Submitted:

24 January 2025

Posted:

24 January 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature Review

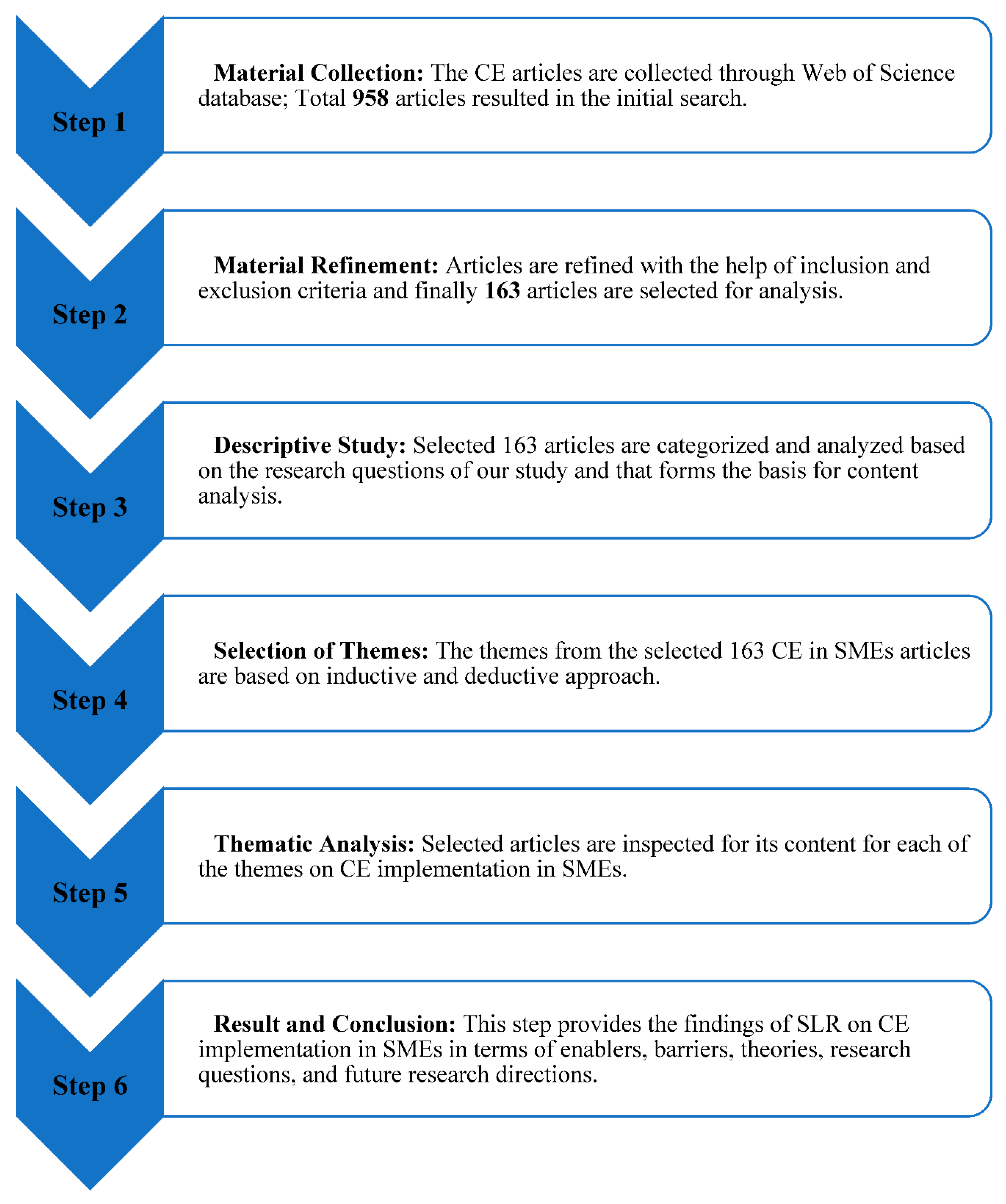

3. Methodology

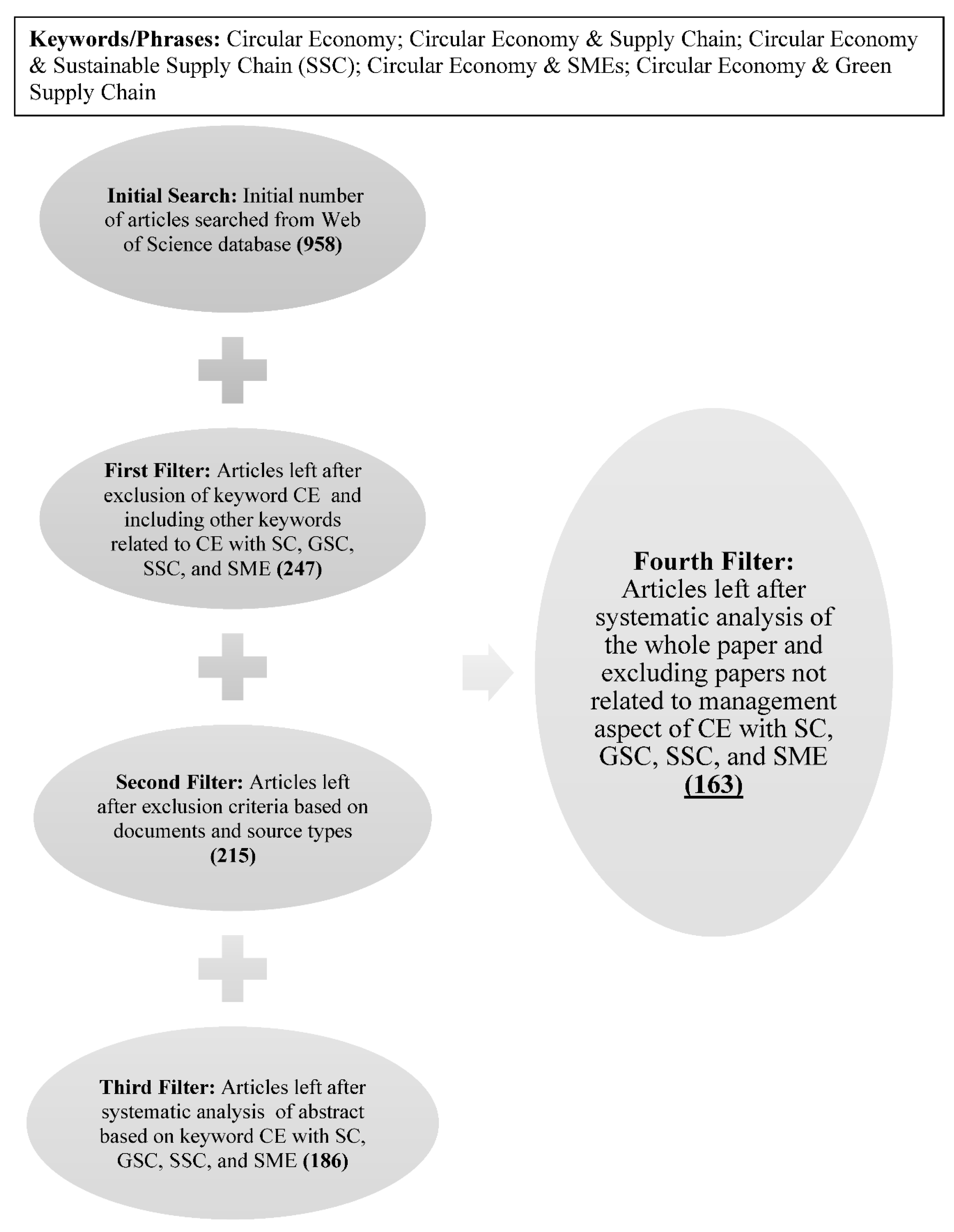

3.1. Material Collection

3.2. Article Selection

4. Current Trends of Circular Economy Research in SMEs

4.1. Content Analysis

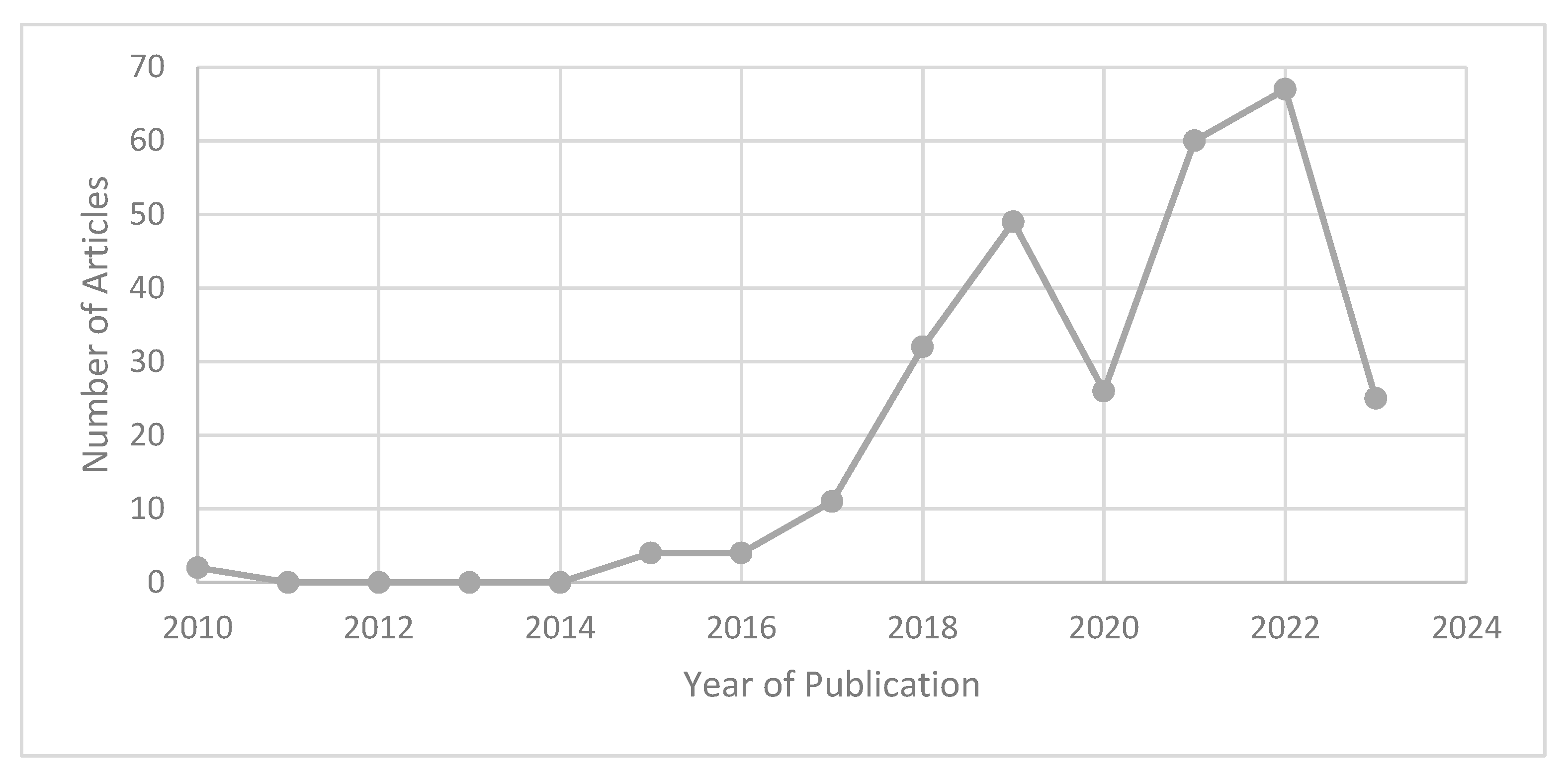

4.1.1. Trends

4.2. Research Questions Addressed by Previous Research

4.2.1. Research Questions

4.3. Research methodology and Theory that are used to answer the research questions

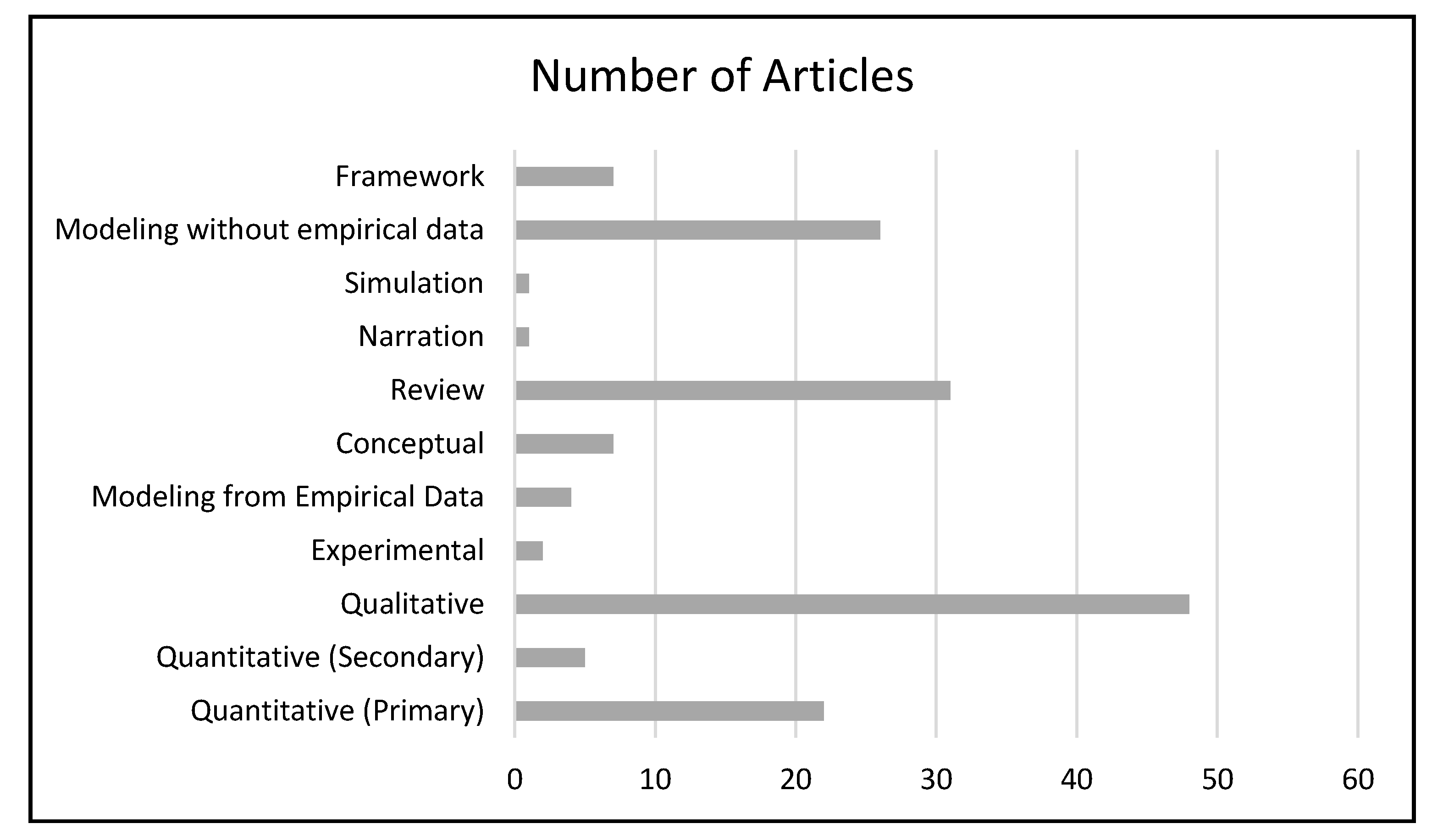

4.3.1. Research Methodology

4.3.2. Theory

4.4. Enablers and Challenges

4.4.1. Enablers

4.4.2. Challenges

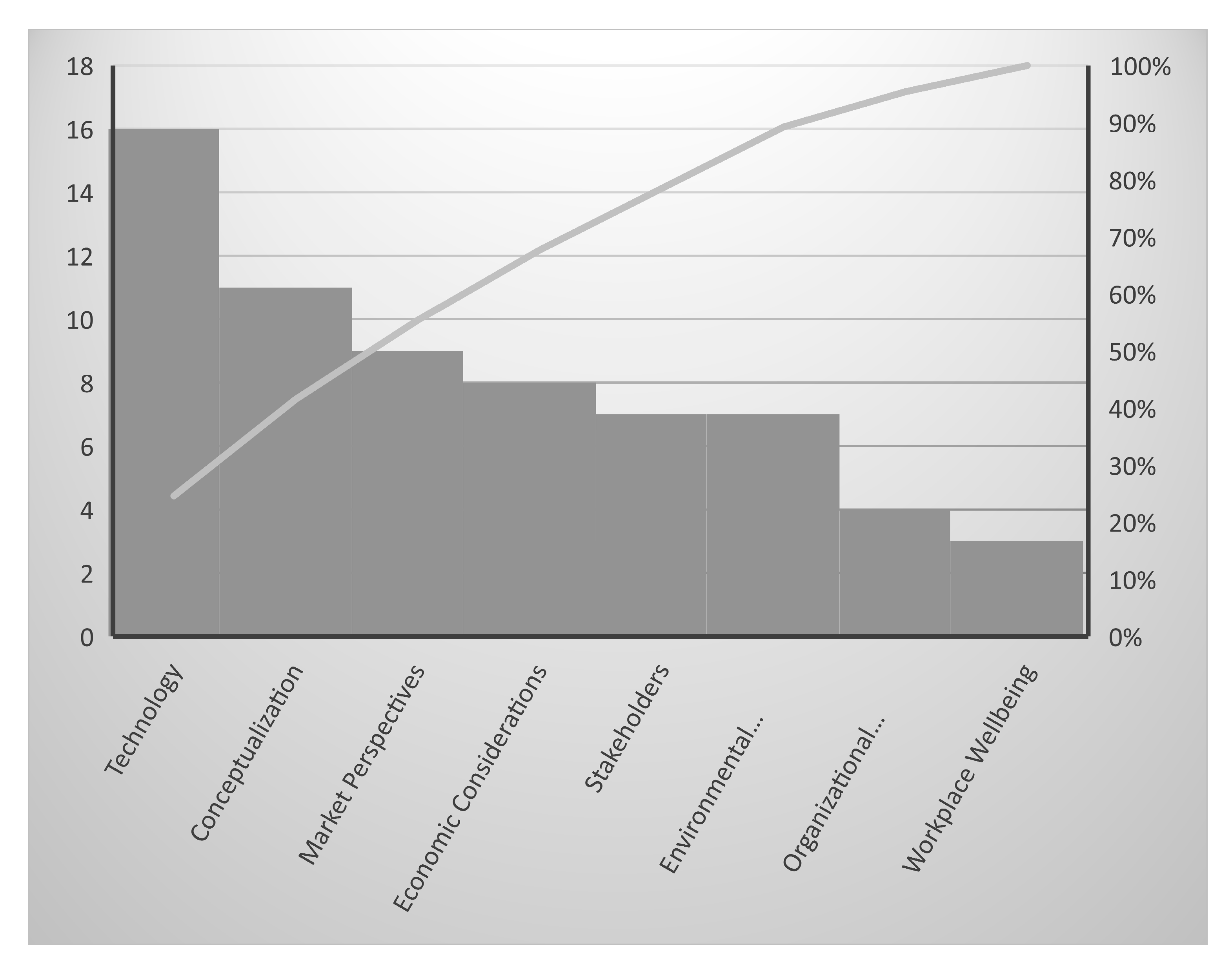

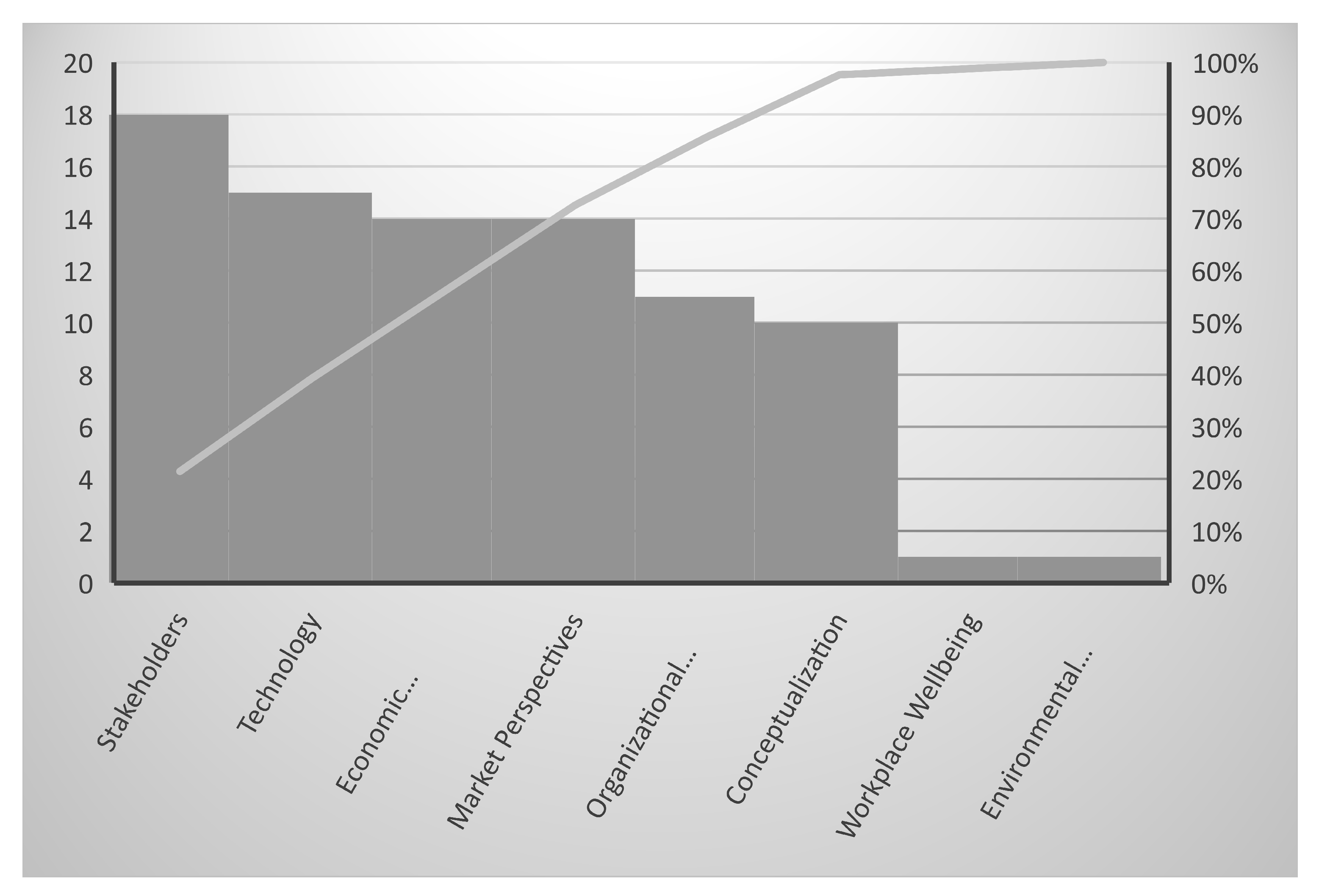

5. Meta-Analysis

5.1. Research Trends, Questions, Methods, and Theories

5.2. Enablers and Challenges

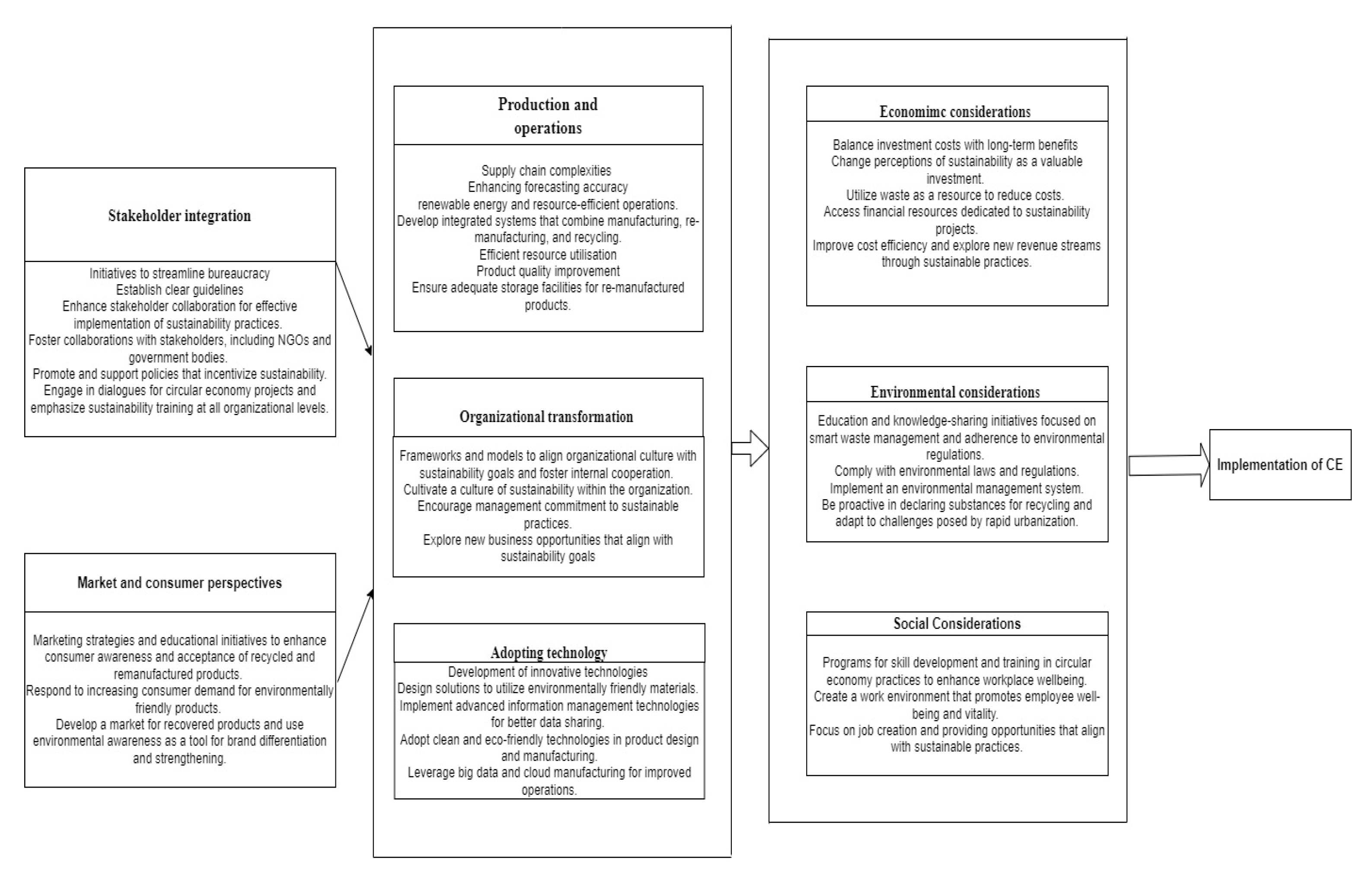

5.3. Strategies, Practices and Framework for Circular Economy Adoption

6. Discussion

- (a)

- Conceptualization, Design, Implementation, and Operations:

- (b)

- Stakeholders:

- (c)

- Adopting Newer Technology:

- (d)

- Organizational Transformation:

- (e)

- Introducing Workplace Wellbeing:

- (f)

- Economic Considerations:

- (g)

- Market Perspectives:

- (h)

- Environmental Considerations:

7. Conclusions

7.1. Implications

7.2. Future Directions

- A landscape of research questions, theories, drivers, and challenges on CE adoption in SMEs in the last decade.

- This review helps both practitioners and researchers to develop a pathway for CE adoption and understand the whole gamut of drivers and challenges to manage successful CE adoption.

- The information synthesized from this research shows the power of systematic literature review through content analyses and visualize large volume of content in a structured manner from peer reviewed journals.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CE | Circular Economy |

| SMEs | Small and Medium Enterprises |

| SLR | Systematic Literature Review |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analysis |

Appendix A

| Title | Year | Author | Summary |

|---|---|---|---|

| Sustainability and SMEs | |||

| Sustainability-oriented innovation of SMEs: a systematic review | 2014 | Johanna Klewitz, Erik G.Hansen | The paper reviewed sustainability-oriented innovation in SMEs and found that practices are still more on eco-innovation in comparison to innovation related to triple bottom-line. |

| Drivers of Sustainability Practices and SMEs: A Systematic Literature Review | 2018 | Neetu Yadav, Kritesh Gupta, Leela Rani, Deewanshi Rawat | The paper reviewed the drivers and classified them as external (stakeholders and tangible aspects of the business sector) and internal drivers (employees, organisation culture, brand image and reputation, competitive advantage and strategic intent, environment management capability, and size of the firm). |

| Barriers to sustainability for small and medium enterprises in the framework of sustainable development—Literature review | 2019 | Juanita Álvarez Jaramillo, Jhon Wilder Zartha Sossa, Gina Lía Orozco Mendoza | The paper reviewed and identified 175 barriers and classified them according to sector, sustainability tool, and internal or external to the organisation. The common barriers observed are lack of resources, the high initial capital cost of implementing sustainability measures, and lack of expertise. |

| Integrated green lean approach and sustainability for SMEs: From literature review to a conceptual framework | 2019 | Rebecca Siegel, Jiju Antony, Jose Arturo Garza-Reyes, Anass Cherrafi, Bart Lameijer | The paper reviewed challenges, success factors, tools and techniques, sustainability aspects, frameworks, and benefits of green Lean on manufacturing SMEs. The observed that generic framework with social dimension is missing in literature. |

| Sustainability and financial performance of small and medium sized enterprises: A bibliometric and systematic literature review | 2019 | Francesca Bartolacci, Andrea Caputo, Michela Soverchia | The review reveals three themes. (1) the role and impact of innovation and entrepreneurship (2) corporate social responsibility (3) green management and environmental issues. |

| The relationship between organizational culture, sustainability, and digitalization in SMEs: A systematic review | 2020 | Isensee, C., Teuteberg, F., Griese, K. M., & Topi, C. | Integrative view on organizational culture, level of environmental sustainability, and level of digitalization and their interactions. |

| Circular Economy Reviews | |||

| Product services for a resource-efficient and circular economy – a review | 2015 | Tukker, A. | The paper reviewed the application of product service system the focus was on resource efficiency due to circular economy adoption. |

| Designing the business models for circular economy—Towards the conceptual framework | 2016 | Lewandowski, M. | The paper reviewed the existing CE business models and identified the gaps in the existing body of work. The study also proposed a new framework for better implementation of CE. |

| A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems | 2016 | Ghisellini, P., Cialani, C., Ulgiati, S. | The paper reviewed the features of CE implementation at micro, meso, and macro level of an organization. The paper also highlighted the strength and weakness of CE implementation at different levels. |

| Towards circular economy implementation: a comprehensive review in context of manufacturing industry | 2016 | Lieder, M., Rashid, A. | The paper reviewed CE efforts around resource scarcity, waste generation, and economic advantages. The proposes an implementation strategy using top-down and bottom-up approach concurrently. |

| A systematic review on drivers, barriers, and practices towards circular economy: a supply chain perspective | 2018 | Kannan Govindan, Mia Hasanagic | The paper reviewed the drivers, barriers, and practices, which influence the implementation of CE in the context of supply chain. |

| Circular economy business models: The state of research and avenues ahead | 2020 | Marcos Ferasso, Tatiana Beliaeva, Sascha Kraus, Thomas Clauss | The paper mainly reviewed different business models in the context of CE. The study also highlighted several emerging topics connected with managerial, supply- and demand-side, networking, performance, and contextual considerations of CE business models. |

| Circular economy metrics: Literature review and company-level classification framework | 2021 | Christian Vinante, Pasqualina Sacco, Guido Orzes, Yuri Borgianni | The paper reviewed the metrics and organized them according to the proposed circular value chain framework. The study identified 365 different firm level metrics and classified them in 23 categories. |

| A systematic literature review of the transition to the circular economy in business organizations: Obstacles, catalysts, and ambivalences | 2021 | Milla Sarja, Tiina Onkila, Marileena Mäkelä | The paper reviewed and identified different types of catalysts, obstacles, and conflicting factors affecting CE implementation. |

| Circular Economy Business Models in the SME Sector | 2021 | Katarzyna Brendzel-Skowera | The paper reviewed CE business models in the context of SME. Based on CMMI levels the maturity index of CE business model is created. The study found circular raw materials, recovery of raw materials, modification, and repair as most frequently implemented business models. |

| Circular economy in manufacturing companies: A review of case study literature | 2021 | Marit Moe Bjørnbet, Christofer Skaar, Annik Magerholm Fet, Kjersti Øverbø Schulte | The paper reviewed the body of research in the context of CE implementation in manufacturing industries. The study found that field has indeed moved from conceptual works to empirical works and more research is happening about implementation tools. |

| Proposing Circular Economy Ecosystem for Chinese SMEs: A Systematic Review | 2021 | Zhejun Min, Sukanlaya Sawang, Robbert A. Kivits | The paper reviewed enablers and barriers of CE adoption in Chinese SMEs. Enablers identified are network, innovation, and reputation. Barriers are lack of resources such as time, finance, and human resource. |

| The first two decades of Circular Economy in the 21st century: a bibliographic review | 2021 | Joao Francisco Pinto Anaruma, Jorge Henrique Caldeira de Oliveira,Francisco Anaruma Filho, Wesley Ricardo de Souza Freitas Adriano Alves Teixeira |

A mapping of the principal players and main discussions about Circular Economy made. in the first two decades of the 21st century and an analysis about the growth and changes about the theme |

| How financial performance is addressed in light of the transition to circular business models - A systematic literature review | 2022 | Amal Kanzari, Josefine Rasmussen, Henrik Nehler, Fredrik Ingelsson | This paper reviews how financial performance relates to circular business models across different transition phases: ideate and design, implement and test, evaluate and improve. It identifies gaps in understanding financial outcomes, suggesting research needs for each phase, like the lack of prospective financial evaluation in design and guidelines for retrospective evaluations. The review highlights the need for long-term perspectives and business model-level considerations in financial assessments for circular economy transitions. |

| Implementing circular economy strategies in the automobile industry – a step toward creating sustainable automobiles |

2022 | Amit Patel and Sumer Singh | This study aims to highlight the impacts of a rapidly growing automobile industry on the environment and how implementation of Circular Economy (CE) principles and strategies can help us in improving its sustainability without compromising on our existing economic models |

| Circular economy and sustainable development: a review and research agenda | 2023 | Lamba, H. K., Kumar, N. S., & Dhir, S. | The paper found various frameworks and indicators to define and assess the circular economy, circular business models and use cases, global and industrial contexts of application of circular economy and different dimensions of the circular economy. |

| Business management perspectives on the circular economy: Present state and future directions | 2023 | Ahmad, F., Bask, A., Laari, S., & Robinson, C. V. | The paper reviewed the current state of CE research in business management and identified Six streams: strategy, learning and innovation, consumer behaviour and remanufacturing, supply chains and implementation, circular business models, industrial symbiosis, and emerging technologies. |

| A critical review of the current state of circular economy in the automotive sector | 2023 | Prochatzki, Georg, Prochatzki G.; Mayer, Ralph; Haenel, Josephin; Schmidt, Anja; Götze, Uwe; Ulber, Martin; Fischer, Anne; Arnold, Marlen Gabriele |

The aim of this review is to use the status quo for highlighting the need for action to promote higher-quality circular methods, which favour sustainable economy. |

| Circular economy practices in supply chain finance: a state-of-the-art review | 2023 | Soumya Prakash Patra Vishal Ashok Wankhede Rohit Agrawal |

The findings of the study help to recognize the most influential and productive research in circular SCF in terms of journals and trends. Further research is recommended to explore this area in depth to recognize potential integrating factors that help in smooth acceptance of circular finance in supply chains. |

| Sometimes linear, sometimes circular: States of the economy and transitions to the future | 2023 | Piero Morseletto | This study also explains which aspects encourage an economy to lean towards either the linear or the circular (i.e., profit, scarcity, circumstances, and business opportunities), why the economy should be circular, and which factors (e.g., redundancy, overproduction, fast consumption) prevent the systematic application of circular practices by favouring the throwaway society. |

| How does circular economy work in industry? Strategies, opportunities, and trends in scholarly literature | 2023 | Ana Cristina Silvério, João Ferreira, Paula Odete Fernandes, Marina Dabić |

The results of this study help practitioners assess EC from a new point of view and design competitive strategies for a circular model without neglecting economic growth and competitive advantage, in addition to serving as crucial evidence for policymakers, helping them leverage policies to circumvent sustainability concerns and promote circularity. |

| Unpacking the circular economy: A problematizing review | 2023 | Tulin Dzhengiz, ElizabethM. Miller, Jukka-Pekka Ovaska, Samuli Patala | The paper focuses on underlying assumptions of CE and also review problematizing to critically analyse framing of CE. |

| S. No. | Authors | Research Questions |

|---|---|---|

| 1 | (Dey et al., 2019) | How are CE fields of action related to sustainabilityperformance? What are the issues and challenges and opportunities of adopting CE in SMEs?; What key strategies, resources, and competences and capability facilitate effective implementation of CE in SMEs? |

| 2 | (Chauhan & Singh, 2019) | How is the concept of Industry 4.0 defined and operationalized in the literature? What are the main topics, trends, and theories in the debate on Industry 4.0 in SCM?; What are the potential avenues for future research and practice in this area? |

| 3 | (Viegas et al., 2019) | What are the elements of the forward PSC processes that impact PSC reverse flows? In what stages of the PSC are the reverse flows identified?; What does the academic literature recommend for improving PSC reverse flows? |

| 4 | (Lopes de Sousa Jabbour et al., 2019) | The changes required within OM, particularly in relation to the design of products, production planning and control (PPC) and logistics/supply chains, with regard to the new technology, capabilities and work procedures and inter- and intra-organizational relationships needed to support a CE; How OM decision-making can support each CE business model in the ReSOLVE framework; How designers, operations managers and logistics/supply chain managers can develop skills aligned with more sustainable production and consumption systems? |

| 5 | (Yang et al., 2019) | How complementarity effects of ECO and RA on CSR performance exists; What are some critical contextual factors affecting this complementarity? |

| 6 | (Shen et al., 2019) | How should the supply chain develop optimal product line design for green and non-green products? How should the supply chain differentiate product quality for optimal green and non-green product line design?; Can supply contracts be simplified when selling both green and non-green products? |

| 7 | (Farooque et al., 2019) | What part(s) of CE were integrated into SCM or value chain (from a sustainability viewpoint)?; What part(s) of CE were integrated into SCM functions?; Which circular business models were discussed in the publication?; What role did technology play in integrating CE in SCM?; Which industrial sector did it focus upon?; Which country was the context of the research?; What was the research/analysis methodology?; What were the key findings, lessons, recommendations for the short and long-term future? |

| 8 | (Martins & Pato, 2019) | Which are the existent literature reviews on supply chain sustainability; What are their methodological features; What are their main objectives and subject matters? |

| 9 | (Sandvik & Stubbs, 2019) | How can the Scandinavian fashion industry create a system of textile-to-textile recycling? What are the drivers, inhibitors, and enablers of creating a system of textile-to-textile recycling?; What is the role of technology and innovation to catalyse change in sorting and recycling of textiles?; What types of changes are needed to enable textile-to-textile recycling? |

| 10 | (Chiappetta Jabbour et al., 2019) | How can HRM and the CE be articulated theoretically? What is the role of stakeholders’ theory and the resource-based view (RBV) in triggering this articulation?; What are the main research propositions which can be derived from the relationship between HRM and the CE? |

| 11 | (Tsolakis et al., 2019) | How should academic and business stakeholders navigate value chain analysis, design and management options defined by terpenes? What is a fundamental network structure that could guide the deployment of supply network operations defined by terpenoid feedstock?; Which are the key uncertainty dimensions that could impact the value and viability of terpene-based circular supply networks? |

| 12 | (Piyathanavong et al., 2019a) | Have companies in the manufacturing sector of Thailand adopted GM, CP, GL, GSCM, RLs and CE to improve the environmental sustainability of their operations?; What have been the main reasons that have contributed for Thai manufacturing companies to implement GM, CP, GL, GSCM, RLs and CE?; What barriers have manufacturing companies in Thailand faced when implementing GM, CP, GL, GSCM, RLs and CE? |

| 13 | (Russo et al., 2019) | Do consumers’ purchase intentions, willingness-to-pay for and intention to switch to bio-based products depend upon the degree to which consumers are involved in the product itself? Do consumers’ personal values affect their purchase intention and willingness-to-pay for bio-based products? In addition, do these values lead consumers to switch from purchasing traditional new products to products made with bio-based materials? How do consumer demographics and previous purchasing experiences affect one’s intention to purchase or switch to bio-based products? |

| 14 | (Singhal, Tripathy, et al., 2019) | How to establish the relationship of various influential factors with the PI of consumers toward the remanufactured products? What are the most critical factors which impact the PI of consumers toward remanufactured products? |

| 15 | (Ünal et al., 2019) | Which managerial practices can companies implement to design a circular economy business model and how can companies create and capture value from a circular economy business model? |

| 16 | (Nascimento et al., 2019) | How can Industry 4.0 technologies be integrated into CE practices on a theoretical and practical basis? What characteristics should be considered for integrating Industry 4.0 technologies with current CE business models?; How can electronic waste and scrap materials be reused with smart production system technologies such as 3D printing? |

| 17 | (Rajput & Singh, 2019) | What are the dimensions of Industry 4.0 and CE? What are the joint effects of the dimensions of Industry 4.0 and CE? |

| 18 | (Singhal, Jena, et al., 2019) | How to prioritize the critical factors which influence the PI of the consumers towards remanufactured products? For what type of product, consumers are more conscious about the environment? |

| 19 | (Kalverkamp & Young, 2019) | What manifestations of reverse supply-chain “loops” in SCs can be identified at product, component, and material levels? What related differences emerge regarding SCs separate from OEM control, changing market context and innovation when comparing more independent SCs to “typical” CLSCs?; Are “loops” controlled by independent actors favorable from an environmental perspective? |

| 20 | (Tura et al., 2019a) | What are the drivers and barriers for developing new business in circular economy? |

| 21 | (Hogeboom et al., 2018) | How investors include water sustainability criteria in their investment decisions? |

| 22 | (Lopes de Sousa Jabbour et al., 2018a) | How the ReSOLVE framework of the CE can be applied and further developed by linking it to Industry 4.0 approaches |

| 23 | (Perey et al., 2018) | How do organizations reframe waste as being a source of value in a Circular Economy? |

| 24 | (Veleva & Bodkin, 2018a) | How is value created from collaborations between small entrepreneurial players and large, well-established companies with sustainability commitments? |

| 25 | (Leising et al., 2018) | How can new ways of supply chain collaboration contribute to the transition towards CE in the Dutch building sector? |

| 26 | (Homrich et al., 2018) | What are the main research streams, the core topics, authors, and journals? What is the definition of circular economy?; What is the most up-to-date thinking, trends, and gaps in the literature? |

| 27 | (Liu et al., 2018) | Which theories are portable? Which can be applied to either area?; Which theoretical perspectives may be conveyed from one perspective to the other when seeking to understand various phenomena?; Which theories can be more effective in understanding the other field? |

| 28 | (Govindan & Hasanagic, 2018) | What are the drivers, practices, and barriers towards the circular economy in a supply chain? |

| 29 | (Larsen et al., 2018) | How can the RSC contribute to the financial performance of the firm? Which exogenous contingency factors influence the size of the RSC’s contribution?; How do the contingency factors relate to the RSC’s contribution? |

| 30 | (Franco, 2017) | Which factors hinder established firms’ ability to go fully circular? How do these factors interact with each other in order to move firms and industries towards a circular production system? |

| 31 | (Despeisse et al., 2017) | What are the characteristics of 3DP processes and resultingproducts that enable CE principles such as re-use, modularity,upgrade, refurbishment and remanufacture?; How can we enable designers to consider CE principles when using 3DP and how can this be built into the design process?; What are the economic, organisational and sustainability impacts of 3DP on materials supply chains?; How can small-scale production, pre-processing and postprocessing technologies for 3DP feedstock enable the localization of material supply chains?; As a more distributed market emerges for raw materials, including consumers and SMEs, is there an accompanying increase in demand for disclosure of material data?; What types of information heuristics are needed to control a circular 3DP economy?; How do information heuristics enable and incentivise more efficient patterns of consumption?; How are entrepreneurs using 3DP to realise opportunities in the CE?; What are the barriers inhibiting entrepreneurial response using 3DP?; How are organisations capturing value when using 3DP to implement CE concepts?; How does the availability of 3DP for repair and remanufacturing enable service-based business models?; Does the UK have the correct mix of skills, workforce and industry [in 3DP] to benefit from a transition towards a circular economy?; How can designers and engineers be educated about the potential applications and benefits of 3DP for the CE, and how should their skills be developed? |

| S. No. | Authors | Drivers/ Enablers/ Motivators/ Success Factors |

|---|---|---|

| 1 | (Sarja et al., 2021b) | Expected economic and other benefits; Managerial support and existing management systems |

| 2 | (Khan, S.A.R., Shah, A.S.A., Yu, Z. and Tanveer, 2022) | Information Communication Technology; Digitalization of process; Pro-Environmental Policies; Integrated logistical infrastructure; Economy and competitive markets; Supplier Training; Accessibility to finance and risk mitigation; Product and material characteristics; Extensive collaboration |

| 3 | (Hina, M., Chauhan, C., Kaur, P., Kraus, S., & Dhir, 2022) | Internal drivers: Organisational drivers; Resource availability and optimisation; Financial drivers; Product and process development; External drivers: Policies and regulations; Supply chain-related drivers; Society and environment as drivers; Stakeholder pressure; Infrastructure |

| 4 | (Ostermann, C. M., da Silva Nascimento, L., Steinbruch, F. K., & Callegaro-de-Menezes, 2021) | Internal Dimension: Business - Profitability; Market strategies; Organizational - Business principles; Top management and staff commitment; Knowledge; Operational - Productive process (cost reduction, safety, stability and efficiency); Increased product and service quality and efficiency; Technical Factors - Available technology; Innovation; External Dimension: Government and industry - Government incentives; Laws and regulation; Network influence; Supply chain; Competitive global advantage; Social - Economic growth; Consumer trends; Social concern; Education; Human and animal health; Environmental - Trends in the availability of natural resources; Environmental impact |

| 5 | (Min et al., 2021a) | Internal Enablers: Resources - Network=> Strategic partnerships built between large corporations and SMEs; Industrial clusters; Stakeholder Involvement; Capabilities - Innovation=> Business model innovation; Organisational innovation; Reputation=> SMEs’ social prestige; Finance=> Profitability; Continuous value capture; External Enablers: Political Aspect - Government incentive; Social Aspect - Public awareness; Media exposure; Community requirements; Environment Aspect - Recovery of local environment; Legal Aspect - CE Laws and regulations |

| 6 | (Dijkstra et al., 2020a) | Competitive advantage and product differentiation; Consumer demand for green products; Accessing green, niche, or new markets; Improving efficiency; Cost savings from using waste as input, high prices of virgin materials; Management or entrepreneurial commitment to sustainability; R&D funding or access to finance; Collaboration or partnerships with stakeholders (NGOs, governments) and within the supply chain; Government regulations |

| 7 | (Mura et al., 2020b) | Support for companies in the development of personnel training oriented to sustainability at multiple levels (e.g. actions aimed at individuals, firms, companies); Support for the participation of companies and entrepreneurs in European or transnational projects in the field of sustainability; Dialogue between institutions, bodies and associations of the territory for the implementation of projects on the circular economy; Support in the procurement of raw materials with low environmental impact/identification of suppliers with low environmental impact; Facilitation of access to financial resources in the area of sustainability; Promotion of policies dedicated to sustainability (e.g. tax benefits, loans, subsidies) |

| 8 | (Bhatia et al., 2020) | Availability of sufficient quantity of used products; Technical/ operational feasibility for product recovery; Profitability of recovery process; Market for recovered products; Increased environmental consciousness; Implementation of government legislations; Awareness of natural resource limitations; Integration of manufacturing, remanufacturing and recycling activities; Efficient use of organization’s resources; Availability of facilities at suitable locations to store remanufactured products; Adequate capacity of facilities to store remanufactured products; Investment in infrastructure for product returns; Recover economic value from used products; Streamlined flow of product return through reverse logistics network; Adequate information on availability of product returns; Commitment of leadership to bring organizational change; Implementation of appropriate inventory management policies; Use of clean technology; Use of environmental friendly materials; Design of products for recovery; Design of products for disassembly Industry expert; Design of products for remanufacturing Industry expert; Managerial support for implementation for closed-loop supply chain; Managing with uncertain demand and uncertain product return; Determine production quantities of new and recovered products; Increasing raw material prices; Accessibility of used product collection centers for customers; Sales channels for remanufactured products; Shortened product lifecycles; Coordination between closed-loop supply chain partners; Volatile / uncertain raw material prices; Implementation of information technologies to support closed-loop supply chain; Customer commitment in returning used products |

| 9 | (Bhatia & Kumar Srivastava, 2019b) | Economic benefits of implementation of CLSC; Minimize waste generation; Creation of new jobs and opportunities; Environmental and social benefits of implementation of CLSC; Government regulations and support; Increased customer awareness on environment protection; Integration of manufacturing and remanufacturing operations |

| 10 | (Rajput & Singh, 2019) | Artificial Intelligence - block chain and visual computing; Manufacturing Ecosystem - industrial system integration, functional service system, big data and cloud manufacturing factors; Service and Policy Framework - collaborative robotics, laws and policy, infrastructure building, QoS, predictive maintenance and recovery, product service system, EIoT; Circular Economy - CIoT, waste recovery, energy recovery and CPPS; Network Agility - reliability, scalability, modularity, flexibility and value networks factors; Self- automation - integration and interoperability, self- optimization, self- configuring, self- organisations and adaptation |

| 11 | (Paes et al., 2019) | The possibility to turn waste streams into valuable resources; Contributing to environmental improvement and greenhouse gas emission reduction and costs reduction; Stimulation of cooperative projects and production of bio-based chemicals and energy; and job creation and new investment opportunities as the result of the development of a new business model and a new value chain based on organic waste; Boosting companies that focus on green solutions |

| 12 | (Chauhan & Singh, 2019) | Global competition; Data; Enabling technologies; Customers |

| 13 | (Yang et al., 2019) | CSR vision as an internal enabler; Environmental management system as a system regulation; Supply chain cooperation as an external enabler |

| 14 | (Sandvik & Stubbs, 2019) | Design and use of new materials; Increased garment collection and collaboration |

| 15 | (Piyathanavong et al., 2019a) | Environmental awareness; Company's policy and own initiative; Cost savings from conservation; Increase operational efficiency; Improve competitiveness; Compliance with environmental regulations and laws; Promote company's reputation; Improve sustainability of the business; Improve sales and brand recognition; Minimize the environmental impact; Risk mitigation; Pressure for environment friendly products and services; Availability of financial support |

| 16 | (Singhal, Tripathy, et al., 2019) | Attitude; Subjective norm; Perceived behavior control; Personal benefits; Green awareness; Remanufactured product knowledge; Risk perception; Market strategy |

| 17 | (Tura et al., 2019a) | Resource constraints and potential for preventing negative environmental impacts; Potential for improving cost efficiency, finding new revenue streams and gaining profit; Potential for new business development, innovation and synergy opportunities; Increased internationalization and worldwide awareness of sustainability needs; Potential to increase workplaces and vitality; Directing regulations and standard requirements; Supportive funds, taxation and subsidy policies; Potential for improving existing operations; New technologies; Increased information sharing through enhanced information management technologies, e.g. platforms; Potential for reducing supply dependence and avoiding high and volatile prices; Open collaboration and communication practices; Multi-disciplinarity, increased availability of resources and capabilities; Management of (reverse) networks; Potential for differentiation and strengthening the company brand; Increased understanding of sustainability demands; Circularity integrated in company strategy and goals; Development of skills and capabilities for CE |

| 18 | (Salim et al., 2019a) | Economic - Conserve and recirculate rare materials; Cost saving from reuse and recycle of materials; Enhancing competitiveness of producers and distributors; Reducing dependency of raw materials import; Social - Opportunities for job creation; Reducing human health risks; Meeting stakeholder expectations; Environmental - Reducing greenhouse gas emissions; Reducing energy payback time; Ensuring appropriate EoL management strategies via evidence of product and material impacts |

| 19 | (Kiefer et al., 2019) | Perceived lack of physical resources, competences, and dynamic capabilities (RCCs); Degree of novelty of RCCs; Existence of physical RCCs; Sustainable supply chains/networks; Orientation of corporate culture towards sustainability; Main motivation: technology; Main motivation: market; Main motivation: technology-market; Main motivation: firm-specific; Current ratio (slack); Type of financing: internal |

| 20 | (Tsolakis et al., 2019) | Regulatory conformance with market requirements; System level feasibility assessment of given renewable feed stocks; Target market volume demand |

| 21 | (Patricio et al., 2018) | Avoid/reduce disposal costs; Reduce load on their own sewage system; Improve environmental performance; Marketing reasons |

| 22 | (Veleva & Bodkin, 2018a) | Company mission/vision; EU laws; US state mandates; Customer zerowaste/sustain. goals; ESG investor/NGOs; Employee attraction & retention; Resilience/reducing risk/access to raw materials; Reputation; Cost savings; Local sourcing |

| 23 | (Moktadir et al., 2018) | Knowledge about Circular Economy; Customer Awareness; Leadership and Commitment from Top Management; Government Support and Legislation |

| 24 | (Govindan & Hasanagic, 2018) | Policy and economy - Keep within laws and policies of wastemanagement; Economic growth by implementing CE in SC; Health - Public health pays heavy prices for over consumption of resources and energy; Animal health pays heavy prices for over consumption of resources and energy; Environmental protection - Due to Climate change /Global up warming it is important that CE is implemented in SC; Modern agriculture rapidly improves productivity, but it pays a heavy price for over consumption of resources and energy; Demand for renewable energy is increasing and therefore it is important to protect the environment; Society - To protect the future growth of population the implementation of CE is important; Urbanization is increasing and the environment has been negatively affected by this increase; Job creation potential in supply chain; Consumers’ environmental awareness places pressure on industries to develop CE in SC; Product development- Improve the efficiency of materials and energy use in supply chain; Increase the value of products by increasing the quality |

| 25 | (Larsen et al., 2018) | Recovery and resale of end-products; Recovery and reuse of components; Take-back of core product from customers; All RSC-functions; Recovery of end products; Take-back of core products; Take-back of end products |

| 26 | (Nasir et al., 2017a) | Market condition; Customers; Raw material |

| 27 | (Dalhammar, 2016) | Durable design/minimum technical lifetime; Maximum disassembly time; Recycled content mandates; Declaration of substances that can pose a problem for recycling; Declaration of substances/components that may be relevant to recycle; Banning certain design solutions. |

| S. No. | Category | Drivers |

|---|---|---|

| 1 | Conceptualization, design, implementation, and operations | Integrating manufacturing, remanufacturing operations and recycling activities; efficient use of organisation’s resources; competitive advantage and product differentiation; availability of facilities at suitable locations to store remanufactured products; adequate capacity of facilities to store remanufactured products; increase the value of products by increasing the quality |

| 2 | Stakeholders (e.g., policymakers, SMEs’ management commitment, customers’, and suppliers’ pressure) | Collaboration or partnerships with stakeholders (NGOs, governments) and within the supply chain; Promotion of policies dedicated to sustainability (e.g., tax benefits, loans, subsidies); dialogue between institutions, bodies, and associations of the territory for the implementation of projects on the circular economy; support for companies in the development of personnel training oriented to sustainability at multiple levels (e.g., actions aimed at individuals, firms, companies) |

| 3 | Adopting newer technology | Increased information sharing through enhanced information management technologies, e.g., platforms; use of clean technology; use of environmentally friendly materials; design of products for disassembly industry expert; design of products for remanufacturing industry expert; big data and cloud manufacturing factors |

| 4 | Organizational transformation including cultural change and training | Management or entrepreneurial commitment to sustainability; potential for new business development, innovation, and synergy opportunities; leadership and commitment from top management |

| 5 | Introducing workplace wellbeing | Potential to increase workplaces and vitality; creation of new jobs and opportunities |

| 6 | Economic considerations such as cost, investment, etc. | Cost savings from using waste as input, high prices of virgin materials; facilitation of access to financial resources in the area of sustainability; economic benefits of implementation of CLSC; potential for improving cost efficiency finding new revenue streams and gaining profit; supportive funds, taxation and subsidy policies |

| 7 | Market perspectives such as new markets, consumer willingness and demand | Increased customer awareness on environment protection; consumers’ environmental awareness places pressure on industries to develop CE in SC; market for recovered products; potential for differentiation and strengthening the company brand |

| 8 | Environmental considerations such as recycle | Declaration of substances that can pose a problem for recycling; declaration of substances/components that may be relevant to recycle; compliance with environmental regulations and laws; environmental management system as a system regulation; Rapid urbanisation |

| S. No. | Authors | Barriers/Obstacles/Challenges/Issues |

|---|---|---|

| 1 | (Sarja et al., 2021b) | Legislative and regulative aspects; Design and technical aspects; The importance of collaboration; Customers and Demand; Companies’ existing knowledge and learning; Uncertainty of expectations and outcomes; Linear economic model embedded; Shortage of resources |

| 2 | (Khan, S.A.R., Shah, A.S.A., Yu, Z. and Tanveer, 2022) | Financial barriers (measuring financial benefits, financial profitability); Structural barriers (missing exchange of information, unclear responsibility distribution); Operational barriers (infrastructure, supply chain management); Attitudinal barriers (perception of sustainability, risk aversion); Integration of digital technologies; Lack of Information; Political (legal–institutional); Economic Policies; Learning (challenges); Management unwillingness; Complexity in business operations; Stakeholder engagement and integration; Susceptibility to errors; High operating cost; Lack of Human Resource Training; Difficulties in upgrading technology |

| 3 | (Thorley et al., 2021) | Lack of support supply and demand network/constraints to adopting new circular business models; Lack of capital / financial support Government support/economic and financial drivers, support from public institutions, misaligned incentives; Administrative burden; Lack of technical know-how/technical resource/Lag between design and diffusion or lead time to market; Lack of information/information management systems; Company environmental culture/internal conflict; Lack of customer/consumer interest in the environment / Rigidity of consumer behaviour; Lack of qualified personnel in environmental management; Lack of leadership commitment; Lack of environmental awareness, training and support and business routine |

| 4 | (Hina, M., Chauhan, C., Kaur, P., Kraus, S., & Dhir, 2022) | Internal barriers: Company policies and strategies; Financial barriers; Technological expertise; Lack of other resources; Collaborations; Product design; External barriers: Consumer-related barriers; Legislative and economic barriers; Supply chain barriers; Social, cultural and environmental barriers; External stakeholder related barriers |

| 5 | (Kayikci et al., 2021) | Technology Barriers: Technical and technological limitations in capacity and resource; Lack of data integration; Eco-innovation and eco-efficient technological developments; Lack of data privacy and security problems; Lack of smart device development; Limited or underdeveloped availability of information; Producer Barriers: Lack of availability of business process; Ineffective CE framework adoption; Lack of integration and collaboration among SC partners; Product complexity for CE principles; Operational risk; Lack of resources; High initial investment cost; High cost of CE processes and transaction search activities; Mismatch between cost and profit; Lack of financial resources and support; Uncertain market demand; Poor leadership & management; Lack of expert labor; Lack of knowledge and expertise; Lack of producers awareness and perception; Difficulty in defining CE principles; Lack of eco-literacy amongst SC partners; Consumers Barriers: Consumers’ unawareness for some circular products; Misperception of high prices for circular products; Lack of incentive campaigns for circular products; Lack of environmental culture perception in society; Policy Barriers: Lack of conductive legal system; Policy challenges; Lack of effective execution of environmental regulations; Misaligned vision and conflict between central and local governments; Lack of standards for CE performance assessment; Problems of ownership issues in an Eco-Cluster; Lack of governmental support and administrative burden |

| 6 | (Min et al., 2021b) | Internal Barriers: Resources - Lack of time; Lack of capital and investment; Lack of technology and technical expertise; Lack of human resources; Capabilities - Lack of human creativity; SMEs’ short survival time; External Barriers: Political Aspect - Lack of government support; Bureaucratic difficulty in administration; Economic Aspect - National economic system and national funding mechanisms; Market structure; Social Aspect - Public awareness; Legal Aspect - Unclear and complex regulations and standards; Legislation pressure for SMEs |

| 7 | (Dijkstra et al., 2020a) | High investment or transition costs (new technologies, R&D); Complexity of new systems; Low consumer awareness and buy-in, difficulty reaching clients; Lock-in of supply chain agents, lack of political support; Technological bottlenecks; New consumer behaviors and relationships needed; Reluctance within the organization; Sustainability tradeoffs; Competition |

| 8 | (Dey et al., 2019) | External issues and challenges: Lack of financial support; Lack of customers' support; Lack of technology; Lack of public institutional support; Lack of professional in environmental management; Internal issues and challenges: Lack of information system; Lack of technical and financial resources; Lack of management commitment |

| 9 | (Jaeger & Upadhyay, 2020b) | Resource-intensive development models; High start-up costs; Complex supply chains; Challenging B2B cooperation; Innovation diffusion challenge; Structural; Contextual; Cultural; Restricted supply chain; Lack of industrial symbiosis; Logistics; Lack of information on product design and production; Recovery; Recycling; Lack of technical skills; Quality compromise; Disassembly of products is time-consuming and expensive; No surety; CE will help the environment; Quality assurance; Design irrespective of CE; Hygienic issues |

| 10 | (Frei et al., 2020) | Jobbers; Plastic films; Secondary markets seen as threats |

| 11 | (Mura et al., 2020b) | Uncertainty about response times from public administrations in the area of sustainability; Lack of coordination of regulations at EU, national, regional and local level in the field of sustainability; Bureaucratic difficulty in applying the legislation on sustainability (e.g. waste, water) by companies; Difficulty of orientation in the renewable energy market; Lack of clear guidelines to define sustainability in small and medium-sized enterprises; Perception of sustainability as a cost and not as an investment |

| 12 | (Werning & Spinler, 2020) | Performance based sales; Optimal production setup; Potential cannibalization; Fashion vulnerability; Reverse Logistics Organization; End to end visibility and forecast ability; Quality uncertainty of returns; Feedstock volatility/ Quantity uncertainty; Correct forecast of needed spare parts; Willingness to take on long-term strategy; Recovery Process; Reduction of volume benefit; Willingness to have access over ownership; Redesign remarketing process; Control at point of sale; Integration of IoT for performance-based BM; Collaboration between departments; Clean/ waste free production; Awareness of raw material supply; Reverse Logistics Stability; Redesign spare part logistics; Legislation change; Raw material availability volatility |

| 13 | (Zhang et al., 2019a) | Lack of knowledge of smart waste management; Lack of regulatory pressures; Lack of innovation capacity; Difficulties in technologies and their applications; Lack of market pressures and demands; Cost and financial challenges; Lack of environmental education and culture of environmental protection; Lack of stakeholder cooperation, including service provider co-operation; The pursuit of short-term profitability instead of long-term sustainability; Lack of cluster effect; Lack of leadership commitment; Lack of proper standards of waste management |

| 14 | (Bressanelli et al., 2019) | Economic and financial viability challenges - Time mismatch between revenue and cost streams; Financial risk; Operational risk; Market and competition challenges - Cannibalization; IP and know-how access; Brand Image; Product characteristics challenges - Fashion change; Product complexity; Product (mass) customization; Standards and regulation challenges - Taxation and incentives; Measures, metrics, indicators; Lack of standards; Supply chain management challenges - Return flows uncertainty; Transportation and infrastructure; Availability of suitable supply chain partners; Coordination and information sharing; Product traceability; Cultural issues (linear mind-set); Technology challenges - Eco-efficiency of technological processes; Product technology improvement; Data privacy and security; Users’ behaviour challenges - Ownership value; Careless behaviour in product usage; Users’ willingness to pay |

| 15 | (Rajput & Singh, 2019) | Interface designing- design, investment cost, compatibility, interfacing, and networking; Technology Upgradation - infrastructure standardization, semantic interoperability, data analysis, sensor technology and smart devices development; Synergy model - automation system virtualization, process digitalization and automation, collaborative model, CPS standards and specifications, CPS modeling and modeling integration; Fog computation |

| 16 | (Paes et al., 2019) | Logistic cost and supply chain management; Seasonality; Availability and lack of homogenization of the raw material (organic waste); Quality and efficiency of the alternative product, which is not economically competitive with traditional ones; Lack of technical standards and regulation |

| 17 | (Chauhan & Singh, 2019) | High cost; Lack of skills; Lack of infrastructure; Data confidentiality issues |

| 18 | (Tumpa et al., 2019) | Lack of attention to develop theories and research work in green business practices; Lack of collaboration among supply chain partners due to complex supply chain; Less incentives from the government; Lack of interest and effective efforts of stakeholders; Financial constraints; Unskilled workforce; Organizational culture resistance to change; Lack of top management commitment; Lack of third parties to recollect used products; Lack of IT implementation for communication and coordination; Lack of producer's responsibility; Technological obstructions; Lack of government regulations and legislative framework; Low demand for green textile products from customers due to lack of awareness; Lack of promotion of sustainable products |

| 19 | (Sandvik & Stubbs, 2019) | Limited technology which creates a challenge for separating materials; High costs of research and development and building the supporting logistics; Complexity of supply chains including the multitude of stakeholders involved in product development |

| 20 | (Gupta et al., 2019a) | Complexity in business operations; Stakeholder engagement |

| 21 | (Piyathanavong et al., 2019a) | Lack of training and knowledge; Too much effort required; Lack of resources; Lack of support from management level; Lack of benefits from environmental sustainability; Lack of financial support; Lack of environmental regulations and laws; Lack of environmental awareness; Lack of support from government |

| 22 | (Sharma et al., 2019) | Poor government policies; Transportation and infrastructure issues; Traceability issues; Packaging issues; Lack of cold chain; Lack of technology and techniques; Lower productivity; Lack of farmers knowledge and awareness; Food safety and security problems; Poor corporate social responsibility; Greenhouse gas emission |

| 23 | (Tura et al., 2019a) | High costs and lack of financial capability and support ; Lack of tools and methods to measure (long-term) benefits of CE projects; Lack of social awareness and uncertainty of consumer responsiveness and demand; Lack of market mechanisms for recovery; Lack of clear incentives; Complex and overlapping regulation; Lack of governmental support; Lack of CE know-how of political decision-makers; Lack of information and knowledge; Lack of technologies and technical skills; Lack of network support and partners; Strong industrial focus on linear models; Lack of collaboration and resources; Incompatibility with existing (linear) operations and development targets; Silo thinking and fear of risks; Conflicts with existing business culture and lack of internal cooperation; Heavy organizational hierarchy and lack of management support; Lack of CE knowledge and skills |

| 24 | (Shi et al., 2019a) | Barriers related to collection of used cartridges- Restricted and inconsistent polies for import of used cartridges; Imperfect implementation of action plan for establishment of the extended producer responsibility system; Lack of administrative measures for authentication of qualified collectors for used cartridges; Lack of standards for recovery enterprise qualification; No tax offset for purchase of used cartridges; Barriers related to remanufacturing - Lack of regulations for clear intellectual property protection on remanufacturing; Lack of technical standards for remanufacturing of printing consumables; Lack of national quality standards for remanufactured printing consumables; Lack of a certification system for remanufactured printing consumables; Barriers at the enterprise level - Lack of a perfect recycling system for used printing consumables; Lack of consumers’ awareness about proper treatment and disposal of used printing consumables; The low re-manufacturable rate of collected used cartridges; Lack of self-owned intellectual property and innovative technology patents; Restrictions for use of remanufactured cartridges by original manufacturers of new cartridges; Low quality of fake and counterfeit printing consumables damages reputation of remanufacturers; Worry about quality of remanufactured cartridges by consumers |

| 25 | (Salim et al., 2019a) | Policy and Economic - Lack of profitability to recycle; No regulations in place; Lack of economic incentives for collection and recycling; Current collection scheme is not robust; No incentives are given to design for recycling; Social - Lack of consumers’ willingness to return EoL products; Lack of coordination among producers and recyclers; Market - Insufficient quantity of EoL products; Poor market confidence in refurbished and recycled products; Various typical life cycle across PV panels and BESS; New manufacturers introducing price competitive products; PV panels and BESS are emerging technologies with a potential of material changes; Environment - Emissions and pollution generated during recycling; Energy intensive recycling process; Recycling Infrastructure - EoL recycling process complexity; Lack of adequate collection centers and recycling plants |

| 26 | (Kiefer et al., 2019) | Cooperation resources, competences, and dynamic capabilities (RCCs); Future orientation of the main corporate goals; Certification ISO14001; Ecological certification: EMAS; Profitability of capital; Formalization of knowledge; Patents |

| 27 | (Patricio et al., 2018) | Difficult to find a receiver; Investing in installing new equipment; Lack of knowledge; Practical issues (storing, transportation); No economic benefit in participating in a symbiosis; Time limitations, (they need to focus on their core business); Trust in new partnerships |

| 28 | (Veleva & Bodkin, 2018a) | Cost of product/ service or take back; Lack of regulation & incentive; Lack of financing / resources; Lack of awareness & market demand; Complex product design/technical challenges; Lack of brand awareness; Lack of data, indicators to measures impacts (e.g., social); Lack of mature/knowledgeable suppliers; Supplier leverage |

| 29 | (Husgafvel et al., 2018) | Clever products and services; Development of cooperation between product manufacturers and service providers; Energy efficiency; Evaluating and developing of supply value chain; Creating added value; Increase in sectoral cooperation and interaction; Increase in recycle/reuse; Intelligent production and processes; Local or regional resource banks; Material efficiency; Minimizing waste; New symbiosis products; Utilization of by-products and side flows; Developing international guidelines and best practices; Development of harbors operation and management; Development of logistics; Development of operational environment of EU; International vocational education |

| 30 | (Govindan & Hasanagic, 2018) | Governmental issues- Lack of a standard system for performance indicators with regard to measuring CE in SC; Recycling policies in waste management are ineffective to obtain high quality recycling; Unclear vision in regards of CE in SC; Circular economy laws have been insufficiently implemented; Existing laws in waste management are not supporting CE; Economic issues - Weak economic incentives make it difficult for enterprises to implement CE in SC; Insufficient internalization of external costs; Difficulties in establishing correct price of products in SC; Major upfront investment costs in SC by implementing CE; There are both high short-term costs and low short-term economic benefits in SC; High costs are related to recycled materials in SC and therefore they are often more expensive than virgin in the market; High purchasing cost of environmentally friendly materials by the supplier; Production costs are getting higher; Technological issues - Technological limitations by tracking recycled materials; It is difficult for enterprises to manage product quality through the lifecycle of a product; Maintaining quality of products made from recovered materials; Design challenges to reuse and recovery products; Challenges to safe return to the biosphere; Make the right decision in SC to implement CE in the most efficient way; Accurate information regarding materials/tracking in SC towards recycling is not available; Knowledge and skill issues - Lack of reliable information to public and therefore it is difficult to reuse/recycle/ remanufacture products; Lack of public awareness; therefore, it is difficult to reuse/recycle/remanufacture products; Lack of skills by employees in CE; Consumers knowledge and awareness about refurbishment; Poor leadership and management towards CE in SC; Higher priority of other issues or requirements in SC; Organizational structure makes it difficult to implement CE in SC; Circular economy framework issues - Lack of successful business models and frameworks to implement CE in SC; The whole SC needs are not included; Other solutions might be more favorable than implementing CE in SC; Lack of enthusiasm towards CE in SC; Consumer perception towards components that are reused is flawed and therefore makes it more difficult to implement CE; Lack of the thrill of newness by consumers is high; Market issues - Challenges of take-back from other companies; No standards on refurbishment products; Ownership issues for taking advantages of reuse opportunities of CE in SC; Service providers cannot legally retain ownership of a sold product which makes it difficult to implement CE; Limited availability of reuse products; Remanufacturing is consuming and labor-intensive procedure |

| 31 | (Franco, 2017) | Product design and manufacturing; New product development; Price competitiveness and low customer demand; Quantity, quality, timing; Recovery process at end-of-life |

| 32 | (Densley Tingley et al., 2017a) | Cost; Availability/Storage; Lack of client demand; Traceability of steel; Supply chain gaps / Lack of coordination |

| 33 | (Despeisse et al., 2017) | Lack of knowledge from potential customers about the technology and what can be achieved using 3D printing; scale-up challenge; Wait for existing extruder manufacturers or new entrants to develop higher capacity machines; Diversity of 3DP technologies and the different forms of materials these machines use; |

| 34 | (Gilbert et al., 2017) | A vessel’s hull would require to be designed for dismantling to improve reuse; The operation and maintenance schedule must ensure the value of the steel is retained; Data must flow between key stakeholders on the quality of the steel. |

| 35 | (Dalhammar, 2016) | For new types of products, where energy efficiency improvements are rapid, it may not be optimal to prolong lifetime; It is difficult to know now whether manual disassembly will take place in the future; Difficult to foresee technical developments in waste treatment and recycling technology; For many materials/products, compliance must be shown by supplier declaration schemes (as it cannot be proved by inspecting the product); This can be costly and difficult to monitor; Concerns on quality of recycled materials; Sometimes difficult for manufacturer to have this information; Dependent upon suppliers; Material tests can be very expensive; Potential trade secrets involved; Difficult to obtain this information for components from suppliers; May impede innovation and freedom to choose product design in some cases |

| S. No. | Category | Challenges |

|---|---|---|

| 1 | Conceptualization, design, implementation, and operations | Difficulty of orientation in the renewable energy market; Correct forecast of needed spare parts; Lack of attention to develop theories and research work in green business practices; Complexity of supply chains including the multitude of stakeholders involved in product development; Lack of tools and methods to measure (long-term) benefits of CE projects; Make the right decision in SC to implement CE in the most efficient way |

| 2 | Stakeholders (e.g., policymakers, SMEs’ management commitment, customers’, and suppliers’ pressure) | Bureaucratic difficulty in applying the legislation on sustainability (e.g. waste, water) by companies; Lack of clear guidelines to define sustainability in small and medium-sized enterprises; Lack of proper standards of waste management; Lack of CE know-how of political decision-makers; Lack of regulations for clear intellectual property protection on remanufacturing; Lack of technical standards for remanufacturing; Lack of national quality standards for remanufactured products; Lack of a certification system for remanufactured products; Circular economy laws have been insufficiently implemented |

| 3 | Adopting newer technology | Lack of innovation capacity; Limited technology which creates a challenge for separating materials; Lack of technologies and technical skills; Lack of self-owned intellectual property and innovative technology patents; Technological limitations by tracking recycled materials; Design challenges to reuse and recovery products; Difficult to foresee technical developments in waste treatment and recycling technology; Limited innovation and freedom to choose product design in some cases |

| 4 | Organizational transformation including cultural change and training | Reluctance within the organization; Lack of top management commitment; Lack of environmental education and culture of environmental protection; Conflicts with existing business culture and lack of internal cooperation; Organizational structure makes it difficult to implement CE; Lack of successful business models and frameworks to implement CE |

| 5 | Introducing workplace wellbeing | Lack of skills by employees in CE |

| 6 | Economic considerations such as cost, investment, etc. | High investment or transition costs (new technologies, R&D); Perception of sustainability as a cost and not as an investment; High costs of research and development and building the supporting logistics; Weak economic incentives make it difficult for enterprises to implement CE; There are both high short-term costs and low short-term economic benefits; High costs are related to recycled materials in SC and therefore they are often more expensive than virgin in the market; High purchasing cost of environmentally friendly materials by the supplier; Production costs are getting higher; Material tests can be very expensive |

| 7 | Market perspectives such as new markets, consumer willingness and demand | Low consumer awareness and buy-in, difficulty reaching clients; New consumer behaviors and relationships needed; Lack of market mechanisms for recovery; Lack of reliable information to public and therefore it is difficult to reuse/recycle/ remanufacture products; Consumer perception towards components that are reused is flawed and therefore makes it more difficult to implement CE |

| 8 | Environmental considerations such as recycle | Lack of knowledge of smart waste management |

References

- J. Bonner, “SMEs and environmental/social impacts,” 2019.

- B. Jaeger and A. Upadhyay, “Understanding barriers to circular economy: cases from the manufacturing industry,” Journal of Enterprise Information Management, vol. 33, no. 4, pp. 729–745, 2020. [CrossRef]

- M. Moreno, C. De los Rios, Z. Rowe, and F. Charnley, “A conceptual framework for circular design,” Sustainability (Switzerland), vol. 8, no. 9, 2016. [CrossRef]

- K. Boulding E., “The Economics of the Coming Spaceship Earth,” in Environmental Quality in a Growing Economy, 1966, pp. 3–14.

- K. Segerson, D. W. Pearce, and R. K. Turner, “Economics of Natural Resources and the Environment,” Land Econ, vol. 67, no. 2, p. 272, 1991. [CrossRef]

- M. Geissdoerfer, P. Savaget, N. M. P. Bocken, and E. J. Hultink, “The Circular Economy – A new sustainability paradigm?,” 2017. [CrossRef]

- J. Kirchherr, D. Reike, and M. Hekkert, “Conceptualizing the circular economy: An analysis of 114 definitions,” 2017. [CrossRef]

- H. S. Kristensen and M. A. Mosgaard, “A review of micro level indicators for a circular economy – moving away from the three dimensions of sustainability?,” 2020. [CrossRef]

- J. Álvarez Jaramillo, J. W. Zartha Sossa, and G. L. Orozco Mendoza, “Barriers to sustainability for small and medium enterprises in the framework of sustainable development—Literature review,” Bus Strategy Environ, 2019. [CrossRef]

- R. Siegel, J. Antony, J. A. Garza-Reyes, A. Cherrafi, and B. Lameijer, “Integrated green lean approach and sustainability for SMEs: From literature review to a conceptual framework,” 2019. [CrossRef]

- J. Klewitz and E. G. Hansen, “Sustainability-oriented innovation of SMEs: A systematic review,” 2014. [CrossRef]

- N. Yadav, K. Gupta, L. Rani, and D. Rawat, “Drivers of Sustainability Practices and SMEs: A Systematic Literature Review,” European Journal of Sustainable Development, vol. 7, no. 4, 2018. [CrossRef]

- F. Bartolacci, A. Caputo, and M. Soverchia, “Sustainability and financial performance of small and medium sized enterprises: A bibliometric and systematic literature review,” Bus Strategy Environ, 2020. [CrossRef]

- M. Lewandowski, “Designing the business models for circular economy-towards the conceptual framework,” 2016. [CrossRef]

- M. Ferasso, T. Beliaeva, S. Kraus, T. Clauss, and D. Ribeiro-Soriano, “Circular economy business models: The state of research and avenues ahead,” Bus Strategy Environ, vol. 29, no. 8, pp. 3006–3024, 2020. [CrossRef]

- K. Brendzel-Skowera, “Circular economy business models in the sme sector,” Sustainability (Switzerland), vol. 13, no. 13, 2021. [CrossRef]

- M. Sarja, T. Onkila, and M. Mäkelä, “A systematic literature review of the transition to the circular economy in business organizations: Obstacles, catalysts and ambivalences,” 2021. [CrossRef]

- M. Lieder and A. Rashid, “Towards circular economy implementation: A comprehensive review in context of manufacturing industry,” 2016. [CrossRef]

- K. Govindan and M. Hasanagic, “A systematic review on drivers, barriers, and practices towards circular economy: a supply chain perspective,” Int J Prod Res, vol. 56, no. 1–2, pp. 278–311, Jan. 2018. [CrossRef]

- M. M. Bjørnbet, C. Skaar, A. M. Fet, and K. Ø. Schulte, “Circular economy in manufacturing companies: A review of case study literature,” J Clean Prod, vol. 294, 2021. [CrossRef]

- Z. Min, S. Sawang, and R. A. Kivits, “Proposing circular economy ecosystem for Chinese SMEs: A systematic review,” Int J Environ Res Public Health, vol. 18, no. 5, pp. 1–13, 2021. [CrossRef]

- A. Tukker, “Product services for a resource-efficient and circular economy - A review,” 2015. [CrossRef]

- P. Ghisellini, C. Cialani, and S. Ulgiati, “A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems,” J Clean Prod, vol. 114, pp. 11–32, Feb. 2016. [CrossRef]

- F. Hofmann, “Circular business models: Business approach as driver or obstructer of sustainability transitions?,” J Clean Prod, vol. 224, pp. 361–374, 2019. [CrossRef]

- S. Bag, S. Gupta, and C. Foropon, “Examining the role of dynamic remanufacturing capability on supply chain resilience in circular economy,” Management Decision, vol. 57, no. 4, pp. 863–885, 2019. [CrossRef]

- S. Gupta, H. Chen, B. T. Hazen, S. Kaur, and E. D. R. Santibañez Gonzalez, “Circular economy and big data analytics: A stakeholder perspective,” Technol Forecast Soc Change, 2019. [CrossRef]

- C. P. Kiefer, P. D. R. González, and J. Carrillo-hermosilla, “Drivers and barriers of eco-innovation types for sustainable transitions: A quantitative perspective,” Bus Strategy Environ, vol. 28, no. 1, pp. 155-172., 2019. [CrossRef]

- M. Mura, M. Longo, and S. Zanni, “Circular economy in Italian SMEs: A multi-method study,” J Clean Prod, vol. 245, p. 118821, 2020. [CrossRef]

- S. Rajput and S. P. Singh, “Connecting circular economy and industry 4.0,” Int J Inf Manage, vol. 49, pp. 98–113, 2019. [CrossRef]

- M. S. Bhatia and R. Kumar Srivastava, “Antecedents of implementation success in closed-loop supply chain: an empirical investigation,” Int J Prod Res, vol. 57, no. 23, pp. 7344–7360, 2019. [CrossRef]

- T. J. Tumpa, S. M. Ali, M. H. Rahman, S. K. Paul, P. Chowdhury, and S. A. Rehman Khan, “Barriers to green supply chain management: An emerging economy context,” J Clean Prod, vol. 236, 2019. [CrossRef]

- G. Bressanelli, M. Perona, and N. Saccani, “Challenges in supply chain redesign for the Circular Economy: a literature review and a multiple case study,” Int J Prod Res, vol. 57, no. 23, pp. 7395–7422, 2019. [CrossRef]

- P. K. Dey, C. Malesios, D. De, S. Chowdhury, and F. Ben Abdelaziz, “Could lean practices and process innovation enhance supply chain sustainability of small and medium-sized enterprises?,” Bus Strategy Environ, vol. 28, no. 4, pp. 582–598, 2019. [CrossRef]

- P. K. Dey, C. Malesios, D. De, P. Budhwar, S. Chowdhury, and W. Cheffi, “Circular economy to enhance sustainability of small and medium-sized enterprises,” Bus Strategy Environ, vol. 29, no. 6, pp. 2145–2169, 2020. [CrossRef]

- D. Tranfield, D. Denyer, and P. Smart, “Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review,” 2003. [CrossRef]

- M. Farooque, A. Zhang, M. Thürer, T. Qu, and D. Huisingh, “Circular supply chain management: A definition and structured literature review,” 2019. [CrossRef]

- S. Lahane, R. Kant, and R. Shankar, “Circular supply chain management: A state-of-art review and future opportunities,” 2020. [CrossRef]

- M. J. Page et al., “The PRISMA 2020 statement: An updated guideline for reporting systematic reviews,” 2021. [CrossRef]

- P. M. Podsakoff, S. B. Mackenzie, D. G. Bachrach, and N. P. Podsakoff, “The influence of management journals in the 1980s and 1990s,” Strategic Management Journal, vol. 26, no. 5, pp. 473–488, 2005. [CrossRef]

- O. Furrer, H. Thomas, and A. Goussevskaia, “The structure and evolution of the strategic management field: A content analysis of 26 years of strategic management research,” International Journal of Management Reviews, vol. 10, no. 1, pp. 1–23, 2008. [CrossRef]

- A. Vashishth, A. Chakraborty, and J. Antony, “Lean Six Sigma in financial services industry: a systematic review and agenda for future research,” 2019. [CrossRef]

- V. Raja Sreedharan, M. Pattusamy, S. Mohan, and D. Jinil Persis, “A systematic literature review of lean six sigma in financial services: Key finding and analysis,” International Journal of Business Excellence, vol. 21, no. 3, pp. 331–358, 2020. [CrossRef]

- V. Arumugam, J. Antony, and K. Linderman, “A Multilevel Framework of Six Sigma: A Systematic Review of the Literature, Possible Extensions, and Future Research,” Quality Management Journal, vol. 21, no. 4, pp. 36–61, 2014. [CrossRef]

- A. C. Edmondson and S. E. Mcmanus, “Methodological fit in management field research,” Academy of Management Review, vol. 32, no. 4, pp. 1155–1179, 2007. [CrossRef]

- C. J. Chiappetta Jabbour et al., “Who is in charge? A review and a research agenda on the ‘human side’ of the circular economy,” 2019. [CrossRef]

- N. Tsolakis, W. Bam, J. S. Srai, and M. Kumar, “Renewable chemical feedstock supply network design: The case of terpenes,” J Clean Prod, 2019. [CrossRef]

- E. Ünal, A. Urbinati, and D. Chiaroni, “Managerial practices for designing circular economy business models: The case of an Italian SME in the office supply industry,” Journal of Manufacturing Technology Management, vol. 30, no. 3, pp. 561–589, 2019. [CrossRef]

- Y. Yang, L. Chen, F. Jia, and Z. Xu, “Complementarity of circular economy practices: an empirical analysis of Chinese manufacturers,” Int J Prod Res, 2019. [CrossRef]

- A. B. Lopes de Sousa Jabbour et al., “Circular economy business models and operations management,” J Clean Prod, vol. 235, pp. 1525–1539, 2019. [CrossRef]

- I. Russo, I. Confente, D. Scarpi, and B. T. Hazen, “From trash to treasure: The impact of consumer perception of bio-waste products in closed-loop supply chains,” J Clean Prod, vol. 218, pp. 966–974, 2019. [CrossRef]

- D. Singhal, S. Tripathy, and S. K. Jena, “Acceptance of remanufactured products in the circular economy: an empirical study in India,” Management Decision, 2019. [CrossRef]

- V. Veleva and G. Bodkin, “Corporate-entrepreneur collaborations to advance a circular economy,” J Clean Prod, vol. 188, pp. 20–37, 2018. [CrossRef]

- B. Shen, S. Liu, T. Zhang, and T. M. Choi, “Optimal advertising and pricing for new green products in the circular economy,” J Clean Prod, 2019. [CrossRef]

- C. V. Viegas, A. Bond, C. R. Vaz, and R. J. Bertolo, “Reverse flows within the pharmaceutical supply chain: A classificatory review from the perspective of end-of-use and end-of-life medicines,” 2019. [CrossRef]

- M. Kalverkamp and S. B. Young, “In support of open-loop supply chains: Expanding the scope of environmental sustainability in reverse supply chains,” J Clean Prod, vol. 214, pp. 573–582, 2019. [CrossRef]

- C. Chauhan and A. Singh, “A review of Industry 4.0 in supply chain management studies,” 2019. [CrossRef]

- D. L. M. Nascimento et al., “Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal,” 2019. [CrossRef]

- I. M. Sandvik and W. Stubbs, “Circular fashion supply chain through textile-to-textile recycling,” Journal of Fashion Marketing and Management, vol. 23, no. 3, pp. 366–381, 2019. [CrossRef]

- E. Leising, J. Quist, and N. Bocken, “Circular Economy in the building sector: Three cases and a collaboration tool,” J Clean Prod, 2018. [CrossRef]

- A. S. Homrich, G. Galvão, L. G. Abadia, and M. M. Carvalho, “The circular economy umbrella: Trends and gaps on integrating pathways,” 2018. [CrossRef]

- M. A. Franco, “Circular economy at the micro level: A dynamic view of incumbents’ struggles and challenges in the textile industry,” J Clean Prod, 2017. [CrossRef]

- A. B. Lopes de Sousa Jabbour, C. J. C. Jabbour, M. Godinho Filho, and D. Roubaud, “Industry 4.0 and the circular economy: a proposed research agenda and original roadmap for sustainable operations,” Ann Oper Res, vol. 270, no. 1–2, pp. 273–286, 2018. [CrossRef]

- J. Liu, Y. Feng, Q. Zhu, and J. Sarkis, “Green supply chain management and the circular economy: Reviewing theory for advancement of both fields,” 2018. [CrossRef]

- R. K. Yin, “Identifying Your Case ( s ) and Establishing the Logic of Your Case Study,” Case Study Research: Design and Methods, 2013. [CrossRef]

- L. Meherishi, S. A. Narayana, and K. S. Ranjani, “Sustainable packaging for supply chain management in the circular economy: A review,” J Clean Prod, vol. 237, pp. 1175–1182, 2019. [CrossRef]

- R. Dubey, A. Gunasekaran, S. J. Childe, T. Papadopoulos, and P. Helo, “Supplier relationship management for circular economy: Influence of external pressures and top management commitment,” Management Decision, vol. 57, no. 4, pp. 767–790, 2019. [CrossRef]

- A. Fischer and S. Pascucci, “Institutional incentives in circular economy transition: The case of material use in the Dutch textile industry,” J Clean Prod, vol. 155, pp. 17–32, 2017. [CrossRef]

- V. de Souza, J. Bloemhof-Ruwaard, and M. Borsato, “Towards Regenerative Supply Networks: A design framework proposal,” J Clean Prod, 2019. [CrossRef]

- N. Tsolakis and J. S. Srai, “Mapping supply dynamics in renewable feedstock enabled industries: A systems theory perspective on ‘green’ pharmaceuticals,” Operations Management Research, vol. 11, no. 3–4, pp. 83–104, 2018. [CrossRef]

- H. K. Salim, R. A. Stewart, O. Sahin, and M. Dudley, “Drivers, barriers and enablers to end-of-life management of solar photovoltaic and battery energy storage systems: A systematic literature review,” 2019. [CrossRef]

- J. Shi, J. Zhou, and Q. Zhu, “Barriers of a closed-loop cartridge remanufacturing supply chain for urban waste recovery governance in China,” J Clean Prod, vol. 212, pp. 1544–1553, 2019. [CrossRef]

- M. Brettel, F. G. Fischer, D. Bendig, A. R. Weber, and B. Wolff, “Enablers for Self-optimizing Production Systems in the Context of Industrie 4.0,” in Procedia CIRP, 2016, pp. 93–98. [CrossRef]

- J. Posada et al., “Visual Computing as a Key Enabling Technology for Industrie 4.0 and Industrial Internet,” IEEE Comput Graph Appl, 2015. [CrossRef]

- R. Williams, E. McMahon, S. Samtani, M. Patton, and H. Chen, “Identifying vulnerabilities of consumer Internet of Things (IoT) devices: A scalable approach,” in 2017 IEEE International Conference on Intelligence and Security Informatics: Security and Big Data, ISI 2017, 2017. [CrossRef]

- N. Tura, J. Hanski, T. Ahola, M. Ståhle, S. Piiparinen, and P. Valkokari, “Unlocking circular business: A framework of barriers and drivers,” J Clean Prod, vol. 212, pp. 90–98, 2019. [CrossRef]

- S. B. Larsen, D. Masi, D. C. Feibert, and P. Jacobsen, “How the reverse supply chain impacts the firm’s financial performance: A manufacturer’s perspective,” 2018. [CrossRef]

- M. H. A. Nasir, A. Genovese, A. A. Acquaye, S. C. L. Koh, and F. Yamoah, “Comparing linear and circular supply chains: A case study from the construction industry,” Int J Prod Econ, vol. 183, pp. 443–457, 2017. [CrossRef]

- H. Dijkstra, P. van Beukering, and R. Brouwer, “Business models and sustainable plastic management: A systematic review of the literature,” J Clean Prod, 2020. [CrossRef]

- V. Piyathanavong, J. A. Garza-Reyes, V. Kumar, G. Maldonado-Guzmán, and S. K. Mangla, “The adoption of operational environmental sustainability approaches in the Thai manufacturing sector,” J Clean Prod, 2019. [CrossRef]

- L. A. B. Paes, B. S. Bezerra, R. M. Deus, D. Jugend, and R. A. G. Battistelle, “Organic solid waste management in a circular economy perspective – A systematic review and SWOT analysis,” J Clean Prod, vol. 239, 2019. [CrossRef]

- M. Holt and S. Powell, “Health and well-being in small and medium-sized enterprises (SMEs). What public health support do SMEs really need?,” 2015. [CrossRef]

- A. Zhang, V. G. Venkatesh, Y. Liu, M. Wan, T. Qu, and D. Huisingh, “Barriers to smart waste management for a circular economy in China,” J Clean Prod, vol. 240, 2019. [CrossRef]

- C. Dalhammar, “Industry attitudes towards ecodesign standards for improved resource efficiency,” J Clean Prod, vol. 123, pp. 155–166, 2016. [CrossRef]

- D. Densley Tingley, S. Cooper, and J. Cullen, “Understanding and overcoming the barriers to structural steel reuse, a UK perspective,” J Clean Prod, vol. 148, pp. 642–652, 2017. [CrossRef]

- Y. He, Q. Xu, and P. Wu, “Omnichannel retail operations with refurbished consumer returns,” Int J Prod Res, vol. 58, no. 1, pp. 271–290, 2020. [CrossRef]