1. Introduction

The term energy, which is a familiar in our daily life, is defined simply as the ability or capacity to do work. Energy is required for sustaining and improving the quality of life. Energy grows food and keeps people lively. Energy saving is more important in this world to keep the nonrenewable sources of energies for our next generations. More percent of the energy consumption is mainly going for domestic transport and goods transport. Most of the energy requirement is meeting by only petroleum products which is not renewable source of energy. Since petrol and diesel resources are reducing in all over the world including Oman, it is difficult to use this source for all sectors. So, use of solar energy is very important in all sectors because of the renewable nature and availability in all over the world.

The main energy consuming sectors can be divided into four, they are

Agricultural sector

Industrial sector

Transport sector

Domestic sector

In Oman, most of the energy is being consumed in domestic sector, comparing to the other developed countries, like America, Europe continent countries where the consumption is mostly in industrial factor. Overall, Industrial sector is consuming major portion of the petroleum product. Also, agriculture product price is going up because of the petroleum product price hike. It is very important to use the solar energy in agriculture including fishery areas to reduce the price of the food and other related items. This is the main reason of taking up this work and a cost effective solar dryer has been designed according to the Oman context.

1.1. Energy Crisis in the world

In recent years we have experienced energy Crisis in many countries. Energy crisis is due to two reasons,

- ➢

The population growth of the world

- ➢

Increase of the standard of living of human beings and resulting increase of per capita energy consumption.

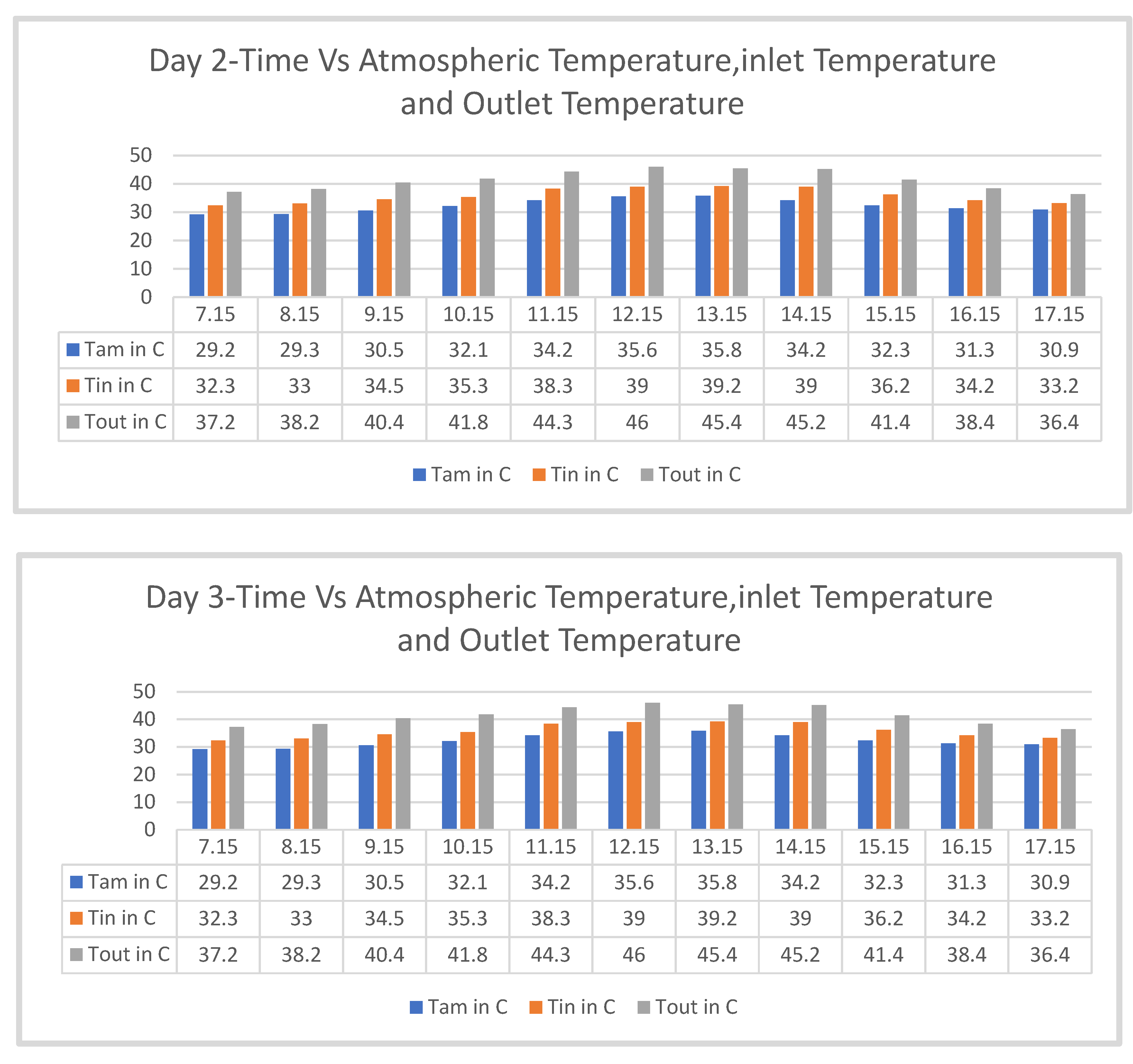

Assuming the present consumption of energy, it is estimated to be of 30 million megawatts, by the year 2030 A.D. However, the present pattern of consumption is more compared to the past, in which the relative energy consumption of countries remains the same, then per capita energy in developed countries remain much more than developing countries. If the standard of living in developing countries increases, the energy requirement in the world in the year 2030 will be much more estimated above. If present trend continues, the world in future will be more crowded than that of today. The conventional sources of energy are developing and may be exhausted by the end of the century or beginning of the next century. The percentage use of various sources for the total energy consumption in the world is given in the

Figure 1

While fossil fuels will be the main source for thermal power, there is fear that they will get exhausted eventually in the next century. Therefore, other systems based on non-conventional and renewable sources are being tried by many countries. These are the followings. Solar energy, Wind energy, Geothermal Energy, Nuclear energy, Bio-mass, Marine energy, Tidal and wave energy.

1.2. Solar Energy

Solar energy has the greatest potential of all the sources of renewable energy, it will be one of the most important supplies of energy especially when other sources in the country have depleted. The use of direct power from the sun’s radiation has many advantages. Solar power is plentifully available in Oman, even in regions remote from the sources of fossil fuels. It is essentially a non-depletable source of energy in comparison with fossil fuels or nuclear fission power and it is cost free in its original radiation form. Of course, there is a significant cost for the capital plant required for converting solar energy to other forms of energy. If solar energy is utilized locally, then need for transporting the energy is avoided. Also, solar power can be used in small units, as for an individual building or home. Solar devices hold promise for the developing world as well as for the economically developed country. Since the solar power burns no fuel, it causes no air or water pollution. The power from the sun intercepted by the earth is approximately 1.8x1011 MW, which is many times larger than the present consumption rate on earth of all commercial energy sources. Thus, in principle solar energy could supply all the present and future energy needs of the world on a continuing basis. The energy radiated by the sun on a bright sunny day is approximately 1 KW/m2 attempts have been made to make use of this energy in raising stem which may be used in driving the prime movers for the purpose of generation of electrical energy. The energy can be concentrated in solar furnaces, for example which can achieve temperature in the region of 500 degrees Celsius within an hour.

1.3. Fishery Sector in Oman

Fishery sector is one the main sector in Oman in giving job opportunities and there are more opportunities in this sector to produce young Omani entrepreneurs. Al Kalbaniyeh [4] stated that the fishery sector is one of the encouraging sectors that can contribute in developing Oman’s economy even though there are many challenges. He has discussed the requirements which should be provided by the government to expand the fishery sector. He also mentioned in his research paper that fishery sector may provide 29,000 new job opportunities to the young people of the Sultanate of Oman. The challenges in Oman’s fisheries sector are the traditional type fishing strategy and storage strategy and the technical gap (Amuthakkannan et al., 2023). There are lot of challenges in technology implementation in the fishery sector and overcoming weak technical capabilities. Chaudhry et al. [6] discussed the opportunities and challenges in the fishing industry of the Muscat governorate. The authors concluded that the lack of knowledge of Omani fishermen about technologies in fishery science is affecting the opportunities for fishing, marketing the captured fish and storing the fishes and also in drying the fishes to convert fresh fish into dry fish. So, it is clear that execution of modern technologies in Oman’s fishery sector will contribute a sustainable growth in the sector and also for the economic development of the nation.

The objective of the paper is given as follows

Development of parabolic solar concentrator.

Development of plate to receive concentrated solar power

To dry fishes to support fishery sector

To identify the effective dryness of fishes.

The first, key challenge in this project is to design and develop solar parabolic collector and the receiver plate. Then the setup as solar dryer. The second key challenge is to identify the quality and dryness of king fishes which is going to take as sample in this paper.

2. Literature Review

2.1. Review Related to Solar Dryer for Fishes

Since the application of solar dryer of this work is at fishermen site, the design should be robust and need to withstand for longer period. Also, it is required less skill to operate the system since the fishermen are not having high skill to understand the technologies. O. Kilanko et al. (2019) discussed in his paper about Design and Performance Evaluation of a Solar Dryer for agriculture purpose. As per the O.Kilanko (2019), the use of solar dryers for preservation of various crops is an area of growing interest for the agricultural sector. This is very useful for small holder farmers in locations of high solar insolation like North Central and Northern Nigeria. In this experiment, author dried the peppers i.e with 200g of scotch bonnet peppers, an average of 81.3% w.b. moisture content was removed from the scotch bonnet pepper within three weeks. He identified that the temperature of drying chamber was higher than the ambient temperature during most hours of the day. The efficiency of the dryer has an average of 28.4% for galvanized steel solar collector. Ag Sufiyan bin Abd Hamid et al. 2019 developed a large-scale solar dryer for drying natural fiber in Malaysia. The dryer is developed with many components such as solar thermal collector, heat exchanger and confine polycarbonate chamber. In the dryer average solar radiance recorded as 612.84 W/m

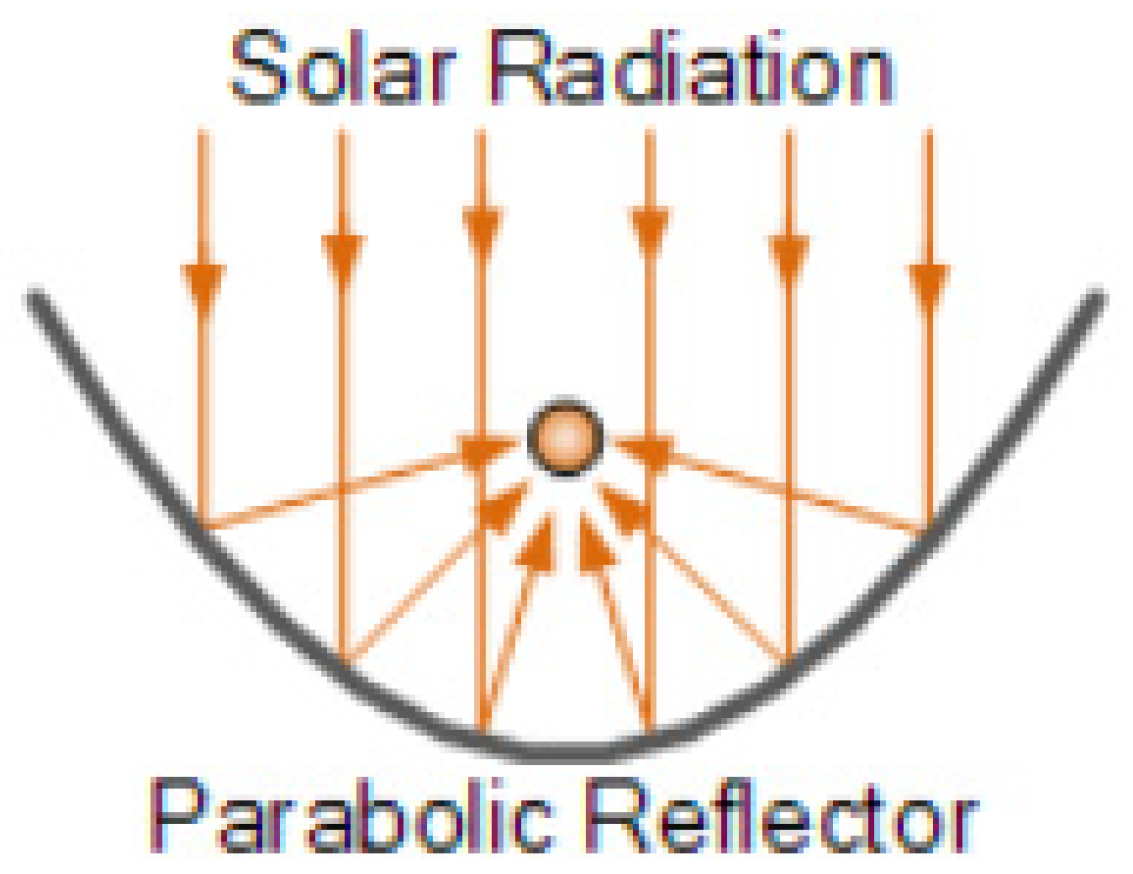

2 and the ambient temperature 32.42 and relative humidity was 60.01 %. The drying of natural fiber completed in 3 days and able to reduce 1004.2 kg weight and 70.7 moisture content wet basis. The performance mentioned as evaporative capacity which is recorded as 68.88 kg/hr. The specific moisture extraction came around 3.55 kg/kWh and the specific energy consumption was 0.28 kWh/kg. Pravin M. Gupta et al. (2017) has done a Review of Solar Dryer for Drying Agricultural Products. They studied about all types of solar dryer but they found that indirect solar dryer is more efficient than other dryers and also give very good quality of product in minimum cost. As per the outcome of this paper, authors claimed that designing of the solar dryer for agriculture product is high efficient in minimum cost. It is useful for farmer for improving quality of agriculture products and giving them best price for their product and it required very less space. It is also used for domestic purpose for drying seasoning products. Raghupathy and Balsubramaniam (2018) studied about the solar drying system for fish preservation. As per the study, solar fish dryer is a multipurpose facility, which is of great importance to the economic growth of coastal area fisheries folk. The parabolic collector’s sunrays reflection is given by the authors which is shown in

Figure 2. Fish drying is performed either using wood or fuels in a mechanical drying process or by placing the fish under the open sun. As per the paper, the authors concluded that the direct, indirect and mixed mode dryers that have shown potential in drying agricultural, aqua cultural products. So, the solar drying system utilizes solar energy to heat up air and to dry any food substance loaded will give more beneficial in reducing wastage of product and helps to dry and preserve without spoiling the food quality. Abdulrahim Al-Ismaili (2021), has done a paper titled “A Review on Solar Drying of Fish”. As per AbdulrahimOman is one of the larger fish producers in the GCC region. Due to high perishable rate of fish products, many preservation techniques were used in Oman such as smoking, drying, chilling, brining and freezing. Solar drying is the most popular technique due to its simplicity and low cost compared to other techniques which is highly suitable for Oman. Shyam S sablani (2002) et al. have done a solar based fish drying in Oman and stated in the conclusion that “the quality of dried fish was better in case of solar drying methods due to lower level of contamination from the sand and insects”. Also they have given that the multi-rack drier has a higher efficiency for commercialization due to large capacity having large surface area per unit land space. This project shows the positive effect in the solar based fish drying methodology in sultanate of Oman.

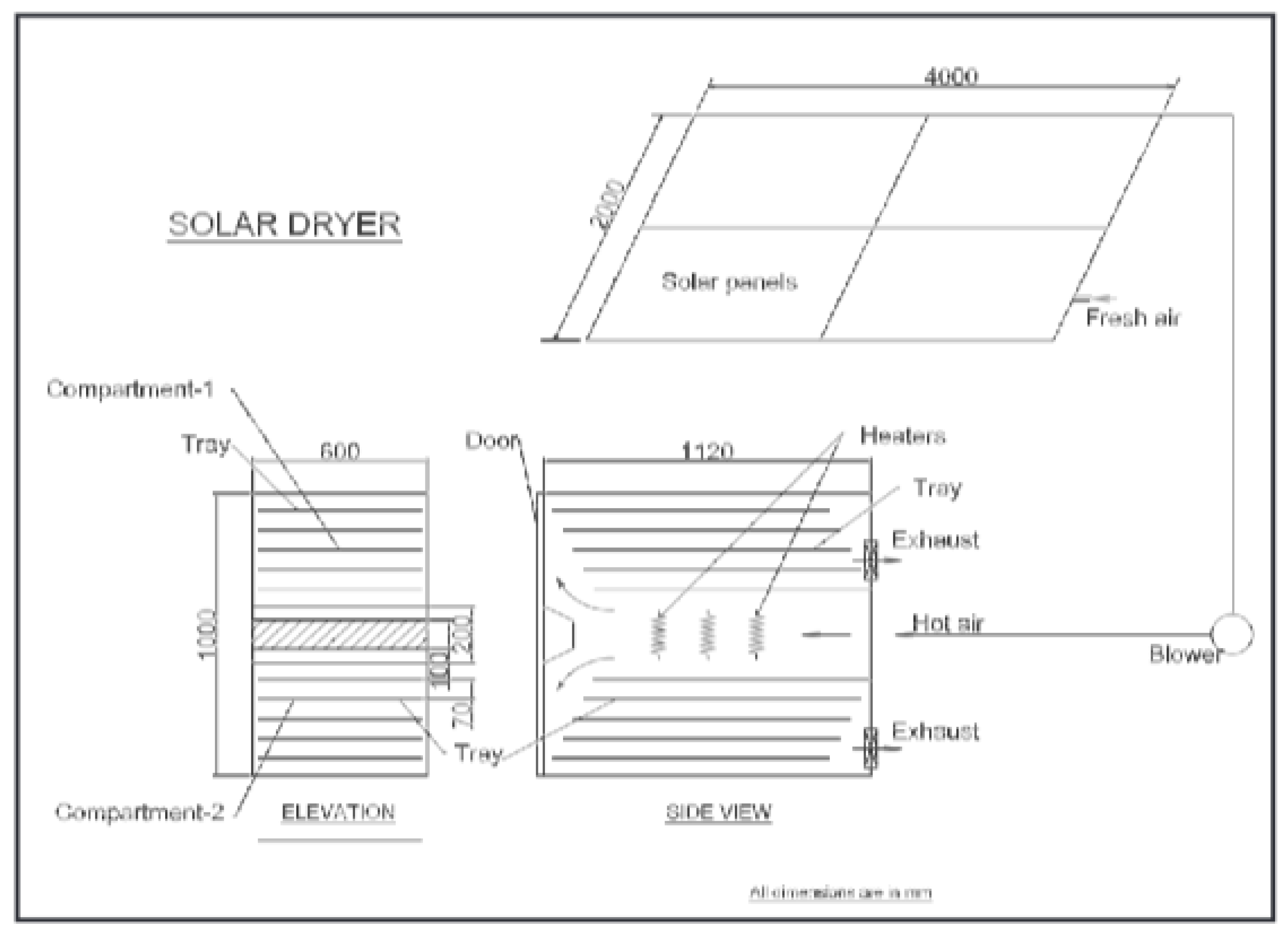

Ankurr Nagori (2021) et al. published a paper titled “Development of Solar Dryer with Electrical Energy Backup for Hygienic Drying of Fish and Fish Products”. In this work, an efficient design for solar drying process is discussed. The

Figure 3 shows their design of solar dryer which is hybrid mode. This dryer will operate using solar during day time and will work using electricity during night time. The authors have given that the methodology is economical and hygiene methodology with more efficiency. They have done a research and analyzed using various parameters such as solar radiation, drying rate, cumulative moisture in fish etc. However, working of dryer using electricity is an expensive one compared to the solar dryer.

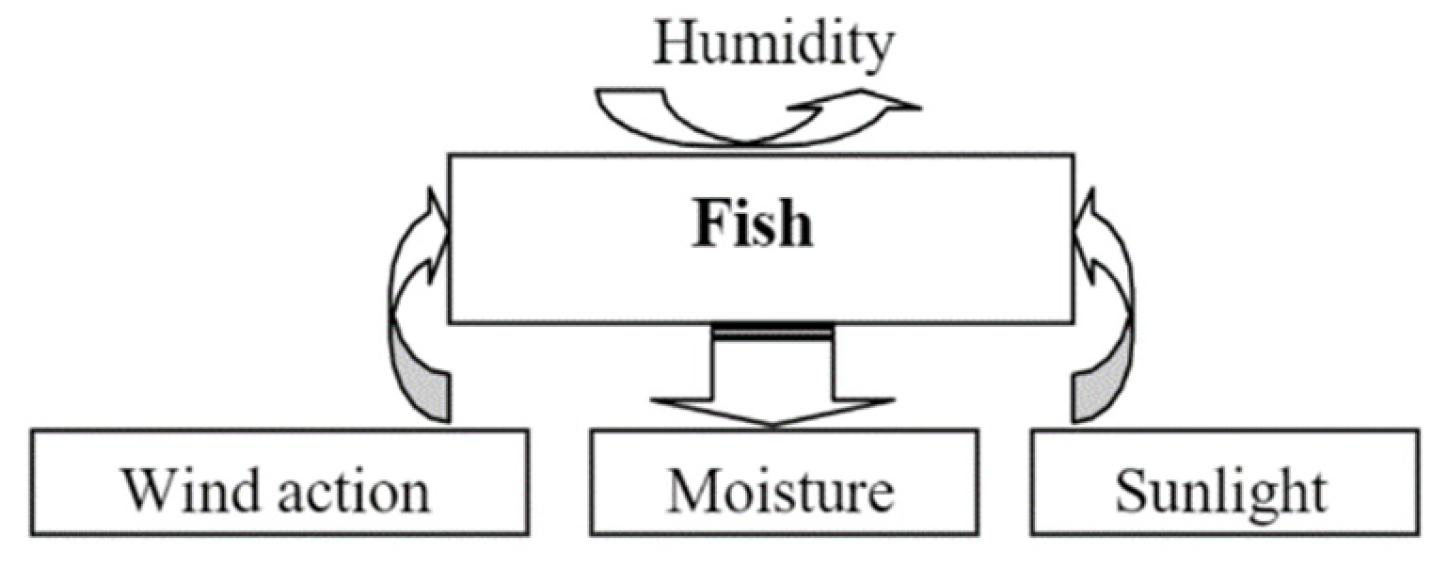

2.2. Review Related to Dry Fish

Normally, drying of fish process is carried out in open air using sunrays during day time to evaporate moisture content in fish. Moisture content should be reduced below 16% to have dry fish in eatable form. In the drying process, shrinkage and irreversible changes will take place in dried fish. The rate of evaporation is mainly depending on the environmental condition when drying process will take place. Redwan Amin (2023) has discussed the fish drying process in his article(Shown in

Figure 4) and discussed about the drying efficiency.

Fitri, N et al., (2022) has done a review on the processing of dried fish and the associated chemical and nutritional changes in their paper. The authors concluded that dried fish was higher lipid and protein content than fresh fish.

They added that dry fish can be produced using hot air drying, microwave vacuum drying, freeze drying, sun drying and salt drying. Saragih, A.F (2022) analyzed the results of drying fish with and without salt using sunlight. They found that there is differences in the result of drying fish with salt and fish without salt which vary such as differences in drying time, fish colour, texture and smell of fish. A salt based dry fish expiry will be more compared to non-salt based dry fishes. Texture of salt based dry fish is less hard compared to non-salt based dry fishes.

Belton, B (2021) has done a global survey in dried fish at the intersection of food science, economy and culture. The authors quoted that the dried fish sector provides employment for millions of people particularly women, who comprise most of the fish drying workforce in many locations globally. They added that the sector also confronts and created significant challenges including food safety concerns and exploitative labour conditions.

Aaisha K. Al saadia (2021) have done microbiological assessment of locally dried fish in Oman. They have taken kingfish samples (locally (in Oman) known as Owal) and analysed the parameters of Total Fungal Count (TFC), Total Viable Count (TVC) and enumeration of E-Coli, Staphylococcus aures and coliforms spices in dried king fish. The authors recommended that dry fish should be processed under more hygiene condition and to use solar drier instead of direct drying on beach sands.

3. Design and development of solar dryer

In this project, it is planned to design a solar based system to dry fishes to help fishermen of sultanate of Oman. In Oman, the fishermen are facing lot of challenges to sell which the fishes which they are catching from sea. To improve the economic background of Omani fishermen, new technologies are required in cold storages to preserve the fishes. But the places where cold storage is not available, fishermen is preferring to go for dry fish process to expand their business. In this project, a parabolic type solar collector will be developed with aluminum plates. After developing the parabolic solar collector, a proper design will be made for a receiver plate to receive the hotness of the parabolic solar collector. In the outside of collector plate, a cabin will setup to place the fishes which are going to dry. After finishing the dry project, a system will be developed to check the dryness of fishes to identify the effectiveness of the drying fish. The design Involves the following phases

- ➢

Design and develop solar parabolic collector

- ➢

Design of receiver tubes.

- ➢

Design of stand for collector and receiver

- ➢

Design of box to place Fishes

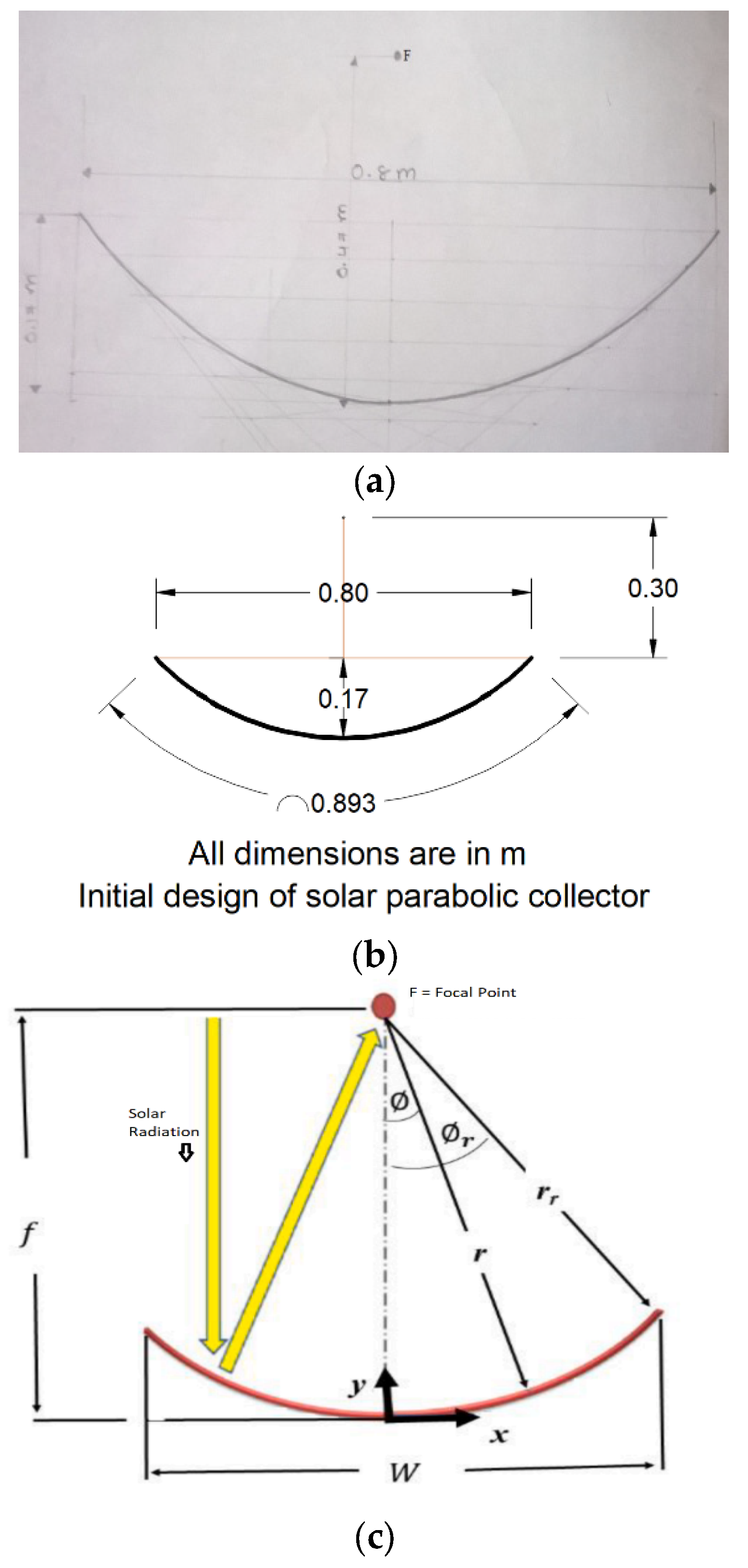

3.1. Design of Parabolic Collector

The parabolic type collector is a solar thermal energy collector designed to collect the sun’s solar radiation over a parabolic surface area, or more generally “concentrate it” onto a small focal point area to increase the solar energy concentration which is received by more than a factor of two which means more overall heat per square meter of trough. The shape of concentrating solar collectors must be specifically designed so that all the inward sunlight reflects off the surface of the collector and arrives at the same focal point no matter what part of the collector the sunlight hits first. Concept of parabolic type concentrator is given in

Figure 5.

The following are the advantages of using parabolic collector

- ➢

Inexpensive

- ➢

Create high temperature on concentrating place

- ➢

Cheap reflector and more span area

- ➢

Maximize harvesting solar energy

- ➢

High conversion ability from solar to thermal

In the design of solar collector, it is required to concentrate more on the design. If there is design fault, the concentration of solar energy will be limited and efficiency will come down. So, to maximize the efficiency, a very careful design of solar collector is needed

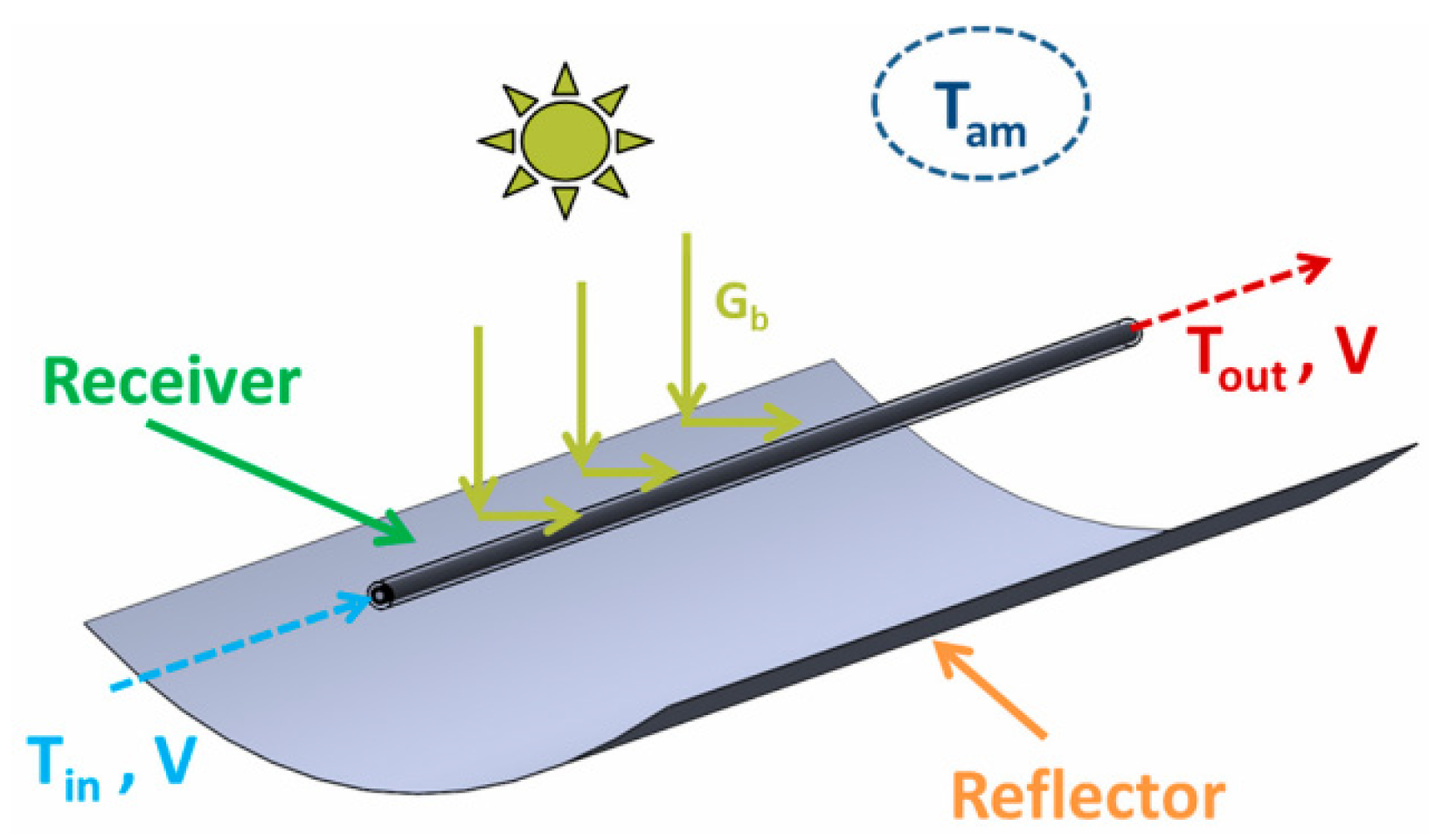

The graphical abstract given by the author Evangelos Bellos and Christos Tzivanidis (2018) with parabolic and a heat exchanger is given in

Figure 6. In this system an evacuated tube is used as receiver to collect the thermal energy. The nomenclature for the design is given in the

Table 1

The design steps involved in parabolic trough collector is as follows

STEP 1

The thermal losses from the cover to the ambient (radiation and convection losses) can be written as below (contact thermal losses are neglected)

The cover temperature is assumed to be close to the ambient temperature because of the existence of an evacuated tube collector. it can be written as follows.

Equation (2) validity is tested by the comparisons between this and other models

Using Equations (1) and (2), it can be written:

with

STEP 2

The thermal losses of the absorber to the cover are only radiation losses because of the vacuum between the absorber and the cover (there are no convection thermal losses):

with

The Equation (6) can be written as below. It is important to state that the cover has been assumed to radiate to the ambient conditions.

Using Equations (2) and (4), it can be written:

Using Equations (8) and (9), it can be said:

or

with

STEP 3

The useful heat can be calculated using the energy balance in the fluid volume:

Furthermore, it can be calculated using the heat transfer from the receiver to the fluid:

The mean fluid temperature can be estimated as:

Using the Equations (13)–(15), it can be written:

Or We can be written as

with

STEP 4

The Equation (11) can be transferred as

The temperature difference between receiver and fluid can be written using Taylor series

Using Equations (17) and (20), it can be written:

Using Equations (19) and (21), We can write

STEP 5

The energy balance in the absorber indicates that the absorbed energy is converted into useful heat and to thermal losses. The absorbed energy is equal to the optical efficiency multiplied by the direct beam solar irradiation. Thus, it can be written:

Using Equations (22) and (23), it can be written:

or

with

and

The other relevant parameter calculations are as follows:

The thermal efficiency of the solar collector

can be calculated as:

Using Equations (23) and (25), the thermal losses (

) can be calculated as:

Using Equations (17) and (25), the receiver temperature (

) can be calculated as:

Using Equations (4) and (25), the cover temperature (

) can be calculated as:

Using Equations (13) and (25), the fluid outlet temperature (

) can be calculated as:

Using Equations (15) and (32), the mean fluid temperature (

) can be calculated as:

The next section will deal about the design of parabolic concentrator and its fabrication.

3.2. Design of Solar Collector

Solar thermal collector traps the sunlight or absorbs solar radiation to generate solar energy for different applications. Solar collectors absorb/concentrates solar from sun radiation. This device is primarily used to absorb the heat and allow to heat water or heat transfer fluid

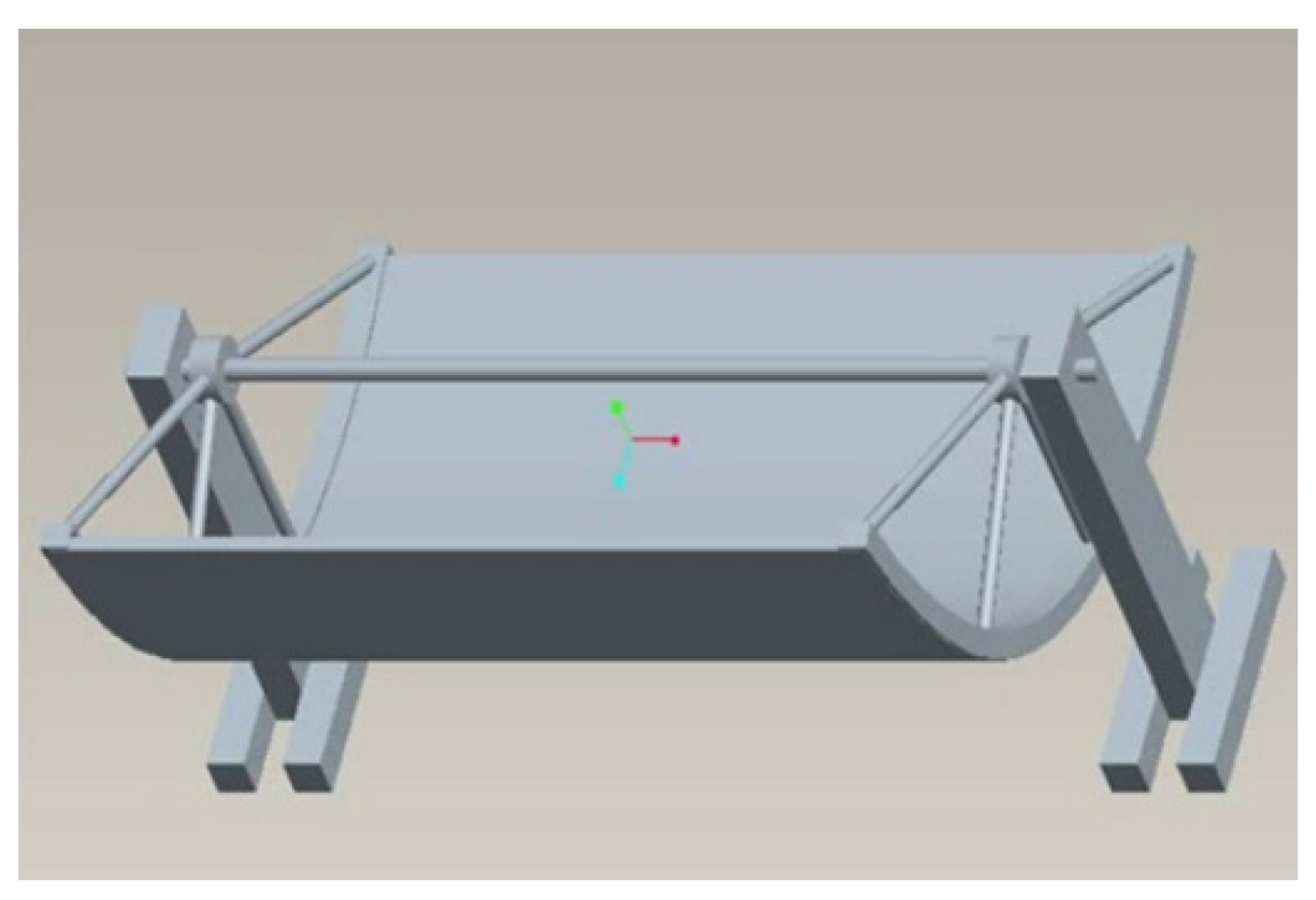

Based on the pencil sketch, the design has been made using CAD model software to do the fabrication

. The CAD model in

Figure 7 shows that there is a parabolic collector with two legs. There is a support system in which the parabolic concentrator can be easily titled according to the sun direction.

Table 2 Shows the dimensions of the proposed parabolic collector.

The fabrication is an essential part of every kind of project because this provide the proper and clear idea for the work which is executed in real time but this has to be followed on to achieves the analysis and also implementation with the best result. So, taking into that consideration, the decent and correct attention have been paid in fabrication work. The beginning of the stage used to select the materials and the next step is the fabrication phase. We have to make sure the design perfection before going to select materials and machining process. CAD model for parabolic design is given in

Figure 8. If there are any limitations, need to select the best methods to do the fabrication. The next step is determining about the requirements of the project and need to execute accordingly. The final step is testing and also analyzing the results to make sure that the project has been completed and implemented as per the requirements. In the initial fabrication work, the aluminum sheet is bent according to the design and the angle suggested. To make perfect smoothness of the trough, a die has been made and then the Al sheet has been bent. The support angles has been provided after the bent. A square support is provided to keep the Al sheet without any movement. The legs are carefully designed to withstand the weight of the parabolic setup. The

Figure 9 shows the various views of the setup.

3.3. Solar Receiver

A receiver for use with parabolic solar concentrators consists of a heat conductive tube helically coiled into a hollow cone shape. Heat conductive fluid is pumped into an entry point in the tube and exits at an exit point from the tube. A casing is provided to cover the cone. An insulator between the cone and casing prevents heat from escaping from the coil. Solar stand and fish stand has also designed in the experiment. A single copper tube which has inner diameter of 40 mm and the outer diameter of 42 mm has been designed and developed. The length of the tube has taken slightly more than the length of the parabolic concentrator. The length of the tube has designed for 1.57 m. The copper tube was painted in the black color to improve absorptivity. The ends of the copper tube were sealed at both ends by thermal silicone material. A vacuum pump was used to remove air lock inside the tube. The use of copper tube is having advantages of copper high mechanical strength, low weight, easy to fabricate, improved absorptivity and corrosion-resistant properties. The copper tube which is used for the experiment is shown in

Figure 9.

Figure 9.

Side and Top view of fabricated solar dryer.

Figure 9.

Side and Top view of fabricated solar dryer.

Figure 10.

Design of Single evacuated Copper tube absorber.

Figure 10.

Design of Single evacuated Copper tube absorber.

After finishing the fabrication, the mounting structure for the fish has been fabricated. The mounting structure should place as per the need to focus all the collected energy on the fishes which is going to dry. Aluminum trays can be painted black to increase the absorptivity. Generally, aluminum has good thermal conductivity so these trays can heat quickly. The fishes have put in the heating tray to absorb the heat fully.

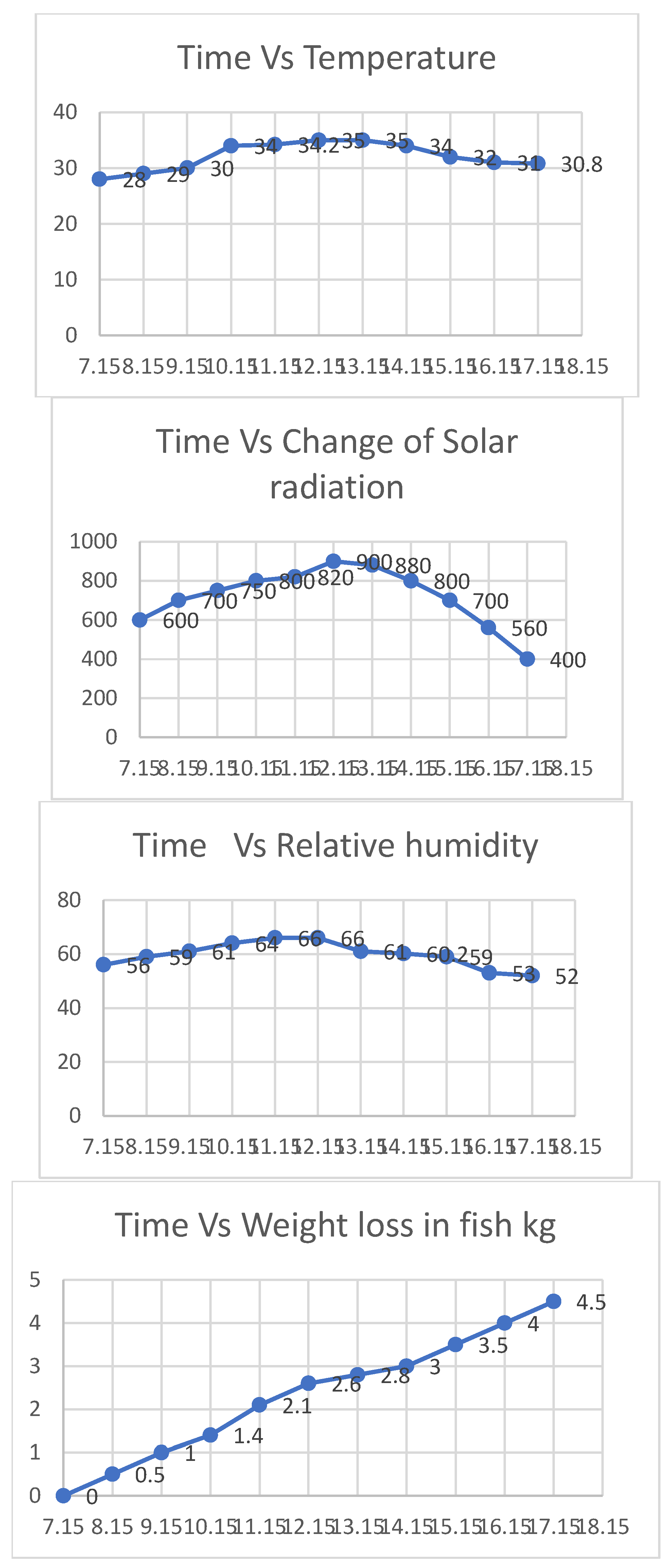

4. Discussion and Anlysis of the Solar Dryer

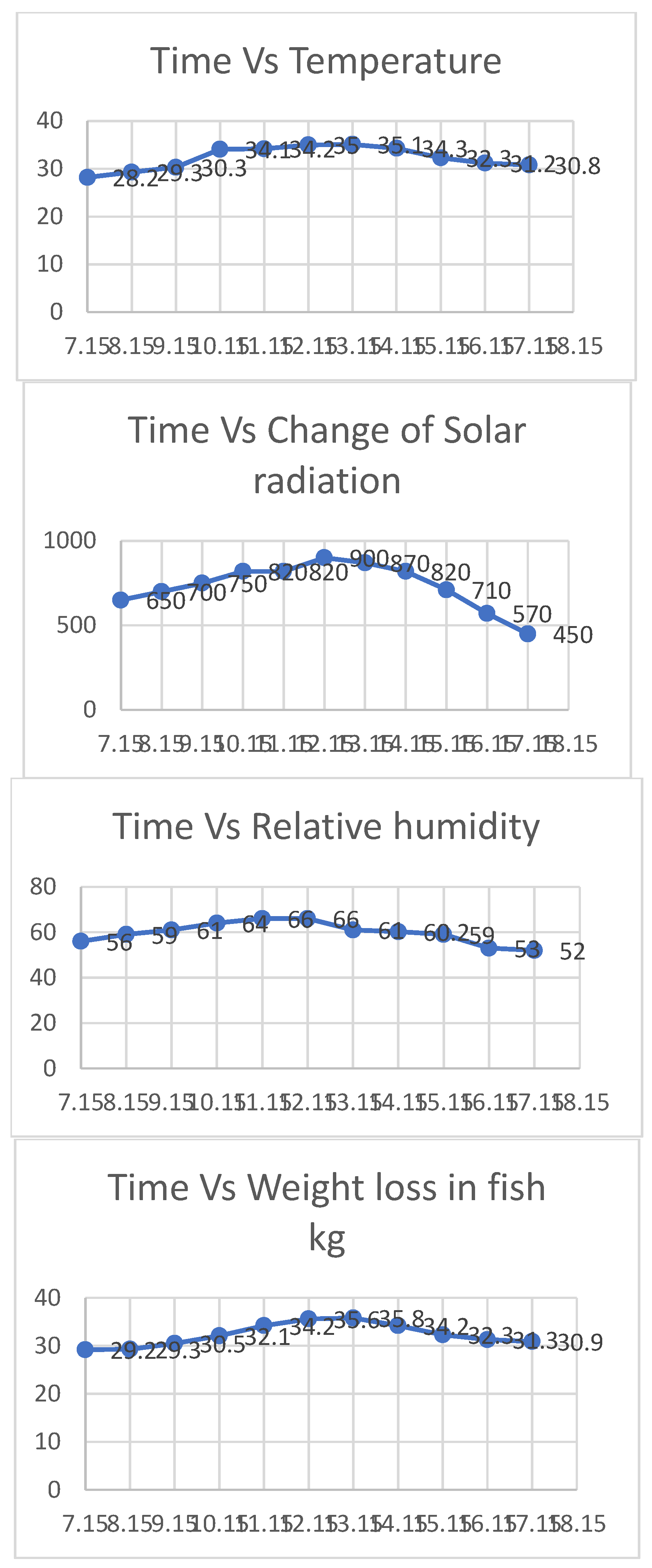

The efficiency of parabolic solar collector is calculated and graphically represented in order to compare different sun radiation, heat production, moisture content in the fish at various time. The performance of solar will vary time to time because of variation in environment. So, solar collector collecting sunlight’s heat according to the climatic condition. The summer climate is different from winter climate and sunny day also different from winter day. According to the test conducted in the solar collector, many parameters such as temperature, humidity and solar radiation have been calculated. These parameters tested in the beginning of hot summer in Oman and also tested in the morning and evening time. King fish (Locally known as Owal) is taken as sample with the weight of 5 kg with medium size. Totally four fishes were taken in the tray for the total weight of 20 kg. Same kind of samples have taken for 3 trials and the statistic taken for all days but tabulated only for 3 days for one best trial. All of the trails were taken in April month of Oman, three days were taken to dry the fishes by trailing to remove 85 to 90% of the moisture content from fresh fish. In the fourth trail, big size fish were taken and found more days to dry. In Oman condition, in our solar dryer model, for king fish drying, it took 6 days for big size fish and it took 3 days for medium size fish during April period.

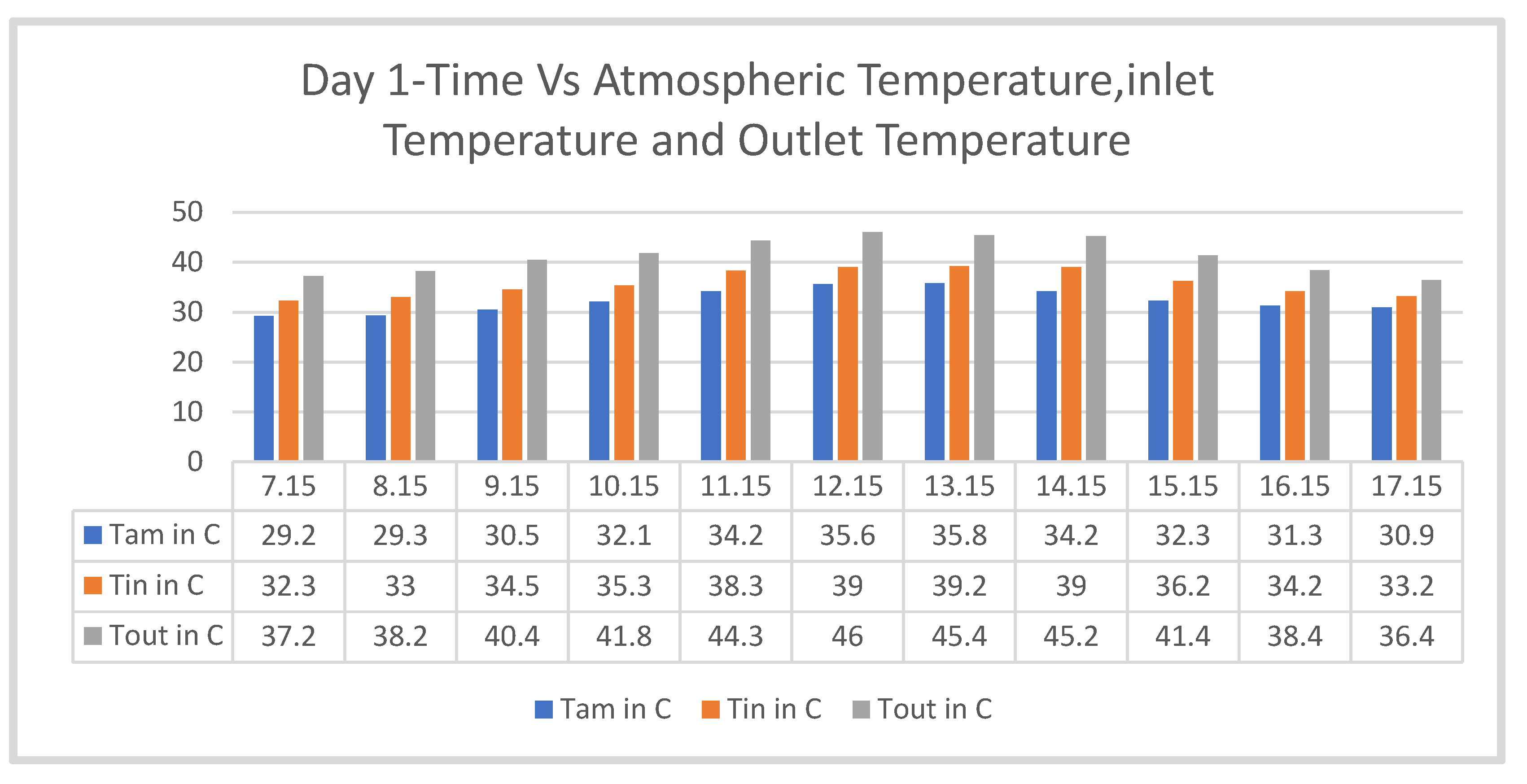

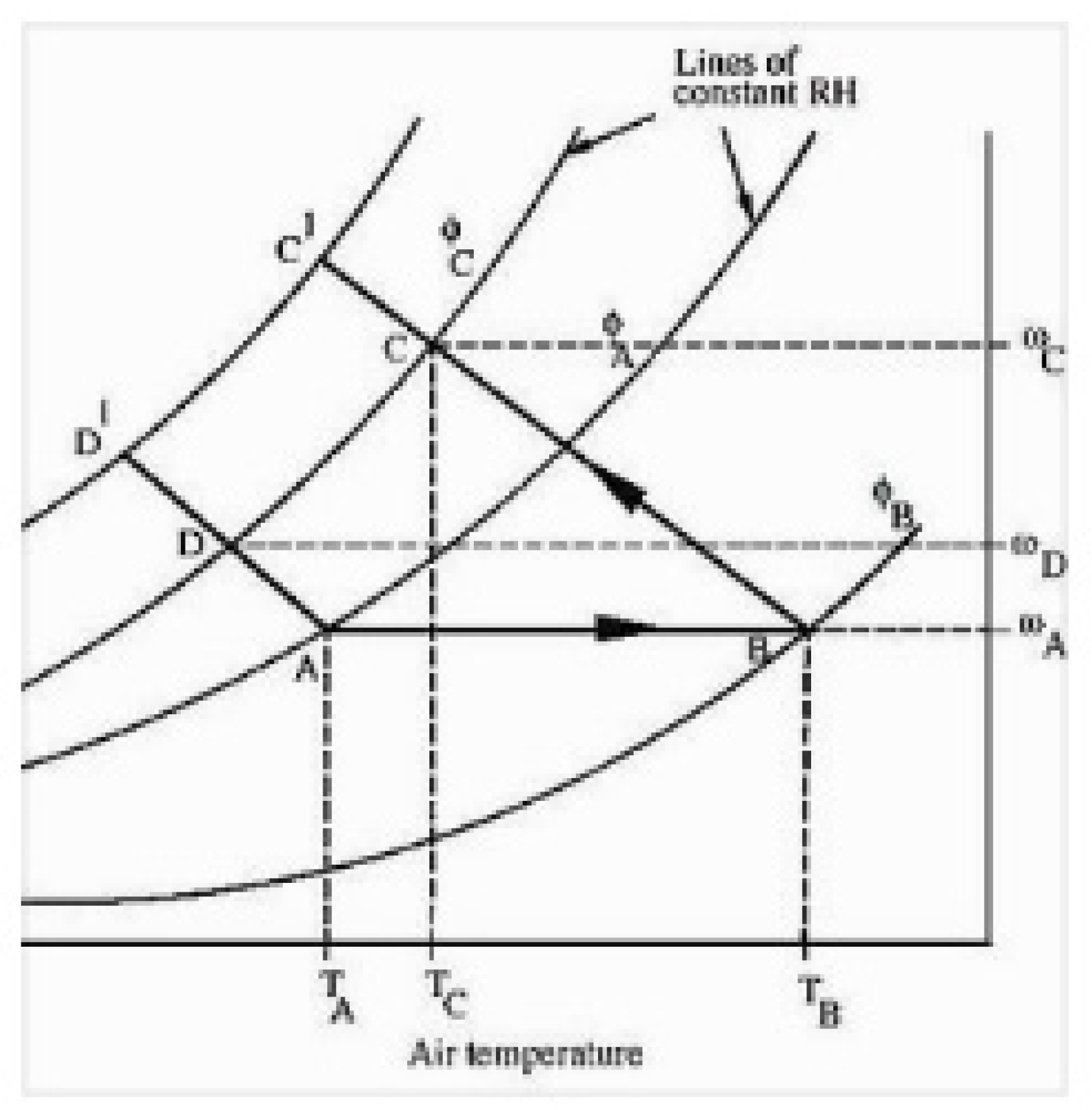

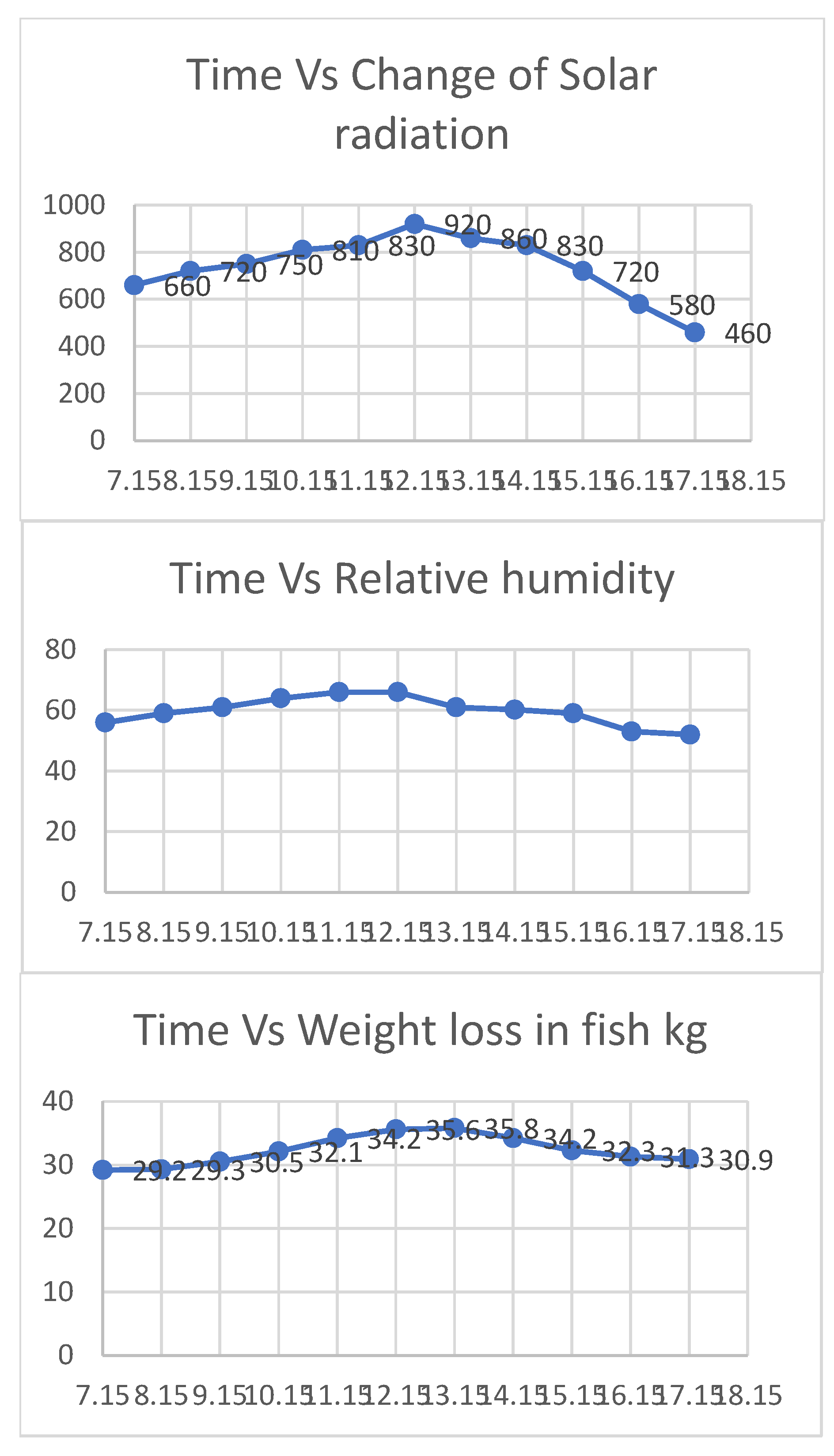

The fish completely dried and gave 3 days 1/3 weight loss in overall kg. So,14kg has been reduced from 20 kg of fish which means 6kg of dry fish was collected from the solar dryer. The temperature, change of radiation and relative humidity is not having much change in three days of the testing period in 2024. The time vs other parameters have been analyzed using line chart and bar chart in the excel sheet and recorded in the following figures

Day 1 Statistics

Day 2 Statistics

Day 3 Statistics

To analyze the performance of the solar dryer, it is required to calculate the parameters of heat transfer, solar irradiation, thermal efficiency, fish drying efficiency etc. The following formulae will help to calculate different parameters.

The relevant other parameters calculations are as follows:

where, mf = Mass flow rate(0.008055 kg/sec) Cp = Specific heat capacity in Kj/kg k = 4.2 KJ/ kg k

Moreover, the solar irradiation (Qs) can be calculated from the equation

where Aa is aperture of the collector which can be calculated as Aa = W × L W= width and L= Length

that is used to calculate thermal efficiency is as follows

From the

Figure 11,

Figure 12 and

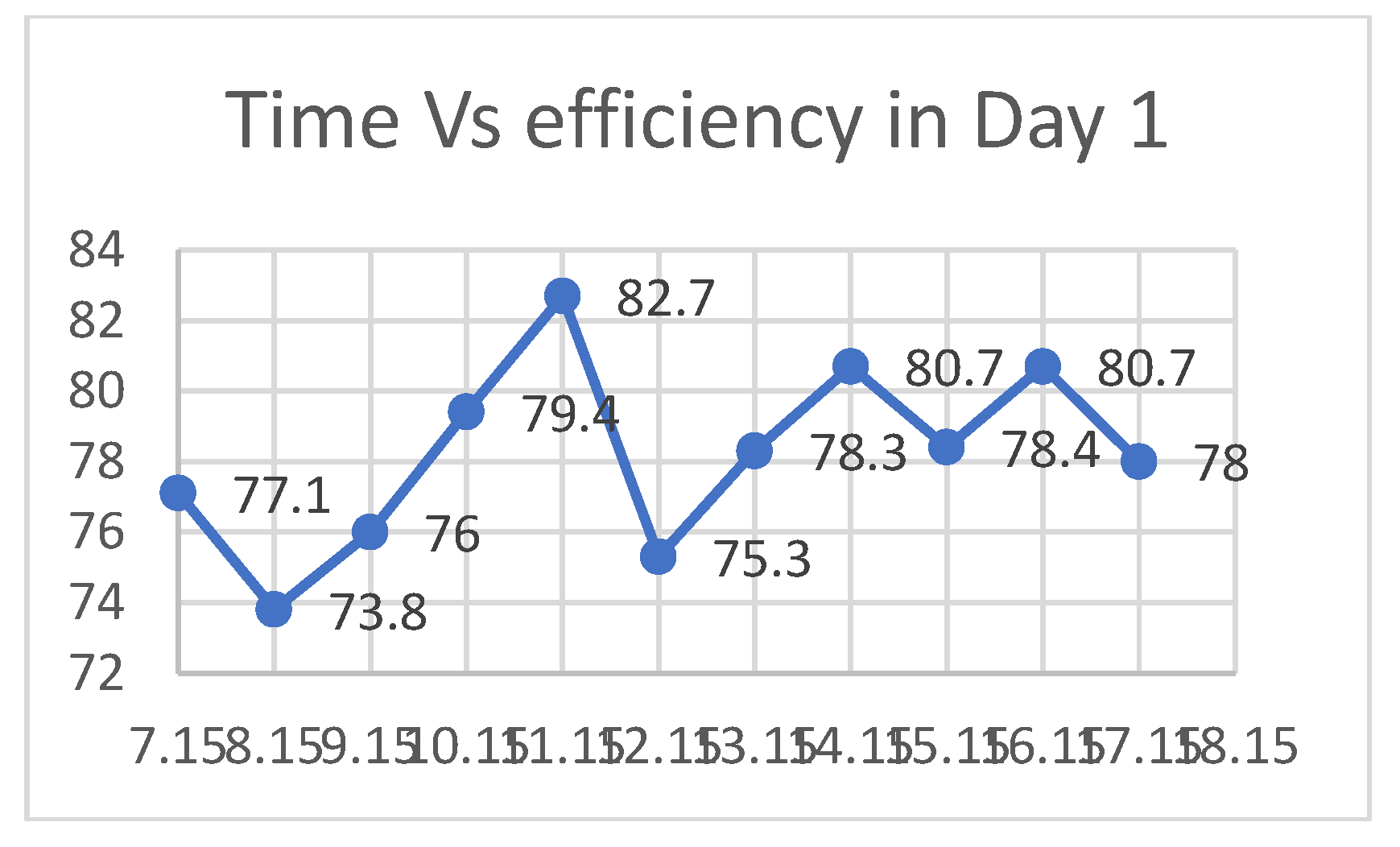

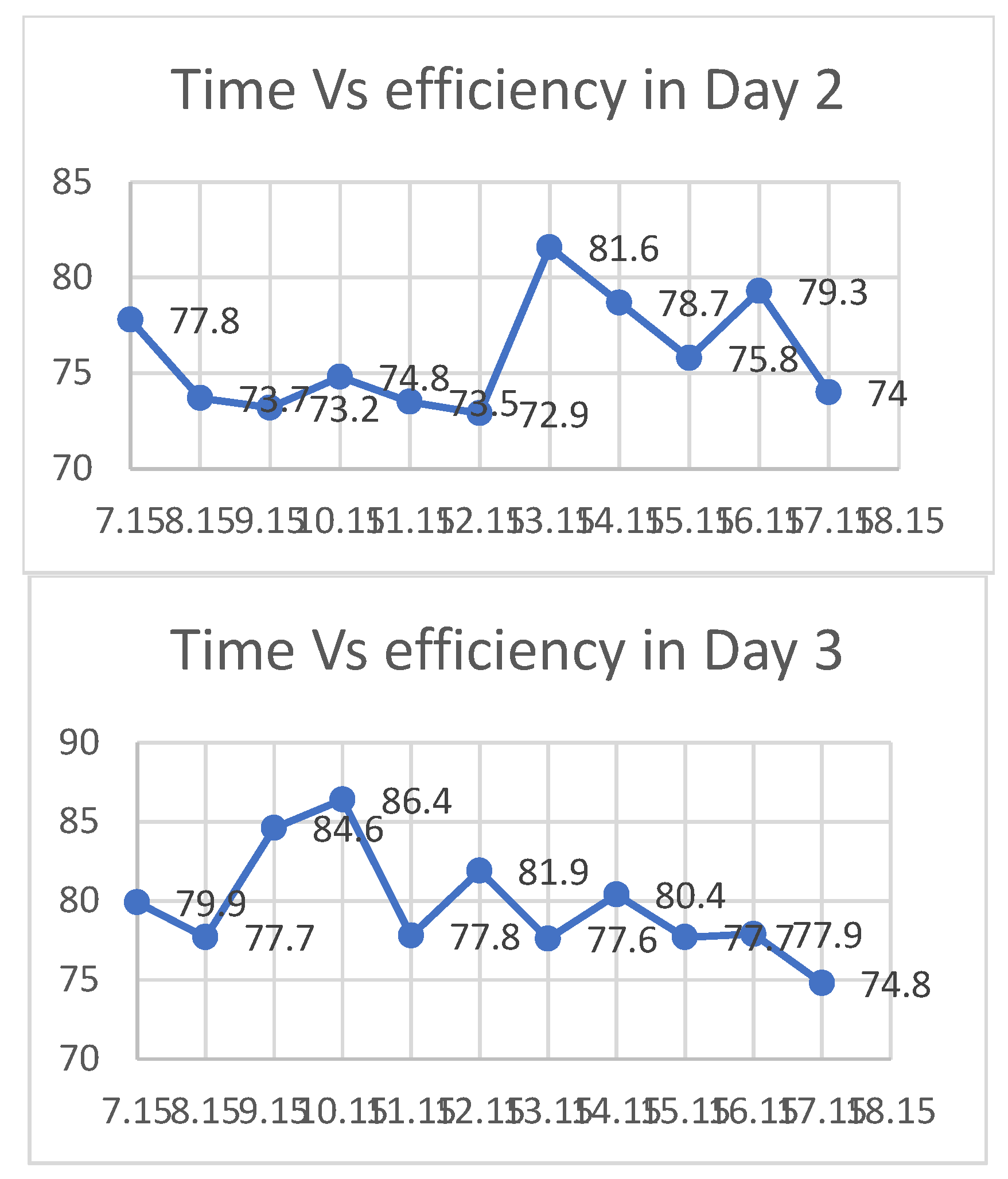

Figure 13, we can understand that the various parameters with respect to the time variation during the testing period. The receiver tube is designed using copper material which will carry heat transfer fluid to dry the fishes. Different parameters related to receiver fluid flow and drying efficiency has been calculated. The temperature of fluid in and out has been measured and tabulated.

After finding temperature, drying efficiency of fishes has been calculated by finding moisture removal from fishes.

Table 6,

Table 7 and

Table 8 shows the drying efficiency and the

Figure 14 shows the efficiency variation due to variation of radiation from sun. Average efficiency of day1, day2 and day3 has been recorded as 78.2%,72.9% and 75.9%.

Overall fish drying efficiency has been calculated as follows

= (78.2+75.9+79.7)/3

= 77.9%

5. Conclusion and Future Recommendations

Since sultanate of Oman is having more sunlight during the day time, it is possible to dry the fishes at the earliest compared to the other countries. If so, it is possible to dry the fishes and this will improve the living style of fishermen. The electrical power requirement for the drying process is zero, so that, the suggested dryer is very economical. Also, it is possible to generate electricity from the sun and possible to change this process as electrical based solar dryer. If so, we can adjust the temperature at any time and even it is possible to use in the night time for the drying process as hybrid mode.

Since Oman is having more chance to improve the fishery sector, this kind of drying process will help to save the fish and possible to export lot to the nearby nations where the demand for drying fish is more. So, all of the analysis shows that the effectiveness of solar drying method is high compared to the traditional drying methodology.

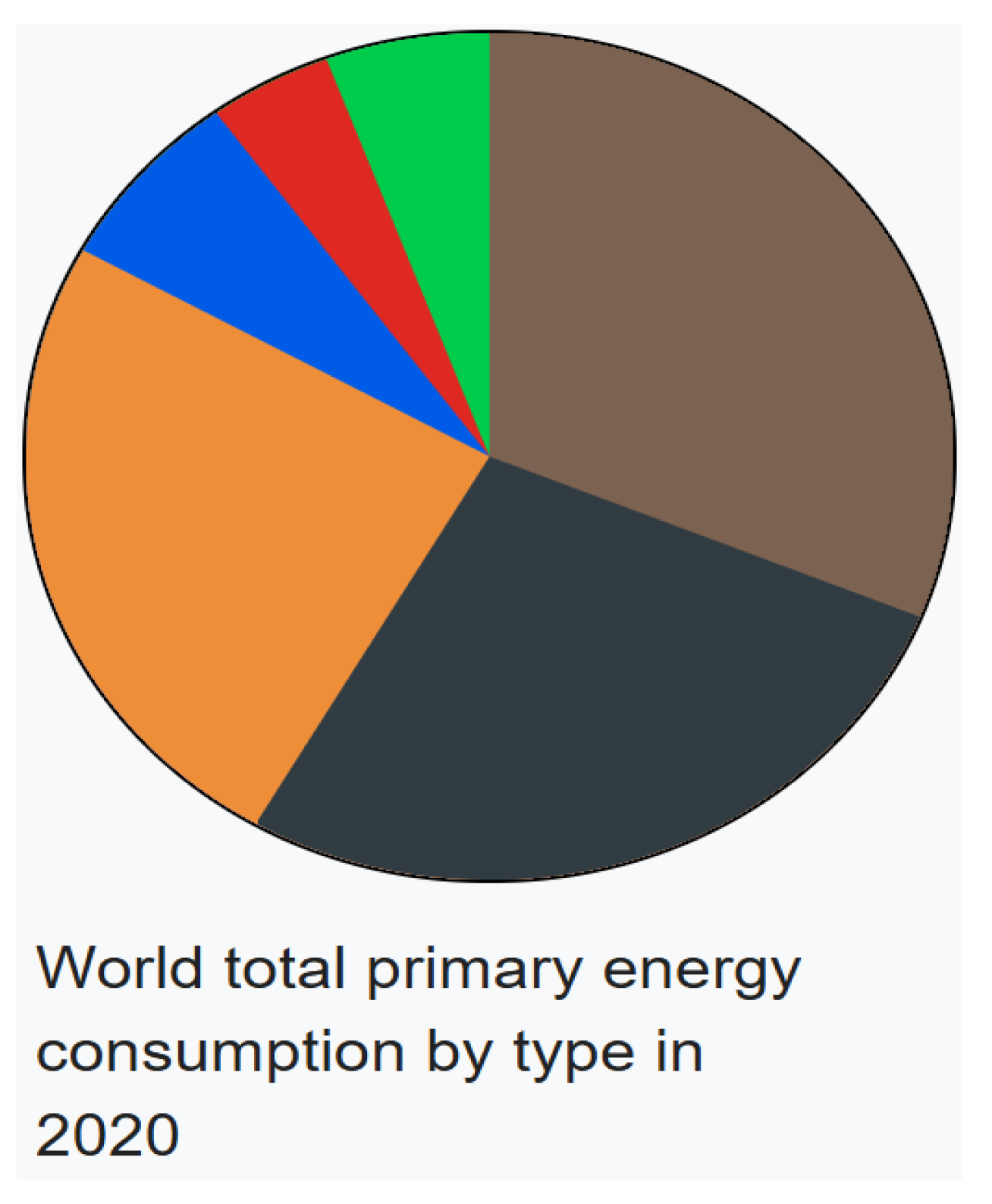

The main objective of this project is the development of solar dryer to provide sufficient amount of heat under given humidity to dry fish which is going waste in the fishery sector of sultanate of Oman. It increases the vapor pressure of the moisture confined within the product and decreases the relative humidity of the drying air so that the moisture carrying capacity of the air can be increased as per the statistical study in this work. In conclusion, the. Solar dryers can be the effective methodology to dry the fishes and also it reduces carbon emissions to the environment as their long-term benefits. The solar dryer serves a green environment compared to the electrical based methodology in the fish drying industries. The technical guidance in designing solar-assisted systems is very important to have high-performance advanced energy utilization systems, and long-life drying systems. The main problems for solar based drying are dust, rain and cloudy weather. Therefore, we have to maintain the drying areas should be dust-free and whenever there is a threat of a dust storm or rain, the drying structure should be closed with water proof cover which is mandatory in this proposed methodology.

There is a possibility of improving the proposed design with

Backup method using electricity

Batteries to operate in night time

Automatic cover during rainy season

Automatic dust cleaning method

Continuous monitoring of moisture content in the drying fish

Overall, the solar dryer is an effective method which will be very useful in future in sultanate of Oman. Since the country focusing the diversified areas to improve the economy of the country, fishery sector will have more potential to contribute the growth of the economy. So, many modern techniques are needed in this sector and as researchers, we believe solar dryer is one of the areas which is required more concentration for the future development.

Compared to the normal process, it is fast and reliable. Similarly, to dry grapes, pine apple, dates, it will take lesser time compared to the normal dry process. Since it is natural, there is no reduction of nutrition value, taste and quality. So, we can say this methodology is more reliable to dry fishes. In future a big size parabolic collector and a special device for stand will help to go faster than the developed methodology in this work.

Figure 15.

Various recorded temperature during the drying process.

Figure 15.

Various recorded temperature during the drying process.

References

- Aaisha K. Al-Saadi, Abdulrahim M. Al-Ismaili, Mohammed Al-Ruzeikib, Ismail M. Al-Bulush (2021), Microbiological Assessment of Locally Dried Fish in Oman: Technical Note, Journal of Agricultural and Marine Sciences [JAMS] Vol. 26 No. 1 (2021): JAMS; 53-56.

- Abdulrahim Al-Ismaili (2021) Journal of agriculture and Marine services, Sultan qaboos university, available at

https://doi.org/10.53541/jams.vol26, iss2, pp1‐9 .

- Ag Sufiyan bin Abd Hamid, Adnan bin Ibrahim, Sohif bin Mat, Kamaruzzaman bin Sopian, Experimental Evaluation on Large Scale Solar Dryer for Drying Natural Fiber in Malaysia, International Journal of Renewable Energy Research-IJRER.

- Aidil Fahmi Saragih*, Erliska Pranandari, Siti Aisyah, Eka Sugiarti, Hikmah Setia Ningrum, Noni Audina Maisya, Eni Marta, Analyzing the results of drying fish with and without salt using sunlight, Indonesian Journal of multidisplinary science, Vol. 1, No. 4, January 2022, pp. 295-300 P-ISSN: 2808-5957 E-ISSN: 2808-6724.

- Al Kalbaniyeh, F.; Qanat, M. Sagueni: Maximize the Utilization of the Fisheries Sector to Provide 29 Thousand Jobs and Increase the Contribution to GDP and Economic Diversification. 2016. Available online: https://alroya.om/post/162280 (accessed on 27 February 2024).

- Al-Saadia, A. K., Al-Ismaili, A. M., Al-Ruzeikib, M., & Al-Bulushib, I. M. (2020). Microbiological Assessment of Locally Dried Fish in Oman: Technical Note. Journal of Agricultural and Marine Sciences [JAMS], 26(1), 53–56. Retrieved from https://journals.squ.edu.om/index.php/jams/article/view/359.

- Amin, Redwan. (2023). Dried and Dehydrated Fishery Products. 10.13140/RG.2.2.27689.16485.

- Amuthakkannan,R Mahmood Hamed Awadh Al Yaqoubi (2023), Development of IoT Based Water Pollution Identification to Avoid Destruction of Aquatic Life and to Improve the Quality of Water, International Journal of Engineering Trends and Technology Volume 71 Issue 10, 355-370, October 2023 ISSN: 2231–5381. [CrossRef]

- Amuthakkannan, R.; Vijayalakshmi, K.; Al Araimi, S.; Ali Saud Al Tobi, M. A Review to do Fishermen Boat Automation with Artificial Intelligence for Sustainable Fishing Experience Ensuring Safety, Security, Navigation and Sharing Information for Omani Fishermen. J. Mar. Sci. Eng. 2023, 11, 630. [CrossRef]

- Ankit Kumar, Kamred Udham Singh, Mukesh Kumar Singh, Alok Kumar Singh Kushwaha, Abhishek Kumar, and Shambhu Mahato Design and Fabrication of Solar Dryer System for Food Preservation of Vegetables or Fruit Hindawi Journal of Food Quality Volume 2022, Article ID 6564933, 14 pages . [CrossRef]

- Ankur Nagori., P N Joshi., C N Ravishankar 2021 Development of Solar Dryer with Electrical Energy Backup for Hygienic Drying of Fish and Fish Products, Fishery Technology 51 (2014) : 112–116.

- Asaad Yasseen Al-Rabeeah, Istvan Seres, Istvan Farkas,Experimental investigation of improved parabolic trough solar collector thermal efficiency using novel receiver geometry design,International Journal of Thermofluids,Volume 18,2023,100344,ISSN 2666-2027. [CrossRef]

- Bellos, Evangelos, and Christos Tzivanidis. 2018. “Analytical Expression of Parabolic Trough Solar Collector Performance” Designs 2, no. 1: 9. [CrossRef]

- Ben Belton, Derek S. Johnson, Eric Thrift, Jonah Olsen, Mostafa Ali Reza Hossain, Shakuntala Haraksingh Thilsted (2022), Dried fish at the intersection of food science, economy, and culture: A global survey, Fish and fisheries, Volume23, Issue4,July 2022.

- Chaudhry, I.S.; Al-Harthi, A.H.; Al-Shihimi, G.M.; Al-Saiti, K.M.; Al-Siyabi, M.S. Millennial outlook towards opportunities and challenges in fishing industry of Muscat Governorate of Oman. Middle East J. Manag. 2019, 4, 1–21. Available online: https://tradingeconomics.com.

- Fitri, N.; Chan, S.X.Y.; Che Lah, N.H.; Jam, F.A.; Misnan, N.M.; Kamal, N.; Sarian, M.N.; Mohd Lazaldin, M.A.; Low, C.F.; Hamezah, H.S.; et al. A Comprehensive Review on the Processing of Dried Fish and the Associated Chemical and Nutritional Changes. Foods 2022, 11, 2938. [CrossRef]

- Muscat daily, Oman lifts ban on kingfish fishing ( 2023) Article published on 15 oct 2023 in Muscat Daily newspaper, Available at: https://www.muscatdaily.com/2023/10/15/oman-lifts-ban-on-kingfish-fishing/.

- O. Kilanko et al. 2019, Design and Performance Evaluation of a Solar Dryer, International Conference on Engineering for Sustainable World, Journal of Physics: Conference Series 1378 (2019) 032001 IOP Publishing. [CrossRef]

- Pravin M. Gupta, Roshan G. Pandav, Raviprakash V. Singh, Sagar K. Khuje 2017 Review of Solar Dryer for Drying Agricultural Products, IJSRD—International Journal for Scientific Research & Development Vol. 4, Issue 11, 2017 ISSN (online): 2321-0613.

- Raghupathy and Balasubramaniam (2018) A study on solar drying system for fish preservation, Asia pacific Journal, Vol: I. Issue LXXXVIII, May 2018 Available at : https://www.researchgate.net/publication/333262957_ A_STUDY_ON_ SOLAR_DRYING_ SYSTEM_FOR_FISH_PRESERVATION.

- Sendhil Kumar Natarajan, Elavarasan Elangovan, Rajvikram Madurai Elavarasan,Anand Balaraman, Senthilarasu Sundaram(2022), Review on solar dryers for drying fsh, fruits, and vegetables, Environmental Science and Pollution Research (2022) 29:40478–40506.

- Shyam S Sablani,Mohammad Shafiur Rahman,., Osman Mahgoub Abdulaziz Al-Marzouqi 2002 Sun And Solar Drying Of Fish Sardines, Conference: 13th International Drying Symposium, Beijing, P. R. China At: 1662-1666.

- Swami, Virbhadra & T R, Anil. (2018). Experimental analysis of solar fish dryer using phase change material. The Journal of Energy Storage. 20. [CrossRef]

Figure 2.

Solar rays in parabolic collector. Raghupathy and Balsubramaniam (2018).

Figure 2.

Solar rays in parabolic collector. Raghupathy and Balsubramaniam (2018).

Figure 3.

Solar dryer design (Ankur Nagori (2021) et al.).

Figure 3.

Solar dryer design (Ankur Nagori (2021) et al.).

Figure 4.

Fish drying process (Redwan Amin (2023).

Figure 4.

Fish drying process (Redwan Amin (2023).

Figure 5.

Concept of Parabolic type concentrator (Swami, Virbhadra & T R, Anil. (2018).).

Figure 5.

Concept of Parabolic type concentrator (Swami, Virbhadra & T R, Anil. (2018).).

Figure 6.

Design abstract for parabolic trough collector given by Evangelos Bellos and Christos Tzivanidis (2018).

Figure 6.

Design abstract for parabolic trough collector given by Evangelos Bellos and Christos Tzivanidis (2018).

Figure 7.

Parabolic collector design (Asaad Yasseen Al-Rabeeah et al., 2023) Pencil drawing (b) Auto CAD drawing (c) Geometry of concentrator.

Figure 7.

Parabolic collector design (Asaad Yasseen Al-Rabeeah et al., 2023) Pencil drawing (b) Auto CAD drawing (c) Geometry of concentrator.

Figure 8.

CAD model for parabolic design.

Figure 8.

CAD model for parabolic design.

Figure 11.

Parameter Analysis (Day 1).

Figure 11.

Parameter Analysis (Day 1).

Figure 12.

Parameter Analysis (Day 2).

Figure 12.

Parameter Analysis (Day 2).

Figure 13.

Parameter Analysis (Day 3).

Figure 13.

Parameter Analysis (Day 3).

Figure 14.

Time Vs Efficiency Analysis. Day 1,Day 2 and Day 3.

Figure 14.

Time Vs Efficiency Analysis. Day 1,Day 2 and Day 3.

Table 1.

Nomenclature for the design of parabolic solar collector.

Table 1.

Nomenclature for the design of parabolic solar collector.

| A |

Area, m2 |

K1 |

Coefficient of Equation (4), W/K |

| C |

Concentration ratio |

K2 |

Coefficient of Equation (11), W/K4 |

| cp |

Specific heat capacity under constant pressure, J/kg K |

K3 |

Coefficient of Equation (17), W/K |

| D |

Diameter, m |

K4 |

Coefficient of Equation (25) |

| f |

Collector focal distance, m |

K5 |

Coefficient of Equation (25), W/K4 |

| Gb |

Solar direct beam radiation, W/m2 |

L |

Collector length, m |

| h |

Heat transfer coefficient between fluid and absorber, W/m2 K |

m |

Mass flow rate, kg/s |

| hout |

Heat transfer coefficient between cover and ambient, W/m2 K |

Nu |

Nusselt number |

| k |

Thermal conductivity, W/mK |

Pr |

Prandtl number |

| K |

Incident angle modifier |

Q |

Heat flux, W |

| Re |

Reynolds number |

V |

Volumetric flow rate, m3/s |

| T |

Temperature, K |

W |

Collector width, m |

Table 2.

Parabolic collector Dimensions.

Table 2.

Parabolic collector Dimensions.

| Description |

Dimensions |

| Width of aperture of Parabolic collector |

0.8 m |

| Parabola focal distance |

0.893 m |

| Radius of the parabola |

0.47m |

| Parabolic collector length |

1.5m |

| Parabolic collector width |

0.8m |

| Arc radius |

0.17m |

| Materials |

Al plates, GI Pipes and MS Sheets and wood |

Table 3.

Solar collector dimensions.

Table 3.

Solar collector dimensions.

| Description |

Dimensions |

| Length |

1.57 m |

| Outer Diameter |

42 mm |

| Inner diameter |

40 mm |

| Thickness of wall |

2 mm |

| Material |

copper |

| Type |

Single tube absorber |

Table 4.

Time vs various parameters (Day 1).

Table 4.

Time vs various parameters (Day 1).

| Time |

Temperature

In Celsius |

Change of Solar radiation (w/m2) |

Relative humidity |

Weight loss

In kg (From 20kg of fish) |

7.15

8.15

9.15

10.15

11.15

12.15

13.15

14.15

15.15

16.15

17.15 |

28.3

29.1

30.4

34.5

34.2

35.6

35.5

34.6

32.2

31.5

30.8 |

600.8

700.3

750.4

800.5

820.6

900.7

880.4

800.6

700.6

560.3

400.4 |

55.2

58.4

60.5

62.5

64.3

65.5

62.5

60.6

58.6

55.5

54.4 |

0

0.5

1

1.4

2.1

2.6

2.8

3.0

3.5

4.0

4.5 |

Table 5.

Time vs various parameters (Day 2).

Table 5.

Time vs various parameters (Day 2).

| Time |

Temperature |

Change of Solar radiation (w/m2) |

Relative humidity |

Weight loss

In kg (from 20kg) |

7.15

8.15

9.15

10.15

11.15

12.15

13.15

14.15

15.15

16.15

17.15 |

28.2

29.3

30.3

34.1

34.2

35

35.1

34.3

32.3

31.2

30.8 |

650.2

700.8

750.6

820.3

820.5

900.4

870.5

820.6

710.2

570.1

450.8 |

56.5

59.4

61.5

64.5

66.4

66.4

61.5

60.2

59.3

53.1

52.5 |

4.5

5.0

5.2

5.4

6.0

7.0

7.5

8.0

8.4

8.6

8.8 |

Table 6.

Time vs various parameters (Day 3).

Table 6.

Time vs various parameters (Day 3).

| Time |

Temperature |

Change of Solar radiation (w/m2) |

Relative humidity |

Weight loss

In kg (From 20 Kg) |

7.15

8.15

9.15

10.15

11.15

12.15

13.15

14.15

15.15

16.15

17.15 |

29.2

29.3

30.5

32.1

34.2

35.6

35.8

34.2

32.3

31.3

30.9 |

660.4

720.5

750.6

810.3

830.5

920.6

860.6

830.3

720.2

580.4

460.8 |

56.6

59.4

61.2

64.5

66.6

66.6

61.7

60.2

59.7

53.5

52.2 |

8.8

9.0

9.2

9.8

10.6

11.0

11.8

12.5

13.0

13.5

14.0 |

Table 6.

Various Temperatures and the efficiency of solar collector (Day 1).

Table 6.

Various Temperatures and the efficiency of solar collector (Day 1).

Day 1 |

Time |

Gb in

W/m2

|

Tam In C |

Tin in C |

Tout

in C |

Drying Efficiency |

% Drying Efficiency %η |

| 7.15 |

600.8 |

28.3 |

32.2 |

36.5 |

0.771123 |

77.1 |

| 8.15 |

700.3 |

29.1 |

32.8 |

37.6 |

0.738486 |

73.8 |

| 9.15 |

750.4 |

30.4 |

33.7 |

39 |

0.760971 |

76.0 |

| 10.15 |

800.5 |

34.5 |

34.3 |

40.2 |

0.794101 |

79.4 |

| 11.15 |

820.6 |

34.2 |

37.5 |

43.8 |

0.827169 |

82.7 |

| 12.15 |

900.7 |

35.6 |

40.1 |

46.4 |

0.753608 |

75.3 |

| 13.15 |

880.4 |

35.5 |

39.0 |

45.4 |

0.783222 |

78.3 |

| 14.15 |

800.6 |

34.6 |

38.5 |

44.5 |

0.80746 |

80.7 |

| 15.15 |

700.6 |

32.2 |

37.7 |

42.8 |

0.784305 |

78.4 |

| 16.15 |

560.3 |

31.5 |

33.2 |

37.4 |

0.807633 |

80.7 |

| 17.15 |

400.4 |

30.8 |

32.8 |

35.7 |

0.780349 |

78.0 |

| |

|

|

|

|

|

Avg |

78.2 |

Table 7.

Various Temperatures and the efficiency of solar collector (Day 2).

Table 7.

Various Temperatures and the efficiency of solar collector (Day 2).

Day 2 |

Time |

Gb in W/m2

|

Tam In C |

Tin in C |

Tout |

Drying Efficiency |

% Drying Efficiency %η |

| 7.15 |

650.2 |

28.2 |

33.3 |

38 |

0.778818 |

77.8 |

| 8.15 |

700.8 |

29.3 |

33.8 |

38.6 |

0.737959 |

73.7 |

| 9.15 |

750.6 |

30.3 |

34.5 |

39.6 |

0.73206 |

73.2 |

| 10.15 |

820.3 |

34.1 |

35.8 |

41.5 |

0.748665 |

74.8 |

| 11.15 |

820.5 |

34.2 |

38.4 |

44 |

0.735351 |

73.5 |

| 12.15 |

900.4 |

35 |

39.3 |

45.4 |

0.729927 |

72.9 |

| 13.15 |

870.5 |

35.1 |

39.8 |

46.4 |

0.816884 |

81.6 |

| 14.15 |

820.6 |

34.3 |

39.5 |

45.5 |

0.78778 |

78.7 |

| 15.15 |

710.2 |

32.3 |

36.5 |

41.5 |

0.758533 |

75.8 |

| 16.15 |

570.1 |

31.2 |

34.6 |

38.8 |

0.793749 |

79.3 |

| 17.15 |

450.8 |

30.8 |

33.8 |

36.9 |

0.740906 |

74.0 |

| |

|

|

|

|

|

Avg |

75.9 |

Table 8.

Various Temperatures and the efficiency of solar collector (Day 3).

Table 8.

Various Temperatures and the efficiency of solar collector (Day 3).

Day 3 |

Time |

Gb in W/m2

|

Tam In C |

Tin in C |

Tout |

Drying Efficiency |

% Drying Efficiency %η |

| 7.15 |

660.4 |

29.2 |

32.3 |

37.2 |

0.799419 |

79.9 |

| 8.15 |

720.5 |

29.3 |

33.0 |

38.2 |

0.777597 |

77.7 |

| 9.15 |

750.6 |

30.5 |

34.5 |

40.4 |

0.846893 |

84.6 |

| 10.15 |

810.3 |

32.1 |

35.3 |

41.8 |

0.864277 |

86.4 |

| 11.15 |

830.5 |

34.2 |

38.3 |

44.3 |

0.778389 |

77.8 |

| 12.15 |

920.6 |

35.6 |

39 |

46 |

0.819242 |

81.9 |

| 13.15 |

860.6 |

35.8 |

39.2 |

45.4 |

0.776203 |

77.6 |

| 14.15 |

830.3 |

34.2 |

39 |

45.2 |

0.804529 |

80.4 |

| 15.15 |

720.2 |

32.3 |

36.2 |

41.4 |

0.777921 |

77.7 |

| 16.15 |

580.4 |

31.3 |

34.2 |

38.4 |

0.779663 |

77.9 |

| 17.15 |

460.8 |

30.9 |

33.2 |

36.4 |

0.748209 |

74.8 |

| |

|

|

|

|

|

Avg |

79.7 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).