1. Introduction

Cold region facility agriculture refers to an agricultural model that ensures crop growth and continuous production through the use of facilities in low temperature, short daylight, and variable climate conditions. It is primarily found in high latitude and high altitude regions such as Northeast Asia, Northern Europe, and North America [

1]. Cold region facility agriculture not only provides a stable supply of agricultural products, reduces the need for long distance transportation, and ensures food security, but also contributes to regional economic development to some extent. However, due to the high energy demand for temperature regulation, lighting, and ventilation in cold region facility agriculture, particularly during winter when heating demand peaks, operational costs rise significantly, exacerbating the energy burden and environmental impact. Therefore, the development of efficient energy saving technologies to achieve low energy consumption and sustainable development in facility agriculture is one of the core research topics in cold region agriculture [

2].

In recent years, to address the high energy consumption challenges of facility agriculture in cold regions, many scholars have focused on research into energy-saving technologies. These technologies primarily focus on heating, lighting, ventilation, and intelligent control systems [

3]. For instance, geothermal heat pumps and solar thermal systems widely used in heating systems can reduce dependence on traditional energy sources by utilizing underground constant temperatures and solar energy [

4]. In lighting systems, intelligent light control systems and LED plant lights have gradually replaced traditional high-pressure sodium lamps, improving lighting energy efficiency. The intelligent ventilation technology in ventilation systems monitors environmental parameters in real-time via sensors and automatically adjusts ventilation intensity according to demand, optimizing energy consumption [

5]. However, existing studies predominantly focus on the development of individual technologies, and there is a lack of systematic research on the synergistic effects of multiple energy-saving technologies in extremely cold environments. Moreover, the practical application of intelligent integrated energy-saving systems remains unclear. Additionally, the current technologies still face limitations in terms of economic viability and adaptability, particularly in the harsh conditions of cold climates, which restricts the large-scale promotion and application of energy-saving solutions [

6].

To address these issues, this paper proposes an intelligent, multi technology integrated energy saving solution to tackle the high energy consumption challenges in cold region facility agriculture. The innovations of this study include the following aspects: (1) Synergistic application of multiple technologies: This study innovatively integrates geothermal heat pumps, solar collectors, intelligent light control systems, LED plant lamps, and intelligent ventilation systems. By applying multiple energy saving technologies in synergy, it effectively improves the overall energy efficiency of greenhouses under extreme low temperature and short daylight conditions; (2) Intelligent control systems: Based on sensor networks and data analysis, this study develops an intelligent control system that enables the subsystems to automatically adjust temperature, humidity, and lighting according to real time changes in external climatic conditions and internal greenhouse environments, further enhancing energy saving effects; (3) Economic and applicability evaluation: This study not only verifies the energy efficiency of the integrated energy saving solution but also evaluates the economic feasibility of different energy saving technologies through investment payback period and operational cost analysis, identifying high cost performance technologies that offer significant promotion value, thus providing practical technical references for cold region facility agriculture.

In conclusion, the integrated energy saving solution proposed in this study significantly improves the overall energy efficiency of cold region greenhouses and provides scientific evidence and practical support for the low carbon, sustainable development of cold region facility agriculture.

1.1. Current Situation and Challenges of Energy saving Technologies in Facility Agriculture in Cold Region

The rapid development of facility agriculture in cold regions has promoted the continuous progress of energy saving technologies to address the high energy consumption requirements for greenhouse environmental regulation. Currently, the widely applied energy saving technologies in facility agriculture in cold regions mainly focus on aspects such as heating, lighting, ventilation, heat insulation, and intelligent control. Each of these technologies has contributed to improving the energy efficiency of facility agriculture and reducing costs. However, under the extreme climatic conditions in cold regions, the application of energy saving technologies still faces some specific challenges. This paper will conduct a classified review of the existing energy saving technologies and point out the technical deficiencies and research challenges in their application in cold regions [

7].

1.1.1. Heating and Insulation Technologies

Heating and heat insulation technologies are among the most fundamental energy saving requirements in facility agriculture in cold regions. Due to the long periods of low temperatures in winter in cold regions, greenhouses must be equipped with effective heating systems, and at the same time, heat loss needs to be reduced through heat insulation materials.

1.1.2. Ground Source Heat Pump System

The ground source heat pump (GSHP) system is an efficient heating technology that utilizes the constant temperature of the underground environment to supply heat to greenhouses. By transferring heat from the ground to the greenhouse through heat exchange, GSHPs reduce the dependence on traditional fuel based heating. In cold region environments, the GSHP technology demonstrates significant energy saving potential, especially in winter when the external temperatures are low, as it provides a continuous and stable heat supply. However, the initial installation cost of GSHP systems is relatively high, and in extreme cold conditions, the underground temperature may be too low, limiting the system's heating capacity. Additionally, the operation of GSHP systems requires a stable power supply, which may be restricted in some remote cold regions [

8].

1.1.3. Solar Heating System

The solar heating system collects solar energy through solar collectors, converts it into thermal energy, and transmits it to the greenhouse via a hot water circulation system. In cold regions, although there is abundant sunlight during the winter days, the daylight hours are short, and the nighttime temperatures are extremely low, which limits the effectiveness of solar heating systems. To address this limitation, researchers have attempted to combine solar heating with thermal storage technologies, storing excess heat during sunlight hours and releasing it at night. However, solar heating systems come with high installation costs, significant maintenance challenges, and still require backup heating systems on overcast days with insufficient sunlight [

9].

1.1.4. Thermal Insulation Material

The use of thermal insulation materials can significantly reduce the heating demand of greenhouses. Commonly used high efficiency insulation materials include multilayer composite materials, vacuum insulation panels, and nanoparticle thermal coatings. Multilayer composites are particularly effective in reducing heat loss, while also efficiently reflecting solar radiation during the summer months. The advent of nanoparticle thermal coatings has introduced new possibilities for the development of insulation materials, with their excellent thermal conductivity properties effectively controlling heat loss within the greenhouse [

10]. However, the application of these advanced insulation materials in cold region environments still faces challenges, such as the durability, corrosion resistance, and high cost of the materials under extreme cold conditions. Furthermore, the research and optimization of insulation materials require continued exploration to ensure their long term stability and high energy efficiency.

1.2. Lighting and Light Control System

In cold areas, due to the short sunshine time in winter, the demand for artificial light in greenhouses is higher. In order to meet the lighting needs of crops, lighting technology plays an important role in facility agriculture in cold areas.

1.2.1. LED Plant Light

LED plant lights, known for their high efficiency and low energy consumption, have gradually replaced traditional light sources such as high pressure sodium lamps. The spectral tunability and high luminous efficacy of LED plant lights enable them to adjust the spectrum and light intensity according to the specific needs of different crops. This not only enhances the efficiency of light energy utilization but also reduces electricity consumption. Moreover, studies have shown that LED plant lights can provide optimized lighting at various growth stages, thereby improving crop yield and quality. However, under the unique conditions of cold region greenhouses, LED plant lights still face certain limitations, such as stability under low temperatures, high initial installation costs, and the need for personalized adjustment of the light spectrum to meet the specific requirements of different crops [

11].

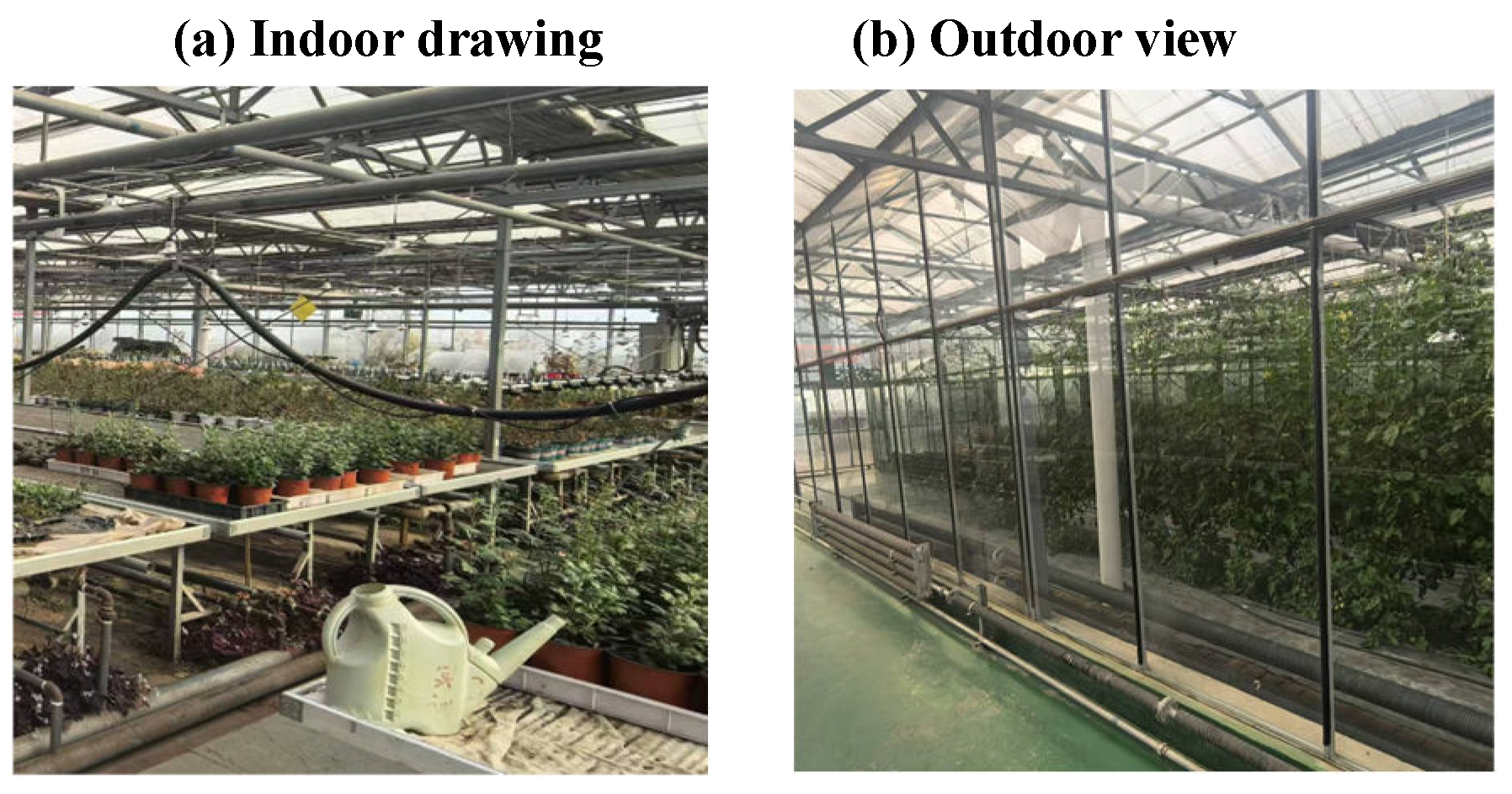

Figure 1.

Supplementary Lighting System Inside the Greenhouse.

Figure 1.

Supplementary Lighting System Inside the Greenhouse.

1.2.2. Intelligent Light Control System

The intelligent light control system uses sensors to continuously monitor the light intensity both inside and outside the greenhouse, as well as the lighting needs of the crops, automatically adjusting the switching and brightness of artificial lights to ensure the optimal distribution of light resources. In cold region facility agriculture, the energy saving benefits of intelligent light control systems are particularly evident. When natural light levels inside the greenhouse are sufficient, the system automatically reduces or turns off artificial lighting, thus reducing electricity consumption. However, the application of current intelligent light control systems in cold regions still faces challenges, such as the accuracy and stability of sensors, the system’s adaptability, and its reliability under extreme climatic conditions [

12].

1.3. Ventilation and Cooling System

In the greenhouse in the cold area, the ventilation system is not only used for cooling, but also for regulating temperature and humidity and discharging excessive carbon dioxide. An effective ventilation system can ensure the stability of the environment inside the greenhouse and promote the healthy growth of crops.

1.3.1. Natural Ventilation and Mechanical Ventilation

Natural ventilation mainly depends on the design of the greenhouse structure. It realizes air exchange through temperature differences and air currents to achieve the effects of cooling and humidity regulation. Mechanical ventilation, on the other hand, forcibly expels the hot air inside the greenhouse through fans or ventilation ducts to achieve the purpose of rapid temperature reduction. Although natural ventilation has advantages in terms of energy saving, opening windows for ventilation in cold regions during winter with low temperatures and bad weather will lead to heat loss and is not suitable for all day use. The forced effect of mechanical ventilation is good, but its operation consumes relatively high energy, and it needs to cooperate with the heating system in winter to ensure the stability of the indoor temperature [

13].

1.3.2. Intelligent Ventilation System

The intelligent ventilation system monitors the data such as temperature, humidity and carbon dioxide concentration inside and outside the greenhouse through sensors, and adjusts the ventilation intensity in real time. It can dynamically adjust the ventilation strategy in combination with the external climatic conditions to avoid unnecessary energy consumption. However, the main challenge faced by the intelligent ventilation system in its application in cold regions lies in the impact of extremely cold weather on the equipment. For example, the sensors may fail or work unstably under low temperature conditions. In addition, the intelligent ventilation system has higher requirements for hardware and control software, which increases the cost and maintenance difficulty of the system [

14].

1.4. Research Deficiencies and Challenges

Although the energy saving technology of facility agriculture in cold region has made remarkable progress, it still faces many challenges in practical application. These challenges provide direction for future research and highlight the need to improve the efficiency of energy saving techniques in facility agriculture in cold regions.

1.4.1. The Degree of Technology Integration Is Insufficient

Most existing energy saving technologies are applied individually, lacking systematic and integrated energy saving solutions. In cold region facility agriculture, different energy saving technologies (such as heating, lighting, ventilation, and insulation) often operate independently. This isolation leads to resource waste and a reduction in energy efficiency. Research has shown that integrating and optimizing multiple energy saving technologies, combined with a unified management system via intelligent control, can significantly improve energy utilization efficiency. Therefore, future research should explore how to achieve the system integration of various energy saving technologies under intelligent control systems to maximize energy saving effects [

15].

1.4.2. The Adaptability of Intelligent Control System Is Insufficient

Although intelligent control systems have been applied in cold region facility agriculture, their adaptability and autonomy remain insufficient when faced with extreme climatic conditions and rapidly changing environments. Existing systems are largely based on preset parameters for control, lacking the ability for self learning and real time adjustments. Therefore, future research could explore the integration of machine learning and adaptive algorithms into intelligent control systems, enabling them to automatically adjust the environmental parameters within the greenhouse under extreme weather conditions in cold regions, thus further enhancing the system's intelligence [

16].

1.4.3. Insufficient Durability And Suitability Of Energy Materials

Although high efficiency heat insulation materials have demonstrated good energy saving effects in greenhouses in cold regions, the issues regarding the durability and long term applicability of these materials under extremely cold conditions have not been fully investigated. The energy saving materials used in facility agriculture in cold regions are required to possess stronger corrosion resistance, compressive strength, and long lasting heat insulation effects, which pose higher requirements for future material research and development. Further exploration of more cost effective and durable heat insulation materials will become an important direction for future research [

17].

Figure 2.

High efficiency insulation panels.

Figure 2.

High efficiency insulation panels.

2. Experimental Design and Data Collection of Energy saving Technologies in Cold Regions

This study selects cold region facility agriculture greenhouses in Heilongjiang as the experimental site, focusing on evaluating the energy efficiency performance of the heating, lighting, and ventilation systems under the application of energy saving technologies. The experimental period spans from winter to early spring (November to March of the following year), with the aim of assessing the effectiveness of various energy saving technologies in reducing energy consumption and improving the greenhouse environment under extreme low temperatures and insufficient light conditions. This chapter will provide a detailed description of the experimental design background, data collection methods, and specific applications of the core energy saving technologies.

2.1. Experimental Design Overview

2.1.1. Experimental Location

The experiment was conducted in a typical cold-region facility agriculture greenhouse located in Heilongjiang Province. This region experiences extremely low winter temperatures, with an average temperature range of -18°C to -5°C, short daylight hours, and frequent snow cover [

18]. The selection of the experimental site was based on the following conditions:

Climatic Characteristics: The greenhouse is situated in a cold climate with short daylight hours, making it suitable for testing the applicability of energy-saving technologies in extreme low-temperature environments.

Heating Demand: The heating demand in Heilongjiang during winter is high, especially at night and under low light conditions, making it crucial to test the energy-saving performance of heating systems.

Lighting Conditions: Winter natural lighting is weak, providing an ideal setting to assess the practical performance of the intelligent light control and LED lighting systems in cold region.

Figure 3.

experimental location.

Figure 3.

experimental location.

2.1.2. Experiment Time and Cycle

The experiment began in early November and lasted until the end of March, covering the coldest winter and spring transition periods in the cold region. During the experiment, sensors and monitoring equipment were used to collect temperature and humidity, light intensity, carbon dioxide concentration, energy consumption and other data inside the greenhouse to analyze the energy efficiency performance of various energy-saving technologies under different climate conditions.

2.2. Data Acquisition and Monitoring Program

In order to ensure the accuracy and comprehensiveness of experimental data, a multi-level data acquisition scheme was designed, including energy consumption monitoring of heating, lighting and ventilation systems, and recording of environmental parameters in the greenhouse [

19]. The collection frequency of all kinds of data is set according to the characteristics of indicators. The specific methods are as follows:

2.2.1. Heating Energy consumption Data Acquisition

The energy consumption data of the heating system is recorded through an energy metering device, with a collection frequency of once per day to ensure detailed tracking of monthly heating demand variations. The data collected includes the following components:

Daily Heating Energy Consumption: Daily records of the energy consumption of the heating system to analyze its energy saving performance under varying temperature conditions.

Greenhouse Interior Temperature: Temperature sensors monitor the temperature distribution across different areas of the greenhouse, allowing for assessment of the insulation performance of the thermal materials and the heating system.

2.2.2. Lighting System Data Acquisition

The acquisition of energy consumption and light intensity data of the lighting system is accomplished through the intelligent light control system and light sensors, with a collection frequency of once per hour. The following main indicators are monitored:

Light intensity: Records the light intensity within the greenhouse to ensure that the light requirements of crops are met under short-day conditions.

Energy consumption of lighting: Records the energy consumption of the lighting system on a daily basis to facilitate the comparison of energy consumption differences before and after the application of energy-saving technologies.

Intelligent light control response: Monitors the automatic adjustment effect of the intelligent light control system under different light conditions to assess the sensitivity and stability of the system.

2.2.3. Data Collection of Ventilation Systems

Data acquisition for the ventilation system mainly pays attention to aspects such as system energy consumption, air humidity, and carbon dioxide concentration, with a collection frequency of once per hour. The collected contents include:

Ventilation energy consumption: Daily records of the energy consumption data of the ventilation system are made to calculate the energy-saving effect of the intelligent ventilation system.

Air humidity: The humidity variations in the greenhouse are monitored through humidity sensors to determine the regulation effect of the intelligent ventilation system on air quality.

Carbon dioxide concentration: The carbon dioxide concentration inside the greenhouse is monitored to ensure that the ventilation system can meet the air demands for crop growth.

2.3. Specific Application and Setting of Energy-Saving Technology

To achieve high energy efficiency, three core energy saving technologies were applied in this experiment: the heating system combining ground source heat pumps and solar thermal collectors, the lighting system consisting of high efficiency LED plant lights and an intelligent light control system, as well as the intelligent ventilation system. The following are the detailed configurations and application methods of each technology.

2.3.1. Heating System

Technology Overview: The low winter temperatures in Heilongjiang make the heating system the primary energy consumption source for greenhouses. This experiment integrates a ground-source heat pump system, a solar thermal collection system, and high-efficiency insulation materials within the greenhouse heating system.

Ground-source Heat Pump System: Utilizing the constant underground temperature, the ground-source heat pump technology transfers heat from the ground to the greenhouse. The system provides base heating during extreme cold weather, reducing the reliance on traditional fuels or electric heating [

20].

Solar Thermal Collection System: Solar thermal collectors are installed on the south-facing roof of the greenhouse. The absorbed solar energy is transferred to the greenhouse heating pipes through a water circulation system. A thermal storage tank is used to store excess heat during the day and gradually release it at night, helping to alleviate nighttime heating demands [

21].

High-efficiency Insulation Materials: The greenhouse walls are covered with multilayer composite insulation materials and a nanoparticle thermal coating to minimize heat loss. The multilayer insulation materials consist of a reflective layer and an insulating layer. The reflective layer blocks external cold air, while the insulating layer ensures stable internal temperatures [

22].

Expected Outcomes: By integrating the ground-source heat pump and solar thermal collection technologies with the application of high-efficiency insulation materials, the heating system is expected to reduce heating energy consumption by approximately 20%, especially under extreme low temperatures and nighttime conditions.

2.3.2. Illuminating System

Technology Overview: Due to the short daylight hours in Heilongjiang during the winter, this experiment utilizes high-efficiency LED plant lights and an intelligent light control system to ensure that the lighting needs of crops are met while minimizing energy consumption.

LED Plant Lights: LED lights are ideal for various crop growth needs due to their adjustable spectral characteristics. By providing a combination of red and blue light, LED plant lights enhance photosynthetic efficiency and, compared to traditional lighting, significantly reduce energy consumption.

Intelligent Light Control System: The intelligent light control system uses light sensors to monitor the intensity of natural light and dynamically adjusts the output intensity of the LED plant lights based on outdoor light conditions. On sunny days when natural light is abundant, the system automatically reduces or turns off the artificial lighting, thereby minimizing unnecessary electricity consumption [

23].

Expected Outcomes: The combination of the intelligent light control system and LED plant lights is expected to reduce lighting energy consumption by 15% to 20%. The energy-saving effect will be more pronounced in February and March, as daylight gradually increases.

2.3.3. Ventilating System

Technology Overview: Under the extreme cold conditions of winter in Heilongjiang, the ventilation demand for greenhouses is relatively low, but effective control of air humidity and carbon dioxide concentration is necessary. This experiment implements an intelligent ventilation system to achieve precise, demand-based ventilation and reduce unnecessary energy consumption.

Intelligent Ventilation Control: The intelligent ventilation system integrates temperature, humidity, and carbon dioxide sensors to monitor environmental parameters inside the greenhouse in real time. When humidity levels are high or carbon dioxide concentrations increase, the system automatically activates or adjusts the ventilation equipment. In extreme cold weather, the system reduces the ventilation frequency to maintain stable greenhouse temperatures.

Zonal Ventilation Design: The intelligent ventilation system is designed to control ventilation intensity in different areas of the greenhouse based on the specific climatic needs of each zone. For instance, ventilation is reduced in areas near the heating system, while increased ventilation is applied to areas with higher humidity, ensuring that the microclimate conditions are optimal for crop growth [

24].

Expected Outcomes: The intelligent ventilation system is expected to effectively balance air quality and energy consumption within the greenhouse, with a predicted reduction in ventilation energy consumption of approximately 15% to 18%.

2.4. Data Analysis Method

The collected data is processed through the following analytical methods to evaluate the effectiveness and economy of the energy-saving technology.

2.4.1. energy Consumption Analysis

The energy consumption difference of heating, lighting and ventilation systems before and after application of different energy-saving technologies is compared, and the energy-saving rate of each system is analyzed. The energy consumption analysis will be combined with the climate conditions in the cold area of Heilongjiang Province, and the application effect of each technology in extreme environments will be revealed by comparing the energy-saving effect month by month.

2.4.2. Technical and Economic Evaluation

Based on the initial installation cost, operation and maintenance cost of each energy-saving technology, the return on investment cycle [

25] is calculated. The economic evaluation will consider the actual energy consumption cost in Heilongjiang region, and provide scientific basis for the promotion of energy-saving technology in facility agriculture in cold region.

2.4.3. Environmental Adaptability Assessment

Based on the data of temperature and humidity, light and carbon dioxide concentration in the greenhouse, the adaptability and stability of various energy-saving technologies in the extreme environment in the cold region were evaluated [

26]. Special attention is paid to the real-time response ability of the intelligent control system to verify its stability and reliability under extremely cold conditions.

3. Analysis of Experimental Results

In this study, a number of energy-saving technologies were applied in agricultural greenhouses in cold areas of Heilongjiang province, and the energy-saving effects and economy of each energy-saving technology under different environmental conditions were evaluated by monitoring the energy consumption of heating, lighting and ventilation systems on a monthly basis. The results show that the integrated energy-saving technology can effectively reduce the total energy consumption of the greenhouse, and show good economic benefits. The following is an analysis of the specific experimental results.

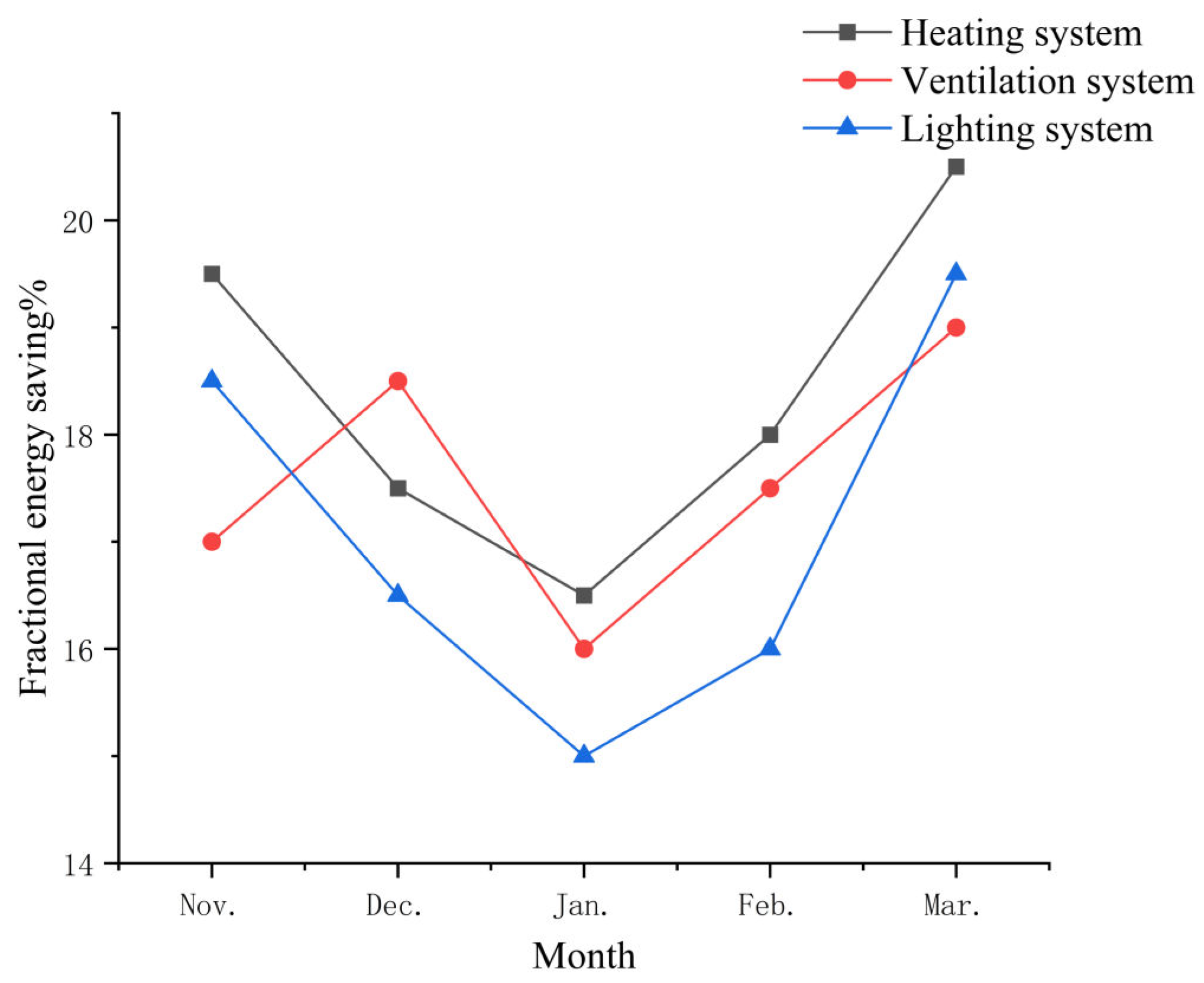

3.1. Analysis of Energy-Saving Effect Of Heating System

In the cold region of Heilongjiang, heating is the primary source of energy consumption for greenhouses during the winter. This study employs an integrated heating solution combining ground-source heat pumps, solar thermal collection systems, and high-efficiency insulation materials to reduce winter heating energy consumption. Experimental data show that this combination significantly reduces the energy consumption of the greenhouse while maintaining a stable internal temperature. The energy-saving rate of the heating system reached 19% to 20% in the relatively warmer months of November and March, while it was slightly lower, around 16%, during the extremely cold months of January and February.

Table 1.

Comparison of energy consumption of heating system.

Table 1.

Comparison of energy consumption of heating system.

| Time |

Conventional heating energy consumption

(kWh) |

Energy consumption of energy-saving technology

(kWh) |

Fractional energy saving

(%) |

| Nov. |

14.500 |

11.750 |

19.0 |

| Dec. |

17.500 |

14.350 |

18.0 |

| Jan. |

19.500 |

16.385 |

16.0 |

| Feb. |

18.500 |

15.540 |

16.0 |

| Mar. |

13.500 |

10.400 |

20.0 |

| Aggregate |

83.500 |

68.425 |

17.6 |

Results Analysis: The ground-source heat pump system utilizes the constant underground temperature to provide a stable heat source under low-temperature conditions. The solar thermal collection system effectively supplies heat during the day when sunlight is abundant, while at night, the heat retention is supported by the insulation materials to minimize heat loss. Overall, the heating system achieves an energy-saving rate of 17.6%, presenting an efficient and low-carbon solution to meet the high energy demand of winter in cold regions.

3.2. Analysis of energy-saving effect of lighting system

Under the short daylight conditions in Heilongjiang during winter, the greenhouse's artificial lighting demand increases. This study uses an intelligent light control system and high-efficiency LED plant lights, dynamically adjusting light intensity to optimize energy consumption. Experimental data show that the lighting system achieves an average energy-saving rate of 18.6%, with the highest energy- saving rate reaching 20.3% in March. The specific results are shown in the table below.

Table 2.

Lighting system energy consumption comparison.

Table 2.

Lighting system energy consumption comparison.

| Time |

Conventional lighting energy consumption

(kWh) |

Energy consumption of energy-saving technology

(kWh) |

Fractional energy saving

(%) |

| Nov. |

3.500 |

2.870 |

18.0 |

| Dec. |

4.300 |

3.500 |

19.0 |

| Jan. |

4.800 |

3.940 |

17.9 |

| Feb. |

4.600 |

3.750 |

18.5 |

| Mar. |

3.200 |

2.550 |

20.3 |

| Aggregate |

20.400 |

16.610 |

18.6 |

Results Analysis: The intelligent light control system monitors the natural light intensity in real time and dynamically adjusts the output intensity of the LED plant lights, effectively reducing artificial lighting energy consumption. The LED plant lights not only consume less energy but also enhance light energy utilization efficiency, optimizing the light requirements for crop growth.

3.3. Analysis of energy saving effect of ventilation system

The extremely cold winter conditions in Heilongjiang Province make the main task of the greenhouse ventilation system to maintain air quality and humidity. In this study, an intelligent ventilation system combined with zoning control and on-demand ventilation is used to optimize the ventilation efficiency. The results show that the energy saving rate of the ventilation system is 17.4%, especially in March, reaching 19.2%. The specific results are shown in the table below.

Table 3.

Ventilation system consumption comparison.

Table 3.

Ventilation system consumption comparison.

| Time |

Conventional ventilation energy consumption

(kWh) |

Energy consumption of energy-saving technology

(kWh) |

Fractional energy saving

(%) |

| Nov. |

1.200 |

0.900 |

17.5 |

| Dec. |

1.100 |

0.915 |

16.8 |

| Jan. |

1.000 |

0.850 |

15.0 |

| Feb. |

1.100 |

0.900 |

18.2 |

| Mar. |

1.200 |

0.970 |

19.2 |

| Aggregate |

5.600 |

4.625 |

17.4 |

Analysis of the results: The intelligent ventilation system effectively reduced the heat loss in extremely cold weather, and further optimized the energy consumption through zoning control in the months when the temperature rose.

3.4. Comprehensive energy saving effect analysis

To comprehensively assess the overall energy-saving effect of the various energy-saving technologies, this study integrates energy consumption data from the heating, lighting, and ventilation systems. The results show that, under collaborative application of these technologies, the total energy consumption of the greenhouse was reduced by 17.8%. In the extreme climatic conditions of the cold region, the integrated application of heating, lighting, and ventilation systems not only ensured the stability of the greenhouse but also significantly improved energy utilization efficiency. The specific results are shown in the table and figure below.

Table 4.

Comprehensive energy saving effect analysis.

Table 4.

Comprehensive energy saving effect analysis.

| System |

Conventional energy consumption

(kWh) |

Energy consumption of energy-saving technology

(kWh) |

Fractional energy saving

(%) |

| Heating system |

83.000 |

68.425 |

17.6 |

Lighting

system |

20.400 |

16.610 |

18.6 |

| Ventilation system |

5.600 |

4.625 |

17.4 |

| Aggregate |

109.000 |

89.660 |

17.8 |

Analysis of results:

Figure 4.1 shows the energy saving performance of different systems in each month. The comprehensive energy saving system showed the best energy saving effect in November and March when the temperature was moderate, while the energy saving effect was slightly reduced in January and February when the temperature was extremely cold, but it was still significant. The results show that the coordinated management of multiple energy-saving technologies has significant energy-saving advantages in facility agriculture in cold region.

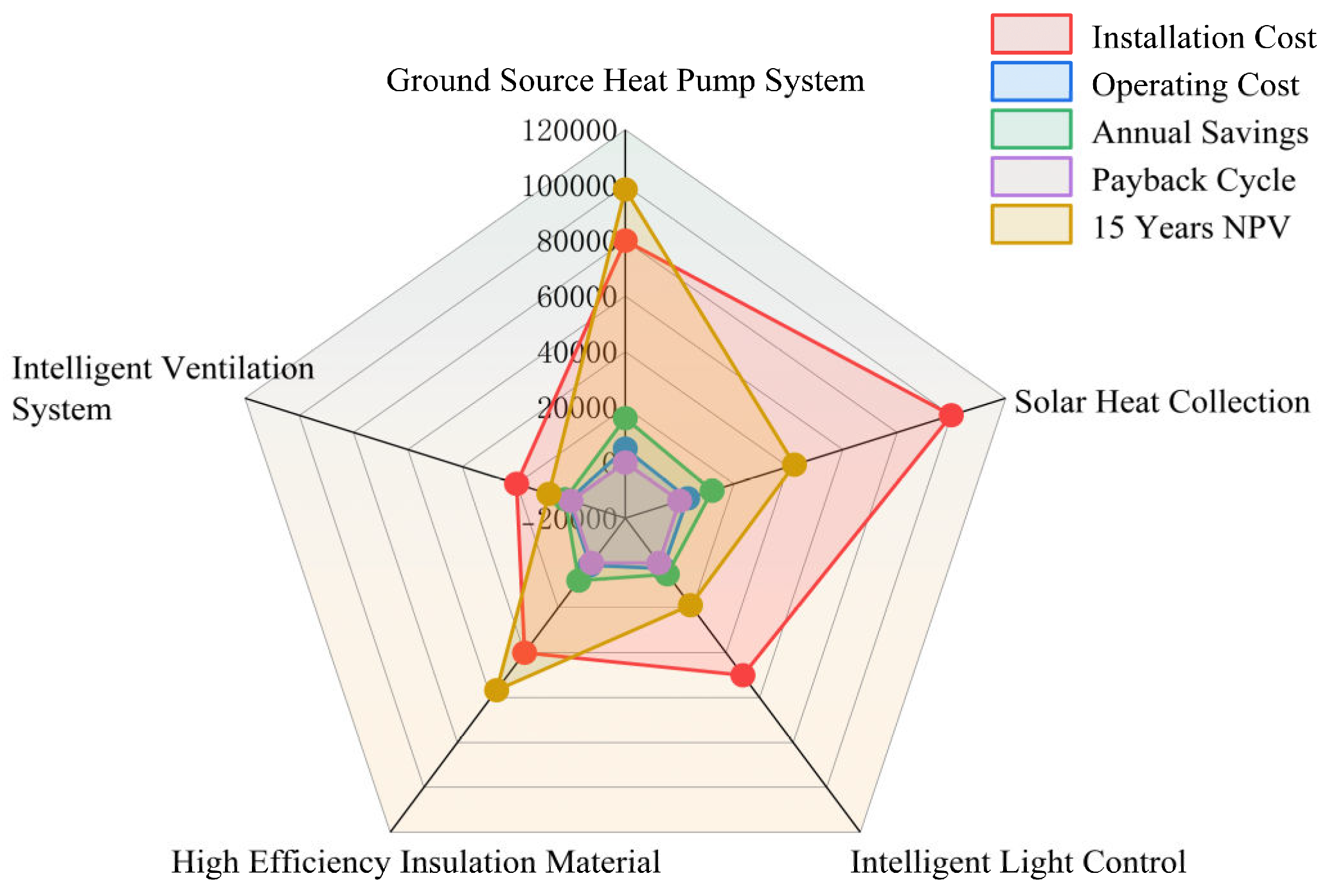

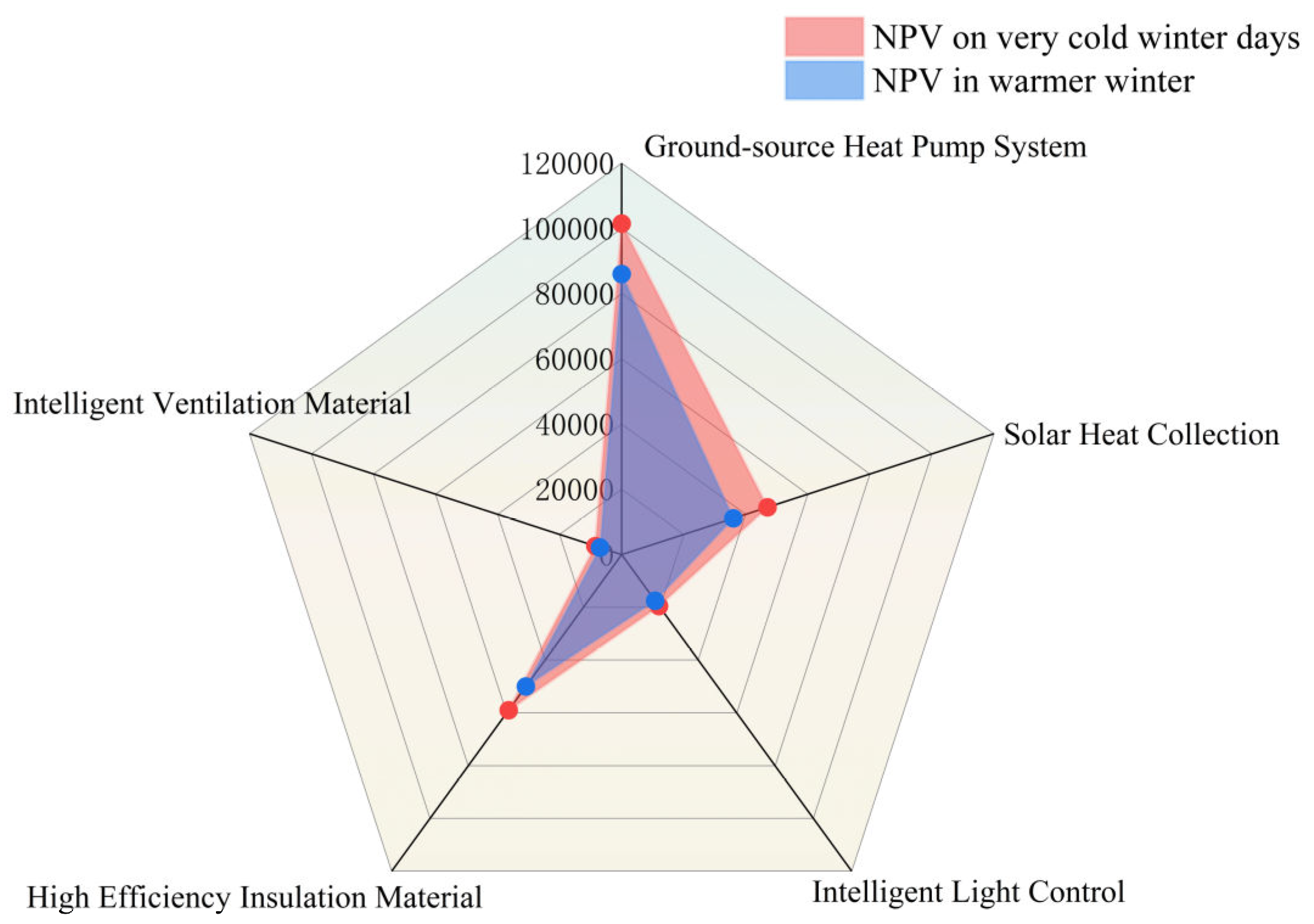

3.5. Economical Analysis

Based on the verification of energy-saving effects, this study further analyzes the economic viability of different energy-saving technologies by calculating their payback period and net present value (NPV). Considering a project lifespan of 15 years and a discount rate of 5%, the economic analysis results for each energy-saving technology are shown in

Table 5 and

Figure 5.

Results Analysis: As shown in

Figure 5, under different energy price scenarios, the NPV of the ground-source heat pump system and high-efficiency insulation materials remains relatively stable, indicating strong adaptability, with a short payback period of 5 years, making them suitable for widespread application in cold regions. In contrast, the solar thermal collection system and intelligent light control system are more sensitive to fluctuations in energy prices, showing higher economic viability in scenarios with rising energy prices. Overall, the ground-source heat pump system, high-efficiency insulation materials, and intelligent light control system all demonstrate strong economic feasibility.

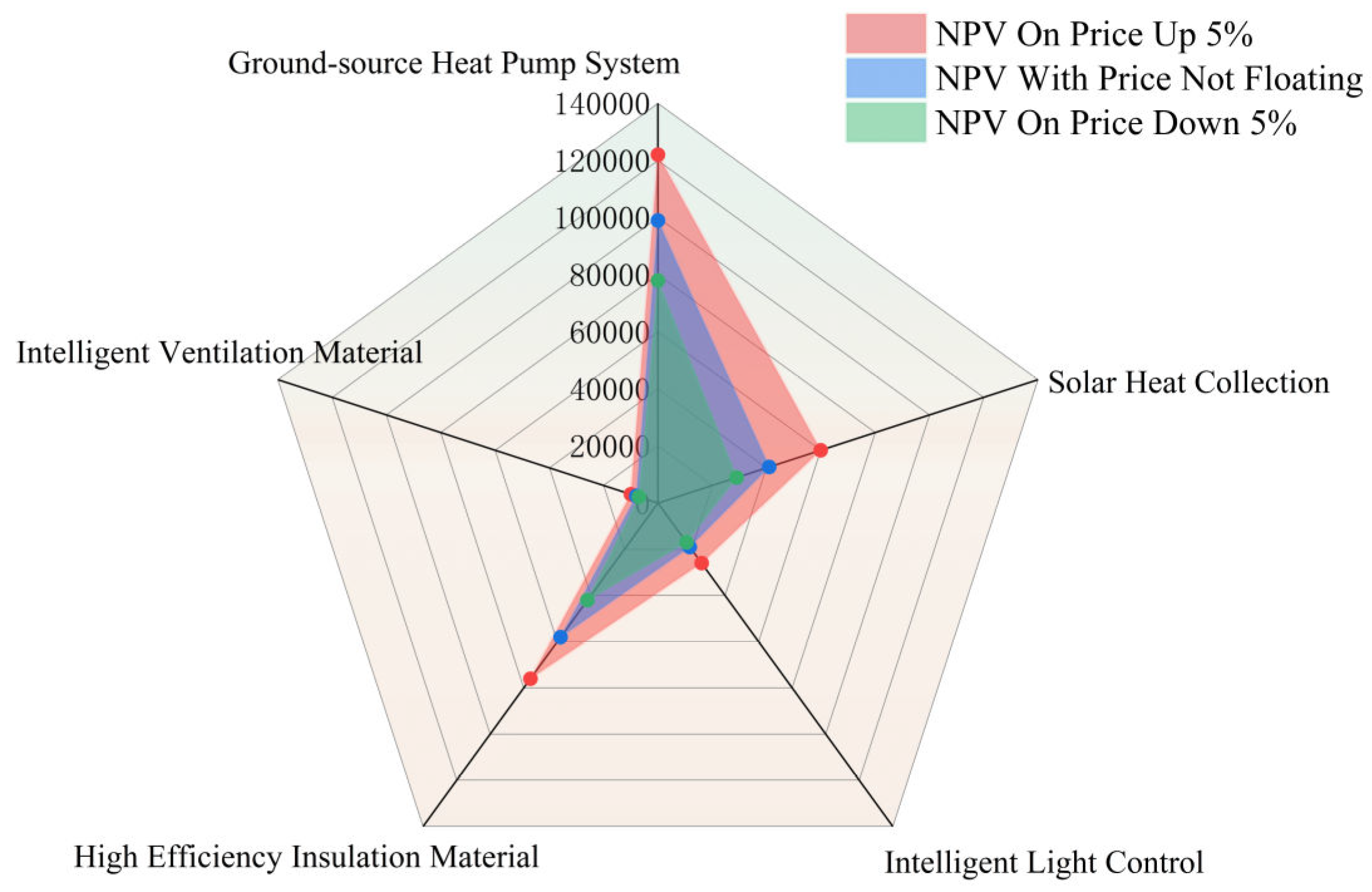

3.6. Sensitivity Analysis: Effects of Energy Price Fluctuations And Changing Climate Conditions

To further evaluate the adaptability of each energy-saving technology, this study conducted a sensitivity analysis under energy price fluctuations and seasonal variations, examining their impact on NPV. The analysis simulated scenarios with energy price growth rates of 5%, 0% (stable), and +5%, as well as the effects of moderate climate (reduced heating demand) and extreme cold climate (increased heating demand) on NPV. The results are shown in

Figure 6 and

Figure 7.

Results Analysis: In the scenario of rising energy prices, the NPV of all energy-saving technologies significantly increased, especially for the ground-source heat pump system and high-efficiency insulation materials. This indicates that, in an environment of increasing energy prices, the economic viability of energy-saving technologies is substantially enhanced. In contrast, the solar thermal collection system and intelligent light control system show higher sensitivity to price fluctuations, making them more suitable for application in situations with high energy prices.

Results Analysis: Under extreme cold conditions, heating and insulation-related technologies, such as the ground-source heat pump system and high-efficiency insulation materials, show higher NPVs, making them particularly suitable for application in harsh environments. The NPV of LED plant lights and intelligent light control systems is less affected by seasonal variations, demonstrating good seasonal adaptability and suitability for year-round operation. The intelligent ventilation system performs better under warmer seasonal conditions, making it well-suited for applications that require seasonal adjustments.

Conclusion: The sensitivity analysis indicates that the application of energy-saving technologies offers strong economic benefits under various energy price and climate conditions, particularly in scenarios of rising energy prices or extreme cold climates, where the payback periods of the ground-source heat pump system and high-efficiency insulation materials are shortened.

This chapter provides a detailed analysis of the experimental results for energy-saving technologies applied in greenhouses within the cold regions of Heilongjiang, focusing on heating, lighting, and ventilation systems. The study shows that the integrated application of the ground-source heat pump, solar thermal collection, intelligent light control system, LED plant lights, and intelligent ventilation system significantly reduced the overall energy consumption of the greenhouse, achieving an energy-saving effect of approximately 17.8%. Additionally, the economic viability and adaptability of these technologies under different energy prices and climate conditions were validated, with the ground-source heat pump system and high-efficiency insulation materials showing strong economic performance in extreme cold and rising energy price scenarios. The sensitivity analysis further demonstrates that the economic benefits of energy-saving technologies increase with rising energy prices or harsher climate conditions, confirming the robustness and adaptability of the integrated energy-saving system under various scenarios. In comparison to traditional energy-saving solutions, the multi-technology integration proposed in this study not only achieves significant improvements in energy savings but also positively impacts the crop growth environment, providing both scientific evidence and practical support for the sustainable development of facility agriculture in cold regions.

4. Conclusion and Prospect

4.1. Research Conclusions

This study proposes and validates an intelligent, multi-technology integrated energy-saving solution, specifically designed for facility agriculture in cold regions, particularly in extremely cold areas such as Heilongjiang. By combining the ground-source heat pump system, solar thermal collection, intelligent light control system, LED plant lights, and intelligent ventilation system, the overall energy-saving rate achieved is 17.8%, with significant energy savings realized in the heating, lighting, and ventilation systems. Financial analysis indicates that the solution is highly cost-effective, especially under scenarios of energy price fluctuations and extreme climate conditions. The results demonstrate that the collaborative application of multiple technologies and intelligent control excels in both energy efficiency and environmental stability, providing an efficient and feasible energy-saving solution for cold-region agriculture.

4.2. Outlook and Future Application Potential

The results of this study demonstrate the potential of the integrated energy-saving solution in cold-region facility agriculture, but there is still room for optimization in its implementation and application. Future research directions include:

Wider Application Verification in Cold Regions: Conduct experiments in different cold regions (e.g., Northern Europe, North America) to verify the adaptability and optimization potential of the technology combination.

Economic and Cost Optimization: Focus on reducing the manufacturing and installation costs of key equipment and materials to enhance the cost-effectiveness of the solution, promoting its adoption in small- and medium-sized facility agriculture.

Adaptability of the Intelligent Control System: Integrate machine learning and other technologies to enable the system to automatically adjust its control strategies based on historical data and real-time changes, improving stability in extreme environmental conditions.

Integration of Diverse Renewable Energy Sources: Explore the combination of wind, biomass, and other renewable energy technologies to diversify the energy mix, further reducing reliance on traditional energy sources.

Environmental Impact Assessment: Use lifecycle assessment methods to evaluate the carbon emissions and environmental impacts of the energy-saving solution, promoting the shift of facility agriculture towards a greener and more sustainable future.

In conclusion, the integrated energy-saving solution presented in this study performs excellently in terms of energy efficiency, intelligent control, and economic viability. Through further optimization and cost control, and by expanding its application scope, this solution can provide strong support for the sustainable development of cold-region facility agriculture.

References

- Guangyong L, Xiaoyan L, Cuihong J, et al. Analysis on impact of facility agriculture on ecological function of modern agriculture [J]. Procedia Environmental Sciences, 2011, 10: 300 306.

- Tan F, Zhang L, Zhao Y, et al. Climatic suitability and development potential of facility agriculture at county level in China [J]. Science of The Total Environment, 2024: 177108.

- Bora G C, Nowatzki J F, Roberts D C. Energy savings by adopting precision agriculture in rural USA [J]. Energy, Sustainability and Society, 2012, 2: 1 5.

- Fu X, Zhou Y, Yang F, et al. A review of key technologies and trends in the development of integrated heating and power systems in agriculture [J]. Entropy, 2021, 23(2): 260.

- Kondrateva N P, Bolshin R G, Belov V V, et al. Energy saving electric equipment applied in agriculture [C]//2019 International Science and Technology Conference" EastConf". IEEE, 2019: 1 3.

- Engler N, Krarti M. Review of energy efficiency in controlled environment agriculture [J]. Renewable and Sustainable Energy Reviews, 2021, 141: 110786.

- Li Y, Sun D, Xia T, et al. Performance of a novel internal insulation in Chinese solar greenhouse for the cleaner and energy saving production in high latitudes and cold regions [J]. Journal of Cleaner Production, 2023, 412: 137442.

- Ozgener O. Use of solar assisted geothermal heat pump and small wind turbine systems for heating agricultural and residential buildings [J]. Energy, 2010, 35(1): 262 268.

- Bundschuh J, Chen G, Tomaszewska B, et al. Solar, wind and geothermal energy applications in agriculture: back to the future? [J]. Geothermal, wind and solar energy applications in agriculture and aquaculture, 2017: 1 32.

- Kiktev N, Lendiel T, Vasilenkov V, et al. Automated Microclimate Regulation in Agricultural Facilities Using the Air Curtain System [J]. Sensors, 2021, 21(24): 8182.

- Neo D C J, Ong M M X, Lee Y Y, et al. Shaping and tuning lighting conditions in controlled environment agriculture: A review [J]. ACS Agricultural Science & Technology, 2022, 2(1): 3 16.

- Hadj Abdelkader O, Bouzebiba H, Pena D, et al. Energy efficient IoT based light control system in smart indoor agriculture [J]. Sensors, 2023, 23(18): 7670.

- Harmon J D, Brumm M C, Jacobson L D, et al. Field performance evaluation of a ventilation system: A swine case study [J]. Applied engineering in agriculture, 2012, 28(2): 251 257.

- Norton T, Sun D W, Grant J, et al. Applications of computational fluid dynamics (CFD) in the modelling and design of ventilation systems in the agricultural industry: A review [J]. Bioresource technology, 2007, 98(12): 2386 2414.

- Shamshiri R, Kalantari F, Ting K C, et al. Advances in greenhouse automation and controlled environment agriculture: A transition to plant factories and urban agriculture [J]. International Journal of Agricultural and Biological Engineering, 2018, 11(1): 1 22.

- Haroon A, Shah M A, Asim Y, et al. Constraints in the IoT: the world in 2020 and beyond [J]. International Journal of Advanced Computer Science and Applications, 2016, 7(11).

- Landolfi R, Nicolella M. Durability assessment of ETICS: Comparative evaluation of different insulating materials [J]. Sustainability, 2022, 14(2): 980.

- Chen H, Meng F, Yu Z, et al. Spatial–temporal characteristics and influencing factors of farmland expansion in different agricultural regions of Heilongjiang Province, China [J]. Land Use Policy, 2022, 115: 106007.

- zu Westerhausen S M, Schneider J, Lachmayer R. Reliability analysis for sensor networks and their data acquisition: A systematic literature review [J]. Proceedings of the Design Society, 2023, 3: 3065 3074.

- Sarbu I, Sebarchievici C. General review of ground source heat pump systems for heating and cooling of buildings [J]. Energy and buildings, 2014, 70: 441 454.

- Pelay U, Luo L, Fan Y, et al. Thermal energy storage systems for concentrated solar power plants [J]. Renewable and Sustainable Energy Reviews, 2017, 79: 82 100.

- Wiprächtiger M, Haupt M, Heeren N, et al. A framework for sustainable and circular system design: Development and application on thermal insulation materials [J]. Resources, Conservation and Recycling, 2020, 154: 104631.

- De Paz J F, Bajo J, Rodríguez S, et al. Intelligent system for lighting control in smart cities [J]. Information Sciences, 2016, 372: 241 255.

- Lin Z, Yao T, Chow T T, et al. Performance evaluation and design guidelines for stratum ventilation [J]. Building and environment, 2011, 46(11): 2267 2279.

- Tsoutsos T, Gekas V, Marketaki K. Technical and economical evaluation of solar thermal power generation [J]. Renewable energy, 2003, 28(6): 873 886.

- Sikder I U. Knowledge based spatial decision support systems: An assessment of environmental adaptability of crops [J]. Expert Systems with Applications, 2009, 36(3): 5341 5347.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).