Submitted:

23 January 2025

Posted:

25 January 2025

You are already at the latest version

Abstract

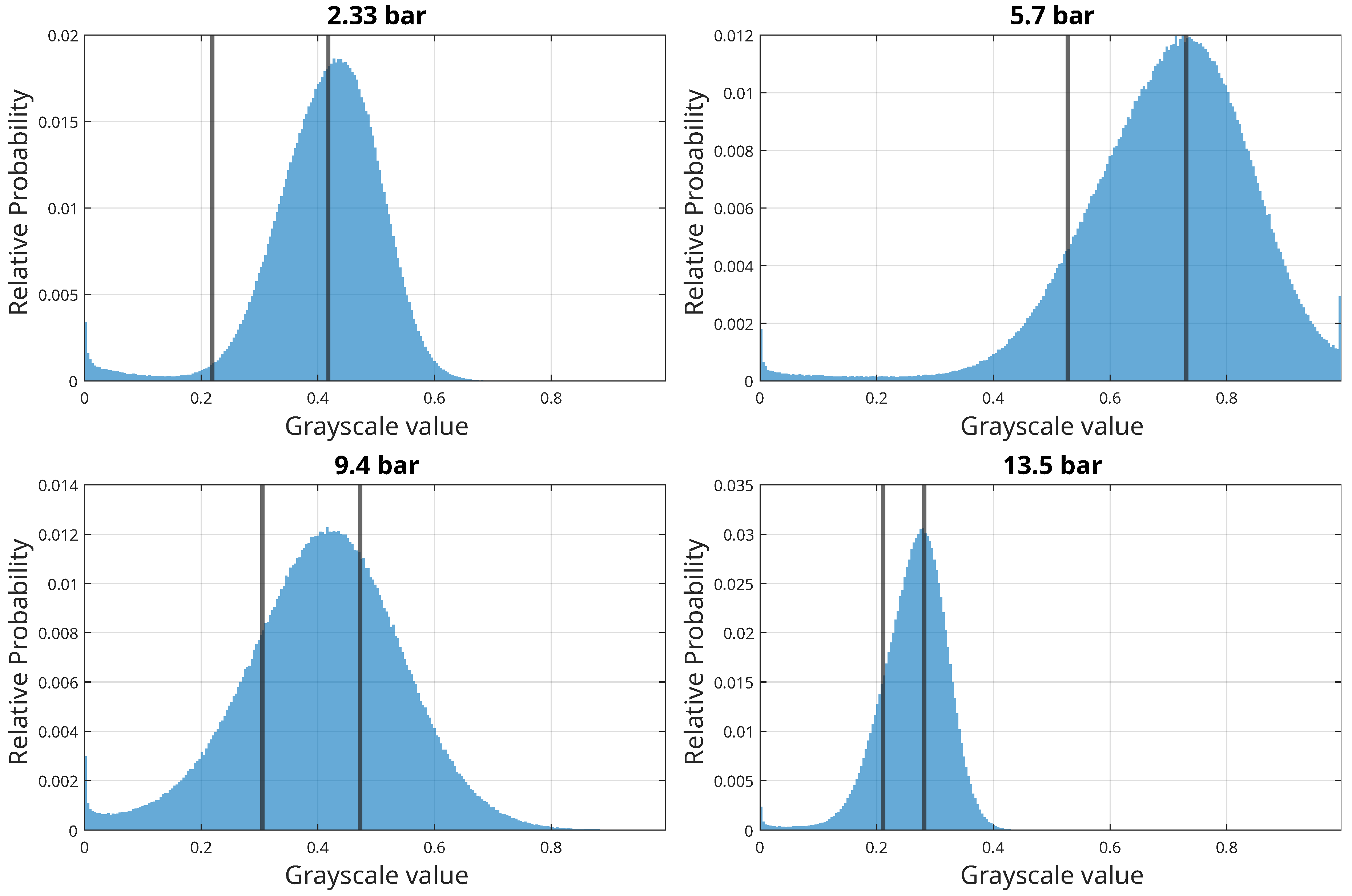

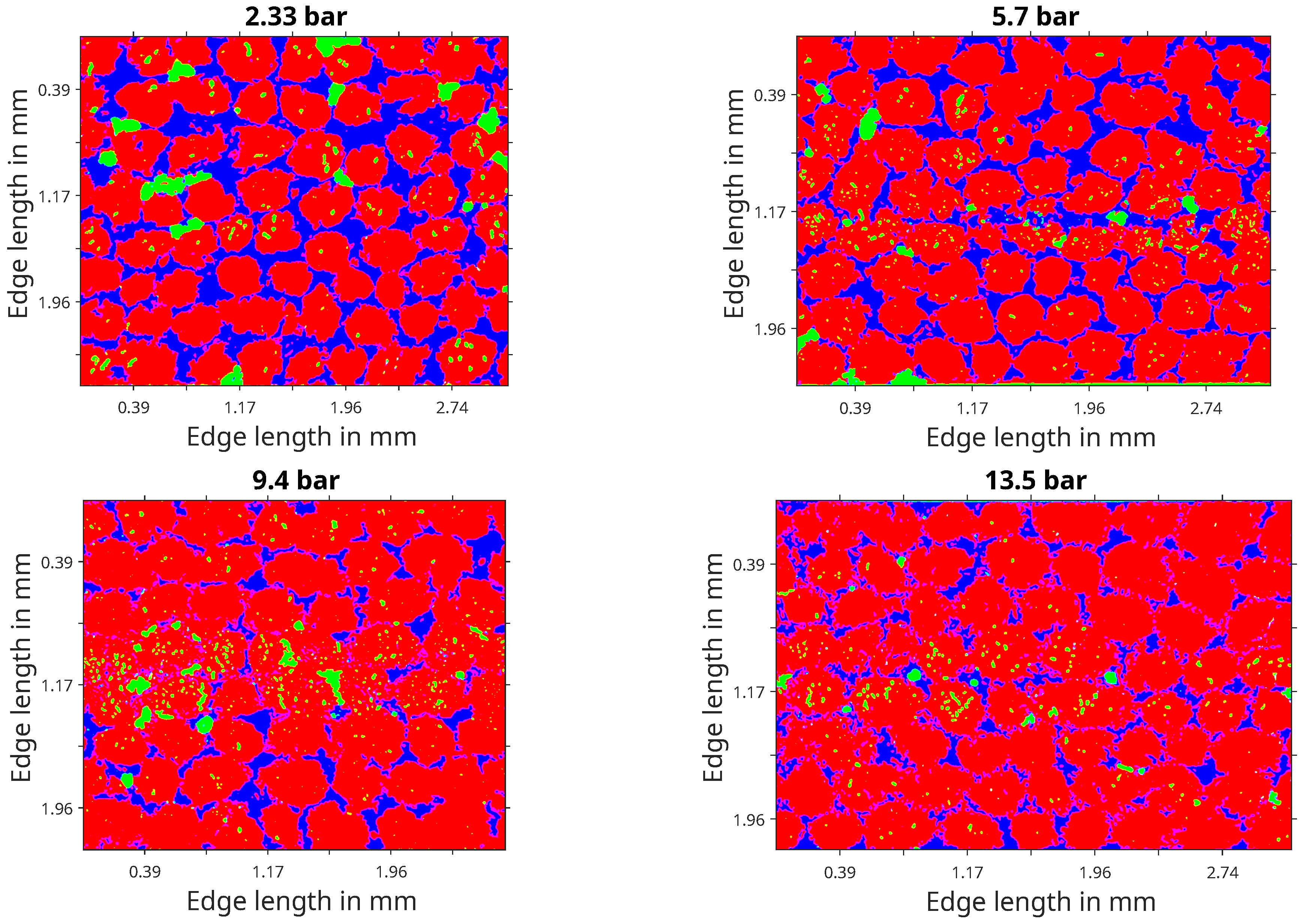

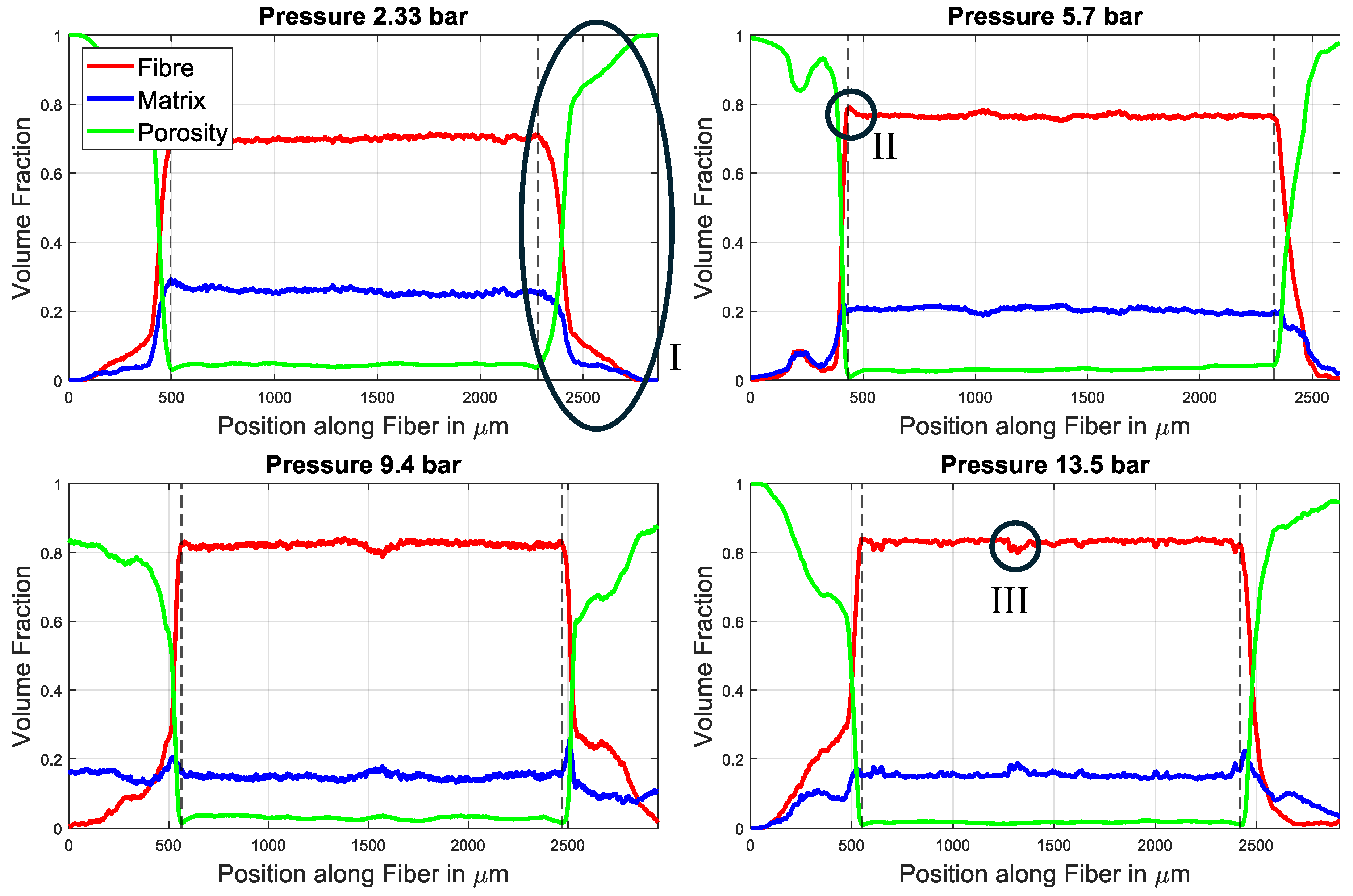

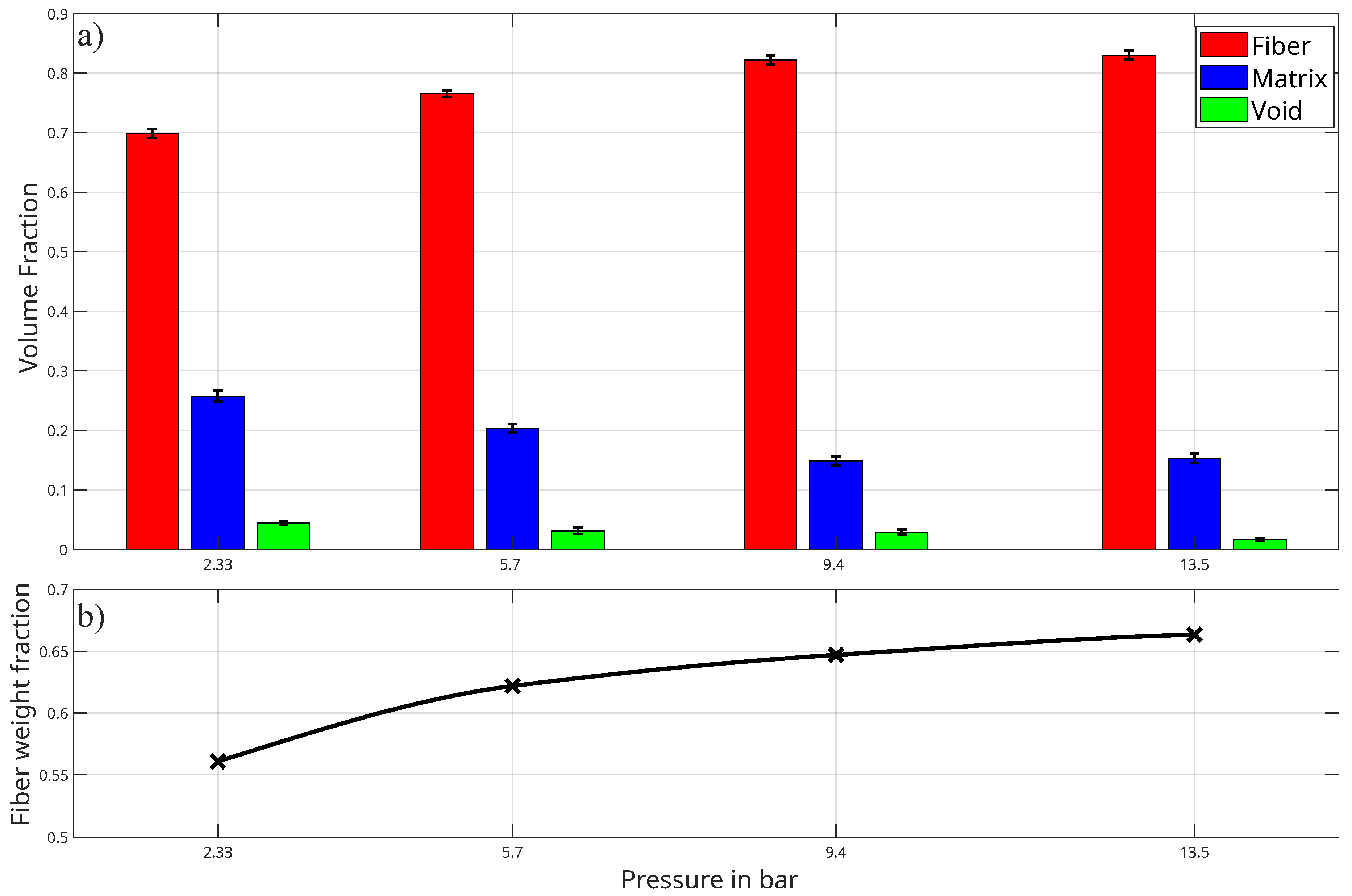

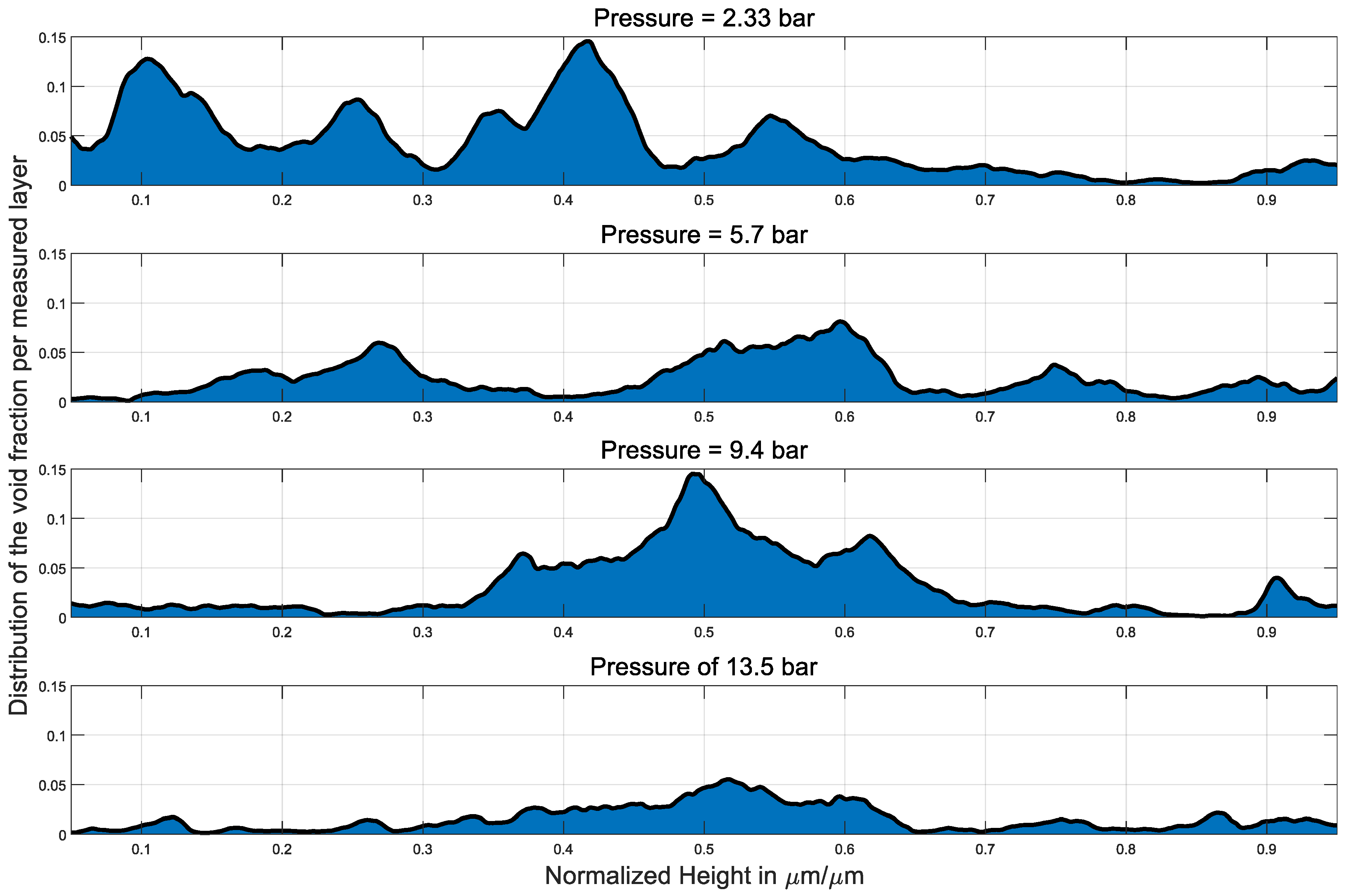

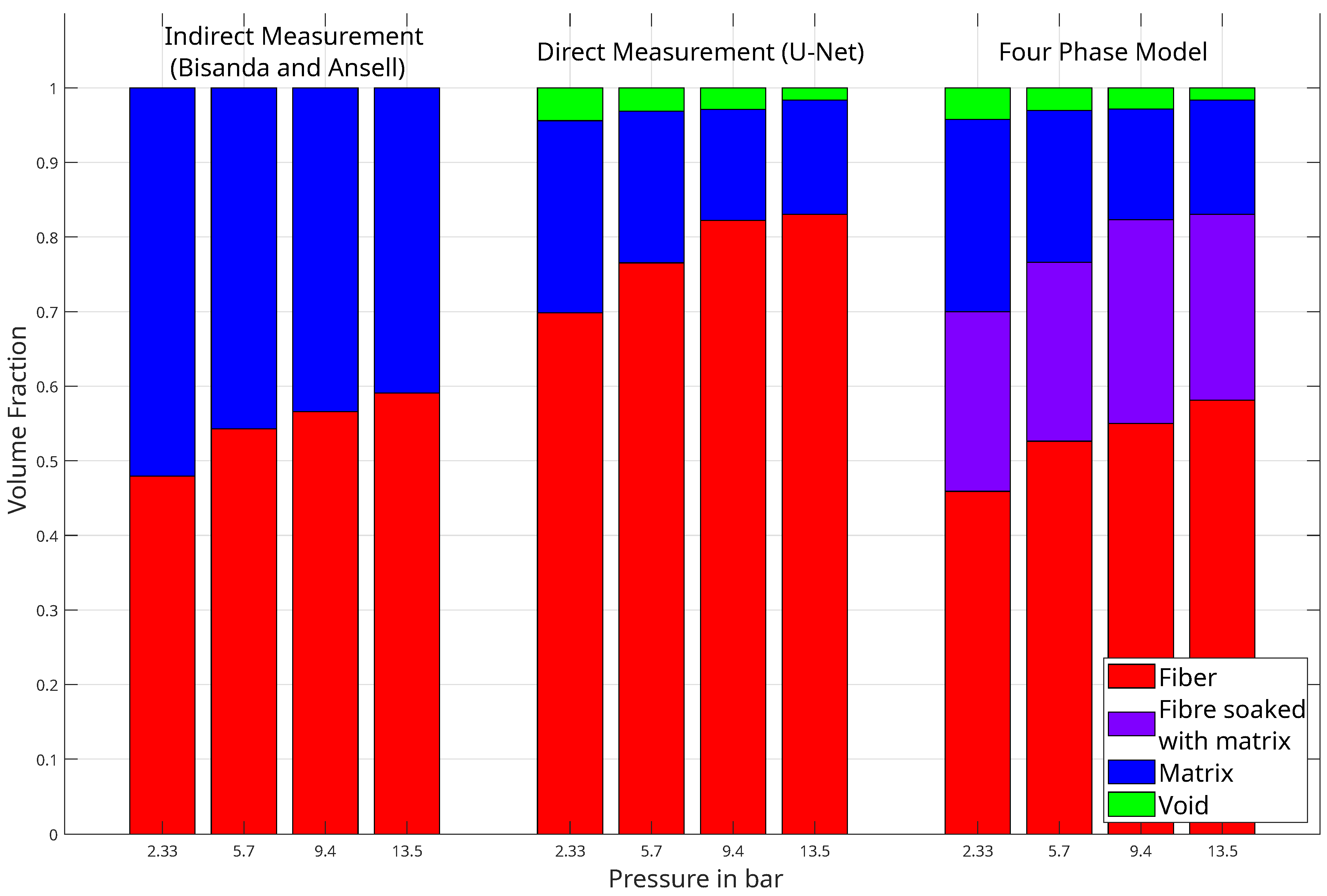

The fiber volume fraction significantly influences the mechanical properties of fiber-reinforced composites. However, accurate measurements can be particularly challenging in natural fiber-reinforced polymers. This study compares indirect methods using gravimetric and volumetric measurements with a U-Net-based direct method using micro-CT images for flax fiber-reinforced polymers made via compression molding at 2.33–13.5 bar. A notable discrepancy was observed between the direct and indirect methods, with the latter yielding a fiber volume fraction approximately 25% lower than what can be determined optically. This difference may arise from the matrix being absorbed by the fibers, resulting in a mixed region between dry fiber and pure matrix, further explained using a four-phase model. Our findings indicate that the volume fraction is dependent on the applied pressure. Specifically, we established a linear relationship between the fiber volume fraction and the pressure up to 9.4 bar, beyond which the fiber volume fraction plateaued. Furthermore, we examined the impact of void distribution in relation to pressure. At lower pressures, voids are distributed irregularly throughout the composite, whereas at higher pressures, the overall number of voids decreases, and they tend to concentrate primarily in the center.

Keywords:

1. Introduction

2. Materials and Methods

2.1. Manufacturing of Flax Fiber-Reinforced Polymer Samples Using Compression Molding

2.2. Indirect Measurement of the Fiber Volume Fraction

2.3. Direct Measurement of the Fiber Volume Fraction

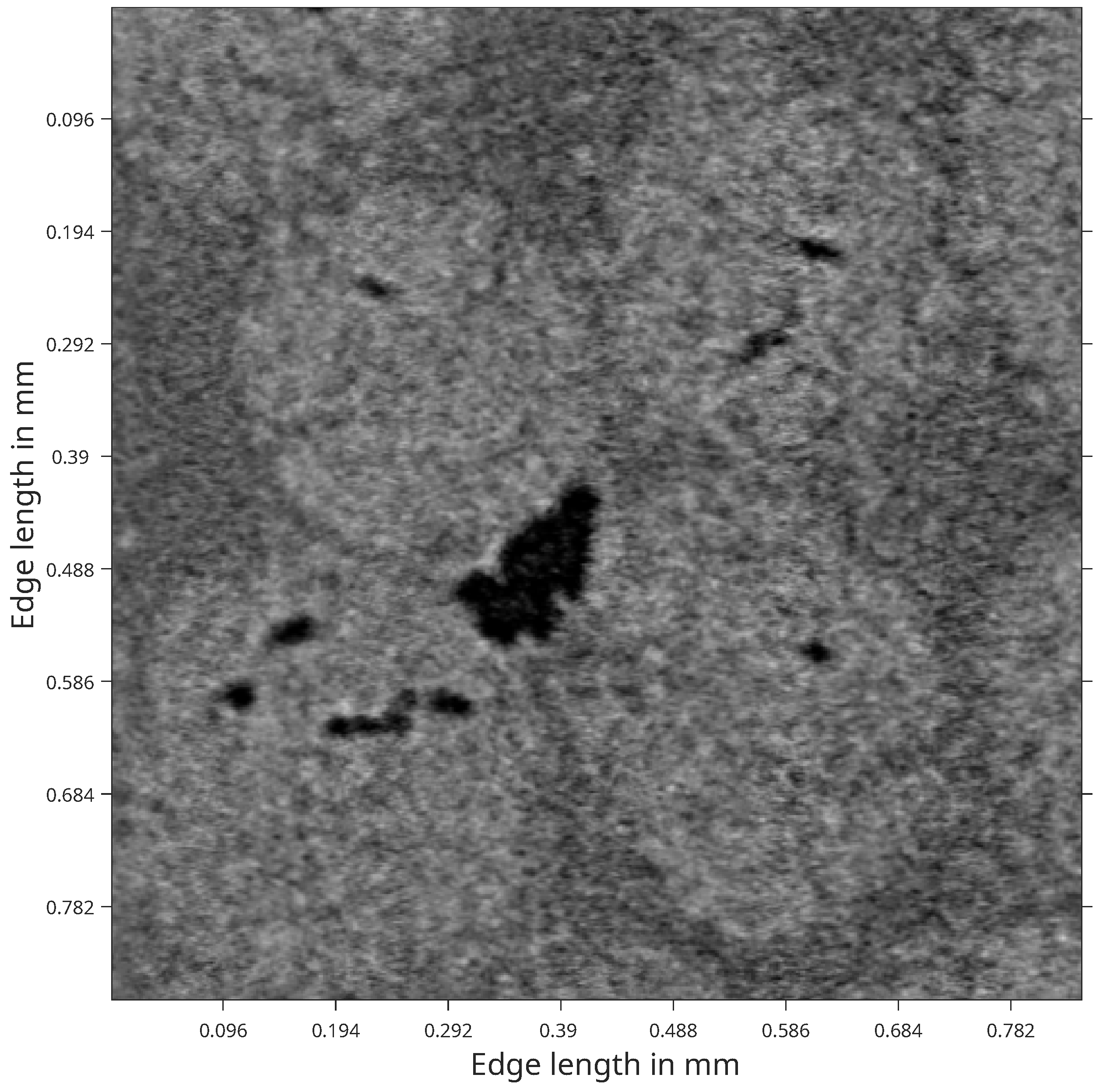

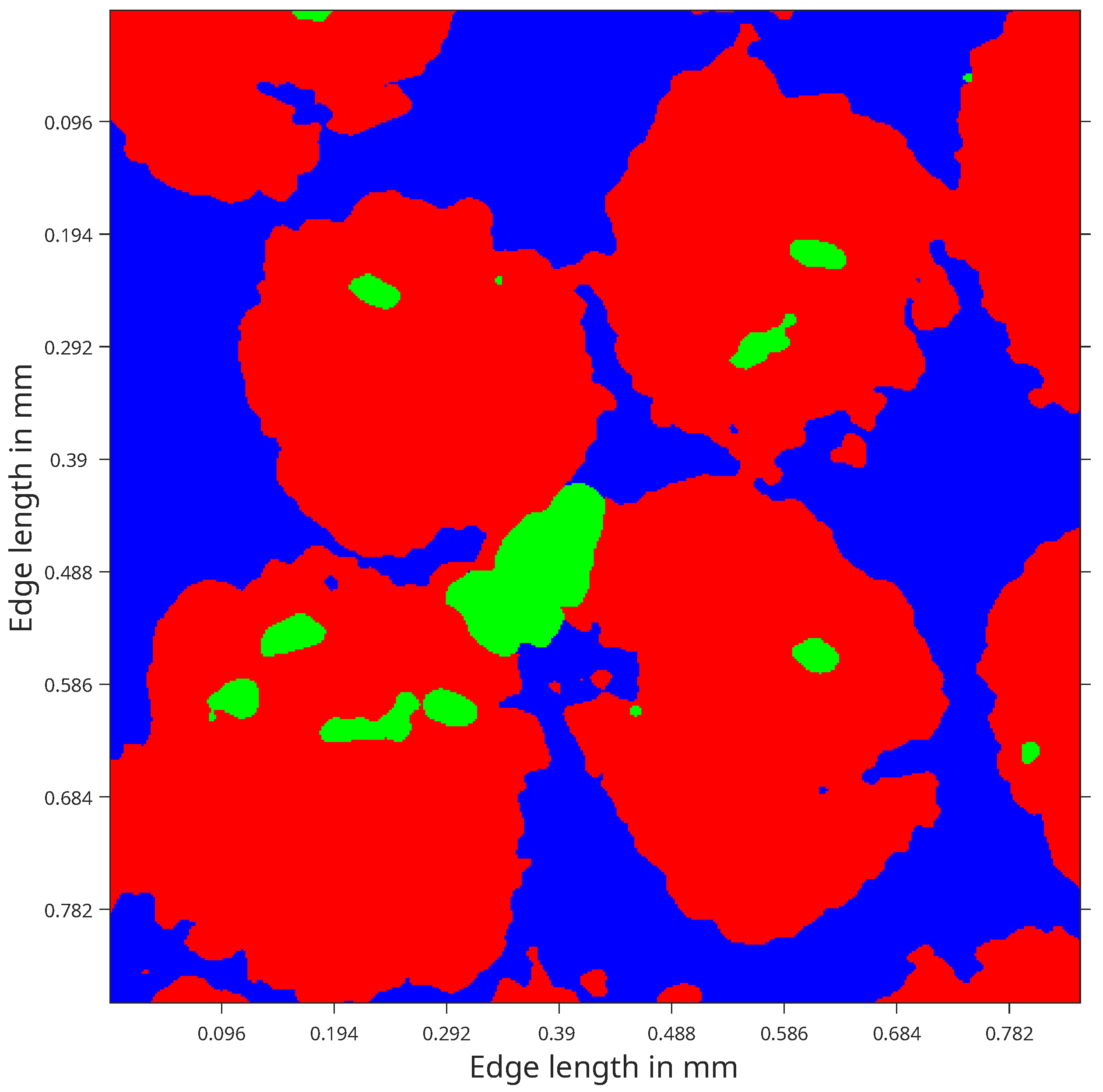

2.3.1. Data Representation Overview

2.3.2. Data Impurities

2.3.3. Summary of Data Processing Pipeline

2.3.4. Data and Data Augmentation

- Rotation (Uniform between 0 and 360 degrees)

- Translation (Uniform over the whole original image)

- Uniform Scaling (Uniform between and )

- Mirroring (Horizontal and Vertical)

2.3.5. Expert’s Segmentation Dataset

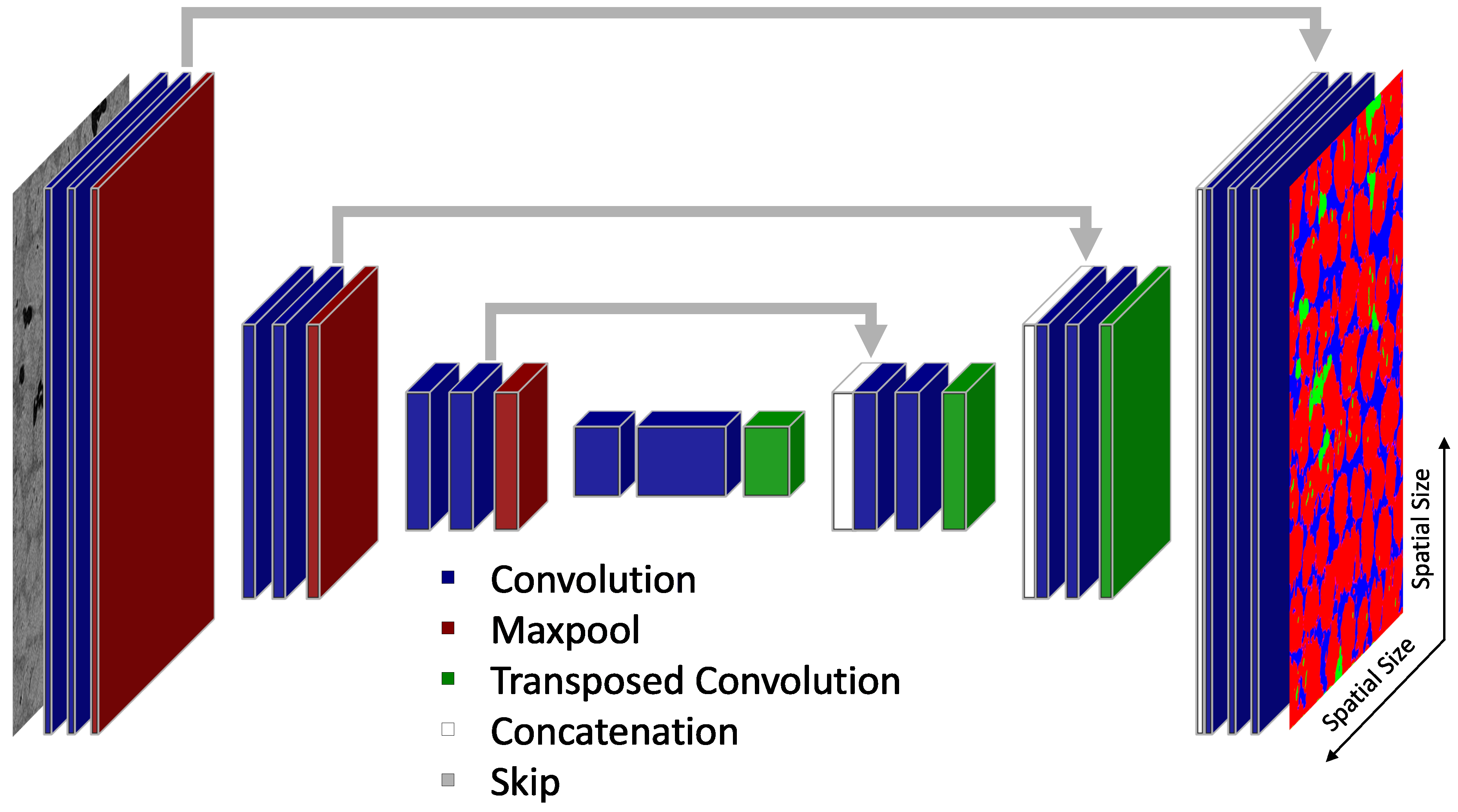

2.3.6. Neural Network Architecture and Training

2.3.7. Hyperparameter Optimization

- Learning Rate (0.01 to 1, 20 linearly spaced values)

- Batch Size (1 to 40, 10 non-uniform spaced values)

- Data set Size (1 to 40, 10 non-uniform spaced values)

- Data set Iterations (1 to 40, 10 non-uniform spaced values)

- Class Weights 1-3 (3 Distinctive Hyperparameters, 0 to 1 each, 30 linearly spaced values each)

- Convolutional Kernel Size (3 and 5, 2 values)

- Data Augmentation Noise (0 to 0.05, 10 linearly spaced values)

- Input/Output Size (128 to 256, 3 Uniform spaced Values)

2.3.8. Neural Network Testing

2.3.9. Software and Hardware Infrastructure

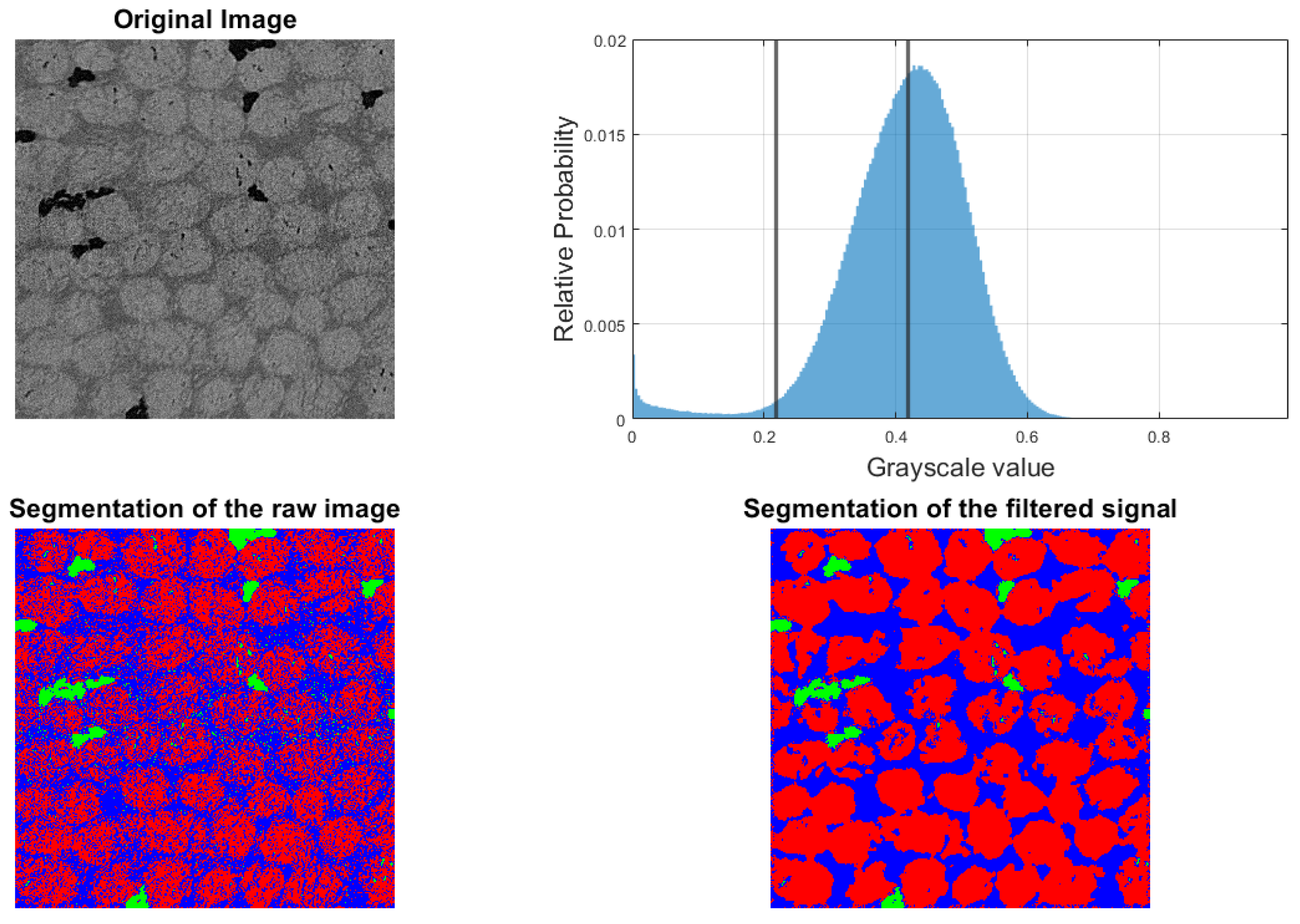

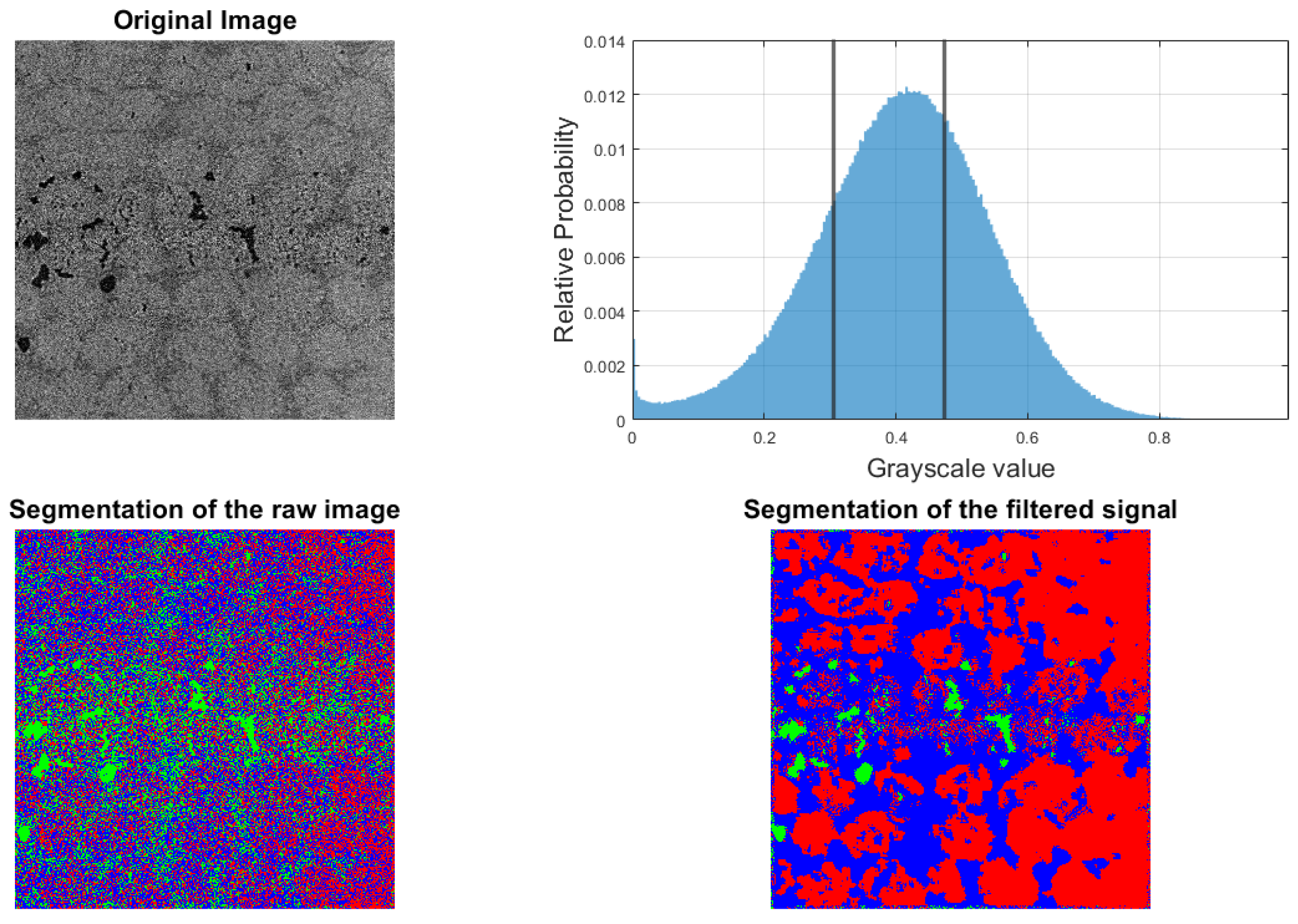

2.3.10. Comparison Against Commercial Software Segmentation Tools

3. Results & Discussion

3.1. Neural Network Data Processing

3.2. Pressure Dependence of Volume Fractions

3.3. Discrepancy Between Direct and Indirect Fiber Volume Fraction

4. Conclusion

Funding

Acknowledgments

Appendix A. Regions of Interest

Appendix B. Evaluation of U-Net Performance

| Fiber Volume Fraction | Matrix Volume Fraction | Void Volume Fraction | |||||||

| U-Net | Expert | Difference | U-Net | Expert | Difference | U-Net | Expert | Difference | |

| 2.33 Bar | 67.5% | 69.6% | -2.1% | 28.8% | 27.3% | 1.5% | 3.6% | 3.0% | 0.6% |

| 5.7 Bar | 72.3% | 74.3% | -2.0% | 25.3% | 23.5% | 1.8% | 2.4% | 2.2% | 0.2% |

| 9.4 Bar | 78.1% | 80.8% | -2.7% | 19.2% | 16.6% | 2.6% | 2.7% | 2.6% | 0.1% |

| 13.5 Bar | 81.7% | 84.0% | -2.2% | 16.5% | 14.5% | 2.0% | 1.8% | 1.5% | 0.2% |

| Mean | -2.3% | 2.0% | 0.3% | ||||||

Appendix C. Evaluation of Otsu’s Thresholding Performance

| Raw Image | Filtered Image | |||||

| Pressure in bar |

Fiber in % |

Matrix in % |

Void in % |

Fiber in % |

Matrix in % |

Void in % |

| 2.33 | 50.13 | 46.67 | 3.32 | 62.63 | 34.88 | 2.49 |

| 5.7 | 42.46 | 46.25 | 11.29 | 66.37 | 31.88 | 1.75 |

| 9.4 | 30.76 | 47.54 | 21.70 | 53.07 | 44.00 | 2.93 |

| 13.5 | 36.97 | 45.35 | 17.68 | 64.72 | 33.71 | 1.57 |

| Fiber Volume Fraction | Matrix Volume Fraction | Void Volume Fraction | |||||||

| Otsu | Expert | Difference | Otsu | Expert | Difference | Otsu | Expert | Difference | |

| 2.33 Bar | 62.6% | 69.6% | -7.0% | 34.9% | 27.3% | 7.5% | 2.5% | 3.0% | -0.5% |

| 5.7 Bar | 66.4% | 74.3% | -7.9% | 31.9% | 23.5% | 8.4% | 1.7% | 2.2% | -0.5% |

| 9.4 Bar | 53.1% | 80.8% | -27.7% | 44.0% | 16.6% | 27.4% | 2.9% | 2.6% | 0.3% |

| 13.5 Bar | 64.7% | 84.0% | -19.2% | 33.7% | 14.5% | 19.2% | 1.6% | 1.5% | 0.1% |

| Mean | -15.5% | 15.6% | -0.3% | ||||||

Appendix D. Summary of the Volume Fractions

| Fiber Volume Fraction | Matrix Volume Fraction | Void Volume Fraction | ||||

| Pressure in bar |

Mean in % |

Standard Deviation in % |

Mean in % |

Standard Deviation in % |

Mean in % |

Standard Deviation in % |

| 2.33 | 69.85 | 0.73 | 25.74 | 0.87 | 4.4 | 0.35 |

| 5.7 | 76.53 | 0.54 | 20.34 | 0.69 | 3.12 | 0.57 |

| 9.4 | 82.24 | 0.77 | 14.85 | 0.74 | 2.9 | 0.47 |

| 13.5 | 83.06 | 0.73 | 15.32 | 0.79 | 1.6 | 0.22 |

| Pressure in bar |

Roe in % |

Bisanda in % |

| 2.33 | 47.83 | 47.93 |

| 5.7 | 54.13 | 54.28 |

| 9.4 | 57.08 | 56.6 |

| 13.5 | 58.35 | 59.07 |

| Pressure in bar |

Gradient of Fiber in |

Gradient of Matrix in |

Gradient of Void in |

Gradient of Roe in |

Gradient of Bisanda in |

| 2.33 - 5.7 | 1.98 | -1.6 | -0.38 | 1.87 | 1.88 |

| 5.7 - 9.4 | 1.54 | -1.48 | -0.06 | 0.8 | 0.63 |

| 9.4 - 13.5 | 0.19 | 0.11 | 0.31 | 0.31 | 0.6 |

References

- Pan, N. Theoretical determination of the optimal fiber volume fraction and fiber–matrix property compatibility of short fiber composites. Polymer Composites 1993, 14, 85–93. [Google Scholar] [CrossRef]

- Zaghloul, M.Y.; Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Influence of Stress Level and Fibre Volume Fraction on Fatigue Performance of Glass Fibre-Reinforced Polyester Composites. Polymers 2022, 14. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.C.; See, S.K. Electrical properties of unidirectional carbon-epoxy composites in wide frequency band. Journal of Physics D: Applied Physics 1990, 23, 916–921. [Google Scholar] [CrossRef]

- Shah, D.U. Developing plant fibre composites for structural applications by optimising composite parameters: a critical review. Journal of Materials Science 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Daniel, I.M. Engineering mechanics of composite materials; OXFORD UNIVERSITY PRESS, 2006.

- Menczel, J.D.; Prime, R.B. Thermal Analysis of Polymers; Wiley, 2009. [CrossRef]

- D20 Committee. Test Methods for Void Content of Reinforced Plastics. [CrossRef]

- D20 Committee. Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Transactions on Systems, Man, and Cybernetics 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Cann, M.T.; Adams, D.O.; Schneider, C.L. Characterization of Fiber Volume Fraction Gradients in Composite Laminates. Journal of Composite Materials 2008, 42, 447–466. [Google Scholar] [CrossRef]

- Sencu, R.M.; Yang, Z.; Wang, Y.C.; Withers, P.J.; Rau, C.; Parson, A.; Soutis, C. Generation of micro-scale finite element models from synchrotron X-ray CT images for multidirectional carbon fibre reinforced composites. Composites Part A: Applied Science and Manufacturing 2016, 91, 85–95. [Google Scholar] [CrossRef]

- El Messiry, M. Theoretical determination of the fiber volume fraction distribution for natural fiber fabric reinforced polymer composite. Journal of Industrial Textiles 2018, 48, 904–925. [Google Scholar] [CrossRef]

- Niels de Beus.; Michael Carus.; Martha Barth. Carbon Footprint and Sustainability of Different Natural Fibres for Biocomposites and Insulation Material: Study providing data for the automotive and insulation industry.

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results in Engineering 2023, 19, 101271. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Athiyah, S.F.; Shazleen, S.S.; Rafiqah, S.A.; Harussani, M.M.; Kamarudin, S.H.; Razman, M.R.; Rahmah, M.; Zainudin, E.S.; et al. A Review on Mechanical Performance of Hybrid Natural Fiber Polymer Composites for Structural Applications. Polymers 2021, 13. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Wang, F.; Zhou, S.; Lu, Z.; Ran, S.; Li, L.; Shao, J. Thermal and mechanical performance of unidirectional composites from bamboo fibers with varying volume fractions. Polymer Composites 2019, 40, 3929–3937. [Google Scholar] [CrossRef]

- Georgiopoulos, P.; Kontou, E.; Georgousis, G. Effect of silane treatment loading on the flexural properties of PLA/flax unidirectional composites. Composites Communications 2018, 10, 6–10. [Google Scholar] [CrossRef]

- Gning, P.B.; Liang, S.; Guillaumat, L.; Pui, W.J. Influence of process and test parameters on the mechanical properties of flax/epoxy composites using response surface methodology. Journal of Materials Science 2011, 46, 6801–6811. [Google Scholar] [CrossRef]

- Ronneberger, O.; Fischer, P.; Brox, T. U-Net: Convolutional Networks for Biomedical Image Segmentation. In Medical Image Computing and Computer-Assisted Intervention – MICCAI 2015; Navab, N., Hornegger, J., Wells, W.M., Frangi, A.F., Eds.; Springer International Publishing: Cham, 2015; Vol.9351, Lecture Notes in Computer Science; pp. 234–241. [Google Scholar] [CrossRef]

- Azad, R.; Aghdam, E.K.; Rauland, A.; Jia, Y.; Avval, A.H.; Bozorgpour, A.; Karimijafarbigloo, S.; Cohen, J.P.; Adeli, E.; Merhof, D. Medical Image Segmentation Review: The success of U-Net.

- Blarr, J.; Kunze, P.; Kresin, N.; Liebig, W.V.; Inal, K.; Weidenmann, K.A. Novel thresholding method and convolutional neural network for fiber volume content determination from 3D micro-CT images. NDT & E International 2024, 144, 103067. [Google Scholar] [CrossRef]

- Galvez-Hernandez, P.; Kratz, J. The effect of convolutional neural network architectures on phase segmentation of composite material X-ray micrographs. Journal of Composite Materials 2023, 57, 2899–2918. [Google Scholar] [CrossRef]

- Galvez-Hernandez, P.; Gaska, K.; Kratz, J. Phase segmentation of uncured prepreg X-Ray CT micrographs. Composites Part A: Applied Science and Manufacturing 2021, 149, 106527. [Google Scholar] [CrossRef]

- BComp Ltd. ampliTex TM, 2021.

- Entropy Resins. 305 - Compression Moulding Epoxy, 2024.

- Entropy Resins. CPF Fast, 2024.

- Kern-sohn. Kern Digitalscale EMB 1000-2, 2024.

- Muthuvel, B.; Bhattacharyya, D.; Bickerton, S. Development of innovative flow visualisation methods to investigate the stages of Wet Compression Moulding (WCM) process. IOP Conference Series: Materials Science and Engineering 2020, 912, 052013. [Google Scholar] [CrossRef]

- Francucci, G.; Palmer, S.; Hall, W. External compaction pressure over vacuum-bagged composite parts: Effect on the quality of flax fiber/epoxy laminates. Journal of Composite Materials 2018, 52, 3–15. [Google Scholar] [CrossRef]

- ME-Meßsysteme. KM115 200kN, 2024.

- Roe, P.J.; Ansell, M.P. Jute-reinforced polyester composites. Journal of Materials Science 1985, 20, 4015–4020. [Google Scholar] [CrossRef]

- Oksman, K. High Quality Flax Fibre Composites Manufactured by the Resin Transfer Moulding Process. Journal of Reinforced Plastics and Composites 2001, 20, 621–627. [Google Scholar] [CrossRef]

- Madsen, B. Properties of plant fibre yarn polymer composites: An experimental study, [1. oplag] ed.; Vol. Nr. 082, Rapport / BYG. DTU, BYG. DTU: [Lyngby], 2004.

- Bisanda, E.; Ansell, M.P. The effect of silane treatment on the mechanical and physical properties of sisal-epoxy composites. Composites Science and Technology 1991, 41, 165–178. [Google Scholar] [CrossRef]

- MADSEN, B.; THYGESEN, A.; LILHOLT, H. Plant fibre composites – porosity and volumetric interaction. Composites Science and Technology 2007, 67, 1584–1600. [Google Scholar] [CrossRef]

- Pinter, P.; Dietrich, S.; Bertram, B.; Kehrer, L.; Elsner, P.; Weidenmann, K.A. Comparison and error estimation of 3D fibre orientation analysis of computed tomography image data for fibre reinforced composites. NDT & E International 2018, 95, 26–35. [Google Scholar] [CrossRef]

- U.A. Mortensen.; S. Rasmussen.; L.P. Mikkelsen.; A. Fraisse.; T.L. Andersen. The impact of the fiber volume fraction on the fatigue performance of glass fiber composites. Composites Part A 2023. [CrossRef]

- Walsh, J.; Othmani, A.; Jain, M.; Dev, S. Using U-Net Network for Efficient Brain Tumor Segmentation in MRI Images.

- Azad, R.; Aghdam, E.K.; Rauland, A.; Jia, Y.; Avval, A.H.; Bozorgpour, A.; Karimijafarbigloo, S.; Cohen, J.P.; Adeli, E.; Merhof, D. Medical Image Segmentation Review: The Success of U-Net. IEEE Transactions on Pattern Analysis and Machine Intelligence 2024, pp. 1–20. [CrossRef]

- Badran, A.; Parkinson, D.; Ushizima, D.; Marshall, D.; Maillet, E. Validation of Deep Learning Segmentation of CT Images of Fiber-Reinforced Composites. Journal of Composites Science 2022, 6, 60. [Google Scholar] [CrossRef]

- Tran, T.; Stough, J.V.; Zhang, X.; Haggerty, C.M. Bayesian Optimization of 2D Echocardiography Segmentation. In Proceedings of the 2021 IEEE 18th International Symposium on Biomedical Imaging (ISBI). IEEE; 2021; pp. 1007–1011. [Google Scholar] [CrossRef]

- Sicard, D.; Briois, P.; Billard, A.; Thevenot, J.; Boichut, E.; Chapellier, J.; Bernard, F. Deep Learning and Bayesian Hyperparameter Optimization: A Data-Driven Approach for Diamond Grit Segmentation toward Grinding Wheel Characterization. Applied Sciences 2022, 12, 12606. [Google Scholar] [CrossRef]

- van Dyk, D.A.; Meng, X.L. The Art of Data Augmentation. Journal of Computational and Graphical Statistics 2001, 10, 1–50. [Google Scholar] [CrossRef]

- Mumuni, A.; Mumuni, F. Data augmentation: A comprehensive survey of modern approaches. Array 2022, 16, 100258. [Google Scholar] [CrossRef]

- Uysal, E.S.; Bilici, M.Ş.; Zaza, B.S.; Özgenç, M.Y.; Boyar, O. Exploring The Limits Of Data Augmentation For Retinal Vessel Segmentation.

- Venema, G. Foundations of geometry, ed., 2nd ed. ed.; Pearson: Boston, 2012. [Google Scholar]

- Ben Naceur, M.; Akil, M.; Saouli, R.; Kachouri, R. Fully automatic brain tumor segmentation with deep learning-based selective attention using overlapping patches and multi-class weighted cross-entropy. Medical image analysis 2020, 63, 101692. [Google Scholar] [CrossRef] [PubMed]

- Kervadec, H.; Bouchtiba, J.; Desrosiers, C.; Granger, E.; Dolz, J.; Ayed, I.B. Boundary loss for highly unbalanced segmentation. Medical image analysis 2021, 67, 101851. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Shami, A. On Hyperparameter Optimization of Machine Learning Algorithms: Theory and Practice. Neurocomputing 2020, 415, 295–316. [Google Scholar] [CrossRef]

- Jia Wu.; Xiu-Yun Chen.; Hao Zhang.; Li-Dong Xiong.; Hang Lei.; Si-Hao Deng. Hyperparameter Optimization for Machine Learning Models Based on Bayesian Optimizationb. JOURNAL OF ELECTRONIC SCIENCE AND TECHNOLOGY 2019.

- Frazier, P.I. Bayesian Optimization. In Recent Advances in Optimization and Modeling of Contemporary Problems; Gel, E.; Ntaimo, L.; Shier, D.; Greenberg, H.J., Eds.; INFORMS, 2018; pp. 255–278. [CrossRef]

- Bezanson, J.; Edelman, A.; Karpinski, S.; Shah, V.B. Julia: A Fresh Approach to Numerical Computing.

- Pal, A. Lux: Explicit Parameterization of Deep Neural Networks in Julia, 2023. [CrossRef]

- Avizo. Artificial Intelligence for 3D Visualization and Analysis Software | Thermo Fisher Scientific - DE. https://www.thermofisher.com/de/de/home/electron-microscopy/products/software-em-3d-vis/3d-visualization-analysis-software/artificial-intelligence.html, 17.01.2025.

- Industrial CT Software | Volume Graphics. Deep Segmentation, 17.01.2025.

- Song, Y.; Shen, C.; Damiani, R.; Lange, D. Image-based Restoration of the Concrete Void System Using 2D-to-3D Unfolding Technique. Construction and Building Materials 2020. [Google Scholar] [CrossRef]

- Anderson, J.; SPARNINS, E.; JOFFE, R.; WALLSTROM, L. Strength distribution of elementary flax fibres. Composites Science and Technology 2005, 65, 693–702. [Google Scholar] [CrossRef]

- Camata, G.; Corotis, R.; Spacone, E. Simplified stochastic modeling and simulation of unidirectional fiber reinforced composites. Probabilistic Engineering Mechanics 2004, 19, 33–40. [Google Scholar] [CrossRef]

- Phoenix, S.L. Stochastic strength and fatigue of fiber bundles. International Journal of Fracture 1978, 14, 327–344. [Google Scholar] [CrossRef]

- Stamboulis, A.; Baillie, C.A.; Peijs, T. Effects of environmental conditions on mechanical and physical properties of flax fibers. Composites Part A: Applied Science and Manufacturing 2001, 32, 1105–1115. [Google Scholar] [CrossRef]

- Munson, D.E.; May, R.P. Dynamically Determined High-Pressure Compressibilities of Three Epoxy Resin Systems. Journal of Applied Physics 1972, 43, 962–971. [Google Scholar] [CrossRef]

- Barhdadi, E.H.; Lipinski, P.; Cherkaoui, M. Four Phase Model: A New Formulation to Predict the Effective Elastic Moduli of Composites. Journal of Engineering Materials and Technology 2007, 129, 313–320. [Google Scholar] [CrossRef]

- Le Duigou, A.; Kervoelen, A.; Le Grand, A.; Nardin, M.; Baley, C. Interfacial properties of flax fibre–epoxy resin systems: Existence of a complex interphase. Composites Science and Technology 2014, 100, 152–157. [Google Scholar] [CrossRef]

- Célino, A.; Fréour, S.; Jacquemin, F.; Casari, P. The hygroscopic behavior of plant fibers: a review. Frontiers in chemistry 2013, 1, 43. [Google Scholar] [CrossRef]

- Le Duigou, A.; Merotte, J.; Bourmaud, A.; Davies, P.; Belhouli, K.; Baley, C. Hygroscopic expansion: A key point to describe natural fibre/polymer matrix interface bond strength. Composites Science and Technology 2017, 151, 228–233. [Google Scholar] [CrossRef]

- Bachchan, A.A.; Das, P.P.; Chaudhary, V. Effect of moisture absorption on the properties of natural fiber reinforced polymer composites: A review. Materials Today: Proceedings 2022, 49, 3403–3408. [Google Scholar] [CrossRef]

- Katariya, P.K.; Rajput, C.D. Micromechanics Analysis of Fiber Reinforced Composite. International Journal of Engineering Research and 2015, V4. [Google Scholar] [CrossRef]

- El Sawi, I.; Fawaz, Z.; Zitoune, R.; Bougherara, H. An investigation of the damage mechanisms and fatigue life diagrams of flax fiber-reinforced polymer laminates. Journal of Materials Science 2014, 49, 2338–2346. [Google Scholar] [CrossRef]

- Aslan, M.; Mehmood, S.; Madsen, B. Effect of consolidation pressure on volumetric composition and stiffness of unidirectional flax fibre composites. Journal of Materials Science 2013, 48, 3812–3824. [Google Scholar] [CrossRef]

| Learning Rate | 0.531 |

| Batch Size | 5 |

| Data Set Size | 1 |

| Data Set Iterations | 3 |

| Class Weights 1-3 | 0.103, 0.931, 0.379 |

| Convolutional Kernel Size | 3 |

| Data Augmentation Noise | 0.01 |

| Input/Output Size | 192 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).