Submitted:

08 November 2024

Posted:

12 November 2024

You are already at the latest version

Abstract

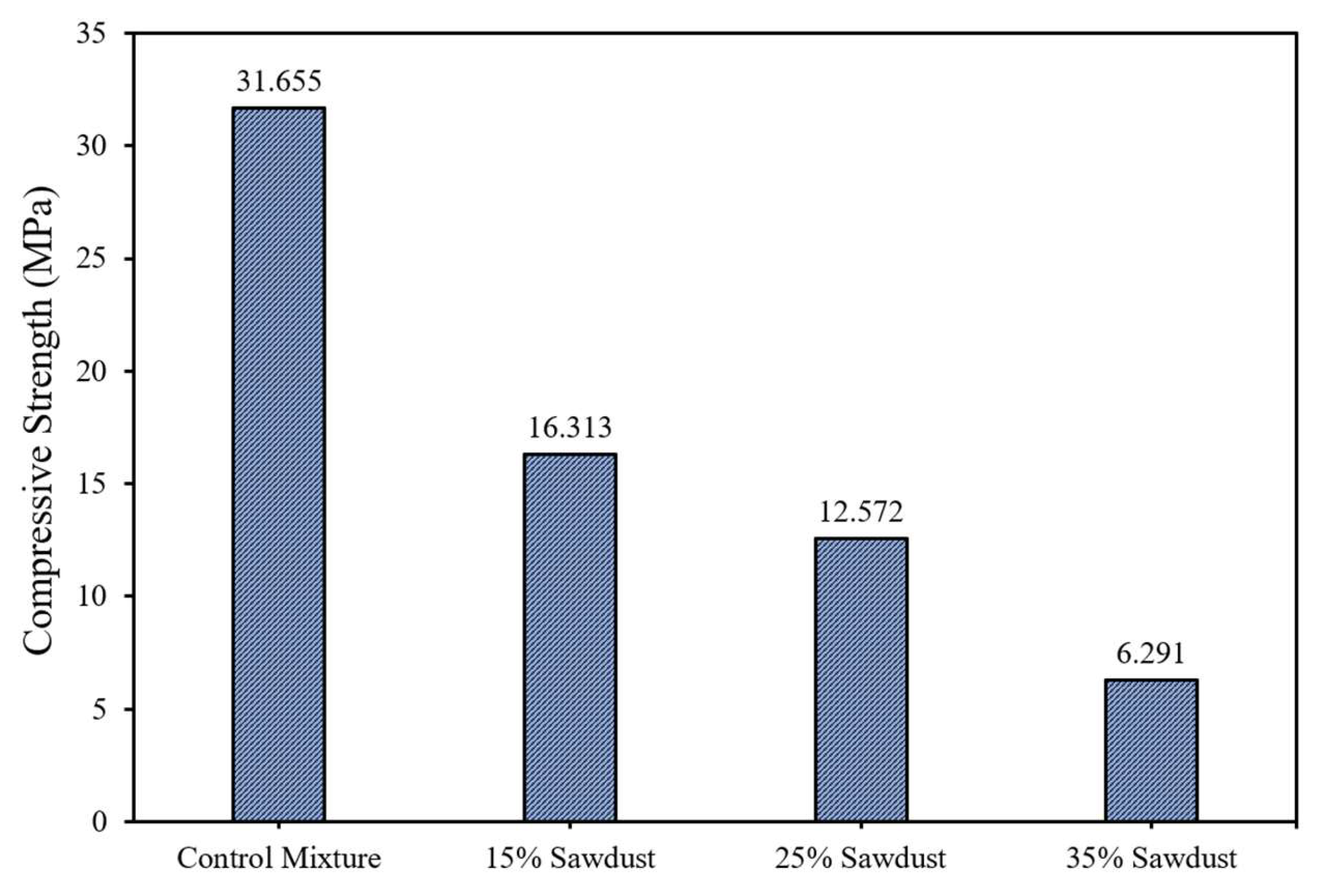

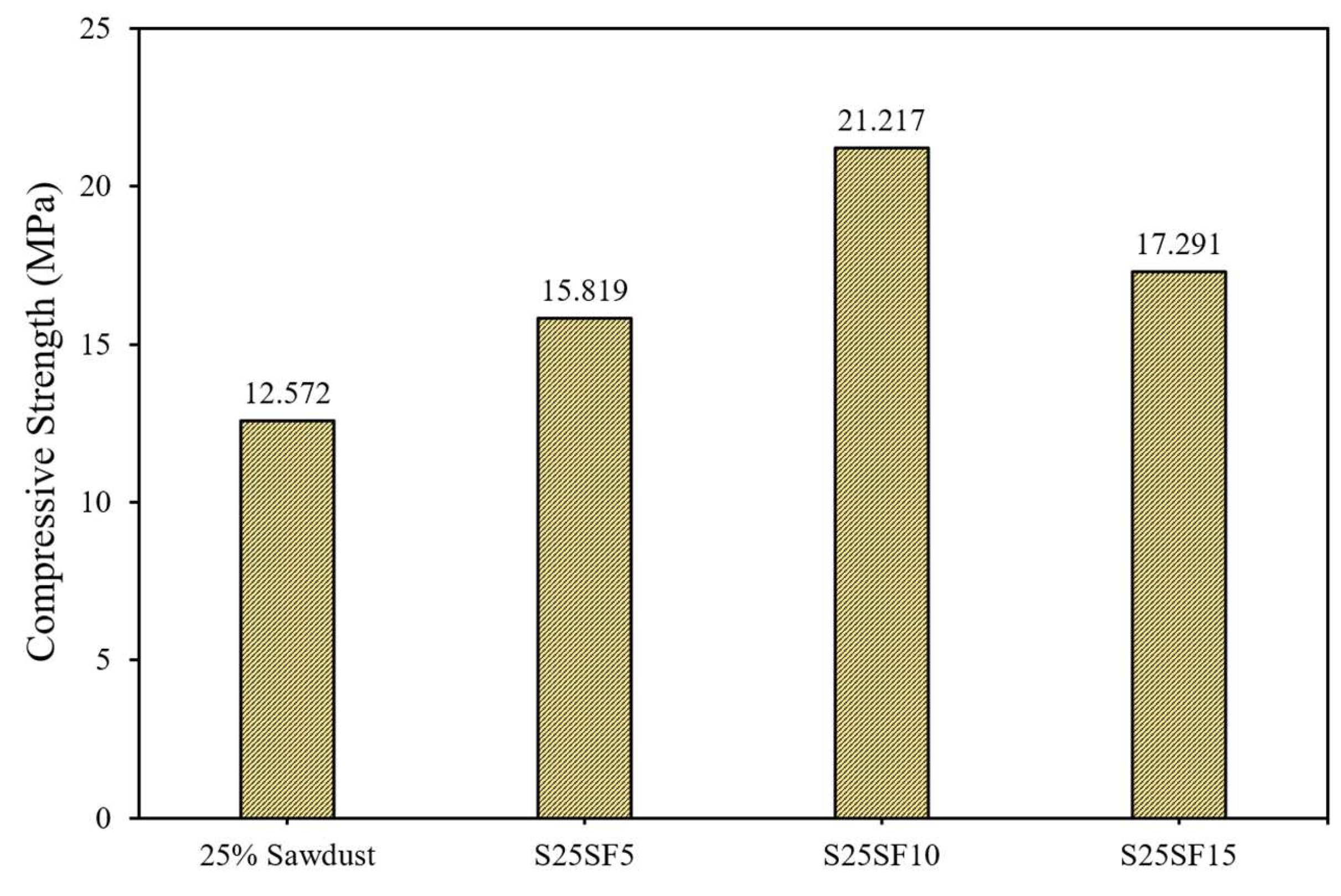

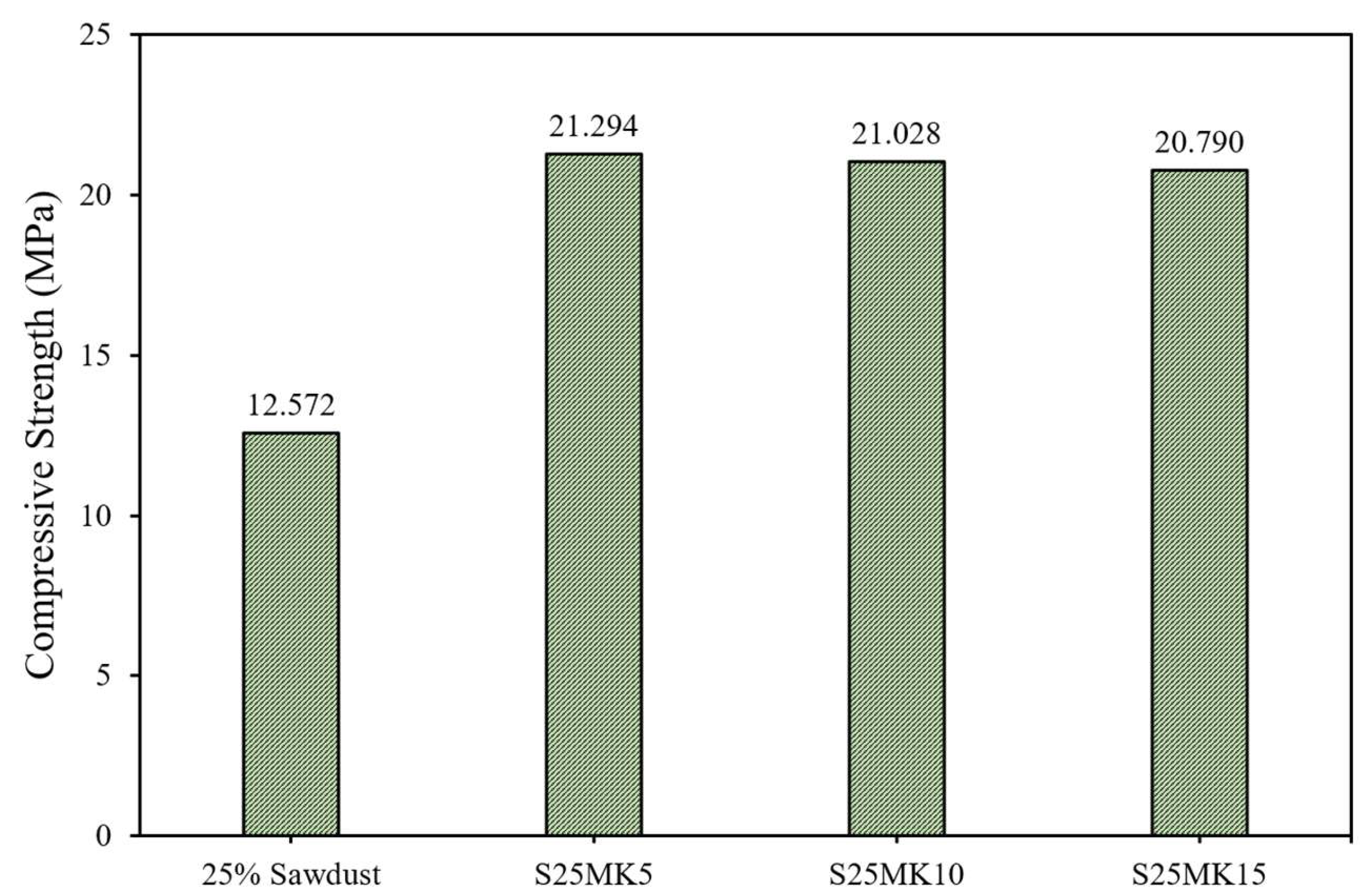

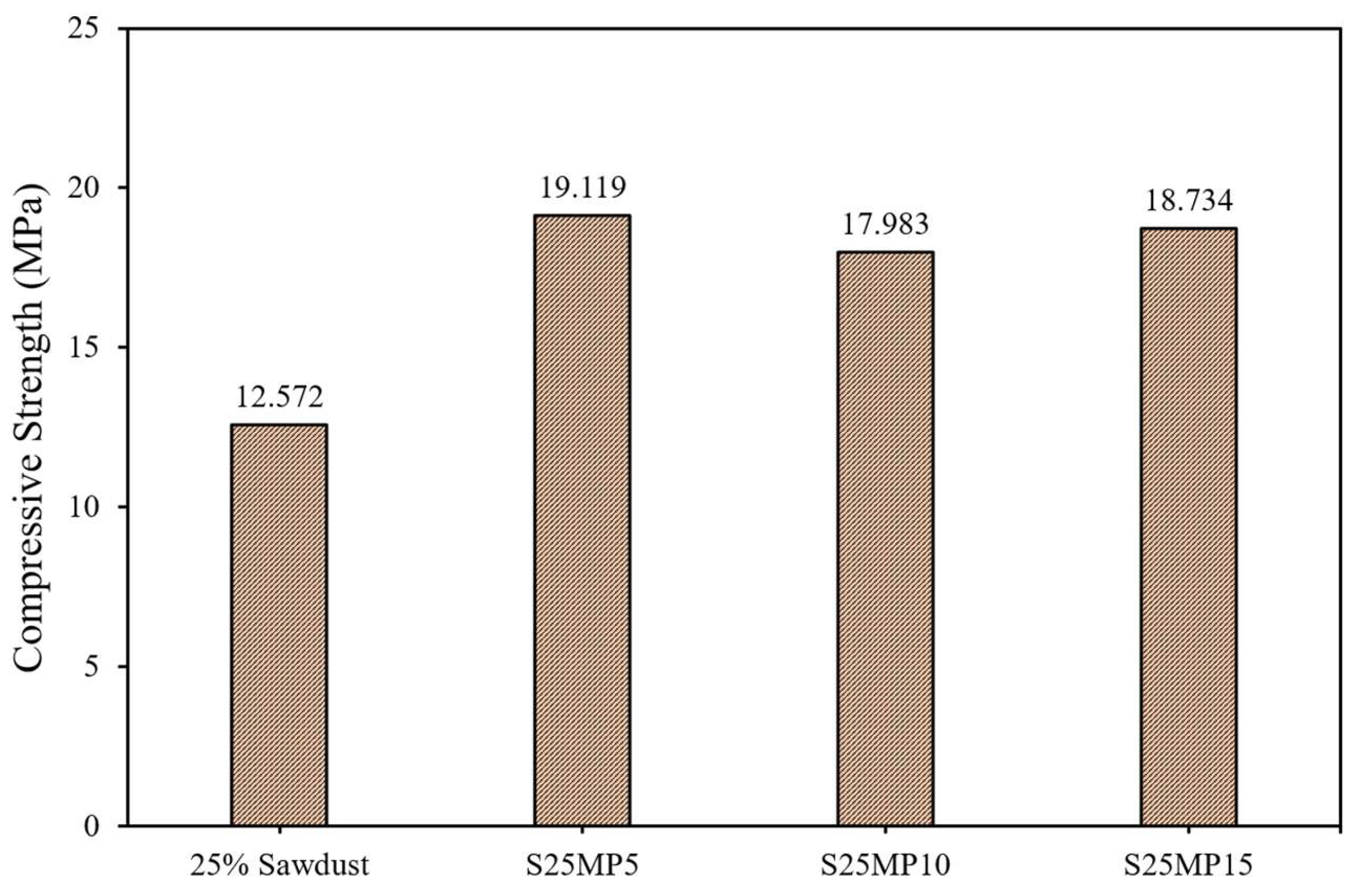

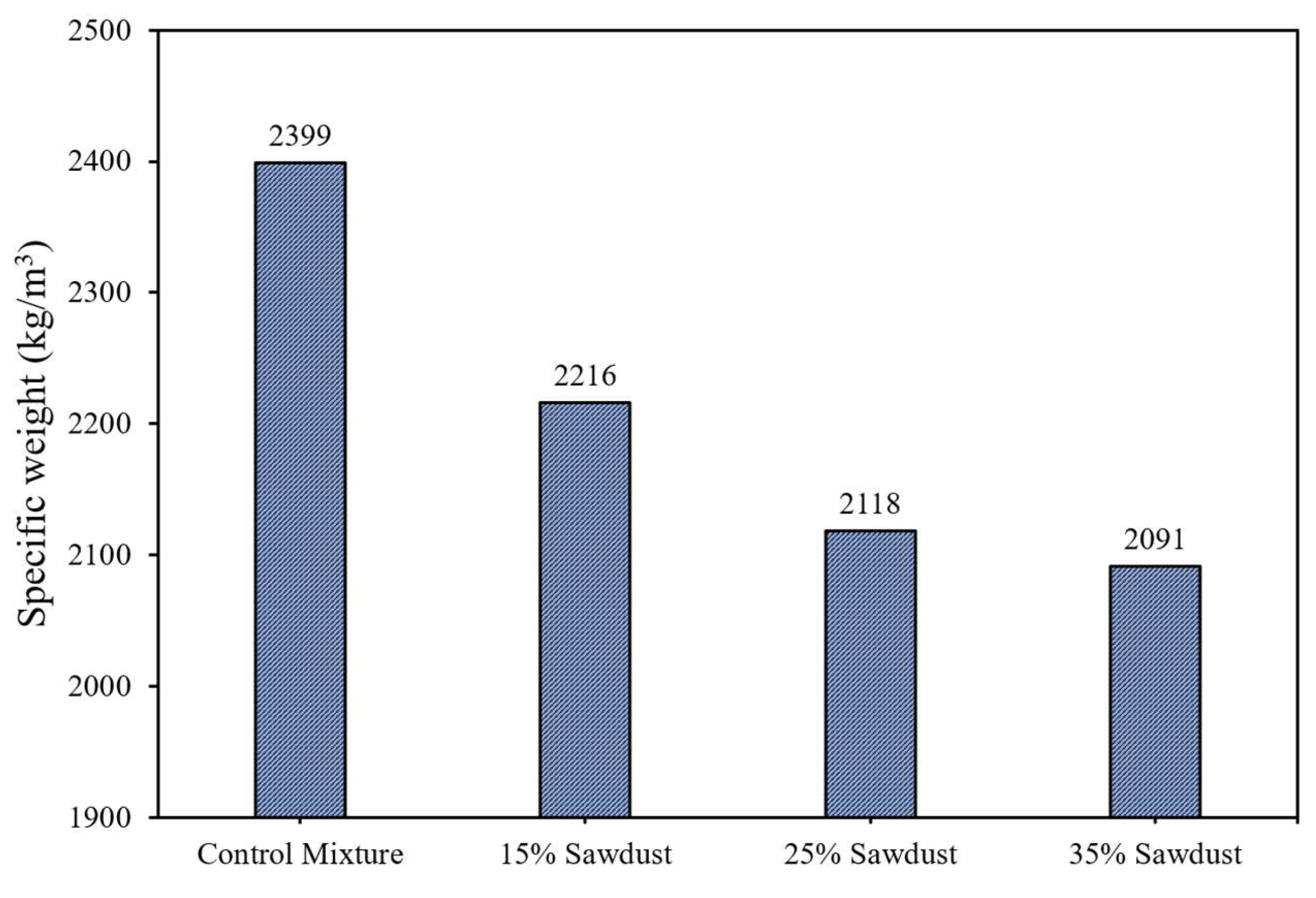

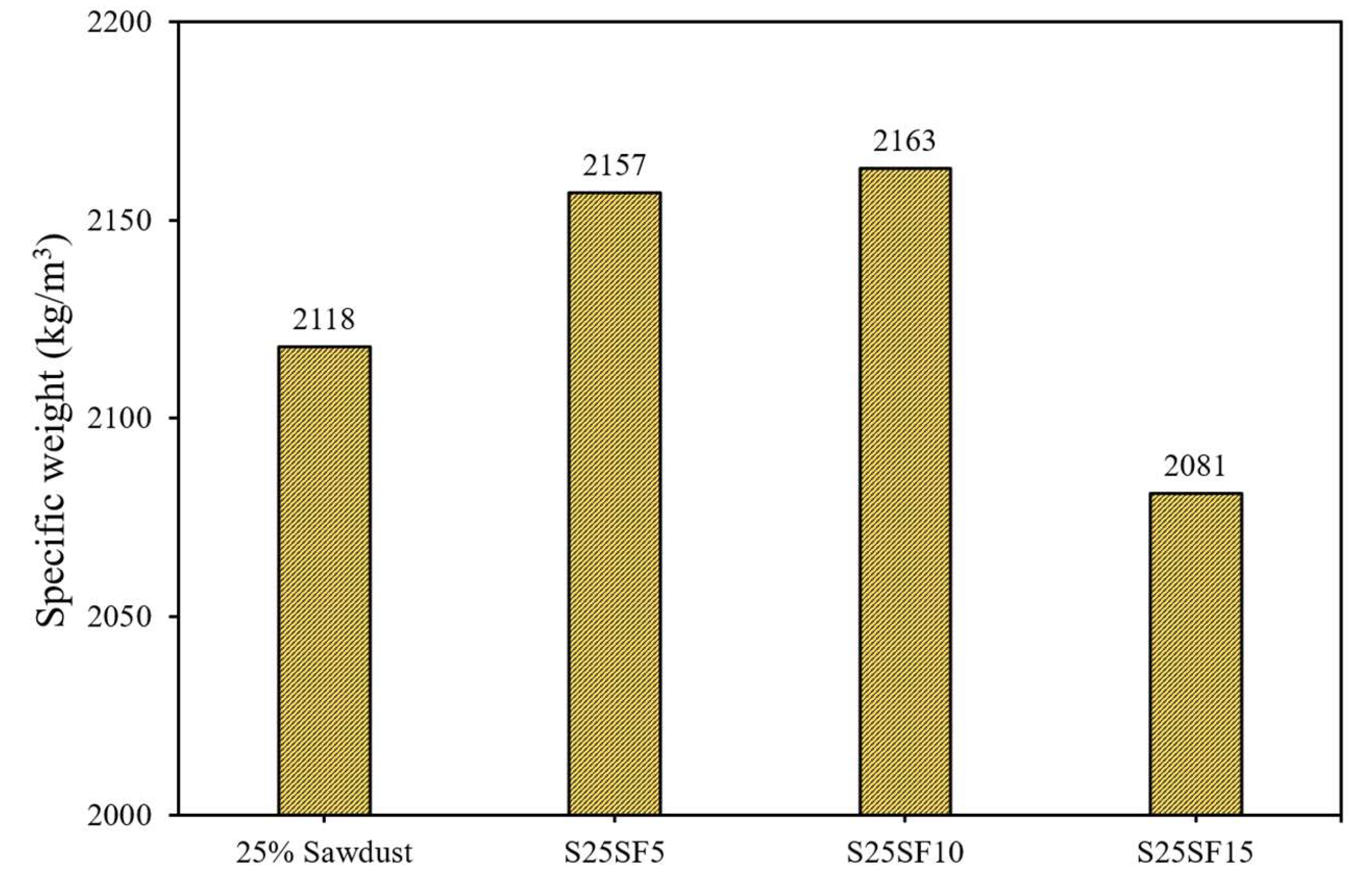

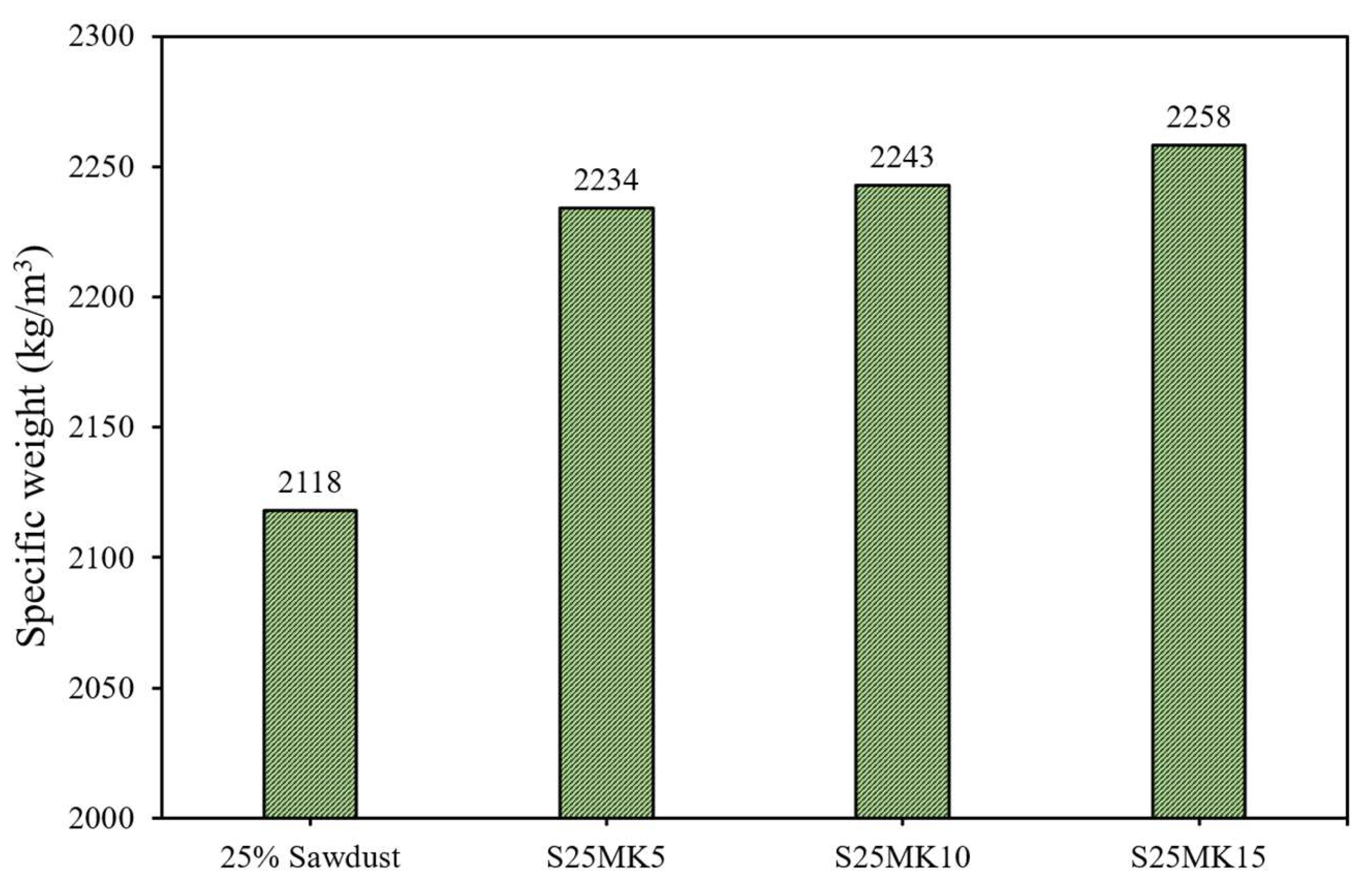

This research explores the innovative use of sawdust as a sustainable aggregate in concrete, addressing both environmental and structural challenges. The study investigates the effects of incorporating sawdust at varying proportions (15%, 25%, and 35%) into concrete mixtures, aiming to reduce carbon emissions and promote lightweight construction. Recognizing the negative impact of waste glass powder on concrete strength, this research introduces silica fume (SF), metakaolin (MK), and marble powder (MP) as potential additives to enhance the compressive strength and reduce the specific weight of sawdust concrete. The experimental program involved 13 concrete mixtures, with SF, MK, and MP added at 5%, 10%, and 15% by mass to a 25% sawdust mix. Results indicate that increasing sawdust content significantly decreases compressive strength, with reductions from 31.655 MPa in the control to 6.291 MPa at 35% sawdust. However, the addition of SF and MK notably improved strength, with SF enhancing it by 68.8% at 10% addition and MK by 69.3% at 5%. MP, while less effective, still increased strength by 42.9%. Sawdust addition consistently reduced concrete density, from 2399 kg/m³ in the control to 2091 kg/m³ at 35% sawdust. SF further reduced density, whereas MK and MP increased it. The study concludes that 10% SF or 5% MK are optimal for improving sawdust concrete properties, offering a balance of enhanced strength and reduced weight. This research contributes to sustainable construction practices by demonstrating the viability of sawdust and specific additives in creating environmentally friendly, lightweight concrete solutions.

Keywords:

1. Introduction

2. Material and Methods

2.1. Materials

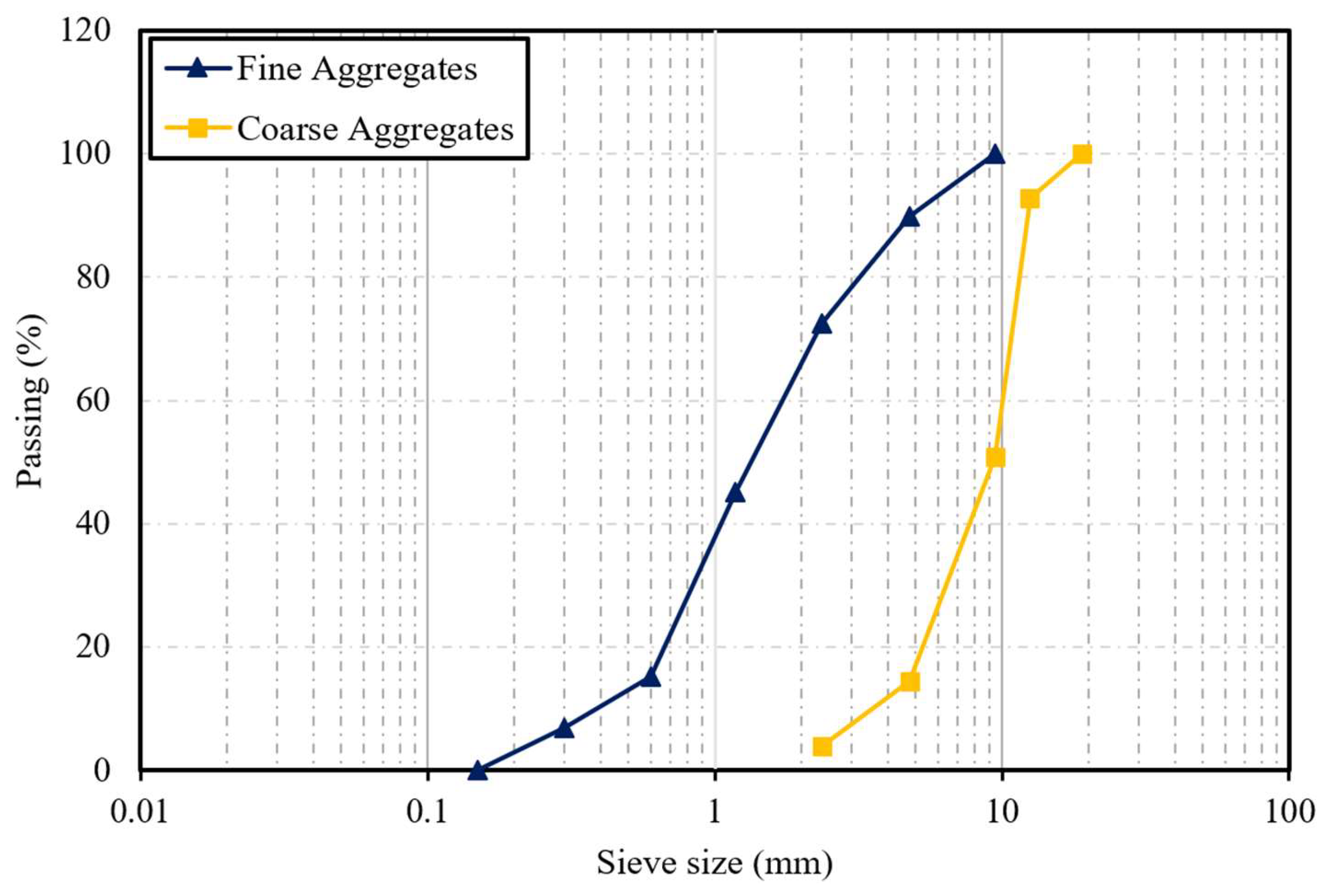

2.1.1. Aggregates

2.1.2. Cement and Water

2.1.3. Sawdust

2.1.4. Silica Fume (SF), Metakaolin (MK), Marble Powder (MP)

2.2. Mix Composition

2.3. Cast and Curing

2.4. Testing:

4. Results and Discussions

4.1. Compressive Strength

4.2. Density

5. Conclusions

- Increasing sawdust content significantly reduces the compressive strength of concrete. The compressive strength decreased from 31.655 MPa for the control mixture (0% sawdust) to 16.313 MPa, 12.572 MPa, and 6.291 MPa with 15%, 25%, and 35% sawdust, respectively.

- Additives such as silica fume (SF), metakaolin (MK), and marble powder (MP) improved the compressive strength of concrete with sawdust. Silica fume enhanced strength by 68.8% with 10% addition in a 25% sawdust mix. Metakaolin also significantly improved strength by 69.3% at 5% addition. Marble powder demonstrated lower improvements, with a 42.9% increase, mainly acting as a filler without significant pozzolanic activity. Overall, metakaolin led to the greatest increase in compressive strength, with silica fume being the next most effective, followed by marble powder.

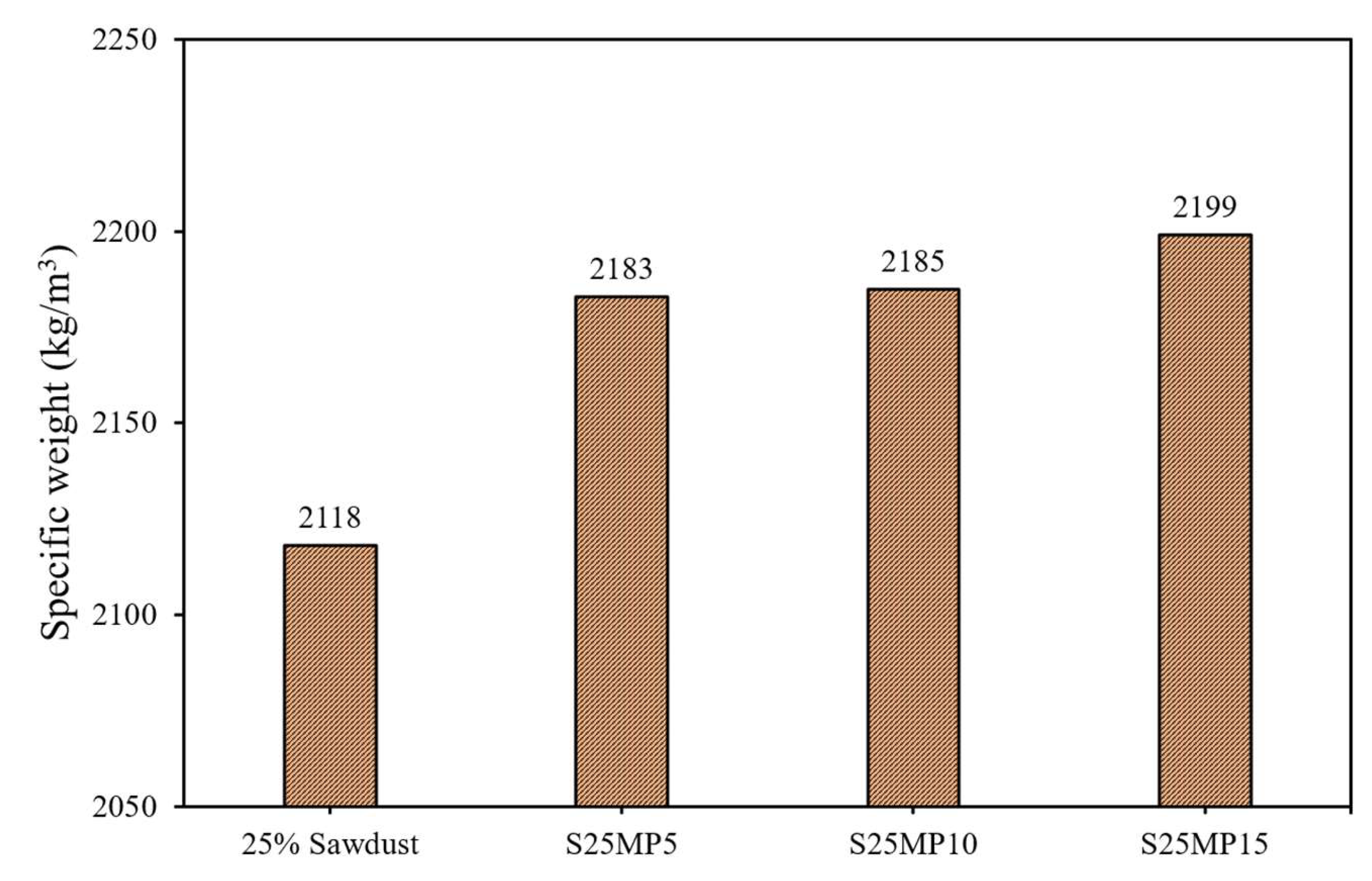

- Sawdust addition consistently reduced concrete density, from 2399 kg/m³ in the control to 2091 kg/m³ with 35% sawdust, due to its lower inherent density and irregular particle size. Silica fume reduced the density of the sawdust concrete samples, while metakaolin and marble powder increased the specific gravity of the sawdust concrete mixture.

- Given that incorporating 10% silica fume greatly increases the strength of sawdust concrete while simultaneously reducing the weight of the mixture, silica fume is an ideal additive, like metakaolin, for sawdust concrete. Therefore, it is suggested to use metakaolin in the amount of 5% or silica fume in the amount of 10% to improve the properties of sawdust concrete.

Declaration of Competing Interest

Data availability

References

- Záleská, M.; Pavlíková, M.; Pokorný, J.; Jankovský, O.; Pavlík, Z.; Černý, R. Structural, mechanical and hygrothermal properties of lightweight concrete based on the application of waste plastics. Construction and Building Materials 2018, 180, 1–11. [Google Scholar] [CrossRef]

- Pournoori, P.; TQ, A.D.; Rajaee, A.; Ghodratnama, M.; Abrishami, S.; Masoodi, A.R. Experimental exploration of fracture behavior (pure mode III) in eco-friendly steel fiber-reinforced self-compacting concrete with waste tempered glass as coarse aggregates. Scientific Reports 2024, 14, 9043. [Google Scholar] [CrossRef]

- Colangelo, F.; Cioffi, R.; Liguori, B.; Iucolano, F. Recycled polyolefins waste as aggregates for lightweight concrete. Composites Part B: Engineering 2016, 106, 234–241. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Al Muhit, B.A.; Jumaat, M.Z.B. Utilization of oil palm kernel shell as lightweight aggregate in concrete–A review. Construction and building materials 2013, 38, 161–172. [Google Scholar] [CrossRef]

- Demirboğa, R.; Örüng, İ.; Gül, R. Effects of expanded perlite aggregate and mineral admixtures on the compressive strength of low-density concretes. Cement and Concrete Research 2001, 31, 1627–1632. [Google Scholar] [CrossRef]

- Ganiron, T. Effect of sawdust as fine aggregate in concrete mixture for building construction. International Journal of Advanced Science and Technology 2014, 63, 73–82. [Google Scholar] [CrossRef]

- Miri, H.; Rajaee, A.; Ghodratnama, M.; Quchan, A.D.T.; Sheikhi, M.; Pournoori, P. Experimental and numerical investigation on water absorption and strength of lightweight concrete containing LECA and cold bitumen powder. International Journal of Sustainable Building Technology and Urban Development 2024, 15, 307–327. [Google Scholar] [CrossRef]

- Farahinia, E.; Sheikhi, M.; Amirhossein, D.T.Q.; Rajaee, A.; Ghodratnama, M.; Banihashem, S.M.; Pournoori, P. Experimental and numerical exploration of mechanical properties of sawdust concrete due to the addition of waste glass powder. International Journal of Sustainable Building Technology and Urban Development 2024, 15, 328–353. [Google Scholar] [CrossRef]

- Sawant, A.; Sharma, A.; Rahate, R.; Mayekar, N.; Ghadge, M. Partial replacement of sand with sawdust in concrete. Int Res J Eng Technol 2018, 5, 3098–3101. [Google Scholar]

- Orozco, C.; Tangtermsirikul, S.; Sugiyama, T.; Babel, S. Examining the endpoint impacts, challenges, and opportunities of fly ash utilization for sustainable concrete construction. Scientific Reports 2023, 13, 18254. [Google Scholar] [CrossRef]

- M. Amirnia, M. M. Amirnia, M. Sheikhi, N. Talebi, P. Pournoori, and A. Rajaee, "Evaluation of hardened properties of structural concrete containing waste tiles and volcanic ash.".

- Kumar, R. Effect of metakaolin on mechanical characteristics of the mortar and concrete: A critical review. Materials Today: Proceedings, 2023. [Google Scholar] [CrossRef]

- Baradaran, M.S.; Qazanfari, R.; Baradaran, S. Study of soil reinforcement in the east of Mashhad using glass granule. Materials Research Express 2023, 10, 055202. [Google Scholar] [CrossRef]

- S. BaridJavan, M. S. BaridJavan, M. Sheikhi, P. Pournoori, and A. Rajaee, "Glass powder and PVC granules as partial replacement of cement and aggregate; An experimental study.".

- Hamada, H.M.; et al. Effect of silica fume on the properties of sustainable cement concrete. Journal of Materials Research and Technology 2023, 24, 8887–8908. [Google Scholar] [CrossRef]

- Prakash, B.; Saravanan, T.J.; Kabeer, K.S.A.; Bisht, K. Exploring the potential of waste marble powder as a sustainable substitute to cement in cement-based composites: A review. Construction and Building Materials 2023, 401, 132887. [Google Scholar] [CrossRef]

- Baradaran, S.; Rahimi, J.; Ameri, M.; Maleki, A. Mechanical performance of asphalt mixture containing eco-friendly additive by recycling PET. Case Studies in Construction Materials 2024, 20, e02740. [Google Scholar] [CrossRef]

- Baradaran, S.; Aliha, M.; Maleki, A.; Underwood, B.S. Fracture properties of asphalt mixtures containing high content of reclaimed asphalt pavement (RAP) and eco-friendly PET additive at low temperature. Construction and Building Materials 2024, 449, 138426. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, M.; Mehta, S.; Belarbi, R. Utilization of treated saw dust in concrete as partial replacement of natural sand. Journal of cleaner production 2020, 261, 121226. [Google Scholar] [CrossRef]

- Ahmed, W.; Khushnood, R.A.; Memon, S.A.; Ahmad, S.; Baloch, W.L.; Usman, M. Effective use of sawdust for the production of eco-friendly and thermal-energy efficient normal weight and lightweight concretes with tailored fracture properties. Journal of Cleaner Production 2018, 184, 1016–1027. [Google Scholar] [CrossRef]

- Cheng, Y.; You, W.; Zhang, C.; Li, H.; Hu, J. The implementation of waste sawdust in concrete. Engineering 2013, 5, 943. [Google Scholar] [CrossRef]

- Oyedepo, O.J.; Oluwajana, S.D.; Akande, S.P. Investigation of properties of concrete using sawdust as partial replacement for sand. Civil and Environmental Research 2014, 6, 35–42. [Google Scholar]

- Osei, D.Y.; Jackson, E.N. Compressive strength of concrete using sawdust as aggregate. International Journal of Scientific & Engineering Research 2016, 7, 1349–1353. [Google Scholar]

- Olutoge, F. Investigations on sawdust and palm kernel shells as aggregate replacement. ARPN Journal of Engineering and Applied Sciences 2010, 5, 7–13. [Google Scholar]

- Standard, A. C150: Standard Specification for Portland Cement. Annual Book of ASTM Standards, 2009. [Google Scholar]

- Concrete, A.S.F.T.M.C.C.-O.; Aggregates, C. , Standard specification for silica fume used in cementitious mixtures. ASTM International, 2011.

- Hameed, M.S.; Sekar, A.; Saraswathy, V. Strength and permeability characteristics study of self-compacting concrete using crusher rock dust and marble sludge powder. Arabian journal for science and engineering 2012, 37, 561–574. [Google Scholar] [CrossRef]

- Afshoon, I.; Miri, M.; Mousavi, S.R. Comprehensive experimental and numerical modeling of strength parameters of eco-friendly steel fiber reinforced SCC containing coarse copper slag aggregates. Construction and Building Materials 2023, 367, 130304. [Google Scholar] [CrossRef]

- Testing concrete: Method for determination of compressive strength of concrete cubes., B. S. I. (BSI), 1983.

| Material | Chemical composition (%) | ||||||||

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | C3S | |

| Portland Cement | 20.9 | 4.5 | 3.8 | 63.5 | 2.7 | 2 | 0.5 | 0.5 | 1.15 |

| Material | Setting Time | Compressive Strength (kg/cm2) | ||||

| Initial (min) | Final (min) | 3 days | 7 days | 28 days | ||

| Portland Cement | 200 | 260 | 170 | 290 | 400 | |

| Material | Chemical composition (%) | |||||

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | LOI | |

| Sawdust | 87 | 2.5 | 2 | 3.5 | 0.24 | 4.76 |

| Material | Silica Fume |

| particle sizes (µm) | 98% of particles less than 45 µm |

| Bulk density | 200-300 kg/m3 |

| Specific weight | 2200 kg/m3 |

| Melting point | 1550-1570 oC |

| Material | Chemical composition (%) | ||||||||

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | LOI | ||

| Silica Fume | 89.22 | 1.2 | 2.12 | 1.87 | 1.61 | 0.56 | 1.06 | 2.6 | |

| Metakaolin | 67 | 30 | 0.02 | 0.02 | 0.04 | 0.5 | 0.7 | 1 | |

| Marble Powder | 0.22 | 0.18 | 0.44 | 55.07 | 0.34 | 0.56 | 0.11 | 42.86 | |

| Mix ID | Coarse Aggregates (kg/m3) |

Fine Aggregates (kg/m3) |

Water (kg/m3) |

Cement (kg/m3) |

Sawdust (kg/m3) | SF (kg/m3) | MK (kg/m3) | MP (kg/m3) |

| Control | 880 | 812 | 218 | 400 | 0 10.5 18.5 25.7 18.5 |

0 | 0 | 0 |

| S15 | 880 | 690 | 264 | 400 | 0 | 0 | 0 | |

| S25 | 880 | 611 | 277 | 400 | 0 | 0 | 0 | |

| S35 | 880 | 528 | 284 | 400 | 0 | 0 | 0 | |

| S25SF5 | 880 | 611 | 277 | 400 | 20.8 | 0 | 0 | |

| S25SF10 | 880 | 611 | 277 | 400 | 18.5 | 41.6 | 0 | 0 |

| S25SF15 | 880 | 611 | 277 | 400 | 18.5 | 62.4 | 0 | 0 |

| S25MK5 | 880 | 611 | 277 | 400 | 18.5 | 0 | 20.8 | 0 |

| S25MK10 | 880 | 611 | 277 | 400 | 18.5 | 0 | 41.6 | 0 |

| S25MK15 | 880 | 611 | 277 | 400 | 18.5 | 0 | 62.4 | 0 |

| S25MP5 | 880 | 611 | 277 | 400 | 18.5 | 0 | 0 | 20.8 |

| S25MP10 | 880 | 611 | 277 | 400 | 18.5 | 0 | 0 | 41.6 |

| S25MP15 | 880 | 611 | 277 | 400 | 18.5 | 0 | 0 | 62.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).