Submitted:

19 December 2024

Posted:

20 December 2024

You are already at the latest version

Abstract

Purpose: This systematic literature review aimed to analyze trends, key findings, and research opportunities in manufacturing sustainability from 2019 to 2023. Methodology: A systematic review of 134 publications was conducted, focusing on technological advancements, research gaps, and the impact of global events on manufacturing sustainability. Findings: The review revealed: (1) A shift towards advanced technologies like AI and blockchain, driving sustainability improvements; (2) Significant research gaps in social, policy, and regulatory dimensions; (3) The COVID-19 pandemic's role in accelerating digital transformation in manufacturing. Practical implications: Strategic recommendations are provided for industry, policymakers, and academics to address identified gaps and leverage emerging technologies for sustainable manufacturing. Originality: This review offers a comprehensive analysis of current trends and critical areas for future research in manufacturing sustainability, particularly in the context of rapid technological advancements and global disruptions.

Keywords:

1. Introduction

2. Methodology

2.1. Research Approch

2.2. Keywords and Databases

2.3. Inclusion and Exclusion Criteria

- ▪

- Inclusion Criteria: Articles published between 2019 and 2023; Articles from Q1-ranked journals; and Articles focusing on sustainable manufacturing, covering economic, environmental, social, technological, operational, policy, or regulatory dimensions

- ▪

2.4. Journal Selection Process

- ▪

- Initial Identification: Articles were retrieved from databases using predetermined keywords.

- ▪

- Duplicate Screening: Duplicate articles were removed to avoid redundancy.

- ▪

- Relevance Review: Titles, abstracts, and methodologies were assessed to ensure alignment with the research topic.

- ▪

2.5. Data Analysis

- ▪

- Research Trends: Identifying the most-discussed sustainability dimensions, such as environmental, economic, and technological.

- ▪

- Research Gaps: Highlighting less-explord dimensions such as social, policy, and regulatory aspects.

- ▪

2.6. Proses Validation

2.7. Methodological Contribution

- ▪

- Comprehensiveness: A thorough analysis of high-quality literature across various dimensions of sustainable manufacturing

- ▪

- Relevance: Emphasis on recent trends and future research opportunities, particularly in underexplored dimensions like social and policy aspects.

- ▪

3. Results and Analysis

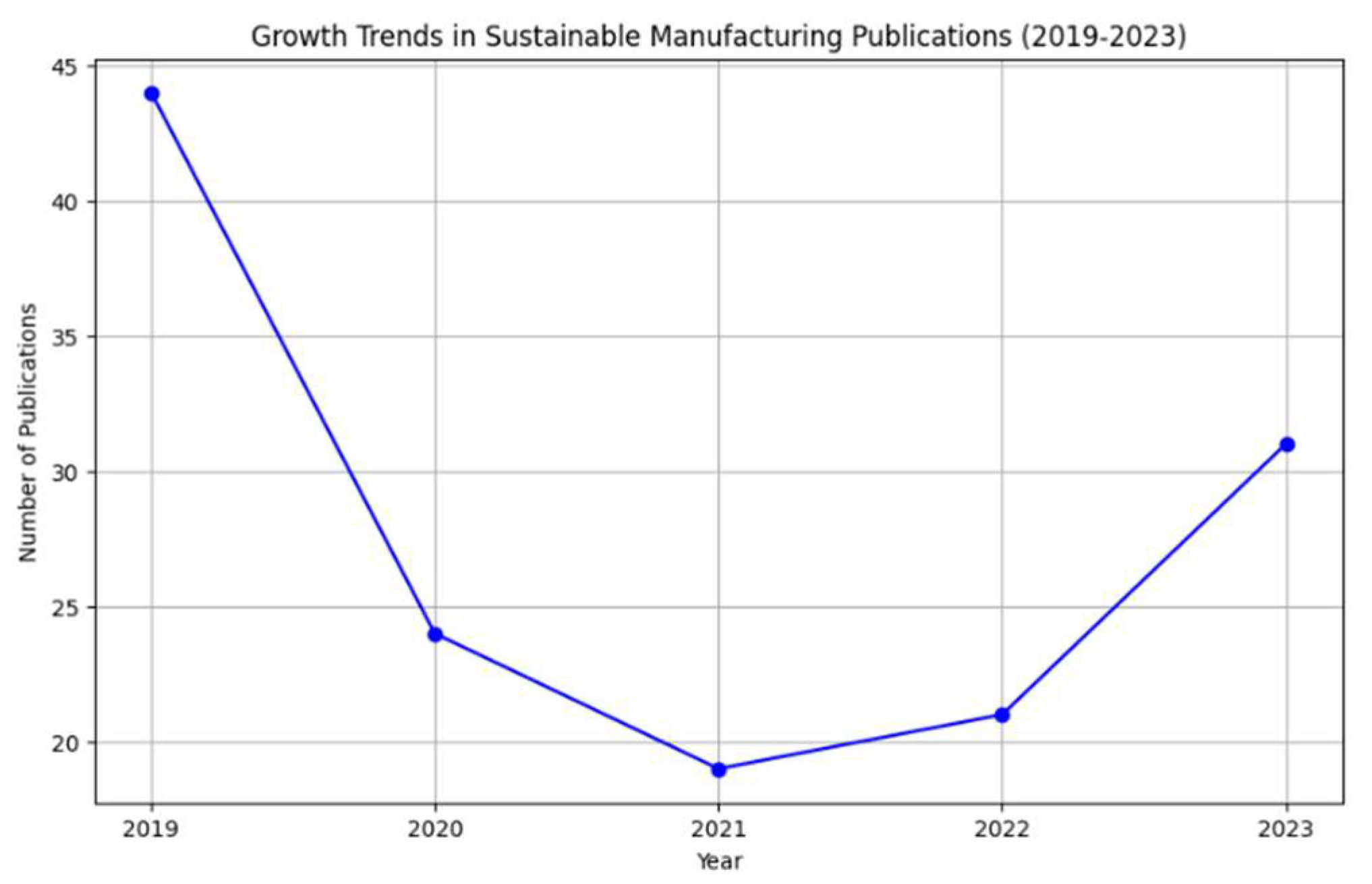

3.1. Growth Trends in Publication (2019-2023)

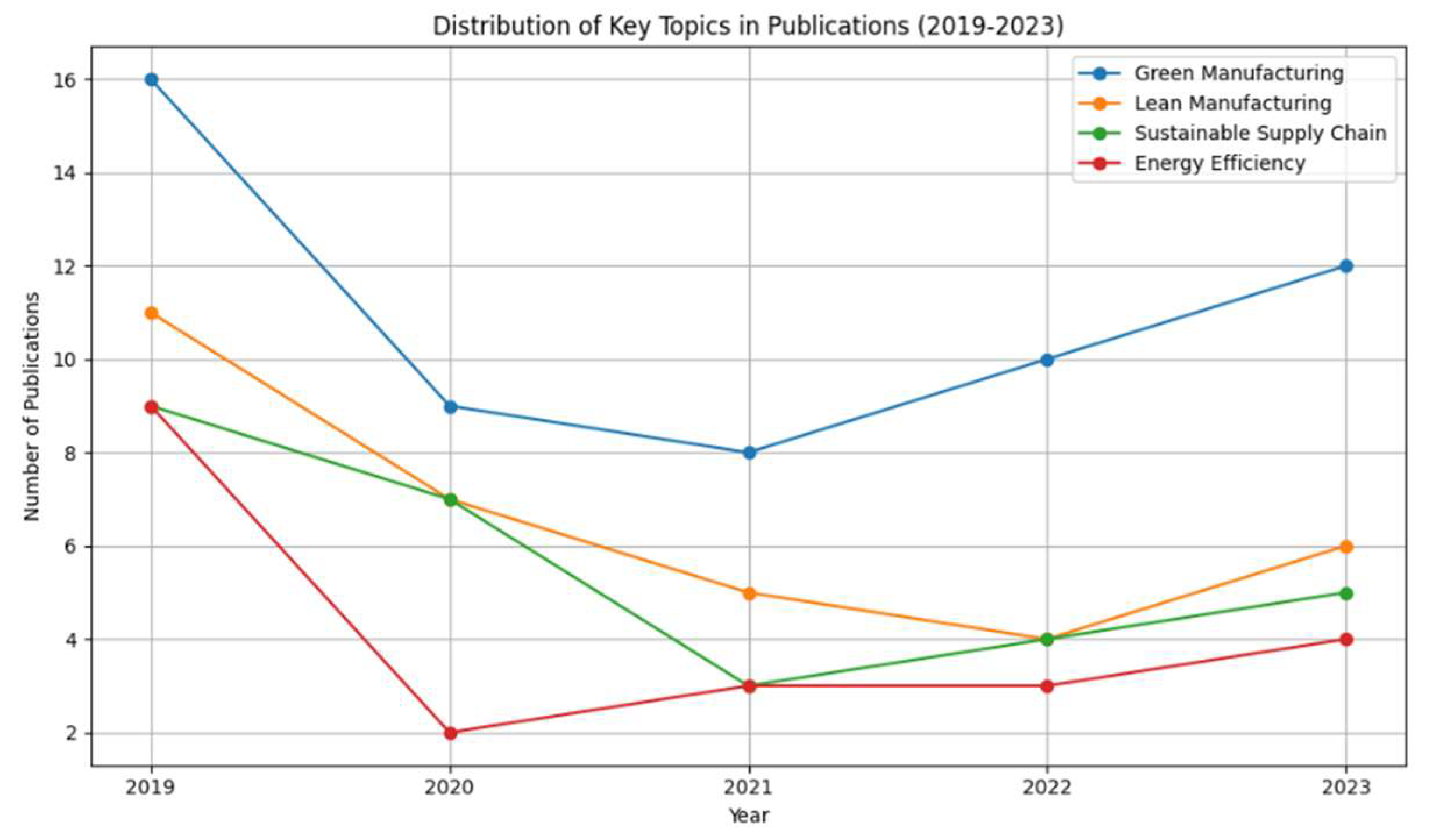

3.2. Distribution of Key Topics per Year

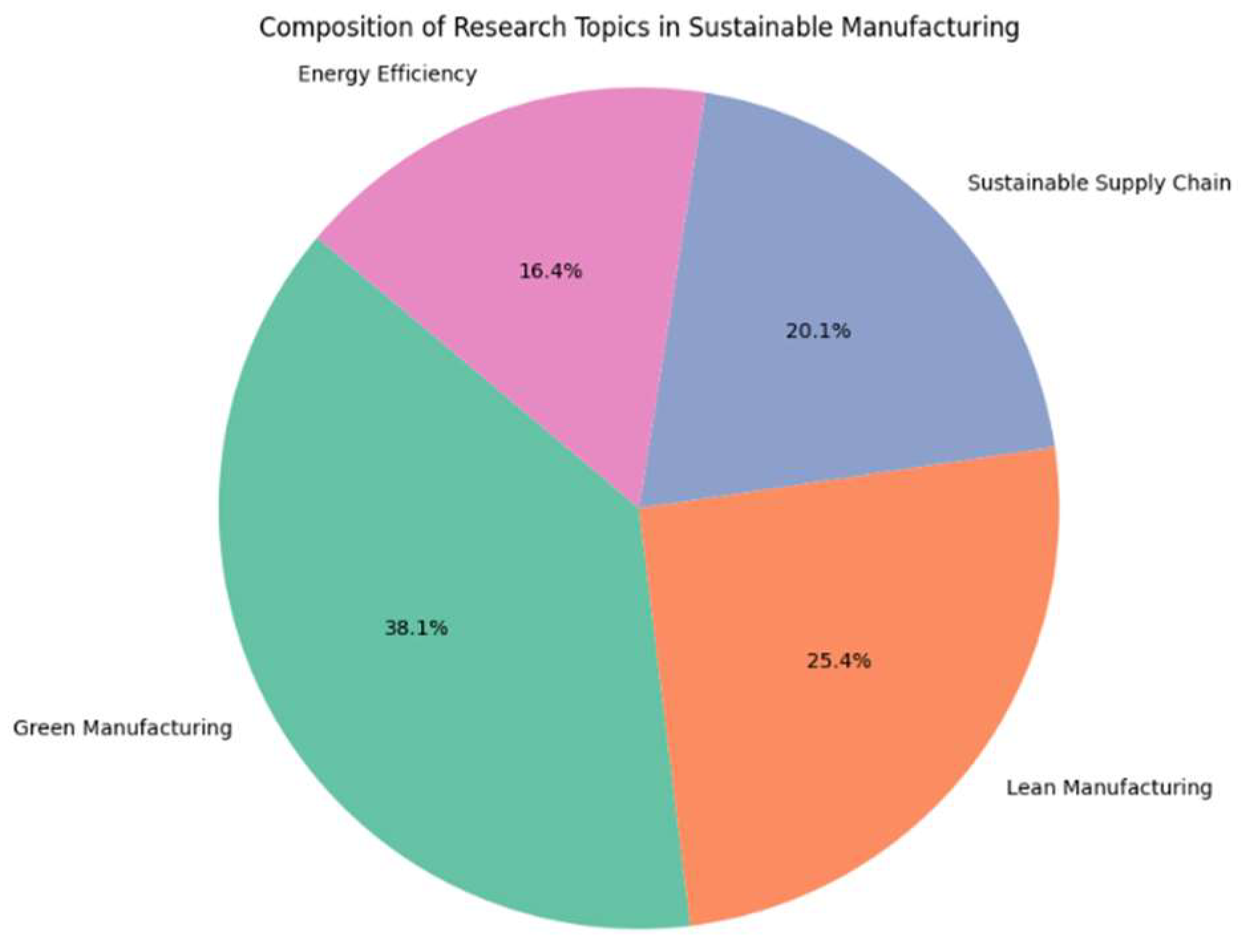

3.3. Changes in the Dominance of Sustainability Dimensions

3.4. Relationship Between Trends and External Events

- 1)

-

Impact of COVID-19 Pandemic (2020-2021):

- ▪

- A notable decline in overall publications was observed in 2020, particularly in Green Manufacturing (from 16 in 2019 to 9 in 2020) and Energy Efficiency (from 9 to 2).

- ▪

- This decline likely reflects the disruption caused by the pandemic to research activities and industrial operations [55].

- ▪

- However, research on Sustainable Supply Chain maintained relative stability, possibly due to increased focus on supply chain resilience during the pandemic.

- 2)

-

Post-Pandemic Recovery (2022-2023):

- ▪

- A gradual increase in publications across all topics, with Green Manufacturing showing the strongest recovery (10 in 2022, 12 in 2023).

- ▪

- This trend aligns with the global emphasis on “building back better” and integrating sustainability into post-pandemic recovery strategies [56].

- 3)

-

Rise of Industry 4.0 Technologies:

- ▪

- An increasing integration of Industry 4.0 concepts across all topics, particularly evident in the later years of the study period.

- ▪

- This trend reflects the growing recognition of digital technologies’ potential in enhancing sustainability in manufacturing [57].

- 4)

-

Global Climate Initiatives:

- ▪

- The consistent focus on Green Manufacturing and the growth in Energy Efficiency research correlate with increased global attention to climate change and sustainability goals.

- ▪

- This trend aligns with major international initiatives like the Paris Agreement and the UN Sustainable Development Goals [58]

- 5)

-

Circular Economy Momentum:

- ▪

- A noticeable increase in research related to circular economy principles, particularly within Green Manufacturing and Sustainable Supply Chain topics.

- ▪

- This trend corresponds with global policy shifts towards circular economy models, such as the EU Circular Economy Action Plan [59].

4. Discussion

4.1. Implications of Findings on Sustainability Theory and Practice

4.2. Research Gaps

- ▪

- Digital Skills Gap: There is a notable lack of research on strategies to bridge the growing mismatch between the skills required for digital manufacturing and the current capabilities of the workforce, especially in developing countries [22].[44,52,65]. This gap is concerning as it hampers the effective adoption of advanced technologies.

- ▪

- ▪

- ▪

- Policy Incentives: Research evaluating the effectiveness of various policy incentives—such as subsidies for low-carbon technologies or carbon taxes—in promoting sustainable manufacturing practices is scarce [39]. Such evaluations are necessary to understand how policies can effectively drive sustainability.

- ▪

- ▪

- ▪

- ▪

- ▪

- International Regulatory Frameworks: There is a lack of research focused on creating harmonized international regulations that promote transparency and sustainability in global supply chains[28,63]. Such frameworks are necessary to facilitate cooperation among multinational corporations operating under diverse regulatory environments.

4.3. The Relationship Between Technology and Sustainability Outcomes

- ▪

- Blockchain technology has improved supply chain transparency and traceability, reducing risks of unsustainable practices [66]. For example, blockchain enables real-time tracking of materials and ensures compliance with sustainability standards, potentially reducing material wastage by up to 20% in the electronics sector.

- ▪

- IoT and smart sensors enable real-time monitoring and quality control, leading to waste reduction and increased process efficiency [19]. These technologies have been shown to optimize production processes, enabling product lifecycle tracking, inspection, and storage management.

- ▪

- ▪

- ▪

- AI-driven programs enhance workforce skills through tailored training and upskilling initiatives, boosting productivity and job satisfaction [71]. The OECD survey found that both workers and employers are generally positive about AI’s impact on performance and working conditions.

- ▪

- Digital platforms create new employment opportunities in data management, software development, and other digital-based sectors [72]. This shift towards digital skills is crucial for adapting to the changing nature of work in sustainable manufacturing.

- ▪

- High initial investment costs for implementing advanced technologies like AI and digital twins) [7].

- ▪

- Digital infrastructure gap between developed and developing countries, limiting global technology adoption [40].

- ▪

- Regulatory lag behind technological advancements, particularly for emerging technologies like blockchain and AI [5].

- ▪

- Integrating blockchain technology to ensure ethical labor practices and enhance social sustainability [66].

- ▪

- Expanding the use of digital twins to model and optimize the entire product lifecycle, including social and environmental impacts [19].

- ▪

- Developing AI systems that can balance economic, environmental, and social objectives in real-time decision-making[71].

4.4. Challenges of Implementation

4.5. Opportunities for Future Research

5. Conclusions

- ▪

- Accelerate the adoption of sustainability technologies through comprehensive digital workforce training programs.

- ▪

- Integrate AI for process optimization, focusing on both environmental and economic benefits [39]

- ▪

- Develop long-term strategies for upskilling and reskilling workers to ensure they can effectively utilize and adapt to new technologies.

- ▪

- Invest in collaborative platforms to share best practices and lessons learned in sustainable manufacturing across the industry.

- ▪

- Develop and implement fiscal incentive policies, such as tax credits for green technology investments.

- ▪

- Support the harmonization of cross-country policies to facilitate global adoption of sustainable practices [28]

- ▪

- Create flexible regulatory frameworks that can accommodate rapid technological advancements while ensuring environmental protection and social equity.

- ▪

- Establish public-private partnerships to drive research and development in sustainable manufacturing technologies.

- ▪

- Direct research efforts towards understanding the social dimensions of sustainable manufacturing, particularly the impact of digital transformation on worker welfare.

- ▪

- ▪

- Develop interdisciplinary research programs that integrate technological, social, and policy perspectives on sustainable manufacturing.

- ▪

- Investigate the long-term implications of emerging technologies on sustainability outcomes in manufacturing.

6. Patents

Author Contributions

References

- S. Bag and J. H. C. Pretorius, “Relationships between industry 4.0, sustainable manufacturing and circular economy: proposal of a research framework,” 2022. [CrossRef]

- M. Timperi, K. Kokkonen, and L. Hannola, “Digital twins for environmentally sustainable and circular manufacturing sector: visions from industry professionals,” Prod Manuf Res, vol. 12, no. 1, Dec. 2024. [CrossRef]

- A. B. L. de Sousa Jabbour, C. J. C. Jabbour, C. Foropon, and M. Godinho Filho, “When titans meet – Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors,” Technol Forecast Soc Change, vol. 132, pp. 18–25, Jul. 2018. [CrossRef]

- G. Yadav, A. Kumar, S. Luthra, J. A. Garza-Reyes, V. Kumar, and L. Batista, “A framework to achieve sustainability in manufacturing organisations of developing economies using industry 4.0 technologies’ enablers,” Comput Ind, vol. 122, p. 103280, Nov. 2020. [CrossRef]

- C. Bai, P. Dallasega, G. Orzes, and J. Sarkis, “Industry 4.0 technologies assessment: A sustainability perspective,” Int J Prod Econ, vol. 229, p. 107776, Nov. 2020. [CrossRef]

- M. Piccarozzi, B. Aquilani, and C. Gatti, “Industry 4.0 in Management Studies: A Systematic Literature Review,” Sustainability, vol. 10, no. 10, p. 3821, Oct. 2018. [CrossRef]

- M. Ghobakhloo, “Industry 4.0, digitization, and opportunities for sustainability,” J Clean Prod, vol. 252, p. 119869, Apr. 2020. [CrossRef]

- C. Bai, P. Dallasega, G. Orzes, and J. Sarkis, “Industry 4.0 technologies assessment: A sustainability perspective,” Int J Prod Econ, vol. 229, p. 107776, Nov. 2020. [CrossRef]

- B. Tjahjono, C. Esplugues, E. Ares, and G. Pelaez, “What does Industry 4.0 mean to Supply Chain?,” Procedia Manuf, vol. 13, pp. 1175–1182, 2017. [CrossRef]

- M. P. P. Pieroni, T. C. McAloone, and D. C. A. Pigosso, “Business model innovation for circular economy and sustainability: A review of approaches,” J Clean Prod, vol. 215, pp. 198–216, Apr. 2019. [CrossRef]

- C. J. Chiappetta Jabbour, P. D. C. Fiorini, N. O. Ndubisi, M. M. Queiroz, and É. L. Piato, “Digitally-enabled sustainable supply chains in the 21st century: A review and a research agenda,” Science of The Total Environment, vol. 725, p. 138177, Jul. 2020. [CrossRef]

- B. Trenerry et al., “Preparing Workplaces for Digital Transformation: An Integrative Review and Framework of Multi-Level Factors,” Front Psychol, vol. 12, Mar. 2021. [CrossRef]

- Y. Lu, Y. Tan, and H. Wang, “Impact of Environmental Regulation on Green Technology Adoption by Farmers Microscopic Investigation Evidence From Pig Breeding in China,” Front Environ Sci, vol. 10, Apr. 2022. [CrossRef]

- Y. Hao, X. Niu, and J. Wang, “Impacts of haze pollution on China’s tourism industry: A system of economic loss analysis,” J Environ Manage, vol. 295, p. 113051, Oct. 2021. [CrossRef]

- J. Zhu, Y. Fan, X. Deng, and L. Xue, “Low-carbon innovation induced by emissions trading in China,” Nat Commun, vol. 10, no. 1, p. 4088, Sep. 2019. [CrossRef]

- A. Draghici, C.-F. Baban, M.-L. Gogan, and L.-V. Ivascu, “A Knowledge Management Approach for The University-industry Collaboration in Open Innovation,” Procedia Economics and Finance, vol. 23, pp. 23–32, 2015. [CrossRef]

- A. Muhammad Iqbal, A. Shahid Khan, F. Bashir, and A. Amat Senin, “Evaluating National Innovation System of Malaysia Based on University-industry Research Collaboration: A System Thinking Approach,” Asian Soc Sci, vol. 11, no. 13, May 2015. [CrossRef]

- H. Gholami, F. Abu, J. K. Y. Lee, S. S. Karganroudi, and S. Sharif, “Sustainable Manufacturing 4.0—Pathways and Practices,” Sustainability, vol. 13, no. 24, p. 13956, Dec. 2021. [CrossRef]

- N. T. Ching, M. Ghobakhloo, M. Iranmanesh, P. Maroufkhani, and S. Asadi, “Industry 4.0 applications for sustainable manufacturing: A systematic literature review and a roadmap to sustainable development,” J Clean Prod, vol. 334, p. 130133, Feb. 2022. [CrossRef]

- A. Moldavska and T. Welo, “The concept of sustainable manufacturing and its definitions: A content-analysis based literature review,” J Clean Prod, vol. 166, pp. 744–755, Nov. 2017. [CrossRef]

- A. Papetti, M. Marconi, M. Rossi, and M. Germani, “Web-based platform for eco-sustainable supply chain management,” Sustain Prod Consum, vol. 17, pp. 215–228, Jan. 2019. [CrossRef]

- S. A. Rehman Khan and Z. Yu, “Assessing the eco-environmental performance: an PLS-SEM approach with practice-based view,” International Journal of Logistics Research and Applications, vol. 24, no. 3, pp. 20 May; 21. [CrossRef]

- A. Carrera-Rivera, W. Ochoa, F. Larrinaga, and G. Lasa, “How-to conduct a systematic literature review: A quick guide for computer science research,” MethodsX, vol. 9, p. 101895, 2022. [CrossRef]

- D. Tranfield, D. Denyer, and P. Smart, “Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review,” British Journal of Management, vol. 14, no. 3, pp. 207–222, Sep. 2003. [CrossRef]

- S. Bag and J. H. C. Pretorius, “Relationships between industry 4.0, sustainable manufacturing and circular economy: proposal of a research framework,” International Journal of Organizational Analysis, vol. 30, no. 4, pp. 864–898, Jun. 2022. [CrossRef]

- T. J. C. J. C. M. L. T. P. M. J., and W. V. A. Higgins Julian P.T., Cochrane Handbook for Systematic Reviews of Interventions (Version 6.3).

- L. Ligorio, A. Venturelli, and F. Caputo, “Tracing the boundaries between sustainable cities and cities for sustainable development. An LDA analysis of management studies,” Technol Forecast Soc Change, vol. 176, p. 121447, Mar. 2022. [CrossRef]

- S. Luthra, K. Govindan, D. Kannan, S. K. Mangla, and C. P. Garg, “An integrated framework for sustainable supplier selection and evaluation in supply chains,” J Clean Prod, vol. 140, pp. 1686–1698, Jan. 2017. [CrossRef]

- A. Bastas, “Sustainable Manufacturing Technologies: A Systematic Review of Latest Trends and Themes,” Sustainability, vol. 13, no. 8, p. 4271, Apr. 2021. [CrossRef]

- A. N. Hermawan, I. Masudin, F. Zulfikarijah, D. P. Restuputri, and S. S. R. Shariff, “The effect of sustainable manufacturing on environmental performance through government regulation and eco-innovation,” International Journal of Industrial Engineering and Operations Management, vol. 6, no. 4, pp. 299–325, Aug. 2024. [CrossRef]

- A. Chiarini, “Industry 4.0 technologies in the manufacturing sector: Are we sure they are all relevant for environmental performance?,” Bus Strategy Environ, vol. 30, no. 7, pp. 3194–3207, Nov. 2021. [CrossRef]

- O. Okorie, R. Subramoniam, F. Charnley, J. Patsavellas, D. Widdifield, and K. Salonitis, “Manufacturing in the Time of COVID-19: An Assessment of Barriers and Enablers,” IEEE Engineering Management Review, vol. 48, no. 3, pp. 167–175, Sep. 2020. [CrossRef]

- F. Sgarbossa, S. Arena, O. Tang, and M. Peron, “Renewable hydrogen supply chains: A planning matrix and an agenda for future research,” Int J Prod Econ, vol. 255, p. 108674, Jan. 2023. [CrossRef]

- L. M. Camarinha-Matos, A. D. Rocha, and P. Graça, “Collaborative approaches in sustainable and resilient manufacturing,” J Intell Manuf, vol. 35, no. 2, pp. 499–519, Feb. 2024. [CrossRef]

- E. Battistoni, S. Gitto, G. Murgia, and D. Campisi, “Adoption paths of digital transformation in manufacturing SME,” Int J Prod Econ, vol. 255, p. 108675, Jan. 2023. [CrossRef]

- S. Nahavandi, “Industry 5.0—A Human-Centric Solution,” Sustainability, vol. 11, no. 16, p. 4371, Aug. 2019. [CrossRef]

- O. Okorie, R. Subramoniam, F. Charnley, J. Patsavellas, D. Widdifield, and K. Salonitis, “Manufacturing in the Time of COVID-19: An Assessment of Barriers and Enablers,” IEEE Engineering Management Review, vol. 48, no. 3, pp. 167–175, Sep. 2020. [CrossRef]

- A. Sartal, R. Bellas, A. M. Mejías, and A. García-Collado, “The sustainable manufacturing concept, evolution and opportunities within Industry 4.0: A literature review,” Advances in Mechanical Engineering, vol. 12, no. 5, May 2020. [CrossRef]

- L. Wang, Y. Sun, Y. Du, H. Tian, W. Zhan, and T. C. Zhang, “Treatment of soda ash chromite ore processing residue by Waste-Molasses-Based Ball Milling: A new strategy for disposal of waste with waste,” J Clean Prod, vol. 374, p. 133981, Nov. 2022. [CrossRef]

- A. G. Machado, M. P. Winroth, and E. H. D. Ribeiro da Silva, “Sustainable manufacturing in Industry 4.0: an emerging research agenda,” Int J Prod Res, vol. 58, no. 5, pp. 1462–1484, Mar. 2020. [CrossRef]

- N. T. Ching, M. Ghobakhloo, M. Iranmanesh, P. Maroufkhani, and S. Asadi, “Industry 4.0 applications for sustainable manufacturing: A systematic literature review and a roadmap to sustainable development,” J Clean Prod, vol. 334, p. 130133, Feb. 2022. [CrossRef]

- E. Battistoni, S. Gitto, G. Murgia, and D. Campisi, “Adoption paths of digital transformation in manufacturing SME,” Int J Prod Econ, vol. 255, p. 108675, Jan. 2023. [CrossRef]

- G. Narkhede, S. Chinchanikar, R. Narkhede, and T. Chaudhari, “Role of Industry 5.0 for driving sustainability in the manufacturing sector: an emerging research agenda,” Journal of Strategy and Management, Feb. 2024. [CrossRef]

- M. Kaur, M. Palazzo, and P. Foroudi, “Circular supply chain management in post-pandemic context. A qualitative study to explore how knowledge, environmental initiatives and economic viability affect sustainability,” Qualitative Market Research: An International Journal, vol. 27, no. 4, pp. 572–607, Sep. 2024. [CrossRef]

- F. Sgarbossa, S. Arena, O. Tang, and M. Peron, “Renewable hydrogen supply chains: A planning matrix and an agenda for future research,” Int J Prod Econ, vol. 255, p. 108674, Jan. 2023. [CrossRef]

- International Energy Agency, “Energy Efficviency,” 2023.

- T. Nguyen, Q. H. Duong, T. Van Nguyen, Y. Zhu, and L. Zhou, “Knowledge mapping of digital twin and physical internet in Supply Chain Management: A systematic literature review,” Int J Prod Econ, vol. 244, p. 108381, Feb. 2022. [CrossRef]

- O. Okorie, R. Subramoniam, F. Charnley, J. Patsavellas, D. Widdifield, and K. Salonitis, “Manufacturing in the Time of COVID-19: An Assessment of Barriers and Enablers,” IEEE Engineering Management Review, vol. 48, no. 3, pp. 167–175, Sep. 2020. [CrossRef]

- M. Kaur, M. Palazzo, and P. Foroudi, “Circular supply chain management in post-pandemic context. A qualitative study to explore how knowledge, environmental initiatives and economic viability affect sustainability,” Qualitative Market Research: An International Journal, vol. 27, no. 4, pp. 572–607, Sep. 2024. [CrossRef]

- Y. Zhang, S. Ren, Y. Liu, and S. Si, “A big data analytics architecture for cleaner manufacturing and maintenance processes of complex products,” J Clean Prod, vol. 142, pp. 626–641, Jan. 2017. [CrossRef]

- M. Kaur, M. Palazzo, and P. Foroudi, “Circular supply chain management in post-pandemic context. A qualitative study to explore how knowledge, environmental initiatives and economic viability affect sustainability,” Qualitative Market Research: An International Journal, vol. 27, no. 4, pp. 572–607, Sep. 2024. [CrossRef]

- A. K. Hadi, A. P. Setiawan, O. V. Indrian, and E. F. Rosyid, “Evaluation of Sustainability Supply Chain Performance in the Food Industry: A Case Study,” Jurnal Teknik Industri, vol. 24, no. 2, pp. 95–108, Aug. 2023. [CrossRef]

- T. C. Ng, S. Y. Lau, M. Ghobakhloo, M. Fathi, and M. S. Liang, “The Application of Industry 4.0 Technological Constituents for Sustainable Manufacturing: A Content-Centric Review,” Sustainability, vol. 14, no. 7, p. 4327, Apr. 2022. [CrossRef]

- G. Fuertes et al., “Opportunities of the Technological Trends Linked to Industry 4.0 for Achieve Sustainable Manufacturing Objectives,” Sustainability, vol. 14, no. 18, p. 11118, Sep. 2022. [CrossRef]

- J. Sarkis, “Supply chain sustainability: learning from the COVID-19 pandemic,” International Journal of Operations & Production Management, vol. 41, no. 1, pp. 63–73, Dec. 2020. [CrossRef]

- E. B. Barbier and J. C. Burgess, “Sustainability and development after COVID-19,” World Dev, vol. 135, p. 105082, Nov. 2020. [CrossRef]

- A. G. Frank, L. S. Dalenogare, and N. F. Ayala, “Industry 4.0 technologies: Implementation patterns in manufacturing companies,” Int J Prod Econ, vol. 210, pp. 15–26, Apr. 2019. [CrossRef]

- J. D. Sachs, G. Schmidt-Traub, M. Mazzucato, D. Messner, N. Nakicenovic, and J. Rockström, “Six Transformations to achieve the Sustainable Development Goals,” Nat Sustain, vol. 2, no. 9, pp. 805–814, Aug. 2019. [CrossRef]

- P. Ghisellini, C. Cialani, and S. Ulgiati, “A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems,” J Clean Prod, vol. 114, pp. 11–32, Feb. 2016. [CrossRef]

- J. Elkington, Cannibals with Forks: The Triple Bottom Line of 21st Century Business. 1997.

- A. T. Hazen, I. Russo, I. Confente, and D. Pellathy, “Supply chain management for circular economy: conceptual framework and research agenda,” The International Journal of Logistics Management, vol. 32, no. 2, pp. 510–537, Apr. 2021. [CrossRef]

- Y. Hong, M.-J. Kim, and Y. W. Sohn, “The Relationship between Job Insecurity and Safety Behavior: The Buffering Role of Leadership Ethics,” Sustainability, vol. 15, no. 18, p. 13910, Sep. 2023. [CrossRef]

- H. Chen, L. Li, and Y. Chen, “Explore success factors that impact artificial intelligence adoption on telecom industry in China,” Journal of Management Analytics, vol. 8, no. 1, pp. 36–68, Jan. 2021. [CrossRef]

- S. Rajput and S. P. Singh, “Industry 4.0 − challenges to implement circular economy,” Benchmarking: An International Journal, vol. 28, no. 5, pp. 1717–1739, May 2021. [CrossRef]

- G. Malhotra, “Impact of circular economy practices on supply chain capability, flexibility and sustainable supply chain performance,” The International Journal of Logistics Management, vol. 35, no. 5, pp. 1500–1521, Aug. 2024. [CrossRef]

- L. Jimenez-Castillo, J. Sarkis, S. Saberi, and T. Yao, “Blockchain-based governance implications for ecologically sustainable supply chain management,” Journal of Enterprise Information Management, vol. 37, no. 1, pp. 76–99, Feb. 2024. [CrossRef]

- M. Willenbacher, J. Scholten, and V. Wohlgemuth, “Machine Learning for Optimization of Energy and Plastic Consumption in the Production of Thermoplastic Parts in SME,” Sustainability, vol. 13, no. 12, p. 6800, Jun. 2021. [CrossRef]

- O. Oguntola, K. Boakye, and S. Simske, “Towards Leveraging Artificial Intelligence for Sustainable Cement Manufacturing: A Systematic Review of AI Applications in Electrical Energy Consumption Optimization,” Sustainability, vol. 16, no. 11, p. 4798, Jun. 2024. [CrossRef]

- M. Geissdoerfer, P. Savaget, N. M. P. Bocken, and E. J. Hultink, “The Circular Economy – A new sustainability paradigm?,” J Clean Prod, vol. 143, pp. 757–768, Feb. 2017. [CrossRef]

- A. Almasri and M. Ying, “Adopting Circular Economy Principles: How Do Conflict Management Strategies Help Adopt Smart Technology in Jordanian SMEs?,” Aug. 13, 2024. [CrossRef]

- “The impact of AI on the workplace: Main findings from the OECD AI surveys of employers and workers,” Mar. 2023. [CrossRef]

- L. M. Villar, E. Oliva-Lopez, O. Luis-Pineda, A. Benešová, J. Tupa, and J. A. Garza-Reyes, “Fostering economic growth, social inclusion & sustainability in Industry 4.0: a systemic approach,” Procedia Manuf, vol. 51, pp. 1755–1762, 2020. [CrossRef]

- A. Marrucci, R. Rialti, and M. Balzano, “Exploring paths underlying Industry 4.0 implementation in manufacturing SMEs: a fuzzy-set qualitative comparative analysis,” Management Decision, Mar. 2023. [CrossRef]

- T. Masood and P. Sonntag, “Industry 4.0: Adoption challenges and benefits for SMEs,” Comput Ind, vol. 121, p. 103261, Oct. 2020. [CrossRef]

- M. A. Al-Hakimi, A. K. Al-Swidi, H. M. Gelaidan, and A. Mohammed, “The influence of green manufacturing practices on the corporate sustainable performance of SMEs under the effect of green organizational culture: A moderated mediation analysis,” J Clean Prod, vol. 376, p. 134346, Nov. 2022. [CrossRef]

- H. T. S. Caldera, C. Desha, and L. Dawes, “Evaluating the enablers and barriers for successful implementation of sustainable business practice in ‘lean’ SMEs,” J Clean Prod, vol. 218, pp. 575–590, May 2019. [CrossRef]

- D. T. Parra-Sánchez, “Exploring the Internet of Things adoption in the Fourth Industrial Revolution: a comprehensive scientometric analysis,” Journal of Innovative Digital Transformation, Nov. 2024. [CrossRef]

- D. G. Campos and R. Scherer, “Digital gender gaps in Students’ knowledge, attitudes and skills: an integrative data analysis across 32 Countries,” Educ Inf Technol (Dordr), vol. 29, no. 1, pp. 655–693, Jan. 2024. [CrossRef]

- J. James, “Confronting the scarcity of digital skills among the poor in developing countries,” Development Policy Review, vol. 39, no. 2, pp. 324–339, Mar. 2021. [CrossRef]

- A. Martins, M. C. Branco, P. N. Melo, and C. Machado, “Sustainability in Small and Medium-Sized Enterprises: A Systematic Literature Review and Future Research Agenda,” Sustainability, vol. 14, no. 11, p. 6493, May 2022. [CrossRef]

- R. Belinski, A. M. M. Peixe, G. F. Frederico, and J. A. Garza-Reyes, “Organizational learning and Industry 4.0: findings from a systematic literature review and research agenda,” Benchmarking: An International Journal, vol. 27, no. 8, pp. 2435–2457, Jul. 2020. [CrossRef]

- N. Etemadi, P. Van Gelder, and F. Strozzi, “An ISM Modeling of Barriers for Blockchain/Distributed Ledger Technology Adoption in Supply Chains towards Cybersecurity,” Sustainability, vol. 13, no. 9, p. 4672, Apr. 2021. [CrossRef]

- R. Dubey, D. J. Bryde, C. Foropon, M. Tiwari, Y. Dwivedi, and S. Schiffling, “An investigation of information alignment and collaboration as complements to supply chain agility in humanitarian supply chain,” Int J Prod Res, vol. 59, no. 5, pp. 1586–1605, Mar. 2021. [CrossRef]

- A. Ullrich, M. Reißig, S. Niehoff, and G. Beier, “Employee involvement and participation in digital transformation: a combined analysis of literature and practitioners’ expertise,” Journal of Organizational Change Management, vol. 36, no. 8, pp. 29–48, Dec. 2023. [CrossRef]

- V. D. Wardhana, I. Gautama So, D. L. Warganegara, and M. Hamsal, “Mitigating disruption through adaptive organization and organization learning to create a transformation business model,” Journal of Business & Industrial Marketing, vol. 38, no. 9, pp. 1822–1836, Aug. 2023. [CrossRef]

- A. P. M. Sianipar, G. Yudoko, A. Adhiutama, and K. Dowaki, “Community Empowerment through Appropriate Technology: Sustaining the Sustainable Development,” Procedia Environ Sci, vol. 17, pp. 1007–1016, 2013. [CrossRef]

- S. Sedkaoui and R. Benaichouba, “Generative AI as a transformative force for innovation: a review of opportunities, applications and challenges,” European Journal of Innovation Management, Aug. 2024. [CrossRef]

- A. W. Head, “Reconsidering evidence-based policy: Key issues and challenges,” Policy Soc, vol. 29, no. 2, pp. 77–94, May 2010. [CrossRef]

- H. Saabye, T. B. Kristensen, and B. V. Wæhrens, “Developing a learning-to-learn capability: insights on conditions for Industry 4.0 adoption,” International Journal of Operations & Production Management, vol. 42, no. 13, pp. 25–53, Dec. 2022. [CrossRef]

- N. Karanjkar, A. Joglekar, S. Mohanty, V. Prabhu, D. Raghunath, and R. Sundaresan, “Digital Twin for Energy Optimization in an SMT-PCB Assembly Line,” in 2018 IEEE International Conference on Internet of Things and Intelligence System (IOTAIS), IEEE, Nov. 2018, pp. 85–89. [CrossRef]

- S. Kim, “Interdisciplinary Approaches and Methods for Sustainable Transformation and Innovation,” Sustainability, vol. 7, no. 4, pp. 3977–3983, Apr. 2015. [CrossRef]

- A. Jamwal, R. Agrawal, M. Sharma, and A. Giallanza, “Industry 4.0 Technologies for Manufacturing Sustainability: A Systematic Review and Future Research Directions,” Applied Sciences, vol. 11, no. 12, p. 5725, Jun. 2021. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).