M. Artificial intelligence and blockchain implementation in supply chains: a pathway to sustainability and data monetisation? Annals of Operations Research 2023, 327, 157–210.

- Younis, H.; Sundarakani, B.; Alsharairi, M. Applications of artificial intelligence and machine learning within supply chains: systematic review and future research directions. Journal of Modelling in Management 2022, 17, 916–940.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).