Submitted:

14 September 2024

Posted:

17 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

Aim of the Paper

2. Method

2.1. Search Strategy

2.2. Inclusion and Exclusion Criteria

2.3. Methodological Quality Assessment

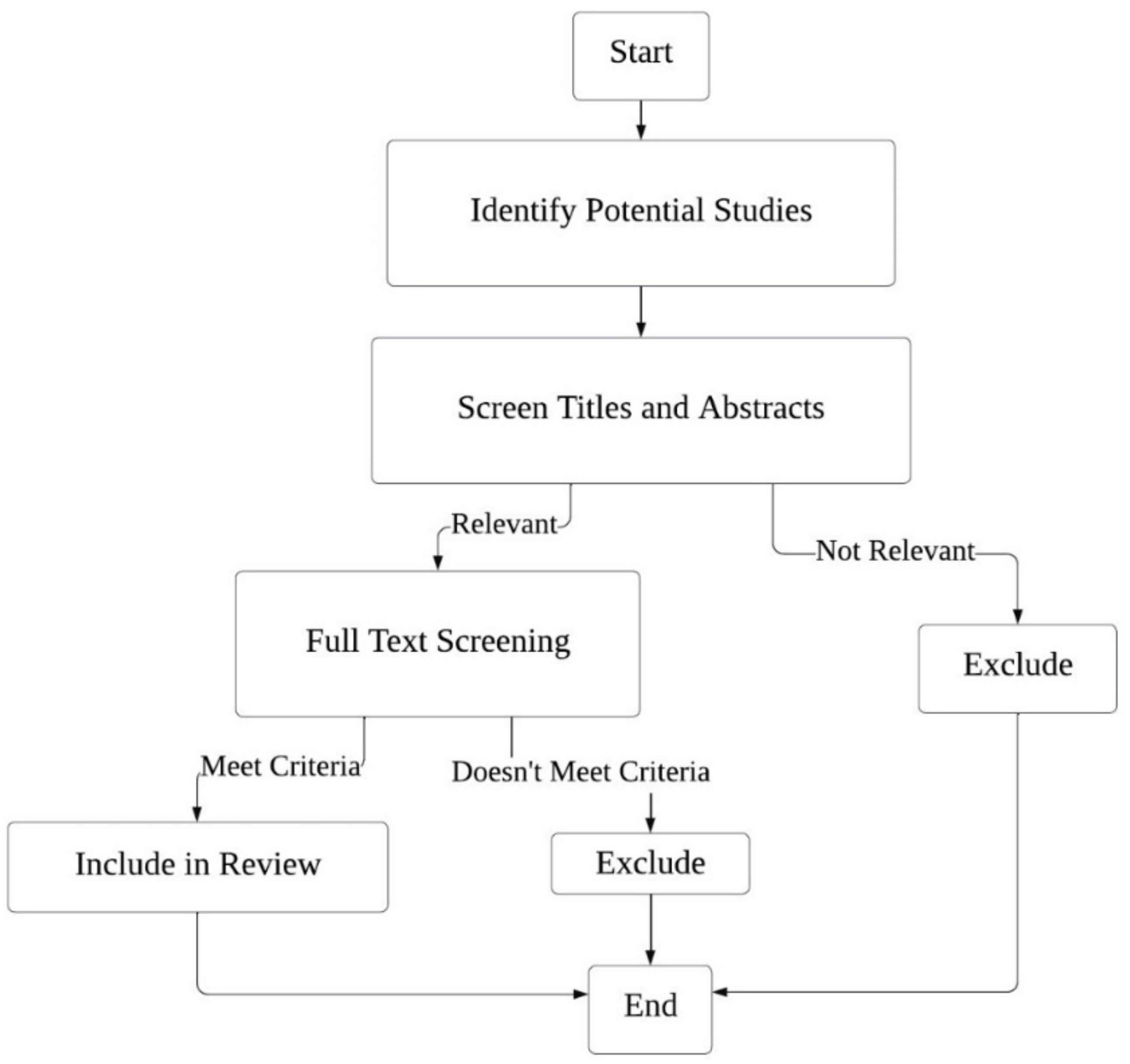

2.4. Selection of Studies

2.5. Data Extraction and Analysis

3. Results

4. Discussion

5. Conclusion

References

- Aboutorab, H.; Hussain, O.K.; Saberi, M.; Hussain, F.K.; Chang, E. A survey on the suitability of risk identification techniques in the current networked environment. Journal of Network and Computer Applications 2021, 178, 102984. [Google Scholar] [CrossRef]

- Aggarwal, C.C.; Ashish, N.; Sheth, A. The internet of things: A survey from the data-centric perspective. Managing and Mining Sensor Data 2013, 383–428. [Google Scholar]

- Alcacer, V.; Cruz-Machado, V. Scanning the industry 4.0: A literature review on technologies for manufacturing systems. Engineering Science and Technology, an International Journal 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Ali, E.; Gossaye, W. The effects of supply chain viability on supply chain performance and marketing performance in case of large manufacturing firm in Ethiopia. Brazilian Journal of Operations & Production Management 2023, 20, 1535. [Google Scholar]

- Ali, I.; Phan, H.M. Industry 4.0 technologies and sustainable warehousing: A systematic literature review and future research agenda. The International Journal of Logistics Management 2022, 33, 644–662. [Google Scholar] [CrossRef]

- Aljohani, A. Predictive analytics and machine learning for real-time supply chain risk mitigation and agility. Sustainability 2023, 15, 15088. [Google Scholar] [CrossRef]

- Allen, R.C. Why the industrial revolution was british: commerce, induced invention, and the scientific revolution 1. The Economic History Review 2011, 64, 357–384. [Google Scholar] [CrossRef]

- Allioui, H.; Mourdi, Y.; others. Unleashing the potential of AI: Investigating cutting-edge technologies that are transforming businesses. International Journal of Computer Engineering and Data Science (IJCEDS) 2023, 3, 1–12. [Google Scholar]

- Ammar, M.; Haleem, A.; Javaid, M.; Walia, R.; Bahl, S. Improving material quality management and manufacturing organizations system through Industry 4.0 technologies. Materials Today: Proceedings 2021, 45, 5089–5096. [Google Scholar] [CrossRef]

- Azevedo, F.; Reis, J.L. Big data analysis in supply chain management in Portuguese SMEs “leader excellence”. New Knowledge in Information Systems and Technologies 2019, 2, 621–632. [Google Scholar]

- Baah, C.; Opoku Agyeman, D.; Acquah, I.S. K.; Agyabeng-Mensah, Y.; Afum, E.; Issau, K.; Ofori, D.; Faibil, D. Effect of information sharing in supply chains: understanding the roles of supply chain visibility, agility, collaboration on supply chain performance. Benchmarking: An International Journal 2022, 29, 434–455. [Google Scholar] [CrossRef]

- Beier, G.; Kiefer, J.; Knopf, J. Potentials of big data for corporate environmental management: A case study from the German automotive industry. Journal of Industrial Ecology 2022, 26, 336–349. [Google Scholar] [CrossRef]

- Blome, C.; Schoenherr, T.; Rexhausen, D. Antecedents and enablers of supply chain agility and its effect on performance: a dynamic capabilities perspective. International Journal of Production Research 2013, 51, 1295–1318. [Google Scholar] [CrossRef]

- Bonilla, S.H.; Silva, H.R. O.; da Silva, M.; Franco Gonçalves, R.; Sacomano, J.B. Industry 4.0 and sustainability implications: A scenario-based analysis of the impacts and challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef]

- Borges Migliavaca, C.; Stein, C.; Colpani, V.; Barker, T.H.; Munn, Z.; Falavigna, M.; (PERSyst), P.E. R.-. -S. R. M. G. How are systematic reviews of prevalence conducted? A methodological study. BMC Medical Research Methodology 2020, 20, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Bramer, W.M.; De Jonge, G.B.; Rethlefsen, M.L.; Mast, F.; Kleijnen, J. A systematic approach to searching: an efficient and complete method to develop literature searches. Journal of the Medical Library Association: JMLA 2018, 106, 531. [Google Scholar] [CrossRef]

- Brandon-Jones, E.; Squire, B.; Autry, C.W.; Petersen, K.J. A contingent resource-based perspective of supply chain resilience and robustness. Journal of Supply Chain Management 2014, 50, 55–73. [Google Scholar] [CrossRef]

- Broo, D.G.; Schooling, J. A framework for using data as an engineering tool for sustainable cyber-physical systems. IEEE Access 2021, 9, 22876–22882. [Google Scholar] [CrossRef]

- Brusset, X. Does supply chain visibility enhance agility? International Journal of Production Economics 2016, 171, 46–59. [Google Scholar] [CrossRef]

- Cadden, T.; McIvor, R.; Cao, G.; Treacy, R.; Yang, Y.; Gupta, M.; Onofrei, G. Unlocking supply chain agility and supply chain performance through the development of intangible supply chain analytical capabilities. International Journal of Operations & Production Management 2022, 42, 1329–1355. [Google Scholar]

- Camarinha-Matos, L.M.; Fornasiero, R.; Ramezani, J.; Ferrada, F. Collaborative networks: A pillar of digital transformation. Applied Sciences 2019, 9, 5431. [Google Scholar] [CrossRef]

- Carroll, C.; Booth, A. Quality assessment of qualitative evidence for systematic review and synthesis: is it meaningful, and if so, how should it be performed? Research Synthesis Methods 2015, 6, 149–154. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, H.; Naghshineh, B.; Govindan, K.; Cruz-Machado, V. The resilience of on-time delivery to capacity and material shortages: An empirical investigation in the automotive supply chain. Computers & Industrial Engineering 2022, 171, 108375. [Google Scholar]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. International Journal of Production Economics 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Dash, R.; McMurtrey, M.; Rebman, C.; Kar, U.K. Application of artificial intelligence in automation of supply chain management. Journal of Strategic Innovation and Sustainability 2019, 14, 43–53. [Google Scholar]

- de Assis Santos, L.; Marques, L. Big data analytics for supply chain risk management: research opportunities at process crossroads. Business Process Management Journal 2022, 28, 1117–1145. [Google Scholar] [CrossRef]

- Denavs, I. (2020). Mitigating Transnational Passport Threats: A Mixed Methods Study.

- Doetzer, M. The role of national culture on supply chain visibility: Lessons from Germany, Japan, and the USA. International Journal of Production Economics 2020, 230, 107829. [Google Scholar] [CrossRef]

- Dubey, R. Unleashing the potential of digital technologies in emergency supply chain: the moderating effect of crisis leadership. Industrial Management & Data Systems 2023, 123, 112–132. [Google Scholar]

- Dubey, R.; Altay, N.; Gunasekaran, A.; Blome, C.; Papadopoulos, T.; Childe, S.J. Supply chain agility, adaptability and alignment: empirical evidence from the Indian auto components industry. International Journal of Operations & Production Management 2018, 38, 129–148. [Google Scholar]

- Dubey, R.; Bryde, D.J.; Foropon, C.; Graham, G.; Giannakis, M.; Mishra, D.B. Agility in humanitarian supply chain: An organizational information processing perspective and relational view. Annals of Operations Research 2022, 319, 559–579. [Google Scholar] [CrossRef]

- Dubey, R.; Bryde, D.J.; Foropon, C.; Tiwari, M.; Dwivedi, Y.; Schiffling, S. An investigation of information alignment and collaboration as complements to supply chain agility in humanitarian supply chain. International Journal of Production Research 2021, 59, 1586–1605. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Fosso Wamba, S.; Roubaud, D.; Foropon, C. Empirical investigation of data analytics capability and organizational flexibility as complements to supply chain resilience. International Journal of Production Research 2021, 59, 110–128. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Blome, C.; Luo, Z. Antecedents of resilient supply chains: An empirical study. IEEE Transactions on Engineering Management 2017, 66, 8–19. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Luo, Z.; Roubaud, D. Upstream supply chain visibility and complexity effect on focal company’s sustainable performance: Indian manufacturers’ perspective. Annals of Operations Research 2020, 290, 343–367. [Google Scholar] [CrossRef]

- Dubey, R.; Luo, Z.; Gunasekaran, A.; Akter, S.; Hazen, B.T.; Douglas, M.A. Big data and predictive analytics in humanitarian supply chains: Enabling visibility and coordination in the presence of swift trust. The International Journal of Logistics Management 2018, 29, 485–512. [Google Scholar] [CrossRef]

- Durach, C.F.; Kembro, J.; Wieland, A. A new paradigm for systematic literature reviews in supply chain management. Journal of Supply Chain Management 2017, 53, 67–85. [Google Scholar] [CrossRef]

- Eckstein, D.; Goellner, M.; Blome, C.; Henke, M. The performance impact of supply chain agility and supply chain adaptability: the moderating effect of product complexity. International Journal of Production Research 2015, 53, 3028–3046. [Google Scholar] [CrossRef]

- Emon, M.M. H.; Khan, T.; Siam, S.A. J. Quantifying the influence of supplier relationship management and supply chain performance. Brazilian Journal of Operations & Production Management 2024, 21, 2015. [Google Scholar] [CrossRef]

- Engelhardt-Nowitzki, C.; Markl, E. The Future of Industrial Supply Chains: A Heterarchic System Architecture for Digital Manufacturing? Data-Centric Business and Applications: Evolvements in Business Information Processing and Management 2019, 1, 217–241. [Google Scholar]

- Fatorachian, H.; Kazemi, H. Impact of Industry 4.0 on supply chain performance. Production Planning & Control 2021, 32, 63–81. [Google Scholar]

- Fayezi, S.; Zutshi, A.; O’Loughlin, A. Understanding and development of supply chain agility and flexibility: a structured literature review. International Journal of Management Reviews 2017, 19, 379–407. [Google Scholar] [CrossRef]

- Fernando, Y.; Bee, P.S.; Jabbour, C.J. C.; Thome, A.M. T. Understanding the effects of energy management practices on renewable energy supply chains: Implications for energy policy in emerging economies. Energy Policy 2018, 118, 418–428. [Google Scholar] [CrossRef]

- Fletcher, S.R.; Johnson, T.; Adlon, T.; Larreina, J.; Casla, P.; Parigot, L.; Alfaro, P.J.; del Mar Otero, M. Adaptive automation assembly: Identifying system requirements for technical efficiency and worker satisfaction. Computers & Industrial Engineering 2020, 139, 105772. [Google Scholar]

- Gadekar, R.; Sarkar, B.; Gadekar, A. Investigating the relationship among Industry 4.0 drivers, adoption, risks reduction, and sustainable organizational performance in manufacturing industries: An empirical study. Sustainable Production and Consumption 2022, 31, 670–692. [Google Scholar] [CrossRef]

- Garbellano, S.; Da Veiga, M. do R. Dynamic capabilities in Italian leading SMEs adopting industry 4.0. Measuring Business Excellence 2019, 23, 472–483. [Google Scholar] [CrossRef]

- Garcia Alcaraz, J.L.; Morales Garcia, A.S.; Diaz Reza, J.R.; Blanco Fernandez, J.; Jimenez Macias, E.; i Vidal, R. Machinery lean manufacturing tools for improved sustainability: the Mexican maquiladora industry experience. Mathematics 2022, 10, 1468. [Google Scholar] [CrossRef]

- Ghadge, A.; Er Kara, M.; Moradlou, H.; Goswami, M. The impact of Industry 4.0 implementation on supply chains. Journal of Manufacturing Technology Management 2020, 31, 669–686. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: a strategic roadmap toward Industry 4.0. Journal of Manufacturing Technology Management 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Foroughi, B.; Tseng, M.-L.; Nikbin, D.; Khanfar, A.A. A. Industry 4.0 digital transformation and opportunities for supply chain resilience: a comprehensive review and a strategic roadmap. Production Planning & Control.

- Gligor, D.; Gligor, N.; Holcomb, M.; Bozkurt, S. Distinguishing between the concepts of supply chain agility and resilience: A multidisciplinary literature review. The International Journal of Logistics Management 2019, 30, 467–487. [Google Scholar] [CrossRef]

- Gligor, D.M.; Esmark, C.L.; Holcomb, M.C. Performance outcomes of supply chain agility: when should you be agile? Journal of Operations Management 2015, 33, 71–82. [Google Scholar] [CrossRef]

- Golgeci, I.; Gligor, D.M. The interplay between key marketing and supply chain management capabilities: the role of integrative mechanisms. Journal of Business & Industrial Marketing 2017, 32, 472–483. [Google Scholar]

- Hasan, M.M.; Jalal Siam, S.A.; Haque, A. THE SIGNIFICANCE OF CUSTOMER SERVICE IN ESTABLISHING TRUST AND ENHANCING THE REPUTATION OF THE BANKING INDUSTRY IN BANGLADESH. Business and Economics in Developing Countries 2023, 1, 71–75. [Google Scholar] [CrossRef]

- He, L.; Xue, M.; Gu, B. Internet-of-things enabled supply chain planning and coordination with big data services: Certain theoretic implications. Journal of Management Science and Engineering 2020, 5, 1–22. [Google Scholar] [CrossRef]

- Hmamed, H.; Cherrafi, A.; Benghabrit, A.; Tiwari, S.; Sharma, P. (2023). The adoption of I4. 0 technologies for a sustainable and circular supply chain: an industry-based SEM analysis from the textile sector. Business Strategy and the Environment.

- Hofmann, E.; Rusch, M. Industry 4.0 and the current status as well as future prospects on logistics. Computers in Industry 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Hsiao, W.W.-W.; Lin, J.-C.; Fan, C.-T.; Chen, S.S.-S. Precision health in Taiwan: A data-driven diagnostic platform for the future of disease prevention. Computational and Structural Biotechnology Journal 2022, 20, 1593–1602. [Google Scholar] [CrossRef]

- Huang, K.; Wang, K.; Lee, P.K. C.; Yeung, A.C. L. The impact of industry 4.0 on supply chain capability and supply chain resilience: A dynamic resource-based view. International Journal of Production Economics 2023, 262, 108913. [Google Scholar] [CrossRef]

- Iftikhar, A.; Ali, I.; Arslan, A.; Tarba, S. Digital innovation, data analytics, and supply chain resiliency: A bibliometric-based systematic literature review. Annals of Operations Research 2022, 1–24. [Google Scholar] [CrossRef]

- Imtiaz, M.; Hamid, A.B. A.; Nadarajah, D.; Mehmood, S.A.; Ahmad, M.K. Enhancing SMEs Performance through Supply Chain Collaboration and moderation of Supply Chain Technology Implementation. Brazilian Journal of Operations & Production Management 2023, 20, 1494. [Google Scholar]

- Irfan, I.; Sumbal, M.S. U. K.; Khurshid, F.; Chan, F.T. S. Toward a resilient supply chain model: critical role of knowledge management and dynamic capabilities. Industrial Management & Data Systems 2022, 122, 1153–1182. [Google Scholar]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Production Planning & Control 2021, 32, 775–788. [Google Scholar]

- Jajja, M.S. S.; Chatha, K.A.; Farooq, S. Impact of supply chain risk on agility performance: Mediating role of supply chain integration. International Journal of Production Economics 2018, 205, 118–138. [Google Scholar] [CrossRef]

- Juan, S.-J.; Li, E.Y.; Hung, W.-H. An integrated model of supply chain resilience and its impact on supply chain performance under disruption. The International Journal of Logistics Management 2022, 33, 339–364. [Google Scholar] [CrossRef]

- Kagermann, H. (2014). Change through digitization—Value creation in the age of Industry 4.0. In Management of permanent change (pp. 23–45). Springer.

- Kalaiarasan, R.; Olhager, J.; Agrawal, T.K.; Wiktorsson, M. The ABCDE of supply chain visibility: A systematic literature review and framework. International Journal of Production Economics 2022, 248, 108464. [Google Scholar] [CrossRef]

- Kang, M.; Stephens, A. Supply chain resilience and operational performance amid COVID-19 supply chain interruptions: Evidence from South Korean manufacturers. Uncertain Supply Chain Management 2022, 10, 383–398. [Google Scholar] [CrossRef]

- Kaur, R.; Chana, I.; Bhattacharya, J. Data deduplication techniques for efficient cloud storage management: a systematic review. The Journal of Supercomputing 2018, 74, 2035–2085. [Google Scholar] [CrossRef]

- Kim, S.T.; Lee, H.-H.; Lim, S. The Effects of Green SCM Implementation on Business Performance in SMEs: A Longitudinal Study in Electronics Industry. Sustainability 2021, 13, 11874. [Google Scholar] [CrossRef]

- Kurt, R. Industry 4.0 in terms of industrial relations and its impacts on labour life. Procedia Computer Science 2019, 158, 590–601. [Google Scholar] [CrossRef]

- Le, V.; Vu, X.-B. B.; Nghiem, S. Technical efficiency of small and medium manufacturing firms in Vietnam: A stochastic meta-frontier analysis. Economic Analysis and Policy 2018, 59, 84–91. [Google Scholar] [CrossRef]

- Lee, S.-Y. Sustainable supply chain management, digital-based supply chain integration, and firm performance: a cross-country empirical comparison between South Korea and Vietnam. Sustainability 2021, 13, 7315. [Google Scholar] [CrossRef]

- Li, C.; Chen, Y.; Shang, Y. A review of industrial big data for decision making in intelligent manufacturing. Engineering Science and Technology, an International Journal 2022, 29, 101021. [Google Scholar] [CrossRef]

- Livoreil, B.; Glanville, J.; Haddaway, N.R.; Bayliss, H.; Bethel, A.; de Lachapelle, F.F.; Robalino, S.; Savilaakso, S.; Zhou, W.; Petrokofsky, G.; others. Systematic searching for environmental evidence using multiple tools and sources. Environmental Evidence 2017, 6, 1–14. [Google Scholar] [CrossRef]

- Lohmer, J.; Bugert, N.; Lasch, R. Analysis of resilience strategies and ripple effect in blockchain-coordinated supply chains: An agent-based simulation study. International Journal of Production Economics 2020, 228, 107882. [Google Scholar] [CrossRef] [PubMed]

- Lyu, T.; Guo, Y.; Geng, Q. Research on paths of opportunistic behavior avoidance and performance improvement in food supply chain from the perspective of social control. Frontiers in Psychology 2023, 13, 1101543. [Google Scholar] [CrossRef]

- Mariani, M.; Borghi, M. Industry 4.0: A bibliometric review of its managerial intellectual structure and potential evolution in the service industries. Technological Forecasting and Social Change 2019, 149, 119752. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How do scholars approach the circular economy? A systematic literature review. Journal of Cleaner Production 2018, 178, 703–722. [Google Scholar] [CrossRef]

- MILLER, S.M. (2023). Tracing the twenty-year evolution of developing AI for eye screening in Singapore: A master chronology of SiDRP, SELENA+ and EyRis.

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The industrial management of SMEs in the era of Industry 4.0. International Journal of Production Research 2018, 56, 1118–1136. [Google Scholar] [CrossRef]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; Group, P.-P. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015 statement. Systematic Reviews 2015, 4, 1–9. [Google Scholar] [CrossRef]

- Mubarik, M.S.; Naghavi, N.; Mubarik, M.; Kusi-Sarpong, S.; Khan, S.A.; Zaman, S.I.; Kazmi, S.H. A. Resilience and cleaner production in industry 4.0: Role of supply chain mapping and visibility. Journal of Cleaner Production 2021, 292, 126058. [Google Scholar] [CrossRef]

- Nagy, J.; Olah, J.; Erdei, E.; Mate, D.; Popp, J. The role and impact of Industry 4.0 and the internet of things on the business strategy of the value chain—the case of Hungary. Sustainability 2018, 10, 3491. [Google Scholar] [CrossRef]

- Nawijn, F.; Ham, W.H. W.; Houwert, R.M.; Groenwold, R.H. H.; Hietbrink, F.; Smeeing, D.P. J. Quality of reporting of systematic reviews and meta-analyses in emergency medicine based on the PRISMA statement. BMC Emergency Medicine 2019, 19, 1–8. [Google Scholar] [CrossRef]

- Ncubukezi, T. Human errors: A cybersecurity concern and the weakest link to small businesses. Proceedings of the 17th International Conference on Information Warfare and Security 2022, 395. [Google Scholar]

- Ng, K.K. H.; Chen, C.-H.; Lee, C.K. M.; Jiao, J.R.; Yang, Z.-X. A systematic literature review on intelligent automation: Aligning concepts from theory, practice, and future perspectives. Advanced Engineering Informatics 2021, 47, 101246. [Google Scholar] [CrossRef]

- Ng, T.C.; Lau, S.Y.; Ghobakhloo, M.; Fathi, M.; Liang, M.S. The application of industry 4.0 technological constituents for sustainable manufacturing: A content-centric review. Sustainability 2022, 14, 4327. [Google Scholar] [CrossRef]

- Nottbrock, C.; Van Looy, A.; De Haes, S. Impact of digital Industry 4.0 innovations on interorganizational value chains: a systematic literature review. Business Process Management Journal 2023, 29, 43–76. [Google Scholar] [CrossRef]

- Patel, B.S.; Nagariya, R.; Singh, R.K.; Sambasivan, M.; Yadav, D.K.; Vlachos, I.P. Development of the House of Collaborative Partnership to overcome supply chain disruptions: evidence from the textile industry in India. Production Planning & Control.

- Pereira, A.C.; Alves, A.C.; Arezes, P. Augmented reality in a lean workplace at smart factories: a case study. Applied Sciences 2023, 13, 9120. [Google Scholar] [CrossRef]

- Pereira, A.C.; Romero, F. A review of the meanings and the implications of the Industry 4.0 concept. Procedia Manufacturing 2017, 13, 1206–1214. [Google Scholar] [CrossRef]

- Pereira, M.M.; Frazzon, E.M. A data-driven approach to adaptive synchronization of demand and supply in omni-channel retail supply chains. International Journal of Information Management 2021, 57, 102165. [Google Scholar] [CrossRef]

- Petersen, K.; Vakkalanka, S.; Kuzniarz, L. Guidelines for conducting systematic mapping studies in software engineering: An update. Information and Software Technology 2015, 64, 1–18. [Google Scholar] [CrossRef]

- Pivoto, D.; Waquil, P.D.; Talamini, E.; Finocchio, C.P. S.; Dalla Corte, V.F.; de Vargas Mores, G. Scientific development of smart farming technologies and their application in Brazil. Information Processing in Agriculture 2018, 5, 21–32. [Google Scholar] [CrossRef]

- Pournader, M.; Ghaderi, H.; Hassanzadegan, A.; Fahimnia, B. Artificial intelligence applications in supply chain management. International Journal of Production Economics 2021, 241, 108250. [Google Scholar] [CrossRef]

- Praveena, A.; Bharathi, B. An approach to remove duplication records in healthcare dataset based on Mimic Deep Neural Network (MDNN) and Chaotic Whale Optimization (CWO). Concurrent Engineering 2021, 29, 58–67. [Google Scholar] [CrossRef]

- Purssell, E. Can the critical appraisal skills programme check-lists be used alongside grading of recommendations assessment, development and evaluation to improve transparency and decision-making? Journal of Advanced Nursing 2020, 76, 1082–1089. [Google Scholar] [CrossRef] [PubMed]

- Pussegoda, K.; Turner, L.; Garritty, C.; Mayhew, A.; Skidmore, B.; Stevens, A.; Boutron, I.; Sarkis-Onofre, R.; Bjerre, L.M.; Hróbjartsson, A.; others. Systematic review adherence to methodological or reporting quality. Systematic Reviews 2017, 6, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Qu, T.; Lei, S.P.; Wang, Z.Z.; Nie, D.X.; Chen, X.; Huang, G.Q. IoT-based real-time production logistics synchronization system under smart cloud manufacturing. The International Journal of Advanced Manufacturing Technology 2016, 84, 147–164. [Google Scholar] [CrossRef]

- Quigley, J.M.; Thompson, J.C.; Halfpenny, N.J.; Scott, D.A. Critical appraisal of nonrandomized studies—a review of recommended and commonly used tools. Journal of Evaluation in Clinical Practice 2019, 25, 44–52. [Google Scholar] [CrossRef] [PubMed]

- Reischauer, G. Industry 4.0 as policy-driven discourse to institutionalize innovation systems in manufacturing. Technological Forecasting and Social Change 2018, 132, 26–33. [Google Scholar] [CrossRef]

- Ren, S.; Zhang, Y.; Liu, Y.; Sakao, T.; Huisingh, D.; Almeida, C.M. V. B. A comprehensive review of big data analytics throughout product lifecycle to support sustainable smart manufacturing: A framework, challenges and future research directions. Journal of Cleaner Production 2019, 210, 1343–1365. [Google Scholar] [CrossRef]

- Richey Jr, R.G.; Morgan, T.R.; Lindsey-Hall, K.; Adams, F.G. A global exploration of big data in the supply chain. International Journal of Physical Distribution \& Logistics Management 2016, 46, 710–739. [Google Scholar]

- Roy, V. Contrasting supply chain traceability and supply chain visibility: are they interchangeable? The International Journal of Logistics Management 2021, 32, 942–972. [Google Scholar] [CrossRef]

- Salkin, C.; Oner, M.; Ustundag, A.; Cevikcan, E. A conceptual framework for Industry 4.0. Industry 4.0: Managing the Digital Transformation.

- Shibin, K.T.; Dubey, R.; Gunasekaran, A.; Hazen, B.; Roubaud, D.; Gupta, S.; Foropon, C. Examining sustainable supply chain management of SMEs using resource based view and institutional theory. Annals of Operations Research 2020, 290, 301–326. [Google Scholar] [CrossRef]

- Shin, B.; Lowry, P.B. A review and theoretical explanation of the ‘Cyberthreat-Intelligence (CTI) capability’that needs to be fostered in information security practitioners and how this can be accomplished. Computers & Security 2020, 92, 101761. [Google Scholar]

- Siddaway, A.P.; Wood, A.M.; Hedges, L.V. How to do a systematic review: a best practice guide for conducting and reporting narrative reviews, meta-analyses, and meta-syntheses. Annual Review of Psychology 2019, 70, 747–770. [Google Scholar] [CrossRef] [PubMed]

- Somapa, S.; Cools, M.; Dullaert, W. Characterizing supply chain visibility--a literature review. The International Journal of Logistics Management 2018, 29, 308–339. [Google Scholar] [CrossRef]

- Sousa, P.R. de, Barbosa, M.W.; Oliveira, L.K. de, Resende, P.T. V. de, Rodrigues, R.R.; Moura, M.T.; Matoso, D. Challenges, Opportunities, and lessons learned: Sustainability in Brazilian omnichannel retail. Sustainability 2021, 13, 666. [Google Scholar] [CrossRef]

- Thomes, P. (2022). Industry—Between Evolution and Revolution: A Historical Perspective. In Handbook Industry 4.0: Law, Technology, Society (pp. 1119–1138). Springer.

- Tran-Dang, H.; Krommenacker, N.; Charpentier, P.; Kim, D.-S. The Internet of Things for logistics: Perspectives, application review, and challenges. IETE Technical Review 2022, 39, 93–121. [Google Scholar] [CrossRef]

- Tse, Y.K.; Zhang, M.; Akhtar, P.; MacBryde, J. Embracing supply chain agility: an investigation in the electronics industry. Supply Chain Management: An International Journal 2016, 21, 140–156. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Bui, T.-D.; Lim, M.K.; Fujii, M.; Mishra, U. Assessing data-driven sustainable supply chain management indicators for the textile industry under industrial disruption and ambidexterity. International Journal of Production Economics 2022, 245, 108401. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Tran, T.P. T.; Ha, H.M.; Bui, T.-D.; Lim, M.K. Sustainable industrial and operation engineering trends and challenges Toward Industry 4.0: A data driven analysis. Journal of Industrial and Production Engineering 2021, 38, 581–598. [Google Scholar] [CrossRef]

- Vashisht, P.; Rani, N. Automation and the future of garment sector jobs in India. The Indian Journal of Labour Economics 2020, 63, 225–246. [Google Scholar] [CrossRef]

- Wan, J.; Li, X.; Dai, H.-N.; Kusiak, A.; Martinez-Garcia, M.; Li, D. Artificial-intelligence-driven customized manufacturing factory: key technologies, applications, and challenges. Proceedings of the IEEE 2020, 109, 377–398. [Google Scholar] [CrossRef]

- Waqas, M.; Honggang, X.; Ahmad, N.; Khan, S.A. R.; Ullah, Z.; Iqbal, M. Triggering sustainable firm performance, supply chain competitive advantage, and green innovation through lean, green, and agile supply chain practices. Environmental Science and Pollution Research 2021, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Williams, B.D.; Roh, J.; Tokar, T.; Swink, M. Leveraging supply chain visibility for responsiveness: The moderating role of internal integration. Journal of Operations Management.

- Won, J.Y.; Park, M.J. Smart factory adoption in small and medium-sized enterprises: Empirical evidence of manufacturing industry in Korea. Technological Forecasting and Social Change 2020, 157, 120117. [Google Scholar] [CrossRef]

- Woo, J.; Shin, S.-J.; Seo, W.; Meilanitasari, P. Developing a big data analytics platform for manufacturing systems: architecture, method, and implementation. The International Journal of Advanced Manufacturing Technology 2018, 99, 2193–2217. [Google Scholar] [CrossRef]

- Xia, W.; Jiang, H.; Feng, D.; Douglis, F.; Shilane, P.; Hua, Y.; Fu, M.; Zhang, Y.; Zhou, Y. A comprehensive study of the past, present, and future of data deduplication. Proceedings of the IEEE 2016, 104, 1681–1710. [Google Scholar] [CrossRef]

- Xing, W.; Hao, J.L.; Qian, L.; Tam, V.W. Y.; Sikora, K.S. Implementing lean construction techniques and management methods in Chinese projects: A case study in Suzhou, China. Journal of Cleaner Production 2021, 286, 124944. [Google Scholar] [CrossRef]

- Xu, L. Da, Xu, E.L.; Li, L. Industry 4.0: state of the art and future trends. International Journal of Production Research 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Yan, T.; Choi, T.Y.; Kim, Y.; Yang, Y. A theory of the nexus supplier: A critical supplier from a network perspective. Journal of Supply Chain Management 2015, 51, 52–66. [Google Scholar] [CrossRef]

- Yao, X.; Zhou, J.; Lin, Y.; Li, Y.; Yu, H.; Liu, Y. Smart manufacturing based on cyber-physical systems and beyond. Journal of Intelligent Manufacturing 2019, 30, 2805–2817. [Google Scholar] [CrossRef]

- Yildirim, N.; Gultekin, D.; Hurses, C.; Akman, A.M. (2023). Exploring national digital transformation and Industry 4.0 policies through text mining: a comparative analysis including the Turkish case. Journal of Science and Technology Policy Management.

- Yin, C.; Gu, H.; Zhang, S. Measuring technological collaborations on carbon capture and storage based on patents: A social network analysis approach. Journal of Cleaner Production 2020, 274, 122867. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, J.Z.; Cao, Y.; Kazancoglu, Y. Intelligent transformation of the manufacturing industry for Industry 4.0: Seizing financial benefits from supply chain relationship capital through enterprise green management. Technological Forecasting and Social Change 2021, 172, 120999. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, G.; Zou, Y.; Qin, S.; Fu, J. Review of job shop scheduling research and its new perspectives under Industry 4.0. Journal of Intelligent Manufacturing 2019, 30, 1809–1830. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, N.; Chen, Z.; Wu, L.; Li, X.; Zhang, L.; Di, L.; Gong, J.; Li, D. Geospatial sensor web: A cyber-physical infrastructure for geoscience research and application. Earth-Science Reviews 2018, 185, 684–703. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, Y.; Wang, B.; Zang, J. Human--cyber--physical systems (HCPSs) in the context of new-generation intelligent manufacturing. Engineering 2019, 5, 624–636. [Google Scholar] [CrossRef]

| Criteria | Inclusion Criteria | Exclusion Criteria |

|---|---|---|

| Publication period | Studies published between 2015, and 2023. | Studies published before 2015 or after the knowledge cutoff date in 2023. |

| Type of document | Peer-reviewed journal articles and conference proceedings. | Non-peer-reviewed documents, books, theses, and dissertations. |

| Type of study | Studies focusing on the integration of Industry 4.0 technologies in supply chain management. | Studies unrelated to Industry 4.0 or lacking a clear focus on supply chain management. |

| Language | Studies published in the English language. | Studies published in languages other than English. |

| Population | No specific population criteria. | Studies with a primary focus on populations unrelated to supply chain management or Industry 4.0 technologies. |

| Research topic | Studies examining the impact of Industry 4.0 on both supply chain visibility and operational efficiency. | Studies not directly related to Industry 4.0 technologies, supply chain visibility, or operational efficiency. |

| Sl. | Authors/Year | Methodology | Country/ Continent | Findings |

|---|---|---|---|---|

| 1. | Fernando et al., (2018) | Quantitative | Malaysia | Addressing knowledge gaps and fostering technological collaboration between multinational and local firms improves energy efficiency for businesses. Initiatives include converting waste into energy, empowering local companies to generate renewable energy within their supply chain networks. |

| 2. | Dubey et al., (2020) | Quantitative (Survey) | India | Supply chain visibility (SCV) significantly influences social and environmental performance under the moderation effect of product complexity in India. |

| 3. | Dubey et al., (2017) | Quantitative (Survey) | India | Reducing behavioral uncertainty amplifies the direct influence of trust and cooperation on bolstering supply chain resilience in India. Positive interaction effects strengthen the dynamics of trust, cooperation, and supply chain visibility. |

| 4. | Dubey et al., (2021) | Quantitative (PLS-SEM) | 24 countries | The synergy between tangible and intangible resources fosters collaboration among disaster relief partners, enhancing supply chain agility across 24 countries. Artificial intelligence-driven big data analytics and intergroup leadership shape humanitarian supply chain dynamics. |

| 5. | Dubey, (2023) | Quantitative (Survey) | India | Crisis leadership enhances the impact of digital technologies, improving information visibility and collaboration within emergency supply chain relief efforts in India. |

| 6. | Dubey et al., (2022) | Quantitative (PLS-SEM) | India | The integration of open innovation and relational view offers a theoretical framework for understanding the interplay among information sharing, supply chain visibility, swift-trust, commitment, and collaboration in humanitarian supply chains in India. |

| 7. | Dubey et al., (2018) | Quantitative (Survey) | India | Effective information sharing and supply chain connectivity resources positively impact supply chain visibility in India. Top management commitment amplifies synergy, enhancing supply chain agility, adaptability, and alignment. |

| 8. | Dubey, Luo, et al., (2018) | Quantitative (Survey) | 205 International Non-Government Organizations | Big Data Predictive Analytics (BDPA) significantly impacts visibility and coordination in humanitarian supply chains for 205 International Non-Government Organizations. Swift trust serves as a mediating factor, challenging its essential role in enhancing actor coordination. |

| 9. | Shibin et al., (2020) | Quantitative (PLS-SEM) | India | Coercive pressures, mediated by top management belief and participation, significantly influence resource selection, impacting supply chain connectivity and information sharing in India. Normative and mimetic pressures show no significant influence on top management participation. |

| 10. | Lyu et al., (2023) | Quantitative (PLS-SEM) | China | Social control effectively diminishes opportunistic behaviors among supply chain members in China. Information sharing with customers curtails opportunistic behaviors, while sharing with suppliers enhances overall supply chain performance. |

| 11. | Brusset, (2016) | Quantitative (Survey) | France | External and internal managerial processes contribute to enhanced agility in France. Limited impact observed from supply chain visibility processes, emphasizing the role of unexplored higher-level processes and routines. |

| 12. | Dubey, Gunasekaran, et al., (2021) | Quantitative (PLS-SEM) | India | Data analytics capability enhances supply chain resilience in India. Big data access, improved data processing capabilities, and human skills contribute to a competitive advantage through effective coordination, domain knowledge, and data science. |

| 13. | Somapa et al., (2018) | Systematic Literature Review (SLR) | - | Supply Chain Visibility (SCV) attributes contribute to benefits surpassing operational efficiency through information accessibility, quality, and usefulness. A process-oriented perspective underscores the correlation between SCV effectiveness and enhanced business performance. |

| 14. | Williams et al., (2013) | Quantitative (Survey) | International participants | Higher supply chain visibility requires a strong organizational information processing capability. Positive association between supply chain visibility and responsiveness is evident with high internal integration. |

| 15. | Baah et al., (2022) | Quantitative (Survey) | Taiwan | Supply chain visibility plays a pivotal role in bolstering reconfigurability and performance in Taiwan. Emphasizes the critical contribution of visibility for learning, coordinating, and integrating. |

| 16. | Baah et al., (2022) | Quantitative (PLS-SEM) | Ghana | Information sharing significantly boosts supply chain visibility, collaboration, agility, and overall performance in Ghana. Enhanced visibility positively influences collaboration, agility, and performance. |

| 17. | Juan et al., (2022) | Quantitative (Structured Equation Modeling) | Taiwan | Supply Chain Complexity (SCC) serves as an external catalyst for Supply Chain Resilience (SCRES) in Taiwan. Supply Chain (SC) flexibility, shaped by SC velocity and visibility, emerges as the sole contributor to SC agility. |

| 18. | Eckstein et al., (2015) | Quantitative (Hierarchical Regression) | Germany | Supply chain agility and adaptability have a positive impact on cost and operational performance in Germany. Product complexity enhances the effects of adaptability. |

| 19. | Cadden et al., (2022) | Hypotheses Testing and Moderation Analysis | UK | Environmental dynamism significantly influences three key Business Divergence Capabilities (BDCs) in the UK. Velocity dimension positively impacts Supply Chain Agility (SCAG), moderated by supply chain organizational learning and data-driven culture. |

| 20. | Jajja et al., (2018) | Quantitative (SEM) | Europe, Aisa, Americas | Heightened supply chain risk correlates positively with supplier and customer integration in Europe, Asia, and the Americas. Integrations positively influence agility performance, acting as mediators between supply chain risk, internal integration, and agility performance. |

| 21. | Gligor et al., (2015) | Non-experimental Survey | - | Higher levels of FSCA positively correlate with increased effectiveness in meeting customer requirements in an international context. The relationship between FSCA and costs is stronger in dynamic and complex settings. |

| 22. | Blome et al., (2013) | Quantitative (PLS) | Germany | Supply- and demand-side competence impact supply chain agility in Germany. Process compliance moderates the relationship between competence and agility. |

| 23. | Waqas et al., (2021) | Structural Equation Modeling (SEM) | China | Locally Grown Agri-food Supply Chain (LGA-SC) practices positively associate with Governance Integrity (GI), Supply Chain Resilience (SCR), Strategic Collaborative Performance Advantage (SCPA), and Strategic Financial Performance (SFP) in China. GI and SCR mediate the relationship between LGA-SC practices and SCPA. |

| 24. | Fayezi et al., (2017) | Secondary Data Analysis (Documentary Research) | - | Successful relationship integration with key partners is crucial for overcoming control dissipation in supply chains. Prioritizing relationship integration in agility and flexibility programs enhances overall supply chain performance. |

| 25. | Tse et al., (2016) | Quantitative (SEM) | China | Supply chain integration and external learning contribute positively to supply chain agility in China. Supply chain agility fully mediates the impact of integration and external learning on overall performance. |

| 26. | D. Gligor et al., (2019) | Multidisciplinary Literature Review | - | Agility and resilience share common dimensions, such as flexibility, speed/acceleration, and environmental scanning. They also have distinct characteristics, highlighting the need for both in supply chain operations. |

| 27. | Roy, (2021) | Systematic Literature Review (SLR) | - | Enhancing supply chain traceability is essential for superior visibility, a critical precursor for effectively coordinating modern supply chains and gaining a competitive edge. |

| 28. | Brandon-Jones et al., (2014) | Quantitative (Survey) | UK | Enhanced connectivity and information sharing lead to improved visibility, subsequently bolstering supply chain resilience and robustness in the UK. Supply base scale moderates this relationship. |

| 29. | Dalenogare et al., (2018) | Mixed-Methods Survey and Case Studies | United States | Positive correlation identified between the implementation of Industry 4.0 technologies and supply chain efficiency in the United States. |

| 30. | Wan et al., (2020) | Qualitative Interviews and Simulation | China | Impact of AI-driven automation in Chinese manufacturing: Increased production speed and reduced errors. |

| 31. | Pereira and Frazzon, (2021) | Quantitative Analysis of IoT Data | Brazil | Integration of IoT devices in Brazilian supply chains enhances real-time monitoring, reducing lead times and minimizing stockouts. |

| 32. | Won and Park, (2020) | Comparative Case Study | South Korea | Adoption of Industry 4.0 in South Korean manufacturing results in improved production flexibility and adaptability to market changes. |

| 33. | Beier, Kiefer and Knopf, (2022) | Experimental Design and Analytics | Germany | Big data analytics in German logistics significantly reduces operational costs through predictive maintenance. |

| 34. | Doetzer, (2020) | Cross-sectional Survey | Japan | Level of Industry 4.0 adoption among Japanese companies positively associated with overall supply chain visibility. |

| 35. | Garcia Alcaraz et al., (2022) | Longitudinal Analysis | Mexico | Evolution of Industry 4.0 technologies in the Mexican automotive sector enhances production efficiency and reduces downtime. |

| 36. | Ng et al., (2021) | Case-Control Study and AI Simulation | Singapore | AI simulations analyze the impact of automation on the supply chain in Singapore, identifying a significant reduction in lead times. |

| 37. | Garbellano and Da Veiga, (2019) | Ethnographic Observations | Italy | Ethnographic studies in Italian manufacturing plants illustrate the transformative impact of automation on worker roles and production processes. |

| 38. | Irfan et al., (2022) | System Dynamics Modeling | Bangladesh | System dynamics modeling assesses the long-term effects of Industry 4.0 adoption in Bangladesh, highlighting increased operational resilience. |

| 39. | He, Xue and Gu, (2020) | Cross-Functional Collaborative Research | China | Collaborative impact of IoT and AI in the Chinese electronics supply chain results in improved demand forecasting accuracy and reduced stockouts. |

| 40. | Kang & Stephens, (2022) | Survey and Comparative Analysis | South Korea | Surveyed South Korean manufacturing firms, finding a positive relationship between Industry 4.0 adoption and improvements in supply chain visibility and operational efficiency. |

| 41. | Carvalho et al., (2022) | Longitudinal Case Studies | Portugal | Longitudinal case studies in Portuguese logistics companies indicate that the integration of Industry 4.0 technologies enhances overall supply chain visibility. |

| 42. | Lohmer et al., (2020) | Agent-Based Modeling and Simulation | United States | Agent-based modeling simulates the impact of automation on the U.S. retail supply chain, demonstrating increased efficiency and reduced lead times. |

| 43. | Le et al., (2018) | Comparative Analysis of Automation | Vietnam | Compared automation levels in Vietnamese manufacturing plants, showing a positive correlation between higher automation and improved operational efficiency. |

| 44. | Hsiao et al., (2022) | Experimental Design and Surveys | Taiwan | Adoption of AI-driven robotics in Taiwanese semiconductor manufacturing leads to enhanced production efficiency and reduced defect rates. |

| 45. | Pivoto et al., (2018) | Qualitative Case Studies | Brazil | Exploration of the implementation of IoT in Brazilian agribusiness reveals improved traceability and real-time monitoring of supply chain activities. |

| 46. | Gadekar et al., (2022) | Longitudinal Observations and Analytics | India | Longitudinally observed the integration of Industry 4.0 technologies in the Indian pharmaceutical supply chain, showcasing reduced lead times and improved regulatory compliance. |

| 47. | Yildirim et al., (2023) | Cross-National Comparative Analysis | South Korea, Germany | Cross-national analysis comparing Industry 4.0 adoption in South Korean and German automotive industries. Highlights differences in approaches and commonalities in efficiency gains. |

| 48. | Zhang et al., (2019) | Simulation Modeling and Interviews | China | Simulation modeling and interviews assess the impact of AI on production scheduling in Chinese manufacturing, showcasing optimized scheduling and resource allocation. |

| 49. | Denavs, (2020) | Mixed-Methods Approach | Mexico | Mixed-methods approach studies the implementation of Industry 4.0 in the Mexican aerospace sector, revealing improved supply chain visibility and streamlined processes. |

| 50. | Vashisht & Rani, (2020) | Comparative Analysis of Robotics | India | Comparative analysis of robotic automation in the Indian textile industry demonstrates a substantial reduction in production time and increased product quality. |

| 51. | Yin et al., (2020) | Network Analysis and Surveys | Japan | Network analysis evaluates the collaborative impact of Industry 4.0 technologies on Japanese manufacturing networks, revealing increased connectivity and knowledge-sharing. |

| 52. | Azevedo & Reis, (2019) | Case-Control Study and Analytics | Portugal | Case-control study and analytics investigate the adoption of big data analytics in Portuguese logistics companies, indicating improved decision-making and resource optimization. |

| 53. | Yu et al., (2021) | Longitudinal Observations and Surveys | China | Longitudinal observations and surveys assess the evolution of Industry 4.0 in Chinese electronics manufacturing, showcasing increased production flexibility and adaptability. |

| 54. | Tran-Dang et al., (2022) | Comparative Case Studies and Interviews | South Korea | Comparative case studies and interviews explore the implementation of IoT in South Korean logistics companies, highlighting improved asset tracking and reduced transit times. |

| 55. | de Assis Santos & Marques, (2022) | Mixed-Methods Research | Brazil | Mixed-methods research assesses the impact of Industry 4.0 on Brazilian automotive supply chains, revealing enhanced agility and responsiveness to market fluctuations. |

| 56. | Kim et al., (2021) | Longitudinal Analysis and Surveys | South Korea | Longitudinal analysis of Industry 4.0 adoption in South Korean semiconductor manufacturing shows a positive impact on production efficiency and reduced error rates. |

| 57. | Sousa et al., (2021) | Qualitative Interviews and Analytics | Brazil | Qualitative interviews and analytics explore the implementation of big data analytics in Brazilian retail supply chains, indicating improved demand forecasting accuracy and inventory management. |

| 58. | MILLER, (2023) | Case-Control Study and Simulation | Singapore | Case-control study and simulations investigate the effects of AI-driven automation on the efficiency of Singaporean pharmaceutical supply chains, showing decreased lead times and increased capacity utilization. |

| 59. | Fletcher et al., (2020) | Comparative Analysis of Robotics | Germany | Comparative analysis of robotic automation in German automotive manufacturing demonstrates a reduction in production costs and enhanced worker safety. |

| 60. | Yin et al., (2020) | Network Analysis and Longitudinal Observations | Japan | Network analysis and longitudinal observations evaluate the collaborative impact of Industry 4.0 technologies on Japanese manufacturing networks, revealing increased connectivity and knowledge-sharing. |

| 61. | A. C. Pereira et al., (2023) | Mixed-Methods Research | Portugal | Mixed-methods research studies the adoption of IoT in Portuguese maritime logistics, showcasing improved tracking and monitoring of maritime assets and shipments. |

| 62. | Huang et al., (2023) | Cross-Sectional Surveys and Analytics | China | Cross-sectional surveys and analytics in Chinese electronics manufacturing assess the impact of IoT on production efficiency, highlighting improved quality control and reduced downtime. |

| 63. | Patel et al., (2022) | Agent-Based Modeling and Interviews | India | Agent-based modeling and interviews simulate the effects of AI-driven automation on the Indian textile industry, demonstrating increased production output and decreased defect rates. |

| 64. | Lee, (2021) | Longitudinal Observations and Analytics | South Korea | Longitudinal observations and analytics examine the effects of big data analytics in South Korean logistics companies, indicating enhanced decision-making capabilities and improved supply chain visibility. |

| 65. | Richey Jr et al., (2016) | Comparative Case Studies | China | Comparative case studies evaluate the implementation of automation in Chinese manufacturing, revealing increased production efficiency and reduced lead times. |

| 66. | Xing et al., (2021) | Network Analysis and Surveys | Portugal | Network analysis and surveys assess the collaborative impact of Industry 4.0 technologies on Portuguese logistics networks, revealing increased connectivity and information exchange. |

| 67. | Camarinha-Matos et al., (2019) | Mixed-Methods Research | United States | Mixed-methods research studies the integration of AI and robotics in the U.S. aerospace sector, showcasing improved efficiency and reduced operational costs. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).