1. Introduction

With the continuous development of advanced technologies such as artificial intelligence, 5G communication, and cloud computing, the application of the Internet of Things in various industries is expanding, covering many fields such as medical care, smart home, agriculture, and remote monitoring. In the field of industrial production, the introduction of Internet of Things technology has brought revolutionary changes to the manufacturing industry and promoted the in-depth development of intelligent manufacturing and industrial automation. Especially under the guidance of the concept of “Industry 4.0”, the industrial Internet of Things, as the core support for realizing intelligent production, is gradually changing the production mode and management mode of traditional industries. The widespread use of IIoT has brought multiple benefits such as improved efficiency, reduced costs and increased flexibility to the industrial industry, but it also faces complex technical challenges, especially in the security, real-time and reliability of device management and data flow.

As the world’s largest industrial manufacturing country, China’s industrial level is still lagging behind developed countries in some areas. With the deep integration of the Internet of Things and intelligent manufacturing, promoting the popularization and application of industrial Internet of Things technology has become a key way for China’s industrial modernization. The infrastructure of the industrial Internet of Things is usually composed of IIoT devices on the “end” side, edge computing nodes and cloud computing platforms, of which the “end” side equipment is responsible for the collection and processing of mass production data, and edge computing reduces the burden of the cloud through near-site data processing, improving the response speed and overall efficiency of the system. With the proliferation of devices, the efficient management of these devices has become an urgent task. By 2025, more than 25 billion iot devices will be connected globally, which not only increases the complexity of management, but also puts higher demands on the scalability and real-time processing power of the platform.

As a bridge connecting field devices and cloud platforms, intelligent gateways play an important role. Intelligent gateways not only ensure the stable operation of the equipment, but also need to effectively process massive data and ensure efficient collaboration with the cloud platform. The existing intelligent gateway management platform still has many problems in software update, device customization support and batch management. In order to cope with these challenges, this paper proposes a solution of intelligent gateway software management platform based on Jenkins cluster management. By introducing automatic deployment and efficient software upgrade mechanism, the cumbersome links in traditional equipment management methods are optimized. We adopted large file transfer technology and breakpoint continuation mechanism, which significantly improved the speed and stability of software upgrade, and solved the problem of batch task construction and distributed management through the task scheduling capability of Jenkins cluster, ensuring the efficient management and real-time update of large-scale equipment.

Through the design and implementation of this platform, it not only provides reliable technical support for the software management of intelligent gateway, but also lays a foundation for the further development of industrial Internet of Things. With the continuous optimization of the platform and the promotion of practical applications, it is expected that this program will become an important support tool for the transformation of intelligent manufacturing, and promote the traditional industry to the direction of intelligence and automation.

2. Related Research

2.1. Global Development Status and Challenges of Industrial Iot Management Platform

With the rapid development of iot technology, industrial iot platforms play a crucial role in intelligent manufacturing. Traditional iot architectures, such as the three - and four-layer models, have played an important role in data acquisition and processing, but still face challenges in handling complex and customized industrial equipment management, especially the management of intelligent gateways. Although domestic platforms such as Ali Cloud and Huawei Cloud have accumulated technical advantages in the field of Internet of Things, they still have shortcomings in meeting the customized needs of industrial intelligent gateways. Internationally, Siemens’ MindSphere and Telit’s DeviceWISE platforms offer mature solutions that enable highly customized device management by integrating devices and systems. M Morsali and K Kianfar The main aim of this study is to arrange waste collection systems and vehicle routes to reduce gas emissions from trucks and empty rubbish bins on time[

1]. The intelligent gateway software management platform based on Jenkins cluster management proposed in this paper aims to improve the management efficiency of industrial Internet of Things by optimizing the functions of cloud and edge, especially in the key links of equipment management, software upgrade and fault recovery, and promote the intelligent transformation of the manufacturing industry. The SONG Hang team analyzes the current state of energy iot, including its key industry drivers, potential technologies and applications, challenges, and related research areas[

2]. The SONG Hang team found no research on supplier relationship management processes, which suggests that IoT-based applications are perceived to add more value downstream than upstream supply chain management processes[

3]. This platform not only draws on successful iot management experience at home and abroad, but also combines the latest technologies to provide solid support for the future development of industrial iot. L Xuan team put forward an intelligent domestic waste removal scheme and established a new mode of intelligent domestic waste removal[

4].

2.2. Analysis of Global Development Trend and Key Problems of Industrial Intelligent Gateway Software Management Platform

Software management is the core module to ensure the continuous and stable running of devices. It involves software version control, update release, storage management, and device life cycle management. Software upgrade is mainly divided into two types: whole package upgrade and differential upgrade. Differential upgrade has become the mainstream because of its reduction of data transmission and storage requirements. WL Lu team made a detailed classification and comparison of research papers on multi-AGV management[

5]. Although major cloud platforms at home and abroad (such as Ali Cloud, Tencent Cloud, Huawei Cloud) have explored software management, there are still certain limitations. Alibaba Cloud’s upgrade scheme is suitable for specific hardware, Tencent Cloud supports multi-protocol devices but has a single strategy, and Huawei Cloud optimizes wireless device management, but platform scalability is limited. Based on previous studies, C Tang’s team made a comprehensive summary and analysis of the current status of motor thermal management technology, beyond specific types of motors[

6]. To solve these problems, this paper proposes an intelligent gateway software management platform based on Jenkins cluster management, combined with the integrated architecture of cloud edge, to improve upgrade efficiency and flexibility through clustering and automated management, ensure efficient software updates in large-scale equipment management, and provide technical support for the development of intelligent manufacturing and industrial Internet of Things platforms. J Chen’s team adopted the method of descriptive research and review to clarify the current practice, status quo, attitude, reasons and ongoing process[

7]. H Cheng’s team mainly introduced the technical connotation of high-performance mechanical connection of aviation carbon fiber composite structure, and summarized the academic development trend and existing problems in connection accuracy and damage[

8]

.

3. Industrial Intelligent Gateway Software Upgrade Technology and Optimization Strategy

3.1. Function and Application Challenges of Industrial Intelligent Gateway Under Cloud Edge Integrated Architecture

Industrial intelligent gateways play a central role, acting as a bridge between field devices and cloud platforms. Its essence is a compact small device with powerful data processing and transmission capabilities, which is commonly used to integrate various industrial equipment, perform data acquisition and forwarding, and support limited local computing tasks. Unlike traditional iot gateways, industrial intelligent gateways are designed with the complexity of the site environment in mind and usually provide rich communication interfaces such as serial ports, Ethernet ports and USB interfaces to ensure seamless connection with a variety of industrial equipment, PLCS, industrial cameras and industrial control platforms . DU Shugang’s team proposed a smart mine iot edge data gateway technology. Through the construction of edge gateway management architecture[

9]. The communication protocols supported by the industrial intelligent gateway enable it to flexibly interact with a variety of devices and platforms for data, driving the process of intelligent manufacturing and industrial automation. The team of SM Kusuma proposed a technology called cloud computing, which allows individuals and organizations to use the services provided by the cloud to solve problems[

10].

Industrial intelligent gateway not only serves as a node for data transmission and equipment integration, but also shoulders more complex edge computing tasks. Through data processing and local decision-making at the gateway, latency can be significantly reduced, response speed can be improved, and bandwidth pressure can be reduced. This is especially important because in many industrial application scenarios, real-time performance and reliability are key requirements. In order to achieve this edge computing function, industrial intelligent gateways are generally designed with a variety of communication methods and network services, including wired and wireless network connections, VPN and other technologies, to ensure stable and efficient data upload, device management and system collaboration.

The requirements of different manufacturers and application scenarios determine the differences in hardware and software design of industrial intelligent gateways. The industrial intelligent gateway designed in this paper is based on Linux platform, adopts non-embedded small device scheme, supports a variety of communication protocols, and can realize efficient connection with a variety of industrial equipment including PLC, industrial cameras and other equipment. Combined with the cloud-edge-end integrated architecture, the intelligent gateway software management system proposed by this platform provides the management function of the whole life cycle, including the monitoring and maintenance of equipment and the support of customized software upgrade. Through this intelligent gateway management platform, it not only improves the automation and intelligence level of equipment operation and maintenance, but also strengthens the software update, version control and other functions to ensure the continuous and stable operation of equipment in a complex industrial environment. This systematic design concept further enhances the value of industrial intelligent gateways in the Industrial Internet of Things, and can better support the needs of modern industrial fields for efficient, reliable and secure data processing.

3.2. Application and Optimization of Eureka Technology in Intelligent Gateway Software Management

When building modern Industrial Internet of Things platforms, microservices architecture has become a key technical means to improve system flexibility and scalability. By breaking down complex systems into multiple independent, loosely coupled service units, microservices architecture can effectively improve the response speed, fault tolerance and maintainability of the system. Service registration and discovery mechanism is the basis to ensure the efficient collaboration of various service components, and service registry plays a crucial role.

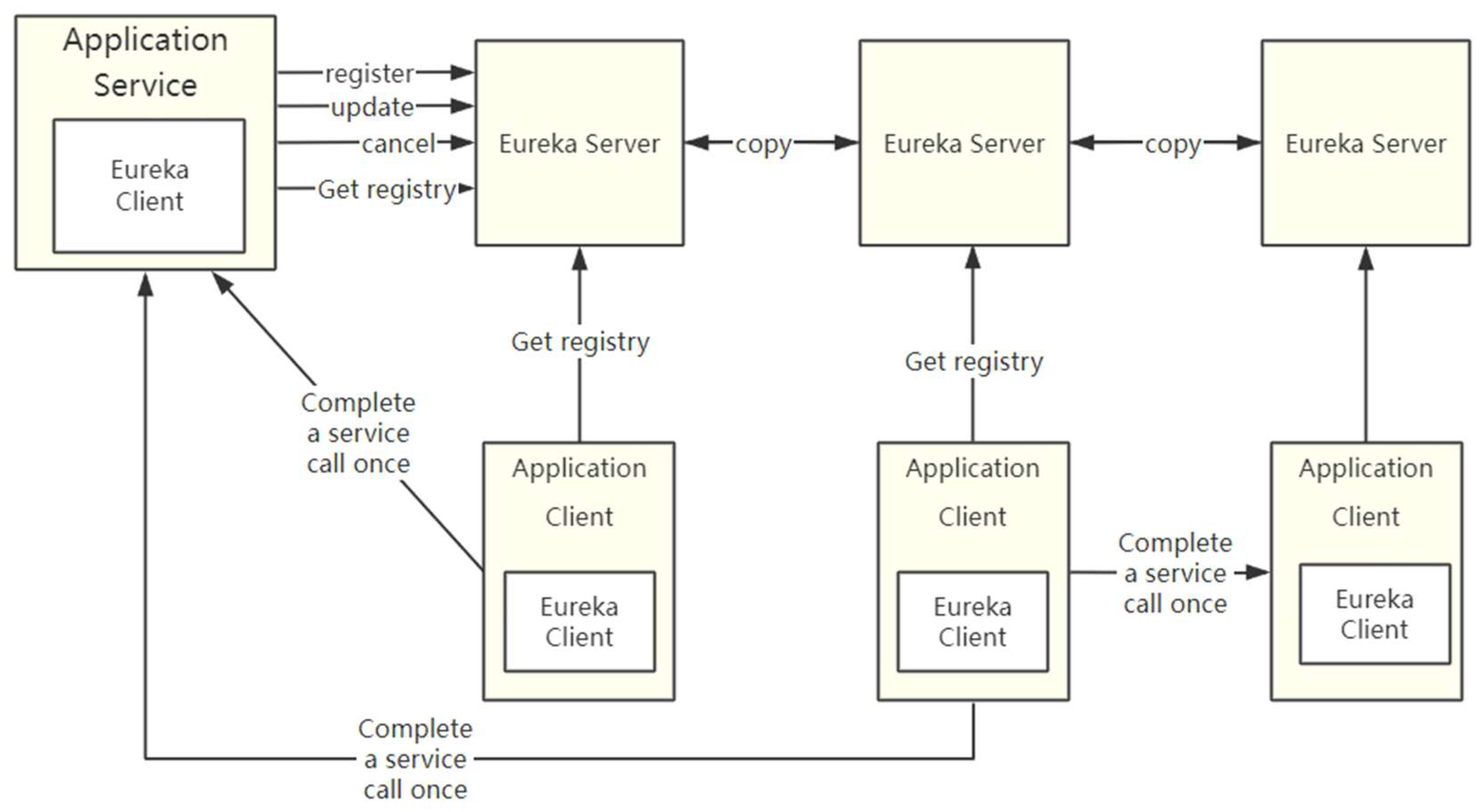

Eureka, the core service registration and discovery component in the Spring Cloud ecosystem, provides a reliable and easily scalable solution. Each intelligent gateway in the industrial Internet of Things platform can dynamically register and discover in the network to achieve seamless access and automatic management of devices. The advantage of this mechanism is that it allows devices in the system to interact with other devices or services in real time without manual configuration, effectively supporting intelligent gateway management under the cloud side integration architecture. As shown in

Figure 1:

Eureka uses the client/server model to manage the registration information on the server side, and the client submits the registration request to the server side. This mode ensures the realization of transparent communication and load balancing mechanism between services, helps to cope with high concurrency scenarios in the industrial Internet of Things, and improves the overall stability and scalability of the system. In the application of intelligent gateway, the high availability and efficiency of Eureka is particularly important, which can ensure the stable data transmission and control instructions between the intelligent gateway and the upper cloud platform.

Combined with Jenkins cluster management capabilities, Eureka provides strong support for automated operation and maintenance of industrial iot platforms. Jenkins’ continuous integration and continuous Delivery (CI/CD) process seamlessly integrates with Eureka’s service registry mechanism for automated updates and version management of the smart gateway software. This not only simplifies the software management process, but also significantly improves the operational efficiency of the system, ensuring that in a dynamic industrial environment, the software and hardware systems can respond quickly and adapt to different needs and challenges. In this way, the combination of microservices architecture and Eureka provides a solid technical support for an intelligent gateway software management platform in the Industrial Internet of Things.

3.3. Optimization and Application of Jenkins Technology in Industrial Internet of Things

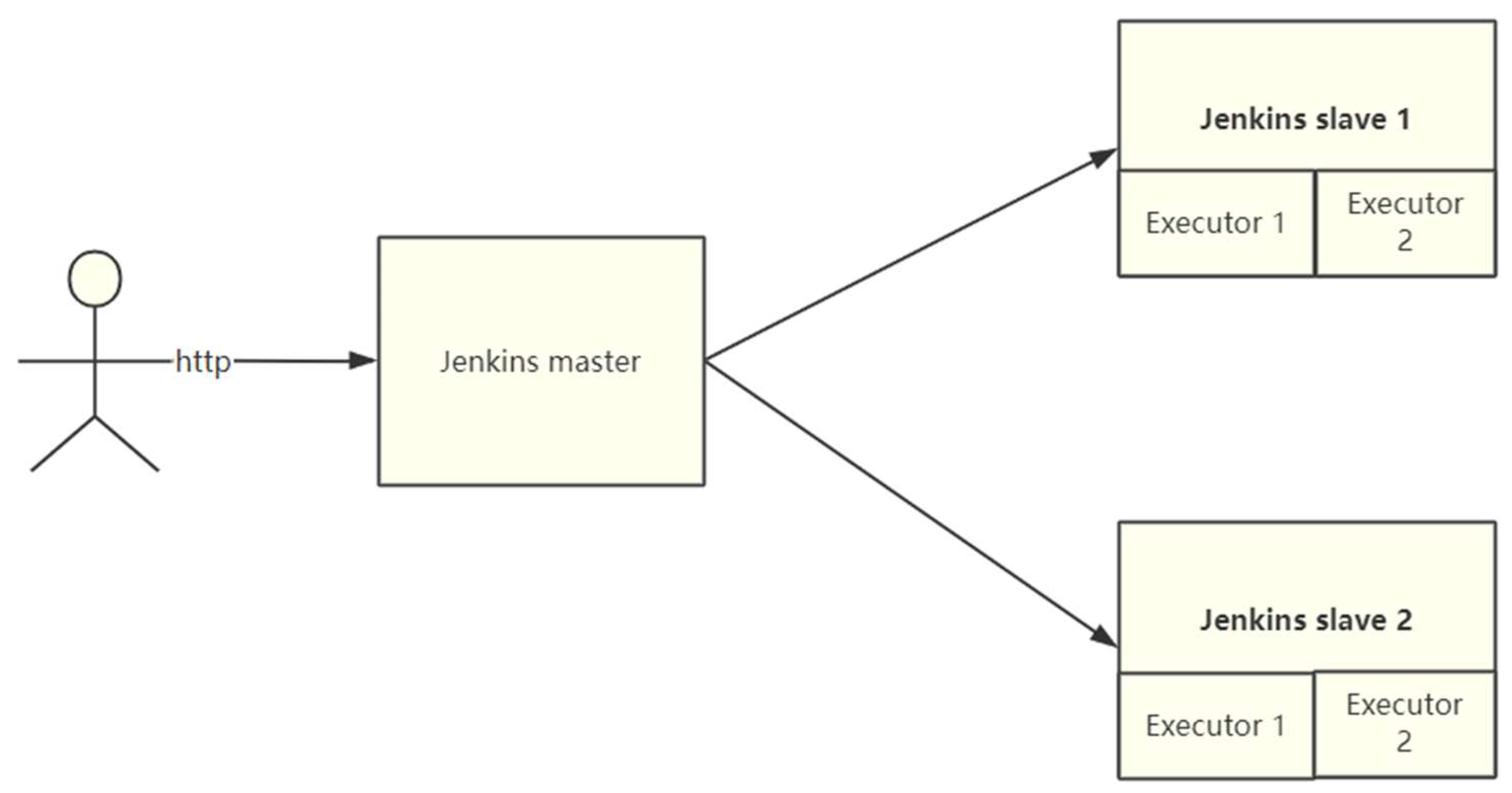

Facing the need for automated deployment and continuous delivery in the Industrial iot services architecture, Jenkins was chosen as one of the key tools. Jenkins is a powerful continuous integration and continuous delivery platform that not only supports the build, test, and deployment of projects, but also extends functionality through flexible plug-in mechanisms. Its master-slave architecture design ensures the efficient scheduling and execution of tasks, in which the master node is responsible for task management and user interaction, and the child node focuses on the running of specific build tasks. To accommodate the highly dynamic and complex nature of industrial iot scenarios, Jenkins is typically deployed as a Docker container to enable rapid iteration, resource isolation, and portability. As shown in

Figure 2:

Jenkins has been used to its advantage in two ways. Projects based on microservices architecture require efficient version management and deployment strategies. Jenkins automates and standardizes CI/CD processes through deep integration with private code bases. Jenkins coordinates task scheduling through the timer function, provides a flexible execution strategy, and is more stable and scalable than other solutions. This comprehensive application not only optimizes the software management process of the intelligent gateway, but also significantly improves the operating efficiency and reliability of the platform, providing strong support for the management of the industrial Internet of Things under the integrated architecture of the cloud edge.

4. Optimization and Upgrade of Intelligent Gateway Software Management Platform

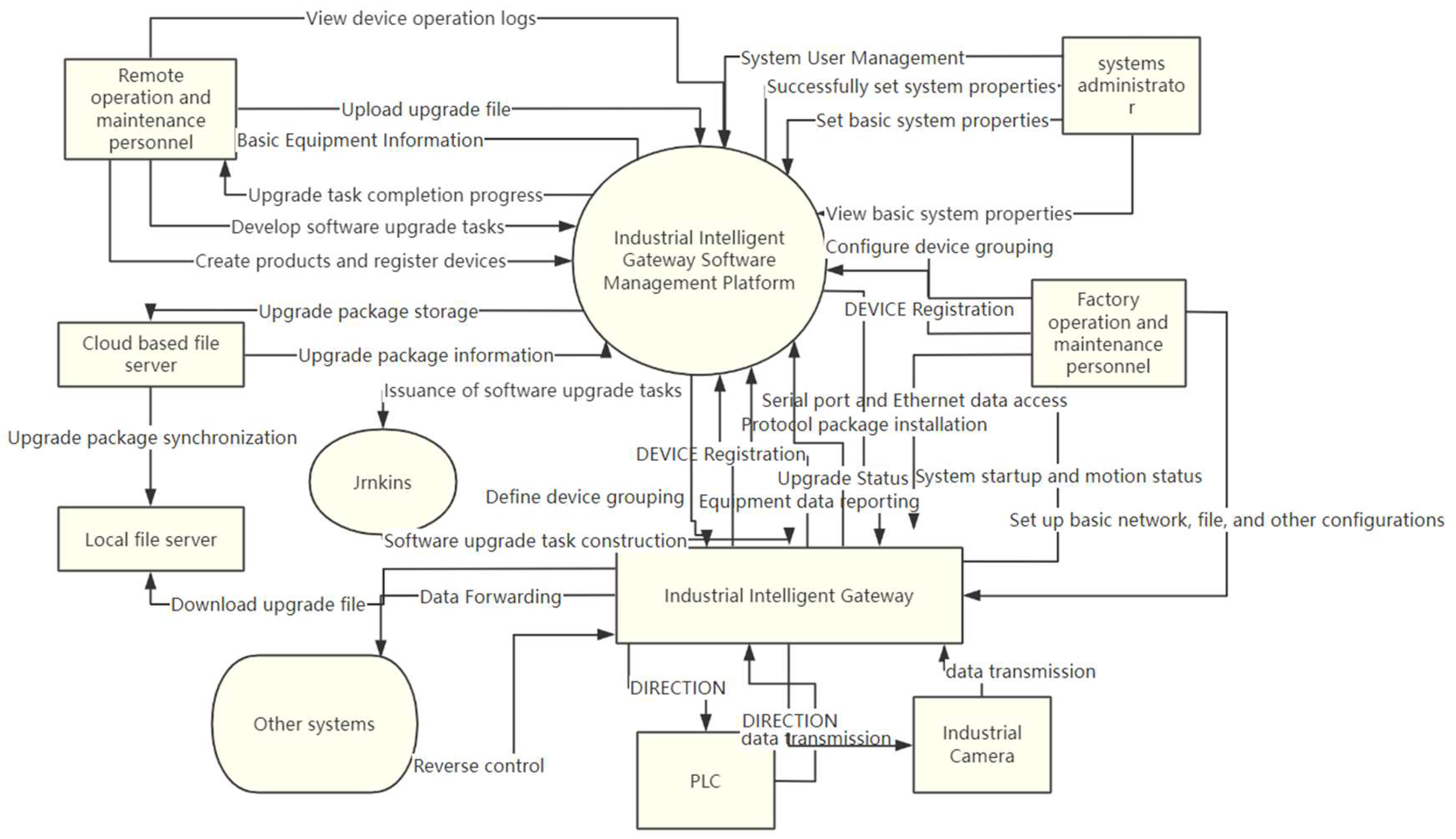

In the construction of intelligent gateway software management platform of industrial Internet of Things, the design and optimization of data flow is the key to ensure the efficient operation and stable maintenance of the system. The platform involves several key physical entities, including industrial intelligent gateways, file servers, and Jenkins clusters, which ensure efficient device management and seamless software upgrades through precise data interaction and control. The user roles of the platform include factory operation and maintenance personnel, third-party operation and maintenance support personnel and platform administrators. The division of different user rights and operational requirements together constitute the business processing logic of the platform, as shown in

Figure 3:

The data flow of the platform mainly focuses on the interaction between the intelligent gateway and the management platform. Considering that the platform architecture is positioned as a cloud service, the efficient transmission and security of data flow is particularly important. The platform completes data transmission in the local network through the way of side synchronization, avoiding the delay and bandwidth bottleneck that may be caused by direct transmission in the cloud. Through this edgecloud collaborative approach, the platform not only improves the speed and stability of data transmission, but also maximizes the reliability of software upgrades, especially in industrial production environments, avoiding upgrade failures caused by network fluctuations or bandwidth restrictions during peak periods.

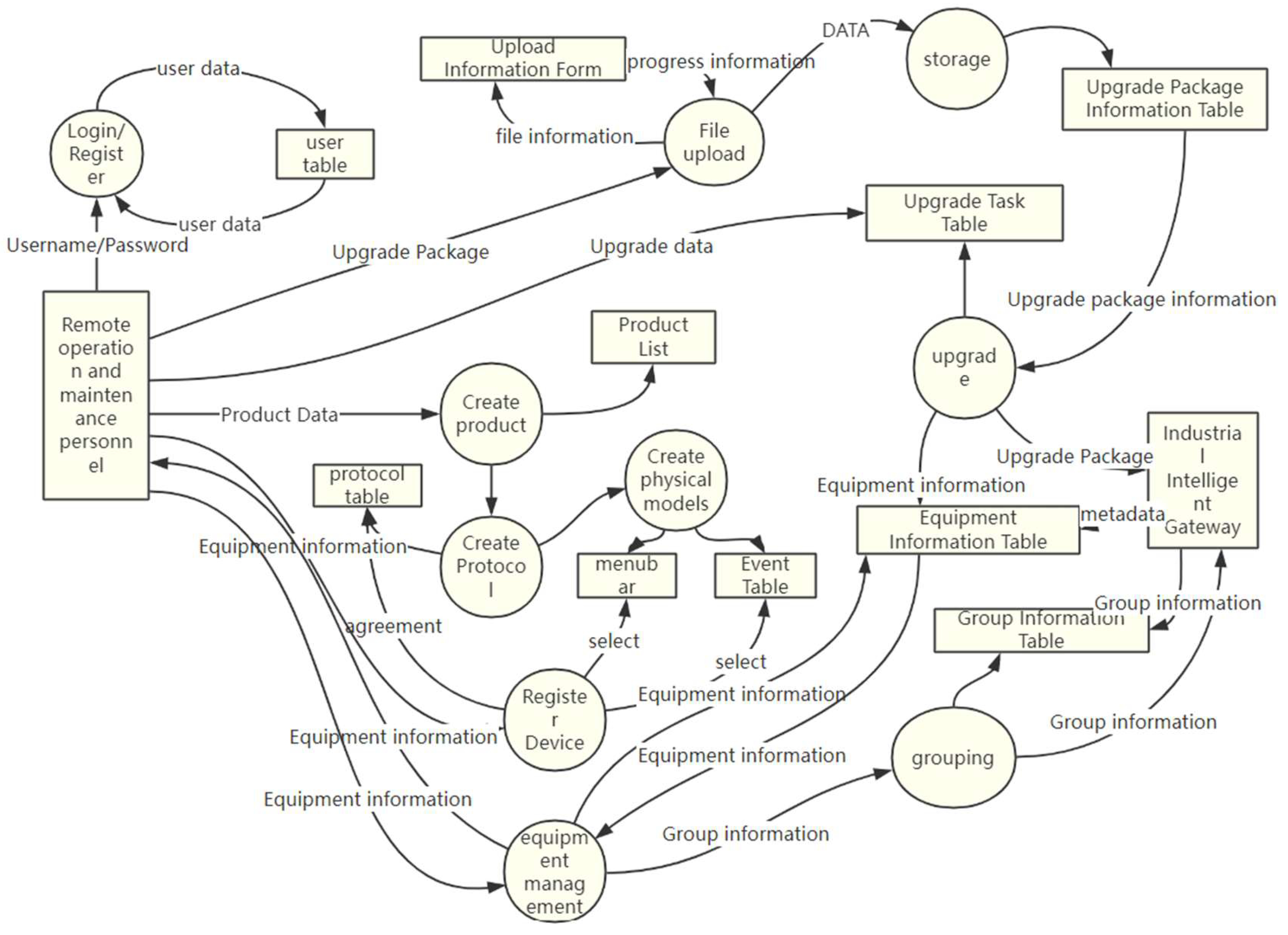

Based on the data flow graph method, the operating process of the platform is analyzed in detail. Through the layer 0 data flow diagram, the internal data storage and processing process of the platform are detailed, and the data flow and user interaction mode of the platform in different operation stages are shown. The core functions of the platform are not only limited to software management, but also include important modules such as device registration, protocol management, device information storage and monitoring. The device registration module adopts automatic registration mechanism and manual configuration to meet the needs of a wide variety of devices in the production environment and complex on-site configuration. Support a variety of communication protocol management functions, to ensure that the platform can flexibly interconnect with various industrial equipment, to provide a unified data acquisition and transmission interface. As shown in

Figure 4:

As the core component of the platform, the device management module provides the whole life cycle management function of the device, including device grouping, information management and real-time status monitoring. Through device group management, the platform can classify equipment by production floor, product line, or other logic to optimize equipment scheduling and fault location. The device information management function ensures that the static and dynamic data of the device can be tracked and maintained in real time, further improving the availability of the platform and the accuracy of equipment management.

In terms of product management, the design of the platform requires support for multi-dimensional equipment information management, including product definition, manufacturer information, equipment classification, etc. This module not only ensures the traceability of equipment information, but also provides a detailed reference for equipment maintenance and upgrade. The platform also needs to support the management of user rights to ensure that users of different roles can only access the data and functions that match their rights. This function not only improves the security of the platform, but also ensures that the platform can fine manage the operation rights of each user in actual operation to avoid security risks.

The performance design of the platform is particularly important. The platform needs to have strong stability to ensure that there is no system downtime during peak production and network fluctuations. When unexpected situations such as power failure and network disconnection occur, the platform needs to have the function of quick restart and recovery to ensure the continuity and stability of production tasks. Batch execution of upgrade tasks requires that the platform can handle upgrade requests of multiple devices at the same time without causing network congestion, so as to reduce the interference to the production line during the upgrade process.

The platform requires pages to load in seconds, ensuring that operations personnel can quickly get the information they need and respond. Platform deployment and equipment upgrade tasks should be completed in the shortest possible time to avoid production stagnation or loss of efficiency due to time delays. In order to ensure the security of data, the platform adopts data encryption technology, and all the transmission and storage of sensitive information are strictly encrypted to prevent data leakage and illegal access.

5. The Realization and Deployment Test of Industrial Intelligent Gateway Software Management Platform

5.1. Test and Performance Evaluation of Industrial Intelligent Gateway Software Management Module

The software management module is the core part of the whole platform, and its testing work mainly focuses on the upload and download of upgrade packages, the flexible configuration of upgrade strategies, and the efficient construction of upgrade tasks.

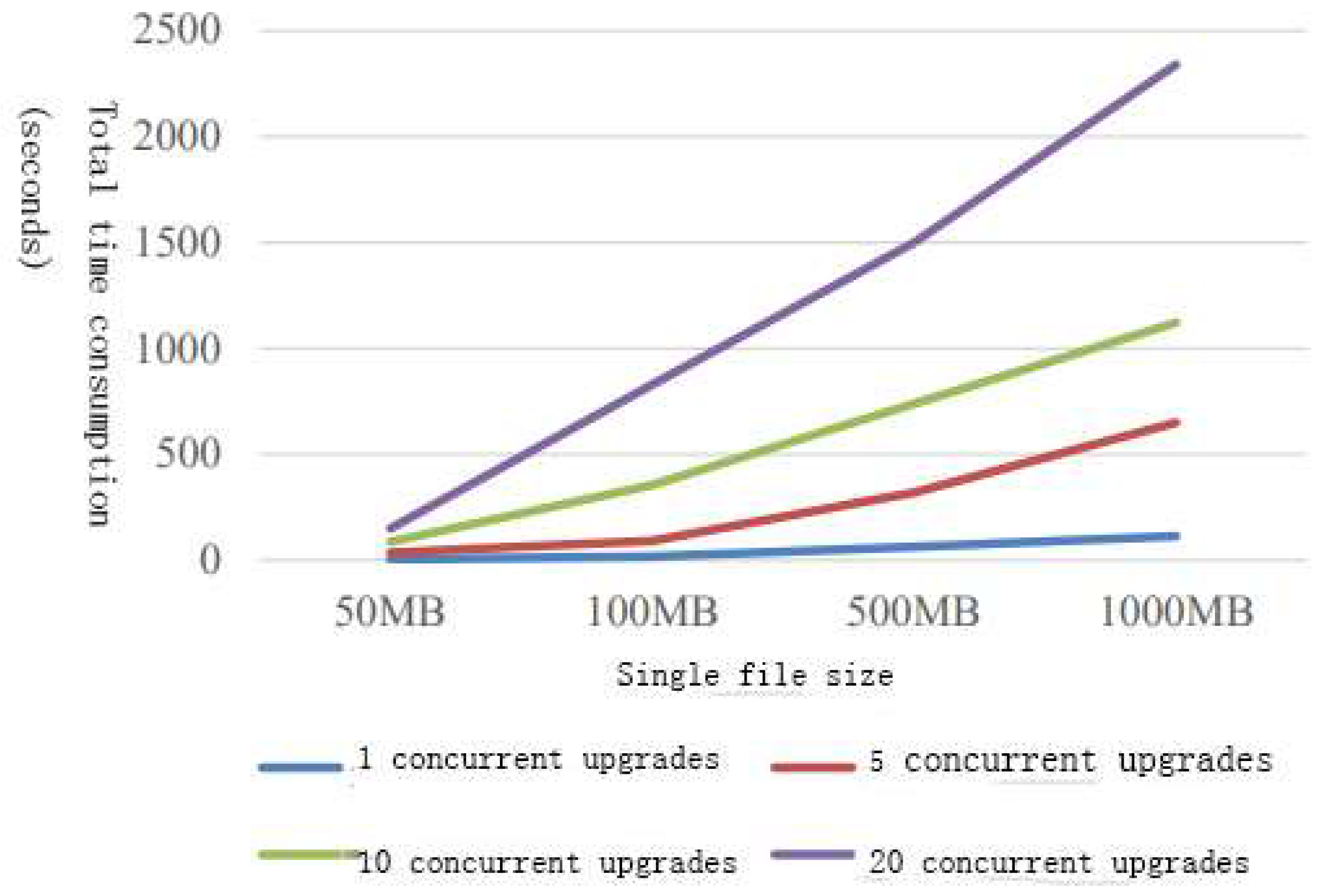

In order to comprehensively evaluate the performance of file upload and whole package upgrade, a refined test scheme for different file sizes is designed. In the process of file upload, the 3MB equal length block processing mechanism is adopted, and the front-end upload thread is set to 6 and the back-end merge thread is set to 12. The network bandwidth in the test environment fluctuates dynamically between 3Mb/s and 15Mb/s to simulate the complex network conditions in the actual industrial scene. In the whole package upgrade test, the batch tasks of 1, 5, 10 and 20 industrial intelligent gateways are analyzed in detail, focusing on the overall time and concurrent processing capability of the initial delivery of the upgrade package. The platform can effectively utilize network resources in the parallel transmission scenario of multiple devices to ensure efficient data transmission and smooth execution of upgrade tasks. By optimizing the blocking mechanism and thread scheduling, the platform further improves the stability and scalability, and provides reliable support for efficient batch upgrading of industrial intelligent gateways. As shown in

Figure 5:

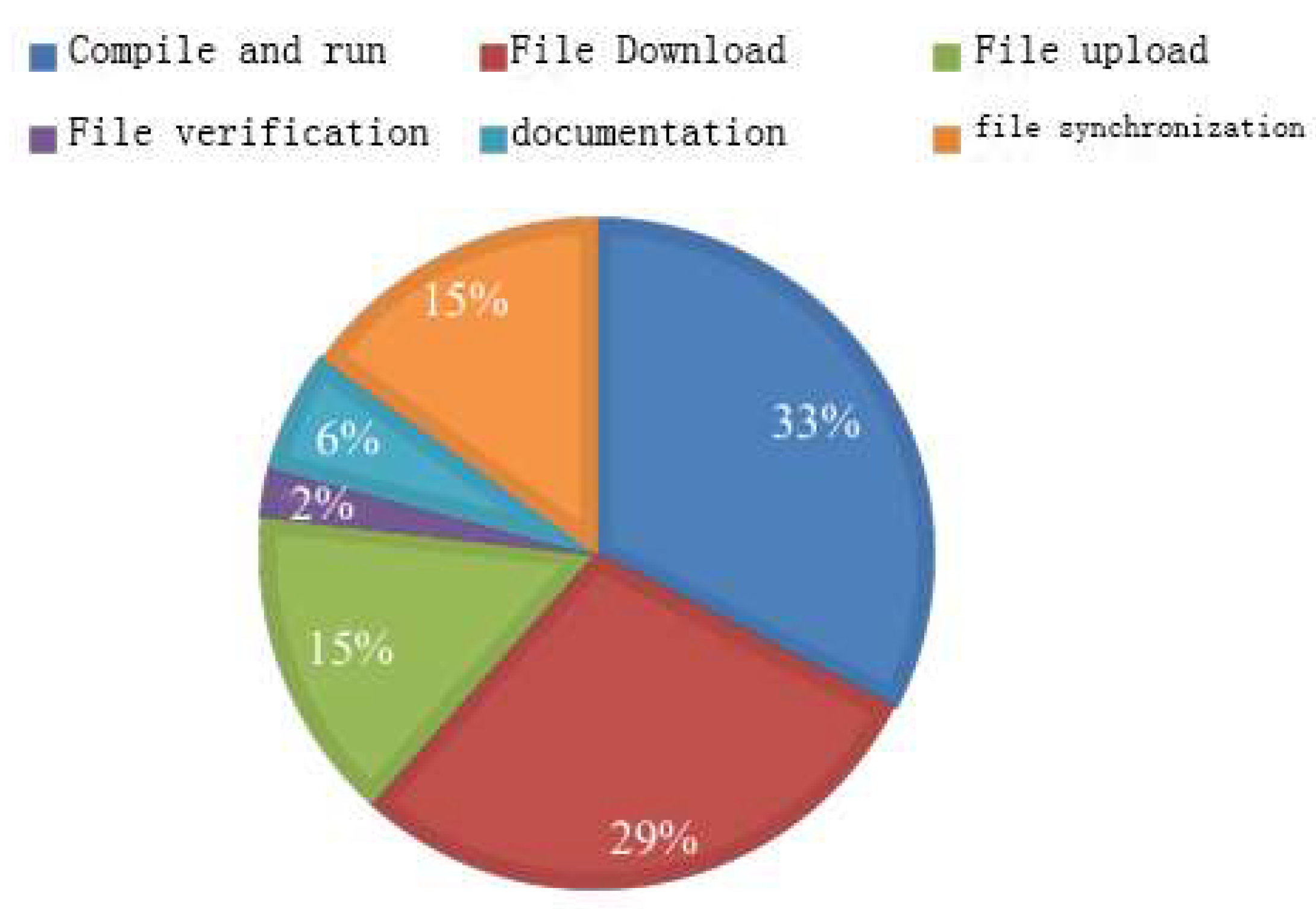

In order to evaluate the performance of the platform in actual scenarios, detailed tests are also conducted for timeliness, including the response time of accessing the platform from the Web side, the startup time of the platform initialization, the time spent in the device registration process, and the efficiency of large file transfer. Through the data collection and statistical analysis of the field deployment environment, the performance of the platform in different application scenarios is summarized. The test results show that the platform can not only quickly respond to a variety of user operations, but also realize efficient management of industrial intelligent gateway upgrade tasks by optimizing resource scheduling and task distribution processes. This provides a reliable technical support for the software management requirements in the industrial Internet of Things scenario, and lays the foundation for further improving the platform performance and the scalability of functional modules.As shown in

Figure 6:

6. Conclusion

An intelligent gateway software management platform based on the integrated architecture of cloud edge is proposed to solve the management and maintenance problems of intelligent gateway and other IoT devices in the industrial Internet of Things. The core functions of the platform include device registration, management, user management and platform management, and Jenkins cluster management technology is adopted to improve the efficiency of software upgrade. Based on the analysis of domestic and foreign research status, the architecture combining cloud and edge computing is designed, and the equipment data processing and upgrade strategy is optimized. The platform provides efficient solutions in large file transfer, whole package and differential upgrade, equipment access and operation management. The test results show that the platform performs well in terms of stability, security and timeliness, and meets the operation requirements under high concurrency and high load environment, providing technical support and reference for intelligent gateway management.

References

- Morsali M, Kianfar K.The effects of internet of things and industrial revolution 4.0 on urban waste management: a case study of Isfahan city[J].International Journal of Environmental Science and Technology, 2024(2):21.

- Hang S, Xiang W, Hua Z.Energy Internet of Things in the Perspective of Internet of Everything: Current Status, Technologies and Case Analysis[J].Southern Energy Construction, 2024, 11(4). [CrossRef]

- Hang S, Xiang W, Hua Z.Energy Internet of Things in the Perspective of Internet of Everything: Current Status, Technologies and Case Analysis[J].Southern Energy Construction, 2024, 11(4). [CrossRef]

- Xuan L, Gan T, Hong W,et al.Design and development of a domestic garbage removal management platform based on the Internet of Things[J].Journal of Physics: Conference Series, 2021, 1827(1):012197 (7pp). [CrossRef]

- Lu W L, Guo S, Song T,et al.Analysis of Multi-AGVs Management System and Key Issues: A Review[J].Computer Modeling in Engineering & Sciences, 2022. [CrossRef]

- Chenqi T, Zhongjun Y, Zhixin L,et al.Research Status and Development Trends of Thermal Management Technologies for Motors[J].Iranian Journal of Science and Technology, Transactions of Mechanical Engineering, 2024, 48(4):2025-2057. [CrossRef]

- Chen J, Huang G, Yang J,et al.Development of a DSP based collaborative computing platform for power system[J].IOP Publishing Ltd., 2024. [CrossRef]

- Cheng H, Luo B, Liang B,et al.Key issues and development trends of mechanical connection relating to aviation CFRP structure performance[J].Journal of Advanced Manufacturing Science and Technology, 2022, 2(4):null-null. [CrossRef]

- Shugang D U, Wanbo D, Xuwei M A,et al.Research on intelligent mining IoT edge data gateway technology[J].Mining & Metallurgy (10057854), 2024, 33(4). [CrossRef]

- Kusuma S M, Veena K N, Kavya K S,et al.Intelligence and Cognitive Computing at the Edge for IoT: Architecture, Challenges, and Applications[J]. 2023. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).